Is Your Chamber Temperature Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for chamber temperature

In today’s competitive landscape, sourcing reliable chamber temperature solutions is critical for businesses aiming to ensure product quality and compliance with international standards. As companies across Africa, South America, the Middle East, and Europe (notably in Germany and Nigeria) expand their operations, understanding the intricacies of chamber temperature control becomes paramount. This guide provides a comprehensive overview of various types of temperature chambers, their applications across different industries, and essential considerations for supplier vetting and cost management.

Navigating the global market for chamber temperature solutions can be daunting, especially when faced with diverse regulatory requirements and technological advancements. This guide empowers international B2B buyers by offering actionable insights into selecting the right equipment tailored to specific operational needs. From precise temperature ranges suitable for testing materials to innovative features that enhance efficiency, this resource will help you make informed purchasing decisions that align with your business objectives.

Whether you are in manufacturing, materials testing, or research and development, understanding the nuances of chamber temperature technology is essential for maintaining a competitive edge. Equip yourself with the knowledge to navigate this complex market, streamline your procurement processes, and ultimately enhance the quality of your products and services.

Understanding chamber temperature Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Environmental Chambers | Wide temperature range, from -80°C to +360°C | Material testing, quality assurance | Pros: High precision, versatile applications. Cons: Higher initial investment. |

| Thermal Cycling Chambers | Rapid temperature changes, programmable cycles | Aerospace, automotive, electronics testing | Pros: Simulates real-world conditions. Cons: Requires advanced control systems. |

| Climatic Chambers | Controls temperature and humidity simultaneously | Pharmaceutical, food industry testing | Pros: Comprehensive environmental testing. Cons: Can be complex to operate. |

| High-Temperature Chambers | Supports extreme heat testing, up to +1,500°C | Metal and composite materials testing | Pros: Essential for high-performance materials. Cons: Specialized equipment may be needed. |

| Low-Temperature Chambers | Effective cooling capabilities, down to -196°C | Cryogenics, superconductors testing | Pros: Critical for specific scientific applications. Cons: Limited general applicability. |

What are the Key Characteristics of Environmental Chambers?

Environmental chambers are designed to maintain a precise temperature range, typically from -80°C to +360°C. These chambers are crucial for material testing across various industries, ensuring products meet quality and reliability standards. Buyers should consider the chamber’s calibration accuracy, the materials it can accommodate, and its compliance with international testing standards. The flexibility and precision offered by these chambers make them an excellent investment for organizations focused on quality assurance.

How Do Thermal Cycling Chambers Benefit B2B Buyers?

Thermal cycling chambers are characterized by their ability to rapidly change temperatures, making them ideal for simulating conditions that products might face during their lifecycle. Commonly used in aerospace and automotive testing, these chambers allow for the assessment of material performance under extreme temperature fluctuations. When purchasing, businesses should evaluate the chamber’s cycle speed, temperature uniformity, and software capabilities for programming tests. The investment in thermal cycling chambers can lead to better product reliability and safety.

What Makes Climatic Chambers Essential for Testing?

Climatic chambers not only control temperature but also humidity, providing a comprehensive testing environment. These chambers are particularly valuable in the pharmaceutical and food industries, where moisture levels can significantly impact product quality. Buyers should look for features that allow for simultaneous temperature and humidity control, as well as the ability to replicate various climatic conditions. While they may involve a higher cost, the ability to conduct thorough environmental testing justifies the investment.

Why Invest in High-Temperature Chambers?

High-temperature chambers are designed to withstand extreme heat, often reaching temperatures of up to +1,500°C. They are essential for testing metal and composite materials that are used in high-performance applications. Businesses should consider the chamber’s maximum temperature capabilities, safety features, and ease of use when evaluating options. Although the initial cost may be substantial, the ability to conduct high-temperature tests can significantly enhance product development and validation processes.

What Advantages Do Low-Temperature Chambers Offer?

Low-temperature chambers are capable of reaching extremely low temperatures, down to -196°C, making them indispensable in fields such as cryogenics and superconductors testing. These chambers allow for the evaluation of materials under conditions that mimic their operational environments. When purchasing, organizations should assess the chamber’s cooling efficiency, temperature stability, and ease of maintenance. Despite their specialized nature, low-temperature chambers are critical for research and development in cutting-edge technologies.

Key Industrial Applications of chamber temperature

| Industry/Sector | Specific Application of Chamber Temperature | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Testing materials for thermal resistance | Ensures safety and reliability of components under extreme conditions | Compliance with aerospace standards, precision in temperature control |

| Automotive | Evaluating performance of automotive parts | Validates durability and performance in various climate conditions | Need for multi-temperature ranges, data logging capabilities |

| Electronics | Thermal cycling tests for electronic components | Enhances product reliability and lifespan | Compact design, integration with existing testing systems |

| Pharmaceuticals | Stability testing of drug formulations | Ensures efficacy and safety of products over time | Regulatory compliance, specific temperature ranges required |

| Construction Materials | Testing concrete and composites under temperature | Validates structural integrity and performance | Customizable chamber sizes, ability to test various materials |

How is Chamber Temperature Used in Aerospace Testing?

In the aerospace industry, chamber temperature is critical for testing materials’ thermal resistance. Components such as engine parts and structural elements are subjected to extreme temperature variations to ensure they can withstand harsh operational conditions. This application solves the problem of material failure in flight, which can lead to catastrophic incidents. Buyers in this sector must ensure that temperature chambers comply with stringent aerospace standards and provide precise temperature control to meet specific testing requirements.

What Role Does Chamber Temperature Play in Automotive Performance Evaluation?

Automotive manufacturers utilize chamber temperature for evaluating the performance of various parts under different climatic conditions. This testing helps validate the durability of components such as tires, batteries, and electronic systems. The key benefit is the assurance that products will perform reliably in diverse environments, enhancing customer satisfaction and safety. Buyers should consider sourcing chambers that offer multi-temperature ranges and robust data logging capabilities to facilitate comprehensive testing.

How is Chamber Temperature Applied in Electronics Thermal Cycling Tests?

In the electronics sector, chamber temperature is employed for thermal cycling tests to assess the reliability of components like circuit boards and semiconductors. These tests simulate real-world conditions where electronic devices experience temperature fluctuations, helping to identify potential failures before products reach the market. The primary value lies in enhancing product longevity and performance. Buyers should look for compact chamber designs that can easily integrate with existing testing setups while ensuring accurate temperature control.

What is the Importance of Chamber Temperature in Pharmaceutical Stability Testing?

In pharmaceuticals, chamber temperature is essential for stability testing of drug formulations. This testing determines how drugs react to various temperature conditions over time, ensuring their efficacy and safety. The application addresses regulatory requirements and helps in maintaining product integrity. Buyers must focus on sourcing chambers that comply with regulatory standards and provide specific temperature ranges required for different formulations, ensuring comprehensive testing and compliance.

How Does Chamber Temperature Impact Construction Material Testing?

For construction materials, chamber temperature is utilized to test the performance of concrete and composites under varying thermal conditions. This application is vital for validating the structural integrity and performance of materials used in construction projects. The key benefit is ensuring that materials can withstand environmental stresses over their lifespan. Buyers should consider customizable chamber sizes that can accommodate various material types and ensure accurate testing results for diverse applications.

Illustrative image related to chamber temperature

3 Common User Pain Points for ‘chamber temperature’ & Their Solutions

Scenario 1: Inconsistent Temperature Control in Manufacturing Processes

The Problem: B2B buyers often face challenges with inconsistent temperature control in manufacturing environments, particularly when dealing with sensitive materials. Fluctuations in chamber temperature can lead to defects in products, increased waste, and compromised quality assurance. This inconsistency can be especially critical in industries such as pharmaceuticals or aerospace, where precision is non-negotiable. Buyers may struggle to identify the root cause of temperature variability, which can stem from inadequate equipment, poor calibration, or environmental factors.

The Solution: To overcome these challenges, buyers should invest in high-quality temperature chambers equipped with advanced control systems capable of maintaining precise temperature settings. It is crucial to specify chambers that utilize reliable PID (Proportional-Integral-Derivative) controllers, which help in accurately managing temperature fluctuations. Additionally, implementing regular maintenance schedules and calibration checks will ensure that the equipment operates within specified parameters. Buyers should also consider chambers with built-in data logging features that allow them to track temperature profiles over time, making it easier to identify trends and address issues proactively. Collaborating with suppliers who offer comprehensive training on equipment use and maintenance can further enhance operational efficiency and product quality.

Scenario 2: Limited Capacity and Flexibility in Testing Environments

The Problem: Many businesses find themselves constrained by the limited capacity and flexibility of their current testing environments. As product lines expand or shift, the existing chamber setup may not accommodate new materials or larger sample sizes. This lack of adaptability can result in increased lead times for product testing, delays in product launches, and ultimately lost revenue. Additionally, businesses operating in multiple regions may face challenges in sourcing temperature chambers that meet varying regulatory standards across markets.

The Solution: To tackle this issue, buyers should seek temperature chambers with modular designs that allow for easy customization and scalability. Chambers that can be retrofitted with additional features or adjusted for different testing requirements provide the flexibility needed to adapt to changing business needs. When sourcing, buyers should prioritize vendors that offer a variety of chamber sizes and temperature ranges to ensure compatibility with diverse testing protocols. Furthermore, choosing equipment that meets international standards (such as ISO or ASTM) can facilitate compliance across different markets, reducing regulatory headaches and streamlining operations. Establishing a strong relationship with a supplier who understands regional requirements can also help ensure that the necessary certifications are met without excessive delays.

Scenario 3: High Energy Costs and Environmental Concerns

The Problem: As energy costs continue to rise, businesses are increasingly concerned about the operational expenses associated with maintaining temperature chambers. Inefficient energy use not only impacts the bottom line but also raises environmental concerns, particularly in regions where sustainability is becoming a significant focus for consumers and regulators. Companies may struggle to balance the need for precise temperature control with the desire to minimize their carbon footprint and energy expenditures.

The Solution: To address energy efficiency and sustainability, buyers should look for temperature chambers designed with energy-saving features, such as enhanced insulation, variable-speed compressors, and advanced heat recovery systems. Investing in equipment that utilizes eco-friendly refrigerants can also reduce environmental impact. When evaluating options, it is beneficial to request energy consumption data from suppliers, allowing buyers to compare operational costs and identify the most efficient solutions. Additionally, implementing energy management systems can help monitor and optimize energy use in real-time, leading to significant cost savings. Finally, buyers should engage with suppliers that prioritize sustainability in their operations, ensuring that their purchase aligns with broader environmental goals.

Strategic Material Selection Guide for chamber temperature

What Are the Key Properties of Common Materials for Chamber Temperature Applications?

When selecting materials for temperature chambers, understanding their properties is crucial for ensuring optimal performance and compliance with international standards. Below are analyses of four common materials used in chamber temperature applications, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

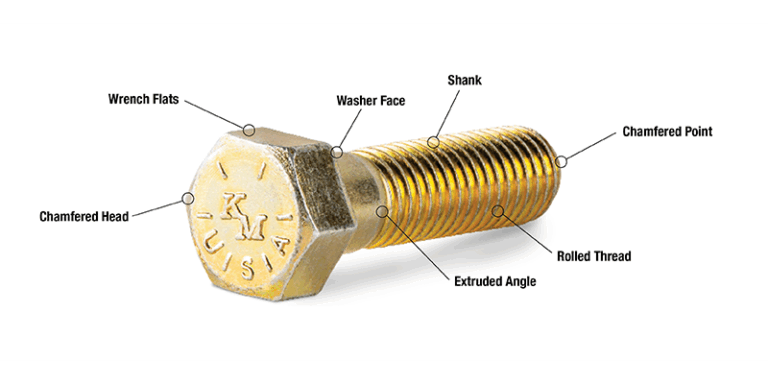

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance and high-temperature tolerance, typically rated up to 800°C. It maintains structural integrity under varying pressure conditions, making it suitable for high-performance applications.

Illustrative image related to chamber temperature

Pros & Cons:

The durability of stainless steel is a significant advantage, as it resists rust and degradation over time. However, it can be more expensive than other materials, and its manufacturing complexity may increase costs due to the need for specialized processing techniques.

Impact on Application:

Stainless steel is compatible with a wide range of media, including corrosive substances, making it ideal for diverse testing environments.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM A240 and DIN 1.4301. The higher initial investment may be justified by the long-term savings in maintenance and replacement costs.

2. Aluminum

Key Properties:

Aluminum offers a good balance of strength-to-weight ratio and thermal conductivity, with a temperature rating typically up to 600°C. It is lightweight and easy to fabricate, which can facilitate quicker manufacturing processes.

Illustrative image related to chamber temperature

Pros & Cons:

The lightweight nature of aluminum makes it easier to handle and install, reducing labor costs. However, it is less durable than stainless steel and may not withstand high-pressure environments as effectively.

Impact on Application:

Aluminum is suitable for applications requiring rapid temperature changes due to its excellent thermal conductivity, but it may not be ideal for corrosive environments unless treated or coated.

Considerations for International Buyers:

When sourcing aluminum components, buyers should consider compliance with standards like ASTM B221. The cost-effectiveness of aluminum can be appealing, particularly for projects with budget constraints.

3. Polycarbonate

Key Properties:

Polycarbonate is a high-performance thermoplastic known for its impact resistance and transparency. It can withstand temperatures ranging from -40°C to 120°C, making it suitable for various applications, including observation windows in chambers.

Pros & Cons:

The transparency of polycarbonate allows for easy monitoring of samples without opening the chamber. However, it has lower temperature resistance compared to metals and may degrade under prolonged exposure to high temperatures.

Impact on Application:

Polycarbonate is ideal for applications where visibility is essential, but its limitations in extreme environments should be considered.

Illustrative image related to chamber temperature

Considerations for International Buyers:

Buyers should look for compliance with standards such as ASTM D5767. The material’s lower cost can be attractive, especially for applications that do not require high thermal resistance.

4. Glass

Key Properties:

Glass is an inert material that can withstand high temperatures (up to 500°C) and offers excellent chemical resistance. Its thermal properties vary depending on the type of glass used.

Pros & Cons:

The chemical inertness of glass makes it suitable for sensitive applications, but it is fragile and can break under stress, which may lead to higher replacement costs.

Impact on Application:

Glass is often used in applications requiring high purity and minimal contamination, such as in pharmaceutical testing.

Considerations for International Buyers:

Compliance with standards like ASTM E438 is crucial, especially in regulated industries. The fragility of glass may necessitate additional protective measures during transport and installation.

Summary Table of Material Selection for Chamber Temperature

| Material | Typical Use Case for chamber temperature | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-performance applications | Excellent corrosion resistance | Higher initial cost | High |

| Aluminum | Lightweight structures | Easy to fabricate | Less durable under pressure | Medium |

| Polycarbonate | Observation windows | Transparency for monitoring | Limited high-temperature use | Low |

| Glass | Sensitive chemical applications | High chemical resistance | Fragile and prone to breakage | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of materials used in chamber temperature applications, enabling informed decision-making tailored to their specific needs.

In-depth Look: Manufacturing Processes and Quality Assurance for chamber temperature

What Are the Key Manufacturing Processes for Chamber Temperature Equipment?

The manufacturing of chamber temperature equipment involves several critical stages that ensure the final product meets stringent performance and quality standards. Understanding these stages can help B2B buyers evaluate potential suppliers and ensure they are investing in reliable equipment.

What Are the Main Stages of Manufacturing Chamber Temperature Equipment?

-

Material Preparation

The first step in manufacturing involves sourcing high-quality materials such as stainless steel, aluminum, and specialized insulation materials. These materials must be resistant to temperature fluctuations and corrosion. Suppliers often conduct a thorough analysis of the materials to ensure they meet specific thermal and mechanical properties. This step may also involve the preparation of electronic components for temperature control systems. -

Forming

The forming stage includes processes like cutting, bending, and machining the materials to create the structural components of the chamber. Advanced techniques such as laser cutting and CNC machining are employed to achieve precision and reduce waste. The use of automated machinery allows for consistent quality across multiple units, which is crucial for B2B buyers looking for reliability in their investments. -

Assembly

During assembly, the formed components are put together, often in a cleanroom environment to minimize contamination. This includes the installation of temperature sensors, heating elements, and control systems. The assembly process requires skilled technicians to ensure that all components are correctly fitted and that wiring is safely managed. Quality control checkpoints are implemented throughout this stage to catch any potential issues early. -

Finishing

The finishing stage involves surface treatments that may include painting, anodizing, or applying thermal insulation. These treatments not only enhance the durability of the chamber but also improve its aesthetic appeal. Additionally, finishing processes must comply with industry standards to ensure the equipment can withstand the intended environmental conditions.

How Is Quality Assurance Implemented in Chamber Temperature Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process for chamber temperature equipment. It ensures that products meet regulatory standards and customer expectations. B2B buyers should be familiar with the various QA methodologies and standards relevant to this equipment.

Which International Standards Govern Chamber Temperature Quality Assurance?

-

ISO 9001

This widely recognized standard outlines the requirements for a quality management system (QMS). Manufacturers of chamber temperature equipment often seek ISO 9001 certification to demonstrate their commitment to quality. This certification involves regular audits and continuous improvement processes, making it a valuable indicator for B2B buyers. -

CE Marking

For European markets, CE marking indicates compliance with health, safety, and environmental protection standards. Equipment with CE marking has undergone rigorous testing and quality assurance processes, providing additional confidence to buyers in Europe. -

API Standards

For industries that require specific temperature control, such as oil and gas, manufacturers may adhere to American Petroleum Institute (API) standards. These standards ensure that the equipment can perform reliably under extreme conditions, which is a key consideration for B2B buyers in these sectors.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is embedded throughout the manufacturing process, with several key checkpoints that ensure product integrity:

Illustrative image related to chamber temperature

-

Incoming Quality Control (IQC)

This initial checkpoint involves inspecting raw materials upon arrival at the manufacturing facility. Materials are assessed for compliance with specifications and quality standards. Non-conforming materials are rejected, preventing defects in the final product. -

In-Process Quality Control (IPQC)

During the manufacturing process, IPQC involves continuous monitoring of production parameters and assembly processes. This includes checking for dimensional accuracy, thermal performance, and the integrity of electrical components. Regular inspections and tests help identify and rectify issues before they escalate. -

Final Quality Control (FQC)

Once the chamber temperature equipment is fully assembled, FQC involves comprehensive testing to ensure it meets all performance specifications. This may include thermal cycling tests, safety assessments, and functionality checks. The results are documented, providing traceability for future reference.

How Can B2B Buyers Verify Supplier Quality Control Practices?

When sourcing chamber temperature equipment, B2B buyers should take proactive steps to verify the quality control practices of potential suppliers.

-

Conduct Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance measures. Buyers can request access to audit reports and certifications to assess the supplier’s compliance with international standards. -

Request Quality Reports

Suppliers should provide documentation of their quality control processes, including IQC, IPQC, and FQC reports. These documents should outline the tests performed, results, and any corrective actions taken. -

Engage Third-Party Inspectors

Utilizing third-party inspection services can offer an unbiased evaluation of a supplier’s quality control practices. These inspectors can conduct on-site assessments and testing, ensuring that the equipment meets the necessary standards before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers operating in diverse regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial.

-

Regional Compliance Requirements

Different regions may have specific regulations and standards that manufacturers must comply with. Buyers should be aware of these requirements and ensure that their suppliers can meet them. -

Cultural Considerations

Communication and negotiation styles may vary significantly across cultures. Buyers should approach discussions about quality assurance with an understanding of local business practices and expectations. -

Logistical Challenges

International shipping can pose risks to equipment quality. Buyers should discuss packaging and handling procedures with suppliers to ensure that products arrive in optimal condition.

By understanding the manufacturing processes and quality assurance practices for chamber temperature equipment, B2B buyers can make informed decisions that align with their operational needs and regulatory requirements. This knowledge ultimately leads to improved investment strategies and enhanced reliability in their supply chains.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘chamber temperature’

In the rapidly evolving landscape of industrial processes, procuring the right chamber temperature systems is critical for ensuring product quality and compliance with various standards. This guide provides B2B buyers with a practical checklist to navigate the procurement process effectively, ensuring they select systems that meet their specific needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, outline your technical requirements. This includes the desired temperature range, load capacity, and any specific features such as data logging or integration with existing systems.

– Why It’s Important: Clear specifications help streamline the sourcing process and ensure that suppliers can meet your technical needs.

– What to Look For: Consider factors like maximum and minimum temperature capabilities, uniformity of temperature distribution, and any industry-specific testing standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in temperature chamber systems. Utilize industry directories, trade shows, and online platforms to compile a list of candidates.

– Why It’s Important: A diverse supplier pool increases your chances of finding a partner that meets your specific requirements and budget constraints.

– What to Look For: Look for suppliers with a proven track record in your industry and positive customer reviews. Assess their product range and technological capabilities.

Illustrative image related to chamber temperature

Step 3: Evaluate Supplier Certifications and Compliance

Ensure that potential suppliers hold relevant certifications and comply with international standards such as ISO and ASTM. This guarantees that their products meet quality and safety benchmarks.

– Why It’s Important: Certifications are a testament to a supplier’s commitment to quality and reliability.

– What to Look For: Request documentation that verifies compliance with industry standards and check if they have any recent audits or inspections.

Step 4: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations that outline the costs, delivery times, and terms of service. Ensure that these quotes are comprehensive and include any additional costs such as installation and training.

– Why It’s Important: A clear and detailed quotation helps prevent unexpected costs and misunderstandings later in the procurement process.

– What to Look For: Compare not just the price but also the terms of warranty, service support, and maintenance options.

Step 5: Assess Technical Support and After-Sales Service

Evaluate the technical support and after-sales service offered by potential suppliers. This includes training for your team, installation support, and ongoing maintenance services.

– Why It’s Important: Robust support ensures that your temperature chamber operates optimally and reduces downtime.

– What to Look For: Check if the supplier offers training sessions, availability of spare parts, and responsive customer service channels.

Step 6: Conduct Site Visits or Demonstrations

If possible, arrange site visits or request demonstrations of the chamber temperature systems in action. This allows you to assess the quality and performance of the equipment firsthand.

– Why It’s Important: Seeing the equipment in operation helps validate the supplier’s claims and gives you confidence in your purchase decision.

– What to Look For: Pay attention to the operational ease, accuracy of temperature control, and overall build quality.

Step 7: Finalize the Contract with Clear Terms

Once you have selected a supplier, finalize the contract by ensuring all terms are clearly defined. This should include payment terms, delivery timelines, and warranty conditions.

– Why It’s Important: A well-defined contract protects both parties and ensures accountability.

– What to Look For: Ensure that the contract includes clauses for dispute resolution, penalties for delays, and conditions for warranty claims.

Illustrative image related to chamber temperature

By following this checklist, B2B buyers can make informed decisions when sourcing chamber temperature systems, ultimately enhancing their operational efficiency and product quality.

Comprehensive Cost and Pricing Analysis for chamber temperature Sourcing

What Are the Key Cost Components for Chamber Temperature Sourcing?

When sourcing chamber temperature systems, understanding the cost structure is crucial for international B2B buyers. The primary components of cost include:

-

Materials: The type and quality of materials used in manufacturing temperature chambers significantly influence costs. High-grade metals and advanced insulation materials may raise expenses but enhance performance and longevity.

-

Labor: Skilled labor is often required for the assembly and calibration of temperature chambers. Labor costs can vary widely depending on the region, with higher wages typically found in developed countries like Germany compared to emerging markets such as Nigeria.

-

Manufacturing Overhead: This encompasses fixed and variable costs associated with production, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead, thus impacting overall pricing.

-

Tooling: Investment in specialized tools and machinery for production is essential. The complexity of the chamber design may necessitate more sophisticated tooling, leading to higher initial costs.

-

Quality Control (QC): Rigorous testing and quality assurance protocols are vital to ensure that temperature chambers meet industry standards. This can add to the overall cost but is necessary for compliance and reliability.

-

Logistics: Transportation and shipping logistics can significantly affect costs, especially for international buyers. Factors such as distance, mode of transport, and customs duties must be considered.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can be influenced by market demand, competition, and the supplier’s reputation.

What Influences Pricing in Chamber Temperature Procurement?

Several factors can influence pricing when procuring chamber temperature systems:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk can lead to significant discounts. Suppliers are often willing to negotiate lower prices for larger orders, making it beneficial for businesses with high demand.

-

Specifications/Customization: Customized chambers tailored to specific operational requirements may incur additional costs. Buyers should clearly define their needs to avoid unnecessary expenditures.

-

Materials: As previously mentioned, the choice of materials can impact costs. Opting for standard materials instead of high-performance ones may lead to savings, but could compromise the chamber’s effectiveness.

-

Quality/Certifications: Chambers that meet international quality standards or possess specific certifications (e.g., ISO, ASTM) may come with a premium price tag. However, such certifications ensure reliability and compliance, which can be critical in regulated industries.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with proven track records may charge more but offer better support and assurance of quality.

-

Incoterms: The agreed terms of shipping (Incoterms) play a crucial role in the final cost. Buyers should be aware of how these terms impact their total expenses, including insurance, duties, and transport costs.

What Tips Can Buyers Use to Optimize Costs in Chamber Temperature Sourcing?

For B2B buyers, particularly from diverse markets like Africa, South America, the Middle East, and Europe, adopting certain strategies can enhance cost-efficiency:

-

Negotiation: Engage in open dialogue with suppliers to negotiate better terms. Understanding the supplier’s cost structure can provide leverage during discussions.

-

Total Cost of Ownership (TCO): Consider not only the initial purchase price but also the long-term costs associated with maintenance, operation, and potential downtime. A slightly higher upfront cost may lead to lower TCO if the chamber is more efficient or durable.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and regional trade agreements that may affect pricing. Building relationships with local suppliers can sometimes mitigate these costs.

-

Conduct Thorough Research: Research multiple suppliers and gather quotes to ensure competitive pricing. Understanding market rates can empower buyers to make informed decisions.

In summary, a comprehensive understanding of the cost components, pricing influences, and strategic tips can significantly aid international B2B buyers in sourcing chamber temperature systems effectively. Buyers should always request indicative prices and be prepared for variations based on specific requirements and market conditions.

Alternatives Analysis: Comparing chamber temperature With Other Solutions

Exploring Alternatives to Chamber Temperature Solutions

In the realm of temperature control for various applications, chamber temperature solutions are widely employed for their precision and versatility. However, several alternative methods can also achieve similar goals, catering to different industrial requirements. This analysis will delve into the performance, cost, implementation, maintenance, and best use cases of chamber temperature solutions compared to other viable technologies.

| Comparison Aspect | Chamber Temperature | Heated Enclosures | Fluid Bath Systems |

|---|---|---|---|

| Performance | High precision for testing under controlled conditions | Good for small-scale applications, less precise | Excellent thermal uniformity, but limited range |

| Cost | Higher initial investment, long-term ROI through accuracy | Moderate cost, but efficiency can vary | Generally lower cost, but operational costs may increase |

| Ease of Implementation | Requires specific setup and calibration | Easier to set up, minimal technical expertise needed | Requires careful management of fluid and temperature settings |

| Maintenance | Regular calibration and servicing needed | Low maintenance, but periodic checks recommended | Requires fluid replacement and maintenance of equipment |

| Best Use Case | Material testing in labs and quality assurance | Small-scale production or prototype testing | Applications needing uniform temperature across samples |

What Are the Advantages and Disadvantages of Heated Enclosures?

Heated enclosures provide a practical alternative for temperature control, especially in smaller production environments. They are generally easier to implement compared to chamber temperature solutions, requiring minimal technical expertise. However, they may lack the precision needed for rigorous testing applications, leading to potential inaccuracies in critical results. This makes them suitable for smaller-scale operations or prototype testing where absolute accuracy is less critical.

How Do Fluid Bath Systems Compare to Chamber Temperature Solutions?

Fluid bath systems are an efficient alternative that excels in applications requiring uniform temperature distribution across samples. They are often more cost-effective in terms of initial investment and are suitable for laboratories focused on chemical reactions or biological experiments. Nevertheless, they require careful management of the fluid medium, including regular replacements and maintenance, which can lead to increased operational costs over time. Their limited temperature range may also restrict their applicability in certain industrial settings.

Conclusion: How to Choose the Right Temperature Control Solution for Your Needs?

Selecting the right temperature control solution depends on various factors, including the specific requirements of your application, budget constraints, and the level of precision required. Chamber temperature solutions offer high precision and reliability, making them ideal for rigorous testing environments. In contrast, heated enclosures and fluid bath systems may provide more cost-effective and simpler alternatives for less demanding applications. B2B buyers should assess their unique needs, including the scale of operation and desired outcomes, to make an informed decision that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for chamber temperature

What Are the Critical Technical Properties of Chamber Temperature?

Chamber temperature specifications are vital for ensuring the reliability and performance of materials and components during testing processes. Here are some key properties that B2B buyers should consider:

1. Temperature Range

The temperature range indicates the minimum and maximum temperatures that the chamber can achieve, typically measured in degrees Celsius (°C). For example, a chamber might operate from -80°C to +360°C. This specification is crucial for industries such as aerospace, automotive, and pharmaceuticals, where materials must be tested under extreme conditions to validate their performance and safety.

2. Temperature Uniformity

Temperature uniformity refers to how evenly the temperature is distributed within the chamber. A variation of more than ±1°C across the testing area can lead to inconsistent results, impacting the reliability of test outcomes. This property is especially important for quality assurance processes, where precision is critical for compliance with industry standards.

3. Load Capacity

Load capacity defines the maximum weight that can be placed in the chamber during testing. This is usually expressed in kilonewtons (kN). Understanding load capacity is vital for buyers to ensure that their testing requirements are met without risking damage to the chamber or inaccurate results. For instance, a chamber with a capacity of up to 250 kN is suitable for heavy materials like metals, while lower capacities are adequate for lightweight materials.

4. Heating and Cooling Rates

The heating and cooling rates determine how quickly the chamber can reach the desired temperature. This specification is measured in degrees per minute (°C/min). Fast heating and cooling rates can significantly reduce testing time and improve efficiency, making it a vital consideration for businesses looking to optimize their testing procedures.

5. Control Precision

Control precision is the ability of the chamber to maintain a set temperature over time, typically measured in terms of stability (e.g., ±0.5°C). High control precision is essential for ensuring that tests are conducted under consistent conditions, which is critical for validating material properties and compliance with international standards.

What Are Common Trade Terms Related to Chamber Temperature?

Understanding industry jargon is essential for navigating procurement and negotiations effectively. Here are some common terms that B2B buyers should be familiar with:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of chamber temperature, buyers often deal with OEMs that provide specialized chambers tailored to specific industry needs.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. This term is significant for B2B buyers who need to understand the financial implications of their orders and plan their inventory accordingly.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price bids from suppliers for specific products or services. When sourcing temperature chambers, submitting an RFQ allows buyers to compare prices and terms from multiple vendors, ensuring they secure the best deal.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is crucial for B2B buyers engaged in international transactions, as they affect cost, risk, and logistics.

5. Calibration

Calibration refers to the process of adjusting the temperature measuring instruments to ensure accuracy. Regular calibration is essential for maintaining the integrity of test results and compliance with industry standards, making it a key consideration for buyers of temperature chambers.

6. Thermal Cycling

Thermal cycling is a testing process that involves repeatedly heating and cooling a material to assess its durability and performance under fluctuating temperature conditions. Understanding this term is important for buyers who require chambers that can effectively simulate real-world environmental changes.

By being informed about these technical properties and trade terms, B2B buyers can make better purchasing decisions, ensuring that their chamber temperature solutions meet the specific needs of their industry.

Navigating Market Dynamics and Sourcing Trends in the chamber temperature Sector

What Are the Current Market Dynamics and Key Trends in the Chamber Temperature Sector?

The chamber temperature sector is experiencing notable growth, driven by the increasing demand for high-precision testing environments across various industries, including pharmaceuticals, automotive, and materials science. Global drivers such as stringent quality assurance standards and regulatory compliance are pushing companies to invest in advanced temperature chambers that can replicate a wide range of environmental conditions. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these dynamics is essential for informed purchasing decisions.

Emerging technologies such as IoT integration and automation are transforming the landscape of chamber temperature solutions. Companies are increasingly looking for systems that offer real-time monitoring and control capabilities, allowing for improved efficiency and reduced operational costs. Additionally, there is a growing trend towards modular designs that enable customization and scalability, catering to varying testing needs without significant capital investment. Buyers should also be aware of the competitive landscape, characterized by both established manufacturers and innovative startups, which may influence pricing and availability.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in the Chamber Temperature Sector?

Sustainability is becoming a critical consideration for B2B buyers in the chamber temperature sector, driven by growing awareness of environmental impacts and regulatory pressures. Companies are increasingly scrutinizing their supply chains for sustainability practices, seeking suppliers that adhere to green certifications and utilize eco-friendly materials. This is particularly relevant for buyers in regions where environmental regulations are becoming more stringent, such as Europe.

Ethical sourcing is equally important, as businesses strive to ensure that their suppliers operate under fair labor practices and contribute positively to local economies. Buyers should prioritize manufacturers that demonstrate transparency in their sourcing processes and provide documentation on their sustainability initiatives. By choosing suppliers with a proven commitment to environmental and social responsibility, companies not only enhance their brand reputation but also mitigate risks associated with supply chain disruptions and regulatory compliance.

What Is the Historical Context of Chamber Temperature Technology and Its Relevance Today?

The evolution of chamber temperature technology dates back several decades, initially serving niche applications in laboratory settings. Over time, advancements in materials science and engineering have significantly broadened the scope of these chambers, allowing for precise temperature control across various applications. The introduction of digital control systems and advanced insulation materials has improved energy efficiency and accuracy, making them indispensable in modern quality assurance processes.

Illustrative image related to chamber temperature

Today, the relevance of chamber temperature technology is underscored by its critical role in ensuring product reliability and compliance with international standards. As industries continue to evolve, the demand for sophisticated testing environments will only increase, solidifying the importance of this technology in global supply chains. Buyers who understand the historical context of these advancements can better appreciate the value and capabilities of contemporary chamber temperature solutions, positioning themselves for strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of chamber temperature

-

How do I choose the right chamber temperature for my applications?

Selecting the right chamber temperature largely depends on the specific materials or components you intend to test. Consider the temperature range required for your tests, as well as the load capacity of the chamber. For example, if you need to test plastics, a chamber that can operate from -80°C to +250°C is ideal. Additionally, assess whether you need features like precise temperature control or compatibility with extensometers for better testing accuracy. -

What are the common applications for temperature chambers in various industries?

Temperature chambers are utilized across multiple industries, including plastics, rubber, composites, and metals. They are essential for quality assurance testing, ensuring that materials perform reliably under specified temperature conditions. Common applications include tensile testing, thermal cycling tests, and durability assessments. Understanding your industry standards—such as ISO and ASTM—will guide you in selecting a chamber tailored to your testing needs. -

What should I consider when vetting suppliers of chamber temperature systems?

When vetting suppliers, prioritize their experience in the industry and customer reviews. Look for certifications that demonstrate compliance with international standards. Evaluate their product range to ensure they offer chambers that meet your specific requirements. Additionally, inquire about their after-sales support, warranty policies, and availability of spare parts, as these can significantly impact your operational efficiency. -

What is the minimum order quantity (MOQ) for temperature chambers?

MOQs for temperature chambers can vary widely among suppliers based on their manufacturing capabilities and product specifications. Some suppliers may allow single-unit purchases, particularly for specialized models, while others may require a minimum of several units for bulk pricing. Always clarify the MOQ during your initial discussions to avoid potential delays in procurement. -

What payment terms should I expect when purchasing temperature chambers internationally?

Payment terms vary by supplier and region but commonly include options such as upfront payment, partial payment upon order confirmation, and balance before shipment. For international transactions, suppliers might also accept letters of credit or escrow services to ensure security for both parties. It’s advisable to negotiate terms that align with your cash flow while considering the supplier’s policies. -

How do I ensure quality assurance (QA) when sourcing temperature chambers?

To ensure quality assurance, request detailed product specifications and testing certifications from potential suppliers. Inquire about their quality control processes, including any standardized testing they perform before shipping. If possible, arrange for a factory visit or request samples to assess the chamber’s performance firsthand. Establishing clear communication regarding your QA expectations from the outset can also help maintain standards. -

What logistics considerations should I be aware of when importing temperature chambers?

Logistics play a crucial role in the timely delivery of temperature chambers. Consider factors such as shipping methods, customs clearance processes, and potential tariffs or taxes that may apply. Ensure that the supplier provides proper packaging to prevent damage during transit. Additionally, it may be beneficial to work with a freight forwarder experienced in handling specialized equipment to streamline the import process. -

Can temperature chambers be customized to meet specific testing requirements?

Yes, many suppliers offer customization options for temperature chambers to cater to specific testing needs. Customizations can include adjustments to the temperature range, load capacity, or integration with specific measurement devices. When discussing customization, be clear about your requirements and the standards you need to meet. This will ensure that the chamber is tailored to your applications, enhancing testing accuracy and reliability.

Top 5 Chamber Temperature Manufacturers & Suppliers List

1. GitHub – Chamber Temperature Control in OrcaSlicer

Domain: github.com

Registered: 2007 (18 years)

Introduction: Chamber Temperature Control in OrcaSlicer utilizes M141/M191 commands to manage the active chamber heater. Key features include:

– Automatic insertion of M191 command in G-code if filament’s activate temperature control and printer’s chamber temperature support are enabled.

– Auxiliary fan activation during heating for air circulation.

– Manual control of chamber temperature using variables in …

2. Zwick Roell – Precision Temperature Chambers

Domain: zwickroell.com

Registered: 2001 (24 years)

Introduction: Temperature Chambers -80 °C to +360 °C

– Temperature range: -80°C to +250°C, -80°C to +360°C, -50°C to +180°C

– Load range: Up to 250 kN, Up to 2.5 kN

– Advantages: Precise temperatures, Flexible extensometer integration, Flexible in use, Can be retrofitted

– Industries: Universal

– Applications: Standard and engineering plastics (ISO 527-1, ASTM D638), Elastomers and rubber (ASTM D412, ISO 37, IS…

3. Creality – Ender 3 V3 SE

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The Ender 3 V3 SE can display chamber temperature in the Creality slicer program. Users can connect an external temperature sensor to monitor the surrounding temperature, especially if the printer is in an enclosure. The slicer allows for setting chamber temperature alongside other parameters like first layer temperature and bed temperature.

4. Prusa – MK3s+ Limitations

Domain: forum.prusa3d.com

Registered: 2013 (12 years)

Introduction: The MK3s+ does not have a chamber heater or thermometer, making the chamber temperature setting in PrusaSlicer ineffective for this model. The setting is not supported on MK3/s/+ printers, nor on Mk4, Mini, or XL models. It may have potential use in Core models, but details are not confirmed. The chamber temperature setting adds GCode commands (M141/M191) to the start of the GCode if a value is se…

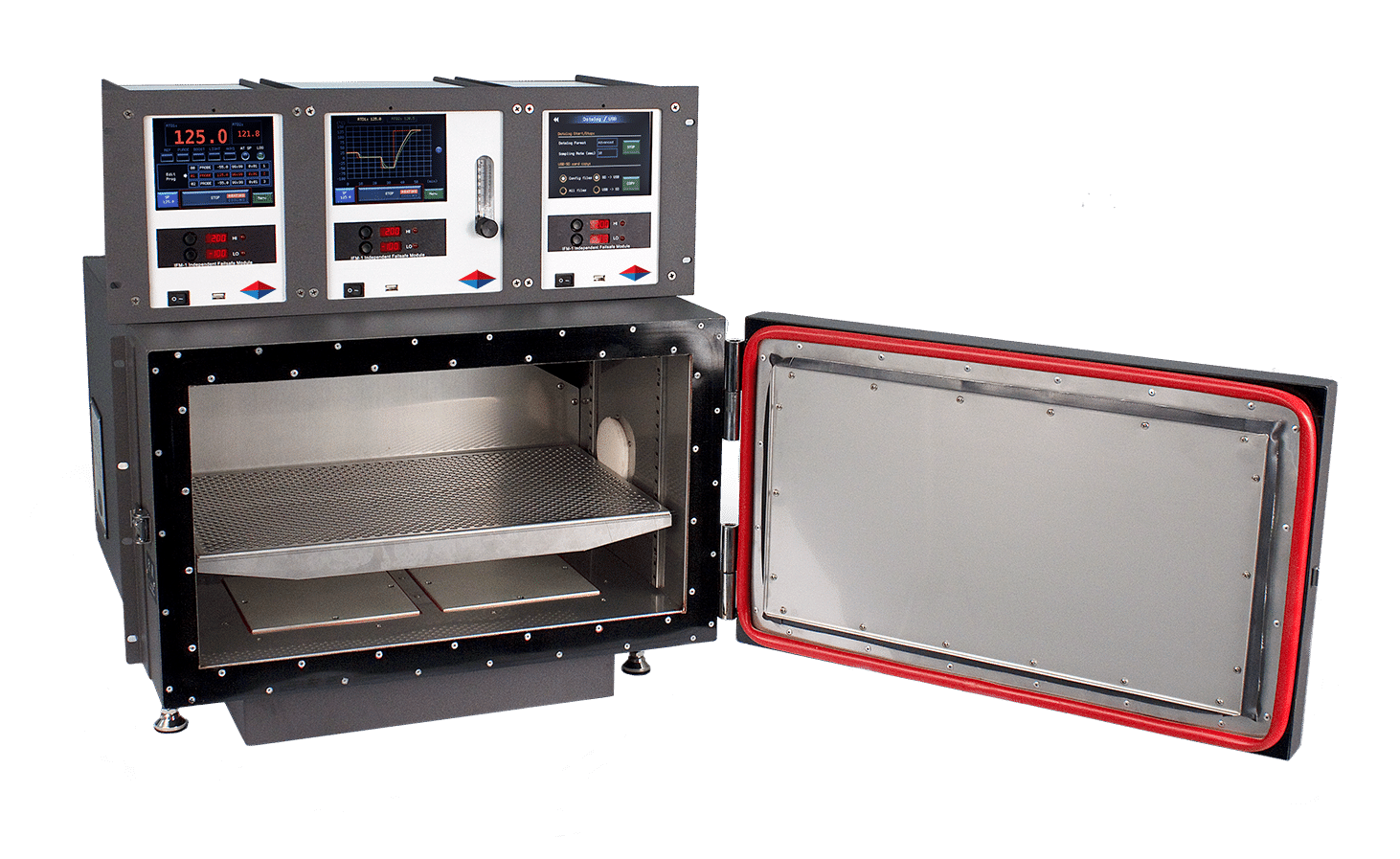

5. IQS Directory – Temperature Chambers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Temperature chambers, also known as environmental test chambers or climatic chambers, are advanced instruments designed to replicate various environmental conditions to evaluate product resilience. They simulate aging processes and extreme conditions to forecast product lifespan and functionality. Key features include:

– Controlled environments with varying heat levels, temperature gradients, and …

Strategic Sourcing Conclusion and Outlook for chamber temperature

In the ever-evolving landscape of quality assurance and material testing, strategic sourcing of chamber temperature solutions is paramount for B2B buyers. By prioritizing precision and reliability, organizations can ensure compliance with international standards, ultimately enhancing product quality and market competitiveness. With a range of options available—from compact, cost-effective chambers to high-performance systems capable of extreme temperature ranges—buyers must assess their specific needs against the capabilities of potential suppliers.

Furthermore, leveraging advanced technologies such as integrated data management systems can streamline operations and improve testing accuracy. As industries in Africa, South America, the Middle East, and Europe continue to grow, the demand for high-quality materials testing will only intensify.

Illustrative image related to chamber temperature

Looking ahead, B2B buyers are encouraged to engage with suppliers who not only offer innovative chamber temperature solutions but also provide robust support and customization options. By doing so, organizations can position themselves for success in a competitive marketplace. Take the next step in optimizing your sourcing strategy—evaluate your needs, explore available technologies, and connect with trusted suppliers to ensure your materials testing processes are efficient and effective.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.