Is Your Air Cylinder Mounting Styles Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for air cylinder mounting styles

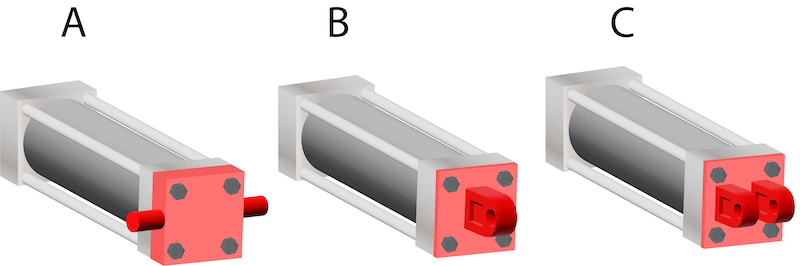

Navigating the complex landscape of air cylinder mounting styles can be a daunting challenge for international B2B buyers. Understanding the nuances of various mounting configurations is crucial for sourcing the right pneumatic solutions that meet specific operational demands, especially in diverse markets such as Africa, South America, the Middle East, and Europe. This comprehensive guide delves into the intricacies of air cylinder mounting styles, encompassing fixed centerline, fixed non-centerline, and pivoted centerline mounts, among others.

By exploring the applications and performance considerations of each mounting style, buyers will gain insights into optimizing cylinder functionality while ensuring longevity and reliability. Additionally, this guide offers practical tips on supplier vetting, cost considerations, and compliance with international standards, enabling informed purchasing decisions. With a focus on real-world applications and regional market trends, B2B buyers from countries like Brazil and Nigeria will be empowered to select the most suitable air cylinder solutions for their unique industrial challenges.

Ultimately, this guide serves as a valuable resource for navigating the global market for air cylinder mounting styles, equipping buyers with the knowledge needed to enhance operational efficiency and drive business success.

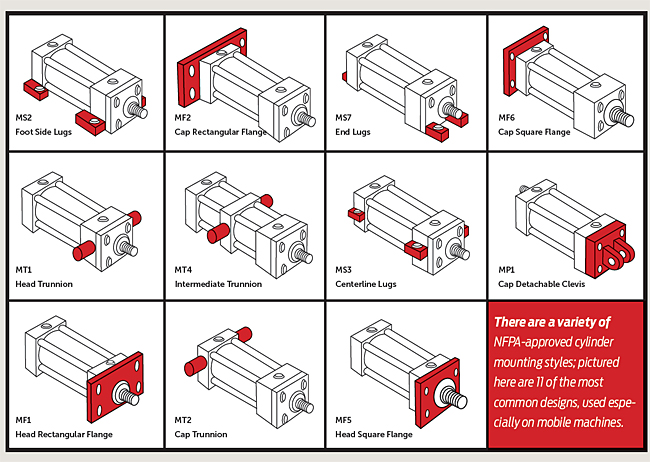

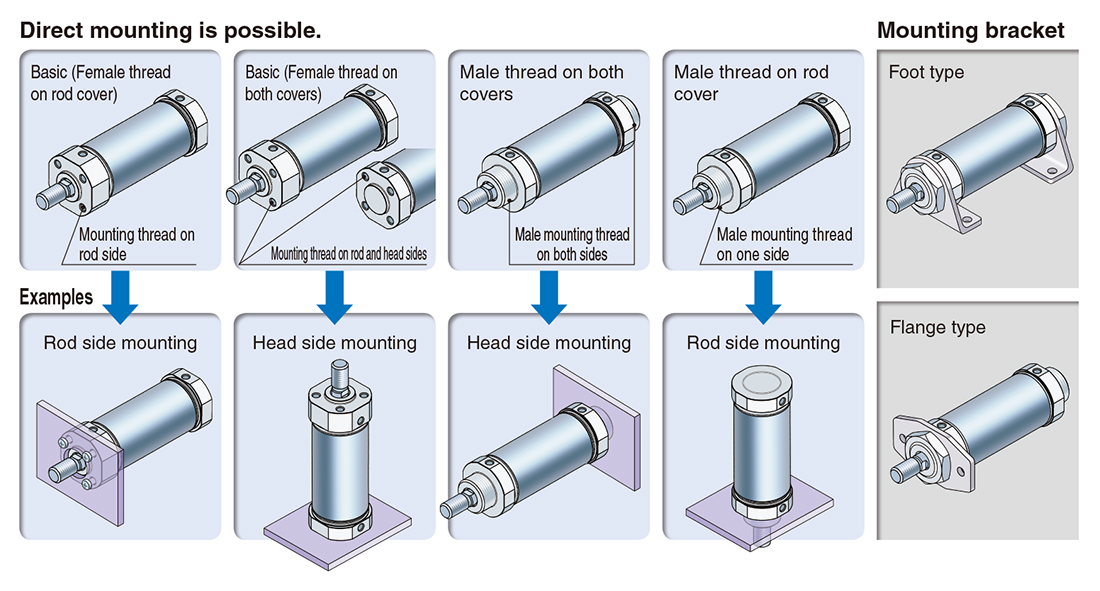

Understanding air cylinder mounting styles Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fixed Centerline Mountings | Aligns thrust on the centerline; offers high stability | Assembly lines, robotic arms | Pros: High stability, good for linear applications. Cons: Sensitive to misalignment. |

| Fixed Non-Centerline Mountings | Thrust is parallel but not on the centerline; easy to install | Material handling, packaging machines | Pros: Simple installation, cost-effective. Cons: Prone to bending stress, requires precise alignment. |

| Pivoted Centerline Mountings | Allows movement in one or more directions; suitable for curved paths | Conveyor systems, lifting equipment | Pros: Flexibility in motion, adapts to misalignment. Cons: May require more maintenance. |

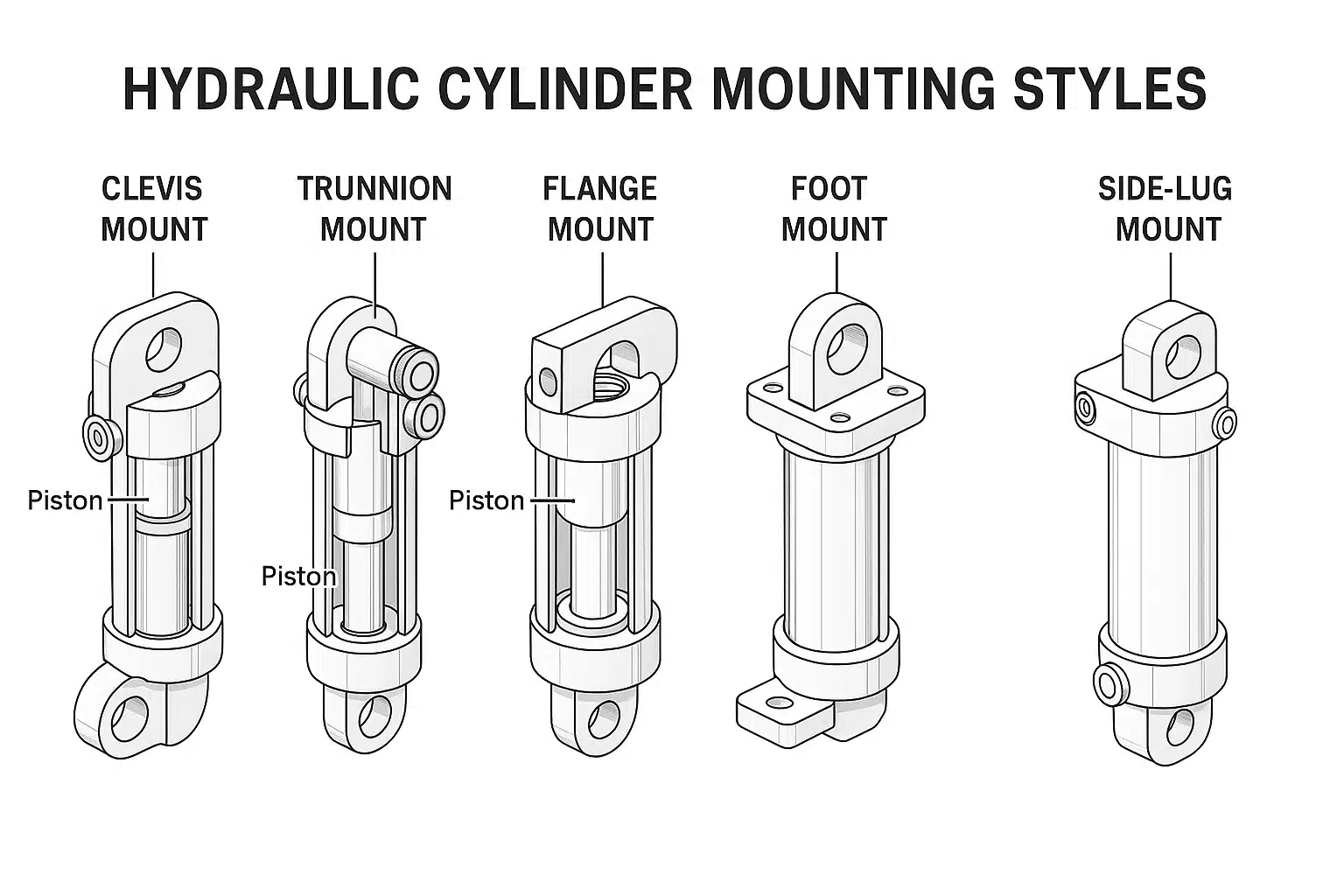

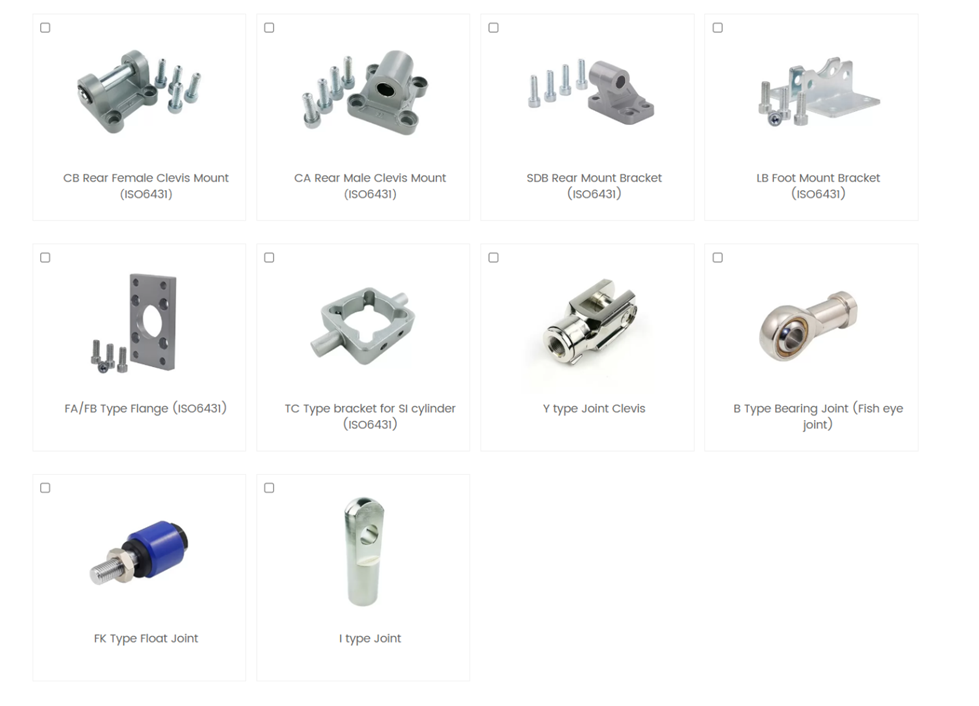

| Clevis Mounts | Versatile with a simple attachment; allows for angular movement | Short-stroke applications, compact machinery | Pros: Easy to install, widely available. Cons: Limited load capacity compared to others. |

| Trunnion Mounts | Supports weight at the balance point; ideal for heavy-duty applications | Heavy machinery, long stroke cylinders | Pros: Enhances stability, suitable for heavy loads. Cons: Can increase overall cylinder length. |

What Are the Characteristics of Fixed Centerline Mountings?

Fixed centerline mountings are characterized by their ability to align the thrust directly on the centerline of the cylinder rod, which enhances stability during operation. They are particularly suitable for applications where linear motion is critical, such as in assembly lines or robotic arms. When purchasing, buyers should consider the need for a rigid structure to prevent misalignment and ensure that the cylinder’s travel path is linear. Additionally, these mounts typically require careful installation to avoid sagging, especially in long-stroke applications.

How Do Fixed Non-Centerline Mountings Differ?

Fixed non-centerline mountings feature thrust that is parallel but not directly on the cylinder’s centerline, making them easier to install. These mounts are commonly used in material handling and packaging machinery. Buyers should be aware that while these mounts offer simplicity and cost-effectiveness, they also introduce bending stresses that can lead to wear over time. Proper alignment is crucial to maximize service life, and buyers should assess the load conditions to ensure safety and efficiency.

Why Choose Pivoted Centerline Mountings?

Pivoted centerline mountings are designed to accommodate curved paths or unavoidable misalignments, allowing for movement in multiple directions. This flexibility makes them ideal for conveyor systems and lifting equipment. When considering this mounting style, buyers should evaluate the application’s need for angular movement and ensure proper maintenance to avoid performance issues. While these mounts can provide significant operational advantages, they may require more frequent servicing due to their complexity.

What Are the Benefits of Clevis Mounts?

Clevis mounts are known for their versatility and ease of installation, allowing for angular movement within short-stroke applications. They are commonly used in compact machinery where space is limited. Buyers should consider the load capacity when selecting clevis mounts, as they may not support heavier loads as effectively as other mounting styles. Their widespread availability and straightforward design make them a popular choice for many applications, but buyers should remain mindful of their limitations.

When Should You Use Trunnion Mounts?

Trunnion mounts are beneficial for applications that require support at the cylinder’s balance point, particularly in heavy-duty machinery and long-stroke cylinders. These mounts enhance stability and allow for better load management. Buyers should consider the overall length of the cylinder when selecting trunnion mounts, as they can increase the cylinder’s footprint. While they provide significant advantages in terms of stability and load-bearing capacity, understanding the application requirements is essential for optimal performance.

Key Industrial Applications of air cylinder mounting styles

| Industry/Sector | Specific Application of air cylinder mounting styles | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Assembly line automation utilizing fixed centerline mounts for robotic arms | Improved efficiency and precision in assembly processes | Compatibility with existing machinery and load requirements |

| Food & Beverage | Packaging systems employing pivoted centerline mounts to accommodate curved paths | Enhanced flexibility in design and layout of packaging lines | Hygiene compliance and material durability in food contact areas |

| Textile Production | Fabric handling systems using fixed non-centerline mounts for fabric tensioning | Consistent tension and reduced wear on materials | Robustness against misalignment and environmental conditions |

| Pharmaceutical | Automated filling machines utilizing various mounting styles for precise dosing | Increased accuracy and reduced operational downtime | Regulatory compliance and precision engineering specifications |

| Construction Equipment | Hydraulic systems with fixed and pivoted mounts for lifting and moving heavy loads | Improved safety and operational efficiency in lifting tasks | Load capacity, environmental resistance, and maintenance ease |

How Are Air Cylinder Mounting Styles Utilized in Automotive Manufacturing?

In the automotive manufacturing sector, air cylinder mounting styles, particularly fixed centerline mounts, play a crucial role in assembly line automation. These mounts ensure that robotic arms operate with precision, focusing thrust along the cylinder’s centerline. This alignment minimizes wear and tear on components, leading to longer service life and reduced maintenance costs. International buyers should prioritize compatibility with existing machinery and ensure that the selected mounts can handle the specific load requirements of their assembly processes.

What Role Do Air Cylinder Mounting Styles Play in Food & Beverage Applications?

In the food and beverage industry, pivoted centerline mounts are often employed in packaging systems to accommodate the curved paths of conveyor belts. This flexibility allows for efficient product handling and packaging without compromising speed or accuracy. These mounts must meet stringent hygiene standards and be made from materials that withstand harsh cleaning processes. Buyers should consider the durability of materials and compliance with food safety regulations to ensure operational effectiveness.

How Are Air Cylinder Mounting Styles Applied in Textile Production?

Textile production facilities utilize fixed non-centerline mounts in fabric handling systems to maintain consistent tension during processing. This mounting style helps prevent fabric damage and ensures smooth operation, which is critical for high-quality output. For international B2B buyers, sourcing mounts that can withstand various environmental conditions, such as humidity and temperature fluctuations, is essential. Additionally, robustness against misalignment is vital to maintain operational efficiency.

What Is the Importance of Air Cylinder Mounting Styles in Pharmaceutical Manufacturing?

In pharmaceutical manufacturing, precise dosing is paramount, making various air cylinder mounting styles essential in automated filling machines. These mounts ensure accurate positioning and movement, reducing operational downtime and enhancing product quality. Buyers should focus on sourcing mounts that comply with industry regulations and precision engineering specifications to ensure reliable performance and safety in sensitive environments.

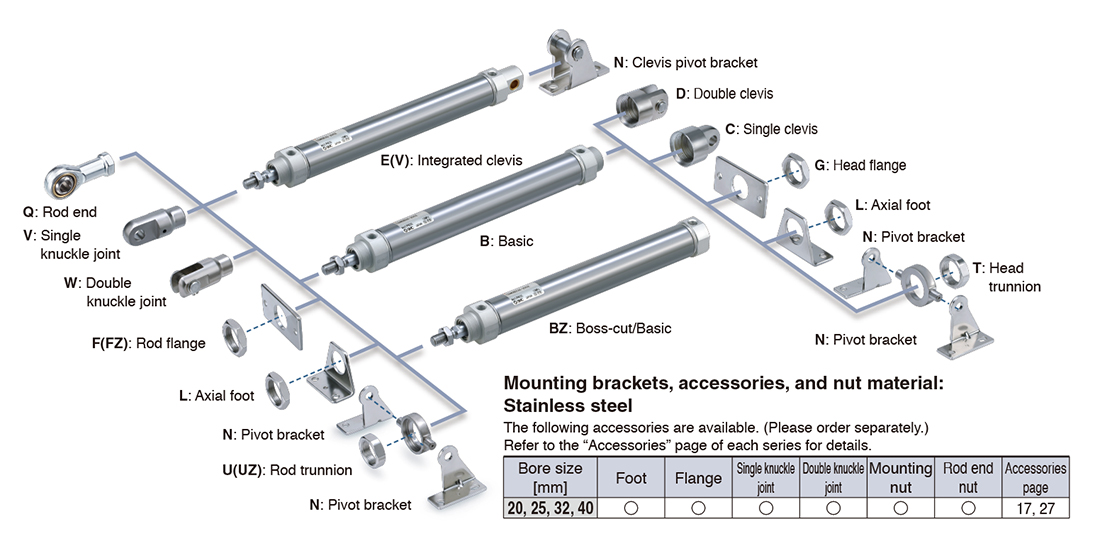

Illustrative image related to air cylinder mounting styles

How Are Air Cylinder Mounting Styles Utilized in Construction Equipment?

Air cylinder mounting styles are integral to hydraulic systems in construction equipment, where both fixed and pivoted mounts are employed for lifting and moving heavy loads. These mounts improve operational efficiency and safety by ensuring that loads are properly balanced and secured during movement. When sourcing for this application, international buyers must consider load capacity, environmental resistance, and the ease of maintenance to ensure long-term functionality and safety in demanding conditions.

3 Common User Pain Points for ‘air cylinder mounting styles’ & Their Solutions

Scenario 1: Misalignment Issues Leading to Premature Cylinder Wear

The Problem: A common challenge faced by B2B buyers is the misalignment of air cylinders during installation. When pneumatic cylinders are not properly aligned, it can lead to uneven wear on seals and bearings, ultimately resulting in premature failure. This misalignment often arises from improper mounting configurations or inadequate structural support, especially in environments where space constraints are a factor. Buyers may find themselves frequently replacing cylinders, leading to increased operational costs and downtime.

The Solution: To mitigate misalignment issues, it is crucial to select the appropriate mounting style based on the specific application requirements. For example, fixed centerline mountings provide excellent stability and are suited for applications where the thrust is directed along the centerline of the cylinder. Buyers should ensure that the mounting surface is rigid and that the travel path of the rod end is linear and well-guided. Additionally, investing in adjustable mounting brackets can provide some leeway for fine-tuning alignment post-installation. Regular maintenance checks should also be implemented to monitor alignment and address any issues before they escalate.

Scenario 2: Difficulty in Sourcing Compatible Mounting Styles

The Problem: B2B buyers often struggle with sourcing air cylinder mounting styles that comply with international standards, particularly when operating across different regions such as Africa, South America, the Middle East, and Europe. Variability in standards can lead to compatibility issues, causing delays in procurement and assembly. This can be frustrating, especially for buyers managing multiple suppliers and ensuring their products are interchangeable and meet local regulations.

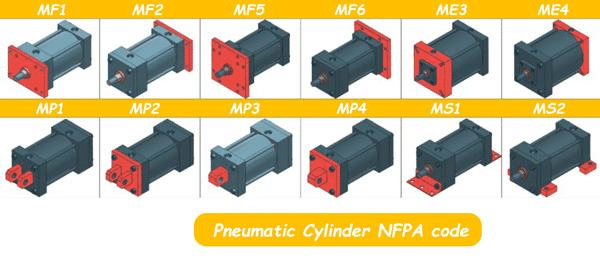

The Solution: To effectively navigate sourcing challenges, buyers should prioritize manufacturers that offer a comprehensive range of mounting styles adhering to NFPA and ISO standards. Conducting thorough research on suppliers that specialize in pneumatic components can save time and reduce compatibility issues. Establishing relationships with global suppliers who understand regional requirements can also streamline the procurement process. Additionally, buyers should utilize online catalogs and consult with technical support teams to ensure the selected mounting styles align with both the application needs and local regulations.

Scenario 3: Limited Knowledge of Mounting Options Leading to Suboptimal Performance

The Problem: Many B2B buyers may lack in-depth knowledge of the various air cylinder mounting styles and their respective advantages, which can lead to suboptimal performance in their applications. This knowledge gap can result in the selection of inappropriate mounting configurations, leading to inefficiencies, increased wear, or even complete system failures. Buyers may find themselves overwhelmed by the technical specifications and terminologies, which can hinder their ability to make informed decisions.

The Solution: To enhance understanding, buyers should engage in educational opportunities such as workshops, webinars, and training sessions offered by manufacturers or industry experts. Additionally, creating a checklist that outlines the key factors—such as load conditions, stroke length, and the environment—can help in evaluating the appropriate mounting style. Utilizing resources like detailed product datasheets and installation manuals can provide valuable insights into the best practices for mounting air cylinders. Consulting with engineers or application specialists during the selection process can also ensure that buyers choose the most effective mounting style for their specific needs, ultimately optimizing performance and extending the life of the equipment.

Strategic Material Selection Guide for air cylinder mounting styles

What Are the Key Materials for Air Cylinder Mounting Styles?

When selecting materials for air cylinder mounting styles, several factors must be considered to ensure optimal performance and longevity. The choice of material impacts durability, cost, and suitability for specific applications. Below, we analyze four common materials used in air cylinder mounting styles: aluminum, steel, stainless steel, and plastic composites.

Illustrative image related to air cylinder mounting styles

How Does Aluminum Perform in Air Cylinder Mounting Applications?

Aluminum is a lightweight and corrosion-resistant material, making it a popular choice for various pneumatic applications. It has a good temperature rating, typically ranging from -40°C to 80°C, and can handle moderate pressure levels.

Pros: Aluminum offers excellent strength-to-weight ratio, which is advantageous in applications where weight is a concern. Its resistance to corrosion makes it suitable for environments exposed to moisture and chemicals. Additionally, aluminum is relatively easy to manufacture and machine, allowing for intricate designs.

Cons: Despite its benefits, aluminum has lower tensile strength compared to steel, which may limit its use in heavy-duty applications. It is also more expensive than some alternatives, and its performance can degrade at higher temperatures.

Impact on Application: Aluminum is compatible with a range of media, including air and water, but may not be suitable for aggressive chemicals.

Considerations for International Buyers: Compliance with international standards such as ASTM and ISO is crucial. Buyers in regions like Africa and South America may prefer aluminum due to its lightweight nature, which can reduce shipping costs.

What Are the Advantages of Using Steel in Mounting Styles?

Steel is renowned for its high strength and durability, making it a go-to material for heavy-duty applications. It can handle high pressures and has a temperature tolerance that can exceed 200°C, depending on the alloy.

Pros: Steel’s strength allows it to support heavier loads and withstand significant stress, making it ideal for demanding environments. It is also cost-effective compared to aluminum and stainless steel.

Cons: The primary drawback of steel is its susceptibility to corrosion, which can lead to premature failure if not properly coated or maintained. Additionally, its weight can be a disadvantage in applications where reducing mass is essential.

Impact on Application: Steel is suitable for a variety of media but may require protective coatings when used in corrosive environments.

Illustrative image related to air cylinder mounting styles

Considerations for International Buyers: Buyers should ensure that the steel used meets local standards and regulations, particularly in regions with stringent quality requirements like Europe.

Why Choose Stainless Steel for Air Cylinder Mounting?

Stainless steel combines the strength of steel with excellent corrosion resistance, making it ideal for harsh environments. It can withstand high temperatures and pressures, often rated up to 300°C.

Pros: The corrosion resistance of stainless steel makes it suitable for applications involving water, chemicals, and high humidity. Its durability ensures a long service life, reducing replacement costs over time.

Cons: Stainless steel is generally more expensive than both aluminum and regular steel. Its manufacturing processes can also be more complex, leading to higher production costs.

Impact on Application: Stainless steel is highly compatible with various media, including aggressive chemicals, making it a versatile choice for many applications.

Considerations for International Buyers: Compliance with ASTM and DIN standards is essential. Buyers in the Middle East, where high temperatures are common, will benefit from stainless steel’s thermal resistance.

How Do Plastic Composites Fit into the Air Cylinder Mounting Landscape?

Plastic composites are gaining popularity due to their lightweight and corrosion-resistant properties. They can handle moderate temperatures and pressures, typically up to 80°C.

Illustrative image related to air cylinder mounting styles

Pros: The primary advantage of plastic composites is their resistance to corrosion and chemical attack, making them suitable for various environments. They are also lightweight, which can help reduce overall system weight.

Cons: Plastic composites generally have lower strength compared to metals, limiting their use in high-load applications. Additionally, they may have a shorter lifespan under extreme conditions.

Impact on Application: Plastic composites are ideal for applications involving non-aggressive media but may not be suitable for high-pressure systems.

Considerations for International Buyers: Buyers should ensure that the composite materials meet local standards and regulations, especially in regions with specific compliance requirements.

Summary Table of Material Selection for Air Cylinder Mounting Styles

| Material | Typical Use Case for air cylinder mounting styles | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight applications, moderate loads | Excellent strength-to-weight ratio | Lower tensile strength | Medium |

| Steel | Heavy-duty applications, high loads | High strength and durability | Susceptible to corrosion | Low |

| Stainless Steel | Harsh environments, chemical exposure | Superior corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic Composites | Non-aggressive media, lightweight applications | Lightweight and corrosion-resistant | Lower strength and shorter lifespan | Medium |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that align with their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for air cylinder mounting styles

What Are the Main Stages in the Manufacturing Process for Air Cylinder Mounting Styles?

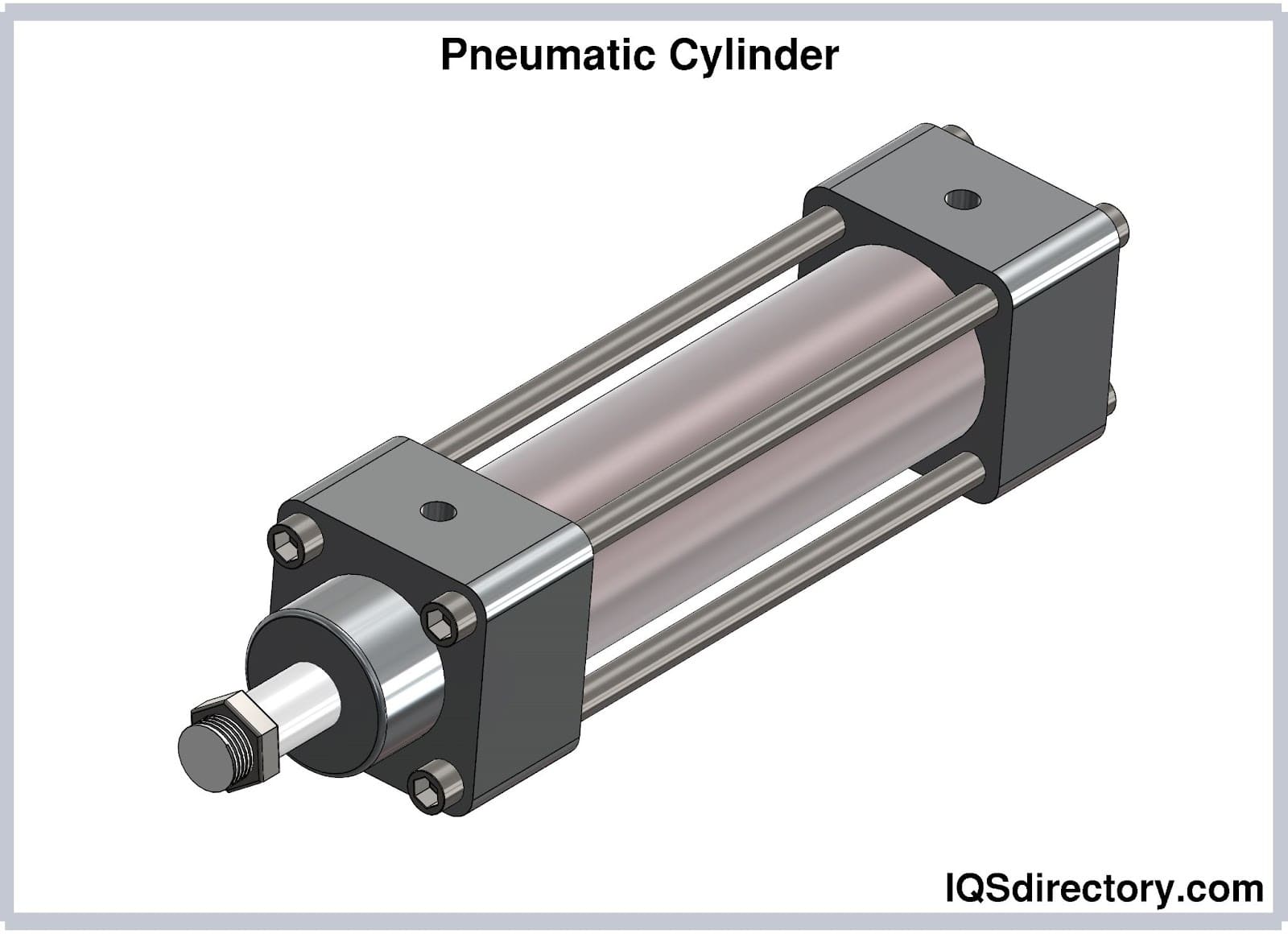

The manufacturing process for air cylinder mounting styles involves several critical stages that ensure the final product meets quality and performance standards. These stages typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Air Cylinder Mounting Styles?

Material preparation is the foundational step in manufacturing air cylinder mounts. Manufacturers typically use high-grade metals such as aluminum, stainless steel, or carbon steel due to their strength and resistance to corrosion. The process begins with sourcing raw materials that meet international standards. This often involves inspecting the materials for defects and ensuring they conform to specifications.

Once the materials are selected, they undergo cutting and machining to achieve the required dimensions. This can involve processes such as laser cutting, water jet cutting, or CNC machining, which provide precision and repeatability. Additionally, surface treatments may be applied at this stage to enhance durability and resistance to environmental factors.

What Techniques Are Used in the Forming Stage of Air Cylinder Mounting Styles?

The forming stage is where the raw materials are shaped into the desired mounting configurations. Techniques such as stamping, forging, and extrusion are commonly employed. Stamping is often used for creating flat components, while forging is preferred for producing stronger, more resilient parts through the application of heat and pressure.

Extrusion, another popular technique, allows for creating complex shapes and profiles that are integral to specific mounting styles. This stage is crucial as it directly impacts the structural integrity and performance of the mounts.

How Is Assembly Conducted for Air Cylinder Mounting Styles?

Once the components are formed, the assembly process begins. This stage involves fitting together various parts, such as brackets, flanges, and rods, to create the final mounting structure. Skilled technicians typically perform this assembly to ensure proper alignment and fit.

During assembly, manufacturers often employ techniques like welding, bolting, or riveting, depending on the design requirements. It is critical to maintain tight tolerances during this stage to avoid misalignment, which can lead to premature wear or failure in the final application.

What Finishing Processes Are Essential for Air Cylinder Mounting Styles?

The finishing stage is designed to enhance the aesthetics and functional properties of the air cylinder mounts. This can include processes such as anodizing, powder coating, or plating. Anodizing, for instance, not only improves corrosion resistance but also increases surface hardness.

Finishing touches may also involve quality checks to ensure that surface imperfections are eliminated, and that any coatings are applied uniformly. This stage is vital for ensuring that the products can withstand the operational environments they are designed for, particularly in harsh conditions.

Illustrative image related to air cylinder mounting styles

What Quality Assurance Standards Should B2B Buyers Look for in Air Cylinder Mounting Styles?

For B2B buyers, understanding the quality assurance processes is essential when sourcing air cylinder mounting styles. Most manufacturers adhere to international standards such as ISO 9001, which outlines requirements for quality management systems. Compliance with these standards indicates that the manufacturer has processes in place to ensure consistent quality and customer satisfaction.

In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for oil and gas applications may also be relevant. These certifications ensure that products meet specific safety and performance criteria.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are critical at various stages of the manufacturing process. Typically, these checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials upon delivery to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify and rectify any deviations from quality standards in real-time.

- Final Quality Control (FQC): A thorough inspection of finished products before they are shipped, ensuring they meet all design specifications and quality standards.

Implementing these checkpoints helps manufacturers maintain high-quality standards and reduces the likelihood of defects in the final product.

Illustrative image related to air cylinder mounting styles

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers. One effective method is to conduct audits of the manufacturing facilities. These audits can assess compliance with international standards and evaluate the effectiveness of the supplier’s quality management system.

Additionally, requesting quality control reports and certifications can provide insights into the supplier’s adherence to standards. Third-party inspections can also be beneficial, as they offer an unbiased assessment of the manufacturer’s processes and products.

What Are the Nuances of Quality Control for International B2B Buyers?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, navigating quality control can be complex. Different countries may have varying standards and regulations that must be adhered to. Therefore, it is essential to ensure that the supplier is familiar with both local and international requirements.

Furthermore, buyers should be aware of potential communication barriers and cultural differences that may impact quality assurance processes. Establishing clear lines of communication and setting expectations upfront can help mitigate these challenges.

In conclusion, understanding the manufacturing processes and quality assurance practices for air cylinder mounting styles is crucial for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with adhering to international quality standards, buyers can ensure they select reliable suppliers that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘air cylinder mounting styles’

To assist B2B buyers in sourcing the right air cylinder mounting styles, this practical guide outlines essential steps to ensure optimal procurement. By following this checklist, you can make informed decisions that enhance performance and reliability in your applications.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for selecting the appropriate air cylinder mounting style. Consider factors such as the cylinder stroke length, load size, and operational environment. This clarity helps in narrowing down options that meet your unique application requirements.

Step 2: Identify Suitable Mounting Types

Familiarize yourself with the main categories of air cylinder mounting styles: fixed centerline, fixed non-centerline, and pivoted centerline. Understanding these types will allow you to align your choice with the thrust direction and application dynamics, ensuring compatibility with your machinery.

Step 3: Evaluate Supplier Capabilities

Before proceeding, assess potential suppliers’ capabilities and product offerings. Look for suppliers who specialize in pneumatic systems and have a proven track record in your industry. Request technical documentation and product catalogs to understand their range of mounting styles and configurations.

Step 4: Review Compliance with Standards

Ensure that the mounting styles you are considering comply with relevant international standards such as NFPA and ISO. Compliance guarantees that the products meet safety and performance benchmarks, which is essential for minimizing risks in your operations.

Step 5: Analyze Material Properties

Different applications may require specific material properties for mounting styles. Consider the mechanical properties of materials used in the mounts, especially if your application involves high pressures or harsh environments. For instance, materials with higher tensile strength are preferred for demanding applications to prevent premature failure.

Step 6: Request and Assess Sample Products

Whenever possible, request samples of the air cylinder mounts you are considering. This allows you to evaluate their fit and functionality within your existing systems. Conduct thorough tests to ensure they meet your performance expectations and can withstand operational stresses.

Step 7: Negotiate Terms and Verify Support Services

Engage in negotiations to secure favorable terms, including pricing, lead times, and warranty provisions. Additionally, verify the supplier’s support services, such as technical assistance and after-sales support. Reliable support is vital for addressing any potential issues that may arise post-purchase.

By following this checklist, B2B buyers can systematically approach the procurement of air cylinder mounting styles, ensuring that their selections are well-suited to their operational needs and long-term performance goals.

Comprehensive Cost and Pricing Analysis for air cylinder mounting styles Sourcing

What Are the Key Cost Components in Air Cylinder Mounting Styles?

When sourcing air cylinder mounting styles, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects cost. Common materials such as aluminum and stainless steel have different price points, impacting overall production costs. Additionally, specialized materials for specific environments (e.g., corrosion-resistant coatings) may incur higher expenses.

-

Labor: Labor costs vary by region and complexity of the mounting style. For instance, more intricate designs require skilled labor, thereby increasing the cost. Understanding local labor market conditions can help buyers gauge potential labor costs.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, rent, and administrative expenses. Buyers should inquire about these costs when negotiating with suppliers.

-

Tooling: Custom tooling can be a significant upfront investment for unique designs. However, if a buyer can commit to larger volumes, suppliers may absorb some of these costs, which can lead to lower prices per unit.

-

Quality Control (QC): Ensuring that mounting styles meet specified quality standards involves additional costs. Buyers should consider how much emphasis a supplier places on quality assurance, as this can affect both price and the reliability of the product.

-

Logistics: Transportation costs can vary widely, particularly for international shipments. Buyers should factor in shipping methods, distances, and potential tariffs that can influence the final price.

-

Margin: Suppliers will typically mark up prices to cover their costs and make a profit. Understanding the margin expectations of suppliers can aid in negotiation efforts.

How Do Price Influencers Affect Sourcing Decisions for Air Cylinder Mounting Styles?

Several factors can influence the pricing of air cylinder mounting styles:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer better pricing for larger orders. Buyers should assess their needs against supplier MOQ policies to optimize costs.

-

Specifications and Customization: Custom designs or specific specifications typically lead to higher prices. Buyers should weigh the necessity of customization against standard options to find a cost-effective solution.

-

Materials and Quality Certifications: High-quality materials and certifications (e.g., ISO standards) can increase costs but may also offer better performance and reliability. Buyers should evaluate whether the added expense aligns with their application requirements.

-

Supplier Factors: The supplier’s location, reputation, and service capabilities can influence pricing. Establishing relationships with reliable suppliers can lead to more favorable terms and pricing.

-

Incoterms: Understanding the chosen Incoterms (e.g., FOB, CIF) is crucial, as they define the responsibilities of buyers and sellers in shipping costs. This can significantly impact the total landed cost of the products.

What Are Effective Buyer Tips for Negotiating Prices on Air Cylinder Mounting Styles?

To maximize cost-efficiency when sourcing air cylinder mounting styles, consider the following tips:

-

Negotiate Terms: Always negotiate terms with suppliers, including pricing, payment terms, and delivery schedules. Leverage volume commitments to secure better rates.

-

Consider Total Cost of Ownership (TCO): TCO includes initial purchase costs and ongoing operational costs, such as maintenance and downtime. Assessing TCO can help buyers make informed decisions that go beyond upfront pricing.

-

Understand Pricing Nuances for International Buyers: Different regions may have varying cost structures and currency fluctuations. Buyers from Africa, South America, the Middle East, and Europe should factor in these elements when planning their budgets.

-

Request Quotes from Multiple Suppliers: Obtaining multiple quotes can provide insights into market pricing and help identify competitive offers. Ensure that all quotes are for comparable products to facilitate effective comparisons.

-

Stay Informed About Market Trends: Regularly monitoring market trends in manufacturing and material costs can provide leverage in negotiations and help anticipate price changes.

Disclaimer on Indicative Prices

Prices for air cylinder mounting styles can vary widely based on numerous factors, including material choices, customization, and order volumes. The information provided is intended as a general guide and may not reflect actual market prices. Buyers should conduct thorough market research and engage with suppliers to obtain accurate pricing for their specific needs.

Illustrative image related to air cylinder mounting styles

Alternatives Analysis: Comparing air cylinder mounting styles With Other Solutions

Introduction: Exploring Alternatives to Air Cylinder Mounting Styles

In the realm of industrial automation, selecting the appropriate mounting style for air cylinders is crucial for optimizing performance and extending equipment lifespan. However, there are alternative solutions that may offer similar functionalities. This section compares traditional air cylinder mounting styles with other viable methods, enabling international B2B buyers to make informed decisions tailored to their unique operational needs.

Comparison Table

| Comparison Aspect | Air Cylinder Mounting Styles | Alternative 1: Electric Actuators | Alternative 2: Hydraulic Cylinders |

|---|---|---|---|

| Performance | High precision and reliability; ideal for repetitive tasks | Excellent for precise positioning; faster response times | High force output; suitable for heavy loads |

| Cost | Moderate initial investment; low maintenance costs | Higher upfront costs; energy-efficient in the long run | Higher initial costs; maintenance can be complex |

| Ease of Implementation | Generally straightforward installation | Requires more complex electrical setup | Installation can be complex; needs hydraulic lines |

| Maintenance | Low maintenance; routine checks | Low maintenance; wear on electrical components | Higher maintenance due to hydraulic fluid management |

| Best Use Case | Ideal for repetitive, linear motion tasks in various industries | Best for applications requiring precision and speed | Optimal for heavy-duty applications with high force demands |

Detailed Breakdown of Alternatives

Electric Actuators

Electric actuators utilize electrical energy to produce motion and are known for their precision and speed. They often come with integrated control systems that allow for easy programmability and adaptability to various tasks. However, their higher initial investment can be a barrier for some businesses. Moreover, while they require less ongoing maintenance compared to hydraulic systems, wear on electrical components can lead to performance issues over time. Electric actuators are particularly beneficial in applications where quick response times and precise positioning are paramount, such as in robotics and assembly lines.

Hydraulic Cylinders

Hydraulic cylinders are designed to handle high forces and heavy loads, making them suitable for industries such as construction and manufacturing. They can deliver substantial power in compact sizes and are ideal for applications that require significant lifting or pushing capabilities. However, they come with a higher initial cost and often require a more complex installation process, including hydraulic lines and pumps. Maintenance can also be more demanding due to the need for regular checks on hydraulic fluid levels and potential leaks. Businesses that engage in heavy-duty applications will find hydraulic cylinders advantageous, but they must be prepared for the associated complexities.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between air cylinder mounting styles and alternative solutions like electric actuators or hydraulic cylinders, it is essential for B2B buyers to consider the specific requirements of their applications. Factors such as performance needs, budget constraints, ease of implementation, and maintenance capabilities should guide the decision-making process. By thoroughly evaluating these aspects, companies can adopt the most suitable technology, ultimately enhancing their operational efficiency and productivity in the long run.

Essential Technical Properties and Trade Terminology for air cylinder mounting styles

What Are the Critical Technical Properties of Air Cylinder Mounting Styles?

When selecting air cylinder mounting styles, understanding key technical properties is essential for optimizing performance and ensuring longevity. Here are some critical specifications to consider:

1. Material Grade

The material grade of the cylinder and its mounting components significantly impacts their durability and resistance to wear. Common materials include aluminum, steel, and stainless steel, each chosen based on the operating environment. For example, stainless steel is ideal for corrosive environments, while aluminum is lighter and often used in applications where weight is a concern. Understanding material grades helps buyers choose the right cylinder for specific operational demands, enhancing reliability.

2. Tolerance

Tolerance refers to the allowable deviation from a specified dimension. In air cylinder applications, precise tolerances are crucial for ensuring that the cylinder operates smoothly and aligns correctly with other components. Poor tolerance can lead to misalignment and premature wear, resulting in increased maintenance costs. Buyers must assess the tolerance specifications to ensure compatibility with existing systems and avoid costly operational disruptions.

3. Load Capacity

Load capacity defines the maximum weight or force the cylinder can handle during operation. This specification varies based on the mounting style chosen. For instance, pivoted centerline mounts may accommodate different load dynamics compared to fixed centerline mounts. Understanding load capacity is vital for buyers to ensure that the selected cylinder can handle the intended application, thereby avoiding failure and ensuring safety.

4. Stroke Length

Stroke length indicates the distance the piston travels within the cylinder. This property affects the range of motion and application suitability. A longer stroke may be necessary for applications requiring extensive movement, while shorter strokes may suffice for compact installations. Buyers should evaluate stroke length in conjunction with the specific application to maximize efficiency and performance.

5. Operating Pressure

Operating pressure is the maximum pressure at which the cylinder can function safely. It is crucial for applications involving high-pressure systems. Buyers need to understand the operating pressure ratings to select cylinders that can withstand the required forces without risking failure, thus ensuring operational safety and reliability.

What Are Common Trade Terms Related to Air Cylinder Mounting Styles?

Familiarizing oneself with industry jargon is essential for effective communication and decision-making in B2B transactions. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the role of OEMs is crucial for buyers looking to source reliable and compatible components for their systems, ensuring consistency in quality and performance.

Illustrative image related to air cylinder mounting styles

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for buyers as it can impact inventory management and cost efficiency. Knowing the MOQ helps in planning purchases and budgeting accordingly.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. This process is essential for obtaining competitive pricing and understanding the market. Buyers should prepare detailed RFQs to ensure they receive accurate and comprehensive responses.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping responsibilities, risk management, and cost implications, ensuring smooth transactions across borders.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. This term is critical for project planning and inventory management. Buyers should consider lead times when scheduling production and ensuring that components arrive in a timely manner to avoid delays in operations.

Illustrative image related to air cylinder mounting styles

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when selecting air cylinder mounting styles, ultimately enhancing operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the air cylinder mounting styles Sector

What Are the Current Market Dynamics and Key Trends in Air Cylinder Mounting Styles?

The air cylinder mounting styles sector is currently experiencing a transformation driven by several global factors. The increasing demand for automation and efficiency across industries is one of the primary drivers. As companies in regions like Africa, South America, the Middle East, and Europe, including Brazil and Nigeria, seek to optimize production processes, the need for advanced pneumatic solutions is rising. Additionally, the push for Industry 4.0 technologies is influencing the sector, as manufacturers are increasingly adopting smart automation solutions that require precise and reliable mounting configurations.

Emerging technologies, such as IoT and AI, are also playing a significant role in shaping sourcing trends. Companies are looking for suppliers that can provide not just products but also integrated solutions that include data analytics for predictive maintenance and performance monitoring. This trend is particularly relevant in regions with burgeoning manufacturing sectors, where operational efficiency can provide a competitive edge.

Illustrative image related to air cylinder mounting styles

Moreover, sustainability is becoming a key concern for B2B buyers. There’s a growing expectation for suppliers to demonstrate environmental responsibility through efficient resource use and waste management. As global supply chains continue to evolve, manufacturers are prioritizing partnerships with suppliers who align with their sustainability goals, further influencing purchasing decisions in the air cylinder mounting styles market.

How Is Sustainability and Ethical Sourcing Impacting the Air Cylinder Mounting Styles Sector?

Sustainability and ethical sourcing are increasingly critical factors for B2B buyers in the air cylinder mounting styles sector. The environmental impact of manufacturing processes, particularly in the production of pneumatic components, has led to a heightened focus on sustainable practices. Companies are now seeking suppliers who adopt eco-friendly materials and manufacturing methods, which not only reduce waste but also minimize carbon footprints.

The importance of ethical supply chains cannot be overstated. Buyers are prioritizing suppliers who uphold fair labor practices and transparency in their operations. Certifications such as ISO 14001, which focuses on effective environmental management systems, and other green certifications are gaining traction. These certifications not only enhance a company’s reputation but also assure buyers of the sustainability of their sourcing choices.

In this context, the trend towards using recyclable and sustainable materials in the production of air cylinder mounting styles is becoming more pronounced. Suppliers who can offer products made from eco-friendly materials or those that adhere to rigorous sustainability standards are likely to stand out in a competitive market. This shift not only aligns with the values of socially conscious buyers but also positions companies favorably in a market that increasingly values corporate responsibility.

Illustrative image related to air cylinder mounting styles

What Is the Evolution of Air Cylinder Mounting Styles and Its Significance for B2B Buyers?

The evolution of air cylinder mounting styles has been marked by advancements in engineering and manufacturing technologies. Initially, basic fixed mounts were the norm, primarily designed for straightforward applications. However, as industries have progressed, so too have the requirements for more versatile and adaptable mounting solutions. The introduction of ISO and NFPA standards facilitated the development of a standardized approach to mounting configurations, allowing for greater interchangeability and ease of installation.

Today, the market offers a diverse range of mounting styles—including fixed centerline, fixed non-centerline, and pivoted centerline mounts—each tailored to meet specific application needs. This evolution is significant for B2B buyers as it enables them to select mounting solutions that optimize performance, improve lifespan, and reduce maintenance costs. Understanding the historical context of these developments can guide buyers in making informed decisions, ensuring they select the most suitable mounting styles for their operational requirements. As the industry continues to evolve, staying abreast of these changes will be crucial for maintaining a competitive edge in a rapidly changing marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of air cylinder mounting styles

-

How do I solve alignment issues with air cylinder mounting?

To resolve alignment issues with air cylinder mounting, start by ensuring that the mounting surface is rigid and level. Misalignment often arises from improper installation or structural flexibility. Use alignment tools during installation to verify that the cylinder’s thrust is aligned with the centerline of the piston rod. Regular maintenance checks are crucial; inspect the mounting hardware for wear and ensure that loads are supported adequately to prevent bending stresses. If misalignment persists, consider using pivoted centerline mounts, which can accommodate some misalignment without compromising performance. -

What is the best mounting style for high-load applications?

For high-load applications, fixed centerline mountings are generally the best choice, as they provide stability and minimize side loads. These mounts focus the cylinder’s thrust along its centerline, which is essential for handling substantial forces. Additionally, ensure that the mounting structure can support the weight and forces exerted during operation. If your application involves dynamic loads or requires flexibility in movement, consider pivoted centerline mounts, which can adjust to varying angles while maintaining structural integrity. -

How can I customize air cylinder mounts for specific applications?

Customizing air cylinder mounts involves selecting the appropriate style and materials based on your application’s requirements. Work closely with suppliers to discuss your specific needs, such as load capacity, stroke length, and environmental conditions. Many manufacturers offer tailored solutions, including modifications to standard mounts or entirely bespoke designs. Be prepared to provide detailed specifications and operational conditions to ensure that the customized mount will perform optimally in your application. -

What are the typical minimum order quantities (MOQs) for air cylinder mounts?

Minimum order quantities (MOQs) for air cylinder mounts can vary significantly by supplier and product type. Some manufacturers may have low MOQs for standard products, while customized mounts often require higher minimums due to the complexity of production. It’s advisable to inquire with multiple suppliers to find the best terms. Additionally, consider your project timeline; placing larger orders may allow for better pricing and availability, especially for international shipping. -

What payment terms should I expect when sourcing air cylinder mounts internationally?

Payment terms for international purchases of air cylinder mounts typically range from upfront payments to net 30 or net 60 days after delivery. Some suppliers may request a deposit, especially for custom orders. It’s important to clarify payment terms before finalizing orders and to consider using secure payment methods such as letters of credit or escrow services for larger transactions. Always ensure that the terms align with your budget and cash flow requirements to avoid disruptions in procurement. -

How do I ensure quality assurance when sourcing air cylinder mounts?

To ensure quality assurance when sourcing air cylinder mounts, partner with reputable suppliers who adhere to international quality standards such as ISO certifications. Request detailed product specifications, including material properties and performance metrics. It may be beneficial to conduct factory visits or audits to assess manufacturing processes. Additionally, consider implementing a quality control process, including receiving inspections and testing samples, to verify that the products meet your requirements prior to full-scale deployment. -

What logistics considerations should I keep in mind for international shipping of air cylinder mounts?

When planning logistics for the international shipping of air cylinder mounts, consider factors such as shipping costs, customs regulations, and delivery timelines. Engage with logistics providers who specialize in international freight to navigate customs clearance efficiently. Ensure that all documentation, including commercial invoices and packing lists, is accurate and complete to avoid delays. Also, be aware of potential tariffs and duties that may apply, and factor these into your total cost analysis. -

How can I vet suppliers for air cylinder mounts effectively?

Vetting suppliers for air cylinder mounts involves thorough research and evaluation of their credentials. Start by reviewing their industry reputation through customer testimonials and case studies. Check for relevant certifications, such as ISO or other quality standards. Engage in direct communication to assess their responsiveness and willingness to provide technical support. Request samples or prototypes to evaluate product quality firsthand. Additionally, consider their capacity to meet your lead times and production needs, especially for custom orders.

Top 8 Air Cylinder Mounting Styles Manufacturers & Suppliers List

1. JH Foster – Pneumatic Cylinders and Mounting Solutions

Domain: jhfoster.com

Registered: 1998 (27 years)

Introduction: Pneumatic cylinders, mounting configurations, NFPA and ISO standards, fixed centerline mountings, fixed non-centerline mountings, pivoted centerline mountings, cylinder stroke, plane of motion, load size and condition, column strength of piston rod, installation space, material properties, pressure ratings, mounting types (MX1, MX2, MS1, MP1, etc.), mounting terminology, benefits and limitations o…

2. Peninsular Cylinders – Air NFPA Cylinders

Domain: peninsularcylinders.com

Registered: 1998 (27 years)

Introduction: Air NFPA Cylinders, HH Mounting Style, designed for various applications, featuring durable construction, multiple mounting options, and compliance with NFPA standards.

3. AutomationDirect – Pneumatic Cylinder Mounting Solutions

Domain: automationdirect.com

Registered: 1999 (26 years)

Introduction: Cylinder mounting options for pneumatic cylinders, including various types of brackets and accessories for secure installation. Options include standard, adjustable, and custom mounts to fit different applications and space requirements.

4. Fright Props – Cylinder Mounting Solutions

Domain: frightprops.com

Registered: 2003 (22 years)

Introduction: Cylinder mounting options for various applications, including compatibility with different types of cylinders, installation methods, and recommended accessories for optimal performance.

5. McMaster – Air Cylinder Mounts

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Air Cylinder Mounts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Northern Hydraulics – Hydraulic Cylinder Solutions

Domain: northernhydraulics.net

Registered: 2002 (23 years)

Introduction: Hydraulic Cylinder Mounting Styles: Welded Cylinders, Universal Double Acting Hydraulic Cylinders, Single Acting Hydraulic Cylinders, Enerpac High Pressure 10,000 PSI Cylinders, Loader Hydraulic Cylinders, Log Splitter Cylinders, Hydraulic Cylinders Parts and Accessories.

7. EKCI – Compact Pneumatic Cylinders

Domain: ekci.com

Registered: 1998 (27 years)

Introduction: Compact pneumatic cylinders are designed for effective motion in tight spaces with a low profile and short stroke application. They come with various mounting options, including rigid mounts for linear motion (bolting through tapped holes or using a sleeve mount) and flexible mounts for pivoting motion (like eye mounts). Designers should consider the primary function of the cylinder and available …

8. Omchele – Pneumatic Cylinders

Domain: omchele.com

Registered: 2023 (2 years)

Introduction: Pneumatic cylinders are used in industrial automation for linear movement and clamping force. The performance of these cylinders is influenced by the type of mounting used, which is crucial for maximizing their life expectancy. Various mounting types are available, each with unique characteristics, advantages, and applications.

Strategic Sourcing Conclusion and Outlook for air cylinder mounting styles

In conclusion, selecting the appropriate air cylinder mounting style is pivotal for optimizing performance and extending the lifespan of pneumatic systems. Key considerations include the application requirements, load conditions, and environmental factors, all of which can significantly impact the functionality of the cylinder. By understanding the distinctions between fixed centerline, fixed non-centerline, and pivoted centerline mountings, buyers can make informed decisions that align with their operational needs.

Strategic sourcing is essential in this context; it enables businesses to identify reliable suppliers who adhere to international standards, ensuring quality and compatibility. As B2B buyers from regions such as Africa, South America, the Middle East, and Europe navigate the complexities of sourcing, leveraging local partnerships and global networks can enhance procurement efficiency and reduce costs.

Looking ahead, as industries evolve and demand for automation grows, the importance of adaptable and robust mounting solutions will only increase. We encourage international buyers to engage with trusted manufacturers and explore innovative mounting options that can meet future challenges. Investing in the right air cylinder mounting styles today will pave the way for operational excellence tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.