Is Your Conveyor Parts Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for conveyor parts

In an increasingly interconnected world, sourcing reliable conveyor parts can present significant challenges for international B2B buyers. With diverse operational needs across industries, from manufacturing to logistics, understanding the nuances of conveyor parts—such as rollers, belts, and motors—is crucial for maintaining efficiency and productivity. This guide delves into the vast landscape of conveyor parts, offering insights into various types, their applications, and the intricacies of supplier vetting. By addressing critical factors such as cost, quality assurance, and logistical considerations, we aim to equip buyers from regions like Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Brazil—with the knowledge necessary to make informed purchasing decisions.

Navigating the global market for conveyor parts requires not only an understanding of product specifications but also an awareness of regional compliance standards and supplier reliability. This guide is designed to be a comprehensive resource, empowering B2B buyers to optimize their procurement strategies. By leveraging actionable insights, buyers can enhance their operational capabilities while ensuring long-term partnerships with reputable suppliers. Whether you are looking to replace outdated components or upgrade your conveyor systems, this guide serves as a critical tool in your sourcing journey.

Understanding conveyor parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Roller Conveyor | Composed of rollers that facilitate the movement of goods; can be gravity or powered. | Warehousing, assembly lines, packaging. | Pros: Low maintenance, easy to install. Cons: Limited incline capabilities. |

| Belt Conveyor | Utilizes a continuous belt to transport materials; can be flat or modular. | Food processing, mining, logistics. | Pros: Versatile, suitable for various materials. Cons: Requires regular maintenance and belt replacements. |

| Skatewheel Conveyor | Features a series of wheels mounted on a frame, allowing for easy manual movement of products. | Shipping, material handling, small parts assembly. | Pros: Lightweight, low-cost solution. Cons: Less durable for heavy loads. |

| Chain Driven Live Roller (CDLR) | Employs a chain drive to move rollers, suitable for heavy loads and accumulation. | Manufacturing, distribution centers. | Pros: High load capacity, effective for heavy items. Cons: More complex installation and maintenance. |

| Ball Transfer Table | Consists of a series of ball casters that allow for multidirectional movement of items. | Assembly lines, packaging, material handling. | Pros: Facilitates easy movement in any direction. Cons: Limited weight capacity compared to other types. |

What Are the Key Characteristics of Roller Conveyors?

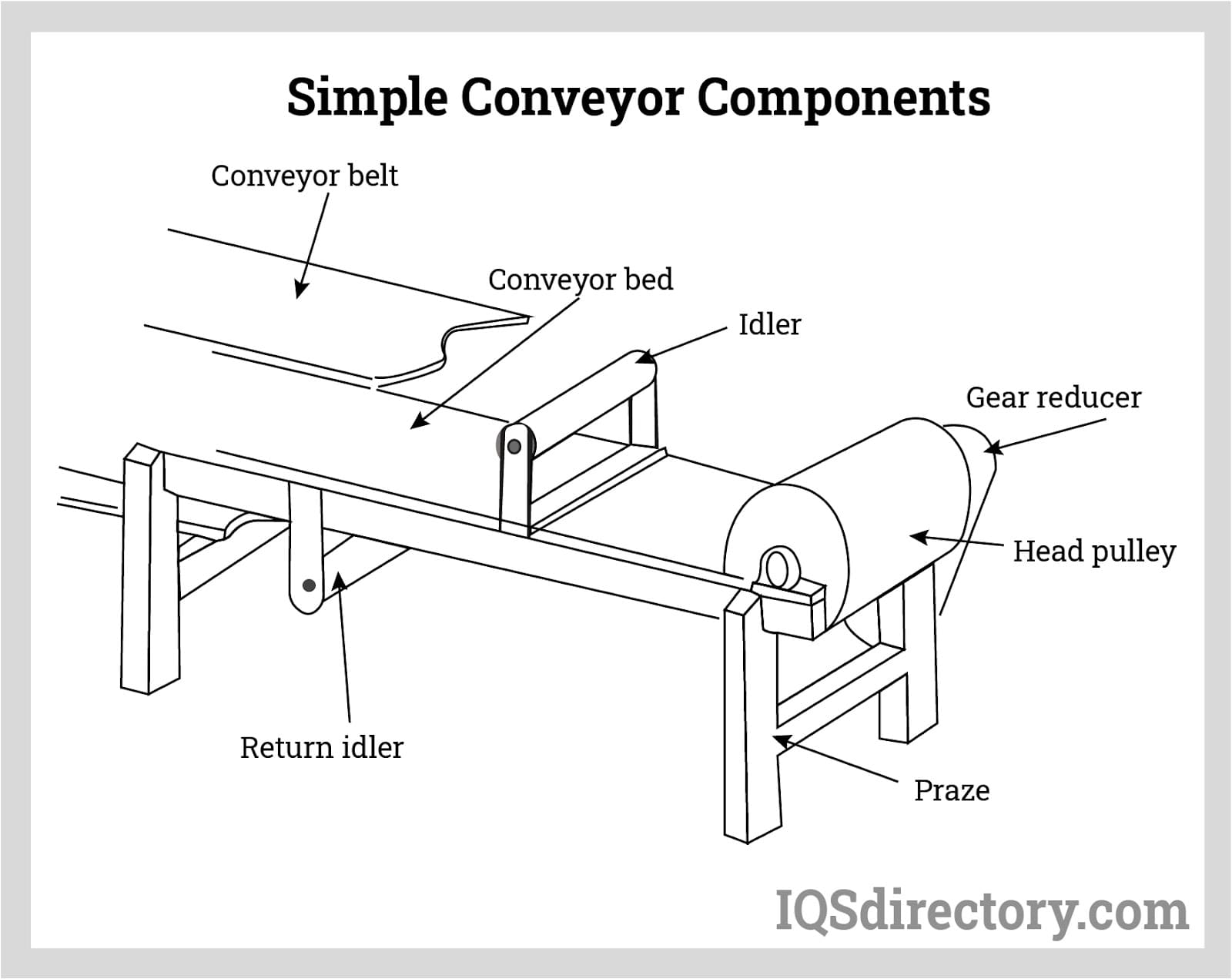

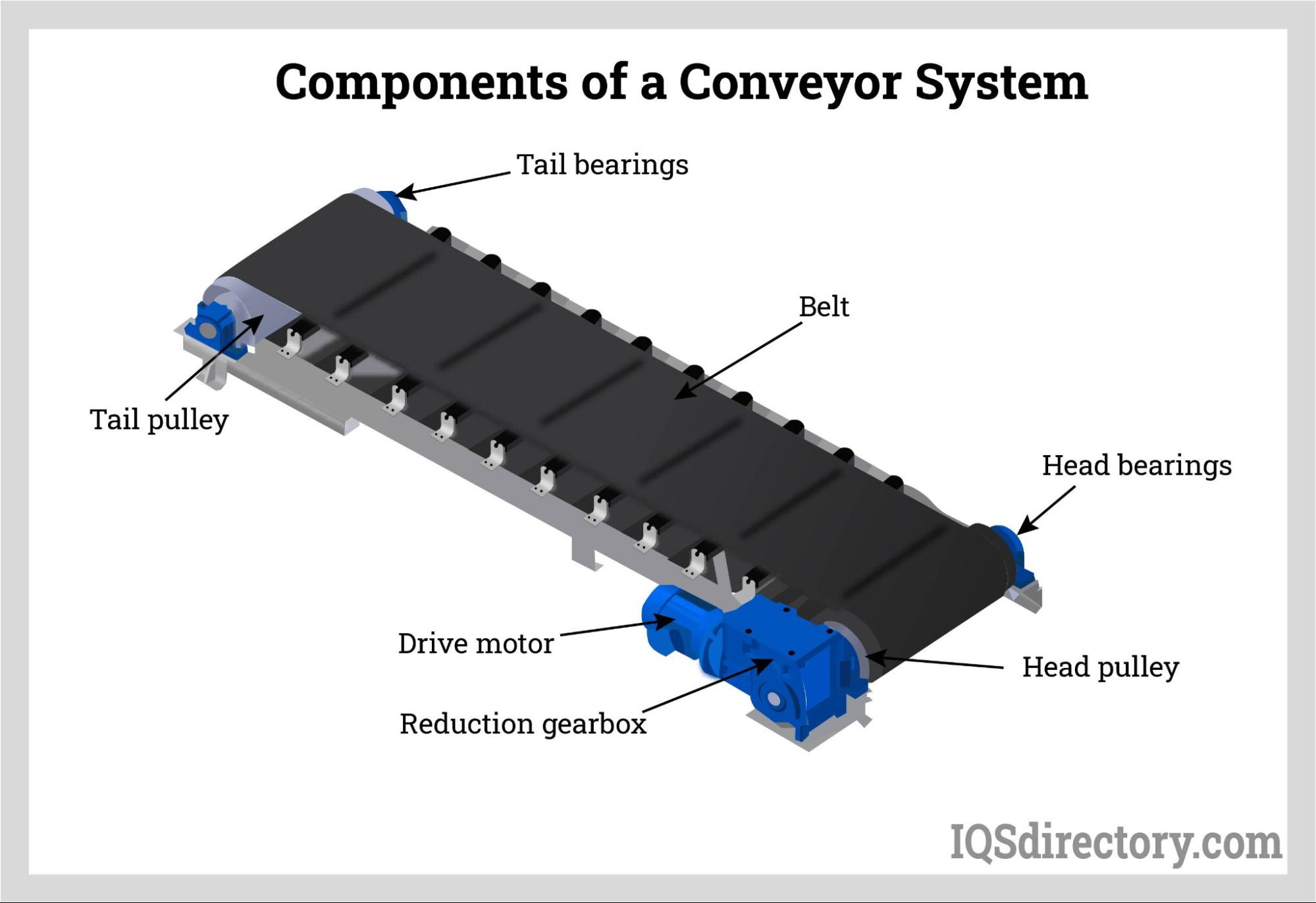

Roller conveyors are one of the most common types used in various industries. They consist of a series of rollers mounted on a frame that can be powered or gravity-fed. This type is ideal for transporting items such as boxes, pallets, and other materials. When considering roller conveyors, B2B buyers should evaluate the load capacity, length, and whether they require powered or gravity options, as these factors will significantly impact operational efficiency and installation costs.

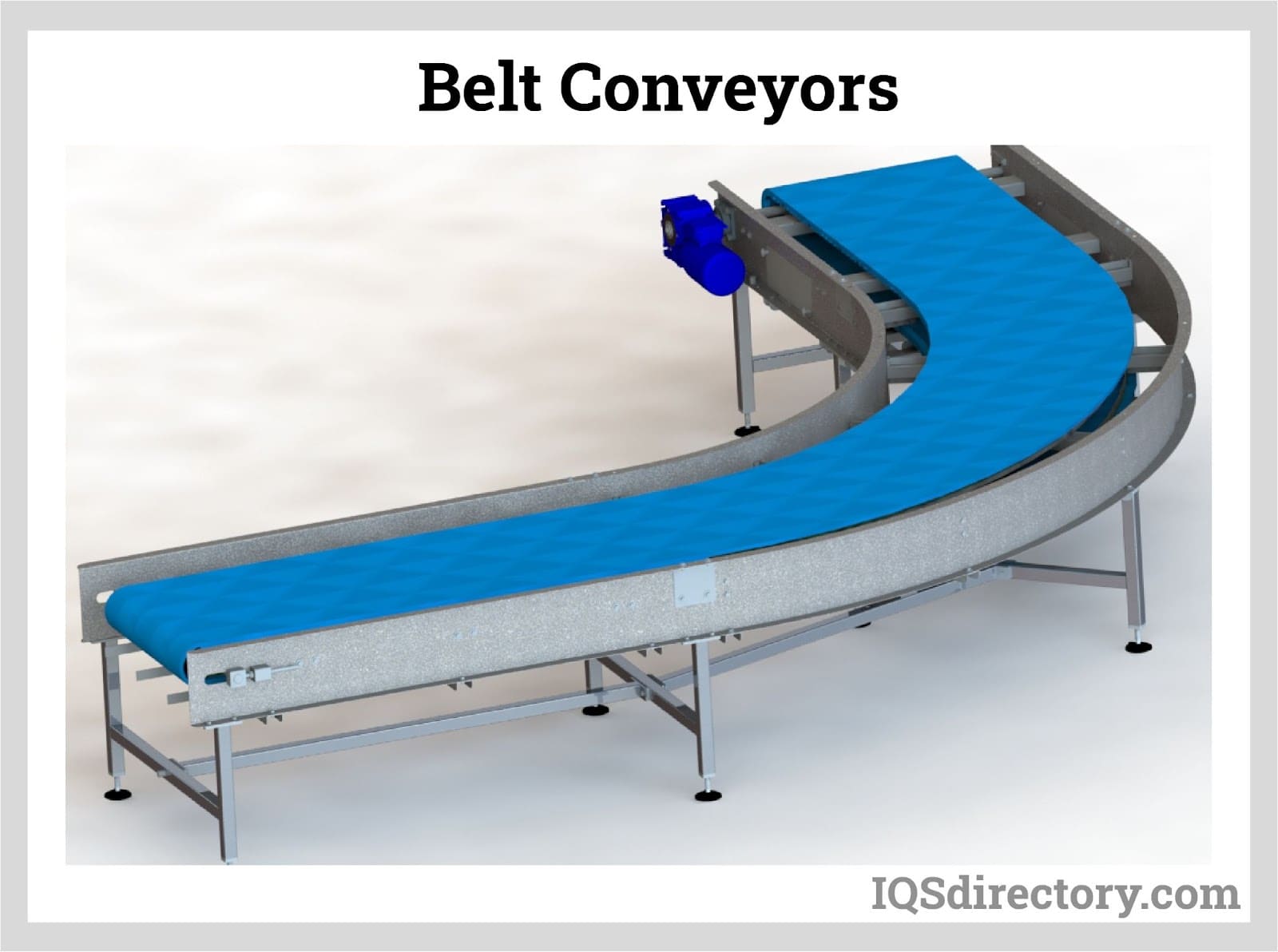

Why Choose Belt Conveyors for Your Business Needs?

Belt conveyors are characterized by their continuous belts that can transport materials across long distances. They are versatile and can handle a wide range of materials, including bulk items and packaged goods. Businesses in sectors like food processing and mining often prefer belt conveyors for their reliability. Buyers should consider the belt material, maintenance requirements, and the specific application needs to ensure optimal performance and longevity.

How Do Skatewheel Conveyors Benefit Material Handling?

Skatewheel conveyors are designed with a series of wheels that enable lightweight items to be moved easily. This type is particularly useful in shipping and small parts assembly. While they are cost-effective and easy to install, buyers should be cautious about their load limits and consider the weight of the materials being handled. They are best suited for environments where manual handling is common and heavy-duty applications are not required.

What Makes Chain Driven Live Roller Conveyors Ideal for Heavy Loads?

CDLR systems are distinguished by their use of a chain drive that powers rollers, making them suitable for transporting heavy loads. They are commonly found in manufacturing and distribution centers. Buyers should note that while CDLR conveyors offer high load capacities, they may require more complex installation and regular maintenance. Understanding the specific load requirements and operational needs will help in selecting the right configuration.

When to Use Ball Transfer Tables in Your Operations?

Ball transfer tables are unique in that they allow items to be moved in any direction, thanks to a series of ball casters. They are particularly beneficial in assembly lines and packaging operations where flexibility is crucial. However, buyers should be aware of their weight limitations compared to other conveyor types. Evaluating the types of products being handled and the required movement flexibility will assist in determining the suitability of ball transfer tables for specific applications.

Key Industrial Applications of conveyor parts

| Industry/Sector | Specific Application of Conveyor Parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Assembly Line Automation | Increases efficiency and reduces labor costs | Quality of materials, compatibility with existing systems, lead time |

| Food and Beverage | Food Processing and Packaging | Ensures hygiene, speed, and consistency in operations | Compliance with food safety standards, durability under sanitation |

| Logistics and Warehousing | Order Fulfillment and Sorting Systems | Enhances throughput and accuracy in inventory management | Flexibility in design, scalability, and integration capabilities |

| Mining and Minerals | Material Handling and Transportation | Improves safety and efficiency in transporting heavy loads | Resistance to harsh environments, maintenance support, and warranty |

| Pharmaceuticals | Automated Drug Packaging and Distribution | Increases precision and compliance with regulations | Regulatory compliance, reliability, and service support |

How Are Conveyor Parts Used in Manufacturing and What Problems Do They Solve?

In manufacturing, conveyor parts are integral to assembly line automation. They facilitate the smooth transfer of components between workstations, significantly increasing operational efficiency and reducing labor costs. Buyers in this sector should consider the quality of materials used in the conveyor parts to ensure durability and compatibility with existing systems. Additionally, lead times for sourcing these components can impact production schedules, making timely delivery a critical factor.

What Role Do Conveyor Parts Play in the Food and Beverage Industry?

Conveyor parts are essential in food processing and packaging, where they help maintain hygiene and speed in operations. Conveyors ensure that products move seamlessly through various stages, from processing to packaging, while adhering to strict food safety standards. For international buyers, it’s crucial to source conveyor parts that are compliant with local regulations and can withstand the rigorous sanitation processes typical in this industry. Durability and ease of maintenance are also key considerations.

How Do Conveyor Parts Enhance Logistics and Warehousing Operations?

In logistics and warehousing, conveyor parts are vital for order fulfillment and sorting systems. They enhance throughput and accuracy, allowing businesses to manage inventory more effectively. The ability to customize conveyor systems to fit specific warehouse layouts is essential for maximizing space and operational efficiency. Buyers should focus on the flexibility of the conveyor design, scalability to accommodate future growth, and integration capabilities with existing technology.

Why Are Conveyor Parts Critical in Mining and Minerals?

In the mining and minerals sector, conveyor parts facilitate the handling and transportation of heavy materials. They improve safety and efficiency, reducing the risk of accidents associated with manual handling. Buyers in this industry must prioritize sourcing conveyor parts that are resistant to harsh environmental conditions and require minimal maintenance. Additionally, having robust warranty and support services can be a deciding factor for long-term operations.

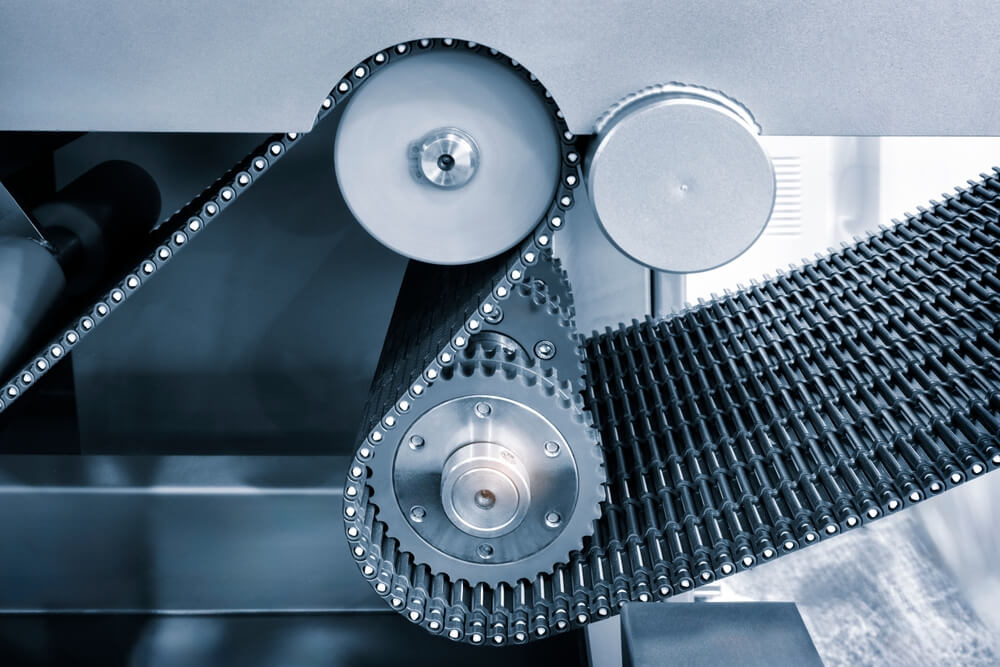

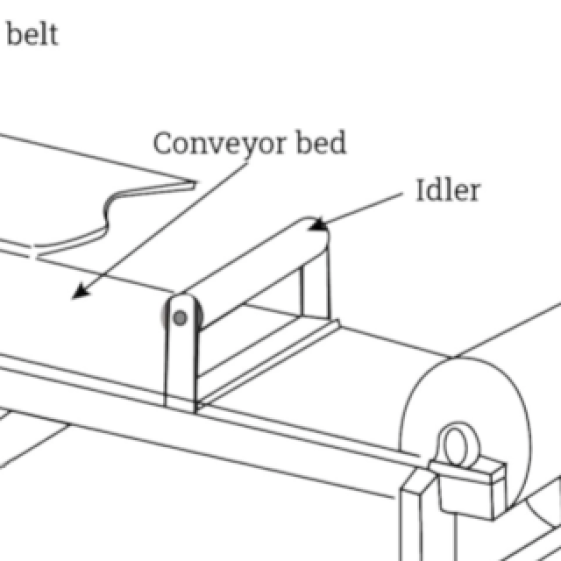

Illustrative image related to conveyor parts

How Do Conveyor Parts Support the Pharmaceutical Industry?

Conveyor parts play a crucial role in the automated packaging and distribution of pharmaceuticals. They ensure precision in the handling of sensitive products and compliance with stringent regulatory requirements. For international buyers, sourcing reliable conveyor parts that meet these regulations is paramount. Moreover, reliability and ongoing service support are essential to minimize downtime and maintain compliance in this highly regulated environment.

3 Common User Pain Points for ‘conveyor parts’ & Their Solutions

Scenario 1: Struggling with Downtime Due to Worn Parts

The Problem: In many manufacturing and distribution facilities, conveyor systems are the backbone of operations. A common pain point for B2B buyers is the unexpected downtime caused by worn-out conveyor parts. For instance, a company in Brazil may experience frequent breakdowns due to degraded rollers or belts, leading to halted production lines. This not only affects productivity but can also result in financial losses and delayed deliveries, tarnishing customer relationships.

The Solution: To combat this issue, B2B buyers should implement a proactive maintenance strategy. This involves regularly inspecting conveyor systems and identifying worn parts before they lead to failure. Establish a routine maintenance schedule that includes visual inspections and functional tests of critical components like rollers, belts, and bearings. It’s also beneficial to maintain an inventory of essential spare parts, sourced from reliable suppliers, to ensure quick replacements when necessary. Utilizing a digital management system to track the condition and maintenance schedules of conveyor parts can significantly reduce downtime. Buyers should also collaborate with manufacturers to understand the expected lifespan of parts and best practices for their upkeep, thus enhancing the longevity of their systems.

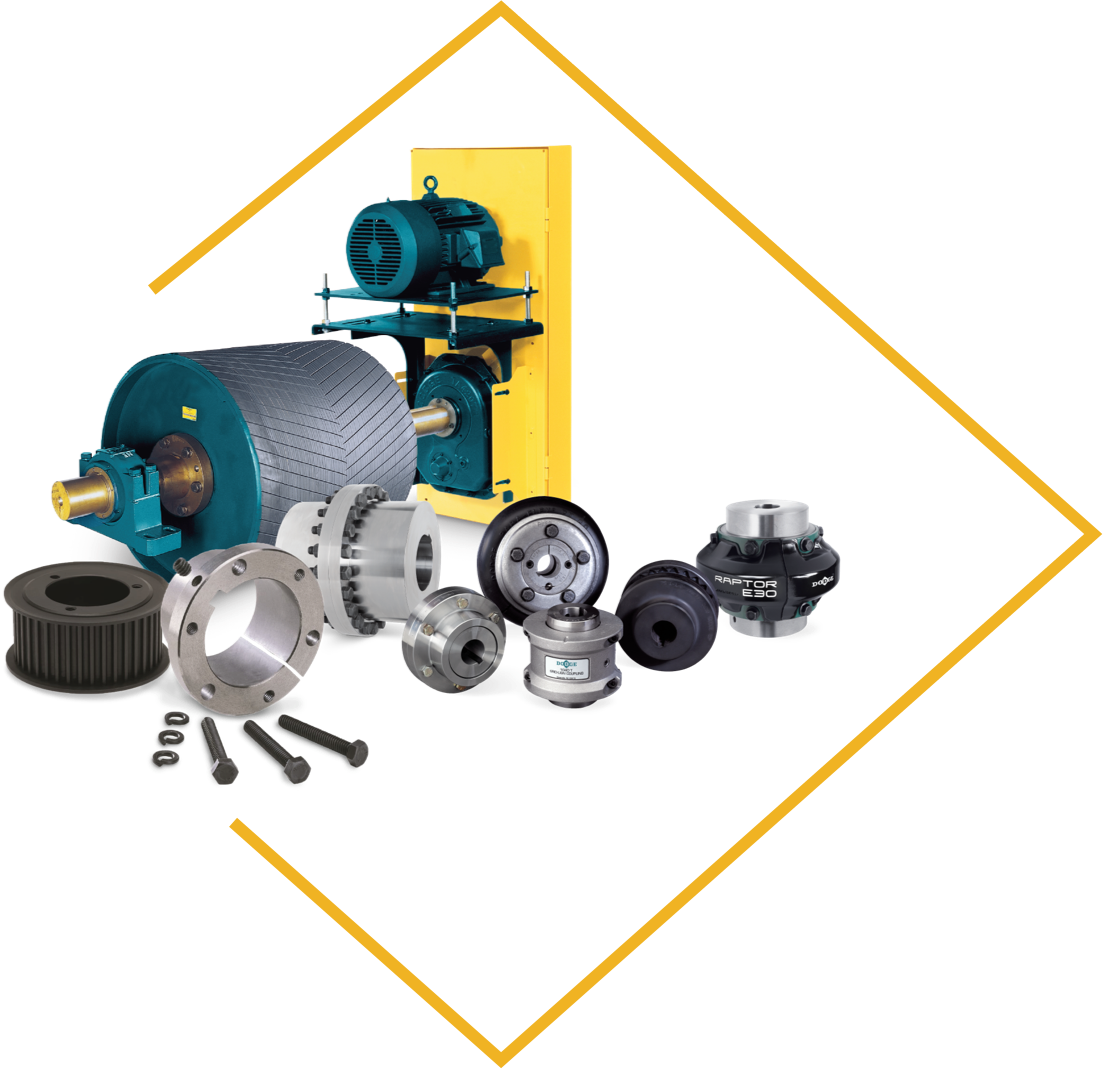

Illustrative image related to conveyor parts

Scenario 2: Difficulty Sourcing Compatible Parts Across Regions

The Problem: B2B buyers, especially in international markets such as the Middle East or Africa, often face challenges in sourcing compatible conveyor parts due to varying standards and specifications. A manufacturing plant in Saudi Arabia might struggle to find the right replacement parts that fit their existing systems, which can differ significantly from those used in Europe or North America. This can lead to delays in repairs and increased operational costs as buyers are forced to adapt their systems or resort to custom solutions.

The Solution: To address this pain point, B2B buyers should prioritize establishing relationships with reputable suppliers who offer a wide range of conveyor parts compatible with various international standards. Conduct thorough research to identify suppliers that specialize in your specific industry and region. Utilize online resources and product catalogs to verify compatibility before making purchases. Additionally, consider collaborating with local distributors who understand regional compliance and can provide tailored solutions. Implementing a robust procurement process that includes a checklist for compatibility can streamline sourcing and ensure you have the right parts on hand, minimizing downtime and operational disruptions.

Scenario 3: Managing Costs While Ensuring Quality

The Problem: Cost management is a significant concern for B2B buyers when it comes to conveyor parts. For instance, a logistics company in Brazil may find itself torn between opting for low-cost parts that may not meet durability standards or investing in high-quality components that stretch their budget. The challenge lies in balancing quality and cost-effectiveness without compromising the efficiency of their conveyor systems.

The Solution: To manage costs effectively, buyers should consider a value-based purchasing approach. This means evaluating conveyor parts not just on initial cost but also on their long-term performance and durability. Conduct a total cost of ownership (TCO) analysis to understand how different parts impact overall operational costs over time, including maintenance, energy consumption, and potential downtime. Engage in discussions with suppliers about bulk purchasing discounts or long-term contracts that can lower per-unit costs while ensuring quality. Additionally, leveraging technology such as predictive analytics can help forecast part failures and optimize purchasing schedules, thereby avoiding emergency replacements that can be more expensive. Investing in training for staff on proper usage and maintenance of conveyor parts can also enhance their lifespan, ultimately leading to cost savings.

Illustrative image related to conveyor parts

Strategic Material Selection Guide for conveyor parts

What Are the Key Properties of Common Materials Used in Conveyor Parts?

When selecting materials for conveyor parts, it is essential to consider their properties, which directly influence performance and longevity. Here, we analyze four common materials: aluminum, galvanized steel, stainless steel, and plastic composites.

Aluminum: Lightweight and Corrosion-Resistant

Aluminum is renowned for its lightweight nature and excellent corrosion resistance, making it ideal for applications where weight reduction is crucial. It has a moderate temperature resistance, typically up to 150°C (302°F), and can withstand moderate pressure.

Pros: Aluminum’s low weight facilitates easier installation and reduces energy consumption during operation. It is also relatively cost-effective compared to other metals, making it a popular choice for many conveyor systems.

Illustrative image related to conveyor parts

Cons: While durable, aluminum is not as strong as steel and can be prone to deformation under heavy loads. Additionally, it may require more frequent maintenance in abrasive environments.

Impact on Application: Aluminum is suitable for transporting lightweight materials and is often used in food processing and packaging industries due to its non-reactive nature.

Considerations for International Buyers: Compliance with standards such as ASTM and EN for aluminum alloys is critical. Buyers in regions like Europe and the Middle East may prefer aluminum for its lightweight properties, particularly in high-temperature environments.

Galvanized Steel: Strength and Durability

Galvanized steel is steel that has been coated with a layer of zinc to enhance its corrosion resistance. It is capable of withstanding high temperatures and pressures, making it suitable for a wide range of industrial applications.

Pros: The primary advantage of galvanized steel is its strength and durability, making it ideal for heavy-duty conveyor systems. The zinc coating provides excellent protection against rust and corrosion.

Cons: While galvanized steel is robust, it is heavier than aluminum, which may increase installation costs. Additionally, it can be more expensive than uncoated steel due to the galvanization process.

Impact on Application: This material is widely used in environments where heavy loads are common, such as manufacturing and distribution centers.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM A123 for hot-dip galvanized coatings. In regions like South America and Africa, where humidity can be high, galvanized steel is often preferred for its corrosion resistance.

Illustrative image related to conveyor parts

Stainless Steel: Superior Corrosion Resistance

Stainless steel is an alloy known for its exceptional corrosion resistance and strength, making it ideal for harsh environments. It can withstand high temperatures and is resistant to a wide range of chemicals.

Pros: The primary advantage of stainless steel is its longevity and ability to maintain structural integrity in corrosive environments. It is also easy to clean, making it suitable for food and pharmaceutical applications.

Cons: Stainless steel can be significantly more expensive than other materials, and its weight may complicate installation. Additionally, it can be more challenging to machine and fabricate.

Impact on Application: Stainless steel is often used in food processing, pharmaceutical, and chemical industries due to its hygienic properties.

Illustrative image related to conveyor parts

Considerations for International Buyers: Compliance with international standards such as ASTM A240 is crucial. Buyers in Europe and the Middle East often prefer stainless steel for its durability and resistance to corrosion.

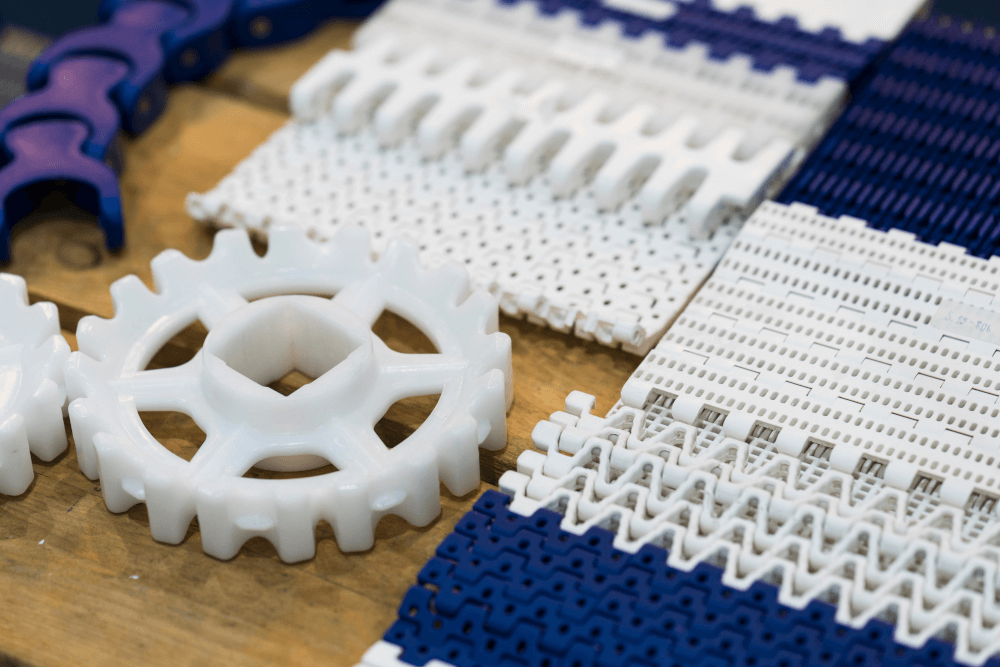

Plastic Composites: Versatility and Lightweight

Plastic composites, including high-density polyethylene (HDPE) and polypropylene, are increasingly popular in conveyor applications. They offer good chemical resistance and can operate effectively in a range of temperatures.

Pros: These materials are lightweight, reducing energy consumption and installation costs. They are also resistant to corrosion and can be manufactured in various colors and designs.

Illustrative image related to conveyor parts

Cons: While plastic composites are versatile, they may not be suitable for heavy loads or high-temperature applications. They can also be less durable than metal options.

Impact on Application: Plastic composites are ideal for lightweight applications, such as packaging and sorting systems, where flexibility and customization are required.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards for plastics, such as ASTM D638. In regions like Africa and South America, the cost-effectiveness of plastic composites may appeal to budget-conscious buyers.

Summary Table of Material Properties

| Material | Typical Use Case for conveyor parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight conveyor systems | Lightweight and corrosion-resistant | Less strong than steel | Medium |

| Galvanized Steel | Heavy-duty industrial applications | Strong and durable | Heavier and more expensive | Medium |

| Stainless Steel | Food and pharmaceutical industries | Superior corrosion resistance | High cost and complex fabrication | High |

| Plastic Composites | Packaging and sorting systems | Lightweight and customizable | Not suitable for heavy loads | Low |

This guide provides actionable insights for B2B buyers in various regions, helping them make informed decisions regarding material selection for conveyor parts.

In-depth Look: Manufacturing Processes and Quality Assurance for conveyor parts

What Are the Main Stages of Manufacturing Conveyor Parts?

The manufacturing of conveyor parts involves several critical stages that ensure quality and performance. Each stage is designed to enhance the durability and functionality of the components used in various conveyor systems.

Illustrative image related to conveyor parts

Material Preparation: What Materials Are Used and How Are They Processed?

The first stage in the manufacturing process is material preparation. Common materials include galvanized steel, aluminum, and various types of plastics, each chosen for their specific properties such as strength, weight, and resistance to corrosion.

During this stage, raw materials are sourced from reputable suppliers, ensuring they meet industry standards. The materials undergo testing for properties like tensile strength and corrosion resistance. Once approved, they are cut to size using techniques such as laser cutting or shearing, which provide precision and reduce waste.

Forming: How Are Conveyor Parts Shaped?

Following material preparation, the forming stage shapes the components into the desired forms. This can include bending, welding, and machining processes.

For instance, roller brackets and supports may be bent using hydraulic presses, while bearings might be machined to meet specific tolerances. Techniques such as extrusion are also utilized for creating complex profiles, especially in aluminum parts. This stage is crucial as it directly affects the functionality and durability of the final product.

Assembly: What Is Involved in the Assembly of Conveyor Parts?

Assembly is the next crucial stage, where individual components are brought together to form complete parts. This process often involves both manual and automated methods.

Quality assurance is integrated during assembly through the use of jigs and fixtures that ensure proper alignment and fitting. For complex assemblies, such as chain-driven live rollers, precision is vital to ensure smooth operation and longevity.

Finishing: What Techniques Are Used for Surface Treatment?

The finishing stage enhances the aesthetic and protective qualities of the parts. Techniques such as powder coating, anodizing, or galvanizing are commonly employed to improve corrosion resistance and durability.

This stage not only contributes to the visual appeal of the parts but also plays a significant role in their performance in harsh environments. Proper finishing can extend the lifespan of conveyor parts, making them more appealing to B2B buyers looking for reliability.

What Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance (QA) is paramount in the manufacturing process of conveyor parts, ensuring that the products meet both industry and customer expectations. For international B2B buyers, understanding the relevant standards is crucial.

Which International Standards Are Relevant for Conveyor Parts?

One of the most recognized international standards is ISO 9001, which outlines requirements for a quality management system. Compliance with ISO 9001 indicates that a manufacturer consistently delivers products that meet customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications such as CE marking (for products sold in Europe) and API standards (for oil and gas applications) can be critical. These certifications ensure that the products adhere to safety, health, and environmental regulations, which is particularly important for buyers in diverse regions such as Africa, South America, and the Middle East.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integral to maintaining high standards throughout the manufacturing process.

What Are the Different QC Checkpoints?

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival. Tests may include checking for physical properties, dimensions, and compliance with specifications.

-

In-Process Quality Control (IPQC): During manufacturing, random samples are tested at various stages. This can involve dimensional checks, material properties tests, and visual inspections. IPQC helps identify defects early, reducing waste and rework.

-

Final Quality Control (FQC): Before shipping, a final inspection ensures that all products meet the required specifications. This includes functionality tests, dimensional checks, and surface quality assessments.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly in international markets, verifying a supplier’s quality control processes is essential to mitigate risks and ensure product reliability.

Illustrative image related to conveyor parts

What Methods Can Buyers Use to Assess Supplier Quality?

-

Supplier Audits: Conducting regular audits allows buyers to assess a supplier’s manufacturing practices, quality control processes, and compliance with standards. This can be done by the buyer’s internal team or through third-party services.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insight into their quality management systems and past performance. Buyers should look for metrics such as defect rates and corrective action reports.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control processes. This is particularly important for international buyers who may not have the capacity to conduct on-site audits.

What Nuances Should International Buyers Consider in Quality Control?

When sourcing conveyor parts from international suppliers, buyers should be aware of specific nuances related to quality control.

How Do Regional Standards and Practices Affect Quality?

Different regions may have varying standards and practices in quality control. For example, while ISO 9001 is globally recognized, the implementation and rigor can vary by country. Buyers should ensure that their suppliers not only claim compliance but also demonstrate it through certifications and audit reports.

Moreover, cultural differences can influence quality perceptions and practices. Building strong relationships with suppliers through regular communication can help bridge these gaps, ensuring that expectations are clearly understood and met.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance mechanisms for conveyor parts is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, alongside rigorous quality control practices, buyers can ensure they procure reliable and high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘conveyor parts’

The following guide provides a structured approach for B2B buyers aiming to procure conveyor parts effectively. This checklist is designed to ensure that you consider all critical aspects of sourcing, from defining technical requirements to evaluating suppliers, thereby enhancing your procurement process.

Illustrative image related to conveyor parts

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the cornerstone of effective sourcing. This step involves detailing the types of conveyor parts you need, including dimensions, materials, and load capacities. A well-defined specification ensures that you communicate your needs accurately to suppliers and helps avoid costly mistakes later in the procurement process.

- Considerations:

- Identify the type of conveyor system (e.g., roller, belt, skatewheel).

- Determine the environment in which the parts will operate (e.g., temperature, humidity).

Step 2: Conduct Market Research

Understanding the market landscape is essential for identifying potential suppliers and products. Research different manufacturers and distributors of conveyor parts to gauge their offerings, prices, and market reputation. This knowledge will empower you to make informed decisions and negotiate effectively.

- Tips:

- Utilize online platforms and industry publications to gather information.

- Attend trade shows or webinars focused on material handling and conveyor systems.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is crucial. Request detailed company profiles, case studies, and references from businesses similar to yours. Assess their experience in your specific industry and their track record with product quality and service reliability.

- What to look for:

- Certifications and compliance with international standards.

- Customer reviews and testimonials that reflect satisfaction and reliability.

Step 4: Request Samples or Prototypes

Once you have shortlisted potential suppliers, requesting samples or prototypes of the conveyor parts is a prudent step. This allows you to evaluate the quality and compatibility of the parts with your existing systems before placing a bulk order.

- Benefits:

- Testing samples can reveal potential issues that may not be apparent in specifications.

- It provides an opportunity to assess the supplier’s responsiveness and support.

Step 5: Verify Supplier Certifications

Ensuring that your suppliers hold relevant certifications is critical for quality assurance. Certifications such as ISO 9001 indicate that a supplier adheres to international quality management standards, which can significantly reduce risks associated with product failure.

- Key Certifications:

- ISO certifications (e.g., ISO 9001 for quality management).

- Industry-specific certifications relevant to conveyor systems.

Step 6: Negotiate Terms and Pricing

Effective negotiation can lead to significant cost savings and favorable terms. Discuss pricing, payment terms, delivery schedules, and warranty options with your selected suppliers. A transparent negotiation process helps build a strong partnership and ensures mutual understanding.

- Strategies:

- Compare offers from multiple suppliers before finalizing.

- Be clear about your budget constraints and seek value-added services.

Step 7: Establish a Maintenance Plan

Once you have procured the conveyor parts, developing a maintenance plan is essential for ensuring long-term performance. Regular maintenance can prevent breakdowns and extend the lifespan of your equipment, ultimately saving costs.

- Considerations:

- Schedule regular inspections and servicing.

- Keep a stock of critical spare parts for quick replacements.

By following this checklist, B2B buyers can navigate the complexities of sourcing conveyor parts, ensuring they make informed decisions that align with their operational needs and business goals.

Comprehensive Cost and Pricing Analysis for conveyor parts Sourcing

What Are the Key Cost Components in Sourcing Conveyor Parts?

When sourcing conveyor parts, understanding the cost structure is crucial for making informed purchasing decisions. The primary components of cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materials typically account for a significant portion of the total cost, influenced by the type of materials used—such as aluminum, galvanized steel, or painted steel. Higher quality materials often lead to increased durability and reduced maintenance costs over time.

Labor costs encompass wages for the workforce involved in manufacturing, assembly, and quality checks. Automation may reduce labor costs but can increase initial investment in machinery.

Manufacturing overhead includes indirect costs such as utilities and facility maintenance, which are spread across all products produced.

Tooling costs can vary significantly based on the complexity of the parts being manufactured. Custom tooling is often necessary for specialized parts, adding to the initial costs.

Illustrative image related to conveyor parts

Quality control ensures that products meet required specifications, which can add to costs but ultimately reduces the risk of defects and returns.

Logistics costs involve transportation, warehousing, and distribution, which can fluctuate based on distance and shipping methods.

Finally, the profit margin is the markup that suppliers apply to cover their expenses and generate profit.

How Do Price Influencers Affect Conveyor Parts Costs?

Several factors influence the pricing of conveyor parts, particularly for international buyers. Volume and Minimum Order Quantity (MOQ) play significant roles in pricing; larger orders often lead to lower per-unit costs.

Specifications and customization can also impact pricing. Customized parts typically require additional engineering and manufacturing processes, which can increase costs.

Illustrative image related to conveyor parts

The choice of materials affects both the upfront cost and the longevity of the parts, influencing the total cost of ownership.

Quality certifications can be a price influencer as well. Parts that meet international standards may carry a higher price tag but offer reassurance regarding reliability and safety.

Supplier factors such as reputation, reliability, and location can also affect pricing. Local suppliers may offer lower shipping costs but might not have the same product range as international suppliers.

Incoterms define the responsibilities of buyers and sellers regarding shipping costs and risks, impacting overall pricing. For example, FOB (Free on Board) shipping terms can lead to different pricing structures than CIF (Cost, Insurance, and Freight).

What Tips Can Buyers Use to Negotiate Better Prices for Conveyor Parts?

When negotiating for conveyor parts, buyers should focus on several strategies to enhance cost-efficiency.

-

Understand Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, operational costs, and lifespan when evaluating offers.

-

Leverage Volume Discounts: If possible, consolidate orders to reach higher quantities that may qualify for discounts.

-

Request Multiple Quotes: Obtaining quotes from several suppliers can provide leverage in negotiations and help identify competitive pricing.

-

Consider Long-term Relationships: Building relationships with suppliers can lead to better pricing and terms over time. Suppliers may offer preferential pricing for repeat business.

-

Be Aware of Pricing Nuances in International Markets: Factors such as currency fluctuations, import tariffs, and local regulations can impact costs. Buyers from regions like Africa, South America, the Middle East, and Europe should be mindful of these variables.

-

Negotiate Payment Terms: Flexible payment terms can improve cash flow and may lead to better pricing arrangements.

Conclusion

Sourcing conveyor parts involves a complex interplay of cost components and pricing influencers. By understanding these elements and employing effective negotiation strategies, international B2B buyers can optimize their sourcing processes and achieve significant savings. Always remember that prices can vary widely based on specific requirements and market conditions, so thorough research and due diligence are essential in making informed purchasing decisions.

Alternatives Analysis: Comparing conveyor parts With Other Solutions

Understanding Alternatives to Conveyor Parts

In the realm of material handling, selecting the right technology is crucial for optimizing operational efficiency. While conveyor parts are a staple in many industries for transporting goods, there are alternative solutions that may better meet specific business needs. This analysis will explore two viable alternatives: Automated Guided Vehicles (AGVs) and Modular Belt Conveyors, comparing them against traditional conveyor parts.

| Comparison Aspect | Conveyor Parts | Automated Guided Vehicles (AGVs) | Modular Belt Conveyors |

|---|---|---|---|

| Performance | High throughput; ideal for continuous flow. | Flexible routing; suitable for dynamic environments. | Versatile; handles various product shapes and sizes. |

| Cost | Moderate initial investment; lower operational costs. | Higher upfront costs; savings on labor over time. | Moderate investment; cost-effective for custom layouts. |

| Ease of Implementation | Quick to install and integrate. | Requires mapping and programming; longer setup time. | Easy to configure and modify as needs change. |

| Maintenance | Regular maintenance needed; parts replacement common. | Low maintenance; fewer moving parts. | Moderate maintenance; belts may require periodic replacement. |

| Best Use Case | High-volume, repetitive tasks. | Warehouses with variable layouts and needs for flexibility. | Assembly lines needing adaptability and product changeover. |

What Are the Advantages and Disadvantages of Automated Guided Vehicles (AGVs)?

Automated Guided Vehicles (AGVs) represent a modern approach to material handling, utilizing navigation technology to transport goods across facilities. The primary advantage of AGVs is their flexibility; they can navigate complex environments without fixed paths, allowing for dynamic routing. This makes them ideal for warehouses with changing layouts or high variability in product types. However, the initial investment can be substantial, and the setup process involves detailed mapping and programming, which may lead to longer implementation times. Additionally, while AGVs require less maintenance than traditional conveyors, they do necessitate a robust technological infrastructure.

How Do Modular Belt Conveyors Compare to Traditional Conveyor Parts?

Modular belt conveyors offer a versatile solution for transporting products of various shapes and sizes. Their modular design allows for easy customization and reconfiguration, making them suitable for assembly lines where product types frequently change. The installation process is relatively straightforward, and they can be adapted to fit specific operational needs. However, while they provide flexibility, they may not achieve the same throughput as traditional conveyor parts in high-volume applications. Maintenance can also be moderate, as belts may need to be replaced periodically, but the overall adaptability often justifies the investment.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When evaluating conveyor parts against alternatives like AGVs and modular belt conveyors, B2B buyers should consider their specific operational requirements. Factors such as the nature of the products being transported, the layout of the facility, and budget constraints will play a significant role in determining the best solution. Buyers should also weigh the importance of flexibility against the need for high throughput. By aligning their choice with both immediate and future operational goals, buyers can ensure they select a solution that not only meets current demands but also adapts to evolving industry needs.

Essential Technical Properties and Trade Terminology for conveyor parts

What Are the Key Technical Properties of Conveyor Parts?

When evaluating conveyor parts, understanding the essential technical specifications is crucial for ensuring operational efficiency and longevity. Here are some critical properties:

-

Material Grade

The material grade of conveyor parts, such as steel or aluminum, determines their strength, durability, and resistance to environmental factors. For example, galvanized steel is commonly used for its corrosion resistance, making it suitable for outdoor or humid environments. Choosing the right material grade helps reduce replacement costs and ensures that the conveyor system can handle the intended load and environmental conditions. -

Tolerance

Tolerance refers to the permissible variation in dimensions of conveyor parts. Precise tolerances are vital for ensuring that components fit together correctly, which is essential for smooth operation. For example, if roller bearings have a tolerance that is too wide, it can lead to misalignment and increased wear on the system. Maintaining tight tolerances minimizes downtime and maintenance costs, making it a key specification for B2B buyers. -

Load Capacity

Load capacity indicates the maximum weight a conveyor part can safely transport. This property is critical for choosing the right components for specific applications. For instance, a conveyor belt with a load capacity of 500 kg is unsuitable for transporting heavier items. Understanding load capacities helps businesses select the appropriate parts to avoid mechanical failures and enhance overall system performance. -

Speed Rating

The speed rating measures how fast a conveyor part can operate while still maintaining functionality. Different applications require different speed ratings; for example, high-speed sorting systems require components designed for rapid movement. Selecting parts with the appropriate speed rating ensures efficiency and reduces the risk of jams or breakdowns. -

Environmental Resistance

This property assesses how well conveyor parts can withstand specific environmental conditions, such as temperature fluctuations, moisture, or exposure to chemicals. For example, conveyor belts used in food processing must meet stringent hygiene standards and be resistant to cleaning agents. Understanding the environmental resistance of parts aids in selecting components that will perform reliably in the intended setting.

What Are Common Trade Terms Used in the Conveyor Parts Industry?

Familiarity with industry jargon can significantly enhance communication and negotiation between buyers and suppliers. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the conveyor parts industry, sourcing from OEMs ensures that buyers receive high-quality components that are specifically designed for their systems, leading to better compatibility and performance. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is essential for B2B buyers, as it impacts inventory management and purchasing strategies. Suppliers often set MOQs to ensure profitability, so buyers should assess their needs carefully before placing orders. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products or services. This process allows buyers to compare offers from multiple vendors, ensuring they secure the best deal. Clear RFQs can streamline procurement and foster competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is vital for B2B transactions, as they affect cost structures and risk management in international shipping. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the goods are received. In the conveyor parts industry, shorter lead times can enhance production efficiency and responsiveness to market demands. B2B buyers should consider lead times when planning their operations to avoid disruptions.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, optimize their supply chains, and ultimately enhance operational efficiency in their conveyor systems.

Navigating Market Dynamics and Sourcing Trends in the conveyor parts Sector

In the conveyor parts sector, international B2B buyers are navigating a landscape shaped by several key market dynamics and technological advancements. Global drivers include the increasing demand for automation in manufacturing and logistics, which is pushing companies to invest in efficient material handling systems. The rise of e-commerce has also accelerated the need for advanced conveyor solutions, particularly in distribution centers. As businesses in Africa, South America, the Middle East, and Europe seek to optimize their supply chains, they are increasingly looking for reliable conveyor parts that enhance operational efficiency and minimize downtime.

Current and emerging trends in sourcing include a shift towards smart technologies, such as IoT-enabled conveyor systems that allow for real-time monitoring and predictive maintenance. Buyers are also prioritizing suppliers who offer comprehensive solutions, including integration services and ongoing support. The emphasis on customizable systems is rising, allowing businesses to tailor solutions to their specific operational needs. Additionally, the demand for rapid delivery times is influencing sourcing strategies, prompting buyers to consider local suppliers or those with robust logistics capabilities to ensure timely access to critical parts.

How Are Sustainability and Ethical Sourcing Impacting the Conveyor Parts Sector?

The growing emphasis on sustainability is reshaping how businesses source conveyor parts. As environmental concerns become more pronounced, companies are increasingly aware of the environmental impact of their supply chains. Ethical sourcing practices are gaining traction, with buyers prioritizing suppliers who demonstrate a commitment to minimizing their carbon footprint and reducing waste.

Certifications such as ISO 14001 and adherence to environmental standards are becoming essential criteria for selecting suppliers. Buyers are now seeking conveyor parts made from recycled or eco-friendly materials, reflecting a broader trend towards circular economy principles. Moreover, companies that invest in sustainable practices often experience enhanced brand loyalty and competitive advantage, as consumers and other businesses increasingly favor environmentally responsible partners.

What is the Historical Context of the Conveyor Parts Market?

The conveyor parts market has evolved significantly over the past few decades. Originally, conveyor systems were primarily mechanical and manually operated, limiting their efficiency and applicability. However, with advancements in technology, the introduction of electric and automated systems has revolutionized the industry. The integration of digital technologies and automation has enabled more sophisticated and efficient conveyor solutions, allowing businesses to streamline operations and reduce labor costs. This historical progression has set the stage for the current landscape, where international B2B buyers are increasingly focused on sourcing innovative and sustainable conveyor solutions that meet the demands of modern industry.

By understanding these dynamics, international B2B buyers can better navigate the complexities of sourcing conveyor parts, ensuring they select the best partners and solutions to drive their operational success.

Frequently Asked Questions (FAQs) for B2B Buyers of conveyor parts

1. How do I solve issues with conveyor parts compatibility?

To address compatibility issues with conveyor parts, first, identify the specific components of your existing system, including dimensions, material specifications, and operational requirements. Consult with manufacturers or suppliers for technical documentation, such as part specifications and compatibility charts. It’s advisable to request samples or prototypes before making bulk orders. Additionally, leveraging the expertise of suppliers who offer customized solutions can help ensure that the parts fit seamlessly into your existing infrastructure, minimizing downtime and operational disruptions.

2. What is the best type of conveyor belt for heavy loads?

For heavy loads, a heavy-duty conveyor belt made from reinforced materials like steel or PVC is typically the best choice. These belts are designed to withstand significant weight and stress while maintaining durability. Consider using a modular belt system, which allows for easy repairs and adjustments. It’s essential to assess the specific load requirements, including weight distribution and environmental factors such as temperature and moisture, to choose the most suitable belt type. Consulting with suppliers for tailored recommendations can also optimize performance.

3. How can I vet suppliers for conveyor parts internationally?

When vetting international suppliers for conveyor parts, consider their reputation, certifications, and experience in the industry. Request references from previous clients and check online reviews to gauge reliability. It’s crucial to verify their compliance with international quality standards, such as ISO certifications. Conducting an audit of their manufacturing facilities, if feasible, can provide insight into their production capabilities. Additionally, initiate small trial orders to assess product quality and service responsiveness before committing to larger purchases.

4. What are the typical minimum order quantities (MOQs) for conveyor parts?

Minimum order quantities (MOQs) for conveyor parts can vary widely based on the supplier and the type of parts required. Standard components may have lower MOQs, while specialized or customized parts typically require larger orders. Discussing your specific needs with suppliers can sometimes lead to flexibility in MOQs, especially if you’re willing to establish a long-term relationship. Always clarify MOQ terms during negotiations to avoid unexpected costs and ensure that your purchasing aligns with operational demands.

5. What payment terms should I expect when sourcing conveyor parts internationally?

Payment terms for international conveyor parts sourcing often include options like advance payment, letters of credit, or payment upon delivery. It’s common for suppliers to request a deposit, typically 30-50% upfront, with the balance due upon shipment or delivery. Always negotiate favorable terms that protect your interests while ensuring the supplier’s security. Additionally, consider using secure payment platforms that offer buyer protection to mitigate risks associated with international transactions.

6. How can I ensure quality assurance (QA) for conveyor parts?

To ensure quality assurance for conveyor parts, establish clear specifications and quality standards with your suppliers before placing orders. Request documentation such as test certificates and compliance reports to verify that parts meet required standards. Implement a quality control process upon receiving goods, including inspections and testing of critical components. Additionally, consider partnering with suppliers who offer warranties or guarantees on their products, providing further assurance of quality and reliability.

7. What logistics considerations should I keep in mind when importing conveyor parts?

When importing conveyor parts, consider factors such as shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder familiar with your destination’s import regulations to streamline the process. Ensure that all documentation, including invoices and customs declarations, is accurate and complete to avoid delays. Additionally, factor in potential tariffs and duties in your overall cost analysis to ensure that your budget accommodates all logistics-related expenses.

8. Can I customize conveyor parts to fit my specific needs?

Yes, many suppliers offer customization options for conveyor parts to meet specific operational needs. This can include tailored dimensions, materials, and functionalities designed for particular applications. When seeking customization, communicate your requirements clearly, including performance expectations and any industry-specific regulations. Collaborating closely with the supplier during the design process can help ensure that the final products meet your unique specifications, ultimately enhancing efficiency and productivity in your operations.

Top 9 Conveyor Parts Manufacturers & Suppliers List

1. McMaster – Conveyor Parts

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Conveyor Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Ashland Conveyor – Replacement Parts

Domain: ashlandconveyor.com

Registered: 1999 (26 years)

Introduction: Conveyor Parts | Replacement Parts | Ashland Conveyor includes a wide selection of replacement parts for conveyor systems such as:

– Gravity Rollers

– Tapered Rollers

– Roller Conveyor

– Skatewheel Conveyor

– FlexExtend Skatewheel

– Telescoping Conveyor

– Ball Transfer Tables

– Ball Transfer Insert Assys

– Flow Rail

– Power Belt Incline

– Power Belt Chain Driven Live Roller

– Controls

– H-Stands

-…

3. Motion – Conveyor Components

Domain: motion.com

Registered: 1994 (31 years)

Introduction: This company, Motion – Conveyor Components, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Emicorp – Key Products

Domain: emicorp.com

Registered: 2003 (22 years)

Introduction: Key product details include: 1. **Motors**: Various gearmotors including 1/20 HP, 1/4 HP, and 1/6 HP models from Leeson. 2. **Gearbox**: 15:1 Right Angle Gear Reducers (MotoVario 030 and 040). 3. **Bearings**: 10mm Cylindrical Bore Bearing, Double Shield #6200ZZ. 4. **Pulleys**: Multiple types including 12″ Drive Pulley, Double V-Guide and 12″ Tail Pulley, Double V-Guide. 5. **Rollers**: 12″ Gravi…

5. Conveyor and Parts – Belts and Components

Domain: conveyorandparts.com

Registered: 2008 (17 years)

Introduction: Belts, Chain, Driver Pad, Guarding, Motors, O-Rings, Photo-Eyes, Reducers, Rollers, Sorter Parts, Accuglide Chain, Accuglide Driver Pad, Automotion Air Bladder, Buschman AC250 Shoe, Buschman AC Lifting Diaphragm, Buschman Drive Wheel 14 Tooth, Lineshaft O-Ring, TGW 2″ Wide Belt.

6. Belt Power – Conveyor Components & Belting

Domain: beltpower.com

Registered: 1998 (27 years)

Introduction: Conveyor Components: Segmented Transfer Plates, Roller Chain Sprockets, Belt Scrapers / Brushes, Belt Trackers, Take-Ups, Clean-In-Place, Wear Strips, Guide Rails, Hose Guarding, Bearing Covers, Hoppers. Conveyor Belting: Lightweight Conveyor Belting, Food Conveyor Belting (FDA, USDA, AAA Dairy), General Conveyor Belting, Incline Conveyor Belting, Machine Tapes / Power Transmission, Airport / Dist…

7. QC Conveyors – Conveyor Parts and Services

Domain: qcconveyors.com

Registered: 2013 (12 years)

Introduction: QC Conveyors offers a range of conveyor parts and services designed to maximize equipment uptime and longevity. Key offerings include: 1. **Spare Conveyor Parts**: Genuine OEM parts ensure optimal machine operation and reliability. 2. **Part Kits**: Designed to streamline maintenance, these kits include recommended maintenance parts, wear parts, and consumables tailored to specific equipment. 3. *…

8. AGI Batco – 2035 Main Assembly Parts Finder

Domain: grainhandlingdirect.com

Registered: 2021 (4 years)

Introduction: [{‘SKU’: ‘20000304P-1’, ‘brand’: ‘AGI Batco’, ‘name’: ‘AGI Batco 2035 Main Assembly Parts Finder’, ‘price_range’: ‘$2.00 – $7,682.00’, ‘standard_ship_time’: ‘2-6 Weeks’}, {‘SKU’: ‘20000304P’, ‘brand’: ‘AGI Batco’, ‘name’: ‘AGI Batco 2035 TD Main Assembly Parts Finder’, ‘price_range’: ‘$2.00 – $6,563.00’, ‘standard_ship_time’: ‘2-6 Weeks’}, {‘SKU’: ‘13030100-26’, ‘brand’: ‘AGI Batco’, ‘name’: ‘AGI …

9. WDS – Durasoft Urethane Shaft Drive Rollers

Domain: wdscomponents.com

Registered: 2014 (11 years)

Introduction: {“products”:[{“sku”:”WDS 565″,”name”:”Durasoft Urethane Shaft Drive Rollers”,”diameter”:”2 1/2 inch”,”starting_price”:”$71.68″},{“sku”:”WDS 450″,”name”:”Conveyor support tube”,”material”:”304 stainless steel”,”starting_price”:”$10.34″},{“sku”:”WDS 444″,”name”:”Stainless steel support bearing self aligning”,”starting_price”:”$21.91″},{“sku”:”WDS 444″,”name”:”Bearing cover”,”starting_price”:”$0.99″}…

Strategic Sourcing Conclusion and Outlook for conveyor parts

In today’s competitive landscape, strategic sourcing of conveyor parts is essential for optimizing supply chains and enhancing operational efficiency. By prioritizing quality, reliability, and cost-effectiveness, international B2B buyers can ensure that their conveyor systems operate at peak performance. The diverse range of components available—from rollers and belts to motors and supports—highlights the importance of selecting the right parts tailored to specific operational needs.

Investing in long-term relationships with suppliers not only fosters innovation but also enables businesses to adapt to changing market demands. For buyers in Africa, South America, the Middle East, and Europe, leveraging local suppliers can reduce lead times and shipping costs, while also supporting regional economies.

Looking ahead, the conveyor parts market is poised for growth, driven by advancements in technology and automation. Buyers are encouraged to stay proactive in their sourcing strategies, continuously evaluating their suppliers and exploring new partnerships to enhance their competitive edge. Engage with your suppliers today to secure the best solutions that align with your operational goals and future growth trajectories.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.