Is Your Bolt Center Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for bolt center

In today’s fast-paced global market, sourcing high-quality fasteners, such as those found at a bolt center, can be a daunting task for B2B buyers. The challenge lies not only in identifying reliable suppliers but also in understanding the diverse range of products available, from standard bolts to specialized fasteners designed for unique applications. This comprehensive guide is designed to navigate the intricacies of the bolt center market, equipping international buyers from Africa, South America, the Middle East, and Europe—including key regions like Saudi Arabia and Germany—with the knowledge needed to make informed purchasing decisions.

Within this guide, we will explore various types of bolts and fasteners, their applications across different industries, and effective strategies for vetting suppliers. Additionally, we will delve into cost considerations, helping you to balance quality with budget constraints. By providing insights into the selection process, we aim to empower you to confidently engage with suppliers, ensuring that your fastening needs are met with precision and reliability. With the right tools and information at your disposal, you can streamline your sourcing efforts and foster successful partnerships in the global market.

Understanding bolt center Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Center Bolt | Centralized fastening, various lengths and diameters | Automotive, construction, manufacturing | Pros: Versatile, easy to install. Cons: Limited load capacity compared to larger bolts. |

| U-Bolt | U-shaped design, used for securing pipes and cables | Plumbing, automotive, structural support | Pros: Strong, stable. Cons: Requires precise installation to avoid misalignment. |

| Eye Bolt | Looped head for attaching cables or ropes | Marine, construction, rigging | Pros: Easy to attach, good for load distribution. Cons: Limited to specific applications. |

| Flange Bolt | Integrated flange for load distribution | Machinery, structural applications | Pros: Reduces the need for washers, secure fit. Cons: Higher cost compared to standard bolts. |

| Carriage Bolt | Rounded head and square neck to prevent spinning | Furniture assembly, construction | Pros: Easy to install, aesthetically pleasing. Cons: Limited thread length can restrict use. |

What are the Characteristics of Center Bolts and Their Suitability for B2B Buyers?

Center bolts are characterized by their centralized fastening mechanism, available in various lengths and diameters. They are widely used in automotive and construction applications, where reliable fastening is critical. B2B buyers should consider the load capacity and installation requirements when selecting center bolts, as their versatility can be advantageous in many projects, though they may not support as much weight as larger bolt types.

How Do U-Bolts Function and Where Are They Commonly Used?

U-bolts are designed in a U-shape, making them ideal for securing pipes and cables in plumbing and automotive applications. Their strength and stability are significant advantages, allowing them to handle substantial loads. However, precise installation is necessary to ensure proper alignment and functionality, which can be a consideration for B2B buyers focused on efficiency and safety in their projects.

What Are Eye Bolts and Their Key Applications in Industry?

Eye bolts feature a looped head, making them suitable for attaching cables or ropes, particularly in marine, construction, and rigging applications. Their design allows for easy attachment and effective load distribution, making them a preferred choice for various lifting operations. Buyers should assess the specific load requirements and environmental conditions when selecting eye bolts to ensure optimal performance.

What Makes Flange Bolts a Smart Choice for Machinery and Structural Applications?

Flange bolts come with an integrated flange, which helps distribute the load evenly, reducing the need for washers in many applications. They are often used in machinery and structural applications where stability is paramount. While they provide a secure fit, B2B buyers should weigh the higher cost against the benefits of enhanced stability and ease of installation.

Why Choose Carriage Bolts for Furniture Assembly and Construction?

Carriage bolts are identified by their rounded heads and square necks, which prevent spinning during installation. This makes them particularly suitable for furniture assembly and construction projects where aesthetics and ease of installation are important. However, buyers should note that the limited thread length may restrict their use in certain applications, requiring careful consideration of project needs.

Key Industrial Applications of bolt center

| Industry/Sector | Specific Application of bolt center | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural assembly and framing | Ensures stability and safety in construction projects | Quality certifications, compliance with local regulations, bulk pricing |

| Automotive | Vehicle assembly and repair | Enhances performance and safety of vehicles | Availability of specialized fasteners, compatibility with vehicle models |

| Manufacturing | Machinery assembly and maintenance | Reduces downtime and improves operational efficiency | Customization options, material specifications, lead times |

| Energy and Utilities | Equipment installation and maintenance | Increases reliability and reduces operational failures | Sourcing for high-strength fasteners, resistance to environmental factors |

| Aerospace and Defense | Aircraft assembly and repair | Ensures safety and compliance with stringent industry standards | Aerospace-grade materials, international shipping options, traceability |

How is Bolt Center Utilized in the Construction Sector?

In the construction industry, bolt centers are crucial for the assembly and framing of structures. They provide a reliable source for high-quality fasteners that ensure the stability and safety of buildings. International buyers, especially from regions like Africa and the Middle East, need to consider local compliance regulations and quality certifications when sourcing these products. Additionally, bulk pricing options can significantly benefit large-scale projects, making it essential to establish a strong supplier relationship for ongoing needs.

What Role Does Bolt Center Play in the Automotive Industry?

In the automotive sector, bolt centers supply fasteners for vehicle assembly and repair processes. High-performance fasteners are vital for ensuring vehicle safety and functionality. Buyers from Europe and South America should prioritize suppliers that offer specialized fasteners compatible with various vehicle models. The ability to source hard-to-find components can save time and enhance repair efficiency, making bolt centers an invaluable resource for automotive businesses.

How Does Bolt Center Support Manufacturing Operations?

Manufacturers rely on bolt centers for machinery assembly and maintenance, where the right fasteners can significantly reduce downtime and improve operational efficiency. Sourcing considerations include the availability of customized fasteners tailored to specific machinery requirements and material specifications that meet industry standards. For international buyers, understanding lead times and ensuring reliable supply chains are critical to maintaining production schedules.

What are the Applications of Bolt Center in Energy and Utilities?

In the energy and utilities sector, bolt centers provide fasteners for the installation and maintenance of various equipment. High-strength fasteners are essential for ensuring the reliability of installations, especially in challenging environments. Buyers must consider sourcing fasteners that are resistant to environmental factors, such as corrosion. Establishing a partnership with a bolt center can facilitate timely procurement of materials, which is vital for minimizing operational failures.

How is Bolt Center Essential for Aerospace and Defense Industries?

The aerospace and defense industries require precision-engineered fasteners to ensure the safety and performance of aircraft and military equipment. Bolt centers can supply aerospace-grade materials that comply with stringent industry standards. For international buyers, considerations such as traceability and compliance with global shipping regulations are paramount. A reliable bolt center can provide the necessary documentation and support to meet these rigorous requirements, helping businesses navigate the complexities of the aerospace supply chain.

3 Common User Pain Points for ‘bolt center’ & Their Solutions

Scenario 1: Difficulty Sourcing Specialized Fasteners

The Problem: For many B2B buyers, finding the right fasteners can be a daunting task, especially when dealing with specialized or hard-to-find items. A company in the automotive or manufacturing sector may require specific bolt types that are not available through standard suppliers. This not only leads to delays in production but can also escalate costs as buyers are forced to settle for subpar alternatives or pay premium prices to expedite shipping from distant suppliers.

The Solution: To effectively navigate this challenge, B2B buyers should establish a relationship with a reliable bolt center like Bolt Center. First, identify the exact specifications needed, including dimensions, materials, and any relevant industry standards. Once this information is clear, reach out to the bolt center’s knowledgeable staff, who can assist in sourcing the specific fasteners required. Leveraging their extensive inventory and expertise can save significant time and ensure that the correct items are procured. Additionally, consider joining loyalty programs or establishing a bulk purchasing agreement for frequently needed items to streamline future orders.

Scenario 2: Inefficient Inventory Management

The Problem: Many businesses struggle with managing their inventory of bolts and fasteners, leading to either stockouts or overstocking issues. This can be particularly problematic for companies with diverse projects requiring various fastener types. Having too many unnecessary items ties up capital and storage space, while running out of critical components can halt production lines and delay project timelines.

The Solution: Implementing a robust inventory management system can alleviate this issue significantly. Begin by conducting a thorough audit of existing fasteners and assess usage patterns over time. Once you have a clear understanding of your needs, engage with Bolt Center to set up a tailored inventory solution. This may include establishing minimum order quantities for critical items or utilizing a just-in-time inventory approach, which allows you to receive fasteners as needed without overcommitting to stock. Additionally, regular communication with the bolt center can help anticipate supply needs based on upcoming projects, ensuring that you always have the right fasteners on hand without excess.

Scenario 3: Lack of Technical Support for Fastener Applications

The Problem: B2B buyers often encounter challenges when selecting the right fasteners for specific applications, particularly when dealing with complex machinery or unique construction projects. Without adequate technical support, businesses may struggle to ensure that they are using the correct fasteners, leading to potential safety hazards, performance issues, or costly rework.

The Solution: To mitigate this risk, it is crucial to leverage the technical expertise available at bolt centers. When approaching a bolt center like Bolt Center, provide detailed information about the project or machinery in question. The staff can offer invaluable insights into which fasteners will best suit the application, taking into consideration factors such as load requirements, environmental conditions, and compatibility with existing components. Additionally, consider requesting samples or conducting small-scale tests with recommended fasteners to evaluate their performance before making larger purchases. This proactive approach not only enhances the safety and reliability of your projects but also fosters a collaborative relationship with the bolt center that can lead to ongoing support and guidance.

By addressing these common pain points with actionable solutions, B2B buyers can enhance their operational efficiency, minimize costs, and ensure that their fastening needs are met with precision and reliability.

Strategic Material Selection Guide for bolt center

What Are the Key Materials Used in Bolt Center Applications?

When selecting materials for bolts and fasteners, several factors come into play, including mechanical properties, environmental conditions, and application-specific requirements. Here, we analyze four common materials used in bolt center applications: steel, stainless steel, aluminum, and brass.

How Does Steel Perform as a Bolt Material?

Steel is one of the most widely used materials in bolt manufacturing due to its excellent strength and durability. It has high tensile strength and can withstand significant loads, making it suitable for heavy-duty applications. Steel bolts typically have a temperature rating of up to 300°C and can be treated for enhanced hardness.

Pros: Steel is relatively low-cost and can be produced in various grades, such as Grade 5 and Grade 8, which offer different performance characteristics. Its widespread availability makes sourcing straightforward.

Cons: Steel is susceptible to corrosion unless coated or treated, which can increase manufacturing complexity. It may not be suitable for applications exposed to harsh environments without protective coatings.

Impact on Application: Steel bolts are ideal for structural applications and machinery where strength is paramount. However, they may not be suitable for environments with high humidity or corrosive media, which could lead to premature failure.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM or ISO, while those in Europe may prefer DIN specifications. Understanding the corrosion resistance required for specific applications is crucial.

What Advantages Does Stainless Steel Offer for Bolts?

Stainless steel is renowned for its excellent corrosion resistance, making it a preferred choice for applications in marine environments and chemical processing. With a temperature rating that can exceed 800°C, stainless steel bolts maintain their integrity under extreme conditions.

Pros: The primary advantage of stainless steel is its resistance to rust and corrosion, which extends the lifespan of fasteners in challenging environments. It also has good aesthetic appeal, making it suitable for visible applications.

Cons: Stainless steel tends to be more expensive than carbon steel and can be more challenging to machine. Its lower tensile strength compared to high-grade steel may limit its use in heavy-load applications.

Impact on Application: Stainless steel bolts are perfect for applications exposed to moisture, chemicals, and extreme temperatures. However, they may not be the best choice for high-stress environments without careful consideration of the specific grade used.

Considerations for International Buyers: Buyers should verify compliance with international standards such as ASTM A193 or A320, especially in the Middle East, where high corrosion resistance is often required.

How Does Aluminum Compare as a Bolt Material?

Aluminum bolts are lightweight and resistant to corrosion, making them suitable for applications where weight savings are critical, such as in the aerospace and automotive industries. They typically have a temperature rating of around 150°C.

Pros: The lightweight nature of aluminum allows for easier handling and installation, and its corrosion resistance makes it ideal for outdoor applications.

Illustrative image related to bolt center

Cons: Aluminum has lower tensile strength compared to steel, which may limit its use in high-load applications. It can also be more expensive than standard steel options.

Impact on Application: Aluminum bolts are ideal for lightweight structures and applications where corrosion resistance is essential. However, they may not be suitable for heavy-duty applications without reinforcement.

Considerations for International Buyers: When sourcing aluminum bolts, compliance with standards such as ASTM B211 is important, especially for buyers in Europe who may have specific material requirements.

What Role Does Brass Play in Bolt Center Applications?

Brass bolts are known for their excellent corrosion resistance and good mechanical properties. They are often used in applications requiring electrical conductivity and aesthetic appeal.

Pros: Brass is resistant to corrosion and has good machinability, making it easy to work with. Its attractive finish is beneficial for visible applications.

Cons: Brass is generally more expensive than steel and has lower tensile strength, which may limit its use in high-stress environments.

Impact on Application: Brass bolts are suitable for electrical applications and decorative purposes but may not be ideal for structural applications requiring high strength.

Considerations for International Buyers: Buyers should ensure that brass fasteners meet relevant standards, such as ASTM B16, particularly in regions where electrical conductivity is a critical factor.

Summary Table of Material Selection for Bolt Center

| Material | Typical Use Case for bolt center | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty machinery and structural applications | High strength and low cost | Susceptible to corrosion | Low |

| Stainless Steel | Marine and chemical processing applications | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Aluminum | Aerospace and automotive applications | Lightweight and corrosion-resistant | Lower tensile strength | Medium |

| Brass | Electrical and decorative applications | Good corrosion resistance | Higher cost and lower strength | Medium |

This guide provides a comprehensive overview of material selection for bolt center applications, enabling international B2B buyers to make informed decisions based on their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for bolt center

What Are the Key Stages in the Manufacturing Process for Bolts?

The manufacturing of bolts involves a series of well-defined stages that ensure the production of high-quality fasteners suitable for various applications. Understanding these stages is crucial for B2B buyers looking to source reliable products.

Material Preparation: How Are Raw Materials Selected and Processed?

The manufacturing process begins with material selection, typically high-strength steel or alloy materials. These raw materials are subjected to various treatments, such as heat treatment and surface hardening, to enhance their mechanical properties.

Once the appropriate materials are selected, they are cut to size. This stage often involves precision cutting techniques, such as shearing or sawing, to ensure uniformity and reduce waste. The prepared materials are then cleaned to remove any contaminants that could affect the final product’s quality.

Forming: What Techniques Are Used to Shape Bolts?

The next stage is forming, where the raw materials are shaped into bolts through several techniques. Common methods include:

-

Cold Forging: This is a prevalent method for high-volume production, where materials are deformed at room temperature. Cold forging enhances the strength of the bolts and allows for tight tolerances.

-

Hot Forging: In this technique, the materials are heated before forming, which makes them easier to shape. Hot forging is often used for larger bolts or when complex shapes are needed.

-

Thread Rolling: This process involves creating threads on the bolt by rolling it between two dies. It is essential for ensuring the threads are uniform and meet specified tolerances.

Each of these forming techniques impacts the mechanical properties of the final product, making it vital for B2B buyers to understand the processes used by their suppliers.

Assembly: How Are Bolts Finished and Prepared for Market?

After forming, bolts may undergo an assembly process, particularly if they are part of a larger fastening system. This could involve attaching nuts, washers, or other components that enhance the functionality of the bolt.

The assembly stage also includes quality checks to ensure that all components fit correctly and meet design specifications. This is crucial for maintaining the integrity of the fastening system, especially in applications where safety is paramount.

Finishing: What Finishing Techniques Ensure Durability?

Finishing processes are critical for enhancing the performance and longevity of bolts. Common finishing techniques include:

-

Plating: Applying a protective coating, such as zinc or nickel plating, helps prevent corrosion and wear.

-

Coating: Specialized coatings, like epoxy or PTFE, can be applied for additional protection in harsh environments.

-

Heat Treatment: This process alters the microstructure of the material to improve strength and durability, making it essential for high-stress applications.

B2B buyers should inquire about the finishing processes used by suppliers to ensure that the products will perform as expected in their specific applications.

How is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the final products meet international standards and customer expectations. For B2B buyers, understanding the QA measures in place can help in selecting reliable suppliers.

What International Standards Should B2B Buyers Look For?

Manufacturers often comply with international quality standards, such as ISO 9001, which outlines requirements for a quality management system. Adherence to these standards indicates that a manufacturer has established processes to ensure product quality and customer satisfaction.

Other industry-specific certifications may also be relevant, including:

-

CE Marking: Required for products sold in the European Economic Area, indicating compliance with safety and environmental protection standards.

-

API Certification: Important for manufacturers producing bolts for the oil and gas industry, ensuring compliance with stringent safety and performance standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are critical throughout the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before production begins. Suppliers should have robust procedures to verify that incoming materials meet specified standards.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, this involves regular inspections and measurements to ensure that components are being produced within specified tolerances.

-

Final Quality Control (FQC): The final checkpoint occurs before products are shipped. This includes comprehensive testing to verify that the finished bolts meet all specifications and performance standards.

What Testing Methods Are Commonly Used in Quality Control?

Several testing methods are employed to ensure the integrity and performance of bolts:

-

Tensile Testing: Measures the strength of the bolt by applying a pulling force until it breaks.

-

Hardness Testing: Assesses the material’s resistance to deformation, which is crucial for determining its suitability for specific applications.

-

Corrosion Testing: Evaluates the durability of the protective coatings applied to the bolts, ensuring they can withstand harsh environments.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential. Here are some strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the supplier’s manufacturing processes, quality control systems, and compliance with international standards.

-

Quality Control Reports: Requesting detailed QC reports can provide insights into the supplier’s testing methods, results, and any corrective actions taken to address issues.

-

Third-Party Inspections: Engaging independent inspection agencies can offer unbiased assessments of product quality and compliance with specifications before shipment.

What Are the Nuances of Quality Control for International Trade?

International B2B transactions come with unique challenges. Buyers must be aware of potential discrepancies in quality standards and practices across different countries. Understanding local regulations, customs requirements, and certifications can help mitigate risks.

Additionally, communication plays a vital role in ensuring that suppliers understand the specific quality requirements of international buyers. Establishing clear expectations and maintaining open lines of communication can enhance cooperation and ensure that products meet the necessary standards.

Conclusion

For B2B buyers in search of reliable bolt suppliers, understanding the manufacturing processes and quality assurance measures is vital. By focusing on the key stages of manufacturing, relevant international standards, and effective verification methods, buyers can make informed decisions that align with their quality expectations and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bolt center’

In today’s global marketplace, sourcing quality fasteners and bolts is essential for businesses across various sectors. This guide serves as a practical checklist for B2B buyers aiming to procure products from a bolt center effectively. By following these steps, you can streamline your purchasing process and ensure that you obtain the right products to meet your operational needs.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is the first step in sourcing from a bolt center. Consider the type of fasteners you need, including size, grade, material, and application. This clarity will help you communicate effectively with suppliers and ensure that the products you receive meet your expectations.

- Key Considerations:

- Identify the exact measurements and tolerances required for your projects.

- Specify any industry standards that need to be adhered to, such as ASTM or ISO certifications.

Step 2: Research Potential Suppliers

Not all bolt centers are created equal. Conduct thorough research to identify suppliers that specialize in the types of fasteners you need. Look for companies with a strong reputation in the industry and positive customer reviews.

- Methods of Research:

- Utilize online platforms and directories to find suppliers in your region.

- Check trade publications and industry forums for recommendations and insights.

Step 3: Evaluate Supplier Capabilities

Before making a commitment, assess the capabilities of potential suppliers. This includes their inventory range, production capabilities, and lead times. A supplier’s ability to meet your demands in a timely manner can significantly impact your operations.

- What to Look For:

- A diverse inventory that includes standard and hard-to-find fasteners.

- Flexible lead times that align with your project schedules.

Step 4: Verify Quality Assurance Processes

Quality is paramount when it comes to fasteners. Ensure that your chosen bolt center has robust quality control measures in place. This will help mitigate risks associated with defective products that could lead to costly project delays.

- Quality Assurance Checks:

- Inquire about certifications (e.g., ISO 9001) that demonstrate a commitment to quality.

- Request samples to evaluate the quality of products before placing a bulk order.

Step 5: Assess Customer Service and Support

A responsive and knowledgeable customer service team can greatly enhance your sourcing experience. Evaluate how potential suppliers handle inquiries and whether they offer technical support for product selection.

- Indicators of Good Service:

- Availability of knowledgeable staff who can assist with technical questions.

- Clear communication channels for order tracking and after-sales support.

Step 6: Review Payment and Shipping Terms

Understanding the payment and shipping terms is crucial for budgeting and planning. Confirm the payment methods accepted by the supplier and any associated fees. Additionally, clarify shipping options and lead times to avoid unexpected delays.

- Important Details:

- Look for suppliers that offer flexible payment options tailored to your business needs.

- Ensure shipping methods align with your delivery schedules to maintain project timelines.

Step 7: Establish a Long-term Relationship

Once you’ve selected a supplier, focus on building a long-term partnership. A reliable bolt center can become an invaluable resource for ongoing projects and future needs, providing you with access to specialized products and industry insights.

- Building Relationships:

- Maintain regular communication and provide feedback on products and services.

- Explore opportunities for bulk purchasing or exclusive arrangements for recurring orders.

By following this checklist, B2B buyers can navigate the complexities of sourcing from bolt centers, ensuring that they obtain high-quality products that meet their operational needs while fostering fruitful supplier relationships.

Comprehensive Cost and Pricing Analysis for bolt center Sourcing

When considering sourcing from a bolt center, understanding the comprehensive cost structure and pricing dynamics is essential for making informed purchasing decisions. A well-rounded analysis encompasses various cost components and price influencers that can significantly affect your bottom line.

What Are the Key Cost Components in Bolt Center Sourcing?

-

Materials: The primary cost driver in bolt sourcing is the raw materials used in manufacturing. Common materials include steel, stainless steel, and specialty alloys, each with varying prices influenced by market demand and availability. For international buyers, fluctuations in material costs can vary regionally, affecting overall pricing.

-

Labor: Labor costs encompass wages for manufacturing workers, engineers, and quality control personnel. These costs can differ based on geographic location, with regions that have higher labor standards typically incurring more substantial expenses. Understanding local labor markets is vital for evaluating supplier pricing.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses associated with the production facility. Manufacturers with advanced technologies may have higher initial overhead but can achieve cost efficiencies over time.

-

Tooling: Custom tooling for specialized fasteners can add to the initial investment. While this cost is often amortized over large production runs, it’s crucial for buyers to consider how tooling costs impact pricing, especially for low-volume orders.

-

Quality Control (QC): Ensuring product quality is non-negotiable, and costs associated with QC processes can vary significantly. Higher investment in quality assurance often correlates with better product reliability and fewer defects, which is particularly important for international buyers concerned about compliance and safety standards.

-

Logistics: Transportation costs can fluctuate based on shipping methods, distances, and any tariffs or duties applicable for international shipments. Understanding these logistics costs is vital for calculating the Total Cost of Ownership (TCO).

-

Margin: Finally, suppliers will include their profit margins in the pricing structure. This margin can vary widely based on competition, market demand, and the supplier’s position within the supply chain.

How Do Price Influencers Affect Bolt Center Sourcing?

Several factors can influence the pricing of fasteners sourced from a bolt center:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often results in lower per-unit prices. Suppliers may have MOQs that can affect smaller buyers, making it essential to negotiate terms that suit your purchasing capacity.

-

Specifications and Customization: Highly specialized or custom products may incur additional costs. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Materials and Certifications: The quality of materials and any required certifications can significantly impact pricing. International buyers should verify that suppliers can meet relevant industry standards to avoid compliance issues.

-

Supplier Factors: The reputation and reliability of the supplier can also influence pricing. Established suppliers may charge a premium for their reliability and service, while newer entrants may offer lower prices to capture market share.

-

Incoterms: Understanding shipping terms is critical in international sourcing. Incoterms dictate who bears the cost and risk at different points in the shipping process, which can affect overall pricing.

What Tips Can Help Buyers Achieve Cost-Efficiency?

-

Negotiate Effectively: Always engage in negotiations. Suppliers may offer discounts for larger orders or flexible payment terms that can ease cash flow.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also potential costs related to shipping, duties, and the long-term reliability of the products. A lower upfront cost may lead to higher maintenance costs.

-

Research Pricing Nuances: International buyers should be aware of regional pricing dynamics. For example, sourcing from Europe may incur higher shipping costs, while suppliers in South America may offer competitive pricing due to lower labor costs.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing, priority on orders, and access to exclusive products or deals.

-

Stay Informed on Market Trends: Regularly monitor market trends for material prices and supplier innovations. This knowledge can provide leverage during negotiations and help forecast future pricing.

Disclaimer on Indicative Prices

Prices for bolts and fasteners can vary widely based on specifications, market conditions, and supplier pricing strategies. It is advisable for buyers to request detailed quotes tailored to their specific needs to ensure accurate budgeting.

Alternatives Analysis: Comparing bolt center With Other Solutions

Introduction: Understanding Alternatives in Fastening Solutions

When considering fastening solutions, it is crucial for B2B buyers to evaluate various options available in the market. Bolt Center, known for its extensive inventory and specialized customer service, is a prominent player in the fastener industry. However, there are several alternatives that may also cater to specific needs. This analysis will compare Bolt Center with two viable alternatives: traditional hardware stores and online fastener suppliers. Each option has unique advantages and challenges that can influence purchasing decisions.

Comparison Table

| Comparison Aspect | Bolt Center | Traditional Hardware Stores | Online Fastener Suppliers |

|---|---|---|---|

| Performance | High quality, specialized fasteners | Varies; often lacks specialized items | Wide selection; quality can vary |

| Cost | Competitive pricing | Generally higher due to overhead | Often lower due to direct sales |

| Ease of Implementation | Easy to find products in-store | Requires physical visit; limited stock | Convenient ordering from anywhere |

| Maintenance | Minimal; focused on product knowledge | Staff training needed for expertise | Customer service can be variable |

| Best Use Case | Specialized projects, hard-to-find items | General repairs, household projects | Bulk orders, standard fasteners |

Detailed Breakdown of Alternatives

Traditional Hardware Stores

Traditional hardware stores provide a broad range of fasteners and tools, catering primarily to local consumers. They often have knowledgeable staff who can assist with common fastening needs. However, these stores typically do not stock specialized or hard-to-find items, limiting their utility for more complex projects. The pricing may also be higher due to the operational costs associated with maintaining a physical storefront. For everyday repairs and basic projects, traditional hardware stores may suffice, but for specialized requirements, they might fall short.

Online Fastener Suppliers

Online fastener suppliers offer a vast inventory of fasteners that can be shipped directly to the buyer’s location, making them a convenient option for bulk orders. They often provide competitive pricing due to lower overhead costs. However, the quality of products can vary significantly between suppliers, and buyers may have to rely on reviews and ratings to ensure they are getting quality items. Additionally, while online suppliers can save time and effort, they lack the immediate customer service and personalized assistance available at physical locations like Bolt Center.

Conclusion: Making the Right Choice for Fastening Needs

When selecting a fastening solution, B2B buyers should assess their specific needs against the strengths and weaknesses of each option. Bolt Center excels in providing specialized fasteners and expert assistance, making it an ideal choice for unique projects. Conversely, traditional hardware stores may be more suitable for general repairs, while online fastener suppliers are advantageous for bulk purchasing and cost savings. By carefully considering these factors, buyers can make informed decisions that align with their operational requirements and budget constraints.

Essential Technical Properties and Trade Terminology for bolt center

What are the Essential Technical Properties of Bolts?

Understanding the technical properties of bolts is crucial for B2B buyers, as these factors directly influence product performance, reliability, and compatibility with various applications. Here are some key specifications to consider:

1. Material Grade

Bolts are manufactured from different materials, each with unique properties. Common grades include:

– Grade 2: Low carbon steel, suitable for light-duty applications.

– Grade 5: Medium carbon steel, offering higher tensile strength, commonly used in automotive and machinery applications.

– Grade 8: High carbon alloy steel, ideal for heavy-duty applications due to its superior strength and durability.

Knowing the material grade helps buyers select bolts that meet the specific requirements of their projects, ensuring safety and effectiveness.

2. Diameter and Length

The diameter and length of a bolt are critical for determining its load-bearing capacity and suitability for specific applications. These dimensions are often denoted in inches or millimeters. Selecting the correct size is essential to avoid structural failure or issues with assembly, which can lead to costly downtime.

3. Thread Pitch

The thread pitch refers to the distance between threads and is crucial for ensuring proper engagement with nuts and other fasteners. Common thread pitches include coarse and fine threads. Understanding thread pitch is vital for compatibility with existing components, which can prevent assembly errors and enhance overall performance.

4. Tolerance

Tolerance defines the allowable variation in dimensions and is critical for ensuring the proper fit of bolts in their intended applications. Tight tolerances are necessary for precision machinery, while looser tolerances may be acceptable in less critical applications. This specification is important for B2B buyers who prioritize quality control and product reliability.

5. Finish and Coating

The finish or coating applied to bolts can significantly affect their corrosion resistance and appearance. Common finishes include zinc plating, black oxide, and hot-dip galvanizing. Selecting the right finish is essential for applications exposed to harsh environments, as it prolongs the lifespan of the fasteners.

What are Common Trade Terms in the Bolt Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some commonly used terms in the bolt sector:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or components that are then used in another company’s end product. In the bolt industry, this could involve manufacturers supplying bolts for automotive or machinery production. Understanding OEM relationships helps buyers identify quality sources for their fastener needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand, as it can impact inventory management and cash flow. Knowing the MOQ can help buyers negotiate better terms and make informed purchasing decisions.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and availability from suppliers for specific products. This is a critical step in the procurement process, allowing businesses to compare options and ensure they receive competitive pricing and terms.

4. Incoterms

Incoterms (International Commercial Terms) are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. These terms clarify who is responsible for shipping, insurance, and tariffs, which is vital for B2B buyers engaged in cross-border purchasing.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for effective project planning and inventory management, as it helps businesses ensure they have the necessary materials when needed.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and reduce risks in their fastening applications.

Navigating Market Dynamics and Sourcing Trends in the bolt center Sector

What are the Key Market Dynamics and Trends in the Bolt Center Sector?

The bolt center sector is undergoing significant transformation driven by globalization, technological advancements, and evolving customer needs. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking reliable suppliers that can offer a diverse range of fastening solutions. The demand for high-quality, specialized fasteners is rising due to the growth of industries such as automotive, construction, and manufacturing.

One notable trend is the integration of e-commerce platforms, which allows buyers to source products more conveniently and efficiently. These platforms enable buyers to compare prices, check inventory levels in real-time, and access detailed product specifications, facilitating informed purchasing decisions. Additionally, advancements in logistics and supply chain management are improving delivery times and reducing costs, making it easier for international buyers to engage with bolt centers worldwide.

Another emerging trend is the increasing reliance on data analytics to understand market demands better and optimize inventory management. Companies that leverage data can anticipate customer needs and adjust their offerings accordingly, enhancing competitiveness. Furthermore, the rise of customization is becoming significant, as buyers seek unique fasteners tailored to specific applications, pushing suppliers to innovate their product lines continually.

How is Sustainability and Ethical Sourcing Addressed in the Bolt Center Sector?

Sustainability is becoming a crucial focus for the bolt center sector, as businesses are increasingly aware of their environmental impact. B2B buyers are now prioritizing suppliers who practice ethical sourcing and offer eco-friendly products. This shift is largely driven by consumer demand for transparency and the growing regulations surrounding environmental standards.

The importance of ethical supply chains cannot be overstated; companies that adopt sustainable practices not only reduce their carbon footprint but also enhance their brand reputation. Buyers are actively looking for bolt centers that provide certifications for sustainable practices, such as ISO 14001 or those that comply with the EU’s REACH regulations. Additionally, the use of recycled materials in the manufacturing of fasteners is gaining traction, offering an eco-friendly alternative that appeals to environmentally conscious consumers.

Furthermore, bolt centers are exploring innovations in materials science, such as the development of biodegradable fasteners and coatings that minimize environmental impact. By aligning their sourcing strategies with sustainability goals, suppliers can attract a broader customer base while contributing to a more sustainable future.

What is the Evolution and Historical Context of the Bolt Center Sector?

The bolt center sector has evolved significantly over the past few decades, transitioning from traditional brick-and-mortar establishments to more sophisticated, tech-driven operations. Historically, sourcing bolts and fasteners was a manual and time-consuming process, often limited to local suppliers. However, the advent of the internet and e-commerce has revolutionized how businesses approach procurement.

As industries have advanced, so too has the complexity of fastening solutions required. The development of specialized fasteners for unique applications has led to the emergence of bolt centers that cater specifically to these needs. Today, buyers expect not only a wide range of products but also expert knowledge and customer service, which has become a hallmark of successful bolt centers.

In summary, the bolt center sector is characterized by dynamic market trends, a growing emphasis on sustainability, and an ongoing evolution in response to technological advancements. International B2B buyers must stay informed about these developments to make strategic sourcing decisions that align with their operational goals and values.

Frequently Asked Questions (FAQs) for B2B Buyers of bolt center

-

How do I solve sourcing issues for hard-to-find fasteners?

To address sourcing challenges for hard-to-find fasteners, consider partnering with specialized suppliers like Bolt Center. They often maintain extensive inventories and can assist in locating specific items that larger retailers may not carry. Establishing a strong relationship with your supplier can also provide access to custom solutions and alternative products. Additionally, leverage online platforms to research and connect with multiple suppliers, ensuring you compare options based on product availability, quality, and lead times. -

What is the best strategy for negotiating payment terms with suppliers?

When negotiating payment terms, it’s essential to assess your cash flow and the supplier’s policies. Start by researching industry standards and determining what you can realistically offer. Aim for terms that provide flexibility, such as net 30 or net 60 days, which can help manage your finances effectively. Establishing a strong relationship with the supplier can also facilitate better terms. Always ensure that any agreed-upon terms are documented in the contract to avoid misunderstandings. -

What are the minimum order quantities (MOQ) typically required for fasteners?

Minimum order quantities (MOQ) for fasteners can vary significantly among suppliers. Many manufacturers have MOQs ranging from 50 to 500 pieces, depending on the type and size of the fastener. For bulk orders, it’s common to negotiate lower MOQs. If you’re a smaller buyer, consider reaching out to suppliers who offer flexibility or are willing to accommodate smaller orders, particularly if you express interest in future larger purchases. -

How can I ensure quality assurance when sourcing fasteners internationally?

To ensure quality assurance when sourcing fasteners internationally, start by selecting reputable suppliers with proven track records. Request samples to evaluate product quality before placing a bulk order. Additionally, inquire about their quality control processes and certifications, such as ISO 9001. Utilizing third-party inspection services can also provide an extra layer of assurance, ensuring that the products meet your specifications and quality standards before shipment. -

What logistics considerations should I be aware of when importing fasteners?

When importing fasteners, key logistics considerations include shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder familiar with your destination country’s import laws. Understand the tariffs and duties applicable to your products to avoid unexpected costs. Additionally, plan for potential delays in shipping and customs clearance, and consider using incoterms to clarify responsibilities for shipping, insurance, and freight. -

How do I vet suppliers for international fastener procurement?

To effectively vet suppliers for international fastener procurement, begin by researching their reputation through online reviews and testimonials. Check for industry certifications and compliance with international standards. Request references from other clients, and conduct background checks on their financial stability and operational history. Consider visiting the supplier’s facility if feasible, or engaging a third-party auditor to assess their capabilities and reliability. -

What customization options are available for fasteners?

Many suppliers offer customization options for fasteners, including size, material, coating, and threading. When discussing your needs with a supplier, be clear about your specifications and any unique requirements. Customization can enhance performance in specific applications, but be aware that it may involve longer lead times and higher costs. Always confirm that the supplier can meet your customization requests within your project timelines. -

How can I effectively communicate my fastener needs to suppliers?

Effective communication with suppliers about your fastener needs involves being clear and specific. Prepare detailed specifications, including dimensions, materials, and any industry standards that must be met. Use visual aids, such as drawings or photos, to illustrate your requirements. Establish a consistent point of contact for ongoing discussions, and be open to feedback from the supplier, as they may offer insights or alternatives that better meet your needs.

Top 6 Bolt Center Manufacturers & Suppliers List

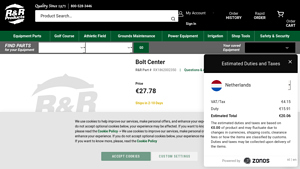

1. RR Products – Quality Replacement Parts

Domain: rrproducts.com

Registered: 1997 (28 years)

Introduction: This company, RR Products – Quality Replacement Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

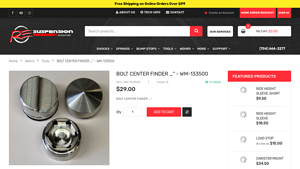

2. Resuspension – BOLT CENTER FINDER

Domain: resuspension.com

Registered: 2003 (22 years)

Introduction: {“product_name”: “BOLT CENTER FINDER”, “sku”: “WM-133500”, “price”: “$29.00”, “description”: “Sold in sets. With a tape measure end to hook the tape on, and a pointed end to read the tape. The flat end swivels so you never have to time the hex head. Just slap them on and measure.”, “compatibility”: “Fits 1/2” bolts”, “availability”: “In stock”}

3. BoltCenter – Construction Tools & Materials

Domain: boltcenter.az

Introduction: BoltCenter offers a wide range of construction tools and materials including bolts, screws, washers, nuts, rivets, shear studs, abrasive disks, cutting discs, grinding discs, flap discs, metal mesh, steel mesh panels, expanded metal mesh, perforated sheets, plaster wire, razor mesh, micro expanded metal mesh, marine group locks, carabiners, switches, tension terminals, rope accessories, chains, hi…

4. Bolt – AI-Powered Website and App Development

Domain: support.bolt.new

Introduction: Bolt is a platform designed for creating websites and apps using AI. Key features include a QuickStart guide for building, editing, and publishing apps quickly, support for various integrations (GitHub, Netlify, Figma, Supabase, Stripe), and best practices for maximizing token efficiency and effective prompting. Users can manage accounts, billing, and subscriptions, including team plans for corpor…

5. L& – 1/2 inch Fine Thread Bolt

Domain: truckspring.com

Registered: 1999 (26 years)

Introduction: {“SKU”:”CB120800″,”Diameter”:”1/2 inch”,”Length”:”8 inches”,”Minimum Thread Length”:”5-1/2 inches”,”Thread Size”:”20″,”Thread Type”:”Fine”,”Head Size”:”3/4 x 7/16 inch”,”Price”:”$6.41″,”Stock Status”:”20+ In Stock”,”Shipping”:”Ships Today if ordered before 1pm EST Monday – Friday”,”Manufacturer”:”L&H Threaded Rods Corporation”,”Warranty”:”Limited Lifetime Warranty on all L&H U-bolts and hardware”}

6. BOLT CENTER – Hardware Store

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: BOLT CENTER, located at 20 W Louise Ave, Salt Lake City, Utah, is a hardware store with a 5.0 rating based on 1 review. The store’s phone number is (801) 486-5007, and their website is boltcenter.com. The business is unclaimed on Yelp.

Strategic Sourcing Conclusion and Outlook for bolt center

In the dynamic landscape of fasteners and hardware, strategic sourcing plays a critical role for international B2B buyers. Understanding the nuances of suppliers like Bolt Center can empower businesses in Africa, South America, the Middle East, and Europe to optimize their procurement processes. With a focus on quality, expertise, and a broad inventory, Bolt Center stands out as a reliable partner for sourcing hard-to-find fasteners and components, enhancing operational efficiency and reducing downtime.

Illustrative image related to bolt center

By leveraging the services offered at Bolt Center, buyers can access personalized support and tailored solutions that cater to unique project requirements. This not only ensures the right products are sourced but also fosters long-term relationships built on trust and reliability. As global markets continue to evolve, the importance of sourcing quality materials from reputable suppliers cannot be overstated.

Looking ahead, international buyers are encouraged to explore the extensive offerings of Bolt Center to elevate their supply chain strategies. Embrace the opportunity to collaborate with a partner that prioritizes customer service and product availability, and position your business for success in a competitive marketplace. Engage with Bolt Center today to unlock the full potential of your sourcing strategy.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.