Is Your Creative Urethanes Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for creative urethanes

In an increasingly competitive global market, sourcing high-quality creative urethanes can be a daunting task for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe strive for innovation and efficiency, understanding the diverse applications and properties of polyurethane products becomes critical. This guide serves as a comprehensive resource, addressing essential aspects such as the various types of urethane products, their specific applications, effective supplier vetting processes, and cost considerations.

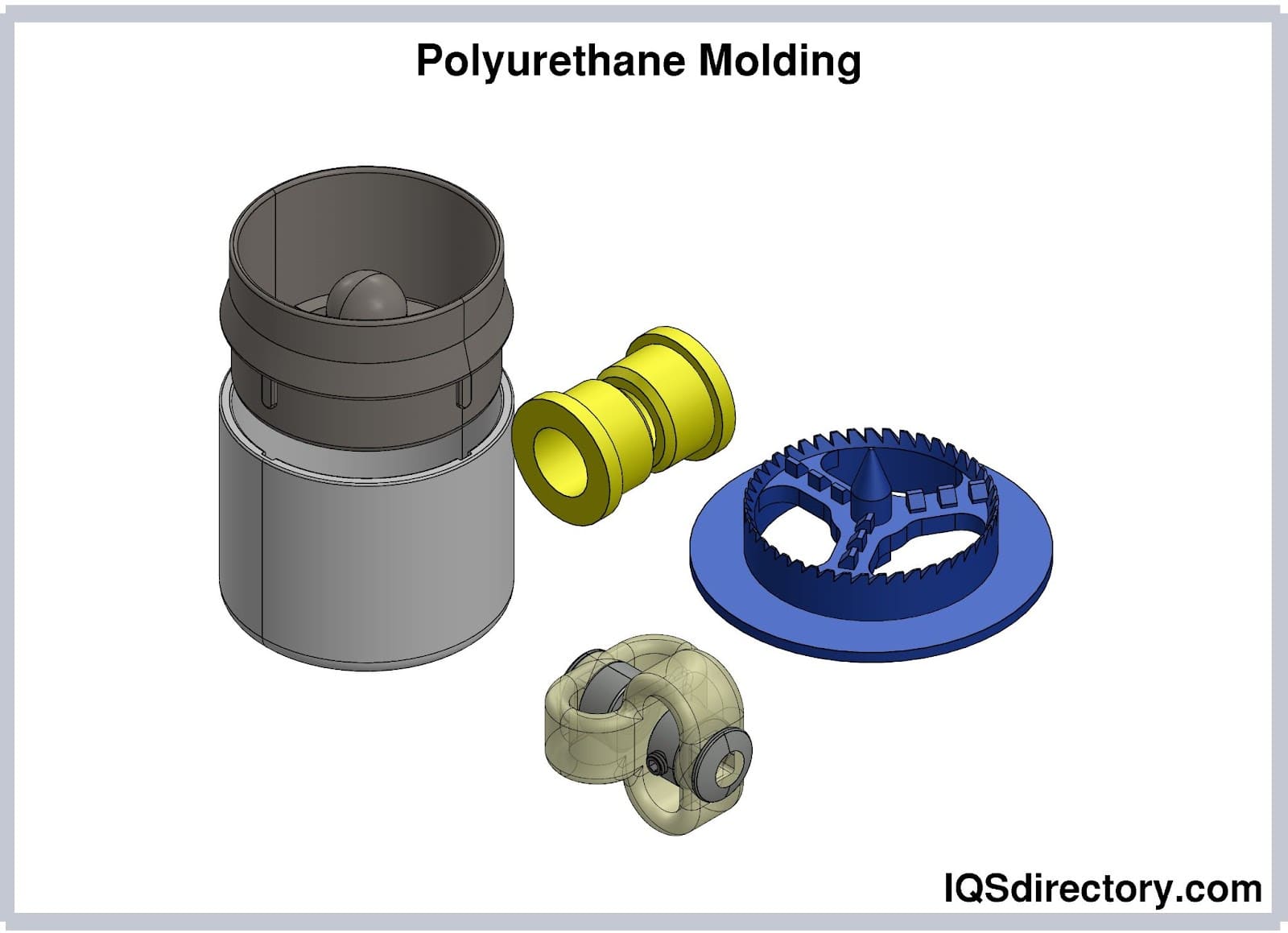

By delving into the intricacies of polyurethane molding, casting, and custom solutions, this guide empowers decision-makers to make informed purchasing choices that align with their unique operational needs. Whether you’re looking for durable molded parts for industrial applications or specialized components for recreational products, this resource will help you navigate the complexities of the urethane market.

Furthermore, we highlight the importance of quality assurance and supplier reliability, ensuring that you partner with manufacturers who not only meet your specifications but also adhere to industry standards. With actionable insights and expert advice, this guide positions you to optimize your procurement strategy, ultimately enhancing your product offerings and operational efficiency in a global landscape.

Understanding creative urethanes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cast Urethane | High strength, excellent wear resistance, customizable | Industrial parts, automotive components | Pros: Durable, tailored designs. Cons: Longer lead times for custom orders. |

| Reaction Injection Molding | Fast production, complex shapes, and high precision | Electronics, medical devices | Pros: Quick turnaround, intricate designs. Cons: Limited material options. |

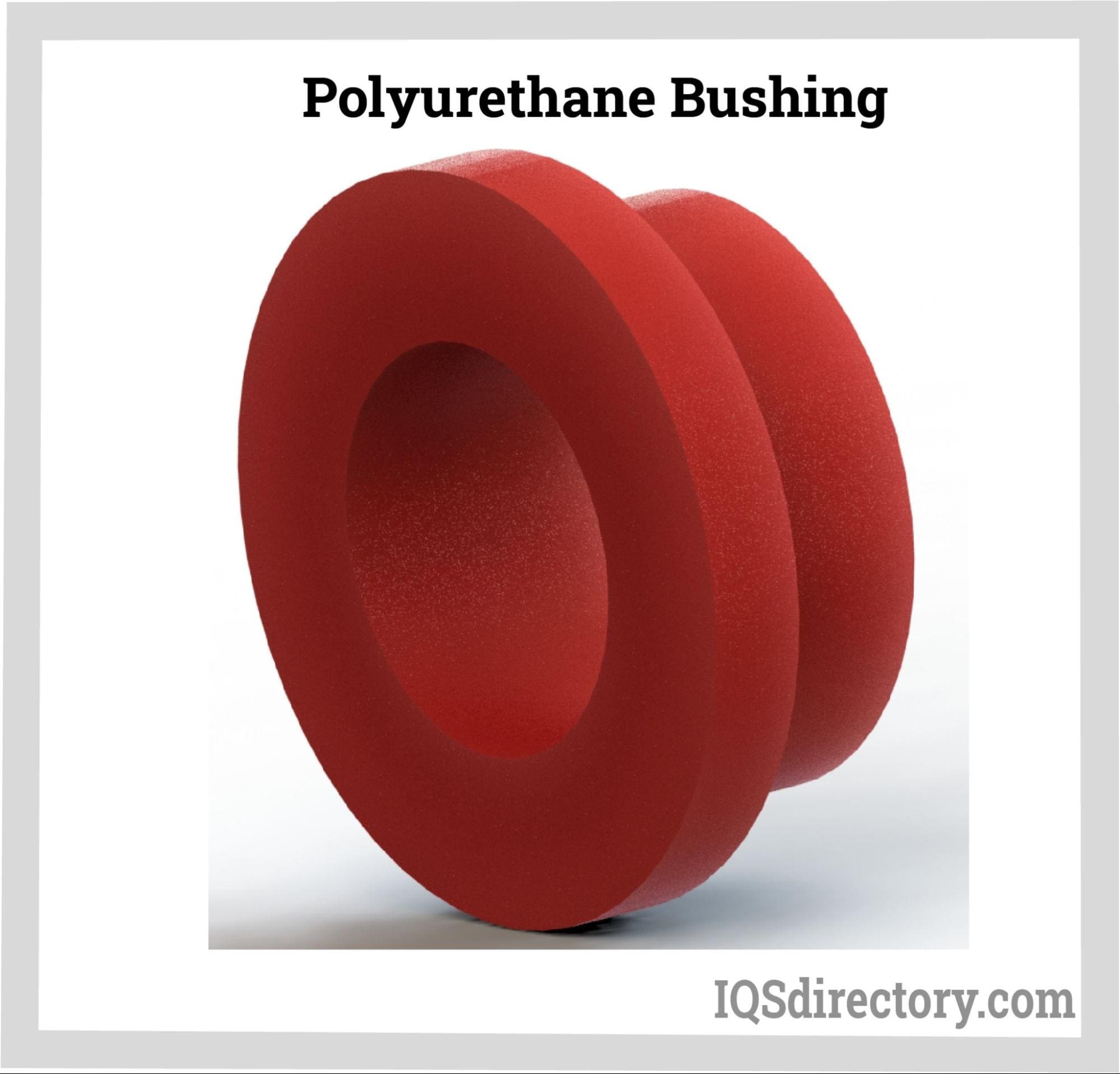

| Polyurethane Bushings | Friction-reducing, resilient, replaces traditional lubricants | Automotive, machinery | Pros: Reduces maintenance, enhances performance. Cons: May require specific fitment. |

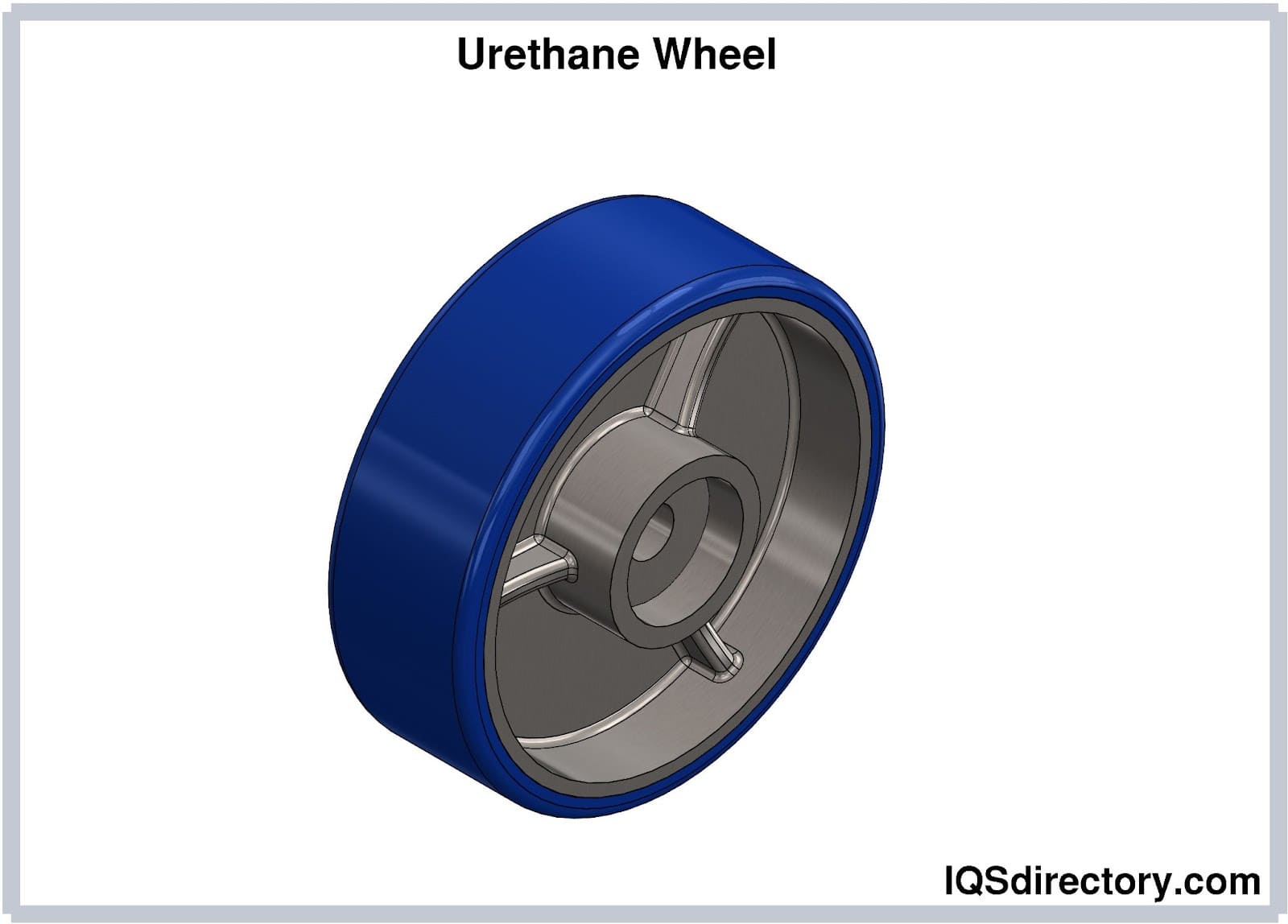

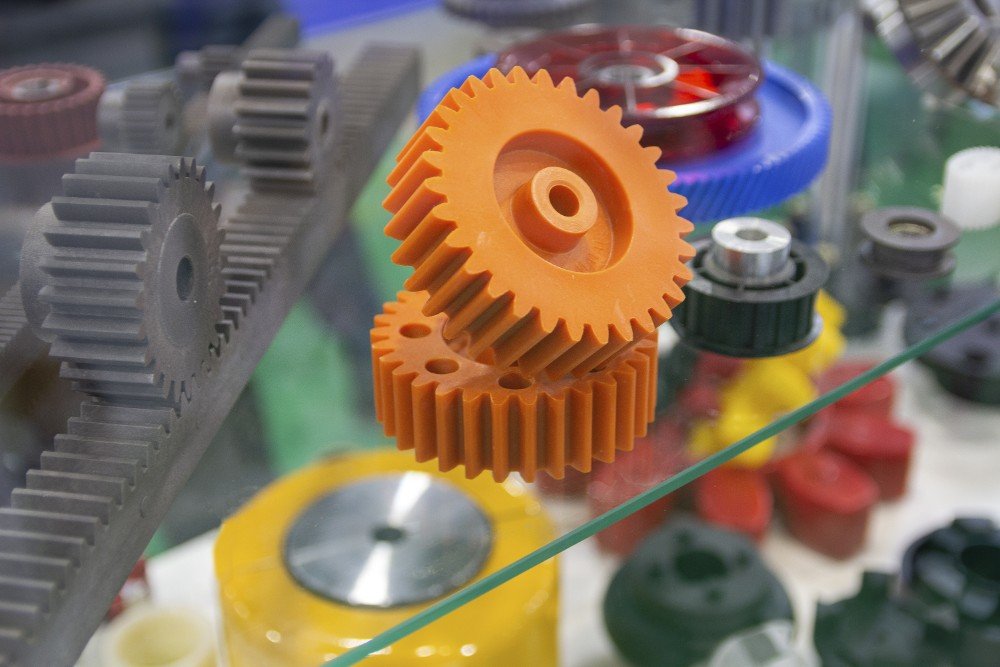

| Urethane Wheels | Soft yet durable, excellent shock absorption | Material handling, transportation | Pros: Smooth operation, customizable hardness. Cons: Can wear out in extreme conditions. |

| Urethane Rollers | Cylindrical, abrasion-resistant, versatile in applications | Manufacturing, conveyor systems | Pros: High durability, reduces noise. Cons: Initial cost can be high. |

What are the characteristics and suitability of Cast Urethane for B2B buyers?

Cast urethane is renowned for its strength and durability, making it ideal for applications requiring high wear resistance. Its customizable nature allows manufacturers to tailor products to specific requirements, such as hardness and flexibility. B2B buyers in industries like automotive and industrial manufacturing can benefit from cast urethane’s performance in harsh environments. However, the customization process may lead to longer lead times, which should be factored into project timelines.

Why is Reaction Injection Molding (RIM) advantageous for complex designs?

Reaction Injection Molding (RIM) excels in producing intricate shapes and high-precision components quickly. This method is particularly beneficial for industries such as electronics and medical devices, where rapid prototyping and production are essential. RIM allows for the integration of multiple materials, enhancing product functionality. Buyers should consider the speed of production and design flexibility, but also note that RIM may have limitations regarding material choices.

How do Polyurethane Bushings improve operational efficiency?

Polyurethane bushings serve as effective friction-reducing components that can replace traditional lubricants, thereby enhancing machinery performance and reducing maintenance needs. They are widely used in automotive and industrial applications where resilience and durability are critical. B2B buyers should evaluate their specific operational requirements, as these bushings may require precise fitment to achieve optimal performance.

What benefits do Urethane Wheels offer in material handling?

Urethane wheels provide a unique combination of softness and durability, allowing for excellent shock absorption and smooth operation. They are commonly used in material handling and transportation applications. The ability to customize the hardness of urethane wheels makes them suitable for various load capacities. Buyers should weigh the advantages of reduced noise and improved handling against the potential for wear under extreme conditions.

In what scenarios are Urethane Rollers the best choice?

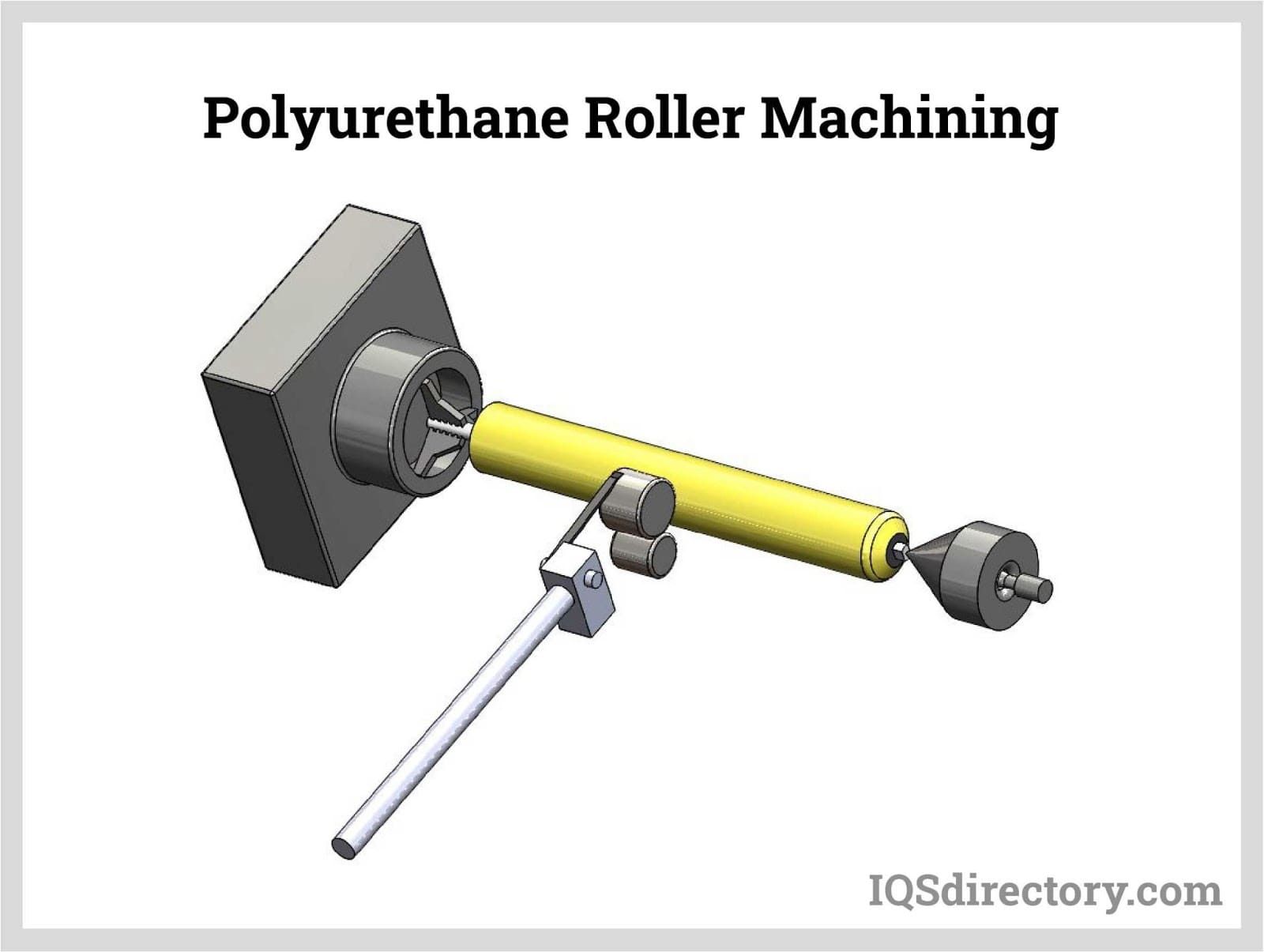

Urethane rollers are cylindrical components known for their abrasion resistance and versatility across numerous applications, including manufacturing and conveyor systems. Their durable construction minimizes noise and enhances operational efficiency. B2B buyers should consider the initial investment costs against the long-term benefits of reduced downtime and maintenance. Additionally, the specific application requirements will dictate the choice of roller design and material specifications.

Key Industrial Applications of creative urethanes

| Industry/Sector | Specific Application of Creative Urethanes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Polyurethane Bushings | Enhanced durability and noise reduction in vehicles | Ensure compliance with automotive industry standards |

| Manufacturing | Custom Molded Parts | Improved efficiency and reduced downtime in production | Look for suppliers with advanced molding capabilities |

| Oil & Gas | Abrasion-Resistant Piping Systems | Increased longevity and reduced maintenance costs | Source from manufacturers with expertise in harsh environments |

| Construction | Urethane Coatings for Equipment | Protection against wear and corrosion | Verify chemical resistance and compatibility with substrates |

| Consumer Goods | Urethane Wheels for Recreational Products | Superior performance and extended product lifespan | Check for customization options to meet specific design needs |

How Are Creative Urethanes Used in the Automotive Industry?

In the automotive sector, creative urethanes are primarily utilized in the production of polyurethane bushings. These components significantly reduce friction between moving parts, leading to enhanced durability and noise reduction in vehicles. For international buyers, particularly in regions like Africa and South America, it is crucial to ensure that these bushings comply with local automotive standards and regulations. Buyers should also prioritize suppliers with proven experience in manufacturing high-performance automotive components to guarantee reliability and safety.

What Role Do Creative Urethanes Play in Manufacturing?

In manufacturing, custom molded parts made from creative urethanes are essential for improving operational efficiency. These parts can be tailored to fit specific machinery, thus minimizing downtime during production processes. For businesses in developing regions, sourcing from manufacturers who offer advanced molding capabilities can lead to significant cost savings and improved product quality. Buyers should consider the supplier’s ability to handle custom orders and their track record in delivering consistent quality.

How Do Creative Urethanes Benefit the Oil & Gas Sector?

Creative urethanes are increasingly used in abrasion-resistant piping systems within the oil and gas industry. These systems are designed to withstand harsh environmental conditions, thereby increasing longevity and reducing maintenance costs. For B2B buyers in the Middle East and Europe, it’s vital to select manufacturers who specialize in producing urethanes suitable for extreme conditions. Buyers should also inquire about the supplier’s certifications and experience in the oil and gas sector to ensure compatibility with industry standards.

What Advantages Do Urethane Coatings Offer in Construction?

In construction, urethane coatings are applied to equipment to protect against wear and corrosion. This application is crucial for extending the lifespan of machinery, particularly in harsh environments. Buyers from regions such as Africa and South America should ensure that the coatings are chemically resistant and compatible with various substrates. It’s also important to work with suppliers who can provide technical support and guidance on application methods to maximize effectiveness.

Why Are Urethane Wheels Important for Consumer Goods?

Urethane wheels are widely used in recreational products due to their superior performance and durability. They provide a smoother ride and can withstand heavy use, making them ideal for various consumer goods applications. For international buyers, especially from Europe and emerging markets, it’s essential to check for customization options to meet specific design needs and ensure that the supplier can deliver high-quality materials consistently.

Illustrative image related to creative urethanes

3 Common User Pain Points for ‘creative urethanes’ & Their Solutions

Scenario 1: Quality Control Challenges in Urethane Products

The Problem: One of the most pressing issues B2B buyers face when sourcing creative urethanes is ensuring the quality and consistency of the products. Variability in material properties can lead to failures in application, resulting in costly downtime and potential safety hazards. This is particularly concerning for industries where precision and reliability are non-negotiable, such as aerospace, automotive, and medical devices. Buyers often struggle to find suppliers that can provide consistent quality across large production runs, leading to frustration and lost trust.

The Solution: To mitigate quality control issues, B2B buyers should prioritize suppliers with robust quality management systems, such as ISO 9001:2015 certification. Before finalizing a partnership, request detailed documentation of the supplier’s quality assurance processes, including testing protocols and performance metrics for their urethane products. Furthermore, consider conducting a pilot run of the products to evaluate their performance in real-world conditions. Establishing clear specifications and performance standards in collaboration with the supplier can also enhance product reliability. Regular communication and feedback loops will ensure that any inconsistencies are addressed promptly.

Scenario 2: Difficulty in Customization for Specific Applications

The Problem: Many B2B buyers require customized urethane solutions tailored to unique applications, yet they often encounter challenges in effectively communicating their needs to suppliers. This can lead to misunderstandings, resulting in products that do not meet performance specifications or fit correctly within existing systems. Buyers may feel overwhelmed by the technical jargon and processes involved in customization, leading to delays and additional costs.

The Solution: To streamline the customization process, buyers should prepare a comprehensive project brief that outlines specific requirements, including desired physical properties (such as hardness, elasticity, and temperature resistance), dimensions, and any special features required for their application. Engage with suppliers early in the process to leverage their expertise; many manufacturers offer design consultations to help refine specifications. Utilizing advanced technologies like CAD modeling can facilitate clearer communication. Additionally, requesting prototypes or samples can provide valuable insights into how well the proposed solutions align with performance expectations before committing to larger orders.

Scenario 3: Navigating Supply Chain Disruptions

The Problem: Global supply chain disruptions have become a significant concern for B2B buyers, particularly in industries reliant on creative urethanes. Delays in material availability can halt production lines and impact project timelines, leading to financial losses. Buyers may struggle to find reliable suppliers who can provide consistent delivery timelines amidst fluctuating global conditions.

Illustrative image related to creative urethanes

The Solution: To navigate supply chain challenges effectively, B2B buyers should diversify their supplier base to mitigate risks associated with single-source dependency. Establishing relationships with multiple urethane manufacturers across different regions can provide alternatives in case of disruptions. Additionally, buyers should engage in proactive inventory management by forecasting demand and maintaining safety stock levels for critical components. Regularly reviewing supplier performance and delivery capabilities can also help identify potential risks early on. Collaborating closely with suppliers to understand their supply chain processes can facilitate transparency and enable buyers to make informed decisions in response to market changes.

Strategic Material Selection Guide for creative urethanes

When selecting materials for creative urethanes, it is essential to consider the specific properties and performance characteristics that will best suit the intended application. Here, we analyze four common materials used in the production of creative urethanes, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of Polyurethane?

Polyurethane (PU) is a versatile elastomer known for its durability and flexibility. It has excellent temperature resistance, typically ranging from -40°F to 200°F (-40°C to 93°C), making it suitable for various environments. PU exhibits good chemical resistance, particularly against oils and solvents, which is critical for applications in the automotive and industrial sectors.

Pros: PU offers high abrasion resistance and can be customized for hardness, making it ideal for applications like wheels, rollers, and seals. Its ability to withstand harsh conditions enhances product longevity.

Cons: The manufacturing process can be complex and may require specialized equipment. Additionally, while PU is generally cost-effective, high-performance formulations can be on the pricier side.

Illustrative image related to creative urethanes

Impact on Application: PU is compatible with various media, including oils and chemicals, making it suitable for automotive, industrial, and recreational applications.

How Does Thermoplastic Polyurethane (TPU) Compare?

Thermoplastic Polyurethane (TPU) shares many properties with traditional PU but offers the added advantage of being thermoplastic. This means it can be reprocessed and reshaped upon heating, allowing for easier recycling and manufacturing.

Pros: TPU is known for its excellent elasticity, transparency, and resistance to oils and greases. Its versatility makes it suitable for applications ranging from medical devices to automotive components.

Cons: While TPU offers superior performance in flexibility and impact resistance, it can be more expensive than standard PU. The processing temperature is also higher, which may complicate manufacturing.

Impact on Application: TPU’s compatibility with various chemicals enhances its use in demanding environments, such as in the oil and gas industry, where exposure to harsh chemicals is common.

What Advantages Does Epoxy Resin Provide?

Epoxy resin is another material that can be used in conjunction with urethanes to enhance performance. Known for its exceptional adhesion and chemical resistance, epoxy resins are often used as a coating or bonding agent.

Pros: Epoxy resins provide excellent mechanical properties and can withstand high temperatures and corrosive environments. They are ideal for applications requiring strong bonds and durability.

Cons: The curing process can be time-consuming, and the material can be brittle if not formulated correctly. Additionally, the cost of epoxy resins can be higher than other urethane materials.

Impact on Application: Epoxy resins are particularly effective in applications where structural integrity is paramount, such as in aerospace and automotive industries.

Illustrative image related to creative urethanes

How Does Silicone Urethane Perform?

Silicone urethane combines the properties of silicone and polyurethane, offering unique advantages in specific applications. It is known for its exceptional temperature resistance, often exceeding 400°F (204°C).

Pros: Silicone urethane is highly flexible and resistant to extreme temperatures and environmental conditions. Its low compression set makes it suitable for seals and gaskets.

Cons: The cost of silicone urethane can be significantly higher than traditional urethanes, which may limit its use in cost-sensitive applications. Additionally, its processing can be more complex.

Illustrative image related to creative urethanes

Impact on Application: Silicone urethane is ideal for applications in the aerospace, automotive, and medical fields, where high performance and reliability are critical.

Summary Table of Material Selection for Creative Urethanes

| Material | Typical Use Case for creative urethanes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane (PU) | Wheels, rollers, seals | High abrasion resistance | Complex manufacturing process | Medium |

| Thermoplastic Polyurethane (TPU) | Medical devices, automotive components | Excellent elasticity and recyclability | Higher processing temperature | High |

| Epoxy Resin | Aerospace, automotive bonding | Exceptional adhesion and chemical resistance | Time-consuming curing process | High |

| Silicone Urethane | Seals, gaskets in extreme conditions | High-temperature resistance | Higher cost and complex processing | High |

In conclusion, selecting the right material for creative urethanes involves evaluating the specific properties and performance requirements of the application. Understanding the pros and cons of each material can help international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, make informed decisions that align with compliance standards and market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for creative urethanes

What Are the Main Stages in the Manufacturing Process of Creative Urethanes?

The manufacturing process for creative urethanes involves several critical stages, each designed to ensure the production of high-quality, durable products tailored to specific applications. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves selecting the appropriate polyurethane raw materials, including polyols and isocyanates. The correct formulation is crucial, as it influences the final properties of the urethane product. Suppliers often utilize specialized software to calculate the precise ratios required for desired performance characteristics, such as hardness, flexibility, and chemical resistance.

-

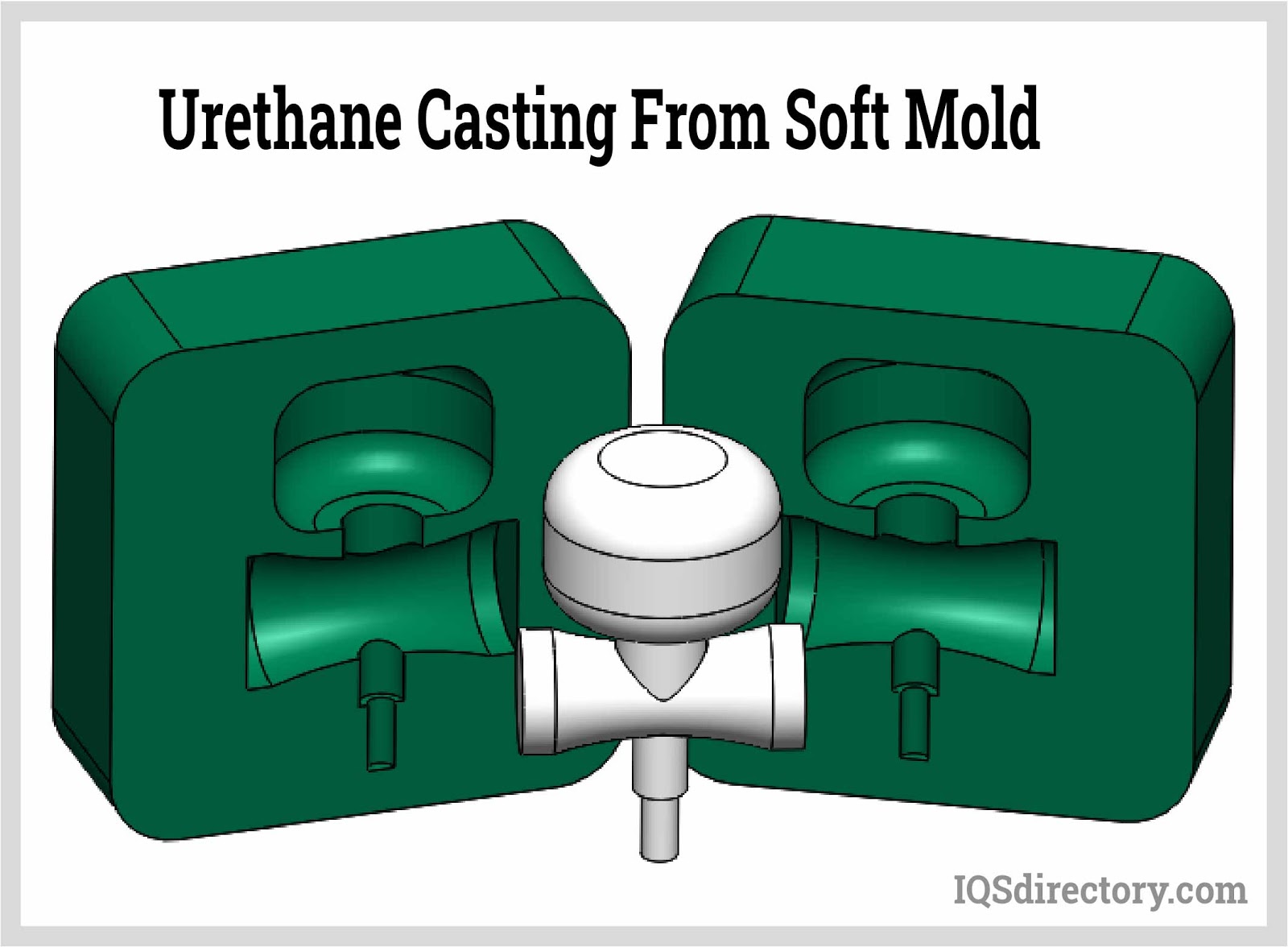

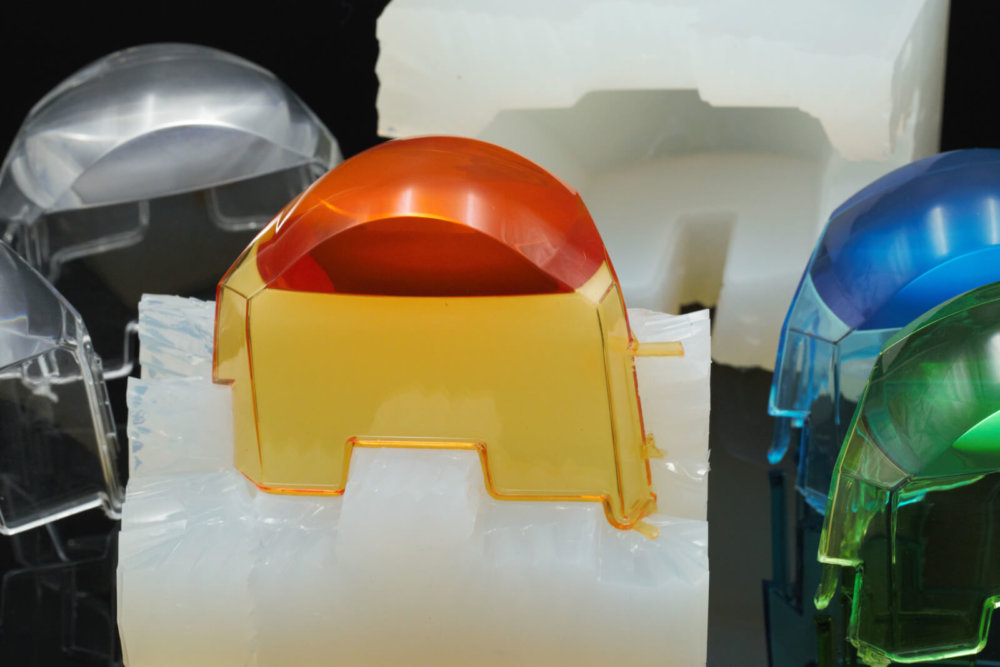

Forming: The forming process can be executed through various methods, such as Reaction Injection Molding (RIM), casting, or blow molding. RIM is particularly beneficial for producing complex shapes with a smooth finish and is commonly used for elastomeric and foamed products. In contrast, casting is often employed for creating solid urethane components, utilizing soft molds made from silicone elastomer for lower volume production runs. Each method is selected based on the product specifications and production volume.

-

Assembly: For products that require multiple components, assembly becomes essential. This can involve bonding, mechanical fastening, or integration with other materials. Quality assurance during assembly is vital to ensure that the final product meets design specifications and performance requirements.

-

Finishing: This stage includes processes such as trimming, polishing, and surface treatments to enhance the product’s aesthetics and functionality. Finishing techniques may also involve applying coatings or treatments to improve wear resistance, UV stability, or chemical resistance, depending on the intended use of the product.

Which Key Techniques Are Used in Creative Urethanes Manufacturing?

In the production of creative urethanes, various advanced techniques are employed to enhance efficiency, precision, and quality. These techniques include:

-

Precision Molding: Utilizing CNC machines and advanced molding technologies ensures that components are produced with high dimensional accuracy. This precision is crucial for applications in industries such as automotive, aerospace, and medical devices.

-

Additive Manufacturing: Integrating 3D printing technologies allows for rapid prototyping and the ability to create complex geometries that traditional methods may not achieve. This flexibility can significantly reduce lead times and costs for custom components.

-

Quality Control Systems: Automated quality control systems are increasingly used to monitor processes in real-time, allowing for immediate adjustments and minimizing defects. These systems often utilize sensors and software to ensure that production meets specified tolerances.

What Are the Quality Control Standards for Creative Urethanes Manufacturing?

Quality control is a cornerstone of the manufacturing process for creative urethanes, ensuring that products meet international standards and customer expectations. Relevant quality assurance standards include:

Illustrative image related to creative urethanes

-

ISO 9001:2015: This globally recognized standard focuses on quality management systems, emphasizing a process approach to enhance customer satisfaction and continuous improvement. Manufacturers should demonstrate compliance through regular audits and documentation.

-

CE Marking: For products sold in the European market, CE marking signifies that the product meets essential health, safety, and environmental protection standards. This is particularly important for industrial applications where regulatory compliance is mandatory.

-

API Standards: For applications in the oil and gas industry, adherence to American Petroleum Institute (API) standards is critical. These standards ensure that products can withstand harsh operating conditions and maintain safety and reliability.

What Are the Key Quality Control Checkpoints in Manufacturing Creative Urethanes?

Quality control in the manufacturing of creative urethanes is implemented through several checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial checkpoint ensures that all raw materials meet specified quality standards before they enter the production line. Suppliers often provide certificates of analysis (CoA) to validate the quality of materials.

-

In-Process Quality Control (IPQC): During manufacturing, real-time monitoring is conducted to ensure that processes are performed according to defined parameters. This may include measuring temperature, viscosity, and other critical factors.

-

Final Quality Control (FQC): Once products are completed, final inspections are carried out to verify that they meet all specifications. This includes visual inspections, dimensional checks, and performance testing.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers looking to source creative urethanes should consider several strategies to verify the quality control processes of potential suppliers:

-

Supplier Audits: Conducting on-site audits can provide insights into a supplier’s manufacturing practices and quality control measures. This allows buyers to assess compliance with industry standards and evaluate the overall production environment.

-

Requesting Documentation: Buyers should request documentation that outlines quality control processes, including inspection reports, testing protocols, and certifications. This documentation can help verify that the supplier adheres to relevant standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an independent assessment of the supplier’s quality practices. These services can provide additional assurance that products meet specified standards and requirements.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding quality control nuances is essential:

-

Regulatory Compliance: Different regions may have varying regulations concerning product safety and quality. Buyers must be aware of local standards and ensure that their suppliers comply with these regulations to avoid potential legal and operational issues.

-

Cultural and Language Barriers: Communication challenges can arise when dealing with suppliers from different countries. Buyers should ensure that there is a clear understanding of quality expectations and processes to avoid misunderstandings.

-

Logistical Considerations: Shipping and handling can impact product quality. Buyers should consider how products are packaged and transported to mitigate risks of damage during transit, which can affect the final quality of urethane products.

By thoroughly understanding the manufacturing processes and quality assurance practices related to creative urethanes, B2B buyers can make informed decisions that align with their operational needs and product specifications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘creative urethanes’

Introduction

Sourcing high-quality creative urethanes for your business requires a strategic approach to ensure you find the right materials and suppliers that meet your specific needs. This step-by-step checklist will guide you through the essential actions to take, helping you make informed decisions that align with your operational requirements and business goals.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly define the technical specifications of the urethane products you need. This includes understanding the desired hardness, elasticity, thermal stability, and any specific industry compliance standards.

- Consider Application Needs: Identify the application for which the urethanes will be used, as this will affect the material properties required.

- Performance Criteria: Outline the performance criteria, such as resistance to wear, chemicals, or temperature extremes, to communicate effectively with potential suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of creative urethanes. Look for manufacturers that specialize in the specific type of urethane products you require.

- Industry Reputation: Check online reviews, testimonials, and case studies to gauge the reputation of the suppliers in your industry.

- Certifications: Verify if they hold relevant certifications, such as ISO 9001, which indicates a commitment to quality management practices.

Step 3: Evaluate Supplier Capabilities

Assess the manufacturing capabilities of shortlisted suppliers to ensure they can meet your production needs. This includes evaluating their technology, equipment, and experience in urethane molding.

Illustrative image related to creative urethanes

- Customization Options: Inquire about their ability to customize products to your specifications, as this can be crucial for unique applications.

- Production Capacity: Ensure the supplier has the capacity to handle your order volumes within your required timelines.

Step 4: Request Samples and Prototypes

Always request samples or prototypes of the urethane products before making a bulk order. This step is vital to assess the quality and performance of the materials.

- Test for Compliance: Use the samples to conduct testing against your defined specifications and application needs.

- Evaluate Physical Properties: Check for consistency in color, texture, and overall quality to ensure they meet your standards.

Step 5: Discuss Pricing and Terms

Once you are satisfied with the samples, engage in discussions about pricing and terms of service. This includes understanding the total cost of ownership beyond just the unit price.

- Negotiate Terms: Discuss payment terms, lead times, and minimum order quantities to find a mutually beneficial agreement.

- Consider Additional Costs: Be aware of shipping, customs duties, and other potential costs that could impact your budget.

Step 6: Verify Supplier Support and Communication

Assess the level of customer support and communication offered by the supplier. Effective communication is critical for a successful partnership.

- Responsiveness: Evaluate how quickly and thoroughly they respond to inquiries and concerns.

- After-Sales Support: Confirm the availability of technical support, warranty, and return policies to safeguard your investment.

Step 7: Finalize Your Purchase Agreement

After completing your due diligence and being satisfied with your chosen supplier, finalize the purchase agreement. Ensure that all terms discussed are documented and agreed upon.

Illustrative image related to creative urethanes

- Clear Documentation: Include specifications, pricing, delivery schedules, and payment terms in the contract.

- Establish Milestones: Set clear milestones for production and delivery to monitor progress and ensure compliance with your expectations.

By following this checklist, B2B buyers can effectively navigate the sourcing process for creative urethanes, ensuring they secure high-quality materials that meet their business needs.

Comprehensive Cost and Pricing Analysis for creative urethanes Sourcing

What Are the Key Cost Components in Creative Urethanes Sourcing?

When sourcing creative urethanes, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type and quality of polyurethane raw materials significantly influence pricing. High-performance materials may cost more but offer better durability and performance, which can reduce long-term costs.

-

Labor: Skilled labor is essential for the precise manufacturing processes involved in producing molded urethane products. Labor costs can vary based on the location of the manufacturing facility, with regions offering lower wage rates potentially reducing overall expenses.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, equipment maintenance, and facility expenses. Efficient manufacturing processes can help minimize overhead costs.

-

Tooling: Custom tooling for specific designs can represent a significant initial investment. However, the cost can be amortized over larger production runs, making it essential for buyers to consider the long-term benefits of tooling investments.

-

Quality Control (QC): Implementing rigorous QC measures ensures that products meet specifications and industry standards. While this adds to the cost, it mitigates risks associated with defective products.

-

Logistics: Shipping costs can vary widely based on distance, shipping method, and terms of delivery. International buyers should factor in customs duties and import taxes that can impact the final cost.

-

Margin: Suppliers typically build in a profit margin, which can vary based on the competitive landscape and the unique value offered by the manufacturer.

How Do Price Influencers Impact Creative Urethanes Pricing?

Several factors can influence the pricing of creative urethanes, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower unit costs due to economies of scale. Buyers should negotiate MOQs to maximize savings.

-

Specifications and Customization: Custom-designed products tailored to specific applications may incur additional costs. Clear communication of requirements can help mitigate these expenses.

-

Materials and Quality Certifications: The inclusion of high-quality materials and certifications (e.g., ISO standards) can raise costs but may provide value through enhanced performance and compliance with industry regulations.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: Understanding Incoterms is essential for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly impact overall costs.

What Negotiation Tips Should Buyers Consider?

B2B buyers should adopt strategic negotiation tactics to optimize costs when sourcing creative urethanes:

-

Request Multiple Quotes: Gathering several quotations from different suppliers can provide a clearer market price and leverage in negotiations.

-

Focus on Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the product, including maintenance, durability, and the potential for reduced downtime. This broader perspective can justify higher upfront costs.

-

Discuss Payment Terms: Flexible payment options can improve cash flow and may allow buyers to negotiate better pricing.

-

Be Transparent About Needs: Clearly outlining project specifications and expected outcomes can foster a collaborative relationship with suppliers, potentially leading to cost savings.

-

Leverage International Trade Agreements: Understanding trade agreements between countries can help buyers capitalize on lower tariffs or duties, reducing overall costs.

What Pricing Nuances Should International Buyers Be Aware Of?

International buyers from regions such as Africa, South America, the Middle East, and Europe should consider the following pricing nuances:

-

Currency Fluctuations: Exchange rate volatility can impact pricing when sourcing from international suppliers. It is advisable to negotiate prices in a stable currency.

-

Cultural Differences in Business Practices: Understanding local business etiquette can facilitate smoother negotiations and foster stronger supplier relationships.

-

Regulatory Compliance: Different regions have varying regulations regarding materials and manufacturing processes. Ensuring compliance can prevent unforeseen costs related to rework or non-compliance penalties.

Disclaimer on Indicative Prices

Prices for creative urethanes can vary widely based on the factors discussed above. Buyers should conduct thorough research and engage with suppliers to obtain the most accurate and relevant pricing information tailored to their specific needs and circumstances.

Alternatives Analysis: Comparing creative urethanes With Other Solutions

Understanding Alternatives to Creative Urethanes

When considering manufacturing solutions for various industrial applications, it is essential to evaluate the available alternatives to creative urethanes. Creative urethanes, known for their durability and versatility, can be compared against alternative materials and methods such as thermoplastics and elastomers. Each option presents distinct advantages and limitations that can influence the decision-making process for B2B buyers.

Comparison Table

| Comparison Aspect | Creative Urethanes | Thermoplastics | Elastomers |

|---|---|---|---|

| Performance | High strength and durability; excellent in harsh environments | Moderate durability; good for general applications | Flexible and resilient; lower fatigue resistance |

| Cost | Higher initial investment; cost-effective in the long run due to longevity | Generally lower upfront cost; variable long-term costs | Moderate cost; dependent on specific formulations |

| Ease of Implementation | Requires specialized equipment for molding | Easier to process; compatible with standard machinery | Requires specific conditions for processing |

| Maintenance | Low maintenance due to high resistance to wear | Moderate; may require replacements more frequently | Regular checks needed to maintain performance |

| Best Use Case | Custom parts in harsh industrial environments | General manufacturing; consumer goods | Applications requiring flexibility and shock absorption |

Detailed Breakdown of Alternatives

Thermoplastics

Thermoplastics, such as polycarbonate or ABS, are often favored for their ease of processing and lower initial costs. They can be molded using standard techniques, making them accessible for various industries. However, while they provide adequate performance for many applications, they lack the exceptional durability and chemical resistance of creative urethanes. This can lead to higher maintenance costs over time, especially in demanding environments.

Elastomers

Elastomers, including rubber and silicone, offer excellent flexibility and resilience, making them suitable for applications requiring shock absorption and cushioning. They can be molded or extruded easily, which simplifies production. However, elastomers may not provide the same level of wear resistance or longevity as creative urethanes, particularly in harsh conditions. Depending on the specific formulation, elastomers might also require more frequent maintenance and replacement.

Illustrative image related to creative urethanes

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate material for your industrial applications, consider factors such as performance requirements, cost implications, ease of implementation, and maintenance needs. Creative urethanes excel in environments that demand high durability and custom solutions, making them ideal for specialized applications. In contrast, thermoplastics and elastomers may serve well for less demanding applications or where cost is a primary concern. Ultimately, the decision should align with your specific operational needs and long-term goals, ensuring you choose a solution that balances initial investment with overall performance and reliability.

Essential Technical Properties and Trade Terminology for creative urethanes

What Are the Key Technical Properties of Creative Urethanes?

Understanding the technical properties of creative urethanes is crucial for B2B buyers seeking reliable materials for industrial applications. Here are some essential specifications:

1. Material Grade

Material grade refers to the quality and formulation of the polyurethane used in manufacturing. Different grades can exhibit varying levels of hardness, flexibility, and resistance to wear and tear. For B2B buyers, selecting the appropriate material grade ensures the product meets specific performance requirements, reducing the risk of failure in critical applications.

2. Tolerance

Tolerance indicates the permissible limit of variation in a manufactured part’s dimensions. In urethane products, maintaining tight tolerances is vital for ensuring proper fit and function in assemblies. For businesses, understanding tolerance requirements can help in avoiding costly reworks and ensuring that components integrate seamlessly into existing systems.

3. Hardness

Hardness, measured on the Shore durometer scale, indicates a material’s resistance to deformation. Urethanes can be formulated to achieve a range of hardness levels, making them suitable for various applications—from soft, flexible components to hard, impact-resistant parts. Selecting the correct hardness is crucial for optimizing performance in specific environments, particularly in industries like automotive and aerospace.

4. Density

Density affects the weight and strength of urethane products. Higher density urethanes typically offer better durability and load-bearing capabilities, making them ideal for heavy-duty applications. B2B buyers should consider density when evaluating the suitability of a urethane product for their specific operational requirements.

5. Thermal Stability

Thermal stability refers to a material’s ability to maintain its properties over a wide temperature range. Urethanes with high thermal stability are essential in applications exposed to extreme heat or cold. Buyers should prioritize thermal stability to ensure longevity and reliability, especially in sectors like oil and gas or food processing.

What Common Trade Terms Should B2B Buyers Know?

Familiarity with industry terminology can enhance communication and facilitate smoother transactions. Here are some common terms related to creative urethanes:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of urethanes, OEMs often rely on custom formulations to meet specific performance standards. Understanding OEM relationships is vital for buyers looking to integrate urethane products into their own manufacturing processes.

Illustrative image related to creative urethanes

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For urethane manufacturers, MOQs can vary significantly based on material type and production processes. Buyers should be aware of MOQs to plan their procurement strategies effectively and avoid excess inventory costs.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price offers from suppliers. This process is critical for B2B buyers looking to compare costs and assess supplier capabilities. A well-structured RFQ can lead to better pricing and terms for urethane products.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international shipping terms that define the responsibilities of buyers and sellers in a transaction. Understanding these terms is crucial for B2B buyers to clarify who bears the costs and risks during transportation, ensuring smoother logistics and compliance with international trade regulations.

5. RIM (Reaction Injection Molding)

RIM is a manufacturing process used to create polyurethane components by mixing two reactive liquid components that cure into a solid material. This technique allows for the production of complex shapes and high-performance parts. B2B buyers should be familiar with RIM when discussing custom urethane solutions, as it impacts design flexibility and manufacturing efficiency.

Illustrative image related to creative urethanes

By understanding these properties and terms, B2B buyers can make informed decisions, ensuring the selection of the right urethane products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the creative urethanes Sector

What Are the Key Market Trends Influencing Creative Urethanes Sourcing?

The creative urethanes sector is witnessing a robust transformation driven by several global market dynamics. One of the primary drivers is the increasing demand for lightweight, durable materials across various industries such as automotive, construction, and consumer goods. As manufacturers seek to enhance performance while reducing weight, urethanes’ unique properties—such as flexibility, resilience, and chemical resistance—make them an ideal choice.

Technological advancements in production techniques, particularly Reaction Injection Molding (RIM) and casting processes, are also shaping the market landscape. These innovations allow for greater customization and efficiency in manufacturing, enabling companies to deliver tailored solutions that meet specific client needs. Furthermore, the rise of Industry 4.0 technologies is influencing sourcing trends, as businesses integrate IoT and AI into their supply chains, enhancing operational efficiency and transparency.

Illustrative image related to creative urethanes

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly prioritizing suppliers that can offer not only high-quality products but also competitive pricing and reliable delivery timelines. The growing focus on sustainability is prompting B2B buyers to seek partners who adhere to eco-friendly practices, further influencing sourcing decisions.

How Is Sustainability Shaping the Creative Urethanes Supply Chain?

Sustainability is emerging as a critical factor in the sourcing of creative urethanes. As environmental concerns intensify, companies are under pressure to minimize their ecological footprint. This has led to a significant shift towards ethical sourcing practices, with B2B buyers increasingly favoring suppliers that utilize sustainable materials and processes.

The environmental impact of polyurethane production is an important consideration. Manufacturers are exploring bio-based polyols and other green alternatives to traditional petroleum-based raw materials. Additionally, certifications such as ISO 14001 and LEED (Leadership in Energy and Environmental Design) are becoming essential criteria for suppliers looking to establish themselves as leaders in sustainability.

Ethical supply chains are not just a trend; they are becoming a standard expectation among international buyers. Companies that prioritize transparency and responsible sourcing practices can differentiate themselves in a competitive market. By choosing suppliers who prioritize environmental stewardship, B2B buyers can not only enhance their brand reputation but also contribute to a more sustainable future.

What Is the Historical Context of Creative Urethanes for B2B Buyers?

The creative urethanes sector has evolved significantly since its inception in the mid-20th century. Initially utilized for its versatility and durability, polyurethane technology has advanced dramatically, particularly with the introduction of Reaction Injection Molding (RIM) in the 1970s. This innovation allowed for the efficient production of complex shapes and components, catering to a wider range of applications across various industries.

As the demand for customized solutions grew, companies like Creative Urethanes, Inc. emerged as key players, leveraging their expertise in molding processes to provide tailored products. The sector has continued to expand, driven by technological advancements and an increasing emphasis on performance and sustainability.

Understanding this historical context is vital for B2B buyers as it highlights the importance of innovation and adaptation in the creative urethanes market. By partnering with established manufacturers that have a proven track record, buyers can ensure they are sourcing high-quality products that meet the evolving demands of their industries.

Frequently Asked Questions (FAQs) for B2B Buyers of creative urethanes

-

How do I ensure the quality of creative urethanes from suppliers?

To ensure the quality of creative urethanes, verify that your supplier adheres to recognized quality standards, such as ISO 9001:2015. Request samples of their products for testing and review their certifications and manufacturing processes. It’s also beneficial to ask for references from other clients to assess their reliability and quality assurance practices. Conducting regular audits or site visits can provide additional insight into their operations and commitment to quality. -

What is the best way to customize urethane products for my specific needs?

The best approach to customizing urethane products is to collaborate closely with your supplier’s engineering team. Provide detailed specifications, including dimensions, performance requirements, and environmental conditions. Discuss potential material options, such as hardness and elasticity, to ensure the final product meets your operational demands. Effective communication and sharing prototypes can facilitate the design process and lead to successful outcomes. -

What are the typical minimum order quantities (MOQs) for creative urethanes?

Minimum order quantities for creative urethanes can vary significantly between suppliers and depend on factors like product complexity and manufacturing processes. Generally, MOQs range from a few hundred to several thousand units. It’s crucial to discuss your requirements with potential suppliers early in the negotiation process to ensure they can accommodate your needs while remaining cost-effective. -

What payment terms should I expect when sourcing urethanes internationally?

Payment terms for international orders typically include options such as advance payment, letters of credit, or payment upon delivery. The specifics can vary based on the supplier’s policies and your negotiation. It’s advisable to clarify payment terms upfront, including currency, payment methods, and any applicable fees, to avoid misunderstandings later in the transaction process. -

How do I vet suppliers of creative urethanes in international markets?

To vet suppliers effectively, start by researching their reputation through online reviews and industry references. Request certifications, financial statements, and product samples to assess quality. Additionally, engage in direct communication to gauge responsiveness and support. Visiting the supplier’s facility, if feasible, can provide insights into their operational capabilities and commitment to quality standards. -

What logistics considerations should I keep in mind when importing urethanes?

Logistics considerations include shipping methods, customs clearance processes, and lead times. Understand the supplier’s shipping policies and whether they offer DDP (Delivered Duty Paid) or FOB (Free on Board) terms. It’s also essential to factor in potential tariffs and import regulations in your country. Partnering with a reliable freight forwarder can help streamline the logistics process and ensure timely delivery. -

What are the advantages of using urethane products in harsh environments?

Urethane products are well-suited for harsh environments due to their exceptional durability, resistance to abrasion, and ability to withstand extreme temperatures and chemicals. They maintain their performance under stress, reducing the need for frequent replacements. This longevity translates to lower total operational costs and increased efficiency in various applications, making them a preferred choice in demanding industries. -

How can I stay updated on the latest innovations in polyurethane technology?

To stay informed about the latest innovations in polyurethane technology, subscribe to industry journals, attend trade shows, and participate in webinars. Networking with industry professionals and joining relevant associations can also provide insights into emerging trends and technologies. Following leading manufacturers and suppliers on social media and their newsletters can keep you updated on new products and advancements in the urethane sector.

Top 5 Creative Urethanes Manufacturers & Suppliers List

1. Creative Urethanes – Molded Urethane Solutions

Domain: molded-urethane.com

Registered: 2001 (24 years)

Introduction: Creative Urethanes, Inc. is a manufacturer of molded urethane products, including cast urethane parts, urethane sheets, and urethane rods. Their products are known for superior strength, durability, and performance in harsh environments. They offer custom-designed products tailored to specific client requirements. The company utilizes state-of-the-art facilities equipped with advanced urethane mol…

2. Mearthane Products Corporation – Durethane Series

Domain: mearthane.com

Registered: 1996 (29 years)

Introduction: Mearthane Products Corporation offers a range of products including Durethane S, Durethane F, Durethane C, Durethane G, Durethane XL, custom products, Durastatic pipe seals & gaskets, vertebrae bend restrictors, and wire saw guide rollers & pulleys. Creative Urethanes specializes in Reaction Injection Molding (RIM) and manufactures rigid, flexible, solid, or foam polyurethane components.

3. Vintage Creative Urethanes – Coal Mining Sticker Decal

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”: “Vintage Creative Urethanes Inc Winchester Virginia Coal Mining Sticker Decal”, “price”: “US $7.95”, “condition”: “not specified”, “shipping”: “Does not ship to Hong Kong”, “location”: “Kenosha, Wisconsin, United States”, “returns”: “Seller does not accept returns”, “seller”: {“username”: “c cabindan1”, “feedback_score”: 5109, “positive_feedback”: “100% positive”}, “category”: “Collectib…

4. LinkedIn – Data Scraping API

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: Linkedin API for scraping Linkedin data. Documentation available at https://docs.scrapingdog.com/linkedin-scraper-api. Direct access through dashboard at https://api.scrapingdog.com/linkedinscraper/68595570d53ffab2195d42eb.

5. Urethane Blog – Key Products

Domain: urethaneblog.typepad.com

Registered: 2003 (22 years)

Introduction: This company, Urethane Blog – Key Products, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for creative urethanes

In today’s competitive landscape, strategic sourcing of creative urethanes is essential for international B2B buyers aiming to enhance product durability and performance across various industries. By partnering with leading manufacturers like Creative Urethanes, Inc. and Mearthane Products Corporation, businesses can leverage high-quality, custom-designed urethane solutions tailored to specific applications. This collaboration not only ensures superior strength and resilience but also supports innovation in product development.

The versatility of polyurethane technologies, from molded components to specialized applications in energy and manufacturing, positions these materials as critical assets in modern supply chains. As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for reliable, performance-driven urethane products is set to increase.

Illustrative image related to creative urethanes

To remain competitive, businesses should actively engage with suppliers who offer advanced manufacturing capabilities and exceptional customer support. By prioritizing strategic sourcing in their procurement processes, international buyers can unlock new opportunities for growth and enhance their operational efficiencies. Embrace the future of polyurethane solutions and consider how these innovations can drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to creative urethanes