Is Your Blunt Roller Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for blunt roller

In the rapidly evolving cannabis market, sourcing the right blunt roller can be a daunting challenge for international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. As consumer preferences shift towards high-quality, expertly rolled blunts, understanding the nuances of blunt rolling machines becomes essential for businesses looking to meet sophisticated customer demands. This comprehensive guide delves into the various types of blunt rollers available, their specific applications within the cannabis industry, and crucial factors to consider when vetting suppliers.

By exploring the diverse options and features of blunt rollers—from manual to automated machines—this guide equips buyers with the insights needed to make informed purchasing decisions. We also address cost considerations, helping businesses navigate budget constraints while ensuring they invest in quality equipment that enhances their product offerings. Furthermore, we provide actionable tips on supplier evaluation, ensuring that buyers can identify reliable manufacturers capable of delivering high-performance machines tailored to their needs.

Empowered with this knowledge, B2B buyers can confidently approach the market, ready to capitalize on trends and satisfy the growing appetite for premium cannabis products. This guide serves not only as a resource for effective sourcing but also as a strategic tool for fostering long-term business success in the competitive global cannabis landscape.

Understanding blunt roller Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Blunt Rollers | Hand-operated, often portable, and user-friendly | Small dispensaries, personal use | Pros: Cost-effective, easy to use. Cons: Time-consuming, less consistent results. |

| Electric Blunt Rollers | Automated, high-capacity, and consistent output | Larger operations, commercial cannabis farms | Pros: High efficiency, uniform quality. Cons: Higher initial investment, requires electricity. |

| Specialty Blunt Rollers | Designed for specific materials (e.g., hemp wraps) | Niche markets, premium product lines | Pros: Tailored for unique products, enhances brand appeal. Cons: Limited versatility, may have a higher cost. |

| Multi-Function Rollers | Combines blunt and joint rolling capabilities | Versatile operations, diverse product offerings | Pros: Flexible, can cater to various customer preferences. Cons: May sacrifice quality for versatility. |

| Customizable Blunt Rollers | Adjustable settings for various sizes and shapes | High-end retailers, bespoke cannabis brands | Pros: Personalized output, caters to specific market demands. Cons: More complex operation, higher cost. |

What Are the Characteristics of Manual Blunt Rollers?

Manual blunt rollers are typically compact, hand-operated devices designed for ease of use. They are ideal for small dispensaries or individual consumers who prefer a more traditional approach to rolling. These rollers require minimal investment, making them accessible for smaller operations. However, the process can be time-consuming, and users may find it challenging to achieve consistent results, which could affect customer satisfaction.

How Do Electric Blunt Rollers Enhance Production Efficiency?

Electric blunt rollers are designed for high-capacity production, providing consistent results with minimal effort. These machines are ideal for larger operations such as commercial cannabis farms and larger dispensaries, where efficiency and uniformity are critical. While the initial investment is higher, the ability to produce a large quantity of high-quality blunts quickly can lead to increased profitability. Buyers should consider the electricity requirements and maintenance costs associated with these machines.

What Makes Specialty Blunt Rollers Unique?

Specialty blunt rollers cater to niche markets by focusing on specific materials, such as hemp wraps or organic options. These machines are particularly valuable for businesses aiming to offer premium products that appeal to discerning consumers. While they enhance brand appeal by providing unique options, their limited versatility may restrict their use for businesses that offer a broader range of products. Buyers should assess their target market’s preferences before investing in these specialized machines.

Why Choose Multi-Function Rollers for Versatility?

Multi-function rollers are designed to accommodate both blunts and joints, making them a versatile choice for businesses with diverse product offerings. This flexibility allows operations to cater to a wider customer base, potentially increasing sales. However, buyers should be aware that these machines may compromise the quality of the rolls compared to dedicated blunt rollers. It’s essential to evaluate the specific needs of the business to determine if this trade-off is acceptable.

How Do Customizable Blunt Rollers Meet Market Demands?

Customizable blunt rollers offer adjustable settings for different sizes and shapes, allowing businesses to tailor their products to specific consumer preferences. This feature is particularly beneficial for high-end retailers and bespoke cannabis brands that want to stand out in a competitive market. While these machines provide personalized output, they may require more complex operation and come with a higher price tag. Buyers should weigh the benefits of customization against the potential learning curve and investment required.

Key Industrial Applications of blunt roller

| Industry/Sector | Specific Application of blunt roller | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Cannabis Retail | Manufacturing pre-rolled blunts for retail sale | Increased product consistency and quality, leading to higher customer satisfaction | Reliability of machine, speed of production, ease of use |

| Event Management | Providing blunts at events and festivals | Enhances guest experience and brand image, driving customer loyalty | Portability, ease of operation, maintenance requirements |

| Cannabis Cultivation | Packaging and distributing products to dispensaries | Streamlined operations and reduced labor costs | Durability, capacity, and compatibility with various wraps |

| Hospitality Industry | Offering unique blunt experiences in lounges or bars | Differentiates offerings, attracting a niche market | Compliance with local regulations, quality of materials used |

| Export and Distribution | Preparing products for international markets | Ensures product quality and compliance with international standards | Adaptability to different regulations, sourcing of materials |

How is the Blunt Roller Used in the Cannabis Retail Sector?

In the cannabis retail industry, blunt rollers are essential for producing pre-rolled blunts that meet customer demands for quality and consistency. By automating the rolling process, businesses can ensure uniformity in size and density, which leads to a smoother smoking experience. This is particularly important as consumers become more discerning about their cannabis products. Buyers in this sector should consider the machine’s reliability and production speed to meet high demand and ensure timely delivery to retail outlets.

What Role Does the Blunt Roller Play in Event Management?

Event management companies use blunt rollers to provide high-quality smoking experiences at festivals and private events. The ability to quickly produce blunts enhances the overall guest experience and helps establish a brand image associated with luxury and enjoyment. When sourcing blunt rollers for this application, event organizers should prioritize portability and ease of operation, ensuring that staff can efficiently roll blunts on-site without extensive training.

Why is the Blunt Roller Important for Cannabis Cultivation?

For cannabis cultivators, blunt rollers facilitate the packaging and distribution of their products to dispensaries. By ensuring that blunts are uniformly rolled, cultivators can streamline their operations, reducing labor costs and increasing throughput. Buyers in this sector should focus on the durability and capacity of the machines, as well as their compatibility with various blunt wraps, to optimize their production processes.

How Can the Blunt Roller Enhance Offerings in the Hospitality Industry?

In the hospitality industry, especially in lounges and bars, blunt rollers are used to create unique smoking experiences for guests. Offering expertly rolled blunts can differentiate a venue from competitors, attracting a niche market of cannabis enthusiasts. When sourcing blunt rollers for this application, businesses must consider compliance with local regulations regarding cannabis consumption, as well as the quality of materials used in the rolling process to ensure a premium product.

What Should Export and Distribution Companies Consider When Using Blunt Rollers?

Export and distribution companies involved in the cannabis trade need to ensure that their products meet international standards. Blunt rollers can help maintain product quality during the preparation of goods for export. Key considerations for buyers include the machine’s adaptability to different regulations across markets and the sourcing of materials that comply with international guidelines. This ensures that products not only meet quality expectations but also adhere to legal requirements in various countries.

3 Common User Pain Points for ‘blunt roller’ & Their Solutions

Scenario 1: Difficulty Achieving Consistent Quality in Production

The Problem: B2B buyers in the cannabis industry often struggle with achieving consistent quality in the blunts produced by blunt rollers. Inconsistent rolling can lead to poor customer satisfaction, as unevenly rolled blunts may burn unevenly or fall apart, resulting in a disappointing smoking experience. This inconsistency can be particularly problematic for businesses aiming to establish a premium brand reputation in competitive markets.

The Solution: To overcome this challenge, buyers should invest in high-quality blunt rolling machines that offer adjustable settings for different types of wraps and user preferences. Look for machines equipped with features that allow for precise control over the amount of cannabis used and the tightness of the roll. Additionally, conducting regular training sessions for staff on how to use these machines effectively can enhance consistency. Consider implementing a quality control process where rolled products are regularly tested for uniformity before distribution. This approach not only ensures a high-quality product but also helps in building a loyal customer base.

Scenario 2: Inefficiency in Production Processes

The Problem: Many businesses face inefficiencies when using blunt rollers, particularly in high-demand situations. Manual rolling can be time-consuming, and the process may become a bottleneck in production lines, especially when orders surge. This inefficiency can lead to missed deadlines and unsatisfied customers, ultimately impacting profitability.

The Solution: To streamline the production process, consider automating the blunt rolling stage with a commercial-grade blunt roller that can handle larger volumes. These machines are designed for high throughput and can significantly reduce the time spent on each roll. Additionally, integrating a pre-grinding step for cannabis can further enhance efficiency, ensuring that employees spend less time on preparation and more on production. Investing in training for employees on using these machines can maximize their potential and minimize downtime, thereby increasing overall operational efficiency.

Scenario 3: Lack of Customization Options for Unique Brand Identity

The Problem: As the cannabis market becomes increasingly saturated, businesses are seeking ways to differentiate their products. However, many blunt rollers do not offer customization options, making it challenging for brands to create unique and appealing products that resonate with their target audience.

The Solution: When sourcing blunt rollers, buyers should prioritize suppliers that offer customizable options, such as different sizes of rollers or the ability to create bespoke designs that reflect their brand identity. Some manufacturers provide the option for custom branding on the rollers themselves, which can enhance brand visibility during the smoking experience. Additionally, integrating unique packaging solutions, such as eco-friendly or themed wraps, can further set a brand apart. Engaging with suppliers who understand the importance of branding in the cannabis industry can lead to more tailored solutions that meet specific marketing goals and consumer preferences.

By addressing these common pain points, B2B buyers can enhance their operational efficiency, maintain product quality, and foster a strong brand identity in the competitive blunt market.

Strategic Material Selection Guide for blunt roller

When selecting materials for blunt rollers, it’s essential to consider various factors that impact performance, durability, and cost. Below is an analysis of four common materials used in the manufacturing of blunt rollers, along with their key properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Plastic in Blunt Rollers?

Plastic, particularly high-density polyethylene (HDPE) and polypropylene (PP), is widely used in blunt rollers due to its lightweight and cost-effective nature. These materials offer good resistance to moisture and chemicals, making them suitable for environments where exposure to cannabis oils and other substances is common.

Pros: Plastics are generally less expensive to produce, lightweight, and easy to mold into complex shapes, allowing for innovative designs. They also provide adequate durability for everyday use.

Cons: However, plastics can be less durable than metal options, especially under high temperatures or prolonged use, leading to potential deformation. They may also be less environmentally friendly, which is an increasing concern among consumers.

Impact on Application: Plastic blunt rollers are compatible with various cannabis products, but their performance may diminish at higher temperatures, which can affect the rolling process.

Considerations for International Buyers: Buyers in regions such as Africa and South America should ensure compliance with local regulations regarding plastic use and recycling. Standards such as ASTM D6400 for compostability could be relevant.

How Do Metals Compare as a Material for Blunt Rollers?

Metals, particularly aluminum and stainless steel, are also popular choices for blunt rollers. These materials are known for their strength and durability, providing a robust option for frequent use.

Pros: Metals offer excellent temperature resistance and are less likely to warp or degrade over time. They also provide a premium feel and aesthetic, appealing to high-end markets.

Cons: The primary drawback of metals is their higher cost and weight compared to plastics. Additionally, manufacturing processes for metal parts can be more complex, leading to longer lead times.

Impact on Application: Metal blunt rollers can handle a wider range of temperatures and are less susceptible to damage from cannabis oils, making them suitable for high-performance applications.

Considerations for International Buyers: Compliance with international standards such as ASTM A240 for stainless steel can be crucial. Buyers in Europe may also look for certifications related to food safety and material safety data sheets (MSDS).

What Role Does Silicone Play in Blunt Roller Manufacturing?

Silicone is increasingly being used in blunt rollers due to its flexibility and heat resistance. This material can withstand high temperatures without deforming, making it a viable option for users who prefer a more durable product.

Pros: Silicone is non-toxic, easy to clean, and provides a good grip, enhancing usability. Its flexibility allows for innovative designs that can accommodate various blunt sizes.

Cons: The main limitation of silicone is its cost, which is generally higher than that of traditional plastics. Additionally, it may not provide the same aesthetic appeal as metal options.

Impact on Application: Silicone blunt rollers can handle sticky materials well, making them ideal for use with cannabis products.

Considerations for International Buyers: Buyers should check for compliance with food-grade silicone standards, especially in regions with strict regulations, such as the EU.

Why Is Wood a Viable Material for Blunt Rollers?

Wood, particularly hardwoods, is sometimes used for blunt rollers, especially in artisanal or bespoke products.

Pros: Wood offers a unique aesthetic appeal and a tactile experience that many consumers find attractive. It is also biodegradable, aligning with sustainability trends.

Cons: However, wood can be less durable than synthetic materials, and it may absorb moisture or odors over time. Additionally, the manufacturing process can be more labor-intensive.

Impact on Application: Wooden blunt rollers may not perform as well in humid environments, which can affect the quality of the roll.

Considerations for International Buyers: Buyers should consider the sourcing of wood materials and ensure compliance with regulations regarding deforestation and sustainable practices.

Summary Table of Material Selection for Blunt Rollers

| Material | Typical Use Case for blunt roller | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Everyday consumer blunt rollers | Lightweight and cost-effective | Less durable under high temperatures | Low |

| Metal | High-performance blunt rollers | Excellent durability and aesthetics | Higher cost and manufacturing complexity | High |

| Silicone | Flexible and heat-resistant rollers | Non-toxic and easy to clean | Higher cost than plastics | Medium |

| Wood | Artisanal or bespoke blunt rollers | Unique aesthetic and biodegradable | Less durable and moisture absorbent | Medium |

This strategic material selection guide provides a comprehensive overview for B2B buyers considering blunt rollers. Understanding the properties and implications of each material can help in making informed purchasing decisions that align with market demands and regulatory standards.

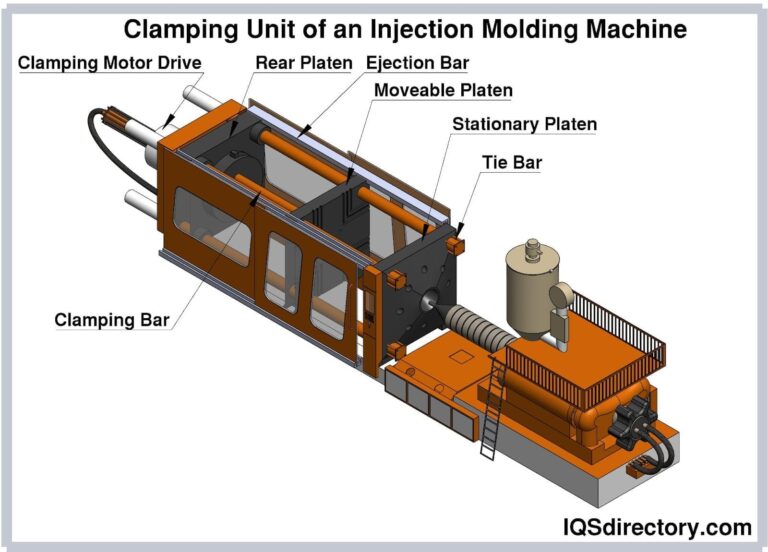

In-depth Look: Manufacturing Processes and Quality Assurance for blunt roller

What Are the Main Stages in the Manufacturing Process of Blunt Rollers?

The manufacturing process of blunt rollers involves several critical stages that ensure the final product meets the high-quality standards expected by B2B buyers. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The first step in manufacturing blunt rollers is the selection and preparation of materials. Common materials used include high-grade plastics and metals, which are chosen for their durability and ability to withstand repeated use. Manufacturers often utilize advanced sourcing techniques to ensure that materials are both cost-effective and of high quality. This may involve partnerships with trusted suppliers and rigorous testing of incoming materials to confirm compliance with industry standards. -

Forming

Once the materials are prepared, the forming stage begins. This process can include injection molding for plastic components and machining for metal parts. Advanced techniques such as CNC machining may be employed to achieve precise dimensions and tolerances, which are crucial for the functionality of the blunt rollers. At this stage, manufacturers focus on optimizing the design to ensure ease of use while maintaining structural integrity. -

Assembly

The assembly phase involves bringing together all the individual components, including the casing, rolling mechanisms, and any additional features such as filters or packing tools. Skilled technicians or automated assembly lines ensure that all parts fit together seamlessly. Quality control measures are often integrated into this stage, where each assembly undergoes initial checks for functionality and fit. -

Finishing

The finishing stage is where the blunt rollers are refined. This may include surface treatments, painting, or applying non-slip coatings to enhance user experience. Final inspections are conducted to ensure that the appearance and functionality meet the specifications outlined in the design phase. Packaging is also an essential part of this stage, as it protects the product during transit and provides an opportunity for branding.

How is Quality Assurance Implemented in Blunt Roller Manufacturing?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for blunt rollers. It encompasses various international standards and industry-specific requirements that ensure the end product is safe and effective for consumers.

-

International Standards and Certifications

Many manufacturers adhere to international standards such as ISO 9001, which emphasizes a systematic approach to quality management. Compliance with ISO standards helps manufacturers implement consistent processes that enhance product quality and customer satisfaction. Additionally, certifications like CE (Conformité Européenne) are essential for products sold in the European market, ensuring they meet safety and environmental standards. -

Quality Control Checkpoints

Quality control is typically divided into several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet predefined specifications.

– In-Process Quality Control (IPQC): During the manufacturing stages, ongoing checks are performed to monitor the production process and identify any deviations from quality standards.

– Final Quality Control (FQC): After assembly, the finished products undergo thorough testing to verify functionality and durability. This may include stress tests, usability assessments, and aesthetic inspections. -

Common Testing Methods

Manufacturers utilize various testing methods to ensure product quality. These include functional testing, where the blunt rollers are tested for ease of use and effectiveness, and durability testing to assess how well the products hold up under typical usage conditions. Additionally, some manufacturers employ third-party testing labs to conduct unbiased assessments, further ensuring quality assurance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to ensure that their suppliers maintain robust quality control practices. Here are several strategies to verify QC measures effectively:

-

Supplier Audits

Conducting supplier audits is an effective way for buyers to assess the quality control processes in place. During an audit, buyers can evaluate the supplier’s adherence to international standards, observe manufacturing practices, and review documentation related to quality assurance. -

Requesting Quality Reports

Buyers should request comprehensive quality reports from suppliers, detailing their QC measures, testing results, and compliance with relevant standards. These reports provide insight into the supplier’s commitment to quality and can help in making informed purchasing decisions. -

Third-Party Inspections

Engaging third-party inspection services can provide an additional layer of assurance. These independent entities can conduct thorough evaluations of the manufacturing process and product quality, ensuring that suppliers meet the necessary standards before products are shipped. -

Understanding QC Nuances for International Transactions

For buyers in regions such as Africa, South America, the Middle East, and Europe, it’s crucial to understand any regional nuances regarding quality certification and compliance. Different markets may have specific regulations or standards that manufacturers need to adhere to, which can impact product quality. Buyers should be familiar with these requirements to ensure that their suppliers are compliant.

What Are the Benefits of Ensuring High-Quality Standards in Blunt Roller Manufacturing?

Investing in high-quality blunt rollers not only enhances user experience but also fosters brand loyalty and market competitiveness. Here are a few key benefits:

-

Enhanced User Satisfaction

Quality blunt rollers improve the rolling experience, leading to a more enjoyable product for consumers. Satisfied customers are likely to return for repeat purchases, positively impacting the supplier’s reputation. -

Reduced Return Rates

High-quality products typically result in lower return rates. By ensuring quality throughout the manufacturing process, suppliers can minimize defects and inconsistencies, leading to fewer customer complaints and returns. -

Competitive Advantage

In a crowded market, quality can set a brand apart. Suppliers that prioritize quality assurance are likely to gain a competitive edge, attracting discerning buyers who value reliability and performance. -

Long-term Cost Savings

While investing in quality may seem more expensive initially, it often results in long-term savings. High-quality products reduce the need for replacements and repairs, ultimately benefiting the bottom line.

By understanding the manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing blunt rollers, ensuring they select suppliers that align with their quality expectations and business goals.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘blunt roller’

When procuring blunt rollers, it’s essential to follow a structured approach to ensure you select a product that meets your operational needs and quality standards. This guide offers actionable steps for B2B buyers looking to source blunt rollers effectively.

Step 1: Identify Your Requirements

Begin by defining the specific requirements for the blunt roller you need. Consider factors such as the volume of production, the type of blunt (size, material), and the user experience you want to deliver. This clarity will guide your selection process and ensure you choose a machine that aligns with your business model.

- Volume Needs: Determine how many blunts you need to roll per hour or day.

- Type of Blunt: Decide whether you require a manual or automatic machine based on your production scale.

Step 2: Research Available Models

Conduct thorough research on the various blunt roller models available in the market. Look for machines that offer features such as adjustable settings for different blunt sizes and ease of use. A comprehensive understanding of available options will enable you to make an informed decision.

- Features to Consider: Look for models that allow for customization, such as different rolling speeds and sizes.

- User Reviews: Analyze feedback from current users to gauge performance and reliability.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, it’s crucial to vet potential suppliers thoroughly. Request company profiles, product catalogs, and references from other buyers in your industry. This step will help you assess the supplier’s credibility and capacity to meet your needs.

- Company Background: Investigate the supplier’s history, reputation, and experience in the blunt rolling machine sector.

- Client Testimonials: Seek testimonials or case studies that highlight their reliability and customer service.

Step 4: Request Samples for Testing

Once you’ve narrowed down your options, request samples of the blunt rollers for testing. This hands-on evaluation will allow you to assess the functionality, ease of use, and quality of the final product.

- Testing Criteria: Focus on the consistency of the roll, ease of operation, and any unique features the machine offers.

- Quality Assurance: Ensure that the sample meets your quality standards before making a bulk order.

Step 5: Verify Compliance with Industry Standards

Confirm that the blunt rollers you are considering comply with relevant industry standards and regulations. This step is vital to ensure the safety and legality of your products in the markets you serve.

- Certifications: Check for certifications such as ISO or CE that indicate quality assurance.

- Regulatory Compliance: Ensure compliance with local regulations regarding cannabis products and manufacturing equipment.

Step 6: Negotiate Terms and Pricing

Engage in negotiations with your selected suppliers to agree on pricing, payment terms, and delivery schedules. Establishing favorable terms can enhance your profitability and ensure timely access to necessary equipment.

- Bulk Discounts: Inquire about discounts for larger orders, which can significantly reduce overall costs.

- Payment Flexibility: Discuss payment terms that align with your cash flow requirements.

Step 7: Plan for After-Sales Support and Maintenance

Lastly, ensure that the supplier provides robust after-sales support and maintenance services. This commitment can minimize downtime and enhance the longevity of your investment.

- Support Services: Confirm the availability of technical support, training, and parts replacement.

- Maintenance Plans: Inquire about maintenance plans that can help you keep the blunt rollers in optimal working condition.

By following this structured checklist, B2B buyers can effectively source blunt rollers that meet their operational needs, ensuring a quality product that enhances their business offerings.

Comprehensive Cost and Pricing Analysis for blunt roller Sourcing

What Are the Key Cost Components for Blunt Roller Manufacturing?

When sourcing blunt rollers, understanding the underlying cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The quality of materials used in manufacturing blunt rollers significantly affects the overall cost. High-grade plastics, metals, and rubber components can increase the price, while cheaper alternatives may compromise durability and functionality.

-

Labor: Labor costs vary by region and can be influenced by the skill level required for assembly and production. In regions with higher labor costs, such as parts of Europe, manufacturers may need to balance quality with pricing to remain competitive.

-

Manufacturing Overhead: This encompasses utilities, facility costs, and administrative expenses associated with production. Efficient manufacturing processes can help minimize overhead, leading to more competitive pricing.

-

Tooling: The initial investment in tooling and machinery for producing blunt rollers can be significant. Custom designs may necessitate specialized tools, which can impact pricing, especially for low-volume orders.

-

Quality Control (QC): Implementing stringent QC measures is crucial for maintaining product standards. While this adds to the cost, it also enhances customer satisfaction and reduces returns, thus providing long-term savings.

-

Logistics: Shipping and handling costs can vary widely based on the origin and destination of the products. International buyers should consider factors such as freight rates, customs duties, and import taxes when calculating total costs.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market competition and demand. Understanding the margin expectations of different suppliers can aid in negotiation.

How Do Price Influencers Affect Blunt Roller Sourcing?

Several factors influence the pricing of blunt rollers, which can have significant implications for international B2B buyers:

-

Volume/MOQ: Suppliers often have Minimum Order Quantities (MOQ) that can affect pricing. Larger orders may lead to volume discounts, while smaller orders could incur higher per-unit costs.

-

Specifications and Customization: Custom-designed blunt rollers tailored to specific needs will generally cost more than standard models. Buyers should weigh the benefits of customization against the increased costs.

-

Materials and Quality Certifications: The materials used and certifications (such as ISO or safety compliance) can impact pricing. Higher-quality materials may attract a premium, but they also offer better performance and longevity.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality and service may charge more but offer better assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers as they dictate the responsibilities of buyers and sellers in shipping, which can affect total costs.

What Negotiation and Cost-Efficiency Tips Should Buyers Consider?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant cost savings:

-

Leverage Volume Discounts: When possible, consolidate orders to meet MOQ requirements, which can help secure better pricing.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors like maintenance, durability, and shipping costs to understand the true cost of ownership over time.

-

Explore Supplier Relationships: Building long-term relationships with suppliers can lead to better terms and pricing. Frequent communication and collaboration can also foster trust and improve negotiation outcomes.

-

Stay Informed About Market Trends: Understanding market trends and pricing fluctuations can provide leverage during negotiations. Being aware of global supply chain issues or material shortages can help in negotiating better terms.

Disclaimer for Indicative Prices

Prices for blunt rollers can vary significantly based on the aforementioned factors. It is advisable to request quotes from multiple suppliers and conduct thorough market research to ascertain a fair price point that aligns with your specific needs and budget constraints.

Alternatives Analysis: Comparing blunt roller With Other Solutions

Exploring Alternatives to Blunt Rollers: A Comprehensive Comparison

In the cannabis industry, the method of rolling blunts is critical to delivering an enjoyable smoking experience. While blunt rollers offer a convenient and efficient way to achieve a perfectly rolled product, there are several alternative solutions that cater to different needs and preferences. This section provides a detailed comparison of the blunt roller against other viable methods, helping international B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Blunt Roller | Hand Rolling | Pre-Rolled Cones |

|---|---|---|---|

| Performance | High – consistent, uniform rolls | Variable – dependent on skill level | High – professionally made, ready to use |

| Cost | Moderate – initial investment needed | Low – minimal investment | Variable – higher per unit cost |

| Ease of Implementation | Easy – straightforward process | Challenging – requires practice | Very Easy – no preparation needed |

| Maintenance | Low – requires basic cleaning | None – but may require skill improvement | None – single-use |

| Best Use Case | Ideal for regular users seeking consistency | Suitable for experienced smokers | Perfect for on-the-go convenience |

In-Depth Analysis of Alternatives

What Are the Advantages and Disadvantages of Hand Rolling?

Hand rolling is a traditional method that allows for personalization and creativity in the rolling process. The main advantage of hand rolling is its cost-effectiveness; it requires minimal tools, making it accessible for all users. However, the performance can be inconsistent, especially for beginners who may struggle with achieving the right tightness and shape. This method is best suited for experienced smokers who enjoy the art of rolling and wish to customize their blunts, but it may not be practical for businesses that require efficiency and uniformity.

How Do Pre-Rolled Cones Compare to Blunt Rollers?

Pre-rolled cones offer a convenient solution for consumers who want to skip the rolling process altogether. These products are typically made by professionals, ensuring a consistent and high-quality smoking experience. The major advantage is ease of use—users simply need to fill the cone with cannabis and seal it. However, the cost per unit can be higher than using a blunt roller, especially for bulk purchases. Pre-rolled cones are ideal for those seeking convenience and speed, particularly in social settings or for commercial sales, but they may lack the personal touch that hand-rolled or blunt-rolled products offer.

Conclusion: Which Blunt Rolling Solution Is Right for Your Business?

When choosing the right blunt rolling solution, B2B buyers should carefully consider their target market, production volume, and desired quality. Blunt rollers provide a balance of performance and ease of use, making them suitable for businesses that require consistency in their product. Hand rolling might appeal to niche markets that value craftsmanship, while pre-rolled cones can cater to consumers seeking convenience. By evaluating these alternatives against specific business goals, companies can select the most appropriate method to enhance their product offerings and satisfy their customers.

Essential Technical Properties and Trade Terminology for blunt roller

What Are the Key Technical Properties of a Blunt Roller?

When sourcing blunt rollers for your business, understanding their technical properties is crucial. Here are some key specifications that influence performance and usability:

-

Material Grade

Blunt rollers are typically made from materials such as plastic, aluminum, or stainless steel. The material grade affects durability, ease of cleaning, and overall user experience. High-grade materials ensure longevity and resistance to wear and tear, which is vital for businesses aiming to maintain quality. -

Rolling Capacity

This specification refers to the amount of cannabis a blunt roller can accommodate at one time. Most models can handle between 0.5 to 1.5 grams, but larger machines may accommodate more. Understanding the rolling capacity is essential for companies that require efficiency and consistency in production, especially in high-demand markets. -

Tolerance Levels

Tolerance indicates the precision with which the blunt roller can create a consistent product. Tighter tolerances result in better-rolled blunts that burn evenly. For businesses, maintaining high tolerance levels can lead to improved customer satisfaction and brand loyalty. -

Ease of Use

This property encompasses the design features that simplify the rolling process, such as ergonomic grips, clear instructions, and intuitive mechanisms. A user-friendly design can reduce training time for employees and improve production speed, which is critical for businesses looking to scale operations efficiently. -

Size and Portability

The dimensions of the blunt roller are important for storage and transport. Compact models are preferable for businesses with limited space or those that participate in trade shows and events. Understanding size specifications allows buyers to make informed decisions about their equipment investments. -

Maintenance Requirements

Knowing the maintenance needs of a blunt roller, including cleaning frequency and part replacements, is essential for ensuring operational efficiency. Machines that require less frequent maintenance can save businesses time and money, making them more attractive for long-term investment.

What Are the Common Trade Terms Associated with Blunt Rollers?

Familiarity with industry jargon is vital for effective communication and negotiation in B2B transactions. Here are several key terms you should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable sources for quality blunt rollers and associated parts. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps businesses budget effectively and avoid overstocking or underordering, which can impact cash flow and storage capacity. -

RFQ (Request for Quotation)

An RFQ is a formal document requesting price quotes from suppliers for specific quantities of products. Crafting a clear RFQ can streamline the procurement process, ensuring you receive competitive pricing and terms from potential vendors. -

Incoterms (International Commercial Terms)

These are standardized international trade terms that define the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms helps businesses clarify shipping costs, risks, and delivery obligations, which is crucial for international transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is vital for inventory management and planning, especially for businesses that operate in fast-paced markets. -

After-Sales Support

This term refers to services provided after the purchase of a product, including maintenance, repairs, and customer service. Reliable after-sales support is essential for businesses to ensure the longevity and efficiency of their blunt rollers.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the blunt roller Sector

What Are the Global Drivers and Key Trends in the Blunt Roller Market?

The blunt roller market is experiencing notable growth, driven by increasing consumer sophistication and a rising demand for quality smoking experiences. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are influenced by several market dynamics. The cannabis industry’s maturation has led to a shift toward premium products, where consumers seek not just functionality but also aesthetics and quality. This trend is evident in the demand for high-end blunt rolling machines that produce smooth, luxurious smoking experiences.

Technological advancements are also reshaping the blunt roller sector. Innovations such as automated rolling machines and customizable options enable businesses to cater to diverse consumer preferences while optimizing production efficiency. As online marketplaces expand, international buyers are increasingly accessing a wider range of products, allowing for competitive pricing and enhanced sourcing flexibility.

Additionally, the integration of e-commerce platforms facilitates direct communication between manufacturers and buyers, fostering transparency and streamlining the procurement process. The growing influence of social media and digital marketing is further driving brand awareness and shaping consumer preferences, particularly among younger demographics. For B2B buyers, understanding these market drivers is crucial for making informed sourcing decisions and capitalizing on emerging opportunities.

How Can Sustainability and Ethical Sourcing Impact the Blunt Roller Industry?

Sustainability is becoming a pivotal consideration in the blunt roller sector. As global awareness of environmental issues rises, international B2B buyers are increasingly prioritizing eco-friendly products and ethical sourcing practices. The environmental impact of production processes, including energy consumption and waste generation, is under scrutiny. Buyers are encouraged to seek out suppliers who utilize sustainable materials and practices, such as biodegradable blunt wraps and recyclable packaging.

The importance of ethical supply chains cannot be overstated. Companies that prioritize fair labor practices and transparency in sourcing are likely to resonate with conscious consumers and businesses. Certifications like Fair Trade and organic labeling can enhance brand reputation and appeal, making them vital for suppliers aiming to differentiate themselves in a competitive market.

Moreover, the shift toward sustainability presents a significant opportunity for innovation. Manufacturers who invest in research and development to create greener products are well-positioned to meet the demands of environmentally conscious buyers. For B2B buyers in regions such as Africa and South America, aligning with suppliers who champion sustainability can also open doors to new markets and customer bases that prioritize responsible consumption.

How Has the Blunt Roller Market Evolved Over Time?

The evolution of the blunt roller market reflects broader shifts in consumer preferences and industry practices. Initially, blunt rolling was a manual skill, often passed down through social circles and communities. However, as cannabis legalization spread and the market matured, the need for consistency and quality led to the development of specialized blunt rolling machines.

The introduction of automated and semi-automated machines has transformed the landscape, allowing for greater efficiency and precision in production. Today, blunt rollers are not just tools for personal use; they are essential equipment for businesses aiming to meet high consumer expectations. As the market continues to evolve, the focus on customization, quality, and sustainability will likely shape the future of blunt rolling, offering B2B buyers new opportunities to innovate and expand their product offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of blunt roller

-

1. How do I select the right blunt roller for my business needs?

When selecting a blunt roller, consider factors such as production capacity, ease of use, and the specific type of blunts you wish to produce. Assess the machine’s output speed and the quality of the finished product, as a smooth, well-rolled blunt enhances customer satisfaction. It’s also essential to evaluate the durability of the materials used in the roller, as this impacts maintenance costs and longevity. Lastly, check for compatibility with various blunt wraps or filters, ensuring flexibility in your offerings. -

2. What are the key features to look for in a blunt rolling machine?

Key features to consider include the machine’s size and portability, automation level, and the ability to handle different blunt sizes. Look for machines that offer adjustable settings for grind consistency and compacting pressure, as these can significantly affect the quality of the roll. Additionally, a user-friendly interface and easy cleaning mechanisms are crucial for operational efficiency. Lastly, consider machines with a warranty and good customer support for troubleshooting. -

3. How can I ensure quality when sourcing blunt rollers from international suppliers?

To ensure quality, start by vetting suppliers through online reviews, industry recommendations, and certifications. Request samples to evaluate the machine’s performance before committing to a bulk order. Establish clear quality assurance (QA) measures, including inspection protocols during production and before shipment. Communicate your quality standards explicitly and consider third-party quality inspections to verify compliance with your specifications. -

4. What are the typical payment terms when importing blunt rollers?

Payment terms can vary significantly based on the supplier and your negotiation skills. Common arrangements include a deposit (often 30-50%) before production, with the balance due upon shipment or delivery. It’s advisable to use secure payment methods like letters of credit or escrow services to mitigate risk. Clarify all terms in a written contract to ensure both parties understand the financial obligations, including potential penalties for late payments. -

5. What are the minimum order quantities (MOQs) for blunt rollers?

Minimum order quantities (MOQs) for blunt rollers can differ depending on the manufacturer and the type of machine. Typically, MOQs can range from a few units for smaller manufacturers to several dozen for larger suppliers. It’s crucial to discuss MOQs upfront, especially if you are a startup or have limited capital. Some suppliers may offer flexibility in MOQs for first-time buyers or larger orders, so it’s worth negotiating. -

6. What logistics considerations should I be aware of when importing blunt rollers?

Logistics considerations include shipping methods, customs regulations, and import duties. Choose a reliable freight forwarder experienced in handling machinery imports to navigate these complexities. Understand the lead times involved in production and shipping, and plan your inventory accordingly. Additionally, familiarize yourself with local regulations regarding the importation of smoking-related equipment to avoid legal issues. -

7. How can I customize blunt rollers to fit my brand?

Customization options may include machine color, branding, and even specific modifications to enhance functionality. Discuss your requirements with suppliers, as many manufacturers offer bespoke solutions. Ensure that you provide clear specifications and design ideas to avoid misunderstandings. Additionally, inquire about the costs and timelines associated with customization, as these can impact your overall budget and delivery schedule. -

8. What are the best practices for maintaining blunt rolling machines?

Regular maintenance is essential for prolonging the lifespan of blunt rolling machines. Establish a routine for cleaning the machine after each use to prevent residue buildup, which can affect performance. Check for wear and tear on parts regularly, replacing any components as needed. Additionally, follow the manufacturer’s guidelines for lubrication and servicing to ensure optimal functionality. Keeping a maintenance log can help track service schedules and anticipate repairs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Blunt Roller Manufacturers & Suppliers List

1. Custom Cones USA – Pre Roll Machines

Domain: customconesusa.com

Registered: 2018 (7 years)

Introduction: Pre Roll Machines, Blunt-Making Equipment, Blunt Rolling Machines, Custom Cones USA, Contact: 833-582-6637, Categories: Pre Rolled Cones, Pre Rolled Blunts, Pre Rolled Smoking Tubes, Blunt Making Equipment, Blunt Packaging, Blunt Tubes, Custom Pre-Rolled Cones, Specialty Pre-Rolled Cones, Retail Cones and Tubes, Pre Roll Machines, Tube Filling Machines, Cannabis Grinders, Pre-Roll Starter Kits, Bl…

2. Inhalco – Blunt & Joint Rollers

Domain: inhalco.com

Registered: 2019 (6 years)

Introduction: Blunt Roller & Joint Roller: A device designed to assist in rolling compact blunts and joints, derived from cigarette rolling machines. Available in various shapes and sizes, it simplifies the rolling process for connoisseurs. Types include Electric Rollers (automated, larger, suitable for high demand) and Manual Rolling Machines (requires manual input, suitable for novices). Instructions for use …

3. Blunt Roller – Rolling Machines & Accessories

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Blunt Roller products available on eBay include various models such as manual and automatic rolling machines, cone loaders, and cigar rollers. Prices range from $7.50 to $42.66, with many items offered as ‘Brand New’ and some with free shipping. Sellers have high positive ratings, and options for bulk purchases are available. Common features include compatibility with different sizes of wraps and …

4. Purple Rose Supply – Cannagar Molds & Roller Kits

Domain: purplerosesupply.com

Registered: 2018 (7 years)

Introduction: Cannagar Molds Joint & Blunt Roller Kits from PURPLE ROSE SUPPLY® include a 60-day risk-free trial, various product categories such as THCa Cannagars, multi cone packer cannagar molds, and accessories. The site offers bundle and save options, limited drops, a gift shop, best sellers under $50, and educational resources including a blog and FAQs.

5. Headshop – Blunt Rolling Essentials

Domain: headshop.com

Registered: 1997 (28 years)

Introduction: This company, Headshop – Blunt Rolling Essentials, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Cyclone – Prerolled Cone Blunt Wraps

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Recommendations for automatic blunt/joint roller machines that can be operated with one hand. Mention of prerolled cone blunt wraps, specifically from a company called Cyclone, and a product called Blizzy Cones that makes pre-roll cones out of backwoods leaves in various flavors like Banana and Russian Cream. Also, a suggestion for a cone filling machine with a built-in grinder that allows for one…

7. SIDE TWIST – Blunt Rolling Machine

Domain: shopmaryjae.com

Registered: 2017 (8 years)

Introduction: Product Name: Blunt Rolling Machine

Brand: SIDE TWIST

Price: $25.00

Dimensions: 1 1/2″ x 6″

Capacity: Takes 2 to 4 grams of flower and a blunt wrap (not included)

Features:

– Quick and easy feeding

– Speed knob for convenience

– Colorful design

– No belts to replace

Available Colors: Blue, Purple, Red, Teal, Yellow

8. Blazy Susan – Bamboo Rolling Machine

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: Blunt Roller products available on Etsy include:

1. Blazy Susan Bamboo Rolling Machine – Sizes: 78mm, 110mm, Extra Large Wide. Sale Price: $6.74 (Original Price: $8.99, 25% off). Free shipping.

2. Juicy Backwood Wrap Roller – Includes FREE Organic Wrap (Non Tobacco). Price: $11.99.

3. RAW Hemp Plastic Rollers – Sizes: 79MM and 110MM. Price: $5.99.

4. Cone Crusher Micro – Fills 3 Pre-rolled Cones, …

9. King Rollers – Long Bed Blunt Roller

Domain: kingrollers.com

Registered: 2012 (13 years)

Introduction: {“product_name”: “Long Bed – Blunt Roller”, “price”: “$219.00”, “description”: “Precision Rolling for Blunts, Cigarillos, and Cannagars. Built for serious smokers and cannabis processors who want a smooth, uniform roll every time.”, “features”: {“rolling_capacity”: “up to 6 inches long”, “adjustable_diameter”: “up to 46 gauge (3/4 inch thick)”, “materials”: “handcrafted from solid mahogany and bra…

Strategic Sourcing Conclusion and Outlook for blunt roller

In conclusion, the strategic sourcing of blunt rollers presents a unique opportunity for international B2B buyers to tap into the evolving cannabis market. With consumers increasingly seeking high-quality, customized smoking experiences, investing in advanced blunt rolling machines can significantly enhance product offerings. These machines not only streamline the rolling process but also ensure consistency and quality, catering to sophisticated consumer preferences across diverse markets, including Africa, South America, the Middle East, and Europe.

As buyers prioritize sourcing durable, efficient, and user-friendly blunt rollers, it’s essential to establish partnerships with reputable manufacturers who understand the nuances of the industry. By leveraging these relationships, businesses can secure competitive pricing and access to innovative technologies that differentiate their products in a crowded marketplace.

Looking forward, the demand for premium cannabis products is poised to grow, making now the ideal time for B2B buyers to invest strategically in blunt rolling solutions. Embrace this opportunity to enhance your product line and meet the expectations of discerning consumers. Take action today by exploring reliable suppliers who can support your business goals and elevate your brand in this dynamic industry.