Is Your Check Valve Design Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for check valve design

In the ever-evolving global market, sourcing the right check valve design poses significant challenges for B2B buyers, particularly in diverse regions such as Africa, South America, the Middle East, and Europe. With the need to ensure operational efficiency and reliability in various applications—from preventing backflow in sensitive systems to maintaining pump priming—making informed decisions is crucial. This comprehensive guide aims to equip international buyers with the essential insights needed to navigate the complexities of check valve selection and procurement.

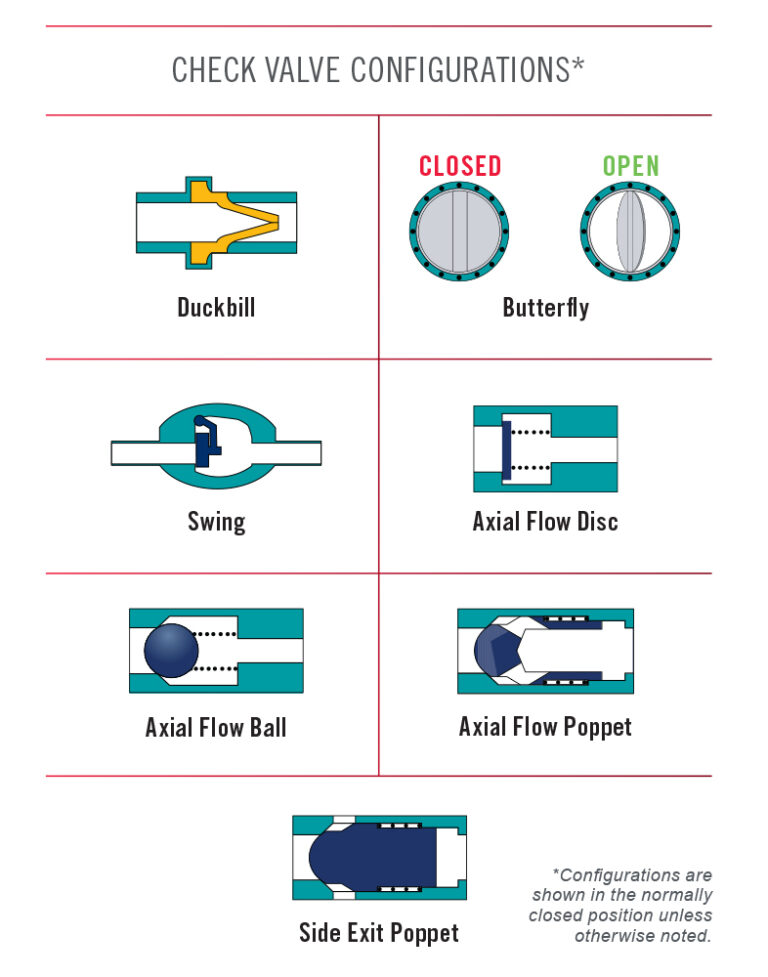

Throughout this guide, we delve into the various types of check valves, including miniature options and their specific applications, as well as the critical factors to consider when vetting suppliers. We will discuss the importance of understanding cracking pressures, maximum working pressures, and the materials used in valve construction. Additionally, cost considerations and flow capacity will be thoroughly examined to help buyers optimize their investments.

By consolidating this wealth of knowledge, we empower B2B buyers to make strategic purchasing decisions that align with their operational needs. Whether you’re in Germany or Nigeria, our guide will provide the tools to assess suppliers effectively, ensuring that you select check valves that not only meet your specifications but also enhance the overall efficiency of your systems.

Understanding check valve design Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ball Check Valve | Utilizes a spherical ball as a sealing element; effective for high flow rates. | Water treatment, HVAC systems, industrial processes. | Pros: High flow capacity; reliable. Cons: Can be prone to wear; not suitable for low flow applications. |

| Swing Check Valve | Features a hinged disc that swings open with flow; ideal for larger pipelines. | Oil and gas, wastewater management, irrigation. | Pros: Minimal pressure drop; durable. Cons: Requires vertical installation; potential for water hammer. |

| Diaphragm Check Valve | Employs a flexible diaphragm to seal; sensitive to low pressure. | Chemical processing, food and beverage, pharmaceuticals. | Pros: Good for low flow; prevents contamination. Cons: Limited to specific pressure ranges; diaphragm wear over time. |

| Duckbill Check Valve | Has a flexible, bill-like design; allows for low-pressure applications. | Medical devices, drainage systems, aquaculture. | Pros: Low cracking pressure; seals around solids. Cons: Not suitable for high-pressure systems; limited flow capacity. |

| Spring-Loaded Check Valve | Incorporates a spring mechanism for positive sealing; versatile in orientation. | Pump systems, fuel lines, hydraulic applications. | Pros: Reliable resealing; effective in various positions. Cons: More complex; may require maintenance over time. |

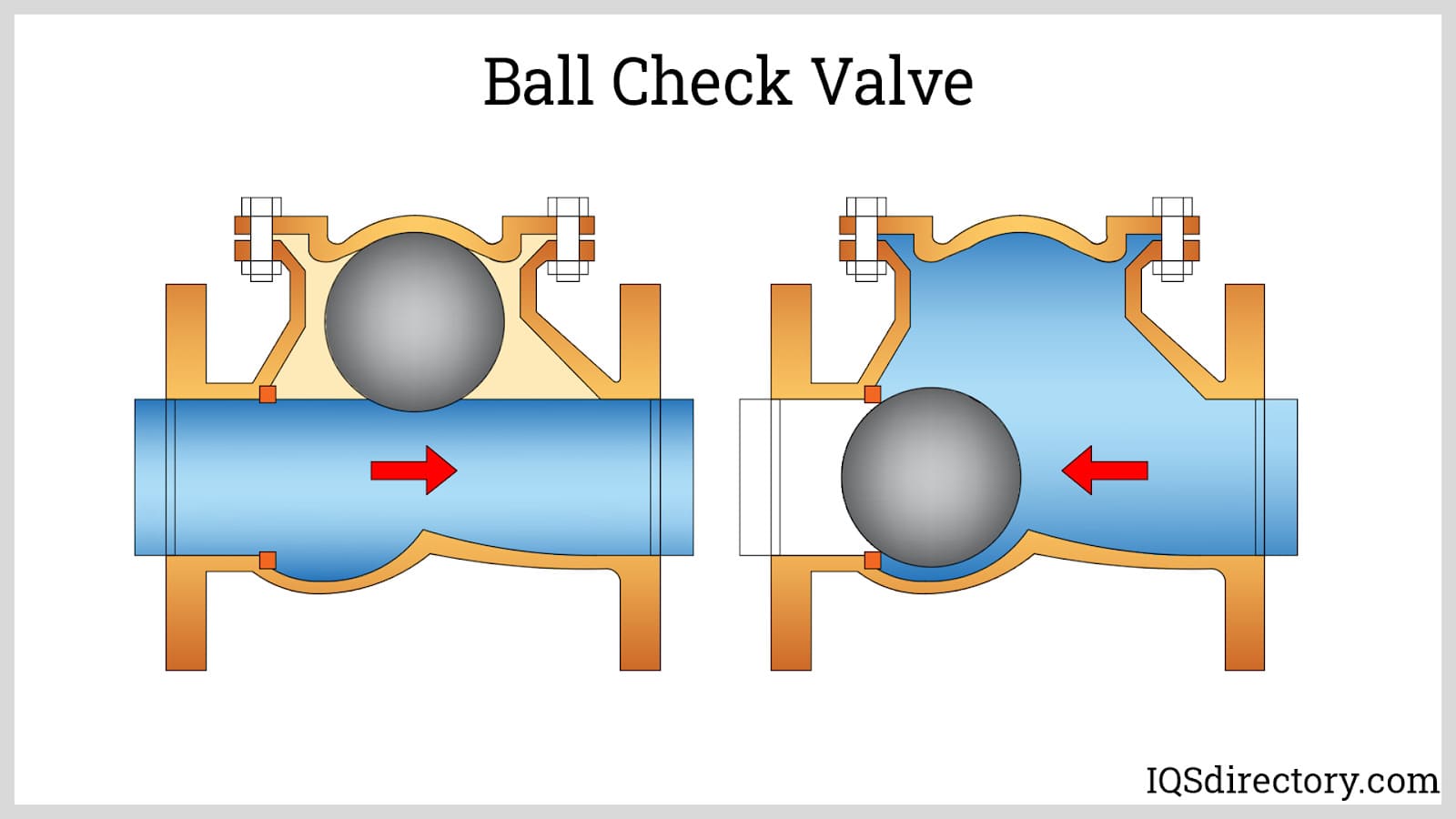

What are the Characteristics of Ball Check Valves and Their Suitability?

Ball check valves are designed with a spherical ball that acts as the sealing element, providing a robust mechanism for preventing backflow. These valves excel in high flow applications, making them ideal for industries such as water treatment and HVAC systems. When purchasing, buyers should consider the valve’s material compatibility with the fluid, as well as the potential for wear over time, especially in high-velocity environments.

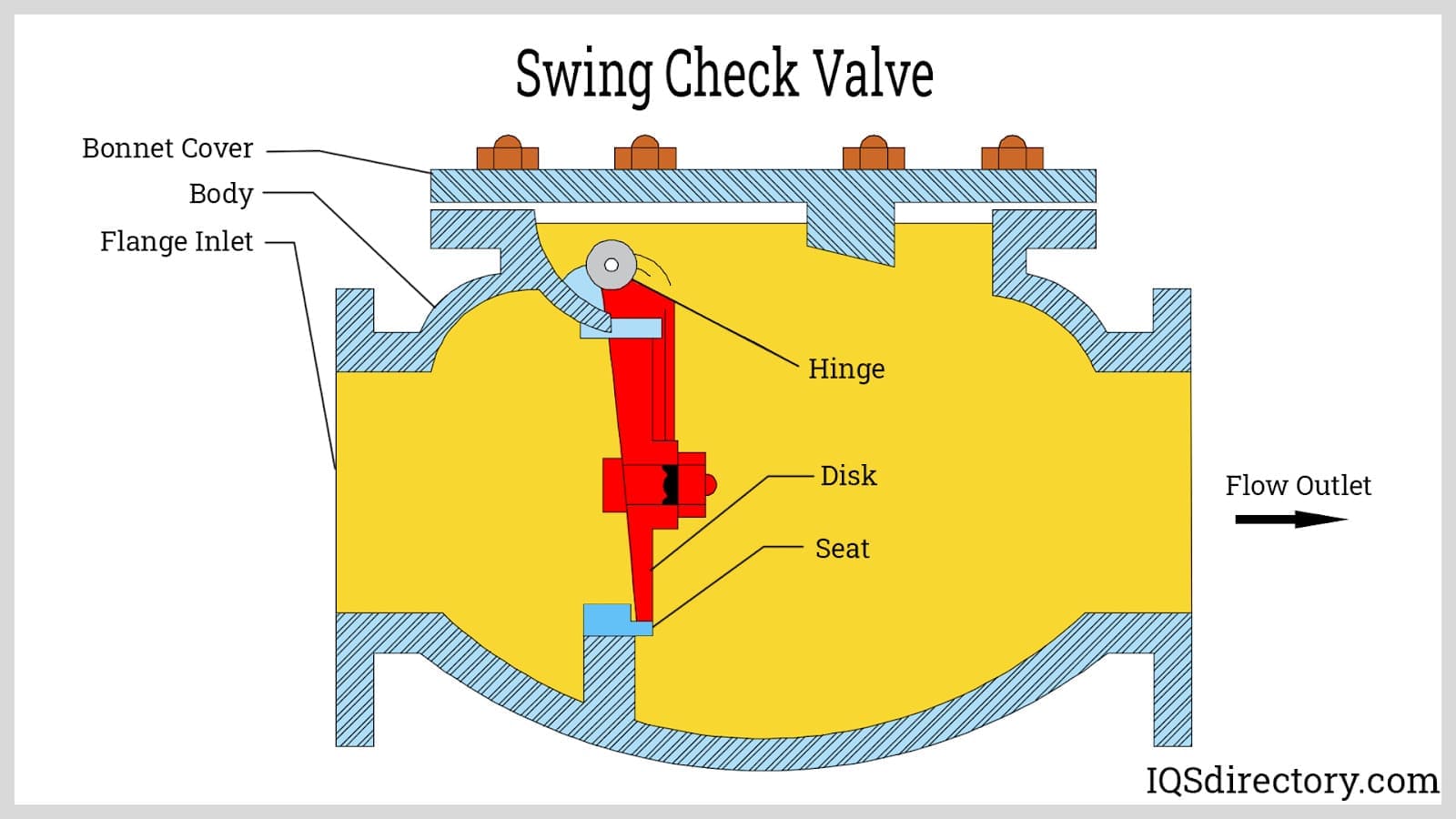

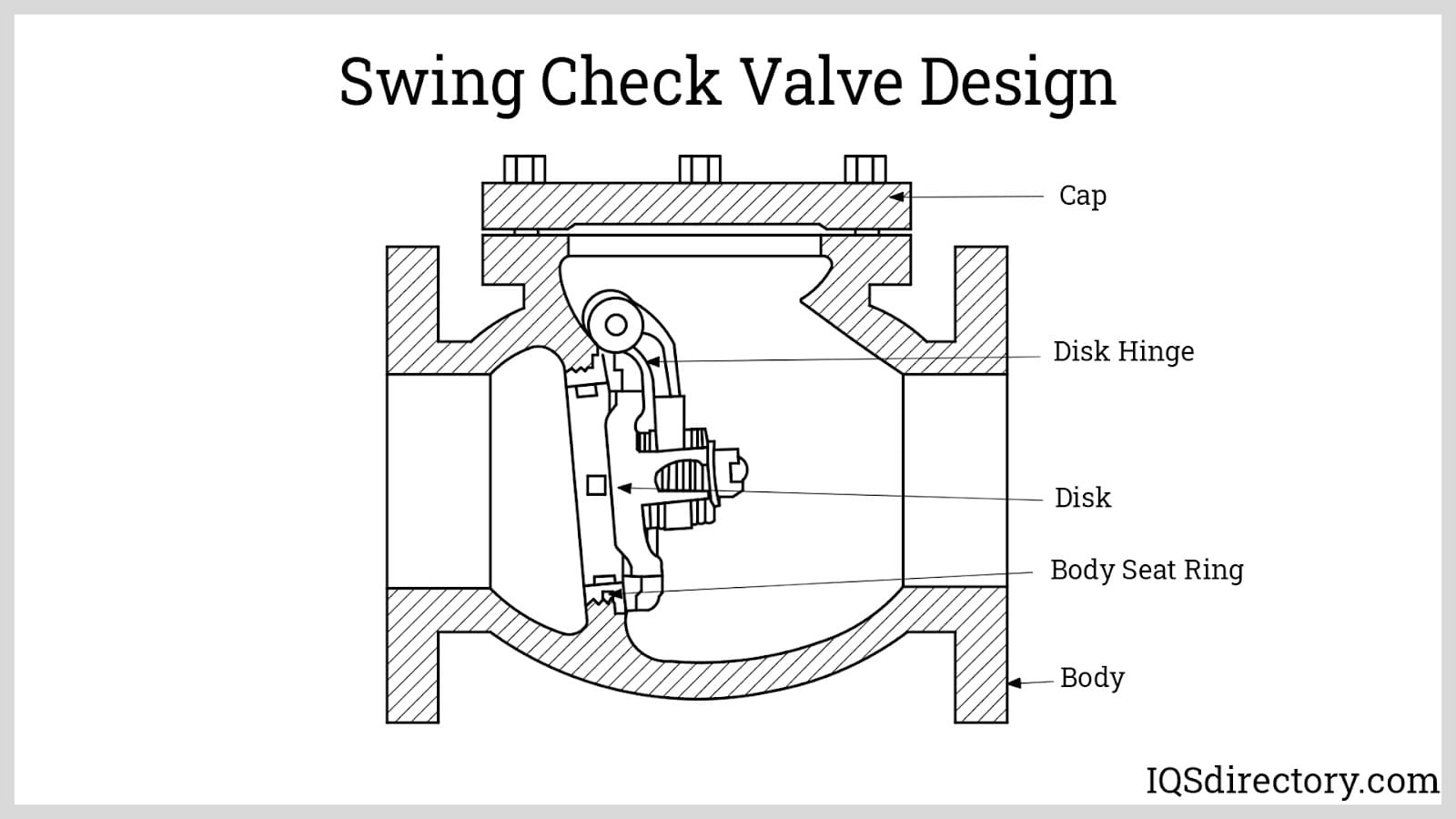

How Do Swing Check Valves Operate and Where are They Used?

Swing check valves utilize a hinged disc that swings open with the flow of liquid, allowing for efficient one-way flow in larger pipelines. They are commonly found in oil and gas applications, as well as in wastewater management. Buyers should note the installation requirements, as these valves are best suited for vertical orientations, and be aware of the potential for water hammer, which can impact system integrity.

What Makes Diaphragm Check Valves Unique for Specific Industries?

Diaphragm check valves utilize a flexible diaphragm to create a seal, making them highly sensitive to low pressure. This design is particularly advantageous in industries such as chemical processing and pharmaceuticals, where contamination prevention is critical. When selecting these valves, buyers should evaluate the pressure ranges and ensure that the diaphragm material is compatible with the fluids being handled, as wear can affect performance.

Why Choose Duckbill Check Valves for Low-Pressure Applications?

Duckbill check valves are characterized by their flexible, bill-like design, which allows them to open easily under low-pressure conditions. They are particularly useful in applications like medical devices and aquaculture. Buyers should consider the low cracking pressure and ability to seal around solids, but must also be cautious of their limitations in high-pressure environments and flow capacity.

What Are the Benefits of Spring-Loaded Check Valves in Various Applications?

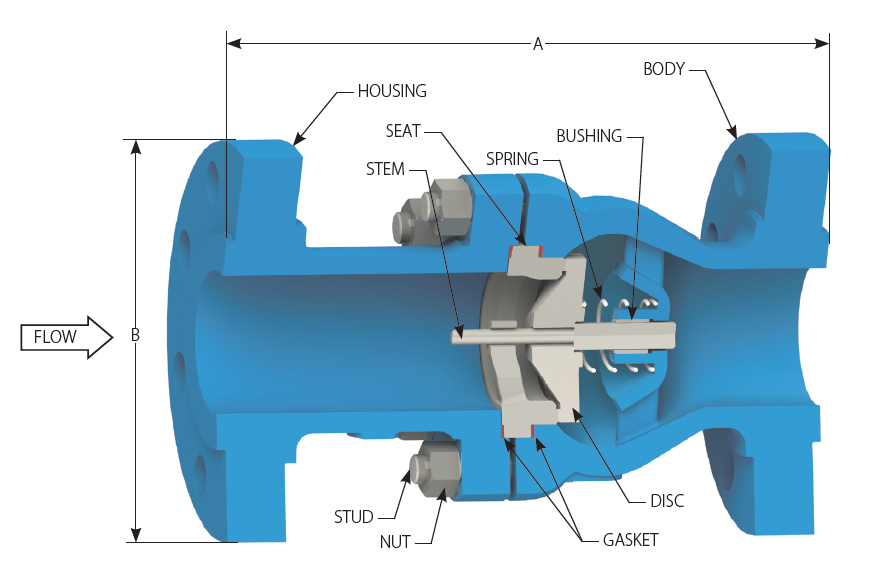

Spring-loaded check valves use a spring mechanism to ensure a positive seal, making them versatile for various orientations, including horizontal and vertical installations. They are commonly used in pump systems and hydraulic applications due to their reliable resealing capabilities. Buyers should be aware of the complexity of these valves and potential maintenance needs, especially in demanding operational environments.

Key Industrial Applications of check valve design

| Industry/Sector | Specific Application of check valve design | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Preventing backflow in pipeline systems | Enhances safety by avoiding spills and contamination | Compatibility with high-pressure and corrosive fluids |

| Water Treatment | Protecting water purification systems | Ensures clean water supply and protects equipment | Resistance to various chemicals and environmental factors |

| Pharmaceutical | Safeguarding sensitive processes in drug production | Maintains purity and prevents contamination | Compliance with industry standards and regulations |

| Food & Beverage | Maintaining hygiene in processing lines | Ensures product safety and quality | Material compatibility with food-grade requirements |

| HVAC | Controlling airflow in ventilation systems | Improves energy efficiency and system reliability | Temperature and pressure ratings specific to HVAC needs |

How is Check Valve Design Used in the Oil & Gas Industry?

In the oil and gas sector, check valves are crucial for preventing backflow in pipeline systems, particularly in high-pressure environments. These valves enhance safety by mitigating the risk of spills and contamination, which can have severe environmental and financial repercussions. Buyers must consider the valve’s compatibility with corrosive fluids and its ability to withstand high pressures, ensuring reliable performance in challenging conditions.

What Role Do Check Valves Play in Water Treatment Systems?

Check valves are integral to water treatment facilities, where they protect purification systems from backflow, ensuring a clean and safe water supply. They help maintain operational integrity by preventing contamination from reverse flows, which is vital for public health. Buyers should prioritize valves that are resistant to various chemicals and can withstand environmental factors like temperature fluctuations, especially in regions with diverse climates.

Why are Check Valves Essential in Pharmaceutical Manufacturing?

In pharmaceutical production, check valves safeguard sensitive processes by ensuring that pure substances remain uncontaminated. These valves are designed to maintain the integrity of the production environment, preventing backflow that could introduce impurities. Buyers in this sector must ensure that their check valves comply with strict industry standards and regulations, including material certifications that guarantee safety and reliability in drug manufacturing.

How Do Check Valves Ensure Safety in Food & Beverage Processing?

In the food and beverage industry, check valves play a vital role in maintaining hygiene throughout processing lines. They prevent backflow that could contaminate products, ensuring that safety and quality standards are met. Sourcing considerations include material compatibility with food-grade requirements, which is essential for compliance with health regulations and to avoid compromising product integrity.

Illustrative image related to check valve design

What Benefits Do Check Valves Provide in HVAC Systems?

Check valves are essential in HVAC systems for controlling airflow and ensuring efficient operation. They prevent backflow, which can lead to energy losses and system inefficiencies. When sourcing check valves for HVAC applications, buyers should focus on temperature and pressure ratings that align with the specific needs of their systems, ensuring optimal performance and reliability in various operating conditions.

3 Common User Pain Points for ‘check valve design’ & Their Solutions

Scenario 1: Ensuring Optimal Cracking Pressure for System Efficiency

The Problem: Many B2B buyers struggle with selecting the appropriate cracking pressure for check valves in their systems. If the cracking pressure is set too high, the valve may not open effectively, leading to insufficient flow rates and potential system failures. Conversely, a cracking pressure that is too low can result in unwanted backflow, damaging sensitive equipment or contaminating processes. This challenge is particularly pronounced in applications across diverse industries, such as water treatment or oil and gas, where precise flow control is critical.

The Solution: To overcome this issue, B2B buyers should conduct a thorough analysis of their system’s operating conditions. This includes identifying the maximum flow pressure and understanding the dynamics of fluid movement within the system. Buyers should work closely with manufacturers to specify check valves with a cracking pressure that is slightly below the normal operating pressure, ensuring that the valves open fully under standard conditions. Additionally, utilizing software tools to model fluid dynamics can provide insights into the optimal cracking pressure needed for specific applications, ultimately enhancing system efficiency and reliability.

Illustrative image related to check valve design

Scenario 2: Managing Temperature Variability to Prevent Valve Failure

The Problem: In regions with extreme temperatures, such as those found in parts of Africa or the Middle East, check valves may face significant challenges related to temperature fluctuations. Buyers often find that the materials used in check valves can expand or contract in response to temperature changes, leading to improper sealing and potential system leaks. This issue is compounded when the media flowing through the valves has varying temperatures, which can further degrade valve performance and reliability.

The Solution: Buyers should prioritize the selection of check valves made from materials that have a high tolerance for thermal expansion, such as specific polymers or metals designed for high-temperature applications. It is essential to specify valves that not only meet the maximum expected temperature but also the minimum, as both extremes can impact valve integrity. Collaborating with suppliers who offer temperature-resistant sealing solutions can also mitigate these risks. Regular maintenance checks that include thermal inspections can ensure that the valves continue to function effectively under fluctuating conditions.

Scenario 3: Preventing Backflow Contamination in Critical Processes

The Problem: In industries such as pharmaceuticals and food processing, the risk of backflow contamination can be a major concern for buyers. When check valves fail to prevent backflow, it can lead to contamination of purified systems, causing significant financial losses and compliance issues. This scenario is particularly critical in applications where maintaining sterile conditions is non-negotiable, and buyers must navigate stringent regulations.

The Solution: To address this challenge, buyers should implement a dual check valve system that adds a layer of security against backflow. By using two check valves in series, the likelihood of backflow is drastically reduced, as the first valve acts as a primary barrier while the second provides an additional layer of protection. Additionally, buyers must ensure that the selected check valves feature bubble-tight seals and are rated for the specific pressures and temperatures of their application. Regular testing and maintenance of the valves should be instituted to verify their performance and integrity, ensuring compliance with industry standards and protecting against contamination risks.

Strategic Material Selection Guide for check valve design

What Are the Key Properties of Common Materials Used in Check Valve Design?

When selecting materials for check valves, it is crucial to consider properties such as temperature and pressure ratings, corrosion resistance, and overall durability. Here, we analyze four common materials used in check valve design: brass, stainless steel, PVC, and PTFE.

How Does Brass Perform in Check Valve Applications?

Brass is a popular choice for check valves due to its excellent machinability and good corrosion resistance, particularly in water and gas applications. It typically has a pressure rating of up to 150 psi and can withstand temperatures ranging from -20°F to 180°F. The main advantages of brass include its affordability and ease of manufacturing, making it suitable for a wide range of applications. However, brass can corrode in certain environments, particularly in the presence of chlorides, which may limit its use in specific applications.

For international buyers, especially in regions like Africa and South America, compliance with local standards such as ASTM B283 is essential. Brass check valves are often preferred in plumbing and HVAC systems due to their cost-effectiveness and reliability.

What Advantages Does Stainless Steel Offer for Check Valve Design?

Stainless steel is renowned for its superior strength, corrosion resistance, and ability to withstand high temperatures and pressures, making it ideal for demanding environments. With pressure ratings often exceeding 500 psi and temperature limits up to 1000°F, stainless steel check valves are suitable for applications involving steam, chemicals, and high-pressure systems. The durability of stainless steel translates to a longer service life, reducing maintenance costs.

However, the higher manufacturing complexity and cost of stainless steel may deter some buyers, particularly in developing regions. Compliance with standards like DIN EN 10088 is critical for buyers in Europe and the Middle East, where stringent regulations govern material selection.

Why Is PVC a Cost-Effective Option for Check Valves?

PVC (Polyvinyl Chloride) is a lightweight and cost-effective material commonly used in check valves for low-pressure applications. It offers excellent corrosion resistance against a wide range of chemicals, making it suitable for water treatment and chemical processing industries. PVC check valves typically have a pressure rating of up to 150 psi and can operate within a temperature range of 32°F to 140°F.

While PVC is less durable than metals, its low cost and ease of installation make it an attractive option for budget-conscious projects. Buyers in Africa and South America may find PVC check valves particularly appealing due to their affordability and availability, but they should ensure compliance with local standards such as ASTM D1784.

What Role Does PTFE Play in High-Performance Check Valves?

PTFE (Polytetrafluoroethylene) is a high-performance plastic known for its exceptional chemical resistance and low friction properties. It is ideal for applications involving aggressive chemicals and extreme temperatures, with a temperature rating of up to 500°F and pressure ratings around 150 psi. PTFE check valves are often used in the pharmaceutical and food processing industries due to their non-reactive nature.

The main drawbacks of PTFE include its higher cost and manufacturing complexity compared to traditional materials. International buyers, particularly in Europe, should ensure that PTFE products meet relevant standards such as FDA and EU regulations for food safety.

Illustrative image related to check valve design

Summary of Material Selection for Check Valve Design

| Material | Typical Use Case for check valve design | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Plumbing and HVAC systems | Affordable and easy to manufacture | Corrosion in chloride environments | Low |

| Stainless Steel | High-pressure and high-temperature applications | Superior strength and durability | Higher cost and manufacturing complexity | High |

| PVC | Water treatment and chemical processing | Lightweight and cost-effective | Less durable than metals | Low |

| PTFE | Pharmaceutical and food processing | Exceptional chemical resistance | Higher cost and complexity | High |

This strategic material selection guide provides B2B buyers with a comprehensive overview of the materials used in check valve design, helping them make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for check valve design

What Are the Main Stages in the Manufacturing Process for Check Valve Design?

The manufacturing process for check valves involves several critical stages, each essential for ensuring the final product meets quality and performance standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used in Check Valve Manufacturing?

The first step in check valve manufacturing is selecting and preparing the appropriate materials. Common materials include brass, stainless steel, plastic, and elastomers for seals. Each material offers unique benefits: metals provide durability and resistance to high pressures, while plastics offer corrosion resistance and lighter weight.

Once the materials are selected, they undergo quality checks to ensure they meet the required specifications. This can include verifying the chemical composition, mechanical properties, and ensuring they are free from defects.

How Is the Forming Process Conducted for Check Valves?

The forming stage involves shaping the prepared materials into the required components of the check valve. Techniques such as machining, injection molding, and stamping are commonly used.

Illustrative image related to check valve design

- Machining: For metal components, precision machining ensures tight tolerances and surface finishes that are critical for sealing and flow efficiency.

- Injection Molding: For plastic components, injection molding allows for complex shapes and high-volume production while maintaining uniformity.

- Stamping: This technique is often used for creating valve bodies and other flat components, ensuring quick and efficient production.

Each forming method must be carefully controlled to maintain quality standards, as even minor deviations can affect the valve’s performance.

What Steps Are Involved in the Assembly of Check Valves?

After forming, the next step is assembly. This phase requires precision to ensure that all components fit together correctly. The assembly process typically involves:

- Component Inspection: Before assembly, each part is inspected to ensure it meets design specifications.

- Assembly Techniques: Components are assembled using methods such as welding, bonding, or mechanical fastening, depending on the materials and design of the valve.

- Sealing: The installation of seals is critical, especially in preventing leaks. Sealing materials must be compatible with the media the valve will handle, such as liquids or gases.

Quality control checks are integrated throughout the assembly process to catch any issues early.

What Finishing Techniques Are Used for Check Valves?

The finishing stage enhances both the aesthetics and functionality of the check valve. This can include processes such as:

Illustrative image related to check valve design

- Surface Treatment: Techniques like anodizing, plating, or coating are applied to enhance corrosion resistance and improve surface finish.

- Cleaning: Thorough cleaning ensures that no contaminants remain on the valve surfaces, which could affect performance.

- Final Inspection: A comprehensive inspection is conducted to ensure that the finished product meets all specifications before it is packaged for shipment.

How Is Quality Assurance Ensured in Check Valve Manufacturing?

Quality assurance (QA) is crucial in check valve manufacturing to ensure that products meet international standards and customer expectations. This involves adhering to relevant quality standards, implementing checkpoints during production, and conducting various testing methods.

What Are the Relevant International Standards for Check Valves?

Manufacturers of check valves must comply with several international standards, including:

- ISO 9001: This standard focuses on quality management systems and is essential for manufacturers to demonstrate their commitment to quality.

- CE Marking: In Europe, check valves must meet health, safety, and environmental protection standards, which is verified through CE marking.

- API Standards: In the oil and gas industry, the American Petroleum Institute (API) provides specific standards that check valves must meet for safety and reliability.

These standards ensure that the manufacturing process is reliable and that the products are safe for use in various applications.

What Are the Key Quality Control Checkpoints in Check Valve Production?

Quality control (QC) checkpoints are integrated into various stages of the manufacturing process to ensure product integrity:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to confirm they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during production helps identify defects early. This can involve measuring tolerances and conducting visual inspections.

- Final Quality Control (FQC): Once the check valves are assembled, they undergo final inspections and testing to ensure they meet all performance criteria.

What Common Testing Methods Are Used for Check Valves?

Testing methods for check valves are vital for validating performance and safety. Common testing methods include:

- Hydrostatic Testing: This test checks for leaks by pressurizing the valve with water, ensuring it can withstand the required operating pressures.

- Functional Testing: Assessing the valve’s ability to open and close under specified conditions ensures that it operates as intended.

- Material Testing: This may include tensile strength tests, hardness tests, and corrosion resistance tests to validate the materials used.

These tests are often documented in detailed reports that can be shared with B2B buyers for transparency.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are several strategies to ensure quality:

- Supplier Audits: Conducting on-site audits of the manufacturing facility can provide insights into their quality assurance practices and compliance with international standards.

- Quality Reports: Requesting documentation such as inspection reports, test results, and certifications can help verify that the supplier adheres to quality standards.

- Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased evaluation of the supplier’s processes and product quality.

What Are the Quality Control and Certification Nuances for International Buyers?

When dealing with suppliers from different regions, B2B buyers must be aware of specific nuances regarding quality control and certifications.

- Regulatory Compliance: Different regions may have varying requirements for certifications and product approvals. It’s crucial to ensure that products meet local regulations.

- Cultural Differences: Understanding the cultural context of the supplier’s region can aid in effectively communicating quality expectations and requirements.

- Logistics and Supply Chain: Buyers should consider the logistics of sourcing from international suppliers, including the potential for delays in compliance and certification processes.

By focusing on these areas, international B2B buyers can ensure they source high-quality check valves that meet their specific needs while maintaining compliance with relevant standards.

Illustrative image related to check valve design

Practical Sourcing Guide: A Step-by-Step Checklist for ‘check valve design’

In today’s competitive industrial landscape, selecting the right check valve design is crucial for ensuring system efficiency and reliability. This guide provides a practical checklist for B2B buyers looking to procure check valves, focusing on key factors that influence performance and compatibility with specific applications.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline the technical specifications required for your check valves. Consider parameters such as flow rate, pressure, temperature, and the type of media (liquid or gas) involved. This step is vital because it sets the foundation for evaluating potential products and ensures that the selected valves meet your operational needs.

Step 2: Assess Material Compatibility

Check valves are constructed from various materials that can significantly impact performance and durability. Ensure that the materials used in the check valve body, seals, and internal components are compatible with the fluids or gases they will handle. For example, if corrosive substances are involved, opt for valves made from corrosion-resistant materials such as stainless steel or specialized plastics.

Step 3: Evaluate Flow Capacity and Efficiency

Understanding the flow capacity of a check valve is essential for system efficiency. Choose valves that can accommodate the maximum required flow rate without causing excessive pressure loss. Oversized valves may not open fully under normal operating conditions, while undersized valves can restrict flow. Look for valves with a flow coefficient (Ck or Kv) that indicates optimal performance.

Step 4: Determine Cracking and Reseal Pressure

Cracking pressure refers to the minimum pressure required to open the valve, while reseal pressure is the pressure at which the valve can re-establish a seal after backflow. Selecting valves with appropriate cracking and reseal pressures is critical for maintaining system integrity and preventing backflow. Consider spring-loaded check valves for applications requiring reliable reseal performance.

Step 5: Examine Supplier Certifications and Quality Assurance

Before finalizing your supplier, verify their certifications and quality assurance processes. Look for industry-standard certifications such as ISO 9001, which indicate adherence to quality management practices. A reputable supplier should also provide documentation regarding their manufacturing processes, testing protocols, and product warranties.

Step 6: Request Samples for Testing

To ensure the selected check valves meet your operational requirements, request samples for testing before making a bulk purchase. This allows you to evaluate the product’s performance in real-world conditions and identify any potential issues. Testing can reveal critical insights into flow characteristics, sealing capabilities, and overall compatibility with your system.

Step 7: Consider Customization Options

If standard check valves do not meet your specifications, inquire about customization options. Many suppliers offer tailored solutions to address unique requirements, such as specific connection types, sizes, or materials. Customization can optimize performance and ensure seamless integration into your existing systems.

By following this checklist, B2B buyers can make informed decisions when sourcing check valve designs, ultimately enhancing system efficiency and reliability while minimizing operational risks.

Comprehensive Cost and Pricing Analysis for check valve design Sourcing

What Are the Key Cost Components in Check Valve Design Sourcing?

Understanding the cost structure of check valve design sourcing is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly influences costs. Common materials include metals (like stainless steel and brass) and various plastics. Metal valves typically offer higher durability and pressure resistance but come at a higher cost compared to plastic alternatives. Buyers should consider the specific media and environmental conditions when selecting materials to ensure longevity and reliability.

-

Labor: Labor costs encompass the wages of skilled workers involved in the manufacturing process. This includes assembly, welding, and machining. Labor costs can vary by region, which can impact the overall pricing of the valves. For instance, sourcing from countries with lower labor costs can reduce expenses, but may also affect quality.

-

Manufacturing Overhead: This includes costs related to the facilities, utilities, and equipment necessary for production. Efficient manufacturing processes can help reduce overhead costs, which can be passed on to buyers in the form of lower prices.

-

Tooling: Tooling costs are incurred for creating molds and dies necessary for producing check valves. Custom tooling can be expensive but is essential for high-volume production. Buyers should weigh the initial investment against the long-term savings from reduced unit costs.

-

Quality Control (QC): Implementing stringent QC measures ensures that the check valves meet industry standards and specifications. While this can add to the initial cost, it ultimately reduces the risk of failures and warranty claims, enhancing the product’s total value.

-

Logistics: Shipping and handling costs are critical, especially for international transactions. Factors like distance, shipping method, and customs duties can significantly affect the final price. Efficient logistics planning can mitigate these costs.

-

Margin: Suppliers will add a profit margin to their cost structure, which varies by market dynamics and competition. Understanding the market allows buyers to negotiate better pricing.

How Do Price Influencers Impact Check Valve Sourcing?

Several factors influence the pricing of check valves that B2B buyers should consider:

-

Volume/MOQ: The minimum order quantity (MOQ) can affect pricing. Higher volumes often lead to discounts, making it cost-effective for buyers to stock up if the product is in demand.

-

Specifications and Customization: Custom designs and specific material requirements can drive up costs. Buyers should clearly communicate their needs to avoid unnecessary expenses.

-

Quality and Certifications: Valves that meet industry certifications (like ISO or API) might command higher prices due to the assurance of quality and compliance. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation, reliability, and location of suppliers can impact pricing. Established suppliers may charge more due to their experience and quality assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. Terms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight) dictate responsibilities and costs associated with shipping, impacting overall pricing.

What Buyer Tips Can Enhance Cost-Efficiency in Check Valve Procurement?

To maximize value, B2B buyers should consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially for bulk orders or long-term contracts. Leverage competitive quotes to negotiate better terms.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes the purchase price, maintenance costs, and potential downtime. Choosing higher-quality valves may reduce long-term expenses despite higher upfront costs.

-

Pricing Nuances for International Buyers: When sourcing from different regions (e.g., Africa, South America, the Middle East, and Europe), be aware of currency fluctuations, import duties, and local regulations that may affect pricing.

-

Disclaimer for Indicative Prices: Always remember that prices can vary based on market conditions, supplier negotiations, and specific project requirements. It is advisable to request detailed quotes tailored to your specifications.

By understanding these cost components and pricing influencers, B2B buyers can make informed decisions that optimize their check valve sourcing strategies.

Alternatives Analysis: Comparing check valve design With Other Solutions

Exploring Alternatives to Check Valve Design: What Are Your Options?

When evaluating the best solutions for preventing backflow in fluid systems, check valves are often a go-to option. However, several alternatives exist that can also effectively manage flow direction and protect systems from contamination. This section compares check valve design with two viable alternatives: diaphragm valves and ball valves. Each solution has unique characteristics that may cater to specific operational needs and environments.

| Comparison Aspect | Check Valve Design | Diaphragm Valve | Ball Valve |

|---|---|---|---|

| Performance | High reliability in preventing backflow; suitable for various pressures | Excellent flow control; ideal for on/off applications | Reliable sealing and minimal pressure drop; suitable for high flow |

| Cost | Moderate initial investment; cost-effective for high-volume applications | Generally higher due to complexity; suitable for specialized applications | Competitive pricing; cost varies based on material and size |

| Ease of Implementation | Simple installation; requires specific orientation in some cases | Requires precise installation and alignment | Easy to install with standard connections; versatile in configurations |

| Maintenance | Low maintenance; infrequent checks needed | Regular maintenance required to ensure diaphragm integrity | Minimal maintenance; durable with long service life |

| Best Use Case | Ideal for preventing backflow in pipelines and pumps | Suitable for applications needing tight sealing and flow regulation | Best for applications requiring quick shut-off and high flow rates |

What Are the Advantages and Disadvantages of Diaphragm Valves?

Diaphragm valves utilize a flexible diaphragm that seals against a valve seat, providing excellent flow control. Their key advantage is the ability to handle corrosive fluids and slurries without direct contact with the valve body, which prolongs service life. However, they require regular maintenance to ensure the diaphragm remains intact and effective. This makes them less ideal for applications where maintenance access is limited or where ongoing costs are a concern.

Illustrative image related to check valve design

How Do Ball Valves Compare in Terms of Functionality?

Ball valves are renowned for their straightforward design, featuring a spherical disc that controls flow. They are particularly effective in applications requiring rapid shut-off and can handle high flow rates with minimal pressure drop. Their low maintenance requirements and durability make them a practical choice for many industries. On the downside, ball valves may not be as effective in applications needing precise flow control, as they are typically either fully open or fully closed.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Selecting the right solution for backflow prevention involves understanding the specific needs of your application. Check valves are often the preferred choice for reliability and simplicity, especially in systems where backflow prevention is critical. However, diaphragm and ball valves offer compelling advantages depending on your operational requirements, such as flow control or rapid shut-off. B2B buyers should assess factors such as cost, maintenance, and performance in their specific context to make an informed decision that aligns with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for check valve design

What Are the Key Technical Properties in Check Valve Design?

When selecting check valves for various applications, understanding essential technical properties is crucial for ensuring optimal performance, reliability, and longevity. Here are some critical specifications:

-

Material Grade

The material of the check valve significantly influences its durability and performance. Common materials include brass, stainless steel, and various plastics. For instance, stainless steel is favored in high-temperature applications due to its strength and resistance to corrosion, while plastic check valves are often used for their lightweight and chemical compatibility. Choosing the right material ensures that the valve can withstand the specific conditions it will face, such as pressure, temperature, and the type of media being transported. -

Cracking Pressure

This term refers to the minimum pressure required to open the check valve and allow flow. Selecting a cracking pressure close to the system’s operational pressure maximizes efficiency and prevents backflow. If the cracking pressure is set too high, it may prevent the valve from opening, while a pressure set too low may lead to unwanted flow. Understanding this property helps B2B buyers tailor their valve choices to specific applications, ensuring seamless operation in their systems. -

Maximum Working Pressure (MWP)

The MWP indicates the highest pressure a check valve can handle during normal operation. It is essential to select valves with an MWP that exceeds the expected pressure in the application to avoid failure. This specification is particularly important in industries dealing with high-pressure systems, such as oil and gas or chemical processing, where valve failure can lead to catastrophic results. -

Flow Capacity

Flow capacity is a measure of the maximum volume of fluid that can pass through the valve without causing excessive pressure loss. An oversized check valve may lead to inefficiencies and turbulence, while an undersized valve can restrict flow and increase pressure drop. Understanding flow capacity ensures that the selected valve aligns with system requirements, optimizing performance and reducing operational costs. -

Temperature Range

The operating temperature range indicates the limits within which a check valve can function effectively. It is vital to consider both the media temperature and the environmental conditions when selecting a valve. Choosing a valve that can withstand the expected temperature range prevents premature wear and potential failure, ensuring reliability in demanding applications. -

Reseal Pressure

Reseal pressure is the pressure at which a check valve can re-establish a seal after being subjected to backflow. In applications where backflow must be minimized, understanding this property is crucial. It often dictates whether a single or double check valve configuration is necessary, especially in sensitive applications like pharmaceuticals or food processing.

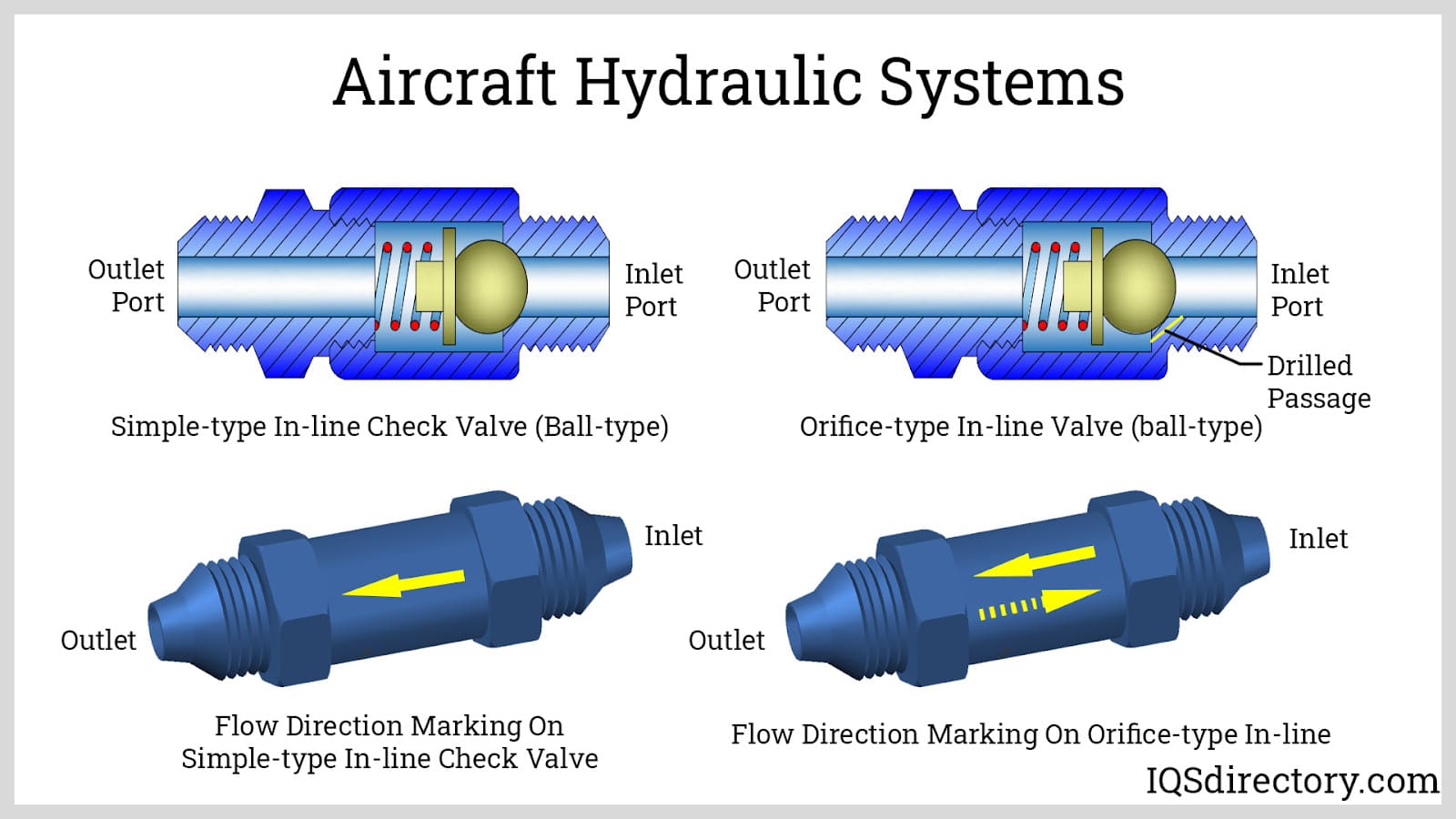

What Are Common Trade Terms Used in Check Valve Procurement?

Understanding industry terminology is essential for effective communication and negotiation in the procurement of check valves. Here are some common terms:

Illustrative image related to check valve design

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of check valves, buyers may seek OEM partners for customized solutions that meet their specific needs, ensuring compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. It’s vital for buyers to understand MOQs to manage inventory effectively and avoid overstocking or stockouts. Negotiating MOQs can also lead to cost savings, making it a crucial consideration in procurement discussions. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery requirements. For B2B buyers, issuing an RFQ is an important step in the procurement process, allowing for comparison of pricing and terms from multiple suppliers. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping agreements. Familiarity with Incoterms is essential for B2B buyers to understand shipping costs, risk management, and delivery timelines, ensuring smooth transactions across borders. -

Lead Time

This term refers to the amount of time it takes from placing an order to the delivery of goods. Understanding lead times helps buyers plan their inventory and production schedules effectively. Longer lead times may require advanced planning to avoid disruptions in operations. -

Testing and Certification

This refers to the processes that ensure check valves meet industry standards and regulations. Buyers should inquire about the testing and certification of valves to ensure they comply with safety and performance standards relevant to their industry, thereby mitigating risks associated with non-compliance.

Navigating Market Dynamics and Sourcing Trends in the check valve design Sector

What Are the Key Market Dynamics and Trends in Check Valve Design?

The global check valve design market is experiencing significant growth, driven by increasing industrialization and the demand for efficient fluid control systems across various sectors, including oil and gas, water treatment, and manufacturing. Notably, emerging markets in Africa and South America are witnessing an uptick in infrastructure projects, prompting a surge in demand for reliable check valve solutions. In Europe, particularly in countries like Germany, stringent regulations on fluid management and safety are pushing manufacturers toward innovative designs that enhance performance while ensuring compliance.

Current trends indicate a shift toward automation and smart technology integration in check valve systems. IoT-enabled check valves that allow for real-time monitoring and predictive maintenance are gaining traction. Additionally, the emphasis on modular designs is rising, enabling customization that meets specific operational needs. B2B buyers should also be aware of the increasing importance of supplier partnerships that offer not only products but also technical expertise and after-sales support.

How Is Sustainability Impacting Sourcing in the Check Valve Sector?

Sustainability has become a cornerstone of sourcing strategies in the check valve design sector. As global awareness of environmental impacts grows, B2B buyers are increasingly prioritizing suppliers that adhere to ethical practices and offer sustainable materials. The use of eco-friendly materials in manufacturing check valves, such as recycled plastics and low-impact metals, is on the rise. Certifications such as ISO 14001 and RoHS compliance are becoming essential for buyers looking to ensure that their supply chains are environmentally responsible.

Moreover, the demand for transparency in supply chains is leading companies to adopt more rigorous standards for sourcing. This transparency is crucial not only for compliance but also for fostering trust with end-users who are increasingly concerned about the environmental footprint of their operations. Companies that can demonstrate a commitment to sustainability are likely to gain a competitive edge in the market.

How Has the Check Valve Design Sector Evolved Over Time?

The evolution of check valve design has been marked by significant technological advancements and changing industry needs. Initially, check valves were simple mechanical devices designed to prevent backflow in pipelines. However, with the advent of new materials and manufacturing processes, modern check valves now feature advanced designs that enhance performance and durability.

The introduction of smart technology has further transformed the sector, allowing for real-time data collection and analysis, which improves operational efficiency and reduces downtime. As industries continue to evolve and adapt to new challenges, the check valve design sector is poised for ongoing innovation, driven by the need for more reliable and efficient fluid control solutions.

Conclusion

For international B2B buyers, particularly in emerging markets, understanding these dynamics is crucial for making informed sourcing decisions. By focusing on technological advancements and sustainable practices, buyers can align their procurement strategies with the future of the check valve design industry, ensuring they remain competitive in a rapidly changing market.

Frequently Asked Questions (FAQs) for B2B Buyers of check valve design

-

How do I choose the right check valve for my application?

Selecting the right check valve involves understanding your system’s specific requirements, including media type, flow direction, pressure ranges, and temperature conditions. Key factors to consider are the valve’s cracking pressure, maximum working pressure, and reseal pressure. Additionally, evaluate the materials used in the valve’s construction to ensure compatibility with the fluids involved. Consulting with manufacturers or industry experts can also provide valuable insights tailored to your application, ensuring optimal performance and longevity. -

What are the advantages of different materials used in check valve design?

Check valves can be constructed from various materials, including metals and plastics, each offering distinct advantages. Metal valves typically provide higher burst pressures, better stress resistance, and can withstand extreme temperatures. Conversely, plastic valves are generally lighter, more cost-effective, and offer excellent corrosion resistance. The choice of material should be guided by the operating environment and the chemical properties of the media, ensuring the valve performs effectively and has a long service life. -

What customization options are available for check valves?

Customization options for check valves often include specific materials, sizes, end connections, and sealing mechanisms. Manufacturers can tailor the design to meet unique application requirements, such as specialized cracking pressures or enhanced flow capacities. Discussing your specific needs with suppliers can lead to solutions that improve system efficiency and performance, as well as ensuring compliance with industry standards and regulations. -

What are the minimum order quantities (MOQs) for check valves?

Minimum order quantities (MOQs) for check valves can vary significantly among manufacturers and suppliers. Typically, MOQs are influenced by production costs and logistics. For custom designs, MOQs may be higher due to setup and tooling requirements. It’s advisable to clarify MOQs with potential suppliers upfront to align with your procurement strategy and ensure that you can meet your operational needs without excessive inventory costs. -

How can I vet suppliers for check valve design?

Vetting suppliers involves assessing their industry experience, reputation, and product quality. Look for certifications such as ISO 9001, which indicate a commitment to quality management. Request references from previous clients and review case studies to gauge their reliability. Additionally, conducting on-site visits or audits can provide insights into their manufacturing processes and capabilities, ensuring they meet your specific requirements and standards. -

What payment terms are commonly offered in international B2B transactions?

Payment terms in international transactions typically range from upfront payments to net 30, 60, or 90 days, depending on the relationship with the supplier and the order size. Options like letters of credit or escrow services can provide additional security for both parties. It’s important to negotiate favorable terms that align with your cash flow needs while also establishing trust with the supplier to facilitate smooth transactions. -

What quality assurance measures should I expect from check valve suppliers?

Quality assurance (QA) measures should include thorough testing of valves for performance, durability, and safety before shipment. Suppliers should provide documentation such as test reports and certifications demonstrating compliance with relevant standards. Regular audits and inspections of manufacturing processes are also crucial. Establishing clear QA expectations in your purchase agreements will help ensure that the products you receive meet your specifications and operational requirements. -

How do logistics impact the sourcing of check valves internationally?

Logistics play a critical role in the timely delivery and overall cost-effectiveness of sourcing check valves internationally. Factors such as shipping methods, customs regulations, and lead times can significantly affect your supply chain. Collaborate closely with suppliers to understand their shipping capabilities and any potential delays. Additionally, consider working with logistics partners experienced in international trade to streamline the import process and mitigate risks associated with transportation.

Top 2 Check Valve Design Manufacturers & Suppliers List

1. CN Control Valve – Swing Check Valves

Domain: cncontrolvalve.com

Registered: 2012 (13 years)

Introduction: Swing check valves are essential in industrial, water, and wastewater applications for controlling the flow of liquids and gases. They consist of a valve body, a disc, and a hinge, where the disc swings open for forward flow and closes to prevent backflow. Common materials include bronze, cast iron, carbon steel, stainless steel, and PVC, selected for their corrosion resistance and ability to with…

2. Idex – Check Valves

Domain: idex-hs.com

Registered: 2007 (18 years)

Introduction: Check valves (CV) are integral components of High-Performance Liquid Chromatography (HPLC) Pumps, allowing fluid to flow in one direction and preventing backflow. The ball/seat configuration is common, where a ball seals against a spherical seat. Key factors affecting performance include material selection, design parameters, and application needs. HPLC pumps have evolved from single piston to mul…

Strategic Sourcing Conclusion and Outlook for check valve design

What Are the Key Takeaways for B2B Buyers in Check Valve Design?

In the realm of check valve design, strategic sourcing is essential for optimizing performance and cost-efficiency. Key considerations include selecting the appropriate cracking pressure, ensuring compatibility of materials, and understanding the specific flow requirements of your application. By focusing on these factors, buyers can prevent costly operational failures and enhance system efficiency.

How Can International Buyers Benefit from Strategic Sourcing in Check Valve Design?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, engaging with reliable suppliers and understanding local market conditions can significantly impact procurement success. Establishing relationships with manufacturers who prioritize quality and compliance with regional standards will not only improve the reliability of check valves but also foster long-term partnerships.

What’s Next for Buyers in the Check Valve Market?

As industries evolve and demand for advanced fluid control solutions grows, staying informed about innovations in check valve design will be crucial. Buyers are encouraged to leverage technology and data analytics for sourcing decisions, ensuring they remain competitive in a dynamic marketplace. Embrace these strategic sourcing insights to enhance operational effectiveness and drive business growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.