Is Your Application Of Forging Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for application of forging

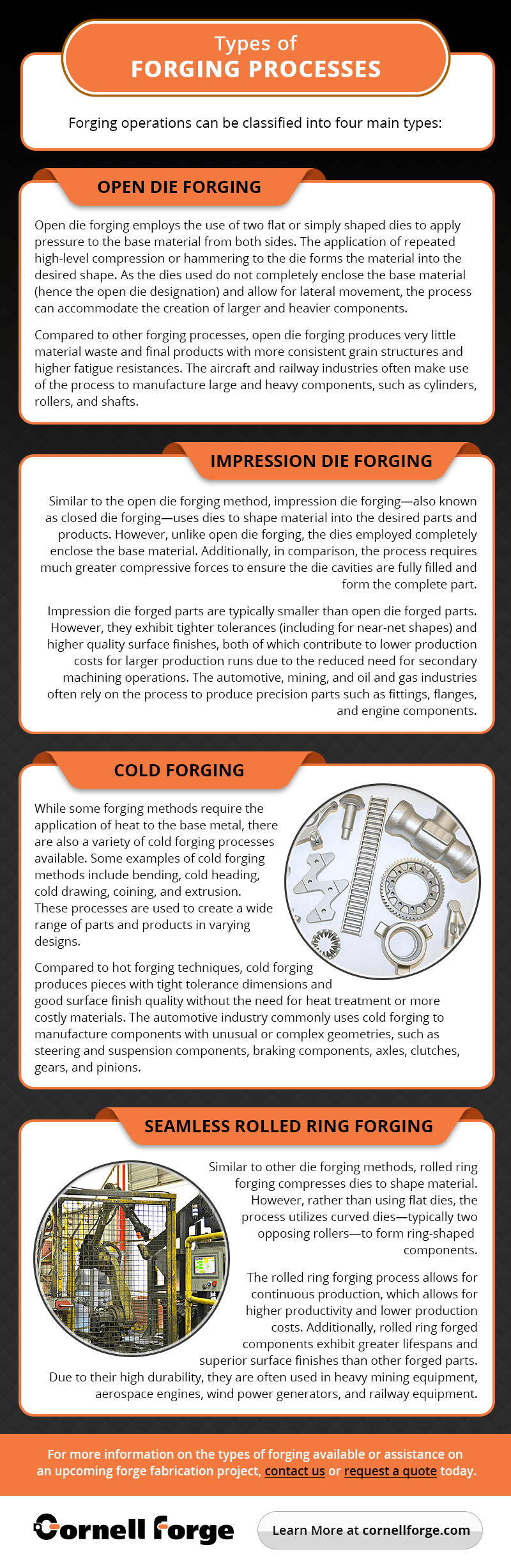

Navigating the complexities of sourcing forged components can be a daunting task for international B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe. The application of forging—a manufacturing process that shapes metal through compressive force—offers unparalleled durability and strength, making it a preferred choice for critical applications in industries such as aerospace, automotive, and construction. However, understanding the various types of forging processes, their specific applications, and the intricacies of supplier vetting can pose significant challenges.

This comprehensive guide delves into the nuances of metal forging, covering essential topics such as the different forging methods, material suitability, and the diverse applications that forged products serve. We will also discuss best practices for assessing suppliers, evaluating costs, and ensuring the quality of the forged components you procure. By equipping you with actionable insights and a deeper understanding of the forging landscape, this guide empowers B2B buyers to make informed purchasing decisions that align with their operational needs and strategic goals. Whether you’re sourcing for large-scale manufacturing or specialized projects, our resource serves as a valuable tool to navigate the global market effectively, ensuring you harness the full potential of forged metal components.

Understanding application of forging Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Open Die Forging | Utilizes a hammer to shape metal without enclosing it in a die. | Aerospace components, automotive parts, hand tools. | Pros: Cost-effective for low volumes. Cons: Less precision, may require secondary operations. |

| Closed Die Forging | Encloses the workpiece in dies, allowing for intricate shapes. | Precision components in automotive and aerospace industries. | Pros: High accuracy and strength. Cons: Higher initial costs, longer lead times. |

| Roll Forging | Uses opposing rolls to shape metal into continuous products. | Manufacturing of shafts, bars, and specialized profiles. | Pros: Efficient for long runs, minimal waste. Cons: Limited to specific shapes. |

| Press Forging | Applies constant pressure to deform metal uniformly. | Gears, crankshafts, and other complex parts. | Pros: Excellent for large volumes, uniform properties. Cons: Equipment costs can be high. |

| Precision Forging | Refines nearly finished products to exact specifications. | Aerospace, medical devices, and high-end automotive parts. | Pros: Reduces need for further machining. Cons: Requires specialized equipment. |

What are the characteristics of Open Die Forging and its applications?

Open die forging is characterized by its flexibility in shaping metal without enclosing it in a die. This method is particularly suitable for larger components or simpler shapes, making it ideal for applications in the aerospace and automotive industries, as well as for producing hand tools. B2B buyers should consider the cost-effectiveness of open die forging for lower volume runs, while being aware that this method may require secondary operations for achieving the desired finish and accuracy.

How does Closed Die Forging stand out in precision manufacturing?

Closed die forging, or impression die forging, involves enclosing the workpiece in two die halves, which allows for intricate shapes and high dimensional accuracy. This method is widely used in the production of precision components for the automotive and aerospace sectors. For B2B buyers, while the initial investment can be higher due to tooling costs, the strength and quality of the forged parts often justify the expense, especially for high-volume production.

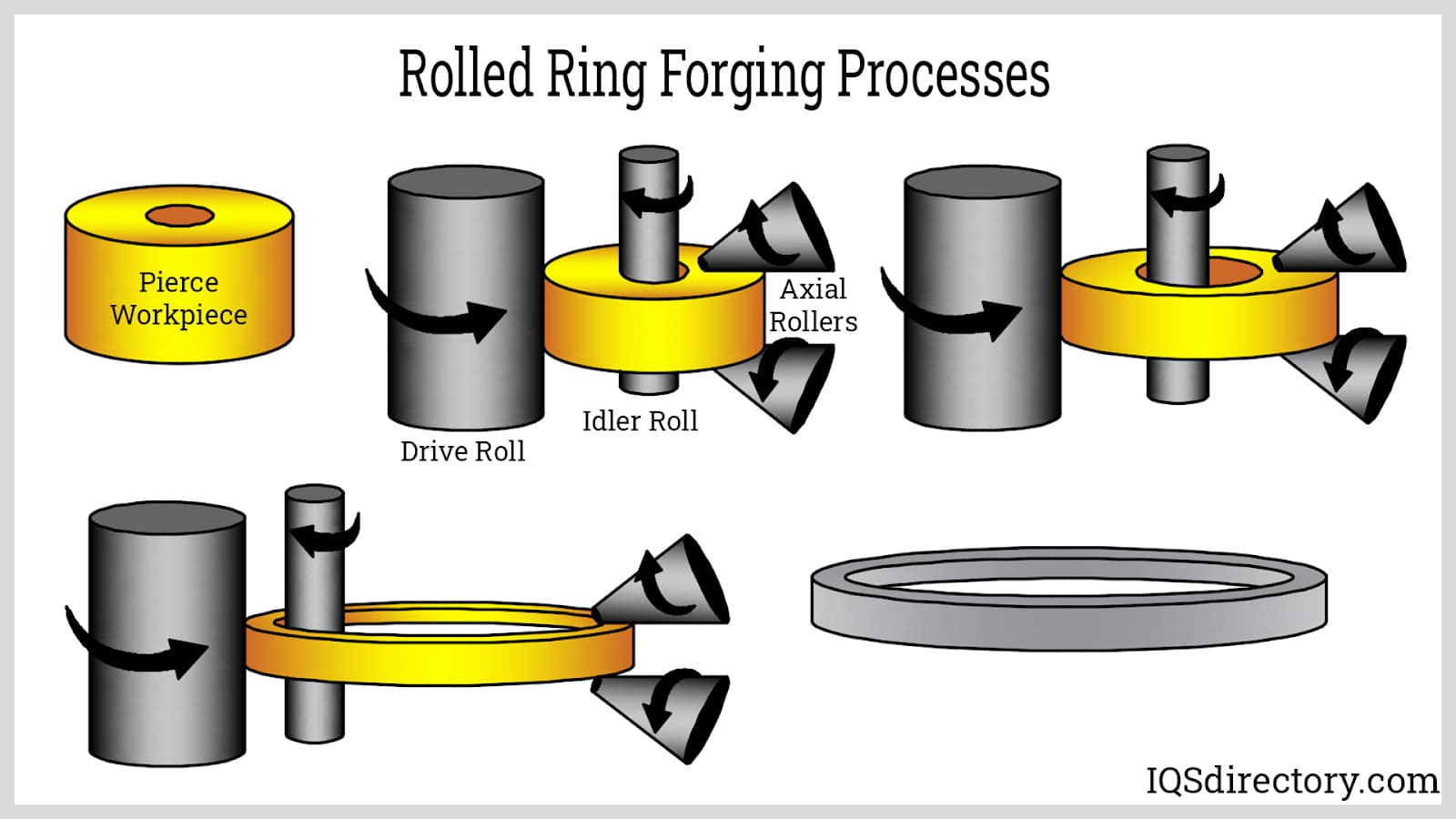

What makes Roll Forging an efficient option for continuous products?

Roll forging employs opposing rolls to shape metal into continuous forms, making it highly efficient for producing long products like shafts and bars. This method minimizes waste and is particularly advantageous for manufacturers looking to produce large quantities. B2B buyers should evaluate roll forging for its cost-effectiveness in long production runs, keeping in mind that it is limited to specific geometries and may not suit all applications.

Illustrative image related to application of forging

Why choose Press Forging for complex parts?

Press forging uses a constant pressure application to deform metal uniformly, making it suitable for producing complex parts like gears and crankshafts. This method is favored for its ability to create parts with consistent mechanical properties. B2B buyers should be aware of the potential high equipment costs but can benefit from the efficiency and uniformity this method offers for high-volume production.

What are the advantages of Precision Forging in high-end applications?

Precision forging is a refinement technique that focuses on achieving exact specifications for nearly finished products. This method is particularly important in industries such as aerospace and medical devices, where precision is critical. B2B buyers should consider precision forging for its ability to reduce subsequent machining needs, although they may need to invest in specialized equipment to achieve these benefits.

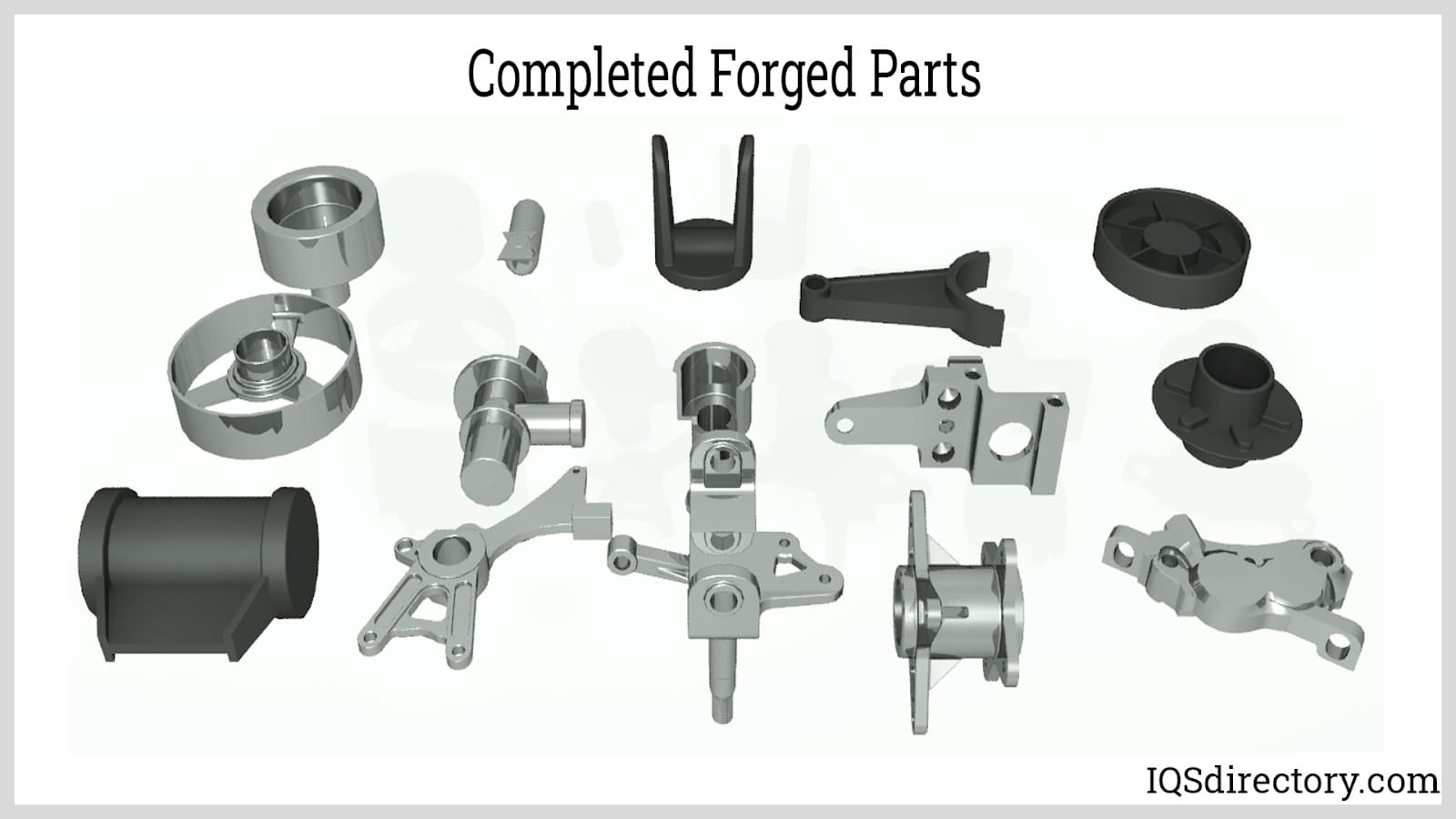

Key Industrial Applications of application of forging

| Industry/Sector | Specific Application of Forging | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of critical aircraft parts | Enhanced strength and durability, crucial for safety and performance | Certifications (e.g., AS9100), material traceability, quality assurance |

| Automotive | Production of crankshafts and gears | Improved fatigue resistance and performance under stress | Compliance with industry standards, cost efficiency, lead times |

| Oil & Gas | Forged components for drilling equipment | Ability to withstand extreme conditions and high pressures | Material specifications, supplier reliability, global sourcing options |

| Construction | Forging of structural components | High load-bearing capacity and longevity of materials | Local regulations, delivery timelines, and customization capabilities |

| Heavy Machinery | Production of large machine parts | Precision and strength for operational efficiency | Technical support, after-sales service, and maintenance agreements |

How is Forging Applied in Aerospace Manufacturing?

In the aerospace industry, forging is essential for producing critical components such as landing gear and turbine shafts. These parts must endure extreme conditions and high stresses, making the durability offered by forged metals invaluable. International buyers must prioritize suppliers with certifications like AS9100, ensuring adherence to stringent quality standards. Additionally, material traceability is crucial to guarantee that parts meet safety regulations, especially in regions where compliance is strictly monitored.

What Role Does Forging Play in Automotive Production?

Forging is widely used in the automotive sector for manufacturing components like crankshafts and gears, which require high strength and fatigue resistance. The forging process enhances the mechanical properties of these parts, ensuring reliability and performance in vehicles. B2B buyers in this industry should consider suppliers who can meet specific industry standards and provide cost-effective solutions while maintaining efficient lead times. This is particularly important in regions with competitive automotive markets.

How is Forging Utilized in the Oil & Gas Sector?

In the oil and gas industry, forging is critical for producing components that must withstand harsh environments, such as those found in drilling equipment. Forged parts offer superior strength and resistance to corrosion, making them ideal for high-pressure applications. Buyers should focus on sourcing materials that meet specific industry requirements and ensure suppliers can handle global sourcing challenges, particularly in emerging markets in Africa and South America.

Why is Forging Important for Construction Applications?

Forged structural components are vital in construction, providing high load-bearing capacity and durability. These parts are essential for the integrity and longevity of buildings and infrastructure. B2B buyers in construction must consider local regulations regarding material specifications and ensure timely delivery to avoid project delays. Customization capabilities can also be a deciding factor, as projects often require specific dimensions and designs.

How Does Forging Enhance Heavy Machinery Production?

In the heavy machinery sector, forging is used to create large, precision-engineered parts that are essential for operational efficiency. The strength and durability of forged components reduce the likelihood of failure, which is critical in high-demand applications. Buyers should look for suppliers that offer technical support and after-sales service to ensure long-term performance and reliability of the machinery, especially in regions where maintenance and service networks may be less developed.

3 Common User Pain Points for ‘application of forging’ & Their Solutions

Scenario 1: Challenges in Material Selection for Forging Applications

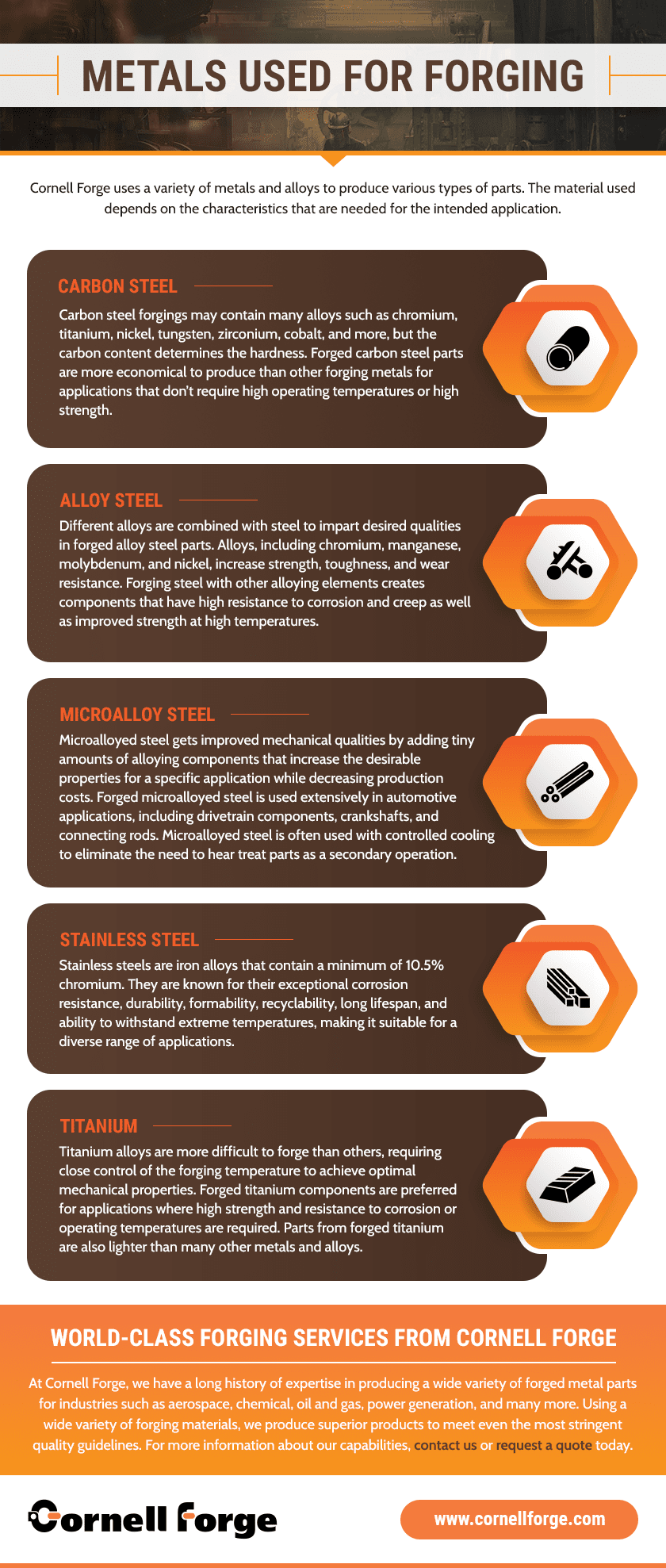

The Problem: One of the primary challenges B2B buyers face when applying forging techniques is selecting the right material for their specific needs. With various metals available, including carbon steel, alloy steel, aluminum, and titanium, it can be overwhelming to determine which material will yield the desired mechanical properties, such as strength, ductility, and resistance to fatigue. Additionally, buyers often struggle with the trade-offs between cost and performance, especially in industries like automotive or aerospace where the stakes are high.

Illustrative image related to application of forging

The Solution: To navigate material selection effectively, buyers should start by clearly defining the performance requirements of the final product, including load-bearing capacities and environmental conditions. Engaging in dialogue with suppliers can provide insights into the properties of different metals and their suitability for specific forging processes. It’s advisable to conduct small-scale trials with different materials before committing to large production runs. This approach not only helps in understanding the forging capabilities of the chosen metal but also allows for adjustments based on performance feedback, ensuring the final product meets all specifications without overspending on unnecessary material costs.

Scenario 2: High Costs Associated with Forging Equipment

The Problem: Another significant pain point for B2B buyers is the substantial investment required for forging equipment. High-capacity presses and hammers can be prohibitively expensive, particularly for smaller manufacturers or those entering the forging market. This financial burden can limit access to advanced forging technologies that enhance precision and efficiency, putting smaller firms at a competitive disadvantage.

The Solution: Buyers can mitigate equipment costs by exploring options such as leasing or sharing equipment with other manufacturers. Collaborative partnerships can lead to shared investments in high-capacity forging presses, reducing the financial risk for all parties involved. Additionally, considering contract forging services can provide access to state-of-the-art equipment without the need for a significant upfront investment. By outsourcing specific forging tasks, companies can focus their resources on core competencies while still benefiting from high-quality forged components.

Scenario 3: Difficulty in Achieving Consistent Quality in Forged Parts

The Problem: Achieving consistent quality in forged parts is a critical concern for B2B buyers, particularly in industries where precision and reliability are paramount, such as aerospace and automotive. Variability in the forging process can lead to defects, such as cracks or inclusions, which compromise the integrity of the final product. This inconsistency can result in costly rework or product recalls, significantly impacting a company’s reputation and bottom line.

Illustrative image related to application of forging

The Solution: To enhance quality consistency, buyers should prioritize working with established forging suppliers that have a proven track record of quality assurance. Implementing robust quality control measures throughout the forging process is essential. This includes conducting thorough inspections of raw materials, employing advanced monitoring technologies during production, and maintaining clear communication with suppliers regarding quality expectations. Additionally, establishing feedback loops for continuous improvement can help identify and rectify quality issues early in the process, ensuring that the final products meet stringent industry standards without incurring additional costs.

Strategic Material Selection Guide for application of forging

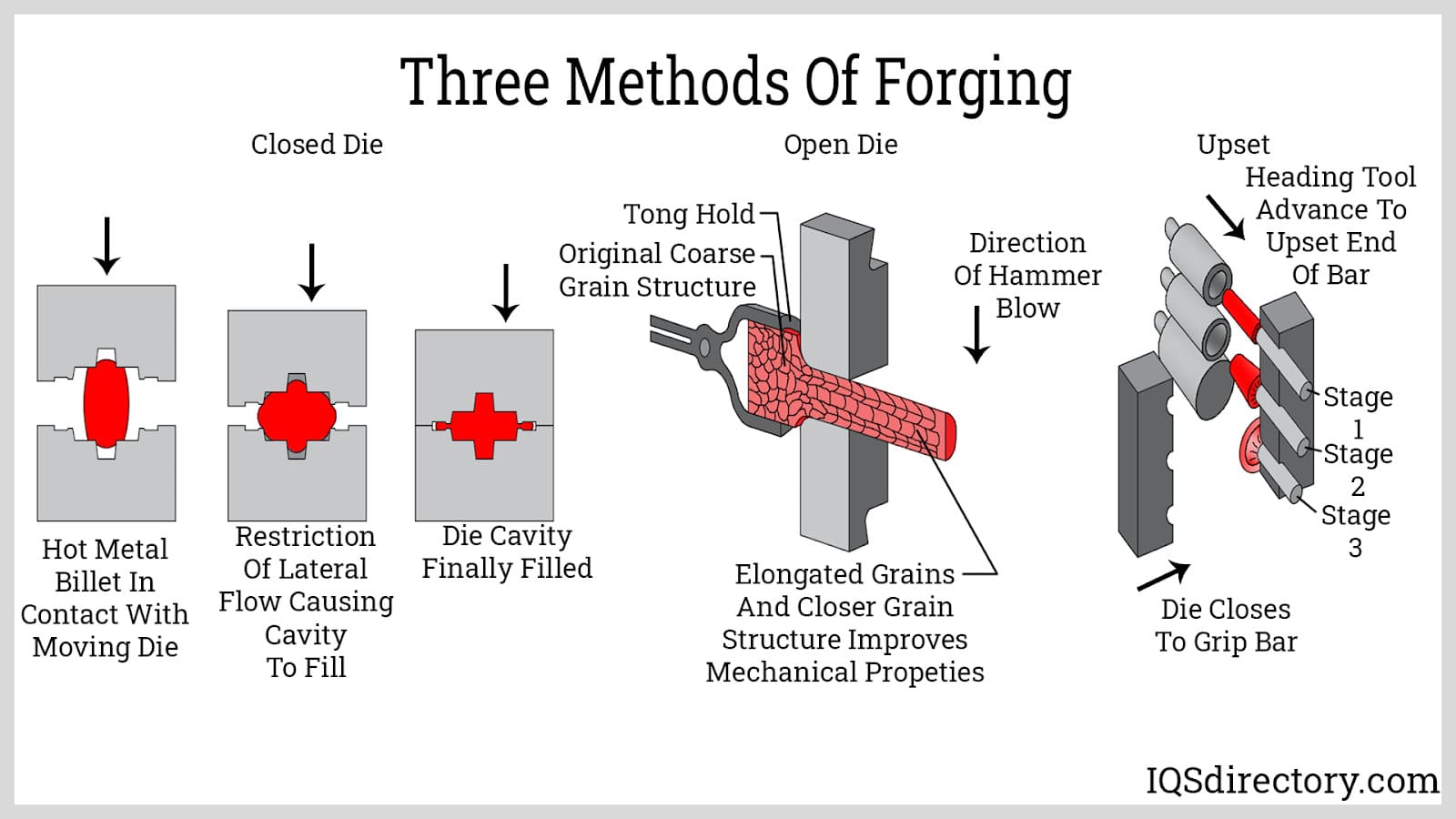

What Are the Key Properties of Carbon Steel in Forging Applications?

Carbon steel is one of the most commonly forged materials due to its excellent mechanical properties. It exhibits high tensile strength, good ductility, and the ability to withstand high temperatures and pressures. Carbon steel can be easily heat-treated to enhance its hardness and strength, making it suitable for demanding applications. However, it is prone to corrosion if not properly treated or coated, which can be a significant drawback in certain environments.

Pros and Cons of Using Carbon Steel

The primary advantages of carbon steel include its durability and cost-effectiveness, making it a preferred choice for large-scale manufacturing. It is relatively easy to forge, which simplifies the manufacturing process. However, the need for surface treatments to prevent corrosion can increase overall costs and complexity. Additionally, while carbon steel is versatile, it may not be suitable for applications requiring high corrosion resistance.

Impact on Application and Buyer Considerations

Carbon steel is widely used in automotive components, construction, and machinery. Buyers from regions like Africa and South America should consider local climate conditions, as high humidity can accelerate corrosion. Compliance with international standards such as ASTM A36 or DIN 17100 is essential for ensuring product quality and performance.

How Does Alloy Steel Perform in Forging Applications?

Alloy steel, which includes elements such as chromium, nickel, and molybdenum, enhances the performance of forged components significantly. These additions improve toughness, wear resistance, and hardenability, making alloy steel suitable for high-stress applications like gears and shafts. The specific properties can vary widely depending on the alloying elements used.

Illustrative image related to application of forging

Pros and Cons of Using Alloy Steel

The key advantage of alloy steel is its superior mechanical properties compared to carbon steel, which allows for the production of lighter and stronger components. However, the complexity of manufacturing processes and the higher cost of raw materials can be a disadvantage. Additionally, alloy steels may require more precise heat treatment processes to achieve desired properties, complicating production.

Impact on Application and Buyer Considerations

Alloy steel is commonly used in industries such as aerospace, automotive, and oil and gas. Buyers should be aware of the specific alloy grades required for their applications and ensure compliance with standards like ASTM AISI or JIS G4053. In Europe, understanding the EN standards for alloy steels is crucial for market entry.

What Are the Advantages of Using Stainless Steel in Forging?

Stainless steel is known for its excellent corrosion resistance, making it an ideal choice for applications exposed to harsh environments. It retains strength and durability at elevated temperatures and is also easy to clean, which is essential for industries like food processing and pharmaceuticals.

Pros and Cons of Using Stainless Steel

The primary advantage of stainless steel is its ability to withstand corrosion and oxidation, enhancing the longevity of forged parts. However, it is generally more expensive than carbon and alloy steels, which can impact budget considerations. The forging process for stainless steel can also be more complex, requiring specialized equipment and techniques.

Illustrative image related to application of forging

Impact on Application and Buyer Considerations

Stainless steel is widely used in medical equipment, automotive parts, and kitchenware. Buyers should consider the specific grade of stainless steel needed, such as 304 or 316, and ensure compliance with international standards like ASTM A240. In regions like the Middle East, where corrosion resistance is crucial, stainless steel is often the preferred choice.

How Does Aluminum Perform in Forging Applications?

Aluminum is a lightweight metal with good corrosion resistance and excellent workability, making it a popular choice for forging. Its low density and high strength-to-weight ratio make it ideal for applications where weight reduction is critical, such as in the aerospace and automotive industries.

Pros and Cons of Using Aluminum

The main advantage of aluminum is its lightweight nature, which contributes to fuel efficiency in transportation applications. Additionally, it is highly resistant to corrosion, reducing maintenance costs. However, aluminum has lower tensile strength compared to steel, which may limit its use in high-stress applications. The cost of aluminum can also be higher, impacting the overall budget.

Illustrative image related to application of forging

Impact on Application and Buyer Considerations

Aluminum is commonly used in aerospace components, automotive parts, and consumer goods. Buyers should be aware of the specific aluminum alloys available and their corresponding properties, ensuring compliance with standards like ASTM B221. In Europe, familiarity with EN standards for aluminum is also important for successful procurement.

Summary Table of Material Selection for Forging Applications

| Material | Typical Use Case for application of forging | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Automotive components, machinery | Cost-effective and durable | Prone to corrosion | Medium |

| Alloy Steel | Gears, shafts, high-stress components | Superior mechanical properties | Higher cost and manufacturing complexity | High |

| Stainless Steel | Medical equipment, automotive parts | Excellent corrosion resistance | Higher cost and complex forging process | High |

| Aluminum | Aerospace components, consumer goods | Lightweight and corrosion-resistant | Lower tensile strength compared to steel | Medium to High |

In-depth Look: Manufacturing Processes and Quality Assurance for application of forging

What Are the Key Stages in the Manufacturing Process of Forging?

The manufacturing process of forging is a critical aspect for B2B buyers interested in acquiring high-quality forged components. Understanding the stages involved can provide insights into the efficiency and reliability of suppliers. The typical forging process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Forging?

Material preparation is the first step in the forging process, which involves selecting the appropriate metal based on the end-use application. Common materials for forging include carbon steels, alloy steels, and stainless steels, as they offer desirable mechanical properties.

Illustrative image related to application of forging

Once the material is selected, it is cut into appropriate sizes and shapes, often referred to as billets or bars. Heat treatment may be applied to enhance ductility and workability. This step is crucial as it ensures that the metal can withstand the stresses of the forging process without cracking or deforming.

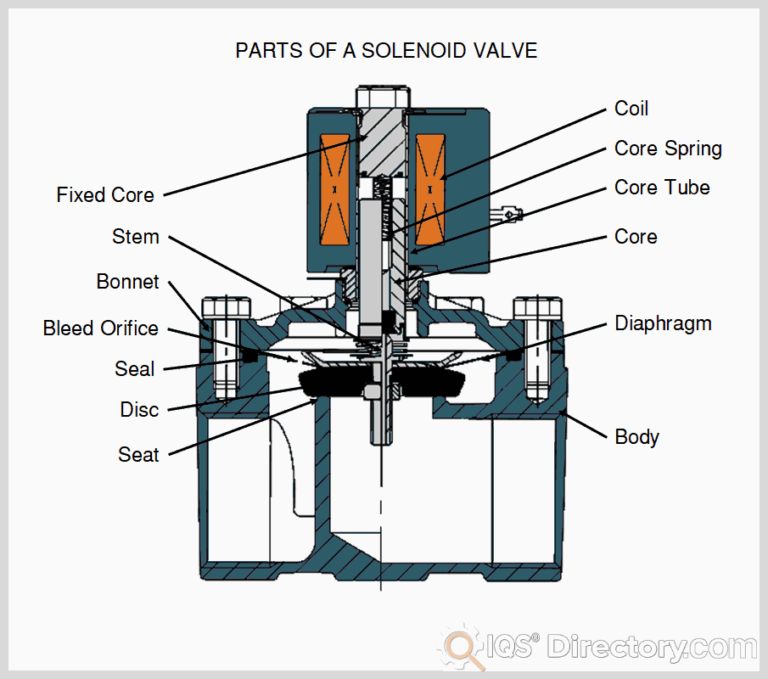

What Techniques Are Used During the Forming Stage?

The forming stage involves shaping the prepared metal under compressive forces using various techniques. The most common methods include:

- Open Die Forging: This technique uses two flat dies to shape the metal without completely enclosing it. It is ideal for large, simple shapes.

- Closed Die Forging: Involves enclosing the metal in a die and applying pressure to shape it precisely. This method is often used for complex geometries and provides superior surface finish.

- Roll Forging: Utilized for creating elongated products with uniform cross-sections, this method passes the metal between two rolls to achieve the desired shape.

- Press Forging: This method applies continuous pressure to the metal, allowing for uniform deformation and minimizing defects.

Each of these techniques has its own advantages and is selected based on the specific requirements of the component being forged, including size, complexity, and material properties.

How Is Assembly Handled in the Forging Process?

In many cases, the forging process may require subsequent assembly, especially when multiple components are involved. Assembly may include processes such as welding or mechanical fastening. It is essential to maintain tight tolerances during assembly to ensure that the final product meets the performance requirements.

What Finishing Processes Are Typically Employed?

Finishing processes are critical for enhancing the surface quality and dimensional accuracy of forged components. Common finishing techniques include:

- Machining: This involves removing excess material to achieve precise dimensions and surface finishes.

- Heat Treatment: Additional heat treatment may be applied to improve hardness, strength, or ductility.

- Surface Treatment: Techniques such as coating, shot peening, or anodizing may be employed to enhance corrosion resistance and surface hardness.

These finishing processes not only improve the aesthetics of the product but also significantly impact its performance and longevity in application.

What Quality Assurance Measures Are Essential for Forging?

Quality assurance (QA) is vital in the forging process to ensure that the final products meet international standards and customer specifications. A robust QA program includes adherence to relevant international standards, checkpoints throughout the production process, and a series of testing methods.

Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers should look for suppliers that comply with international standards such as ISO 9001, which focuses on quality management systems. Industry-specific standards, such as CE marking for products sold in the European Union or API specifications for the oil and gas industry, are also crucial. Compliance with these standards indicates that the supplier has established processes for maintaining quality throughout the manufacturing lifecycle.

Illustrative image related to application of forging

What Are the Key Quality Control Checkpoints in the Forging Process?

Quality control checkpoints are critical at various stages of production, including:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring production processes to identify and rectify any deviations in real time.

- Final Quality Control (FQC): Conducting thorough inspections and tests of the finished products before shipment.

Implementing these checkpoints helps in identifying defects early, reducing waste, and ensuring that the final product adheres to quality standards.

What Common Testing Methods Are Used in Forging Quality Control?

Testing methods play a crucial role in verifying the quality and performance of forged components. Common techniques include:

- Non-Destructive Testing (NDT): Methods such as ultrasonic testing, magnetic particle testing, and dye penetrant testing help detect internal flaws without damaging the components.

- Destructive Testing: Mechanical tests, such as tensile testing and impact testing, provide insights into the material’s properties and performance under stress.

- Dimensional Inspection: Utilizing tools such as calipers and coordinate measuring machines (CMM) to ensure that parts meet specified tolerances.

These testing methods provide B2B buyers with confidence in the reliability and safety of the forged components.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying the quality control practices of potential suppliers is essential for B2B buyers. Here are several effective strategies:

- Conduct Supplier Audits: Regular audits of suppliers can help assess their compliance with quality standards and manufacturing practices. This can include reviewing documentation, production processes, and quality records.

- Request Quality Reports: Suppliers should be able to provide detailed quality reports and certifications that outline their adherence to relevant standards and test results for previous batches.

- Engage Third-Party Inspectors: Utilizing independent third-party inspection services can provide an unbiased assessment of the supplier’s quality practices and product quality.

Understanding these nuances in quality control can help international buyers, particularly those from Africa, South America, the Middle East, and Europe, make informed decisions when selecting forging suppliers.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate additional complexities in quality control due to variations in regional standards and practices. For example:

- Cultural Differences: Understanding local manufacturing practices and quality expectations is crucial when dealing with suppliers from different countries.

- Regulatory Compliance: Each region may have specific regulations governing product safety and quality. Buyers should familiarize themselves with these requirements to ensure compliance.

- Language Barriers: Clear communication regarding quality expectations and specifications is vital to avoid misunderstandings. Utilizing multilingual staff or translators may be beneficial.

By considering these factors, B2B buyers can effectively mitigate risks and foster strong partnerships with forging suppliers globally.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘application of forging’

To assist B2B buyers in the forging industry, this practical sourcing guide offers a step-by-step checklist designed to streamline the procurement process. By following these actionable steps, businesses can ensure they select the right suppliers and materials for their forging applications.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. This includes the type of metal to be forged, dimensions, tolerances, and any specific mechanical properties needed. Having precise specifications helps suppliers understand your needs and ensures that the final product meets your expectations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in forging. Utilize online directories, industry associations, and trade shows to compile a list of qualified manufacturers. Pay attention to their experience, reputation, and geographic location, as these factors can significantly impact lead times and shipping costs.

Illustrative image related to application of forging

Step 3: Evaluate Supplier Certifications and Capabilities

Verify the certifications and capabilities of each supplier to ensure they meet industry standards. Look for ISO certifications, quality management systems, and compliance with local and international regulations. Additionally, assess their forging capabilities, such as the types of metals they work with and the various forging processes they employ.

- Key Considerations:

- Ask for documentation related to quality control.

- Determine if they have experience with similar applications.

Step 4: Request and Compare Quotes

Once you have a shortlist of suppliers, request detailed quotes that include pricing, lead times, and payment terms. Comparing these quotes will help you identify the best value for your investment. Be sure to clarify any additional costs that may arise, such as tooling fees or shipping expenses.

Step 5: Assess Production Capacity and Lead Times

Understand each supplier’s production capacity and lead times to ensure they can meet your demand. Inquire about their current workload and how they prioritize orders. A supplier with sufficient capacity can prevent delays in your production schedule, which is critical for maintaining customer satisfaction.

Step 6: Conduct Site Visits or Virtual Tours

If feasible, arrange site visits or virtual tours of the supplier’s manufacturing facilities. This step allows you to observe their equipment, processes, and overall operations firsthand. Assessing the production environment can provide insights into their commitment to quality and efficiency.

Step 7: Establish Clear Communication Channels

Finally, establish clear communication channels with your chosen supplier. Define points of contact, preferred communication methods, and frequency of updates. Open communication fosters transparency and collaboration, helping to address any issues that may arise during the production process.

By following this checklist, B2B buyers can navigate the complexities of sourcing forged materials and ensure they partner with reliable suppliers that meet their specific needs.

Comprehensive Cost and Pricing Analysis for application of forging Sourcing

What Are the Key Cost Components in Forging Sourcing?

Understanding the cost structure of forging is essential for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. The primary cost components include:

-

Materials: The choice of metal significantly impacts costs. Carbon steels, alloy steels, and stainless steels are commonly used due to their favorable mechanical properties. The price of raw materials fluctuates based on market demand and geopolitical factors, making it crucial for buyers to stay informed about material trends.

-

Labor: Skilled labor is necessary for operating forging machinery and ensuring quality control. Labor costs vary by region, with countries in Europe and North America typically incurring higher wages than those in Asia or South America. Understanding local labor market conditions can help buyers negotiate better pricing.

-

Manufacturing Overhead: This includes costs associated with running the manufacturing facility, such as utilities, rent, and maintenance. Overhead costs are often factored into the pricing structure, so buyers should inquire about these when sourcing.

-

Tooling: Custom tooling can be a significant upfront investment, particularly for closed die forging. The complexity of the tooling required for specific parts can vary widely, affecting the overall cost. Buyers should weigh the initial tooling investment against the long-term benefits of higher quality and reduced scrap rates.

-

Quality Control (QC): Ensuring that forged parts meet specifications often requires rigorous testing and inspection, which adds to the overall cost. Certifications and quality standards (e.g., ISO, ASTM) may also influence pricing, particularly in regulated industries such as aerospace and automotive.

-

Logistics: Transportation and handling costs can vary dramatically based on the supplier’s location and the destination. International shipping, customs duties, and tariffs must be factored into the total cost of ownership.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding the average margins in different regions can aid in negotiations.

What Factors Influence Pricing in Forging Sourcing?

Several key factors can impact pricing for forged components:

-

Volume/MOQ: Buyers often receive better pricing with larger orders. Minimum Order Quantities (MOQs) can also affect costs, as suppliers may have set thresholds that lead to economies of scale.

-

Specifications and Customization: Custom designs and unique specifications often come with higher costs due to the need for specialized tooling and longer production times. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Selection: The choice of material not only affects the base price but can also influence the manufacturing process and subsequent costs. More exotic alloys may lead to higher production costs.

-

Quality and Certifications: Higher quality standards and certifications typically lead to increased costs. However, they can also enhance product reliability and longevity, which is particularly important in critical applications.

-

Supplier Factors: The supplier’s reputation, experience, and location can all influence pricing. Established suppliers may charge a premium for their expertise and reliability.

-

Incoterms: Understanding the terms of shipping and delivery (Incoterms) is crucial, as these can significantly affect total costs. For instance, DDP (Delivered Duty Paid) means the seller bears all risks and costs, while FOB (Free on Board) places more responsibility on the buyer.

How Can Buyers Effectively Negotiate Costs in Forging Sourcing?

To ensure cost-efficiency in forging sourcing, buyers should adopt strategic negotiation tactics:

-

Research and Benchmarking: Familiarize yourself with market prices and supplier capabilities. This knowledge will empower you during negotiations.

-

Total Cost of Ownership (TCO): Consider all aspects of the purchase, including initial costs, maintenance, and logistics. A lower upfront price may lead to higher long-term costs if quality is compromised.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and priority service. Long-term partnerships often yield more favorable terms.

-

Explore Multiple Suppliers: Don’t rely on a single supplier. Engaging multiple sources can create competitive pricing pressure and provide alternatives if issues arise.

Conclusion

Sourcing forged components involves a multifaceted cost structure influenced by various factors. By understanding these components and leveraging strategic negotiation techniques, international B2B buyers can optimize their sourcing strategies, ensuring they receive quality products at competitive prices. Always remember to consult with industry experts and conduct thorough market research to make informed purchasing decisions.

Illustrative image related to application of forging

Alternatives Analysis: Comparing application of forging With Other Solutions

Understanding Alternative Solutions to Forging in Metal Manufacturing

In the competitive landscape of metal manufacturing, businesses often seek the most effective methods to produce durable and high-quality parts. While forging is a widely recognized technique, various alternative solutions exist that can achieve similar outcomes. This analysis focuses on comparing the application of forging with two viable alternatives: casting and machining. By evaluating these methods, B2B buyers can make informed decisions tailored to their specific manufacturing needs.

Comparison of Forging and Alternative Solutions

| Comparison Aspect | Application of Forging | Casting | Machining |

|---|---|---|---|

| Performance | High strength and toughness; reduces inclusions | Good for complex shapes; lower strength than forged parts | Very precise dimensions; can achieve tight tolerances |

| Cost | Moderate initial investment; lower scrap rate | Lower initial investment; higher scrap rates possible | High operational costs; labor-intensive |

| Ease of Implementation | Requires skilled operators and specialized equipment | Easier to set up for simple shapes; less skill required | Requires skilled labor; complex setup for CNC machines |

| Maintenance | Low; forging equipment is robust | Moderate; molds can wear out | High; regular maintenance of machines needed |

| Best Use Case | High-stress applications (e.g., automotive, aerospace) | Complex geometries (e.g., decorative items) | High precision parts (e.g., medical devices, aerospace components) |

Detailed Breakdown of Alternatives

Casting:

Casting involves pouring molten metal into a mold to create a specific shape. This method is advantageous for producing complex geometries that would be challenging to forge. Additionally, casting typically requires a lower initial investment compared to forging. However, the finished products may not possess the same strength and durability as forged components, making them less suitable for high-stress applications. The risk of defects such as porosity and shrinkage can also lead to higher scrap rates.

Machining:

Machining involves removing material from a solid workpiece to achieve the desired shape and dimensions. This method is highly precise, allowing manufacturers to create parts with tight tolerances. Machining is ideal for applications requiring high accuracy, such as in the aerospace or medical industries. However, it often comes with higher operational costs due to labor intensity and the need for skilled operators. Additionally, machining can generate significant waste, which may not be cost-effective for large-scale production.

Conclusion: How to Choose the Right Manufacturing Solution

When selecting the appropriate manufacturing solution, B2B buyers should consider their specific application requirements, production volume, and budget constraints. Forging remains an excellent choice for high-stress components where strength is paramount, while casting may be better suited for complex shapes with lower strength requirements. Machining is ideal for precision applications but may not be cost-effective for high-volume production due to its higher operational costs. Ultimately, understanding the strengths and weaknesses of each method will empower buyers to make informed decisions that align with their manufacturing goals.

Essential Technical Properties and Trade Terminology for application of forging

What Are the Key Technical Properties in Forging?

Understanding the essential technical properties of forged materials is crucial for B2B buyers, especially when selecting components for demanding applications. Here are several critical specifications to consider:

Illustrative image related to application of forging

1. Material Grade

Material grade refers to the classification of metals based on their composition and mechanical properties. Common grades for forging include carbon steel, alloy steel, and stainless steel. The right material grade ensures that the forged part can withstand operational stresses, making it vital for applications in automotive, aerospace, and heavy machinery sectors.

2. Tolerance

Tolerance defines the allowable variation in dimensions of a forged part. In forging, tight tolerances are often required to ensure proper fit and function in assembly. Poor tolerances can lead to increased wear and reduced performance, which may translate into higher costs for replacement or rework. Understanding tolerance specifications helps buyers assess the quality and suitability of forged components for their specific needs.

3. Yield Strength

Yield strength is the maximum stress that a material can withstand before undergoing permanent deformation. For forged components, high yield strength is essential, as it indicates the part’s ability to handle heavy loads and impacts without failing. This property is particularly important in industries where safety and reliability are paramount, such as in the manufacturing of aircraft or automotive parts.

Illustrative image related to application of forging

4. Ductility

Ductility measures a material’s ability to deform under tensile stress without breaking. In forging, a high ductility allows metals to be shaped into complex geometries without cracking. This property is crucial for components that need to endure significant stress and strain during operation, as it enhances their longevity and performance.

5. Hardness

Hardness indicates a material’s resistance to deformation, wear, and scratching. Forged parts often require specific hardness levels to perform effectively in their applications. For example, tools and machinery components need to be hard enough to resist wear while maintaining sufficient toughness to avoid brittleness. Buyers should consider hardness specifications to ensure that forged components will meet the operational demands of their applications.

What Are Common Trade Terms Used in Forging?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B forging market. Here are some common terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that are used in another company’s end product. In the forging industry, understanding whether a supplier is an OEM can help buyers assess the quality and reliability of the parts they are purchasing.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. This term is crucial for buyers as it affects inventory management and cash flow. Knowing the MOQ helps businesses plan their purchasing strategy effectively, especially when sourcing forged components.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. In the forging industry, an RFQ typically includes specifications, quantities, and delivery requirements. Understanding how to create and respond to RFQs can streamline procurement processes and ensure competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, which define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms helps buyers understand shipping costs, risks, and delivery obligations, making it easier to negotiate terms with suppliers.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. In forging, lead times can vary based on the complexity of the part and production capacity. Understanding lead times is essential for effective project planning and inventory management, ensuring that production schedules are met.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing forged components, ultimately leading to more successful procurement outcomes.

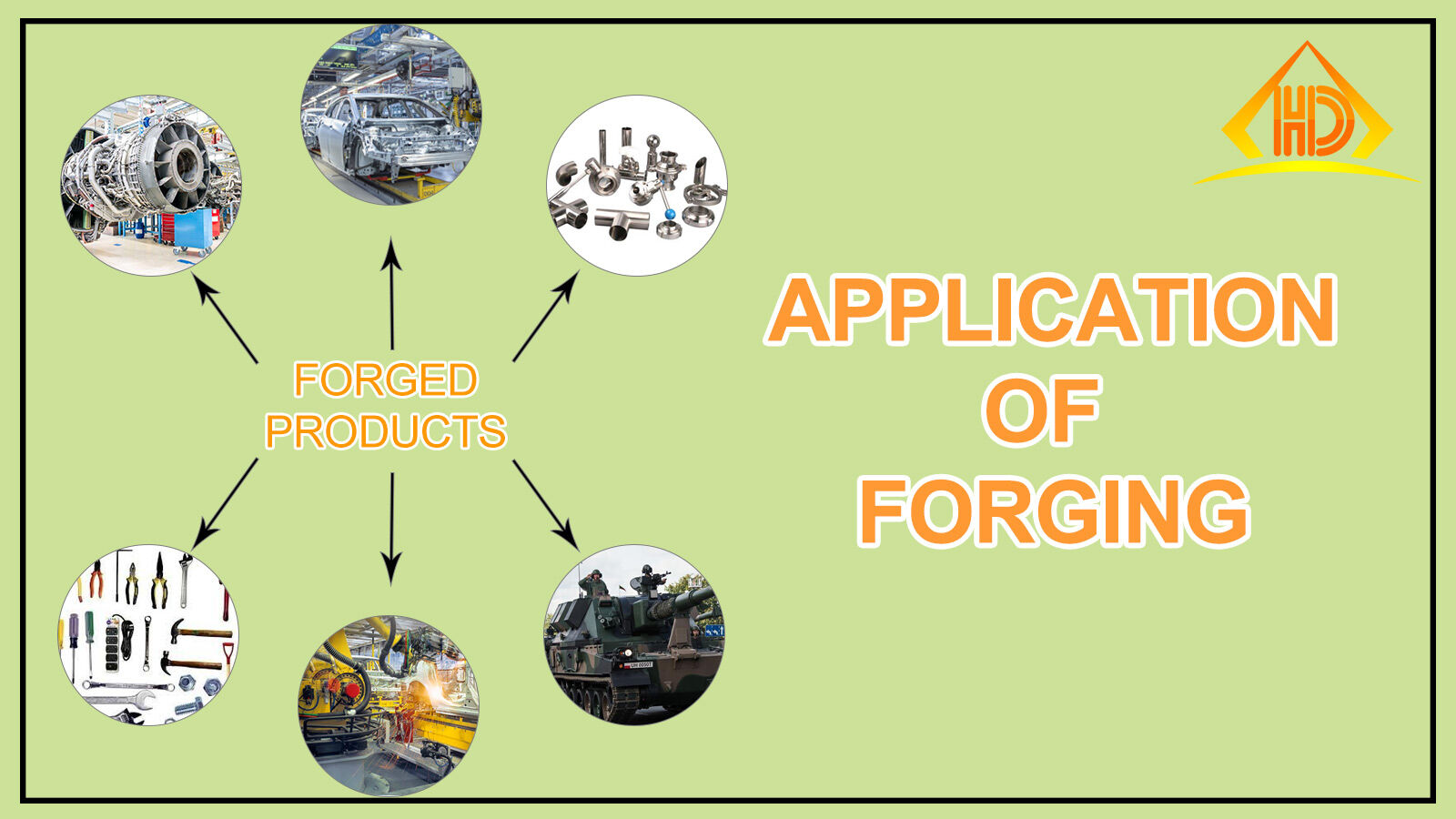

Navigating Market Dynamics and Sourcing Trends in the application of forging Sector

What are the Key Market Trends Influencing the Forging Sector?

The global forging market is witnessing dynamic changes driven by technological advancements and shifting buyer preferences. A significant trend is the increasing adoption of automation and Industry 4.0 technologies. B2B buyers from regions like Africa, South America, the Middle East, and Europe are particularly interested in suppliers that integrate smart manufacturing processes, enabling improved efficiency and precision in production. This trend not only enhances quality but also allows for real-time data analysis, which is invaluable for demand forecasting and inventory management.

Another notable market driver is the rising demand for lightweight yet durable materials in industries such as automotive and aerospace. As manufacturers seek to enhance fuel efficiency and reduce emissions, the forging of advanced alloys, including titanium and aluminum, is becoming more prevalent. Additionally, the automotive sector is increasingly focusing on electric vehicles (EVs), which require specific forged components that meet stringent performance standards.

Geopolitical factors and trade policies also play a crucial role in shaping the forging landscape. Buyers in regions like Europe are particularly sensitive to changes in tariffs and trade agreements, prompting them to seek local suppliers or diversify their sourcing strategies to mitigate risks. This evolution encourages international collaboration and strategic partnerships, facilitating access to innovative forging technologies and materials.

How is Sustainability and Ethical Sourcing Impacting the Forging Industry?

Sustainability is emerging as a critical consideration in the forging sector. B2B buyers are increasingly aware of the environmental impact of their supply chains and are actively seeking partners who prioritize eco-friendly practices. The forging process, while traditionally resource-intensive, is evolving with the introduction of energy-efficient methods and recycling initiatives. The use of recycled metals is gaining traction, significantly reducing the carbon footprint associated with raw material extraction and processing.

Illustrative image related to application of forging

Moreover, ethical sourcing is becoming a non-negotiable aspect of procurement strategies. Buyers are demanding transparency regarding the origin of materials and the social responsibility practices of their suppliers. Certifications such as ISO 14001 for environmental management and responsible sourcing standards are becoming crucial for suppliers aiming to build trust and credibility in the market.

Additionally, the development of ‘green’ materials and eco-friendly forging techniques is gaining momentum. Innovations such as low-energy forging processes and the use of bio-based lubricants are attracting attention from international buyers looking to align their procurement with sustainable goals. By prioritizing sustainability and ethical sourcing, companies can not only enhance their brand reputation but also meet the growing regulatory requirements in various markets.

How Has the Forging Sector Evolved Over Time?

The forging sector has a rich history that dates back to ancient civilizations, evolving significantly in response to technological advancements and market demands. Initially, forging was a manual process, relying on blacksmiths to shape metal through hammering and heat. Over centuries, this process has transformed with the introduction of mechanized tools and hydraulic presses, allowing for greater precision and efficiency.

In the modern era, the forging industry has embraced automation and advanced manufacturing techniques, such as computer numerical control (CNC) and robotics. These innovations have not only improved the quality of forged products but have also reduced production times and costs. The shift towards digital technologies is paving the way for more sustainable practices, including better energy management and reduced waste.

As the global economy continues to evolve, the forging sector is poised to adapt further, driven by the increasing demand for specialized components across various industries. This ongoing evolution presents opportunities for international B2B buyers to engage with suppliers who are at the forefront of innovation, ensuring access to high-quality, reliable forged products that meet the challenges of tomorrow.

Frequently Asked Questions (FAQs) for B2B Buyers of application of forging

-

1. How do I select the right forging supplier for my business needs?

Choosing the right forging supplier involves assessing their capabilities, quality certifications, and experience in your industry. Start by reviewing their portfolio and case studies to ensure they have expertise in the specific type of forging you require, whether it’s open die, closed die, or precision forging. Look for suppliers with ISO certifications, as these indicate adherence to international quality standards. Finally, consider their production capacity and lead times to ensure they can meet your demand without compromising quality. -

2. What is the best type of metal for forging applications in my industry?

The best type of metal for forging largely depends on the application and mechanical properties required. Commonly used metals include carbon steel, alloy steel, and stainless steel due to their strength and durability. For industries like aerospace and automotive, titanium and aluminum are also popular for their lightweight properties. It’s essential to consider factors such as corrosion resistance, fatigue strength, and thermal stability when selecting the material for your specific application. -

3. What are the typical minimum order quantities (MOQs) for forged parts?

Minimum order quantities for forged parts can vary significantly based on the supplier, the complexity of the part, and the forging method used. Generally, MOQs range from a few hundred to several thousand units. Suppliers may offer lower MOQs for simpler designs or when using existing tooling. It’s advisable to discuss your requirements directly with potential suppliers to negotiate favorable terms, especially if you are a small or medium-sized enterprise. -

4. How can I ensure the quality of forged parts before purchasing?

To ensure the quality of forged parts, request detailed documentation of the supplier’s quality assurance processes, including material certifications and inspection reports. Conducting pre-production samples or pilot runs can help assess the quality before committing to larger orders. Additionally, consider implementing third-party inspections or audits, especially for critical applications in industries like aerospace or defense, where precision and reliability are paramount. -

5. What are the common payment terms when sourcing forged components internationally?

Payment terms for international sourcing of forged components can vary widely, but common practices include advance payments, letters of credit, or payment upon delivery. Many suppliers may require a deposit (often 30% to 50%) before production begins, with the balance due upon shipment. It’s essential to clearly define payment terms in the contract to avoid misunderstandings and ensure smooth transactions. Familiarize yourself with international payment methods to mitigate risks. -

6. How do logistics and shipping factors influence the cost of forged parts?

Logistics and shipping costs can significantly impact the overall expense of acquiring forged parts. Factors such as the size and weight of the parts, shipping distance, and chosen method (air freight vs. sea freight) play a crucial role. Additionally, customs duties and taxes in the destination country should be considered. Collaborating with suppliers who have experience in international shipping can help streamline the process and potentially reduce costs. -

7. Are there customization options available for forged components?

Most forging suppliers offer customization options to meet specific design and performance requirements. Customization can include variations in size, shape, and material specifications based on your application needs. Discussing your requirements upfront during the supplier evaluation process is crucial, as it allows you to understand their capabilities and limitations regarding custom forging. Many suppliers also have design engineering teams to assist in creating the optimal solution for your project. -

8. What are the advantages and disadvantages of different forging processes?

Each forging process has its advantages and disadvantages. For instance, open die forging is flexible and suitable for large parts but may require extensive machining. Closed die forging offers high precision and strength but involves higher initial tooling costs. Roll forging is efficient for producing long components with minimal waste but may be limited to specific shapes. Understanding the nuances of each process allows you to select the most appropriate method based on your production volume, complexity, and budget.

Top 4 Application Of Forging Manufacturers & Suppliers List

1. Metal Supermarkets – Key Characteristics of Forged Metal

Domain: metalsupermarkets.com

Registered: 1996 (29 years)

Introduction: Key characteristics of forged metal include dependability in highly stressed and sensitive applications, good strength and toughness, minimal scrap production, and fast production times. The forging process can produce parts quickly, typically within one or two hammer strokes. The types of forging equipment mentioned are hammers, presses, upsetters, and roll forging. The metals that can be forged …

2. Cornell Forge – Custom Forged Steel Parts

Domain: cornellforge.com

Registered: 2000 (25 years)

Introduction: Cornell Forge specializes in various forging techniques including Closed Die Hot Forging, Microalloy Forging, and Stainless Steel Forgings. They offer custom forged steel parts and have expertise in producing components for industries such as aerospace, automotive, defense, medical, and oil and gas. Their forging processes include Hammer Forging, Press Forging, Roll Forging, Open-Die Forging, and …

3. TFG USA – Metal Forging Solutions

Domain: tfgusa.com

Registered: 2008 (17 years)

Introduction: Metal forging is a process that shapes metals using compressive forces through hammering, pressing, or rolling. Key methods include open die forging, closed die forging, cold forging, and roll forging. Each method has specific advantages for size, complexity, and volume. Forging enhances metal strength by refining grain structure and reducing impurities. Common applications include parts for agric…

4. Brockhouse – Forgings for Key Industries

Domain: brockhouse.co.uk

Registered: 1997 (28 years)

Introduction: Forgings are used in various industries including Automotive, Oil and Gas, Power Generation, Construction, Military and Defence, Marine, Mining, and Railway. Key applications include:

– Automotive: Forged crankshafts, steering components, and transmission parts.

– Oil and Gas: Forged drill bits, flanges, and fittings.

– Power Generation: Turbine components and generator shafts.

– Construction:…

Strategic Sourcing Conclusion and Outlook for application of forging

In summary, the application of forging presents significant advantages for international B2B buyers looking to enhance their supply chains. The forging process not only improves the mechanical properties of metals, resulting in stronger and more reliable components, but also minimizes waste, making it a cost-effective choice for high-volume production. Strategic sourcing of forged materials can lead to better quality control, reduced lead times, and enhanced performance in demanding applications, such as aerospace, automotive, and industrial machinery.

As companies from Africa, South America, the Middle East, and Europe seek to optimize their manufacturing capabilities, investing in partnerships with reputable forging suppliers can yield substantial returns. Engaging with experienced manufacturers allows buyers to leverage innovative forging techniques, such as precision and isothermal forging, to meet the evolving demands of their markets.

Looking ahead, the global demand for high-quality forged components is expected to rise, driven by advancements in technology and a focus on sustainability. B2B buyers are encouraged to explore strategic sourcing opportunities that align with their operational goals, ensuring they remain competitive in an increasingly dynamic landscape. Take the next step in your sourcing strategy and explore the transformative potential of forging for your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.