Is Your Automatic Back Scratcher Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for automatic back scratcher

In today’s fast-paced world, sourcing effective and innovative solutions like the automatic back scratcher can present unique challenges for international B2B buyers. As the demand for ergonomic and user-friendly products rises across diverse markets, understanding the nuances of this niche category becomes essential. This guide serves as a comprehensive resource, delving into various types of automatic back scratchers, their applications, and the factors influencing their cost. By examining supplier vetting processes and market trends, we aim to equip buyers with the knowledge needed to make informed purchasing decisions.

With the growing interest in health and wellness products in regions such as Africa, South America, the Middle East, and Europe, the automatic back scratcher is poised to become a staple in both retail and commercial environments. In countries like Brazil and Nigeria, where cultural attitudes towards self-care and convenience are evolving, the potential market for these devices is significant. This guide not only highlights the best options available but also offers insights into market entry strategies and potential partnerships.

By providing actionable insights and expert recommendations, we empower B2B buyers to navigate the complexities of sourcing automatic back scratchers effectively, ensuring they can capitalize on emerging opportunities while meeting the needs of their customers.

Understanding automatic back scratcher Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Adjustable Back Scratcher | Extendable design with manual control | Retail, Spa & Wellness Centers | Pros: Cost-effective; Cons: Requires manual effort |

| Electric Rotating Back Scratcher | Automated rotation with multiple speed settings | Healthcare, Elderly Care Facilities | Pros: Easy to use; Cons: Higher initial investment |

| Smart App-Controlled Scratcher | Connects via smartphone for custom settings | Tech Retailers, Gadget Stores | Pros: Innovative; Cons: Dependence on technology |

| Compact Travel Back Scratcher | Portable, lightweight design | Travel Retail, Outdoor Equipment Suppliers | Pros: Convenient for travel; Cons: Limited features |

| Multi-Functional Back Scratcher | Combines scratching with massage features | Wellness Centers, Fitness Clubs | Pros: Versatile usage; Cons: Potentially higher price |

What Are the Key Characteristics of Manual Adjustable Back Scratchers?

Manual adjustable back scratchers are designed with an extendable arm, allowing users to reach various areas of the back. This type is particularly popular among retailers and wellness centers due to its simplicity and cost-effectiveness. B2B buyers should consider the durability of materials and ease of use, as these factors can significantly influence customer satisfaction. While they require manual effort, they are often seen as a practical choice for businesses looking to provide affordable solutions.

How Do Electric Rotating Back Scratchers Benefit Healthcare Facilities?

Electric rotating back scratchers offer automated rotation and adjustable speed settings, making them ideal for healthcare and elderly care facilities. These devices provide a hands-free experience, allowing patients to enjoy relief without assistance. When purchasing, B2B buyers should evaluate the reliability of the motor and battery life, as these are crucial for consistent performance. While they may involve a higher upfront cost, the convenience and therapeutic benefits can justify the investment.

Why Are Smart App-Controlled Scratchers Gaining Popularity?

Smart app-controlled back scratchers represent the latest trend in personal care technology, allowing users to customize their experience through smartphone connectivity. This type is particularly appealing to tech retailers and gadget stores looking to attract a tech-savvy clientele. B2B buyers should assess compatibility with various operating systems and the ease of app functionality, as these elements can impact user satisfaction. Although they offer innovative features, reliance on technology may deter some consumers.

What Makes Compact Travel Back Scratchers Ideal for Outdoor Retail?

Compact travel back scratchers are lightweight and designed for portability, making them perfect for outdoor equipment suppliers and travel retail. Their convenient design allows users to carry them easily, catering to the travel market’s demand for practical solutions. B2B buyers should focus on the quality of materials and the scratcher’s extendable length, as these factors enhance usability. While they excel in portability, they may lack some advanced features present in larger models.

How Do Multi-Functional Back Scratchers Enhance Wellness Offerings?

Multi-functional back scratchers that combine scratching with massage capabilities are increasingly popular in wellness centers and fitness clubs. These devices offer a comprehensive approach to relaxation and self-care, appealing to consumers looking for more than just a basic scratching tool. B2B buyers should evaluate the range of functionalities and ease of switching between modes. While they may come with a higher price tag, their versatility can attract customers seeking holistic wellness solutions.

Key Industrial Applications of automatic back scratcher

| Industry/Sector | Specific Application of Automatic Back Scratcher | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Patient Comfort in Hospitals | Enhances patient experience, reduces staff workload | Compliance with health regulations, easy to sanitize |

| Hospitality | Spa and Wellness Centers | Improves customer satisfaction and service quality | Durability, aesthetics, and portability |

| Retail | Product Demonstration in Stores | Engages customers, boosts product visibility | Cost-effectiveness, ease of use, and maintenance |

| Elderly Care Facilities | Assisted Living and Nursing Homes | Provides comfort to residents, promotes independence | Ergonomics, safety features, and ease of operation |

| Fitness and Rehabilitation | Physical Therapy and Rehabilitation Centers | Aids in recovery, enhances patient engagement | Customization options, durability, and portability |

How is the Automatic Back Scratcher Used in Healthcare Settings?

In healthcare environments, automatic back scratchers can significantly enhance patient comfort. They are particularly useful for patients with limited mobility, allowing them to relieve itchiness without assistance. This not only improves patient satisfaction but also reduces the workload on healthcare staff. B2B buyers in this sector should consider sourcing products that comply with health regulations and are easy to sanitize, ensuring both safety and hygiene.

What Role Does the Automatic Back Scratcher Play in Hospitality?

In the hospitality industry, especially within spas and wellness centers, automatic back scratchers are used to enhance the overall customer experience. They provide a unique and engaging service that can differentiate a facility in a competitive market. Buyers in this sector should prioritize durability and aesthetics, as these devices need to withstand frequent use while maintaining a pleasing appearance. Portability is also essential for easy integration into various service setups.

How Can Retailers Benefit from Automatic Back Scratchers?

Retailers can utilize automatic back scratchers as part of product demonstrations to engage customers and encourage purchases. By allowing customers to experience the product’s effectiveness firsthand, retailers can boost visibility and sales. Cost-effectiveness and ease of use are critical factors for B2B buyers in this sector, as they aim to maximize return on investment while providing an interactive shopping experience.

Why Are Automatic Back Scratchers Important in Elderly Care Facilities?

Automatic back scratchers serve a crucial role in elderly care facilities by providing residents with a means of personal comfort and promoting independence. This is particularly beneficial for individuals with limited mobility or dexterity. When sourcing these devices, B2B buyers should focus on ergonomics and safety features to ensure that they are user-friendly and minimize the risk of injury.

How Do Automatic Back Scratchers Aid in Fitness and Rehabilitation?

In fitness and rehabilitation centers, automatic back scratchers can assist in patient engagement during therapy sessions. They can help alleviate discomfort and enhance the overall recovery experience for patients. Buyers in this sector should look for customization options and durability to ensure that the devices can meet the diverse needs of their clientele while withstanding rigorous use.

3 Common User Pain Points for ‘automatic back scratcher’ & Their Solutions

Scenario 1: Difficulty in Meeting Diverse Consumer Needs

The Problem: B2B buyers often face the challenge of catering to a diverse customer base with varying needs when it comes to automatic back scratchers. For instance, some consumers may prefer a compact, portable design for travel, while others might seek more advanced features like adjustable length or multiple vibration settings. This variety can make it difficult for retailers to stock a selection that meets all customer preferences, potentially leading to lost sales and customer dissatisfaction.

The Solution: To address this challenge, B2B buyers should conduct comprehensive market research to understand the specific preferences of their target audience. Utilizing surveys, focus groups, or analyzing online reviews can provide insights into what features are most sought after. Buyers should then partner with manufacturers that offer customizable options or a broad product range. By diversifying their inventory to include various styles and functionalities, they can better meet consumer demands and enhance customer satisfaction. Additionally, leveraging online platforms for real-time feedback can guide future stocking decisions.

Scenario 2: Quality Control and Product Reliability Issues

The Problem: One of the prevalent issues that B2B buyers encounter is ensuring the quality and reliability of automatic back scratchers. Inconsistent product quality can lead to high return rates and damage brand reputation, especially if the back scratchers fail to meet customer expectations. Retailers might receive complaints regarding malfunctioning devices or inadequate durability, impacting their sales and customer trust.

The Solution: B2B buyers should prioritize sourcing from reputable manufacturers with a proven track record of quality control. Establishing strong relationships with suppliers who adhere to stringent manufacturing standards is crucial. Buyers can request product samples and conduct thorough testing before making bulk purchases. Additionally, implementing a quality assurance program that includes customer feedback loops can help identify and rectify any quality issues early on. This proactive approach not only enhances product reliability but also fosters brand loyalty among consumers.

Scenario 3: Navigating International Shipping and Import Regulations

The Problem: For B2B buyers operating in different regions, particularly in Africa, South America, the Middle East, and Europe, navigating the complexities of international shipping and import regulations can be daunting. Variations in tariffs, import duties, and compliance with local regulations can lead to unexpected costs and delays in product availability. This situation can hinder business operations and affect customer satisfaction.

The Solution: To effectively manage international shipping challenges, B2B buyers should invest in logistics partnerships with companies experienced in global trade. Understanding the specific import regulations for each target market is essential, so buyers must engage local experts or legal consultants who specialize in international commerce. Implementing a robust supply chain management system that tracks shipments and compliance can help mitigate risks associated with international logistics. Furthermore, maintaining open communication with suppliers regarding shipping times and potential delays can enhance transparency and improve customer relations. By taking these steps, buyers can streamline their import processes and ensure timely delivery of products to their customers.

Strategic Material Selection Guide for automatic back scratcher

What Are the Key Materials for Automatic Back Scratchers?

When selecting materials for automatic back scratchers, it is crucial to consider their properties, advantages, and limitations. The choice of material can significantly impact product performance, manufacturing processes, and market acceptance, especially in diverse regions such as Africa, South America, the Middle East, and Europe.

How Does Plastic Perform as a Material for Automatic Back Scratchers?

Plastic, particularly high-density polyethylene (HDPE) and polypropylene, is commonly used in the manufacturing of automatic back scratchers. These materials are lightweight, resistant to moisture, and can withstand a range of temperatures, making them suitable for various environments.

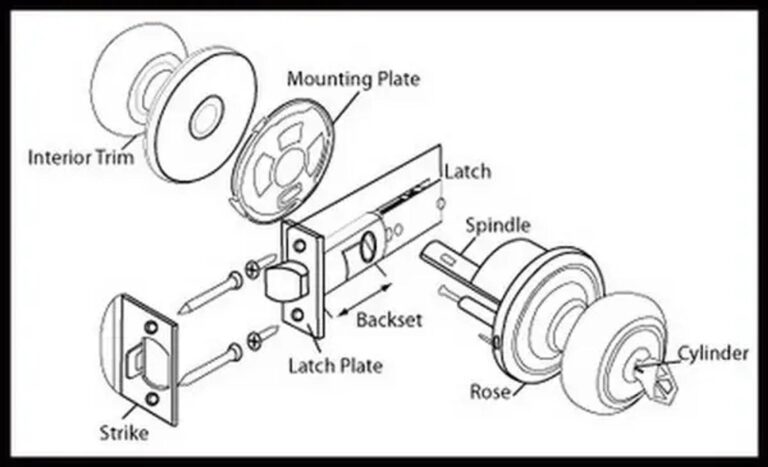

Illustrative image related to automatic back scratcher

Pros: Plastic is cost-effective and easy to mold into intricate shapes, allowing for innovative designs. It is also resistant to corrosion and does not rust, which is advantageous for durability.

Cons: However, plastics may not withstand extreme temperatures well and can become brittle over time. Additionally, they may not provide the same tactile experience as other materials, which could affect user satisfaction.

Impact on Application: In regions with high humidity, such as parts of Africa and South America, plastic’s moisture resistance is a significant advantage. However, compliance with local regulations regarding plastic usage and recycling should be considered.

What Are the Benefits of Using Metal in Automatic Back Scratchers?

Metals such as stainless steel and aluminum are often chosen for their strength and durability. Stainless steel, in particular, is known for its corrosion resistance and ability to maintain structural integrity under stress.

Pros: Metal back scratchers are robust and can withstand heavy use without deforming. They also offer a premium feel, which can enhance the product’s marketability in upscale segments.

Cons: The primary drawback is the higher cost of materials and manufacturing. Metal can be heavier than plastic, which might affect portability, especially in regions where consumers prefer lightweight products.

Impact on Application: In markets like Europe, where consumers may prioritize quality and durability, metal back scratchers can be more appealing. Compliance with standards such as ASTM for material quality is essential.

Why Choose Wood as a Material for Automatic Back Scratchers?

Wood is a traditional material that offers a unique aesthetic appeal and tactile experience. Common types include bamboo and hardwoods, which are often chosen for their natural properties.

Pros: Wood is biodegradable and can be marketed as an eco-friendly option, appealing to environmentally conscious consumers. It also provides a warm feel that enhances user experience.

Cons: However, wood can be susceptible to moisture, leading to warping or mold growth if not treated properly. Additionally, the manufacturing process can be more complex, increasing costs.

Impact on Application: In markets such as Brazil, where eco-friendliness is increasingly valued, wooden back scratchers can attract a niche audience. Compliance with local forestry and sustainability standards is crucial for market acceptance.

What Role Does Silicone Play in Automatic Back Scratchers?

Silicone is gaining popularity for its flexibility and comfort. This material is often used for the scratching surface due to its skin-friendly properties.

Pros: Silicone is durable, resistant to temperature extremes, and easy to clean, making it suitable for personal care products. It also provides a soft touch, enhancing user comfort.

Cons: On the downside, silicone can be more expensive than traditional materials and may require specialized manufacturing processes.

Impact on Application: In regions with high temperatures, such as parts of the Middle East, silicone’s heat resistance is advantageous. Buyers should ensure that silicone products comply with health and safety standards, which can vary by region.

Summary Table of Material Selection for Automatic Back Scratchers

| Material | Typical Use Case for automatic back scratcher | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Lightweight, portable back scratchers | Cost-effective and moisture-resistant | May become brittle over time | Low |

| Metal | High-end, durable back scratchers | Strong and corrosion-resistant | Heavier and more expensive | High |

| Wood | Eco-friendly, aesthetic back scratchers | Biodegradable and unique feel | Susceptible to moisture | Medium |

| Silicone | Flexible, comfortable scratching surfaces | Durable and skin-friendly | Higher manufacturing costs | Medium |

This guide provides a comprehensive overview of material options for automatic back scratchers, helping B2B buyers make informed decisions that align with market demands and regulatory requirements in their respective regions.

In-depth Look: Manufacturing Processes and Quality Assurance for automatic back scratcher

What Are the Main Stages of the Manufacturing Process for Automatic Back Scratchers?

The manufacturing process for automatic back scratchers involves several critical stages, each designed to ensure the final product is functional, durable, and appealing to consumers. The key stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality materials, which may include plastics, metals, and electronic components. This stage is crucial as the choice of materials affects both the durability and functionality of the back scratcher. Suppliers often conduct a thorough analysis of material properties, such as tensile strength and flexibility, to ensure they meet design specifications.

-

Forming: In this stage, raw materials are shaped into the desired components of the back scratcher. Techniques such as injection molding for plastic parts or stamping for metal components are commonly used. The forming process must be precise to ensure that all parts fit together seamlessly, which is essential for the automatic mechanisms to function correctly.

-

Assembly: After forming, the various components are assembled. This can be a manual or automated process, depending on the scale of production. Assembly lines may employ robotic systems to enhance efficiency and consistency. Quality control measures are implemented at this stage to ensure that all components are correctly fitted and that the automatic mechanisms operate smoothly.

-

Finishing: The final stage involves applying surface treatments, such as painting or coating, to enhance the aesthetic appeal and protect against wear and tear. This stage may also include the installation of batteries or electronic circuits, which are essential for the automatic functionality of the back scratcher. Proper finishing is vital, as it can significantly impact the product’s marketability.

What Quality Control Standards Should B2B Buyers Consider for Automatic Back Scratchers?

Quality assurance is a fundamental aspect of manufacturing automatic back scratchers, particularly for B2B buyers who prioritize product reliability and compliance with international standards. Key quality control standards include ISO 9001, CE marking, and industry-specific certifications.

-

ISO 9001: This international standard outlines the criteria for a quality management system (QMS). Companies that adhere to ISO 9001 demonstrate their commitment to quality and continuous improvement. B2B buyers should verify that their suppliers are certified, as this indicates a structured approach to quality management.

-

CE Marking: For products sold in the European market, CE marking is essential. It signifies that the product meets EU safety, health, and environmental protection standards. B2B buyers in Europe should ensure that their suppliers can provide CE certification, as it is a legal requirement for market entry.

-

API Certification: For back scratchers that include medical claims or components, obtaining certification from the American Petroleum Institute (API) or similar bodies may be necessary. This certification ensures that the product meets specific safety and quality standards relevant to its use.

What Are the Key Quality Control Checkpoints During Manufacturing?

To maintain high standards throughout the manufacturing process, several quality control checkpoints should be established. These include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC): Before production begins, raw materials and components are inspected for quality. This process ensures that only materials meeting the required specifications are used, reducing the likelihood of defects in the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to monitor the quality of components and assembly. This stage may involve random sampling and testing to ensure that the manufacturing process adheres to established quality standards.

-

Final Quality Control (FQC): Once assembly is complete, a comprehensive inspection is performed on the finished products. This may include functional testing of the automatic mechanisms, visual inspections for aesthetic defects, and compliance checks with relevant safety standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is crucial. Here are some actionable strategies:

-

Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to evaluate their manufacturing processes and quality control systems firsthand. This can provide insights into the supplier’s adherence to international standards and their overall commitment to quality.

-

Quality Reports: Requesting detailed quality reports can help buyers assess a supplier’s track record in terms of defect rates, compliance with standards, and results from previous quality inspections. These reports should also include data on corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. These inspections can be particularly beneficial for buyers who are unable to perform their own audits due to geographical constraints.

What Quality Control and Certification Nuances Should International Buyers Be Aware Of?

International B2B buyers must navigate several nuances when it comes to quality control and certification. Understanding these complexities can facilitate smoother transactions and ensure compliance with local regulations.

-

Regional Regulations: Different regions have varying standards and regulations regarding product safety and quality. Buyers from Africa and South America, for instance, should familiarize themselves with local standards, which may differ significantly from those in Europe or the Middle East.

-

Documentation Requirements: Buyers should be aware of the documentation required for customs clearance and market entry in different regions. This includes certificates of compliance, safety data sheets, and product specifications. Suppliers should be able to provide these documents as part of their quality assurance process.

-

Cultural Considerations: Cultural differences can impact expectations around quality and reliability. Buyers should consider these factors when assessing suppliers and establishing quality standards that meet both local expectations and international benchmarks.

By understanding the manufacturing processes and quality assurance protocols for automatic back scratchers, B2B buyers can make informed decisions, ensuring they source products that meet their quality standards and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automatic back scratcher’

In the competitive landscape of sourcing automatic back scratchers, having a clear and systematic approach can greatly enhance your procurement process. This guide outlines essential steps to ensure you find the right products and suppliers, tailored to your specific market needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, outline the specific features and functionalities you require in an automatic back scratcher. Consider factors such as size, material, ergonomic design, and automation technology. This clarity will help you communicate your needs effectively to potential suppliers and ensure that the products meet your quality standards.

Step 2: Research Market Trends and Demand

Understanding the current market dynamics is critical for making informed purchasing decisions. Investigate trends in consumer preferences, pricing strategies, and emerging technologies related to automatic back scratchers. This knowledge will enable you to align your sourcing strategy with market demands, ensuring that you procure products that appeal to your target audience.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers to ensure they can meet your quality and delivery requirements. Request detailed company profiles, product catalogs, and references from existing clients, particularly those in similar industries or regions. Look for suppliers with a proven track record of reliability, quality, and innovation, as these factors will significantly impact your business operations.

- Check for Certifications: Ensure that suppliers have relevant industry certifications that guarantee product quality and safety.

- Assess Financial Stability: A financially stable supplier is more likely to fulfill orders consistently and handle potential challenges.

Step 4: Request Samples for Quality Assessment

Once you have shortlisted potential suppliers, request samples of the automatic back scratchers. Evaluating physical samples allows you to assess the product’s quality, functionality, and design firsthand. This step is vital to confirm that the products meet your specifications before committing to a larger order.

Illustrative image related to automatic back scratcher

Step 5: Negotiate Terms and Conditions

Engage in negotiations to establish favorable terms regarding pricing, payment schedules, and delivery timelines. Ensure that you discuss warranties, return policies, and after-sales support as part of the agreement. Clear and mutually beneficial terms will help foster a strong business relationship and minimize future disputes.

Step 6: Establish Logistics and Distribution Plans

Plan the logistics for importing and distributing the automatic back scratchers in your target markets. Consider factors such as shipping costs, customs regulations, and local distribution channels. A well-defined logistics strategy will streamline your supply chain, reducing lead times and enhancing customer satisfaction.

Step 7: Monitor Supplier Performance

After procurement, continuously monitor your suppliers’ performance against the agreed terms. Regularly review aspects such as delivery times, product quality, and responsiveness to issues. This ongoing evaluation will help you maintain a high standard of product offerings and adjust your sourcing strategy as necessary.

By following this structured checklist, B2B buyers can effectively navigate the complexities of sourcing automatic back scratchers, ensuring successful procurement that aligns with their business goals.

Comprehensive Cost and Pricing Analysis for automatic back scratcher Sourcing

What Are the Key Cost Components in Automatic Back Scratcher Sourcing?

When analyzing the cost structure of automatic back scratchers, several components play a critical role in determining the final pricing for B2B buyers.

-

Materials: The choice of materials significantly impacts the cost. Common options include plastics, metals, and electronic components for the automation feature. High-quality materials may increase initial costs but can enhance durability and user satisfaction, leading to higher sales.

-

Labor: Labor costs vary depending on the region of manufacturing. Countries with lower labor costs can provide competitive pricing, but this may come with trade-offs in quality and consistency. Assessing labor regulations and worker skill levels is essential when selecting suppliers.

-

Manufacturing Overhead: This includes costs related to facility operations, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize overhead costs, making it vital for buyers to evaluate the operational efficiency of potential suppliers.

-

Tooling: Depending on the complexity of the design, tooling costs can be significant. Custom designs or specialized features may require higher initial investments in tooling, which can affect the overall pricing structure.

-

Quality Control (QC): Implementing rigorous QC processes is essential for maintaining product standards. Higher QC standards may lead to increased costs but can prevent costly returns and dissatisfied customers in the long run.

-

Logistics: Shipping and handling costs vary based on the distance from the manufacturer to the buyer. International logistics can introduce complexities, including customs duties and tariffs, which should be factored into the total cost.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the typical margins in the industry can help buyers negotiate better deals and ensure they are not overpaying.

How Do Price Influencers Affect Automatic Back Scratcher Costs?

Several factors can influence the pricing of automatic back scratchers in the B2B marketplace:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders often lead to bulk discounts, making it advantageous for buyers to consolidate their purchases to achieve lower unit costs.

-

Specifications and Customization: Custom designs or specific features can increase costs. Buyers should clearly define their needs to avoid unnecessary expenses associated with custom tooling or materials.

-

Quality and Certifications: Products with recognized quality certifications typically command higher prices but can justify these costs through enhanced reliability and marketability.

-

Supplier Factors: The reputation and reliability of suppliers can influence costs. Established suppliers with a track record of quality may charge more, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the Incoterms agreed upon in the contract is crucial. Different terms can affect the total landed cost, including who is responsible for shipping and insurance, potentially impacting overall pricing.

What Tips Can Help B2B Buyers Negotiate Better Prices?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation and cost management strategies are essential:

-

Leverage Volume: Whenever possible, consolidate orders to meet or exceed MOQs. This can lead to significant savings and strengthen negotiating power.

-

Understand Total Cost of Ownership: Consider not just the purchase price but also factors like shipping, duties, and long-term reliability. A higher upfront cost might be justified if it leads to lower operational costs over time.

-

Negotiate Terms: Don’t hesitate to negotiate payment terms, delivery schedules, and other conditions that can enhance cash flow and reduce financial risks.

-

Research Market Trends: Stay informed about market trends and pricing fluctuations. This knowledge can provide leverage during negotiations and help in identifying the best time to place orders.

-

Build Relationships with Suppliers: Establishing long-term relationships with reliable suppliers can lead to better pricing, priority service, and access to exclusive products.

Disclaimer on Indicative Prices

Prices for automatic back scratchers can vary widely based on the factors discussed above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing. Always consider the nuances of international sourcing, including currency fluctuations and local market conditions.

Alternatives Analysis: Comparing automatic back scratcher With Other Solutions

Exploring Alternatives to Automatic Back Scratchers

When considering the purchase of an automatic back scratcher, it’s essential to evaluate other potential solutions that serve similar purposes. This analysis will compare automatic back scratchers with manual back scratchers and massage tools, focusing on performance, cost, ease of implementation, maintenance, and best use cases. By examining these alternatives, B2B buyers can make informed decisions tailored to their specific needs.

| Comparison Aspect | Automatic Back Scratcher | Manual Back Scratcher | Massage Tools |

|---|---|---|---|

| Performance | Consistent and adjustable | Variable effectiveness | Deep tissue relief |

| Cost | Moderate investment | Low cost | Varies widely |

| Ease of Implementation | Plug-and-play convenience | Simple to use | Requires some skill |

| Maintenance | Low maintenance | Minimal upkeep | Moderate upkeep |

| Best Use Case | Regular use for convenience | On-demand relief | Therapeutic sessions |

What are the Benefits and Drawbacks of Manual Back Scratchers?

Manual back scratchers are simple devices, often made of wood or plastic, that allow users to scratch their backs manually. The primary advantage of manual back scratchers is their affordability; they can be purchased for a fraction of the cost of automatic options. However, they require physical effort and may not provide consistent results for users with limited mobility. These scratchers are best suited for occasional relief rather than regular use.

How Do Massage Tools Compare to Automatic Back Scratchers?

Massage tools encompass a wide range of devices, including handheld massagers and foam rollers, designed to relieve muscle tension. They often provide a more comprehensive solution for discomfort and can be used on various body parts. The downside is that they may require more skill and knowledge to use effectively, and the cost can vary significantly based on the technology and features. For organizations focusing on overall wellness, massage tools can be an excellent investment, though they may not specifically address back scratching needs.

Why Choose an Automatic Back Scratcher for Your Business?

Automatic back scratchers offer a blend of convenience and effectiveness. With adjustable settings and ease of use, they cater to individuals seeking consistent relief without the physical strain associated with manual options. Although they represent a moderate investment, their low maintenance requirements and suitability for frequent use make them ideal for businesses that prioritize employee comfort and well-being.

How Can B2B Buyers Make the Right Choice?

When selecting the appropriate solution for back scratching needs, B2B buyers should assess their organization’s specific requirements. Consider the budget, frequency of use, and user demographics. If the goal is to provide quick relief for employees, a manual back scratcher might suffice. Conversely, for those looking to enhance overall comfort and wellness, investing in automatic back scratchers or massage tools could yield better long-term benefits. By weighing these factors, businesses can choose the best option to enhance employee satisfaction and productivity.

Essential Technical Properties and Trade Terminology for automatic back scratcher

What Are the Key Technical Properties of an Automatic Back Scratcher?

When evaluating automatic back scratchers for B2B procurement, several technical properties are critical to ensure product quality and usability. Here are some essential specifications to consider:

-

Material Composition

The material used in manufacturing back scratchers significantly impacts durability and user experience. Common materials include stainless steel, plastic, and silicone. Stainless steel offers strength and resistance to corrosion, while silicone provides flexibility and comfort against the skin. Understanding the material grade is crucial as it affects product longevity, maintenance needs, and user satisfaction. -

Extendable Length

The extendable length of an automatic back scratcher determines its versatility and user-friendliness. Products that can extend to a minimum of 20 inches are generally preferred, as they can accommodate users of varying heights and reach. This property is especially relevant in international markets where consumer preferences may differ. -

Weight and Portability

The weight of the back scratcher influences its portability, which is particularly important for users who may want to carry it for travel or outdoor activities. A lightweight design, ideally under 200 grams, is preferable, as it enhances user convenience without compromising structural integrity. This aspect can be a significant selling point in markets with a high demand for travel-friendly products. -

Power Source and Battery Life

Automatic back scratchers may operate on batteries or rechargeable power. Battery life is a critical specification, with a minimum of 30 hours of use being ideal for consumer satisfaction. B2B buyers should consider power options that align with regional electrical standards and availability, especially in developing markets. -

Safety Features

Safety is paramount when dealing with personal care devices. Features such as rounded edges, non-slip grips, and automatic shut-off mechanisms contribute to user safety. This is particularly important in markets where safety regulations may vary, and consumers are increasingly cautious about product safety.

Which Trade Terms Are Essential for Understanding Automatic Back Scratcher Procurement?

Understanding industry jargon is vital for effective communication and negotiation in the B2B landscape. Here are several key trade terms relevant to automatic back scratchers:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of automatic back scratchers, OEMs can be crucial partners for businesses looking to create branded products without investing in full-scale manufacturing. -

MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to ensure they meet the supplier’s requirements while also managing inventory and cash flow effectively. This is particularly relevant for small businesses or startups entering the automatic back scratcher market. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request pricing and terms from suppliers. This is an essential step in procurement, allowing businesses to compare offers and negotiate better deals. Providing detailed specifications in the RFQ can help suppliers deliver accurate quotations. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is crucial for international transactions, as they dictate who is responsible for costs and risks at various stages of the shipping process. This knowledge helps mitigate misunderstandings and financial disputes. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. In the automatic back scratcher industry, shorter lead times can provide a competitive edge, especially in markets where consumer demand fluctuates rapidly. B2B buyers should consider suppliers with reliable lead times to maintain inventory levels and meet market demands. -

Compliance Standards

Compliance standards refer to regulations that products must meet to be sold in specific markets. Understanding these standards is essential for B2B buyers to ensure that the products comply with local regulations, which can vary significantly across regions such as Africa, South America, the Middle East, and Europe. This is crucial for avoiding legal issues and ensuring consumer safety.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing automatic back scratchers, ensuring they meet market demands while also prioritizing quality and compliance.

Navigating Market Dynamics and Sourcing Trends in the automatic back scratcher Sector

What Are the Key Trends and Dynamics Influencing the Automatic Back Scratcher Market?

The automatic back scratcher market is gaining momentum globally, driven by increased consumer awareness about health and wellness, particularly in regions such as Africa, South America, the Middle East, and Europe. The rise of e-commerce and social media platforms, notably TikTok, has facilitated a surge in demand as innovative products gain visibility and traction among consumers. B2B buyers should pay attention to the growing trend of personalization, where companies are offering customizable back scratchers to meet diverse consumer preferences.

Additionally, technological advancements are shaping product features, with smart automatic back scratchers that integrate sensors or connectivity options becoming increasingly popular. These products not only enhance user experience but also provide valuable data for manufacturers regarding usage patterns. As a result, international buyers must consider suppliers who can keep pace with these technological innovations.

Another significant trend is the focus on affordability without compromising quality. As competition intensifies, manufacturers are exploring cost-effective materials and production methods, which can lead to better pricing strategies for B2B buyers. Understanding regional market dynamics, such as purchasing power and consumer behavior, is essential for buyers looking to source effectively in diverse markets like Brazil and Nigeria.

How Can Sustainability and Ethical Sourcing Impact the Automatic Back Scratcher Supply Chain?

Sustainability and ethical sourcing are increasingly becoming pivotal considerations for B2B buyers in the automatic back scratcher sector. As global awareness of environmental issues rises, businesses are scrutinizing the ecological impact of their supply chains. Buyers should prioritize suppliers that adopt sustainable practices, such as using eco-friendly materials and minimizing waste during production.

The demand for ‘green’ certifications is growing, with consumers actively seeking products that meet specific environmental standards. Certifications such as ISO 14001 (Environmental Management) or FSC (Forest Stewardship Council) can enhance a product’s marketability and appeal. B2B buyers should consider collaborating with manufacturers who emphasize transparency in their sourcing processes, ensuring that raw materials are sourced ethically and sustainably.

Moreover, companies that incorporate sustainability into their business models often see increased customer loyalty and brand reputation, which can lead to higher sales. As such, understanding the importance of ethical supply chains can not only align with corporate social responsibility goals but also provide a competitive advantage in the marketplace.

What Is the Evolution of the Automatic Back Scratcher Industry?

The automatic back scratcher has evolved significantly from its humble beginnings as a simple hand-held tool. Initially designed for personal comfort, these devices have transformed into sophisticated products equipped with various features, including ergonomic designs and automated functionalities.

Over the past decade, technological advancements have played a crucial role in this evolution, with innovations such as rechargeable batteries, adjustable lengths, and even smart capabilities that cater to modern consumer needs. The rise of online retail and social media has further accelerated this transformation, allowing for rapid feedback and iteration on product designs based on consumer preferences.

As the market continues to grow, understanding its history provides B2B buyers with insights into future trends, enabling them to make informed sourcing decisions that align with both consumer demands and technological advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of automatic back scratcher

-

How do I ensure the quality of automatic back scratchers from suppliers?

To ensure the quality of automatic back scratchers, it’s essential to conduct thorough supplier vetting. Request samples before placing bulk orders and verify that the products meet your specific quality standards. Look for suppliers who comply with international quality certifications, such as ISO or CE. Additionally, consider visiting manufacturing facilities if feasible or using third-party inspection services to assess quality control processes and product durability before shipment. -

What are the most important features to look for in an automatic back scratcher?

When sourcing automatic back scratchers, prioritize features such as adjustability, portability, and ease of use. Look for models with ergonomic designs to enhance user comfort and those that come with multiple scratching modes or speeds. Materials should be durable and hypoallergenic, especially if targeting markets with diverse consumer preferences. Incorporating technology, like rechargeable batteries or app connectivity, can also add value and attract modern consumers. -

What is the typical minimum order quantity (MOQ) for automatic back scratchers?

Minimum order quantities can vary significantly depending on the supplier and the customization options selected. Typically, MOQs for automatic back scratchers range from 100 to 1,000 units. Suppliers may offer lower MOQs for standard models but may require higher quantities for customized versions. Always clarify MOQ terms during negotiations to ensure they align with your purchasing strategy and market demands. -

What payment terms are standard for international B2B transactions involving automatic back scratchers?

Standard payment terms for international B2B transactions often include options like 30% upfront payment and 70% before shipment. Some suppliers may offer payment via letters of credit for larger orders, providing additional security. It’s crucial to negotiate payment terms that safeguard your investment while ensuring the supplier has sufficient incentive to fulfill the order. Always review and confirm all terms in a written contract to avoid misunderstandings. -

How can I customize automatic back scratchers for my brand?

Customization options for automatic back scratchers can include branding (logos and colors), design modifications, and feature enhancements. Most suppliers will work with you to create a product that aligns with your brand identity. Discuss your specific requirements during the initial stages of supplier engagement. Be prepared to provide detailed specifications and any necessary artwork for branding to ensure a seamless production process. -

What logistics considerations should I keep in mind when importing automatic back scratchers?

When importing automatic back scratchers, consider shipping methods, customs duties, and lead times. Air freight is faster but more expensive, while sea freight is cost-effective for large shipments but takes longer. Ensure you understand the customs regulations in your target market, including any import taxes or tariffs that may apply. Collaborate with a reliable freight forwarder who can help navigate logistics and ensure timely delivery. -

How can I assess the reliability of a supplier for automatic back scratchers?

To assess supplier reliability, start by checking their business licenses, certifications, and customer reviews. Request references from previous clients and verify their production capacity and delivery timelines. Engaging in direct communication and asking detailed questions about their manufacturing processes can also provide insights into their operations. Consider starting with a smaller order to evaluate their service quality before committing to larger purchases. -

What are the common challenges faced in sourcing automatic back scratchers internationally?

Sourcing automatic back scratchers internationally can present challenges such as language barriers, varying quality standards, and logistical issues. Different regions may have unique market demands, requiring adaptability in product offerings. Additionally, fluctuating shipping costs and customs regulations can impact pricing and delivery schedules. To mitigate these challenges, establish clear communication with suppliers and consider partnering with local agents who understand the market dynamics in your target regions.

Top 1 Automatic Back Scratcher Manufacturers & Suppliers List

1. Target – Automatic Back Scratchers

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Automatic Back Scratchers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for automatic back scratcher

As the automatic back scratcher market continues to evolve, strategic sourcing remains a pivotal component for international B2B buyers. Understanding the dynamics of sourcing these innovative products can enhance competitiveness and meet the growing consumer demand across diverse regions, including Africa, South America, the Middle East, and Europe. Key takeaways emphasize the importance of selecting suppliers that not only deliver quality but also align with sustainability practices.

Investing in automated solutions, such as back scratchers that cater to ergonomic needs, can differentiate your offerings in a crowded marketplace. Additionally, leveraging data from social media trends and e-commerce platforms can inform purchasing decisions and identify potential market gaps.

Looking ahead, businesses should focus on fostering partnerships with manufacturers that prioritize innovation and reliability. This approach will not only streamline supply chains but also enhance customer satisfaction. We encourage B2B buyers to take proactive steps in evaluating their sourcing strategies, ensuring they are well-positioned to capitalize on emerging opportunities in this growing sector. Now is the time to engage with suppliers who are committed to innovation and quality, paving the way for a prosperous future in the automatic back scratcher market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to automatic back scratcher