Is Your Ball Screw Actuator Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for ball screw actuator

In today’s competitive landscape, sourcing reliable ball screw actuators can pose significant challenges for B2B buyers, particularly those operating in diverse international markets. With applications spanning industrial automation, robotics, and material handling, the need for precision and efficiency in actuator systems is paramount. This guide delves into the intricacies of the global market for ball screw actuators, equipping buyers with essential knowledge to navigate their purchasing journey effectively.

Throughout this comprehensive resource, we will explore various types of ball screw actuators, their specific applications, and the critical factors to consider when vetting suppliers. Additionally, we will address cost implications, quality standards, and the latest technological advancements in the field. By consolidating this wealth of information, the guide aims to empower decision-makers from regions such as Africa, South America, the Middle East, and Europe—specifically targeting markets like Saudi Arabia and Germany—enabling them to make informed, strategic procurement choices.

As the demand for high-performance, durable, and efficient ball screw actuators continues to rise, understanding the nuances of the market is crucial. This guide serves as a vital tool for international B2B buyers seeking to enhance their operational capabilities while ensuring compliance with regional standards and expectations. By leveraging the insights provided, buyers can confidently navigate the complexities of sourcing ball screw actuators that meet their specific needs.

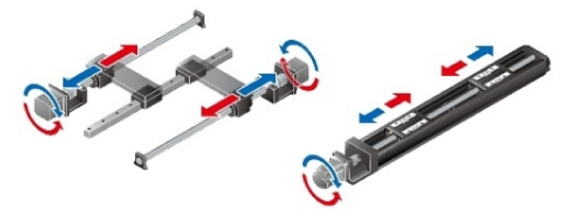

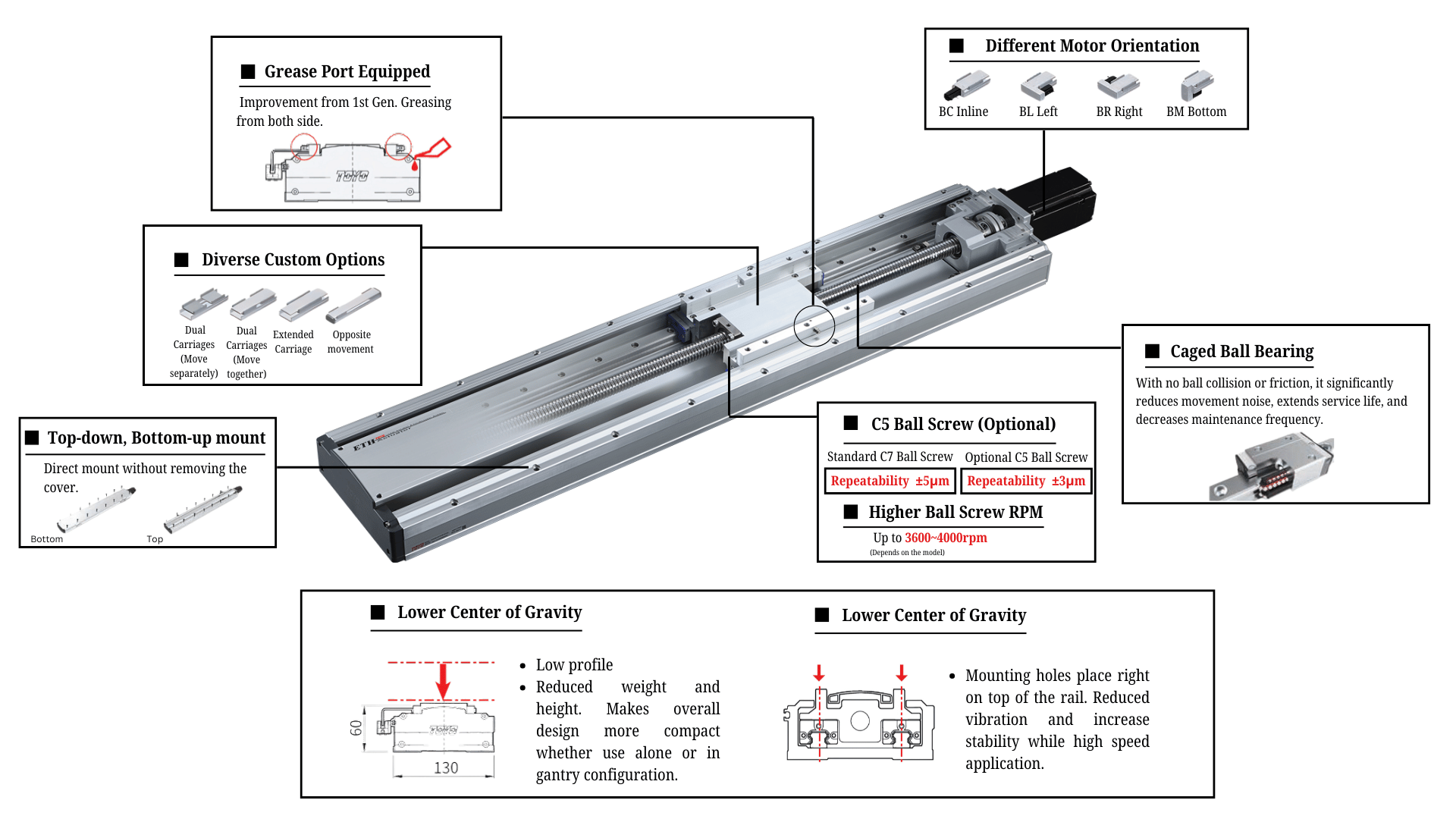

Understanding ball screw actuator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ball Screw Linear Actuators | Integrated V-roller guides, robust aluminum housing, high payload capacity | Industrial automation, material handling | Pros: High precision, durability. Cons: Higher initial cost. |

| High-Duty Cycle Ball Screw Actuators | Designed for continuous operation, high load capacity | Robotics, CNC machines | Pros: Long lifespan, reliable performance. Cons: Requires maintenance. |

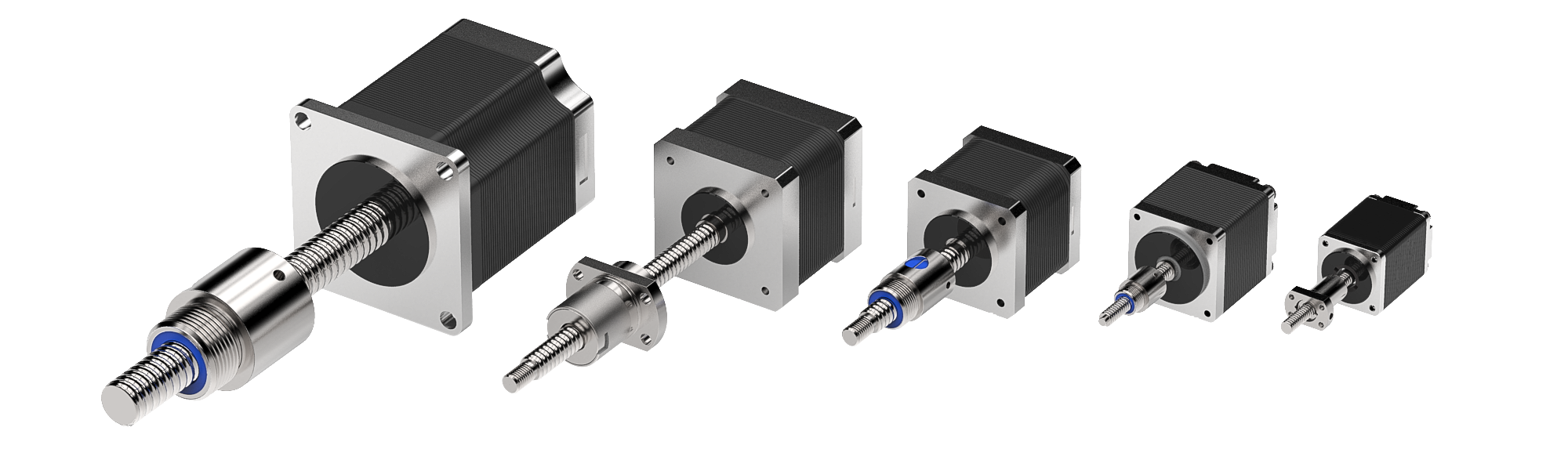

| Miniature Ball Screw Actuators | Compact design, suitable for tight spaces | Medical devices, small automation systems | Pros: Space-efficient, lightweight. Cons: Limited load capacity. |

| Electric Cylinder Ball Screw Actuators | Combines actuator and motor in one unit, easy integration | Packaging, automotive assembly | Pros: Simplified installation, energy-efficient. Cons: May have compatibility issues. |

| Lead Screw Ball Screw Actuators | Utilizes lead screw technology for cost-effective solutions | Cost-sensitive applications, low-speed automation | Pros: Economical, easy to source. Cons: Lower precision compared to ball screws. |

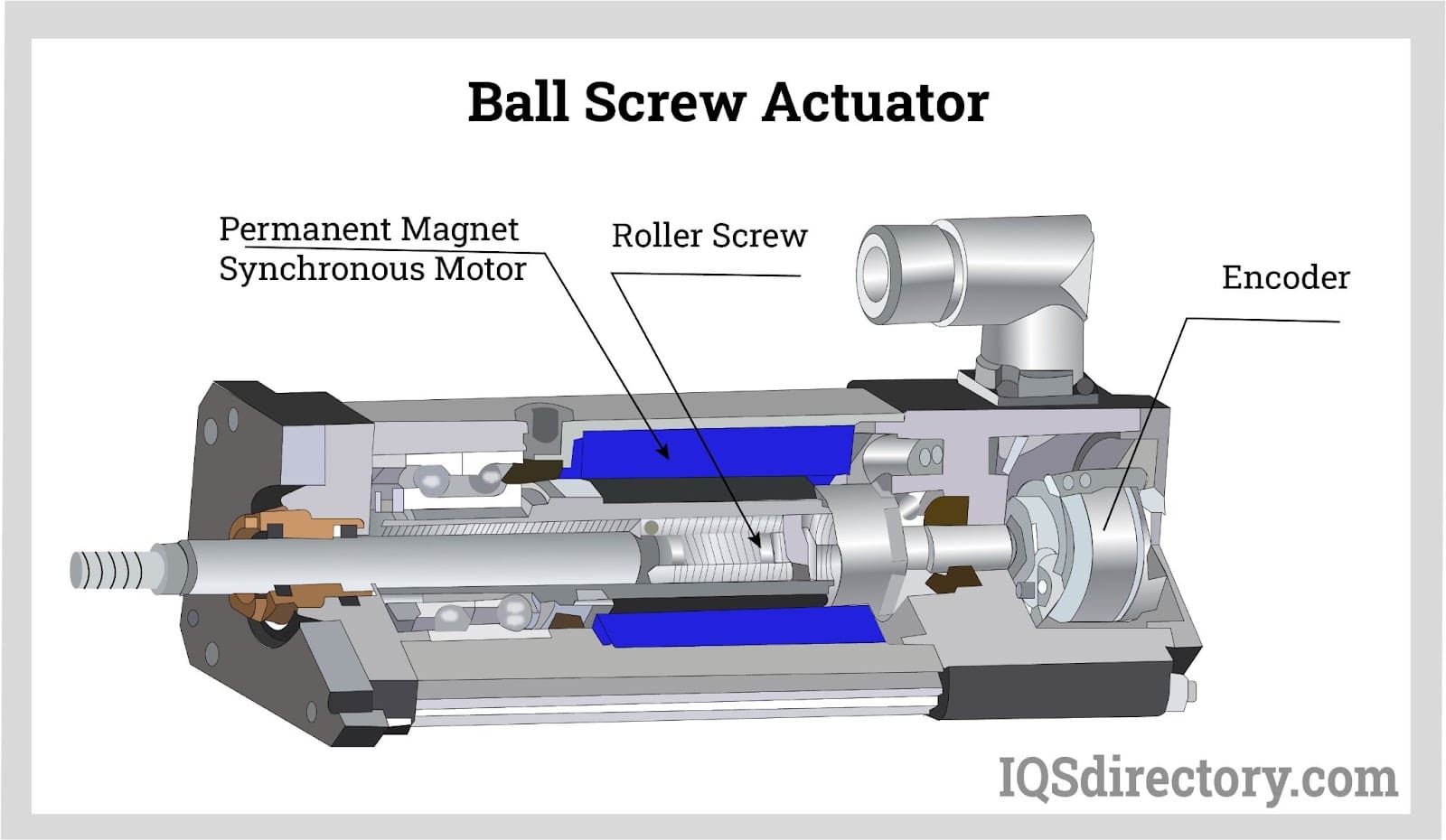

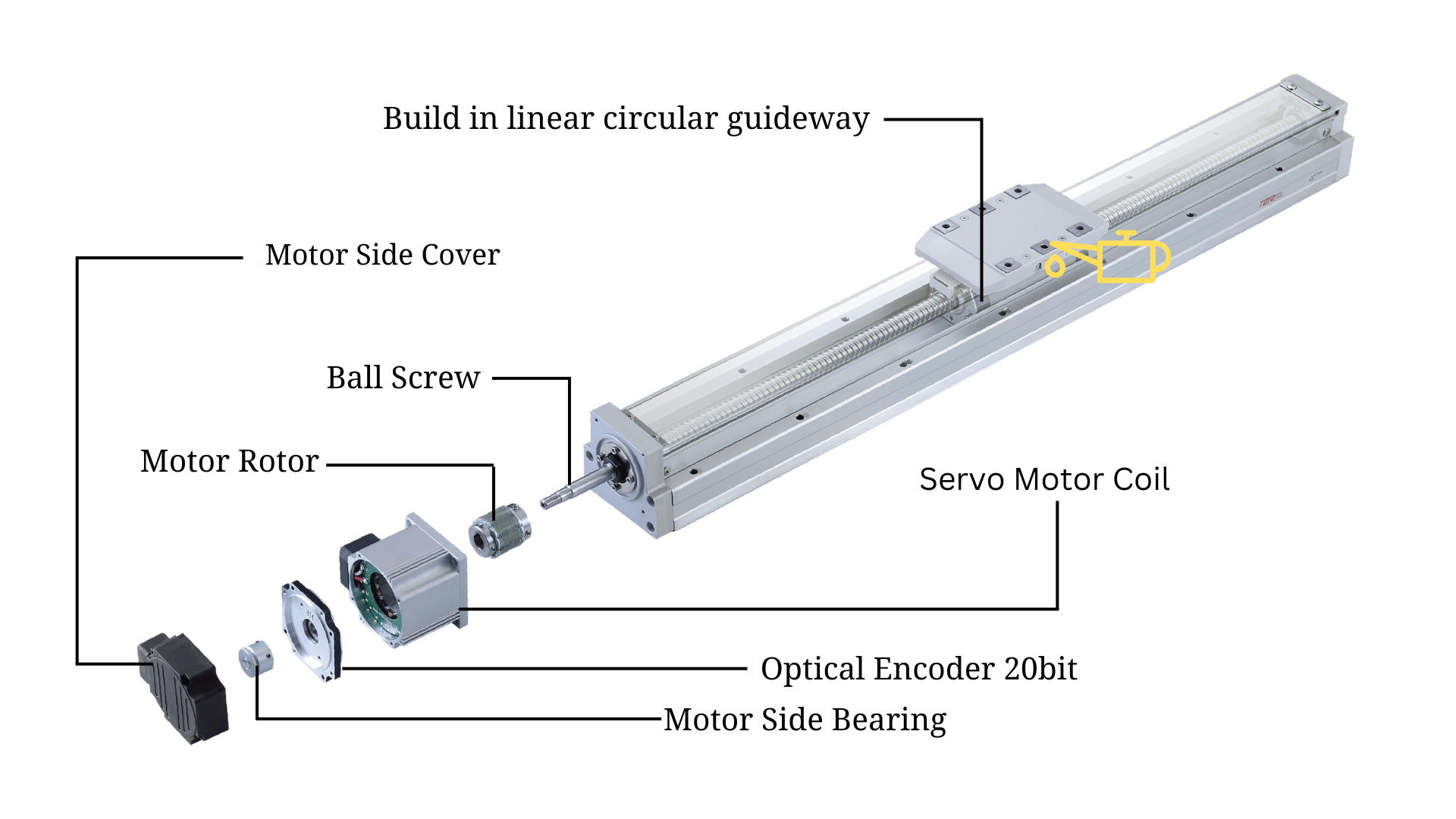

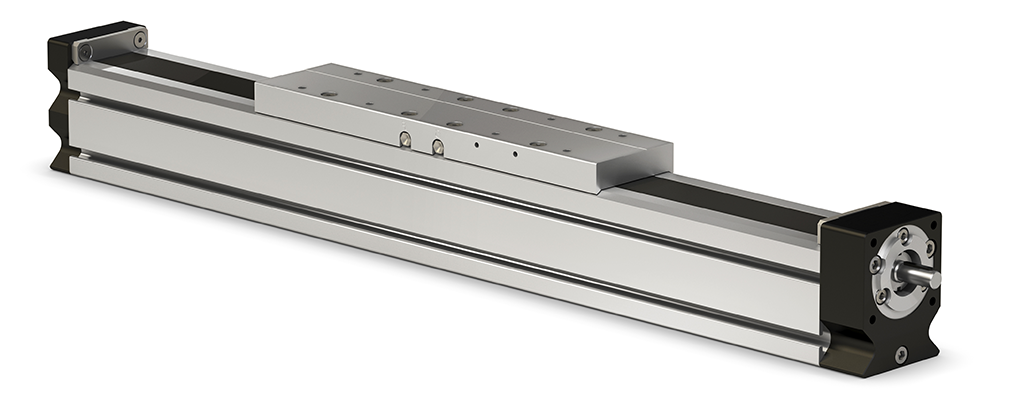

What Are the Characteristics of Ball Screw Linear Actuators?

Ball screw linear actuators are engineered for high-performance applications, featuring integrated V-roller guides that ensure smooth movement and precision. The robust aluminum housing enhances durability and resistance to debris, making them suitable for industrial automation and material handling tasks. With a high payload capacity and customizable stroke lengths, these actuators are ideal for applications that require reliable and efficient motion control. Buyers should consider the initial investment versus long-term benefits, as these actuators tend to have a higher upfront cost but offer superior performance.

Why Choose High-Duty Cycle Ball Screw Actuators for Robotics?

High-duty cycle ball screw actuators are specifically designed for demanding environments where continuous operation is required. They excel in applications like robotics and CNC machinery, where precision and reliability are paramount. These actuators can handle substantial dynamic loads and maintain performance over extended periods. However, buyers must factor in the need for regular maintenance to ensure longevity and optimal functionality, as neglect can lead to performance degradation.

Illustrative image related to ball screw actuator

How Do Miniature Ball Screw Actuators Benefit Space-Constrained Applications?

Miniature ball screw actuators are perfect for applications with limited space, such as in medical devices or compact automation systems. Their lightweight and compact design allows for integration into environments where traditional actuators may not fit. While they offer the advantage of being space-efficient, buyers should be aware of their limited load capacity, making them suitable primarily for lighter applications. This trade-off can be crucial for industries where every square inch counts.

What Are the Advantages of Electric Cylinder Ball Screw Actuators?

Electric cylinder ball screw actuators combine the actuator and motor into a single unit, simplifying installation and reducing the complexity of machinery. They are particularly advantageous in packaging and automotive assembly processes, where space and efficiency are critical. These actuators are energy-efficient and can be easily integrated into existing systems. However, compatibility issues may arise with older machines, requiring careful consideration during the purchasing process.

When to Consider Lead Screw Ball Screw Actuators?

Lead screw ball screw actuators offer a cost-effective solution for applications that do not demand the precision of ball screw actuators. They are ideal for cost-sensitive projects and low-speed automation tasks. While they are easier to source and generally more economical, buyers should note that they provide lower precision and performance compared to traditional ball screw options. Understanding the specific needs of the application will help in making an informed decision regarding their use.

Key Industrial Applications of ball screw actuator

| Industry/Sector | Specific Application of ball screw actuator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automation & Robotics | Automated assembly lines | Increases efficiency and precision in production processes | Compatibility with existing systems, load capacity, and speed |

| Medical Devices | Surgical robots and medical imaging equipment | Enhances accuracy in critical medical procedures | Regulatory compliance, reliability, and precision requirements |

| Aerospace & Defense | Aircraft control surfaces and testing equipment | Ensures safety and reliability in high-stakes environments | Weight considerations, durability under extreme conditions |

| Material Handling & Logistics | Conveyor systems and automated storage solutions | Optimizes material flow and reduces manual labor | Space constraints, payload capacity, and integration capabilities |

| Textile & Manufacturing | Cutting and sewing machines | Improves product quality and reduces waste | Customization options, maintenance support, and delivery time |

How Are Ball Screw Actuators Used in Automation & Robotics?

In the automation and robotics sector, ball screw actuators are integral to automated assembly lines, enabling precise movement and positioning of components. They address challenges such as reducing cycle times and improving accuracy in repetitive tasks. For international buyers, particularly from regions like Africa and Europe, it is crucial to ensure that these actuators are compatible with existing systems and can handle the required load capacities while maintaining high speeds.

What Role Do Ball Screw Actuators Play in Medical Devices?

Ball screw actuators are vital in medical devices, particularly in surgical robots and imaging equipment, where precision is paramount. They facilitate smooth and accurate motion, enhancing the effectiveness of critical medical procedures. Buyers in the medical sector must consider regulatory compliance, reliability, and the precision required for various applications, ensuring the actuators meet stringent industry standards.

Illustrative image related to ball screw actuator

How Are Ball Screw Actuators Essential in Aerospace & Defense?

In aerospace and defense applications, ball screw actuators are used in aircraft control surfaces and testing equipment, where reliability and safety are non-negotiable. These actuators help maintain precise control in high-stakes environments. For B2B buyers in this sector, sourcing considerations include weight constraints and the actuator’s ability to withstand extreme conditions, which are critical for maintaining aircraft performance.

Why Are Ball Screw Actuators Important for Material Handling & Logistics?

In the material handling and logistics sector, ball screw actuators are employed in conveyor systems and automated storage solutions. They optimize the flow of materials, significantly reducing the need for manual labor and improving operational efficiency. Buyers should focus on space constraints and payload capacities when selecting actuators, ensuring they can integrate seamlessly into existing workflows.

How Do Ball Screw Actuators Improve Processes in Textile & Manufacturing?

In the textile and manufacturing industries, ball screw actuators are utilized in cutting and sewing machines to enhance product quality and minimize waste. Their ability to provide precise movement translates to better accuracy in manufacturing processes. B2B buyers should prioritize customization options, maintenance support, and delivery timelines to ensure the actuators align with their specific operational needs.

3 Common User Pain Points for ‘ball screw actuator’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Actuator for Specific Applications

The Problem: B2B buyers often face challenges when trying to select the right ball screw actuator for their specific application needs. With a wide variety of options available, buyers may struggle to determine which actuator provides the best balance of precision, load capacity, and stroke length. This is especially critical in industries such as robotics and industrial automation, where selecting an incompatible actuator can lead to operational inefficiencies, costly downtime, and even damage to machinery.

The Solution: To overcome this issue, buyers should begin by conducting a thorough analysis of their application requirements, including load specifications, stroke length, and environmental conditions. Utilizing tools such as actuator selection software or consulting with manufacturers can streamline this process. For example, specifying the maximum dynamic load and desired precision can help narrow down choices. Additionally, opting for modular actuators that allow for customization can provide flexibility for future adaptations. Engaging in discussions with suppliers about potential application scenarios can also yield valuable insights and recommendations tailored to their specific needs.

Scenario 2: Concerns Over Maintenance and Longevity

The Problem: Another common pain point is the concern over maintenance and the longevity of ball screw actuators. Businesses in industries such as manufacturing and logistics are often wary of the maintenance demands associated with these components. A lack of understanding of maintenance requirements can lead to premature wear, unexpected breakdowns, and increased operational costs. This can be particularly problematic in regions with limited access to technical support or replacement parts.

The Solution: To address maintenance concerns, B2B buyers should prioritize sourcing actuators that come with comprehensive maintenance documentation and support. Manufacturers often provide guidelines for lubrication intervals, inspection routines, and troubleshooting tips. Implementing a proactive maintenance schedule based on these guidelines can significantly enhance the lifespan of the actuator. Furthermore, buyers can invest in actuators with integrated monitoring systems that provide real-time feedback on performance metrics, enabling predictive maintenance strategies. Establishing relationships with local suppliers who can provide timely service and support is also crucial for minimizing downtime.

Scenario 3: Integration Challenges with Existing Systems

The Problem: Many buyers encounter difficulties when trying to integrate new ball screw actuators into existing machinery or automation systems. This can lead to compatibility issues, where the new actuator does not interface correctly with the existing controls or mechanical setups. Such integration challenges can stall projects, increase costs, and complicate timelines, particularly in large-scale industrial environments.

The Solution: To mitigate integration issues, it is essential for buyers to engage in detailed planning and collaboration with both actuator suppliers and system integrators. Before purchasing, buyers should request compatibility data from manufacturers, including dimensional specifications, mounting options, and control interfaces. Utilizing CAD modeling tools to visualize the integration can also be beneficial. Additionally, opting for actuators that offer customizable features, such as adjustable mounting points or flexible control options, can facilitate smoother integration. Collaborating with integrators who have experience in retrofitting existing systems can provide the expertise needed to ensure a seamless transition, ultimately saving time and reducing costs.

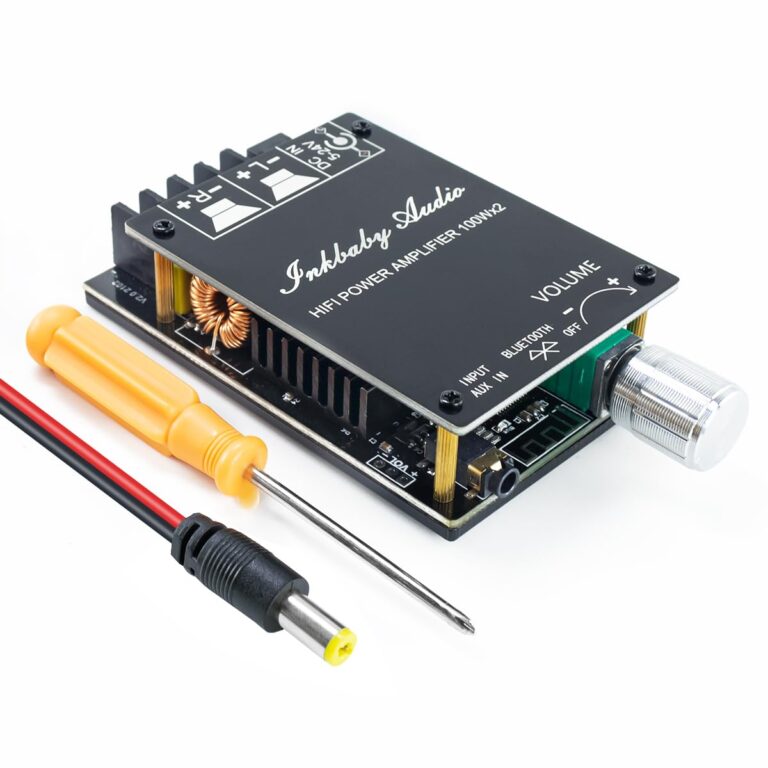

Illustrative image related to ball screw actuator

Strategic Material Selection Guide for ball screw actuator

What Are the Key Materials Used in Ball Screw Actuators?

When selecting materials for ball screw actuators, several factors must be considered, including performance characteristics, environmental conditions, and compliance with international standards. Below is an analysis of four common materials used in the construction of ball screw actuators, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Steel Perform in Ball Screw Actuators?

Key Properties: Steel, particularly high-carbon steel, is known for its exceptional strength and rigidity. It typically has a high-temperature rating and excellent wear resistance, making it suitable for high-load applications.

Pros & Cons: The main advantage of steel is its durability and ability to withstand high stress and pressure. However, it can be prone to corrosion if not properly treated, which may increase maintenance costs. Manufacturing complexity can also be higher due to the need for precise machining and heat treatment.

Illustrative image related to ball screw actuator

Impact on Application: Steel is highly compatible with various media, including oils and greases, making it ideal for industrial environments. However, in corrosive environments, additional protective coatings may be necessary.

Considerations for International Buyers: Compliance with standards such as ASTM A36 or DIN 1.0038 is essential. Buyers from regions like Europe and the Middle East may prefer certified materials that meet stringent quality control measures.

What Are the Benefits of Aluminum in Ball Screw Actuators?

Key Properties: Aluminum is lightweight and has good corrosion resistance, particularly when anodized. It also has a moderate temperature rating, making it suitable for less extreme environments.

Pros & Cons: The lightweight nature of aluminum allows for easier handling and installation. However, it may not withstand as much load as steel, which could limit its application in heavy-duty scenarios. The manufacturing process is generally less complex, allowing for quicker production times.

Impact on Application: Aluminum is ideal for applications where weight reduction is critical, such as in aerospace or portable machinery. However, it may not be suitable for environments with high abrasion or heavy loads without reinforcement.

Considerations for International Buyers: Buyers should ensure that aluminum grades conform to standards such as ASTM B221 or DIN 1725. In regions like Africa and South America, where humidity can be high, corrosion-resistant coatings are advisable.

Why Choose Stainless Steel for Ball Screw Actuators?

Key Properties: Stainless steel offers excellent corrosion resistance and strength, making it suitable for harsh environments. It typically has a high-temperature rating and good fatigue resistance.

Illustrative image related to ball screw actuator

Pros & Cons: The primary advantage of stainless steel is its longevity and resistance to rust and corrosion, which minimizes maintenance. However, it is more expensive than carbon steel and can be more challenging to machine.

Impact on Application: Stainless steel is ideal for applications in food processing, pharmaceuticals, and marine environments, where hygiene and corrosion resistance are crucial. It is compatible with a wide range of media, including aggressive chemicals.

Considerations for International Buyers: Compliance with standards such as ASTM A304 or DIN 1.4301 is vital. Buyers from Europe, particularly Germany, often seek materials that meet the EU’s stringent regulations on material safety and environmental impact.

What Role Does Plastic Play in Ball Screw Actuators?

Key Properties: Engineering plastics, such as POM (polyoxymethylene) or nylon, are lightweight, corrosion-resistant, and offer good wear properties. They have lower temperature ratings compared to metals but can perform well in specific applications.

Pros & Cons: The main advantage of plastic is its resistance to corrosion and low weight, which can reduce overall system weight. However, plastics may not handle high loads or temperatures as effectively as metals, limiting their use in heavy-duty applications.

Impact on Application: Plastic is suitable for applications where weight and corrosion resistance are prioritized, such as in medical devices or consumer electronics. However, compatibility with certain chemicals must be assessed.

Considerations for International Buyers: Buyers should verify that plastics meet industry standards such as ASTM D638 or ISO 527. In regions with high temperatures, such as parts of the Middle East, thermal stability of the chosen plastic is a critical factor.

Illustrative image related to ball screw actuator

Summary Table of Material Selection for Ball Screw Actuators

| Material | Typical Use Case for ball screw actuator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial applications | Exceptional strength and rigidity | Prone to corrosion without treatment | Medium |

| Aluminum | Lightweight machinery and automation | Lightweight and easy to handle | Limited load capacity | Medium |

| Stainless Steel | Food processing and marine applications | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Plastic | Medical devices and consumer electronics | Corrosion-resistant and lightweight | Limited load and temperature capacity | Low |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in ball screw actuators, helping them make informed decisions based on their specific application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for ball screw actuator

What Are the Key Stages in the Manufacturing Process of Ball Screw Actuators?

The manufacturing process for ball screw actuators is intricate, involving several critical stages that ensure the final product meets high-performance standards. Below are the main stages involved:

Material Preparation: What Materials Are Used in Ball Screw Actuator Manufacturing?

The process begins with the selection of high-quality materials. Commonly used materials include hardened steel for the screw and nut, aluminum for the housing, and various polymers for seals and bearings. These materials are chosen for their strength, durability, and resistance to wear, as they contribute to the actuator’s overall performance and longevity.

Once the materials are selected, they undergo thorough inspections to ensure they meet specific standards. This may include checking for material defects, measuring dimensions, and verifying that the chemical composition aligns with industry requirements.

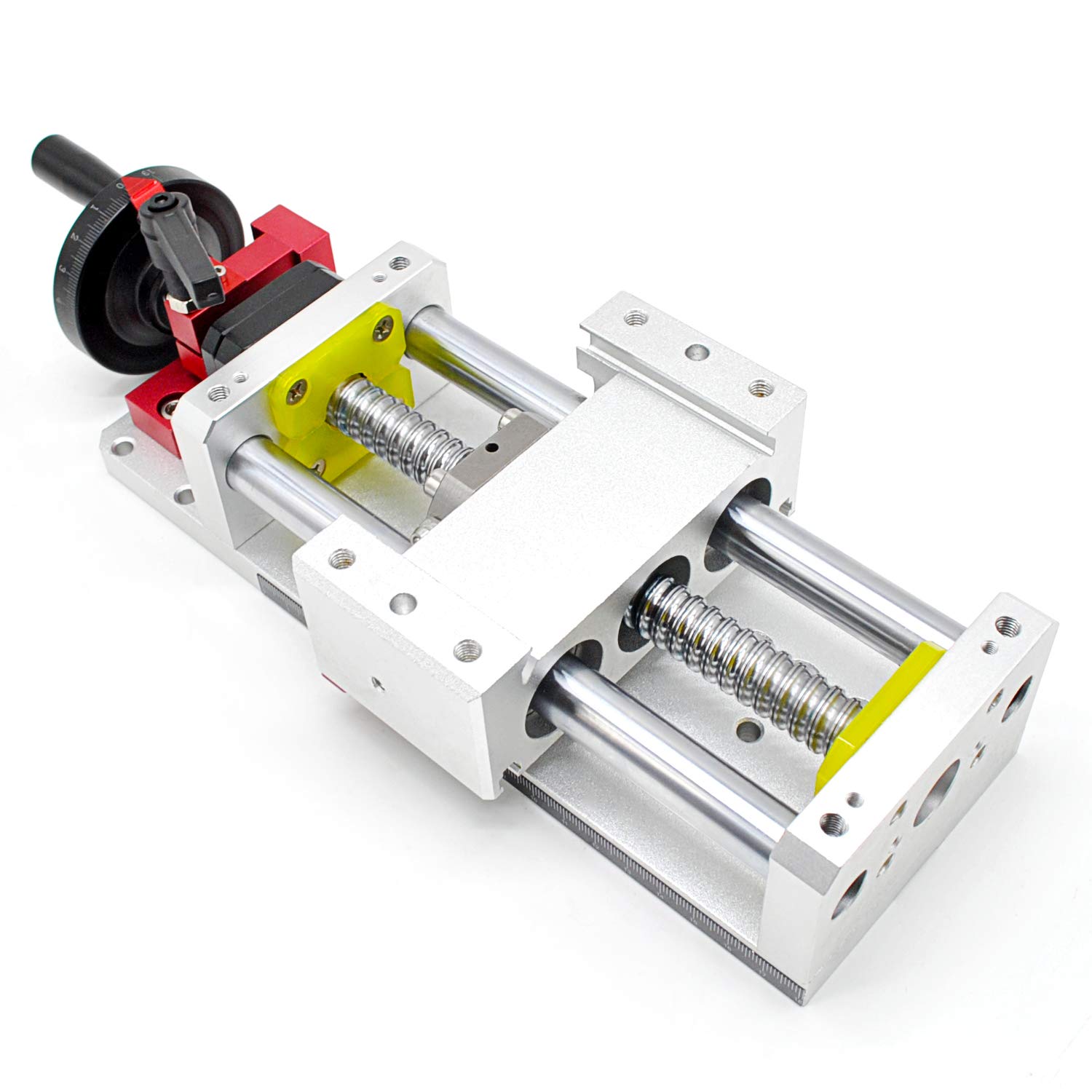

How Are Ball Screws Formed in the Manufacturing Process?

After material preparation, the next stage is forming. This involves precise machining processes such as turning, grinding, and milling to create the ball screw’s threads and surfaces. The ball screw is typically manufactured using a combination of CNC (Computer Numerical Control) machining and traditional methods to achieve high accuracy and tight tolerances.

The threading process is particularly critical, as it directly affects the actuator’s efficiency and load-bearing capacity. The use of advanced techniques, such as heat treatment and surface hardening, further enhances the durability of the screw, allowing it to withstand high cyclic loads.

What Does the Assembly Process Entail for Ball Screw Actuators?

Following the forming stage, assembly takes place. This involves integrating the ball screw with the nut and other components such as the housing, end blocks, and bearings. During this stage, manufacturers pay close attention to the alignment and fit of parts to minimize friction and maximize performance.

Assembly often includes the installation of preloaded ball bearings, which are crucial for reducing backlash and ensuring smooth motion. In some cases, automated assembly systems are employed to enhance precision and efficiency.

Which Finishing Techniques Are Commonly Applied in Ball Screw Actuator Manufacturing?

The final stage of the manufacturing process is finishing, which includes surface treatments and protective coatings. Common finishing techniques include anodizing aluminum parts, applying anti-corrosion coatings, and polishing surfaces to reduce friction.

These finishing processes not only improve the actuator’s aesthetics but also enhance its resistance to environmental factors such as moisture, dust, and chemicals. This is particularly important for actuators used in harsh industrial environments.

How Is Quality Assurance Implemented in Ball Screw Actuator Manufacturing?

Quality assurance (QA) is a critical component in the manufacturing of ball screw actuators, ensuring that each unit meets international and industry-specific standards.

What Are the Relevant International Standards for Ball Screw Actuator Quality?

Manufacturers often adhere to international standards such as ISO 9001, which outlines quality management systems. This certification indicates that a manufacturer follows best practices in quality control and customer satisfaction. Additionally, industry-specific standards like CE marking for European markets and API standards for oil and gas applications may apply, depending on the actuator’s end use.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to identify and rectify any potential issues. Common QC checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitoring during the manufacturing stages, including dimensional checks and functionality tests.

- Final Quality Control (FQC): Comprehensive testing of the completed actuator, including load tests, movement precision, and operational checks.

What Testing Methods Are Commonly Used to Ensure Quality?

Testing methods vary but typically include:

- Load Testing: Evaluating the actuator’s performance under specified loads to ensure it meets operational requirements.

- Precision Testing: Measuring travel accuracy and repeatability to confirm the actuator performs as expected.

- Environmental Testing: Assessing the actuator’s performance in different conditions, such as temperature extremes and exposure to contaminants.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance processes is paramount. Here are several strategies to ensure supplier reliability:

What Steps Can Buyers Take to Conduct Supplier Audits?

Buyers can request audits of the supplier’s manufacturing facilities to evaluate their quality control systems and processes. This includes reviewing documentation related to compliance with international standards and assessing the implementation of QA practices.

How Can Buyers Access Quality Reports and Certifications?

Requesting access to quality reports, certifications, and test results can provide insights into the supplier’s commitment to quality. Most reputable manufacturers maintain detailed records of inspections and testing, which can be shared with prospective buyers.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality assurance processes. These agencies conduct independent evaluations, ensuring that the products meet the agreed-upon specifications and standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers should also be aware of specific nuances related to quality control. Different regions may have varying standards and regulations, which can affect product acceptance in specific markets. Understanding these differences is crucial for ensuring compliance and avoiding potential delays in product acceptance.

In conclusion, the manufacturing processes and quality assurance protocols for ball screw actuators are designed to ensure high-performance and reliable products. By understanding these processes, B2B buyers can make informed decisions and choose suppliers that meet their rigorous standards for quality and performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ball screw actuator’

In the competitive landscape of industrial automation, sourcing a reliable ball screw actuator can significantly influence operational efficiency and product quality. This guide provides a clear checklist to help B2B buyers navigate the procurement process effectively, ensuring that they select the best products for their specific applications.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s essential to outline your technical requirements. Consider factors such as load capacity, stroke length, and environmental conditions where the actuator will be used.

– Payload Requirements: Determine the maximum load the actuator will need to handle.

– Stroke Length: Assess the distance over which the actuator must operate to ensure it meets your application needs.

Step 2: Research Available Options

Conduct thorough research on the types of ball screw actuators available in the market. Understand the differences between various models, such as those with V-roller guides or traditional designs, and identify which features align with your operational requirements.

– Application Suitability: Ensure the actuator is suitable for your specific use case, such as industrial automation, robotics, or material handling.

– Performance Metrics: Look for performance indicators like speed, efficiency, and precision to narrow down your choices.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet potential suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Supplier Reputation: Research supplier reviews and industry standing to gauge reliability.

– Customer Support: Evaluate the level of technical support and after-sales service they provide.

Step 4: Verify Compliance and Certifications

Ensure that the ball screw actuators meet industry standards and regulatory requirements relevant to your market. This step is vital for ensuring product safety and performance.

– International Standards: Look for certifications such as ISO, CE, or specific industry-related standards that demonstrate quality assurance.

– Regional Compliance: Verify if the products comply with local regulations, especially if sourcing from international suppliers.

Step 5: Request and Analyze Quotes

Once you have shortlisted suppliers, request detailed quotes. Analyze these quotes carefully, not just for pricing but also for terms of service and warranty.

– Total Cost of Ownership: Consider not just the upfront cost but also maintenance, operational efficiency, and potential downtime costs.

– Warranty and Support Terms: Ensure that the warranty covers critical components and that support is readily available in your region.

Step 6: Conduct a Trial or Pilot Test

If possible, conduct a trial or pilot test of the selected ball screw actuator in your operational environment. This step can provide invaluable insights into its performance and compatibility.

– Performance Evaluation: Monitor its operation under real conditions to assess reliability and efficiency.

– Feedback Loop: Gather input from your team regarding ease of integration and usability.

Step 7: Finalize the Purchase Agreement

Once satisfied with the trial, finalize your purchase agreement. Ensure all terms are clearly stated, including delivery timelines, payment terms, and return policies.

– Documentation: Keep all agreements and specifications documented for future reference.

– Logistics Coordination: Plan the logistics of delivery and installation to minimize downtime during the transition.

By following this checklist, B2B buyers can ensure a systematic and informed approach to sourcing ball screw actuators that meet their specific needs and enhance operational efficiency.

Comprehensive Cost and Pricing Analysis for ball screw actuator Sourcing

What Are the Key Cost Components in Ball Screw Actuator Manufacturing?

When sourcing ball screw actuators, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly influences the actuator’s performance and durability. Common materials include high-strength aluminum for housings, hardened steel for screws, and various composites for internal components. The cost can vary based on the quality and sourcing of these materials.

-

Labor: Labor costs include the wages of skilled workers involved in manufacturing and assembly. Regions with lower labor costs may offer more competitive pricing, while areas with higher labor standards might yield better quality but at a premium.

-

Manufacturing Overhead: This encompasses indirect costs related to production, such as utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help minimize overhead, which in turn can affect pricing.

-

Tooling: Custom tooling for specific actuator designs or features can add significant upfront costs. However, these costs can be amortized over larger production runs, making them less impactful per unit for high-volume orders.

-

Quality Control (QC): Implementing rigorous quality control processes ensures that actuators meet specified performance standards. While these processes can increase costs, they ultimately enhance reliability and reduce long-term failure rates.

-

Logistics: Shipping costs and the mode of transportation play a vital role in the total cost. International shipments may incur additional fees such as customs duties and taxes, which must be factored into the overall pricing.

-

Margin: Suppliers typically add a profit margin to the total costs, which can vary based on market demand, competition, and the supplier’s positioning in the market.

How Do Pricing Influencers Affect Ball Screw Actuator Costs?

Several factors can influence the pricing of ball screw actuators:

-

Volume/MOQ: Purchasing in bulk can significantly reduce per-unit costs. Suppliers often have minimum order quantities (MOQs) that must be met to secure lower pricing.

-

Specifications and Customization: Custom specifications such as stroke length, load capacity, and integration with existing systems can increase costs. Standardized products are typically less expensive due to economies of scale.

-

Materials and Quality Certifications: Higher-quality materials and certifications (ISO, CE, etc.) can enhance product reliability but also increase costs. Buyers should weigh the benefits of these certifications against their budget constraints.

-

Supplier Factors: Reputation, reliability, and service levels of suppliers can affect pricing. Established suppliers may charge more but offer better support and product guarantees.

-

Incoterms: The choice of Incoterms (International Commercial Terms) can significantly impact logistics costs and responsibilities. Understanding these terms is essential for international buyers to avoid unexpected expenses.

What Tips Can Help Buyers Navigate Cost-Efficiency and Pricing Nuances?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, the following strategies can enhance cost-efficiency:

-

Negotiate Pricing: Engaging in negotiation can lead to better pricing, especially for large orders. Establishing a good relationship with suppliers can also provide leverage in negotiations.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but the long-term costs associated with maintenance, potential failures, and replacement parts. A lower initial cost may lead to higher TCO if the product is less reliable.

-

Understand Pricing Nuances: Different regions may have varying pricing structures due to local economic conditions. Be aware of currency fluctuations, tariffs, and local market demands when sourcing internationally.

-

Request Detailed Quotes: Ask suppliers for itemized quotes that break down costs for materials, labor, and logistics. This transparency can help you make better comparisons and identify areas for potential savings.

In conclusion, understanding the comprehensive cost structure and the factors influencing pricing can empower B2B buyers to make strategic sourcing decisions when procuring ball screw actuators. Always keep in mind that prices are indicative and can vary based on market conditions and specific project requirements.

Alternatives Analysis: Comparing ball screw actuator With Other Solutions

Exploring Alternatives to Ball Screw Actuators: A Comparative Analysis

In the landscape of industrial automation and motion control, ball screw actuators serve as a reliable solution for precision and efficiency. However, it’s essential for B2B buyers to explore viable alternatives that may offer similar or superior benefits depending on the application requirements. This section compares ball screw actuators with lead screw actuators and belt-driven actuators, highlighting their unique features and trade-offs.

| Comparison Aspect | Ball Screw Actuator | Lead Screw Actuator | Belt-Driven Actuator |

|---|---|---|---|

| Performance | High precision and efficiency; suitable for high-duty cycles | Moderate precision; effective for lower loads | High speed; good for rapid movements |

| Cost | Higher initial investment | Generally lower cost | Variable cost depending on design |

| Ease of Implementation | Moderate; requires careful alignment and setup | Easy to implement; fewer components | Simple to set up; often modular |

| Maintenance | Requires regular lubrication and inspection | Low maintenance; fewer parts | Low maintenance; belts may need replacement |

| Best Use Case | Robotics, industrial automation | Light to medium load applications | High-speed applications, packaging |

In-Depth Analysis of Alternatives

Lead Screw Actuators

Lead screw actuators utilize a screw mechanism to convert rotary motion into linear motion. They are generally less expensive than ball screw actuators and are simpler to implement, making them an attractive choice for applications with lower load requirements. While they offer adequate precision, they may not match the high efficiency and speed of ball screws, especially in demanding environments. The low maintenance requirement is a significant advantage, but they may not be suitable for high-cycle applications due to wear over time.

Illustrative image related to ball screw actuator

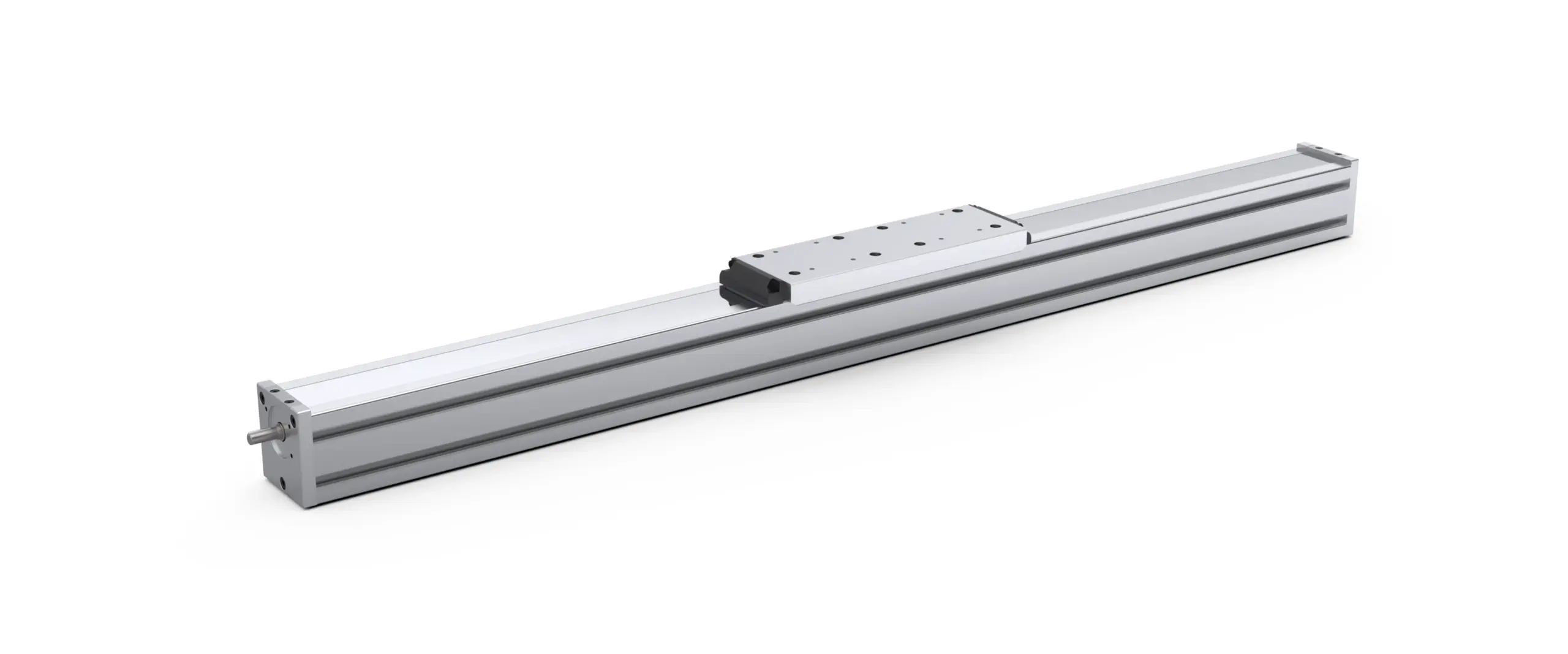

Belt-Driven Actuators

Belt-driven actuators operate on a pulley system, translating rotational motion into linear movement. They excel in applications requiring high speed and rapid movements, such as in packaging and assembly lines. The simplicity of their design allows for quick setup and modularity, which is beneficial for adaptable manufacturing processes. However, while they can achieve high speeds, they may compromise on precision and load capacity compared to ball screw actuators. Additionally, belts may require periodic replacement, adding to long-term maintenance considerations.

Making the Right Choice: How to Select the Best Solution

When choosing between ball screw actuators and their alternatives, B2B buyers should consider specific application requirements, including load capacity, precision, speed, and budget constraints. For applications demanding high precision and reliability, ball screw actuators are often the best choice despite their higher cost. Conversely, for lighter applications or those prioritizing cost-effectiveness and ease of implementation, lead screw or belt-driven actuators may be more suitable. Assessing long-term maintenance needs and operational efficiency can further guide buyers toward selecting the actuator that aligns with their business objectives.

Essential Technical Properties and Trade Terminology for ball screw actuator

What Are the Key Technical Properties of Ball Screw Actuators?

When considering ball screw actuators for industrial applications, understanding their technical properties is essential for making informed purchasing decisions. Here are some critical specifications to consider:

Illustrative image related to ball screw actuator

-

Material Grade

Ball screw actuators are typically constructed from high-strength materials such as stainless steel or aluminum alloys. The choice of material affects durability, weight, and resistance to environmental factors. For example, stainless steel offers excellent corrosion resistance, making it ideal for applications in humid or corrosive environments, which is particularly relevant for industries in regions like the Middle East and South America. -

Lead and Pitch

The lead refers to the distance the nut moves with one complete turn of the screw, while pitch is the distance between threads. A smaller lead provides higher precision but slower movement, while a larger lead allows for faster operation but can sacrifice precision. B2B buyers should match the lead and pitch with their application requirements—industrial automation might prioritize speed, while robotics could demand precision. -

Load Capacity

This property defines the maximum load the actuator can handle without failure. Load capacity is crucial for selecting the right actuator for specific applications, especially in material handling and automation systems. Buyers should consider the dynamic and static load ratings to ensure the actuator meets operational demands without compromising safety. -

Stroke Length

Stroke length indicates the maximum distance the actuator can travel. This specification is vital for applications that require extensive movement, such as in assembly lines or packaging machinery. A longer stroke length allows for more versatility in design but may require more space for installation, which is a critical consideration for space-constrained environments. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. High tolerance levels lead to improved accuracy and performance in applications. In B2B contexts, tight tolerances are often necessary for precision engineering applications, ensuring that components fit together correctly and operate smoothly. -

Speed

The operational speed of a ball screw actuator is a key performance indicator, affecting overall system efficiency. Speed specifications can vary widely; thus, understanding the required speed for specific tasks—such as fast-paced assembly operations—is essential for buyers to ensure compatibility with existing systems.

What Common Trade Terms Should B2B Buyers Know?

Familiarity with industry jargon can significantly enhance communication and negotiation in B2B transactions. Here are some common trade terms relevant to ball screw actuators:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that manufactures products that are used as components in another company’s product. Understanding OEM relationships can help buyers identify reliable suppliers and ensure that they are sourcing quality parts designed for compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand as it impacts purchasing decisions, particularly for businesses looking to manage inventory costs or those needing smaller quantities for prototyping or testing. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. This process is vital for buyers to obtain competitive pricing and terms from multiple suppliers, facilitating better decision-making. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in the shipping of goods. Familiarity with these terms helps buyers understand shipping costs, risk allocation, and delivery responsibilities, which is particularly important for international transactions. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is essential for planning production schedules and inventory management, especially in industries that rely on just-in-time manufacturing processes. -

CAD (Computer-Aided Design)

CAD refers to the use of software to create precise drawings and technical illustrations. Suppliers often provide CAD files for their products, allowing buyers to visualize how components will fit into their designs, which can streamline the engineering process.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement strategies and optimize their selection of ball screw actuators for various applications.

Navigating Market Dynamics and Sourcing Trends in the ball screw actuator Sector

What Are the Current Market Dynamics and Key Trends in the Ball Screw Actuator Sector?

The ball screw actuator market is experiencing significant growth driven by the increasing demand for automation across various industries such as manufacturing, robotics, and material handling. As global supply chains become more interconnected, international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are seeking reliable and efficient motion control solutions. The trend toward Industry 4.0 and smart manufacturing is reshaping sourcing strategies, leading companies to prioritize high-precision and durable actuators that can withstand demanding applications.

Emerging technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) are influencing the design and functionality of ball screw actuators, making them smarter and more adaptable. Buyers are increasingly looking for actuators that integrate seamlessly with advanced control systems, providing real-time feedback and enhanced operational efficiency. Additionally, customization options are gaining traction, allowing buyers to configure actuators to meet specific application requirements, which is crucial for projects in diverse environments.

Another key trend is the growing focus on cost-effectiveness and operational efficiency. With manufacturers under pressure to reduce production costs, the demand for reliable yet economical solutions is rising. This has led to increased competition among suppliers, prompting them to innovate and improve product offerings. As international buyers evaluate potential suppliers, they are looking for those who can provide not just competitive pricing but also superior quality and service.

How Is Sustainability Influencing Sourcing Decisions in the Ball Screw Actuator Sector?

Sustainability is becoming a critical factor in the decision-making process for international B2B buyers. The environmental impact of manufacturing processes and the importance of ethical sourcing are at the forefront of corporate social responsibility initiatives. Buyers are increasingly scrutinizing the supply chains of their suppliers, seeking transparency and adherence to sustainable practices.

In the ball screw actuator sector, manufacturers are adopting green certifications and utilizing eco-friendly materials to reduce their carbon footprint. This includes using recyclable materials and energy-efficient production processes. Buyers from regions with stringent environmental regulations, such as Germany, are particularly focused on sourcing products that comply with these standards.

Moreover, the push for sustainability is encouraging innovation in product design. Suppliers are developing ball screw actuators that not only meet performance requirements but also minimize waste and energy consumption. By choosing suppliers who prioritize sustainability, B2B buyers can enhance their brand reputation and align with the growing consumer demand for environmentally responsible products.

Illustrative image related to ball screw actuator

What Is the Historical Context of Ball Screw Actuators in B2B Applications?

The evolution of ball screw actuators can be traced back to the mid-20th century when they were first introduced as a means to convert rotary motion into linear motion with high efficiency and precision. Originally designed for aerospace and military applications, their versatility soon led to widespread adoption in various industrial sectors.

Over the decades, advancements in materials and manufacturing techniques have significantly improved the performance and reliability of ball screw actuators. The introduction of computer-aided design (CAD) and simulation tools has enabled manufacturers to optimize actuator designs, leading to better load capacities and operational efficiencies.

As industries continue to evolve, the ball screw actuator has established itself as a fundamental component in automation and robotics, providing the precision and durability required for modern applications. This historical context underscores the importance of understanding both technological advancements and market dynamics when making sourcing decisions in today’s competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of ball screw actuator

-

How do I choose the right ball screw actuator for my application?

Choosing the right ball screw actuator involves understanding your specific application requirements, including load capacity, stroke length, speed, and precision. Evaluate the environmental conditions, such as temperature and exposure to contaminants, to ensure compatibility. Additionally, consider the actuator’s mounting options and integration with existing systems. Engaging with manufacturers for customization options can also help tailor the actuator to your needs, ensuring optimal performance in your operational context. -

What factors should I consider when sourcing ball screw actuators internationally?

When sourcing ball screw actuators internationally, consider factors such as supplier reliability, product quality, and compliance with international standards. Research the supplier’s reputation through reviews and case studies. Additionally, assess lead times, shipping logistics, and potential tariffs or import regulations specific to your region. Establishing clear communication regarding specifications, warranties, and after-sales support is essential for a successful partnership. -

What are the typical lead times for ball screw actuators?

Lead times for ball screw actuators can vary significantly based on the manufacturer, customization requirements, and shipping location. Standard actuators may have lead times ranging from 2 to 4 weeks, while customized solutions can take 6 to 12 weeks or longer. To avoid delays, it’s advisable to confirm lead times during the initial inquiry and maintain open communication with the supplier throughout the production process. -

Are there minimum order quantities (MOQs) for ball screw actuators?

Minimum order quantities (MOQs) for ball screw actuators depend on the manufacturer and the specific actuator model. Some suppliers may have an MOQ to optimize production costs, while others may accommodate smaller orders for prototyping or testing purposes. Always inquire about MOQs upfront to ensure they align with your project requirements and budget, especially when sourcing from international suppliers. -

What payment terms are typical for international purchases of ball screw actuators?

Payment terms for international purchases of ball screw actuators often include options like advance payment, partial payments, or net payment terms (e.g., net 30, net 60). Terms can vary based on the supplier’s policies and your credit history with them. It’s crucial to negotiate terms that protect your financial interests while ensuring the supplier’s confidence in fulfilling the order. Consider using secure payment methods or letters of credit for larger transactions. -

How can I ensure quality assurance (QA) for my ball screw actuators?

To ensure quality assurance for ball screw actuators, request documentation such as certificates of compliance and quality control procedures from the supplier. Establish clear QA standards and inspection criteria before production begins. You may also consider third-party inspections to verify product specifications and performance before shipment. Regular communication with the supplier throughout the manufacturing process can help address any potential quality issues proactively. -

What customization options are available for ball screw actuators?

Customization options for ball screw actuators can include variations in stroke length, lead screw diameter, load capacity, and mounting configurations. Some manufacturers offer additional features such as integrated sensors, motor mounts, and specialized coatings for enhanced durability. Engage with the supplier’s engineering team early in the process to discuss your specific needs and explore available customization options that can optimize performance for your application. -

What are the logistics considerations when importing ball screw actuators?

When importing ball screw actuators, logistics considerations include shipping methods, transit times, and customs clearance processes. Choose a reliable freight forwarder familiar with handling industrial equipment to ensure smooth transport. Be aware of potential import duties, taxes, and compliance with local regulations in your destination country. Additionally, having a contingency plan for delays or issues during shipping can help mitigate risks associated with international logistics.

Top 7 Ball Screw Actuator Manufacturers & Suppliers List

1. McMaster – Ball Screw Actuators

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Ball Screw Actuators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. igus – Linear Module for Compact Spaces

Domain: igus.com

Registered: 1995 (30 years)

Introduction: This company, igus – Linear Module for Compact Spaces, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. KSS JAPAN – Miniature Ball Screws and Actuators

Domain: kssballscrew.com

Registered: 2010 (15 years)

Introduction: KSS JAPAN specializes in the manufacturing of Ball Screws and Actuators, focusing on miniature sizes (16mm or less in shaft diameter). Key products include: 1. Ball Screws for ISO(DIN) Standard: Conforming to ISO 3408-2 series1 / DIN 69051-5, featuring reinforced recirculating devices and optimized ball track for improved reliability and durability. 2. Flexible Link (FX Series): A compact sub-unit…

4. THK – Actuator Product Lineup

Domain: thk.com

Registered: 1995 (30 years)

Introduction: Actuator Product Lineup: 1. LM Guide Actuator (full-ball type) – Model KR: High rigidity and accuracy, ball screw lead options from 1 mm to 25 mm. 2. Caged Ball LM Guide Actuator – Model SKR: Higher speed, lower noise, maintenance-free operation. 3. LM Actuator Model GL-N: Lightweight aluminum base, Caged Ball LM Guides, screw or belt drive options, long-term maintenance-free. 4. LM Actuator Model…

5. Toyorobotics – Ball Screw Linear Actuator – ETH Series

Domain: toyorobotics.co

Registered: 2024 (1 years)

Introduction: {“product_name”: “Ball Screw Linear Actuator – ETH Series”, “features”: [“High accuracy and steady moment with secure reliability and quality”, “Stepper or Actuator with Motor can be used”, “Providing +/- 0.01 mm of repeatability”, “Can support payload from 5 Kg to 150 Kg”], “applications”: [“Electric device assembly”, “Liquid filling”, “Welding”, “Press fitting of circuit board and Waferbox”, “Un…

6. CMCO – High Efficiency Ball Screw Actuators

Domain: cmco.com

Registered: 1997 (28 years)

Introduction: This company, CMCO – High Efficiency Ball Screw Actuators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Tolomatic – Roller Screw Linear Actuators

Domain: tolomatic.com

Registered: 1996 (29 years)

Introduction: Tolomatic offers roller screw linear actuators designed for heavy-duty applications, featuring electric, high force, and low maintenance options. Key features include precision-ground threads that match multiple precision-ground rollers, providing efficient force transmission and increased contact area for higher force capability and longer life. The actuators are available in standard planetary r…

Strategic Sourcing Conclusion and Outlook for ball screw actuator

In today’s competitive landscape, strategic sourcing of ball screw actuators can significantly enhance operational efficiency and reduce costs for businesses across various sectors. By understanding the unique features and advantages of these actuators—such as high precision, durability, and versatility in demanding applications—international B2B buyers can make informed decisions that align with their specific automation needs.

The ability to customize actuator specifications, including stroke length and load capacity, allows for tailored solutions that optimize performance in industrial automation, robotics, and material handling. Moreover, prioritizing suppliers that offer robust support and quick lead times is essential for maintaining operational continuity and meeting project deadlines.

Illustrative image related to ball screw actuator

As industries in Africa, South America, the Middle East, and Europe continue to evolve, the demand for advanced motion control solutions is set to rise. Engaging with reputable manufacturers and leveraging innovative technologies will be crucial for staying ahead in this dynamic market. We encourage buyers to explore the diverse offerings available and consider the strategic implications of their sourcing decisions—positioning themselves for success in an increasingly automated future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.