Is Your Brazos Boots Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for brazos boots

In today’s competitive landscape, international buyers face the pressing challenge of sourcing high-quality Brazos boots that meet specific workplace safety and comfort requirements. Whether you are looking for durable steel-toe work boots for construction sites or waterproof options for agricultural settings, understanding the diverse range of products available is essential for making informed purchasing decisions. This comprehensive guide delves into the multifaceted world of Brazos boots, exploring various types, their applications across industries, and crucial factors for supplier vetting.

Our guide empowers B2B buyers from Africa, South America, the Middle East, and Europe—such as those in Nigeria and Brazil—by providing actionable insights into pricing structures, product specifications, and quality standards. By addressing key considerations like safety compliance and material durability, we equip you with the knowledge to navigate the complexities of global sourcing effectively. Furthermore, we highlight the importance of establishing reliable supplier relationships to ensure consistent quality and service, which is vital for maintaining operational efficiency.

As you explore the world of Brazos boots, this guide serves as your trusted resource, enabling you to make confident purchasing decisions that align with your business needs and enhance the safety and comfort of your workforce.

Understanding brazos boots Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Western Work Boots | Classic design, often with decorative stitching, durable leather | Agriculture, construction, ranching | Pros: Stylish, durable; Cons: May lack modern safety features. |

| Steel Toe Work Boots | Reinforced toe for protection, often meets ASTM safety standards | Industrial, construction, manufacturing | Pros: Enhanced safety; Cons: Heavier than non-steel toe options. |

| Waterproof Work Boots | Waterproof materials, slip-resistant soles | Outdoor work, wet environments | Pros: Keeps feet dry; Cons: Can be less breathable. |

| Composite Toe Work Boots | Lightweight protection, non-metallic materials | Security-sensitive environments | Pros: Lighter, non-metal; Cons: May offer less impact resistance than steel toe. |

| Slip-Resistant Work Boots | Specialized outsoles for traction, often oil-resistant | Hospitality, healthcare, manufacturing | Pros: Reduces slip hazards; Cons: May wear out faster in rugged conditions. |

What Are the Characteristics of Western Work Boots?

Western work boots are characterized by their classic design and craftsmanship, often featuring decorative stitching and premium leather. They are suitable for agricultural and ranching applications where style and durability are essential. B2B buyers should consider the balance between aesthetics and functionality, as these boots may lack some modern safety features, making them ideal for environments where style is as important as utility.

Illustrative image related to brazos boots

How Do Steel Toe Work Boots Enhance Safety?

Steel toe work boots are designed with reinforced toes that meet ASTM safety standards, providing essential protection against heavy impacts. They are commonly used in industrial and construction settings where safety is paramount. When purchasing, businesses should evaluate the weight and comfort, as these boots can be heavier than non-steel toe options, potentially leading to fatigue during long work hours.

Why Choose Waterproof Work Boots for Outdoor Applications?

Waterproof work boots are constructed with materials that prevent water penetration while offering slip-resistant soles for stability in wet environments. They are ideal for outdoor work in agriculture or construction during rainy seasons. Buyers should weigh the benefits of keeping feet dry against the potential for reduced breathability, which can lead to discomfort in warmer conditions.

What Advantages Do Composite Toe Work Boots Offer?

Composite toe work boots provide lightweight protection using non-metallic materials, making them suitable for security-sensitive environments where metal detectors are present. They are often used in manufacturing and construction. B2B buyers should assess the balance between weight and impact resistance; while they are lighter than steel toe options, they may not provide the same level of protection in high-impact scenarios.

How Do Slip-Resistant Work Boots Improve Workplace Safety?

Slip-resistant work boots feature specialized outsoles designed to enhance traction, making them essential in hospitality, healthcare, and manufacturing sectors where slip hazards are prevalent. These boots help reduce workplace accidents. However, businesses should consider the durability of the outsoles, as they may wear out more quickly in rugged conditions, potentially requiring more frequent replacements.

Key Industrial Applications of brazos boots

| Industry/Sector | Specific Application of Brazos Boots | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Heavy-duty work boots for construction workers | Enhances worker safety and productivity on-site | Ensure compliance with local safety standards and comfort needs |

| Agriculture | Waterproof and slip-resistant boots for farm work | Protects workers from harsh weather and prevents slips | Focus on durability and ease of cleaning |

| Oil & Gas | Steel toe boots for drilling and extraction operations | Provides foot protection in hazardous environments | Look for ASTM certification and resistance to oil and chemicals |

| Manufacturing | Non-slip work boots for factory settings | Reduces workplace accidents and enhances worker efficiency | Consider weight, comfort, and ease of maintenance |

| Mining | Heavy-duty boots for underground mining operations | Protects against heavy equipment and uneven surfaces | Prioritize ruggedness and compliance with industry safety standards |

How Are Brazos Boots Used in the Construction Industry?

In the construction sector, Brazos boots are essential for workers who face various hazards daily, including heavy materials and uneven terrain. These boots often feature steel toes and slip-resistant soles, which significantly reduce the risk of foot injuries. For international buyers, especially in regions like Africa and South America, it’s crucial to ensure that the boots meet local safety standards and provide comfort for long working hours. Additionally, sourcing boots that are lightweight yet durable can enhance productivity on construction sites.

Illustrative image related to brazos boots

What Role Do Brazos Boots Play in Agriculture?

In agriculture, Brazos boots are particularly valued for their waterproof and slip-resistant features, making them ideal for farm work, which often involves wet and muddy conditions. These boots protect workers’ feet from moisture and slips, ensuring safety while handling livestock or operating machinery. Buyers in the agricultural sector should prioritize boots that are easy to clean and maintain, as this will significantly impact their longevity and cost-effectiveness in harsh environments.

Why Are Brazos Boots Essential in the Oil & Gas Sector?

Brazos boots designed for the oil and gas industry typically include steel toe protection and are made from materials resistant to oil and chemicals. These features are critical for workers involved in drilling and extraction, where foot safety is paramount due to heavy equipment and hazardous materials. For B2B buyers in the Middle East, where oil and gas operations are prevalent, it’s vital to ensure that the sourced boots comply with ASTM safety standards to mitigate workplace injuries.

How Do Brazos Boots Enhance Safety in Manufacturing?

In manufacturing environments, where workers often deal with machinery and assembly lines, non-slip Brazos boots can significantly reduce the incidence of workplace accidents. These boots are engineered to provide comfort and support, allowing workers to remain efficient throughout their shifts. International buyers should consider sourcing options that offer superior grip and durability, especially in high-traffic factory settings, to enhance overall workplace safety.

Illustrative image related to brazos boots

What Are the Key Features of Brazos Boots for Mining Applications?

For the mining industry, Brazos boots must be exceptionally rugged to withstand the harsh conditions of underground operations. These boots often feature reinforced soles and protective toe caps to guard against heavy equipment and uneven surfaces. Buyers in this sector should focus on sourcing boots that comply with stringent safety regulations, ensuring they provide the necessary protection and support for miners working in challenging environments.

3 Common User Pain Points for ‘brazos boots’ & Their Solutions

Scenario 1: Ensuring Safety Compliance in the Workplace

The Problem: B2B buyers in industries like construction and manufacturing face the challenge of ensuring their workforce adheres to stringent safety regulations. Safety compliance is critical, as non-compliance can lead to injuries and costly fines. Buyers often struggle to find boots that not only meet safety standards but also provide comfort for long hours of wear. For instance, a procurement officer may find themselves in a situation where the chosen boots do not have the necessary safety features, such as steel toes or slip-resistant soles, resulting in employee dissatisfaction and increased liability.

The Solution: To effectively source Brazos boots that ensure safety compliance, buyers should prioritize models that explicitly meet ASTM safety standards. Conduct thorough research on the specific safety requirements for their industry and select boots designed for the unique hazards faced by their workers. For example, Brazos offers various models with features like composite toes and slip-resistant outsoles, which can be highlighted in procurement specifications. Engaging directly with Brazos representatives can provide insights into the latest safety innovations and help buyers choose the most suitable options for their workforce. Additionally, consider implementing a trial program where employees can test different models to gather feedback on comfort and performance, ensuring that the selected boots not only comply with safety regulations but also meet the needs of the workers.

Illustrative image related to brazos boots

Scenario 2: Managing Bulk Orders and Inventory Challenges

The Problem: International B2B buyers often encounter difficulties when managing bulk orders of Brazos boots, particularly regarding inventory management and logistics. Variations in demand can lead to overstock or stockouts, complicating inventory management and potentially disrupting operations. For example, a distributor in Nigeria may order a large shipment of boots only to face delays in shipping, resulting in excess inventory that becomes challenging to manage.

The Solution: To mitigate these inventory challenges, B2B buyers should establish a robust inventory management system that forecasts demand accurately. Utilizing data analytics can help predict trends based on historical sales data and seasonal demands. Additionally, buyers should develop a strategic partnership with Brazos for direct access to inventory updates and faster replenishment options. This could include negotiating agreements that allow for smaller, more frequent orders to maintain optimal stock levels without overcommitting to large shipments. Implementing a just-in-time inventory strategy can also help minimize excess stock while ensuring that the right sizes and models are available when needed.

Scenario 3: Customizing Boot Options for Diverse Workforces

The Problem: In diverse work environments, B2B buyers often struggle to accommodate the varying needs of their workforce when selecting Brazos boots. Employees may have different preferences regarding fit, style, and specific features such as waterproofing or insulation. This diversity can lead to dissatisfaction if the selected boots do not cater to all employees’ needs, affecting morale and productivity.

Illustrative image related to brazos boots

The Solution: To address this issue, buyers should consider a comprehensive assessment of their workforce’s specific requirements before making bulk purchases. Conducting surveys or focus groups can provide valuable insights into employee preferences and needs. Once this data is gathered, buyers can work with Brazos to customize orders that reflect the diverse needs of their employees. This may involve selecting a range of boot styles, sizes, and features to create a more inclusive offering. Additionally, establishing a regular review process to gather ongoing feedback from employees can help buyers adjust their selections over time, ensuring that the boots remain suitable for the evolving needs of the workforce.

Strategic Material Selection Guide for brazos boots

What Are the Key Materials Used in Brazos Boots and Their Properties?

When selecting materials for Brazos boots, understanding the properties, advantages, and disadvantages of each material is crucial for B2B buyers. The following analysis focuses on four common materials used in the construction of Brazos boots: leather, rubber, synthetic fabrics, and composite materials.

How Does Leather Impact the Performance of Brazos Boots?

Leather, particularly full-grain leather, is a primary material for Brazos boots. It offers excellent durability, breathability, and comfort, making it suitable for various working environments. Full-grain leather can withstand significant wear and tear, providing a long lifespan for the boots. However, it can be more expensive than other materials and may require regular maintenance to preserve its quality.

Illustrative image related to brazos boots

From a performance perspective, leather has a high resistance to abrasion and is generally water-resistant, especially when treated. However, it may not perform well in extreme temperatures, either hot or cold, unless specifically treated for thermal insulation. International buyers should consider compliance with local standards, such as ASTM for safety footwear, to ensure the leather meets necessary safety and environmental regulations.

What Role Does Rubber Play in Brazos Boots?

Rubber is predominantly used in the outsoles of Brazos boots, providing excellent slip resistance and cushioning. The rubber outsoles are designed to be oil- and slip-resistant, making them ideal for industrial applications where traction is critical. While rubber outsoles are durable and can withstand harsh conditions, they may degrade over time when exposed to extreme temperatures or certain chemicals.

The cost of rubber components is generally moderate, and they are relatively easy to manufacture. However, the environmental impact of rubber production can be a concern for some buyers, particularly in regions with strict sustainability standards. Buyers in Africa and South America should be aware of local preferences for eco-friendly materials and may need to ensure that their suppliers adhere to sustainable practices.

How Do Synthetic Fabrics Enhance Brazos Boots?

Synthetic fabrics, including nylon and polyester, are often used in the linings and upper sections of Brazos boots. These materials are lightweight, breathable, and quick-drying, making them suitable for warmer climates. Additionally, synthetic fabrics can be engineered for specific properties, such as moisture-wicking or enhanced durability.

Illustrative image related to brazos boots

While synthetic fabrics are generally less expensive than leather, they may not offer the same level of durability or comfort over extended periods. They can also be less resistant to abrasion compared to leather. For international buyers, understanding the climate and working conditions in their regions is essential, as synthetic materials may be more suitable for humid or wet environments.

What Advantages Do Composite Materials Offer for Brazos Boots?

Composite materials, such as fiberglass or carbon fiber, are increasingly used in safety toe caps and other protective features of Brazos boots. These materials provide excellent protection while being lighter than traditional steel toe caps, reducing fatigue for the wearer. They are also non-metallic, which can be advantageous in environments where metal detection is a concern.

The primary disadvantage of composite materials is their cost, which tends to be higher than that of steel. Additionally, while composite materials offer good insulation from temperature extremes, they may not provide the same level of protection against punctures as steel. Buyers from the Middle East and Europe should ensure that composite materials comply with local safety standards, such as EN ISO 20345, which governs safety footwear.

Illustrative image related to brazos boots

Summary Table of Material Selection for Brazos Boots

| Material | Typical Use Case for Brazos Boots | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Upper construction | Excellent durability and comfort | Requires maintenance; higher cost | High |

| Rubber | Outsoles | Slip resistance and cushioning | Degrades in extreme conditions | Medium |

| Synthetic Fabrics | Linings and uppers | Lightweight and breathable | Less durable than leather | Low |

| Composite Materials | Safety toe caps | Lightweight and non-metallic | Higher cost; less puncture protection | High |

This strategic material selection guide provides valuable insights for B2B buyers looking to source Brazos boots that meet their specific needs and comply with regional standards. Understanding the properties and implications of each material will aid in making informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for brazos boots

What Are the Main Stages in the Manufacturing Process of Brazos Boots?

The manufacturing process of Brazos Boots involves several key stages, each designed to ensure the highest quality and durability for work boots. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The journey begins with the careful selection of premium materials. Brazos Boots primarily uses American leathers known for their strength and longevity, which are sourced from reputable suppliers. Each material undergoes rigorous testing to ensure it can withstand the harsh conditions typical in various industries, such as construction and agriculture. The preparation stage also includes cutting the leather into specific patterns and preparing additional components like outsoles, safety toes, and waterproof liners.

How Is the Forming Stage Executed?

Once the materials are prepared, they move to the forming stage. This involves shaping the leather and other components into the desired boot form. Brazos employs traditional techniques combined with modern technology to achieve precise shapes and sizes. For example, the leather is often molded over a last to create a comfortable fit. Innovative design elements, such as cushioned insoles and anti-fatigue footbeds, are integrated during this stage to enhance comfort and support.

What Techniques Are Used in the Assembly of Brazos Boots?

The assembly stage is where the boots take their final shape. Master bootmakers, skilled in traditional craftsmanship, stitch the various components together. Brazos Boots focuses on employing techniques that ensure durability, such as double stitching and reinforced seams. Additionally, during this stage, features like slip-resistant soles and composite safety toes are added to meet industry safety standards. This meticulous assembly process is crucial for creating boots that not only look good but also perform exceptionally well in demanding work environments.

How Are Brazos Boots Finished to Ensure Quality?

The finishing stage involves several steps to enhance the boots’ appearance and functionality. This includes applying protective coatings, polishing, and ensuring that each pair meets aesthetic standards. Quality checks are performed at this stage to identify any defects. The boots are then packaged with care, ensuring they are ready for distribution and can withstand the rigors of transport.

Illustrative image related to brazos boots

What Quality Control Measures Are Implemented in Brazos Boots Manufacturing?

Quality assurance is paramount at Brazos Boots, ensuring that every pair meets international standards and customer expectations. The company adheres to ISO 9001 standards, which focus on maintaining consistent quality in manufacturing processes.

What International Standards and Certifications Are Relevant?

In addition to ISO 9001, Brazos Boots complies with various industry-specific standards such as CE marking for safety footwear, which is essential for the European market. For certain industrial applications, adherence to API standards may also be relevant. These certifications indicate that the boots have been tested and verified to meet stringent safety and performance criteria.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Brazos Boots implements several quality control checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint ensures that raw materials meet predefined quality standards before production begins. Leather quality, durability, and compliance with safety requirements are assessed at this stage.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted to ensure that each stage adheres to quality standards. This includes checking stitching patterns, component fitting, and overall assembly quality.

-

Final Quality Control (FQC): Before packaging, each pair of boots undergoes a final inspection to ensure they meet both aesthetic and functional requirements. Any defects identified at this stage result in immediate corrective action.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of Brazos Boots is crucial. Here are actionable steps to ensure due diligence:

Illustrative image related to brazos boots

What Audits and Reports Should Be Requested?

Buyers should request detailed quality control reports from suppliers. These reports should include information on inspection results, compliance with international standards, and records of any corrective actions taken. Additionally, third-party audits can provide an unbiased assessment of the supplier’s quality management system.

How Do Third-Party Inspections Contribute to Quality Assurance?

Engaging third-party inspectors can add an extra layer of assurance. These independent entities can conduct comprehensive audits of the manufacturing facilities, assess quality control processes, and verify compliance with relevant standards. Such inspections can help buyers mitigate risks associated with subpar products.

What Are the Quality Control Nuances for International Buyers?

International buyers should be aware of the specific quality assurance nuances that may affect their procurement decisions. For instance, understanding regional certifications and compliance requirements can help buyers make informed decisions. Additionally, language barriers and differences in quality standards between regions may necessitate a more thorough evaluation of supplier capabilities.

Illustrative image related to brazos boots

Conclusion: Ensuring Quality in Every Pair of Brazos Boots

The manufacturing processes and quality assurance practices of Brazos Boots are designed to deliver high-quality, durable, and safe footwear for a variety of industries. By understanding the stages of production and the robust quality control measures in place, B2B buyers can confidently source products that meet their operational needs. Ensuring that suppliers adhere to international standards and implementing thorough verification processes will further enhance the reliability of their procurement strategy.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘brazos boots’

This guide serves as a practical checklist for international B2B buyers looking to procure Brazos boots. By following these steps, you can ensure that your sourcing process is efficient and effective, ultimately leading to a successful purchase that meets your business needs.

Step 1: Define Your Technical Specifications

Before beginning your search for Brazos boots, clearly outline your technical specifications. Consider factors such as the intended use (e.g., construction, agriculture), required safety features (like steel toes), and specific material preferences (such as waterproof leathers). Having detailed specifications will help you filter suppliers and products more effectively.

Illustrative image related to brazos boots

Step 2: Research Reputable Suppliers

Finding a reliable supplier is critical in ensuring product quality and service. Conduct thorough research on potential suppliers of Brazos boots, focusing on their reputation in the market. Look for online reviews, testimonials, and case studies from businesses similar to yours to gauge their reliability and product quality.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; instead, engage in direct communication to understand their production capabilities and customer service standards.

Step 4: Verify Compliance with Industry Standards

Ensure that the Brazos boots you are considering comply with relevant industry safety standards, such as ASTM certifications for work boots. This is essential not only for worker safety but also for compliance with local regulations in your market. Request documentation from suppliers to verify compliance.

Step 5: Analyze Pricing and Terms of Sale

Pricing is a key factor in your procurement process. Compare prices among different suppliers but also consider the terms of sale, including minimum order quantities, payment terms, and shipping costs. Look for suppliers that offer competitive pricing without compromising on quality or service.

Illustrative image related to brazos boots

Step 6: Request Samples for Evaluation

Before making a bulk order, request samples of the Brazos boots you intend to purchase. This step allows you to evaluate the quality, comfort, and suitability of the boots for your specific needs. Testing the samples also provides an opportunity to assess the supplier’s responsiveness and service quality.

Step 7: Establish a Communication Plan

Once you’ve chosen a supplier, establish a clear communication plan to manage the order process effectively. Set expectations for timelines, delivery schedules, and points of contact for any issues that may arise. Consistent communication is vital for maintaining a strong supplier relationship and ensuring a smooth procurement process.

By following this checklist, you can navigate the sourcing process for Brazos boots with confidence, ensuring that you secure high-quality products that meet your business needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for brazos boots Sourcing

What Are the Key Cost Components in Sourcing Brazos Boots?

When sourcing Brazos Boots, understanding the cost structure is essential for B2B buyers. The main cost components include:

-

Materials: The quality of leather and other materials significantly influences the final price. Brazos Boots are known for using premium leathers, which can elevate costs but enhance durability and comfort.

-

Labor: Skilled craftsmanship is a hallmark of Brazos Boots. Labor costs can vary based on the complexity of the boot design and the expertise required for production.

-

Manufacturing Overhead: This encompasses utilities, facility maintenance, and indirect labor costs associated with the production process. Given the artisanal nature of Brazos Boots, overhead can be a considerable factor.

-

Tooling: Custom tooling for specific designs or modifications can add to the initial investment. This is particularly relevant for buyers looking to customize their orders.

-

Quality Control (QC): Rigorous QC processes ensure that every pair of boots meets safety and quality standards, contributing to overall costs.

-

Logistics: Shipping costs can be substantial, especially for international buyers. Factors such as shipping methods, distance, and customs duties affect the final landed cost.

-

Margin: Supplier margins will vary based on their pricing strategy and market competition. Understanding these margins can help buyers assess the reasonableness of the prices offered.

How Do Price Influencers Affect the Cost of Brazos Boots?

Several factors influence the pricing of Brazos Boots:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for volume discounts. Establishing a relationship with suppliers can lead to better pricing based on anticipated order sizes.

-

Specifications and Customization: Custom designs, materials, or features (e.g., steel toe, waterproofing) can increase costs. Buyers should weigh the necessity of these features against their budget and the intended use of the boots.

-

Quality Certifications: Boots that meet specific safety standards may come at a premium. However, these certifications can be crucial for compliance in certain industries.

-

Supplier Factors: The reliability and reputation of the supplier can affect pricing. Established suppliers with a track record of quality may charge more but offer peace of mind regarding product performance.

-

Incoterms: Understanding the terms of shipping and delivery can significantly influence costs. Options like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) will dictate who bears the shipping costs and risks, impacting the total cost of ownership.

What Buyer Tips Can Enhance Cost-Efficiency When Sourcing Brazos Boots?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are several strategies to optimize costs:

-

Negotiate Effectively: Don’t hesitate to negotiate terms, especially for larger orders. Suppliers may be willing to provide discounts or better payment terms based on your purchasing history or order size.

-

Consider Total Cost of Ownership: Evaluate not just the purchase price but also long-term costs, including maintenance, durability, and replacement rates. Investing in higher-quality boots may yield better value over time.

-

Understand Pricing Nuances: Familiarize yourself with the pricing structure and market conditions in your region. This knowledge can empower you to make informed decisions and identify the best suppliers.

-

Evaluate Shipping Options: Assess different logistics providers and shipping methods. Sometimes, consolidating shipments or using different routes can lower costs.

-

Stay Informed on Market Trends: Keeping abreast of trends in the footwear industry and understanding seasonal demand can help buyers time their purchases to maximize savings.

Disclaimer on Pricing

The prices mentioned in this analysis are indicative and may vary based on market conditions, order specifics, and supplier negotiations. Always consult with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing brazos boots With Other Solutions

Understanding Alternatives in Work Boot Solutions

In the realm of work footwear, selecting the right boots is crucial for ensuring safety, comfort, and productivity in demanding environments. While Brazos Boots have established a strong reputation for quality and durability, it’s essential to consider other viable alternatives that might better suit specific needs or preferences. This analysis compares Brazos Boots against two notable alternatives: Carhartt Boots and Red Wing Boots, evaluating their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Brazos Boots | Carhartt Boots | Red Wing Boots |

|---|---|---|---|

| Performance | High durability, safety features | Excellent grip, weather resistance | Superior craftsmanship, long-lasting |

| Cost | $39.97 – $99.99 | $99.99 – $179.99 | $200 – $400 |

| Ease of Implementation | Widely available, easy to purchase | Available at major retailers | Limited availability, premium outlets |

| Maintenance | Low maintenance, easy to clean | Moderate maintenance, requires care | High maintenance, specialized cleaning |

| Best Use Case | General work environments | Construction, outdoor work | Heavy-duty industrial work |

What Are the Pros and Cons of Carhartt Boots?

Carhartt Boots are renowned for their rugged design and superior grip, making them an excellent choice for outdoor and construction work. They typically feature waterproof materials and slip-resistant soles, ensuring safety in various weather conditions. However, they come at a higher price point, ranging from $99.99 to $179.99, which may not be suitable for all budgets. Additionally, while Carhartt boots are widely available, they may require moderate maintenance to keep them in optimal condition.

Illustrative image related to brazos boots

How Do Red Wing Boots Compare to Brazos Boots?

Red Wing Boots are synonymous with quality and craftsmanship, often considered a premium option for industrial work. They boast exceptional durability, making them ideal for heavy-duty environments. However, this comes with a significant investment, typically ranging from $200 to $400. Red Wing boots often require specialized cleaning and maintenance, which can be a drawback for businesses looking for low-maintenance options. Their availability can also be limited to specific retailers, making them less accessible compared to Brazos Boots.

Conclusion: How to Choose the Right Work Boot Solution for Your Needs?

When selecting the right work boots for your business, it is vital to consider factors such as performance requirements, budget constraints, and maintenance capabilities. Brazos Boots offer a cost-effective and reliable solution for general work environments, while Carhartt and Red Wing boots cater to specific demands and preferences within the construction and industrial sectors. Ultimately, the choice should align with the specific needs of your workforce, ensuring safety, comfort, and productivity are prioritized in the selection process.

Essential Technical Properties and Trade Terminology for brazos boots

What Are the Key Technical Properties of Brazos Boots That Buyers Should Know?

When considering Brazos Boots for industrial applications, understanding their critical technical properties is essential for ensuring quality, durability, and safety. Here are some key specifications that highlight the value of these boots:

-

Material Grade

Brazos Boots are primarily crafted from premium full-grain leather and nubuck. Full-grain leather is the highest quality leather available, known for its durability and ability to develop a rich patina over time. This grade of leather provides superior resistance to wear and tear, which is crucial for work environments. For B2B buyers, investing in boots made from high-quality materials translates to reduced replacement costs and increased employee satisfaction. -

Safety Toe Options

Many Brazos models feature safety toe technology, including steel and composite toes. These elements meet or exceed ASTM safety standards, providing essential protection against heavy falling objects and compression hazards. For businesses, equipping employees with safety toe boots is not just a regulatory requirement but also a proactive measure to reduce workplace injuries and associated liabilities. -

Outsole Composition

The outsoles of Brazos Boots often incorporate oil- and slip-resistant rubber, enhancing grip on various surfaces. This feature is particularly important for industries such as construction and manufacturing, where slip hazards are prevalent. A reliable outsole can significantly decrease the risk of workplace accidents, making it a vital specification for B2B procurement decisions. -

Waterproofing Technology

Models like the Brazos Men’s Waterproof Nubuck Work Boots utilize HydroGuard™ waterproof technology, ensuring that feet remain dry in wet conditions. This property is critical for workers in outdoor or wet environments, as it helps maintain comfort and performance throughout the workday. For buyers, waterproof boots can enhance employee productivity and morale. -

Cushioning and Comfort Features

The inclusion of EVA footbeds and anti-fatigue technology in various models provides additional comfort, reducing foot fatigue during long hours of standing or walking. Comfortable footwear is essential for maintaining worker productivity and reducing downtime due to discomfort or injury. -

Durability Standards

Brazos Boots are engineered to withstand rigorous working conditions, with a focus on longevity and performance. This durability is backed by years of industry experience and innovation. For B2B buyers, sourcing boots with proven durability means lower long-term costs and fewer disruptions in workforce productivity.

What Are Common Trade Terms Relevant to Brazos Boots Procurement?

Understanding industry terminology is crucial for effective communication and negotiation in the B2B space. Here are some common trade terms that buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of Brazos Boots, an OEM might supply specific components like safety toes or outsoles that are integrated into the final product. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for bulk buyers looking to procure Brazos Boots, as understanding MOQ can help in budgeting and inventory management. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer submits to suppliers to request pricing and other details for a specific quantity of goods. For B2B buyers interested in Brazos Boots, issuing an RFQ can help clarify costs and lead times. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers importing Brazos Boots, as they dictate who is responsible for shipping, insurance, and tariffs. -

Lead Time

This refers to the time it takes from placing an order until the goods are delivered. For buyers of Brazos Boots, understanding lead times can help in planning inventory and ensuring that employee needs are met without delay. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and longevity of the product. Knowing the warranty terms for Brazos Boots can help buyers evaluate the risk of investment and the potential for future costs related to replacements or repairs.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing Brazos Boots, ensuring they select the right products for their workforce needs.

Illustrative image related to brazos boots

Navigating Market Dynamics and Sourcing Trends in the brazos boots Sector

What Are the Key Market Dynamics and Trends Influencing the Brazos Boots Sector?

The global market for Brazos boots is significantly influenced by several drivers, primarily the increasing demand for durable and reliable footwear among industrial and agricultural workers. As economies in Africa, South America, the Middle East, and Europe continue to develop, the need for quality workwear that offers both comfort and protection is paramount. Notably, countries like Nigeria and Brazil are seeing a rise in construction and agriculture sectors, which directly boosts the demand for robust work boots.

Emerging B2B technologies are reshaping sourcing trends, with a focus on e-commerce platforms and digital supply chain solutions. International buyers are increasingly utilizing data analytics and AI-driven insights to optimize their purchasing decisions, ensuring they acquire high-quality products at competitive prices. Furthermore, the rise of direct-to-consumer models is enabling manufacturers to engage more directly with buyers, reducing the need for intermediaries and potentially lowering costs.

Market dynamics are also shifting due to increased competition among brands, prompting a focus on innovation in design and materials. Brands are investing in advanced manufacturing technologies and sustainable practices to cater to a more environmentally conscious consumer base, which is becoming a crucial factor in purchasing decisions.

Illustrative image related to brazos boots

How Are Sustainability and Ethical Sourcing Shaping the Brazos Boots Industry?

Sustainability and ethical sourcing have emerged as central themes in the Brazos boots sector, driven by heightened awareness of environmental issues and consumer demand for responsible production practices. The environmental impact of footwear manufacturing can be substantial, with concerns surrounding waste, pollution, and resource consumption. As a result, international buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices.

Ethical supply chains are becoming a non-negotiable standard for B2B transactions. Buyers are looking for manufacturers who utilize eco-friendly materials, such as recycled leathers and sustainable synthetics, and who adhere to fair labor practices. Certifications such as the Global Organic Textile Standard (GOTS) or Fair Trade can enhance a brand’s appeal, providing assurance to buyers that their products align with responsible sourcing standards.

Incorporating ‘green’ certifications into the product offering can also serve as a competitive differentiator, opening doors to markets that prioritize sustainability. As a result, Brazos boots manufacturers are investing in cleaner technologies and processes, ensuring that their product lines not only meet safety and durability standards but also contribute positively to environmental conservation efforts.

What Is the Historical Context Behind Brazos Boots That Matters for B2B Buyers?

Founded in 1965 by John Brazos in Fort Worth, Texas, the brand has a rich history deeply rooted in craftsmanship and quality. Initially, each pair of boots was handmade, reflecting a commitment to superior materials and construction techniques. This dedication to quality has transcended generations, with the company now offering over 200 boot models tailored for various industries, including construction and agriculture.

The evolution of Brazos Boots from a small shop to a nationally recognized brand has been marked by continuous innovation, particularly in addressing the needs of industrial workers. The adoption of advanced manufacturing techniques and a focus on ergonomic design has ensured that Brazos Boots remain competitive in a rapidly changing market. For B2B buyers, understanding this history not only highlights the brand’s reliability but also its adaptability to meet modern-day demands.

Illustrative image related to brazos boots

This legacy of quality craftsmanship combined with an emphasis on safety and innovation makes Brazos Boots a compelling choice for international buyers seeking dependable footwear solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of brazos boots

-

How do I source high-quality Brazos boots for my business?

To source high-quality Brazos boots, start by identifying reputable suppliers or manufacturers who specialize in work footwear. Verify their credentials, including certifications and industry experience. Request product samples to evaluate the quality, comfort, and durability of the boots. Additionally, attending trade shows or industry expos can provide opportunities to meet suppliers face-to-face and establish relationships. Don’t hesitate to ask for references from other businesses that have purchased from them to ensure reliability. -

What is the best pricing strategy for purchasing Brazos boots in bulk?

The best pricing strategy involves negotiating bulk purchase discounts directly with suppliers. Many manufacturers offer tiered pricing based on order quantities, so inquire about Minimum Order Quantities (MOQ) and associated discounts. Additionally, consider seasonal promotions or clearance sales that might provide further savings. Establishing a long-term relationship with the supplier can also lead to better pricing and terms over time. -

What customization options are available for Brazos boots?

Brazos offers various customization options for their boots, including size, color, and materials. For bulk orders, discuss specific customization needs directly with the manufacturer. Custom branding, such as adding your company’s logo, is often available, enhancing brand visibility. Ensure you confirm the lead times for custom orders and any additional costs associated with these modifications. -

What are the key safety standards Brazos boots meet?

Brazos boots are designed to meet or exceed various safety standards, including ASTM (American Society for Testing and Materials) regulations for protective footwear. This includes features like steel toes, slip-resistant soles, and waterproof materials. When sourcing, verify the specific certifications for the models you are interested in, ensuring they align with the safety requirements of your industry and region. -

How can I assess the reliability of a Brazos boots supplier?

To assess a supplier’s reliability, start by researching their market reputation and customer reviews. Look for testimonials from other B2B clients, focusing on their experience with product quality and customer service. Request references and conduct follow-up calls to gauge satisfaction levels. Additionally, check if they have a robust quality assurance process in place, ensuring that the products consistently meet industry standards. -

What payment terms should I expect when ordering Brazos boots internationally?

Payment terms can vary by supplier, but common options include upfront payments, net 30/60 days, or letters of credit for larger orders. Discuss payment methods accepted, such as bank transfers or credit terms, and ensure you understand any associated fees, especially for international transactions. Establishing clear terms in a purchase agreement will help avoid misunderstandings and ensure smooth transactions. -

What logistics considerations should I keep in mind when importing Brazos boots?

When importing Brazos boots, consider shipping methods, customs regulations, and potential tariffs in your region. Partner with a reliable freight forwarder familiar with international trade to navigate these complexities. Ensure you have all necessary documentation ready, including invoices and customs declarations, to facilitate a smooth import process. Planning for potential delays due to customs inspections or shipping logistics is also crucial. -

How do I handle quality assurance for my bulk order of Brazos boots?

Implementing a quality assurance (QA) process for your bulk order involves several steps. First, request pre-shipment samples to evaluate their quality against your specifications. Establish clear acceptance criteria for the boots, including materials, construction, and safety features. Consider conducting an on-site inspection during production or prior to shipment. After receiving the order, carry out random quality checks to ensure the boots meet your standards before distributing them to your customers.

Top 9 Brazos Boots Manufacturers & Suppliers List

1. Brazos – Boots

Domain: academy.com

Registered: 1995 (30 years)

Introduction: This company, Brazos – Boots, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Brazos Boots – Durable Work Boots

Domain: brazosboots.ninth-hall.com

Registered: 2024 (1 years)

Introduction: Brazos Boots has been crafting durable work boots since 1966, based in Texas. Their product lineup includes traditional work boots, steel toe boots, cowboy boots, and specialized boots for electricians and welders. Key features include premium full-grain leathers, rugged rubber outsoles, triple-stitched seams, and Goodyear welt construction. They offer men’s, women’s, and youth sizes, ensuring a r…

3. Lucchese – Brazos Boot – Black

Domain: lucchese.com

Registered: 1997 (28 years)

Introduction: {“name”: “Brazos Boot – Black”, “price”: “$595”, “style_no”: “M3435.74-1001-D-9.5”, “collection”: “Palo Pinto”, “material”: “Nubuck”, “fit”: {“recommendation”: “Order a half size up for a wider fit”, “size_guide”: “Lucchese boots generally run true to size, but may fit slightly smaller than dress shoe sizes.”}, “width_options”: {“D”: “average to medium”, “EE”: “wide”}, “toe_styles”: [{“name”: “Q T…

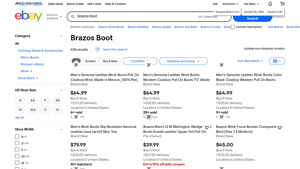

4. Brazos – Men’s and Women’s Boots

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Brand: Brazos, Categories: Men’s Boots, Women’s Boots, Boys’ Shoes, Shoe Sizes: 8, 8.5, 9, 9.5, 10, 10.5, 11, 12, Shoe Widths: B, D, E, EE, M, R, W, Standard, Colors: Beige, Black, Brown, Gray, Green, Multicolor, Red, Upper Materials: Leather, Suede, Rubber, Mesh, Nubuck, Faux Leather, Synthetic, Bullhide Leather, Styles: Western, Combat, Slip-On, Chukka, Chelsea, Biker, Bootie, Snow Boot, Toe Sha…

5. Brazos® Boots – Durable Work Footwear

Domain: brazos-boots.com

Registered: 2024 (1 years)

Introduction: Brazos® Boots offers over 200 boot models designed for durability, comfort, and safety across various industries including construction, manufacturing, agriculture, oil & gas, mining, and transportation. Key features include premium leathers, safety toes, waterproofing, slip-resistant soles, anti-fatigue footbeds, and cushioned insoles. The boots are handcrafted in Fort Worth, Texas, using time-ho…

6. Brazos – Square Toe Boots

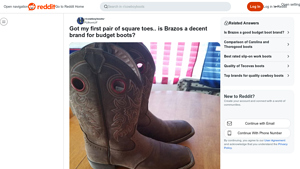

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: First pair of square toe boots; brand: Brazos; budget-friendly; user feedback indicates decent quality; fits better than Justin’s and Ariat’s; approximately $20 cheaper than competitors.

7. Brazos – New & Preloved Items

Domain: poshmark.com

Registered: 2011 (14 years)

Introduction: This company, Brazos – New & Preloved Items, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Klarna – Brazos Amarillo 2.0

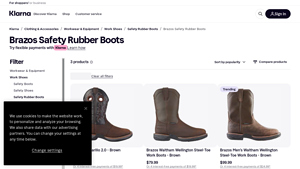

Domain: klarna.com

Registered: 2008 (17 years)

Introduction: {“products”:[{“name”:”Brazos Amarillo 2.0″,”type”:”Safety Rubber Boots”,”color”:”Brown”,”price”:”$79.99″,”payment_option”:”Or 4 payments of $19.99*”,”store_count”:”1 store”},{“name”:”Brazos Waltham Wellington Steel-Toe Work Boots”,”type”:”Steel-Toe Work Boots”,”color”:”Brown”,”price”:”$79.99″,”payment_option”:”Or 4 payments of $19.99*”,”store_count”:”1 store”},{“name”:”Brazos Men’s Waltham Welling…

9. Brazos Boot Shop – Custom Boots

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Brazos Boot Shop – Custom Boots, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for brazos boots

Brazos Boots exemplifies the importance of strategic sourcing for international B2B buyers seeking durable and reliable footwear solutions. With over 200 boot models tailored for diverse industries, including construction and agriculture, Brazos Boots combines quality craftsmanship with innovative design. The commitment to using premium materials ensures that these boots not only meet but exceed safety standards, providing essential protection and comfort for workers in demanding environments.

As buyers from regions such as Africa, South America, the Middle East, and Europe look to enhance their procurement strategies, the value of establishing partnerships with reputable brands like Brazos cannot be overstated. The brand’s dedication to customer service and satisfaction guarantees a supportive buying experience, making it easier for businesses to equip their workforce effectively.

Illustrative image related to brazos boots

Looking ahead, the global demand for high-quality work boots is expected to grow, driven by advancements in safety technology and a focus on worker well-being. International buyers are encouraged to explore the robust offerings from Brazos Boots and consider integrating these products into their supply chains. By doing so, they will not only enhance their operational capabilities but also contribute to the safety and productivity of their teams.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.