Is Your Carrier Oehler Company Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for carrier oehler company

Navigating the complexities of sourcing industrial instrumentation can be a daunting challenge for B2B buyers, especially when considering the diverse needs across global markets. Carrier Oehler Company stands out as a leading provider of comprehensive solutions in pressure, temperature, level, and flow instrumentation, catering to a wide array of industries. This guide is designed to empower international buyers—particularly those from Africa, South America, the Middle East, and Europe, including key markets like Germany and Brazil—by providing actionable insights into the sourcing process.

In the following sections, we will delve into various aspects critical to making informed purchasing decisions. Buyers will gain a deeper understanding of the types of products offered by Carrier Oehler, their specific applications, and essential considerations for supplier vetting. Additionally, we will explore pricing structures, potential cost-saving strategies, and best practices for integrating these solutions into your operations.

By equipping yourself with the knowledge from this guide, you can confidently navigate the global market for Carrier Oehler products, ensuring that you select the most suitable and cost-effective solutions tailored to your operational needs. Whether you are looking to enhance productivity, ensure compliance, or innovate processes, this comprehensive resource aims to facilitate your journey in the industrial automation landscape.

Understanding carrier oehler company Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pressure Instrumentation | Includes pressure sensors, gauges, and regulators. | Oil & gas, water treatment, manufacturing. | Pros: High accuracy, reliability. Cons: May require calibration and maintenance. |

| Temperature Instrumentation | Comprises sensors and switches for monitoring temperature. | HVAC, food processing, pharmaceuticals. | Pros: Essential for safety and compliance. Cons: Potentially high initial costs. |

| Flow Instrumentation | Features flow meters, controllers, and switches. | Chemical processing, water management. | Pros: Enhances efficiency and process control. Cons: Installation complexity. |

| Level Instrumentation | Involves level transmitters, gauges, and switches. | Storage tanks, wastewater treatment. | Pros: Prevents overflow and ensures safety. Cons: Limited by environmental conditions. |

| Actuators | Includes various types like electric, pneumatic, and hydraulic. | Automation, robotics, manufacturing. | Pros: Increases automation efficiency. Cons: Selection can be confusing due to variety. |

What Are the Key Characteristics of Pressure Instrumentation?

Pressure instrumentation is critical in various industries, particularly in oil and gas, water treatment, and manufacturing. This category includes devices like pressure sensors, gauges, and regulators, designed to measure and control pressure levels accurately. B2B buyers should consider the reliability and accuracy of these instruments, as they directly impact safety and operational efficiency. Regular maintenance and calibration are essential to ensure optimal performance, which may add to long-term operational costs.

How Does Temperature Instrumentation Enhance Industrial Operations?

Temperature instrumentation is vital for industries such as HVAC, food processing, and pharmaceuticals. This category includes temperature sensors and switches that monitor and control temperature levels to maintain safety and compliance with industry standards. When purchasing, B2B buyers should evaluate the precision and response time of these instruments, as well as their compatibility with existing systems. While the initial investment may be significant, the long-term benefits in safety and product quality often justify the costs.

What Are the Benefits of Flow Instrumentation in Process Control?

Flow instrumentation encompasses devices like flow meters, controllers, and switches, primarily used in chemical processing and water management applications. These instruments help monitor and regulate the flow of liquids and gases, enhancing process efficiency and control. Buyers should assess the accuracy and installation requirements of these instruments, as complex setups may require specialized knowledge. While flow instrumentation can significantly improve operational efficiency, the complexity of installation and potential need for ongoing adjustments should be factored into purchasing decisions.

Why Is Level Instrumentation Important for Safety and Compliance?

Level instrumentation includes devices such as transmitters, gauges, and switches, used in applications like storage tanks and wastewater treatment facilities. These instruments are essential for preventing overflow and ensuring safe operations. B2B buyers should consider the environmental conditions in which these instruments will operate, as factors like temperature and pressure can affect performance. Although level instrumentation contributes significantly to operational safety, buyers must be aware of potential limitations based on the specific application and environmental factors.

What Role Do Actuators Play in Automation and Robotics?

Actuators are crucial components in automation and robotics, with various types available, including electric, pneumatic, and hydraulic options. They are widely used in manufacturing processes to increase efficiency and reduce manual labor. Buyers should evaluate the specific application requirements and the type of actuator that best fits their needs. While actuators can greatly enhance automation capabilities, the variety available can be overwhelming, necessitating thorough research to ensure the right choice is made for specific operational needs.

Key Industrial Applications of carrier oehler company

| Industry/Sector | Specific Application of Carrier Oehler Company | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Pressure and Flow Instrumentation for pipeline monitoring | Enhanced safety and efficiency in operations | Compliance with international standards and certifications |

| Water Treatment | Level and Flow Control Systems for water management | Improved resource management and cost savings | Durability and reliability in harsh environments |

| Manufacturing | Automation Solutions for process control | Increased productivity and reduced downtime | Compatibility with existing systems and scalability |

| Energy Management | Environmental Monitoring Instruments | Compliance with regulations and sustainability goals | Accuracy and sensitivity of instruments |

| Food and Beverage | Temperature and Pressure Monitoring for processing | Quality assurance and regulatory compliance | Hygiene standards and ease of calibration |

How Does Carrier Oehler Company Address Challenges in the Oil & Gas Sector?

In the oil and gas industry, Carrier Oehler Company provides advanced pressure and flow instrumentation critical for pipeline monitoring. These instruments help prevent leaks and ensure safe operations, addressing the industry’s inherent risks. International buyers must consider compliance with various safety standards, ensuring that the products meet rigorous international certifications. The integration of these systems can significantly enhance operational efficiency, ultimately leading to cost savings and improved safety metrics.

What Role Does Carrier Oehler Play in Water Treatment Solutions?

Carrier Oehler Company’s level and flow control systems are essential in the water treatment sector, where precise management of resources is crucial. These systems facilitate accurate monitoring and control of water levels and flow rates, leading to better resource allocation and reduced operational costs. For buyers in regions like Africa and South America, where water scarcity is a pressing issue, the reliability and durability of these systems in harsh conditions are paramount. Ensuring that the equipment adheres to local environmental regulations is also a key consideration.

How Can Manufacturing Benefit from Carrier Oehler’s Automation Solutions?

In manufacturing, Carrier Oehler’s automation solutions streamline process control, significantly enhancing productivity and minimizing downtime. These solutions integrate seamlessly with existing systems, allowing for efficient scaling and adaptability to various production environments. For international B2B buyers, especially in Europe, understanding compatibility with local automation standards and the potential for customization is crucial. The ability to rapidly respond to production demands can lead to substantial competitive advantages.

Why Is Environmental Monitoring Important in Energy Management?

Carrier Oehler Company offers environmental monitoring instruments essential for energy management, helping businesses comply with environmental regulations while achieving sustainability goals. These instruments monitor emissions and energy consumption, allowing companies to optimize their operations and reduce their carbon footprint. Buyers in the Middle East and Europe must prioritize the accuracy and sensitivity of these instruments to ensure compliance with stringent regulatory frameworks. This not only aids in meeting legal requirements but also enhances corporate responsibility towards environmental stewardship.

How Does Carrier Oehler Ensure Quality in Food and Beverage Processing?

In the food and beverage industry, maintaining strict temperature and pressure controls is vital for quality assurance and regulatory compliance. Carrier Oehler Company provides instruments designed to monitor these critical parameters throughout the processing stages. For international buyers, particularly in regions with varying hygiene standards, the ability to easily calibrate and maintain these instruments is essential. Investing in reliable monitoring solutions not only ensures compliance but also enhances product quality, ultimately driving customer satisfaction and loyalty.

3 Common User Pain Points for ‘carrier oehler company’ & Their Solutions

Scenario 1: Navigating Complex Industrial Instrumentation Needs

The Problem: B2B buyers often grapple with the overwhelming variety of industrial instrumentation products available in the market. With a vast array of pressure, temperature, level, and flow instrumentation, buyers may struggle to identify the right specifications that align with their operational needs. This challenge is exacerbated by a lack of technical knowledge about which instruments are best suited for their specific applications, leading to potential mispurchases that can cause operational inefficiencies and increased costs.

The Solution: To tackle this issue, buyers should leverage Carrier-Oehler Company’s expertise in industrial instrumentation. Begin by engaging with their technical sales team, which can provide tailored recommendations based on your operational requirements. Prepare a detailed list of your application needs, including environmental conditions and performance metrics. By collaborating closely with Carrier-Oehler, you can benefit from their comprehensive product line and ensure that you are selecting well-engineered instruments that have proven reliability in similar applications. Additionally, consider requesting a demo or trial period for critical instruments to validate their performance before making a significant investment.

Scenario 2: Overcoming Supply Chain Challenges in Global Markets

The Problem: International B2B buyers, especially from regions like Africa and South America, often face significant supply chain disruptions. Issues such as shipping delays, customs clearance complications, and fluctuating import regulations can hinder timely access to essential industrial components. This unpredictability can impact project timelines and operational continuity, leading to frustration and financial losses.

The Solution: To mitigate supply chain risks, it’s crucial to establish a proactive communication channel with Carrier-Oehler. Inquire about their international distribution capabilities and shipping timelines to your specific location. Discuss your project timelines and urgency with their logistics team to explore expedited shipping options or bulk purchase agreements that could secure better availability. Furthermore, consider forming a strategic partnership with Carrier-Oehler to develop a tailored supply chain solution, such as local stockholding or consignment arrangements, which can ensure that critical instruments are readily available when needed.

Scenario 3: Ensuring Compliance with Industry Standards and Regulations

The Problem: Many B2B buyers are tasked with ensuring that their equipment meets strict industry standards and regulatory compliance, which can vary significantly across regions. Non-compliance can result in costly fines, operational shutdowns, and reputational damage. This is particularly pertinent for buyers in highly regulated sectors such as energy, environmental monitoring, and manufacturing.

The Solution: To navigate compliance challenges, buyers should utilize Carrier-Oehler’s comprehensive knowledge of industry standards and regulations. Start by conducting a thorough review of the compliance requirements relevant to your industry and region. Reach out to Carrier-Oehler’s experts for assistance in identifying which of their products are certified to meet these standards. They can provide documentation and guidance on how to implement their instruments in a compliant manner. Additionally, consider integrating their calibration and testing services into your procurement process to ensure that all equipment remains compliant throughout its operational lifecycle. This proactive approach can save time and resources while minimizing the risks associated with regulatory non-compliance.

Strategic Material Selection Guide for carrier oehler company

What Are the Key Materials Used in Carrier-Oehler Company Products?

Carrier-Oehler Company specializes in a wide range of industrial instrumentation, which necessitates the careful selection of materials to ensure optimal performance and reliability. Below are analyses of four common materials used in their products, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Stainless Steel Perform in Industrial Applications?

Key Properties: Stainless steel is known for its excellent corrosion resistance, high tensile strength, and ability to withstand extreme temperatures and pressures. It typically performs well in applications involving fluids and gases, making it suitable for pressure instrumentation and flow controls.

Pros & Cons: The durability of stainless steel is a significant advantage, as it can endure harsh environments without degrading. However, its cost can be relatively high compared to other materials, and the manufacturing processes may be complex, requiring specialized equipment.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances, which is crucial for applications in the oil and gas sector, as well as in chemical processing.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM and DIN, which govern the use of stainless steel in industrial applications. This material is widely accepted and preferred in these markets due to its reliability.

What Role Does Brass Play in Industrial Instrumentation?

Key Properties: Brass offers good corrosion resistance, excellent machinability, and moderate strength. It is often used in fittings, valves, and connectors due to its favorable mechanical properties.

Pros & Cons: The primary advantage of brass is its cost-effectiveness and ease of manufacturing. However, it has lower strength compared to stainless steel and can be susceptible to dezincification in certain environments, which may limit its use.

Impact on Application: Brass is suitable for applications involving water and non-corrosive gases, making it ideal for HVAC systems and plumbing applications.

Considerations for International Buyers: Buyers in Africa and South America should consider local environmental conditions that may affect brass performance. Compliance with local standards is essential, as is awareness of any specific regulations related to drinking water systems.

Why Is PVC a Popular Choice for Flow Instrumentation?

Key Properties: Polyvinyl chloride (PVC) is lightweight, resistant to corrosion, and has good chemical resistance. It is commonly used in applications involving water and various chemicals.

Pros & Cons: PVC is highly cost-effective and easy to install, making it a popular choice for many industrial applications. However, it has limitations in terms of temperature and pressure ratings, which can restrict its use in high-stress environments.

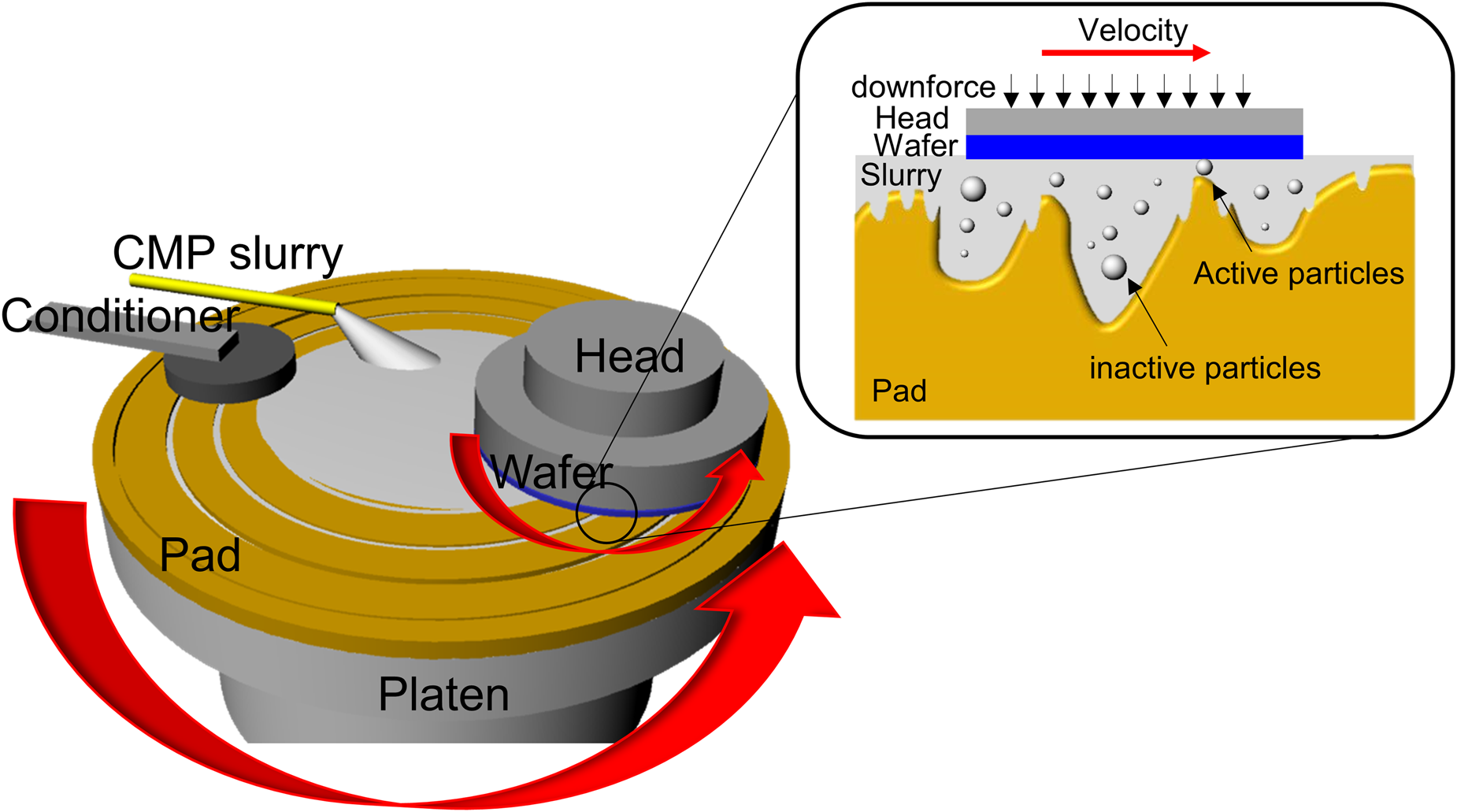

Illustrative image related to carrier oehler company

Impact on Application: PVC is particularly effective in low-pressure applications and is widely used in water treatment facilities and chemical processing plants.

Considerations for International Buyers: Buyers from regions with stringent environmental regulations should ensure that PVC products meet local compliance standards. Understanding the specific chemical compatibility is crucial for ensuring long-term performance.

How Does Aluminum Enhance Product Performance?

Key Properties: Aluminum is lightweight, resistant to corrosion, and has good thermal conductivity. It is often used in applications where weight is a critical factor, such as in mobile instrumentation.

Pros & Cons: The lightweight nature of aluminum makes it easy to handle and install, which can reduce overall project costs. However, it may not be suitable for high-pressure applications, and its strength is lower than that of steel.

Illustrative image related to carrier oehler company

Impact on Application: Aluminum is ideal for applications in environments where weight savings are critical, such as in aerospace and automotive industries.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of specific aluminum grades and their compliance with international standards. Understanding regional preferences for material properties can also guide selection.

Summary Table of Material Selection for Carrier-Oehler Company

| Material | Typical Use Case for Carrier-Oehler Company | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Pressure instrumentation, flow controls | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Brass | Fittings, valves, connectors | Cost-effective and easy to machine | Lower strength, susceptible to dezincification | Medium |

| PVC | Water treatment, chemical processing | Lightweight and cost-effective | Limited temperature and pressure ratings | Low |

| Aluminum | Mobile instrumentation, lightweight applications | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

This strategic material selection guide provides a comprehensive overview for B2B buyers, helping them make informed decisions based on material properties, application suitability, and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for carrier oehler company

What Are the Key Stages in the Manufacturing Process of Carrier-Oehler Company?

Carrier-Oehler Company utilizes a systematic approach to manufacturing that emphasizes efficiency, precision, and adaptability to meet diverse client requirements. The manufacturing process typically involves four main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with sourcing high-quality raw materials that meet industry specifications. Carrier-Oehler ensures that materials are carefully selected based on their durability and performance characteristics, particularly for industrial instrumentation. This stage may involve cutting, machining, and treating materials to ensure they are ready for the next phase.

-

Forming: In this phase, the prepared materials undergo various forming techniques, including machining, welding, and stamping. Carrier-Oehler employs advanced machinery and automated systems to achieve high precision in shaping components. This stage is critical for creating parts that adhere to strict dimensional tolerances, which is essential for the functionality of pressure, temperature, and flow instrumentation.

-

Assembly: The assembly stage is where components come together to form complete instruments. Carrier-Oehler adopts a modular assembly approach, allowing for flexibility in production and customization based on client specifications. Skilled technicians are involved in this stage to ensure that all parts are assembled correctly, taking care to maintain quality standards.

-

Finishing: After assembly, products undergo finishing processes, which may include painting, coating, or surface treatments. These processes not only enhance the aesthetic appeal of the instruments but also improve their resistance to environmental factors. The finishing stage is vital for ensuring that the products can withstand the operational demands of various industries.

How Does Carrier-Oehler Company Ensure Quality Assurance?

Carrier-Oehler Company places a strong emphasis on quality assurance (QA) throughout the manufacturing process. This commitment to quality is reflected in the adherence to international standards, industry-specific certifications, and a comprehensive quality control (QC) system.

-

International Standards and Industry-Specific Certifications: Carrier-Oehler is compliant with ISO 9001, which sets the criteria for a quality management system. This certification ensures that the company consistently meets customer and regulatory requirements. In addition to ISO standards, Carrier-Oehler may also adhere to certifications relevant to the instrumentation industry, such as CE marking and API standards, which ensure that products meet European and American safety and performance criteria.

-

Quality Control Checkpoints: The QC process includes several critical checkpoints:

– Incoming Quality Control (IQC): This initial step involves inspecting raw materials and components upon arrival to verify their compliance with specifications.

– In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections and tests are conducted to identify and rectify any deviations from quality standards.

– Final Quality Control (FQC): Once the products are fully assembled and finished, a final inspection is performed to ensure that they meet all specifications and regulatory requirements before shipping. -

Common Testing Methods: Carrier-Oehler employs a variety of testing methods to validate the performance and reliability of its products. These may include pressure testing, temperature calibration, flow measurement assessments, and environmental simulations. Such rigorous testing ensures that the instruments will perform reliably in real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control processes of suppliers like Carrier-Oehler. Here are actionable insights for ensuring supplier credibility:

-

Conducting Audits: Buyers should consider conducting on-site audits of the manufacturing facilities. This allows for direct observation of the manufacturing processes, quality control measures, and overall compliance with international standards. An audit can provide valuable insights into the supplier’s operational capabilities and commitment to quality.

-

Requesting Quality Control Reports: Buyers should request detailed QC reports that outline the testing methods used, results obtained, and any corrective actions taken in response to identified issues. These reports serve as documentation of the supplier’s commitment to maintaining high-quality standards.

-

Utilizing Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These services can conduct inspections at various stages of production and provide certification that products meet specified standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate several nuances related to quality control when sourcing from suppliers like Carrier-Oehler:

-

Understanding Regional Standards: Different regions may have unique standards and regulations that affect product acceptance. For instance, European buyers might prioritize CE compliance, while buyers in the Middle East may focus on local regulatory requirements. It is crucial for buyers to familiarize themselves with these regional standards to ensure compliance and avoid potential issues.

-

Language and Cultural Barriers: Communication can pose challenges when verifying quality control processes. Buyers should consider working with local representatives or consultants who understand the supplier’s language and culture. This approach can facilitate clearer communication and ensure that quality expectations are adequately conveyed.

-

Building Long-Term Relationships: Establishing strong relationships with suppliers can enhance transparency regarding quality control practices. Regular communication and collaboration can foster a deeper understanding of each party’s expectations and capabilities, ultimately leading to improved product quality and reliability.

Conclusion

In summary, Carrier-Oehler Company employs a comprehensive manufacturing process that emphasizes quality at every stage. By adhering to international standards and implementing robust quality control measures, the company ensures that its products meet the demanding requirements of B2B buyers worldwide. For international buyers, understanding these processes and actively engaging in quality verification can lead to successful partnerships and reliable supply chains.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘carrier oehler company’

This guide serves as a comprehensive checklist for B2B buyers interested in sourcing products from Carrier-Oehler Company, a leader in industrial instrumentation. By following these steps, you can ensure that you make informed purchasing decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Before initiating contact with Carrier-Oehler, clearly outline your technical requirements. This includes determining the types of instrumentation you need—such as pressure, temperature, level, and flow measurement devices. Having precise specifications helps streamline the communication process and ensures that you receive products that meet your operational demands.

Step 2: Conduct Market Research

Understanding the broader market landscape is essential. Research other suppliers of industrial instrumentation and compare their offerings, prices, and reputation. This will not only provide you with alternative options but also give you leverage when negotiating with Carrier-Oehler, ensuring you get the best value for your investment.

Step 3: Evaluate Carrier-Oehler’s Product Line

Carrier-Oehler boasts a comprehensive product range, including actuators, calibration instruments, and environmental monitoring tools. Review their catalog to identify which products align with your specifications. Pay attention to the engineering quality and application history of their instruments, as this can impact your operational efficiency.

Step 4: Verify Supplier Certifications

Ensure that Carrier-Oehler holds relevant certifications and adheres to industry standards. Certifications can indicate the quality and reliability of their products. Look for ISO certifications or other relevant industry-specific accreditations, which can assure you of their commitment to quality and compliance.

Step 5: Request Quotes and Proposals

Once you have a clear understanding of your needs and have evaluated Carrier-Oehler’s offerings, request detailed quotes. Be specific about your requirements and ask for proposals that include pricing, delivery timelines, and terms of service. This will help you compare their offerings with other suppliers and make an informed decision.

Step 6: Check References and Case Studies

Before finalizing your order, ask for references or case studies from Carrier-Oehler. Speak to other clients who have purchased similar products to gauge their satisfaction levels and the performance of the instruments in real-world applications. This feedback can provide valuable insights into the reliability and effectiveness of the products.

Step 7: Negotiate Terms and Finalize the Agreement

Once you are satisfied with the quotes and references, engage in negotiations to finalize the terms of the agreement. Discuss payment terms, warranties, and return policies to ensure that all aspects of the transaction are transparent and acceptable. A well-negotiated agreement can protect your interests and foster a long-term partnership with Carrier-Oehler.

By following this checklist, B2B buyers can confidently navigate the sourcing process with Carrier-Oehler Company, ensuring they select the best solutions for their industrial instrumentation needs.

Comprehensive Cost and Pricing Analysis for carrier oehler company Sourcing

What Are the Key Cost Components for Sourcing from Carrier-Oehler Company?

When sourcing from Carrier-Oehler Company, understanding the cost structure is crucial for B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe. The primary cost components include:

-

Materials: The raw materials used in the production of industrial instrumentation significantly influence the overall cost. Carrier-Oehler’s commitment to quality often means sourcing high-grade materials, which may be costlier but ensures reliability and performance.

-

Labor: Labor costs can vary based on location and the complexity of the manufacturing process. In the U.S., where Carrier-Oehler is based, labor costs are generally higher than in many developing countries. Understanding labor cost implications is essential for international buyers who may consider local assembly or manufacturing options.

-

Manufacturing Overhead: This includes utilities, maintenance, and administrative expenses related to production. Efficient manufacturing processes can help reduce these costs, which is a significant factor in Carrier-Oehler’s pricing strategy.

-

Tooling: The cost of tooling is an essential aspect, especially for customized products. High-quality tooling can improve precision and reduce waste, impacting the final pricing of products.

-

Quality Control (QC): Rigorous quality assurance processes ensure that products meet international standards. While this adds to the cost, it ultimately enhances product reliability, which is crucial for B2B buyers.

-

Logistics: Shipping costs can vary widely depending on the destination and the mode of transportation. International buyers should consider potential tariffs, customs duties, and logistics providers when evaluating costs.

-

Margin: Carrier-Oehler’s pricing will also include a margin that reflects the company’s operational costs and desired profitability. Understanding the margin can provide insight into negotiating prices.

How Do Pricing Influencers Affect Costs for International Buyers?

Several factors can influence the pricing of Carrier-Oehler products, which international buyers should consider:

Illustrative image related to carrier oehler company

-

Volume/MOQ: Bulk purchases often lead to lower per-unit costs. Understanding the Minimum Order Quantity (MOQ) can help buyers strategize their orders for better pricing.

-

Specifications and Customization: Custom products typically incur higher costs due to the additional engineering and manufacturing processes involved. Buyers should weigh the need for customization against the potential price increase.

-

Material Quality and Certifications: Products that meet specific quality standards or certifications can command higher prices. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: Relationships with suppliers can significantly impact pricing. Long-term partnerships often yield better terms and conditions, including pricing.

-

Incoterms: Understanding Incoterms is essential for international transactions. They define the responsibilities of buyers and sellers in shipping and logistics, which can affect overall costs.

What Negotiation Strategies Can B2B Buyers Use to Achieve Cost Efficiency?

To achieve cost efficiency when sourcing from Carrier-Oehler Company, international buyers should consider the following strategies:

-

Leverage Volume Discounts: By consolidating orders, buyers can negotiate better pricing based on higher volumes. This is particularly effective for companies with predictable purchasing patterns.

-

Analyze Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, shipping, and operational costs to assess the TCO. This holistic view can justify a higher upfront cost if the long-term savings are significant.

-

Explore Alternative Payment Terms: Discussing flexible payment options can alleviate cash flow pressures and may open the door to better pricing.

-

Build Relationships: Establishing a rapport with Carrier-Oehler representatives can facilitate negotiations and provide insights into upcoming promotions or pricing adjustments.

-

Be Informed About Market Trends: Keeping abreast of industry trends can provide leverage in negotiations. Understanding competitor pricing and market conditions can help buyers make informed decisions.

Conclusion

Sourcing from Carrier-Oehler Company involves a comprehensive understanding of cost structures and pricing influencers. By leveraging negotiation strategies and considering the total cost of ownership, international buyers can achieve significant cost savings and ensure they are making informed purchasing decisions. Always consult with Carrier-Oehler for the most accurate and current pricing information tailored to specific needs and contexts.

Alternatives Analysis: Comparing carrier oehler company With Other Solutions

Understanding Alternatives in Industrial Instrumentation Solutions

In the competitive landscape of industrial instrumentation, businesses often seek solutions that not only meet their operational requirements but also offer superior value. This analysis explores Carrier Oehler Company and compares it with alternative solutions available in the market. By evaluating performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make informed decisions tailored to their specific needs.

Comparison Table

| Comparison Aspect | Carrier Oehler Company | Alternative 1: Bosch Industrial Solutions | Alternative 2: Johnson Controls |

|---|---|---|---|

| Performance | Comprehensive product line with proven reliability | High efficiency with advanced technology | Strong performance in HVAC and controls |

| Cost | Competitive pricing with cost-effective options | Generally higher due to advanced features | Mid-range pricing, value for quality |

| Ease of Implementation | Moderate complexity, needs proper training | User-friendly, quick installation | Requires specialized knowledge for setup |

| Maintenance | Requires regular calibration and servicing | Low maintenance with smart diagnostics | Moderate maintenance with support options |

| Best Use Case | Ideal for industries needing diverse instrumentation | Best for high-tech manufacturing environments | Suitable for integrated building systems |

Detailed Breakdown of Alternatives

Alternative 1: Bosch Industrial Solutions

Bosch offers a robust range of industrial automation solutions, known for their high efficiency and innovative technologies. Their systems are designed to integrate seamlessly into modern manufacturing setups, making them an attractive choice for businesses looking to upgrade. However, the advanced features come at a premium, which may not be suitable for all budgets. Additionally, Bosch products are generally user-friendly, allowing for quicker installations and reduced training time.

Alternative 2: Johnson Controls

Johnson Controls specializes in building management systems and HVAC solutions, providing strong performance in energy management and controls. Their products are particularly well-suited for integrated building systems, making them a preferred choice for enterprises focused on sustainability. While they offer a moderate maintenance requirement, the initial setup may require specialized knowledge, which could lead to higher implementation costs. Nevertheless, the value they provide in terms of energy efficiency can yield significant long-term savings.

Making the Right Choice for Your Industrial Needs

When selecting an instrumentation solution, B2B buyers should consider their unique operational requirements, budget constraints, and long-term goals. Carrier Oehler Company stands out for its comprehensive product offerings and reliability, making it an excellent choice for businesses needing a broad spectrum of instrumentation. However, if a company prioritizes advanced technology or integrated systems, Bosch or Johnson Controls might be more appropriate alternatives. Ultimately, the decision should align with the company’s specific needs, ensuring that the chosen solution enhances operational efficiency and drives business growth.

Essential Technical Properties and Trade Terminology for carrier oehler company

Understanding the technical properties and trade terminology related to Carrier-Oehler Company is vital for international B2B buyers. This section will clarify essential specifications and jargon, enabling informed purchasing decisions in the industrial instrumentation sector.

What Are the Key Technical Properties of Carrier-Oehler’s Products?

-

Material Grade

The material grade of industrial instrumentation refers to the quality and type of materials used in manufacturing components like sensors, valves, and actuators. Common materials include stainless steel for durability and resistance to corrosion. Understanding material grade is crucial for buyers, as it directly impacts product longevity and performance in various environments. -

Tolerance

Tolerance defines the permissible limits of variation in a physical dimension of a product. For example, in pressure instrumentation, maintaining tight tolerances is essential for accurate measurements. Buyers must consider tolerance levels to ensure compatibility with existing systems and to guarantee reliability in critical applications. -

Pressure Rating

This specification indicates the maximum pressure a component can withstand safely. For pressure instruments, knowing the pressure rating is vital to prevent failures in high-pressure environments, which could lead to safety hazards and costly downtime. -

Temperature Range

The temperature range signifies the operating temperatures within which a product can function effectively. For instance, temperature sensors need to be capable of operating in extreme conditions without loss of accuracy. Buyers must assess the temperature range to ensure the selected instruments meet the demands of their specific applications. -

Flow Capacity

Flow capacity refers to the volume of fluid that can pass through an instrument over a specified period. For flow instrumentation, understanding flow capacity is crucial for selecting the right equipment that can handle the required throughput without compromising performance.

What Are the Common Trade Terms Used in the Industry?

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the context of Carrier-Oehler, understanding OEM partnerships can help buyers identify the reliability and quality of the components they are sourcing. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory planning, particularly when dealing with specialized instrumentation that may have higher costs associated with smaller orders. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products or services. Using RFQs allows buyers to compare offers and ensure they are getting competitive pricing and favorable terms before making a purchasing decision. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding the transportation and delivery of goods. Familiarity with Incoterms is essential for international B2B transactions, as they clarify aspects such as shipping costs, risk transfer, and insurance obligations. -

Lead Time

Lead time is the duration from the placement of an order to its delivery. Understanding lead times is critical for project planning and inventory management, especially in industries where timing is crucial for operational efficiency.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can navigate the complexities of sourcing from Carrier-Oehler Company more effectively, ensuring that they select the right products to meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the carrier oehler company Sector

What Are the Current Market Dynamics and Sourcing Trends Impacting Carrier Oehler Company?

The industrial instrumentation sector, particularly the Carrier Oehler Company, is currently influenced by several global drivers. Increasing automation and the adoption of Industry 4.0 technologies are reshaping how companies approach their sourcing strategies. This transformation is characterized by a growing reliance on data-driven decision-making and the integration of smart technologies, which enhance operational efficiency and reduce costs. For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, these trends signify a shift towards suppliers who can provide comprehensive solutions that not only meet technical specifications but also align with broader business objectives.

Emerging trends in sourcing include an increasing focus on supply chain resilience, especially in light of disruptions caused by geopolitical tensions and the COVID-19 pandemic. Buyers are prioritizing partnerships with suppliers who demonstrate flexibility and reliability in their delivery capabilities. Moreover, the shift towards remote monitoring and predictive maintenance technologies is prompting buyers to seek products that offer enhanced connectivity and integration capabilities, thereby enabling real-time data analysis and operational optimization.

Additionally, sustainability is becoming a key factor in purchasing decisions. Buyers are now more inclined to partner with manufacturers who prioritize eco-friendly practices and offer products that contribute to energy efficiency and waste reduction. This trend is particularly pronounced in regions such as Europe, where regulatory pressures are prompting businesses to adopt more sustainable practices.

How Important Is Sustainability and Ethical Sourcing in the Carrier Oehler Company Sector?

Sustainability and ethical sourcing are not just buzzwords; they are critical components shaping the landscape of the Carrier Oehler Company sector. Environmental concerns are driving businesses to reconsider their sourcing strategies, with a heightened focus on the environmental impact of their supply chains. For B2B buyers, this means selecting partners who adhere to stringent environmental standards and can demonstrate a commitment to reducing carbon footprints.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly concerned about the social and environmental implications of their purchases. This trend is leading to a demand for ‘green’ certifications and materials that indicate a product’s sustainability credentials. Manufacturers that can provide transparent information about their sourcing practices and environmental impact are more likely to attract and retain B2B clients.

Moreover, adopting sustainable practices can enhance a company’s reputation and marketability. Buyers from regions like Germany and Brazil are particularly attentive to corporate social responsibility (CSR) initiatives, making it essential for suppliers like Carrier Oehler to integrate sustainability into their business models. This can include using recyclable materials, minimizing waste in production processes, and ensuring fair labor practices throughout the supply chain.

What Is the Historical Context of Carrier Oehler Company’s Market Position?

Carrier Oehler Company has established itself as a notable player in the industrial instrumentation field, with roots extending back several decades. Initially focusing on providing basic instrumentation solutions, the company has evolved its product line to encompass a comprehensive range of pressure, temperature, level, and flow instrumentation. This evolution reflects the broader market dynamics, where technological advancements and increasing complexity in industrial processes necessitate more sophisticated measurement and control systems.

Over the years, Carrier Oehler has maintained a commitment to quality and innovation, which has enabled it to foster strong relationships with channel partners and international distributors. This legacy has positioned the company favorably within the global market, allowing it to serve diverse industries across multiple regions. As the demand for automation and smart technologies continues to rise, Carrier Oehler’s extensive experience and robust product offerings will be pivotal in meeting the evolving needs of international B2B buyers.

Illustrative image related to carrier oehler company

Frequently Asked Questions (FAQs) for B2B Buyers of carrier oehler company

-

How do I solve supply chain delays when sourcing from Carrier-Oehler Company?

Supply chain delays can be mitigated by establishing clear communication with Carrier-Oehler regarding lead times and order status. It’s advisable to place orders well in advance, especially for customized products. Additionally, consider discussing alternative shipping options or expedited services if timelines are critical. Building a good relationship with your account manager can also help in navigating any potential delays effectively. -

What is the best type of instrumentation for industrial applications?

The best instrumentation for industrial applications depends on specific requirements such as pressure, temperature, flow, or level measurement. Carrier-Oehler offers a comprehensive range of products, including pressure transmitters, flow controllers, and temperature sensors. Evaluating the specific needs of your application, including environmental conditions and compatibility with existing systems, will help in selecting the most suitable products. -

What customization options are available for Carrier-Oehler products?

Carrier-Oehler Company provides a variety of customization options tailored to meet specific application needs. This includes modifications in product specifications, materials, and configurations. To explore customization possibilities, it’s best to consult with a sales representative who can guide you through the available options based on your requirements and provide detailed technical support. -

What are the minimum order quantities (MOQ) for Carrier-Oehler products?

Minimum order quantities can vary depending on the product line and specific agreements. Typically, standardized products may have lower MOQs, while customized solutions might require larger orders. It’s recommended to directly contact Carrier-Oehler’s sales team to clarify MOQ specifics for the products you are interested in, especially if you are looking to place a bulk order. -

What payment terms does Carrier-Oehler offer for international orders?

Carrier-Oehler Company generally offers flexible payment terms that can be negotiated based on the order size and buyer relationship. Common payment methods include wire transfers, letters of credit, and credit terms for established customers. It’s essential to discuss payment options upfront to ensure alignment with your financial processes and to avoid any complications during the transaction. -

How does Carrier-Oehler ensure quality assurance in their products?

Quality assurance at Carrier-Oehler is upheld through rigorous testing and compliance with industry standards. The company employs a systematic approach to quality control, including regular inspections and testing of products throughout the manufacturing process. Buyers can request documentation regarding product certifications and testing protocols to ensure that the instruments meet their operational standards. -

What logistics support does Carrier-Oehler provide for international shipping?

Carrier-Oehler offers various logistics solutions to facilitate international shipping, including collaboration with reliable freight forwarders. They can assist with customs documentation and provide guidance on shipping regulations specific to your country. It’s advisable to discuss logistics during the order process to ensure all aspects of delivery, including timelines and costs, are clearly understood. -

How can I evaluate Carrier-Oehler as a reliable supplier?

To evaluate Carrier-Oehler as a reliable supplier, consider reviewing their track record in delivering quality products and customer service. Check for certifications, client testimonials, and case studies relevant to your industry. Engaging in direct communication with their sales and technical teams can also provide insights into their responsiveness and support capabilities, helping you make an informed decision.

Top 6 Carrier Oehler Company Manufacturers & Suppliers List

1. Dresser Utility – Measurement System Management™

Domain: dresserutility.com

Registered: 2020 (5 years)

Introduction: Measurement System Management™, Rotary Meters, Turbine Meters, Diaphragm Meters, Electronic Volume Correctors & Converters, Electronic Accessories, Test Equipment, Coupling & Repair, Gas Water & Industrial Kobus Pipe Puller, Pressure Control, Safety Shut Off / Relief Valve, Overpressure Protection, Pressure Relief Valves, Valve Automation, Valves/Piping Actuation, Pressure Management Instrumentati…

2. Carrier-Oehler Co. – Industrial Instrumentation Solutions

Domain: automation.com

Registered: 1995 (30 years)

Introduction: Carrier-Oehler Co. offers a comprehensive product line of industrial instrumentation, including:

– Actuators (Digital, Valve, Pneumatic, Rotary, Linear, Electric)

– Calibration Instruments and Calibrators

– Energy Management Systems and Radiation Detectors

– Flow Instrumentation (Flow Transmitters, Flow Controllers, Flow Switches)

– Level Instrumentation (Level Switches, Level Transmitters, L…

3. Carrier Oehler Co. – Automation Machinery

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, Carrier Oehler Co. – Automation Machinery, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. RocketReach – Industrial Automation Solutions

Domain: rocketreach.co

Registered: 2015 (10 years)

Introduction: Industrial Automation, Automation Systems, Industrial Controls, Process Automation, Manufacturing Automation, Industrial Equipment, Automation Solutions, Control Systems Integration, Industrial Robotics, Factory Automation, Automation Engineering, Industrial Technology, Automation Components, Systems Integration, Industrial Controls Systems, Automation Services, Industrial Networking, Motion Contr…

5. IQS Directory – Pressure Gauges

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Pressure gauges for hydronic, industrial, OEM, and refrigeration uses.

6. Carrier-Oehler Company – Hydraulic Systems & Equipment

Domain: bloomberg.com

Registered: 1993 (32 years)

Introduction: Carrier-Oehler Company distributes and supplies hydraulic systems and equipment. The Company offers gauges, instrument calibration, and repair services, as well as provides pressure, temperature, level, flow instrumentation, and hydraulic accessories distribution services.

Strategic Sourcing Conclusion and Outlook for carrier oehler company

In today’s competitive landscape, strategic sourcing is crucial for maximizing operational efficiency and ensuring access to top-tier industrial instrumentation. Carrier-Oehler Company stands out with its extensive product line, encompassing pressure, temperature, level, and flow instrumentation that meets a wide array of industry specifications. By leveraging their international distribution capabilities and well-engineered products, buyers can expect tailored solutions that enhance productivity and reliability in their operations.

For businesses in Africa, South America, the Middle East, and Europe, partnering with Carrier-Oehler can provide a competitive edge through cost-effective sourcing and high-quality instrumentation. Their commitment to customer satisfaction and proven expertise in the field ensures that you receive not just products, but also comprehensive support and guidance tailored to your specific needs.

As you consider your sourcing strategies, prioritize collaboration with manufacturers like Carrier-Oehler who can deliver innovative solutions and foster long-term partnerships. Take the next step in optimizing your supply chain by exploring the diverse offerings of Carrier-Oehler—your gateway to reliable industrial automation solutions that drive success in your market. Reach out today to discover how they can meet your unique requirements and elevate your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.