Is Your Acrylic Character Carabiner Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for acrylic character carabiner

In today’s competitive landscape, sourcing high-quality acrylic character carabiners can pose significant challenges for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. With an array of options available, decision-makers must navigate through varying designs, materials, and suppliers to find products that align with their branding and operational needs. This guide aims to demystify the global market for acrylic character carabiners, offering insights into different types, applications, and customization options available in the marketplace.

Understanding the nuances of supplier vetting, production timelines, and cost considerations is crucial for making informed purchasing decisions. By delving into the specifics of acrylic character carabiners—from their aesthetic appeal in promotional campaigns to their practical uses in outdoor activities—this guide equips international buyers with the knowledge necessary to select the right products for their businesses.

Moreover, we will highlight key trends and best practices that can enhance your sourcing strategy, ensuring that you not only meet your immediate needs but also foster long-term relationships with reliable suppliers. This comprehensive resource is designed to empower you in making confident choices, ultimately leading to successful procurement outcomes in the dynamic world of acrylic character carabiners.

Understanding acrylic character carabiner Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Acrylic Carabiner | Personalized designs, various sizes, and printing options | Promotional products, corporate gifts | Pros: High customization, appealing to specific audiences. Cons: Longer production times for custom orders. |

| Full Bleed Acrylic Carabiner | Double-sided printing, vibrant colors, and full bleed cutting | Branding, merchandise, event giveaways | Pros: Eye-catching designs, effective for brand visibility. Cons: Higher cost due to complex printing techniques. |

| Miniature Acrylic Carabiner | Smaller size options, lightweight, and portable | Keychains, accessories, and small gifts | Pros: Cost-effective for bulk orders, easy to carry. Cons: Limited design space for branding. |

| Epoxy Resin Acrylic Carabiner | Glossy finish, added durability, and depth in design | High-end promotional items, collectibles | Pros: Luxurious appearance, durable for long-term use. Cons: Higher price point may deter budget-conscious buyers. |

| Themed Character Carabiner | Unique shapes and designs based on popular characters or themes | Toy industry, events, and themed promotions | Pros: Appeals to niche markets, strong emotional connection. Cons: Limited to specific demographics, may not suit all businesses. |

What are the Characteristics of Custom Acrylic Carabiners?

Custom acrylic carabiners are tailored to meet specific branding needs, allowing businesses to showcase their logos or designs. Available in various sizes and printing techniques, they serve as effective promotional tools. B2B buyers should consider production times, as custom orders often require longer lead times, which can impact marketing campaigns.

How Do Full Bleed Acrylic Carabiners Enhance Branding?

Full bleed acrylic carabiners feature double-sided printing with vibrant colors that extend to the edges, making them visually striking. These products are ideal for branding at events or as merchandise. Buyers should evaluate the cost versus the potential return on investment, especially for high-visibility campaigns where brand exposure is critical.

What are the Benefits of Miniature Acrylic Carabiners?

Miniature acrylic carabiners are compact and lightweight, making them perfect for keychains or small accessories. They are cost-effective for bulk orders, allowing businesses to distribute them widely. However, their smaller design limits branding space, which may require creativity in design to maximize impact.

Why Choose Epoxy Resin Acrylic Carabiners?

Epoxy resin acrylic carabiners offer a glossy finish and enhanced durability, making them suitable for high-end promotional items. Their appealing aesthetic can attract customers looking for quality products. Buyers should be mindful of the higher price point, which may not align with all budget constraints.

What Makes Themed Character Carabiners Unique?

Themed character carabiners feature designs based on popular characters or themes, appealing to niche markets such as toys and collectibles. They create an emotional connection with consumers, which can enhance brand loyalty. However, businesses should assess whether this niche focus aligns with their broader marketing strategy, as it may not appeal to all demographics.

Illustrative image related to acrylic character carabiner

Key Industrial Applications of acrylic character carabiner

| Industry/Sector | Specific Application of acrylic character carabiner | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Promotional Products | Custom branding for events and giveaways | Enhances brand visibility and customer engagement | Minimum order quantities, customization options |

| Retail and Merchandise | Keychains and accessories for retail display | Drives impulse purchases and increases product appeal | Design flexibility, quality of materials, pricing |

| Outdoor and Adventure Gear | Functional accessories for camping and hiking gear | Provides durability and personalization for outdoor enthusiasts | Material quality, weight capacity, and design options |

| Arts and Crafts | Unique art pieces and collectibles | Attracts niche markets and adds artistic value | Production timelines, artistic integrity, and customization |

| Education and Institutions | Educational tools and student engagement items | Supports learning and engagement through creative designs | Compliance with safety standards, bulk pricing |

How Are Acrylic Character Carabiners Used in Promotional Products?

In the promotional products industry, acrylic character carabiners serve as customizable giveaways that enhance brand visibility. Businesses can imprint their logos or designs on these carabiners, making them effective tools for events, trade shows, and marketing campaigns. The vibrant colors and unique shapes attract attention, making them memorable for potential customers. For international buyers, it is crucial to consider minimum order quantities and available customization options to ensure alignment with branding strategies.

What Role Do Acrylic Character Carabiners Play in Retail and Merchandise?

Retailers utilize acrylic character carabiners as keychains and accessories to enhance product displays. These items not only serve a functional purpose but also act as impulse buys, driving additional sales. By integrating eye-catching designs and colors, retailers can increase the overall appeal of their merchandise. Buyers must focus on design flexibility, quality of materials, and competitive pricing to ensure that these products resonate with their target audience while maximizing profitability.

How Do Acrylic Character Carabiners Benefit Outdoor and Adventure Gear?

In the outdoor and adventure gear sector, acrylic character carabiners are valued for their durability and personalization options. They can be attached to backpacks or gear, providing both functionality and a personal touch for outdoor enthusiasts. This application helps brands create a unique identity in a competitive market. Buyers should prioritize material quality, weight capacity, and design options to ensure that the carabiners meet the rigorous demands of outdoor activities.

Why Are Acrylic Character Carabiners Important in Arts and Crafts?

The arts and crafts industry leverages acrylic character carabiners to create unique art pieces and collectibles. Artists and crafters can customize these products, attracting niche markets and adding artistic value to their offerings. This application not only showcases creativity but also provides a profitable avenue for artisans. Buyers in this sector should pay attention to production timelines, artistic integrity, and customization capabilities to maintain high standards and meet customer expectations.

How Are Acrylic Character Carabiners Used in Education and Institutions?

In educational settings, acrylic character carabiners are utilized as tools to engage students and enhance learning experiences. They can be designed with educational themes or used as rewards in classroom settings, promoting creativity and interaction. Institutions must ensure compliance with safety standards, especially for younger audiences, while also considering bulk pricing options to manage costs effectively. This application supports educational objectives while providing a fun and engaging learning environment.

3 Common User Pain Points for ‘acrylic character carabiner’ & Their Solutions

Scenario 1: Navigating Customization Challenges with Acrylic Character Carabiners

The Problem: B2B buyers often face difficulties when it comes to customizing acrylic character carabiners to align with their brand identity. The challenge lies in the complexity of design specifications, such as color matching, size variations, and ensuring high-quality prints that reflect the intended artwork. Miscommunication with suppliers can lead to errors, resulting in products that do not meet expectations and ultimately affecting brand reputation.

The Solution: To streamline the customization process, buyers should establish clear communication channels with manufacturers. Providing detailed design specifications, including color codes (e.g., Pantone), dimensions, and preferred printing techniques, can significantly reduce misunderstandings. Additionally, requesting a digital proof before full production allows for necessary adjustments. Suppliers often offer mock-ups that can be reviewed and modified before the final product is created. This proactive approach ensures that the final acrylic carabiner not only represents the brand accurately but also meets quality standards.

Scenario 2: Ensuring Durability and Functionality of Acrylic Carabiners

The Problem: Many buyers are concerned about the durability and functionality of acrylic character carabiners, especially in harsh environments or for heavy-duty use. Acrylic is lightweight and visually appealing but may lack the robustness required for certain applications, leading to potential product failures that can disappoint end customers.

The Solution: To address durability concerns, buyers should inquire about the material properties and construction techniques used by suppliers. Opting for thicker acrylic options or additional treatments, such as UV protection or reinforced fittings, can enhance the longevity of the carabiners. It’s also advisable to request samples for real-world testing before placing large orders. By evaluating how the product withstands typical usage scenarios, buyers can make informed decisions that ensure both aesthetics and functionality are met.

Illustrative image related to acrylic character carabiner

Scenario 3: Managing Lead Times and Supply Chain Issues

The Problem: Delays in production and shipping can severely disrupt the supply chain for businesses reliant on acrylic character carabiners for promotional items or product offerings. Buyers often face tight deadlines, and unexpected delays can lead to missed opportunities and dissatisfied customers.

The Solution: To mitigate lead time issues, B2B buyers should establish relationships with multiple suppliers and understand their production timelines. Communicating urgency at the outset of the order process allows suppliers to prioritize and allocate resources accordingly. Additionally, incorporating buffer times into project timelines can help manage expectations. Regular updates and proactive follow-ups with suppliers can also ensure that any potential delays are addressed promptly. By fostering strong supplier relationships and having contingency plans in place, businesses can navigate lead time challenges more effectively and maintain operational continuity.

Strategic Material Selection Guide for acrylic character carabiner

What Are the Key Materials Used in Acrylic Character Carabiners?

When selecting materials for acrylic character carabiners, several options can be considered based on their performance characteristics, cost, and suitability for various applications. This analysis will cover common materials used in the production of acrylic carabiners, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Acrylic

Key Properties: Acrylic is a lightweight, transparent thermoplastic that offers excellent clarity and UV resistance. It has a temperature rating of approximately 80°C (176°F) and is resistant to many chemicals, making it suitable for various environments.

Pros & Cons: Acrylic is known for its high impact resistance and durability, which makes it ideal for products that may experience wear and tear. However, it can be more expensive than other plastics and may require specialized manufacturing techniques, such as laser cutting, to achieve intricate designs.

Impact on Application: Acrylic is compatible with various printing methods, including CMYK printing, allowing for vibrant, full-color designs. Its transparency can enhance the visual appeal of character carabiners, making them popular for promotional items.

Considerations for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should ensure compliance with local regulations regarding plastic materials. Standards such as ASTM and DIN may apply, particularly concerning safety and environmental impact.

Polycarbonate

Key Properties: Polycarbonate is another thermoplastic known for its high impact resistance and temperature tolerance, with a rating of up to 120°C (248°F). It is also resistant to UV light and has good optical clarity.

Illustrative image related to acrylic character carabiner

Pros & Cons: The main advantage of polycarbonate is its exceptional toughness, making it suitable for high-stress applications. However, it can be more expensive than acrylic and may scratch more easily unless coated.

Impact on Application: Polycarbonate carabiners can be used in environments where high durability is required, such as outdoor activities. They can also be printed on, but the finish may not be as vibrant as acrylic.

Considerations for International Buyers: Buyers should verify that polycarbonate products meet international safety standards, especially if they are intended for use in consumer products. Compliance with regulations in different regions is critical.

PVC (Polyvinyl Chloride)

Key Properties: PVC is a widely used thermoplastic that is both flexible and durable. It has a temperature resistance of around 60°C (140°F) and is resistant to a wide range of chemicals.

Pros & Cons: PVC is cost-effective and easy to manufacture, making it a popular choice for budget-conscious projects. However, it may not offer the same level of clarity or aesthetic appeal as acrylic or polycarbonate, which can limit its use in character carabiners.

Illustrative image related to acrylic character carabiner

Impact on Application: PVC is suitable for applications where flexibility and cost are prioritized over aesthetics. It can be used in various environments, but its lower temperature resistance may limit its use in extreme conditions.

Considerations for International Buyers: Buyers should be aware of the environmental regulations surrounding PVC, particularly in Europe, where there are strict guidelines on the use of certain chemicals in plastics. Ensuring compliance with local standards is essential.

ABS (Acrylonitrile Butadiene Styrene)

Key Properties: ABS is a tough thermoplastic known for its strength and impact resistance. It has a temperature rating of about 80°C (176°F) and is resistant to many chemicals.

Pros & Cons: The primary advantage of ABS is its balance between cost and performance. It is less expensive than acrylic and polycarbonate while still providing good durability. However, it may not have the same level of clarity, which can be a drawback for character designs.

Illustrative image related to acrylic character carabiner

Impact on Application: ABS carabiners can be effectively used in a variety of applications, particularly in environments where strength is more critical than appearance. They can be painted or coated for customization.

Considerations for International Buyers: Buyers should check for compliance with international standards, as ABS can sometimes contain additives that may not meet regulations in certain regions, particularly in Europe.

Summary Table of Material Selection for Acrylic Character Carabiners

| Material | Typical Use Case for acrylic character carabiner | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Acrylic | Promotional items, keychains | High clarity and UV resistance | Higher manufacturing complexity | Medium |

| Polycarbonate | Outdoor gear, high-stress applications | Exceptional toughness | More expensive, prone to scratching | High |

| PVC | Budget-friendly products, flexible applications | Cost-effective and easy to manufacture | Limited aesthetic appeal | Low |

| ABS | General-purpose use, strength-focused items | Good balance of cost and performance | Lower clarity than acrylic | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for acrylic character carabiner

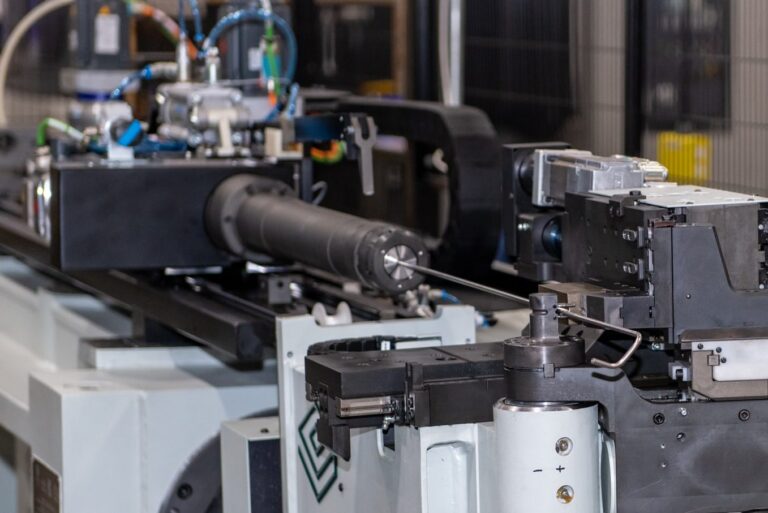

What Are the Main Stages in the Manufacturing Process of Acrylic Character Carabiners?

The manufacturing of acrylic character carabiners involves several critical stages that ensure product quality and aesthetic appeal. These stages include material preparation, forming, assembly, and finishing.

Illustrative image related to acrylic character carabiner

-

Material Preparation: The process begins with selecting high-quality acrylic sheets that meet industry specifications. Suppliers often use PMMA (Polymethyl Methacrylate) due to its excellent clarity and durability. The acrylic sheets are cut to size using precision laser cutting or CNC (Computer Numerical Control) machines, which provide accuracy and reduce waste.

-

Forming: After the material is prepared, forming techniques come into play. Laser cutting is commonly used for creating intricate shapes and designs. This method ensures clean edges and minimizes the need for further finishing. For more complex designs, thermoforming may be employed, where heated acrylic is shaped into molds.

-

Assembly: Once the individual components are formed, they are assembled. This often involves attaching the carabiner clip mechanism, which must function smoothly. During this stage, attention is paid to alignments and fittings to ensure that the final product operates correctly and safely.

-

Finishing: The finishing stage includes polishing edges to enhance clarity and aesthetic appeal. Some manufacturers apply coatings for additional durability or to achieve specific visual effects, such as a crystal or frosted finish. Quality checks are performed throughout these stages to identify any defects early in the process.

How Is Quality Assurance Implemented During Acrylic Carabiner Production?

Quality assurance (QA) is a vital component of the manufacturing process for acrylic character carabiners, ensuring that products meet international standards and customer expectations.

-

International Standards Compliance: Many manufacturers adhere to international quality management systems such as ISO 9001. This certification ensures that organizations follow systematic processes to manage quality effectively. Compliance with regional standards like CE (Conformité Européenne) and industry-specific certifications like API (American Petroleum Institute) may also be necessary, depending on the intended use of the carabiners.

-

Quality Control Checkpoints: Throughout the production process, multiple quality control checkpoints are established:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards. This includes checking for defects in acrylic sheets and verifying supplier certifications.

– In-Process Quality Control (IPQC): During production, operators conduct inspections at various stages. This includes verifying dimensions after cutting and ensuring the proper assembly of components.

– Final Quality Control (FQC): Before shipment, the finished carabiners undergo a comprehensive inspection. This includes functional testing of the clip mechanism and visual inspections for surface defects. -

Common Testing Methods: Manufacturers often employ various testing methods to verify the quality of acrylic character carabiners. These may include:

– Visual Inspection: Checking for scratches, bubbles, and color consistency.

– Functional Testing: Assessing the durability of the carabiner’s clip mechanism under load.

– Stress Testing: Evaluating the acrylic’s resistance to impact and bending.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, ensuring the quality of suppliers is crucial. Here are actionable steps to verify quality control practices:

-

Conducting Supplier Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes and adherence to quality standards. This can be done through on-site visits or remote assessments, depending on logistics and resources.

-

Requesting Quality Assurance Documentation: Buyers should ask for documentation related to quality control processes. This includes certificates of compliance with international standards, inspection reports, and records of testing methods used.

-

Engaging Third-Party Inspection Services: To ensure impartiality, B2B buyers can employ third-party inspection services. These organizations can conduct thorough inspections at various stages of production and provide unbiased reports on quality.

-

Reviewing Customer Feedback and References: It is beneficial to look for reviews from other businesses that have previously worked with the supplier. Testimonials can provide valuable insights into the reliability and quality of the products.

What Are the Quality Control Nuances for International Buyers?

International buyers must navigate specific nuances when dealing with quality control in different regions. Here are some considerations:

-

Understanding Regional Regulations: Different regions may have unique regulations regarding product safety and quality. For example, European markets may have stringent CE marking requirements, while other regions may prioritize different certifications.

-

Cultural Differences in Quality Expectations: Expectations regarding quality may vary between cultures. It is essential to communicate clearly about quality requirements and specifications to ensure alignment between buyers and suppliers.

-

Logistics and Shipping Considerations: International shipping introduces additional risks to product quality. Buyers should discuss packaging and handling procedures with suppliers to minimize the potential for damage during transit.

-

Building Long-Term Relationships: Establishing a long-term relationship with suppliers can enhance trust and improve quality over time. Regular communication and feedback can lead to better alignment in quality expectations and practices.

By understanding the manufacturing processes and quality assurance practices associated with acrylic character carabiners, B2B buyers can make informed decisions when selecting suppliers, ensuring that they receive products that meet their quality standards and business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘acrylic character carabiner’

The following guide is designed to assist B2B buyers in sourcing acrylic character carabiners effectively. By following these steps, you can ensure a successful procurement process, minimizing risks and maximizing quality.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical before initiating the sourcing process. This includes determining the size, thickness, and design features of the acrylic carabiners you require. Consider the end use of the product, as this will influence the material quality and durability needed.

- Size Options: Common sizes range from 2 inches to 4 inches. Specify the dimensions relevant to your branding or customer needs.

- Printing Requirements: Decide if you need single or double-sided printing and the color schemes to be used.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers. Look for companies with a solid reputation in the market for producing custom acrylic products. This step is vital to ensure you partner with a manufacturer that meets your quality standards.

- Supplier Location: Consider suppliers based in regions known for manufacturing quality acrylic products, such as Asia or Europe.

- Market Reviews: Check online reviews and testimonials to gauge customer satisfaction and product quality.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that potential suppliers have the necessary certifications. This ensures compliance with international quality standards, which is especially important for buyers in diverse markets like Africa, South America, and Europe.

- Quality Certifications: Look for ISO certifications or other relevant quality assurance certifications.

- Sustainability Practices: If applicable, inquire about the supplier’s environmental practices and materials used.

Step 4: Request Samples

Request samples of the acrylic carabiners to evaluate the quality firsthand. This allows you to assess the material, printing quality, and overall craftsmanship before placing a bulk order.

Illustrative image related to acrylic character carabiner

- Sample Fees: Be aware that some suppliers may charge for samples, which is often refundable upon placing a larger order.

- Production Time: Understand the lead time for sample production to plan your procurement timeline effectively.

Step 5: Negotiate Terms and Pricing

Once you have identified a supplier that meets your requirements, engage in negotiations regarding pricing, minimum order quantities, and payment terms. Clear negotiations can lead to better pricing and favorable terms.

- Bulk Discounts: Inquire about discounts for larger orders, which can significantly reduce your overall costs.

- Payment Methods: Ensure that the payment methods offered are secure and convenient for your business.

Step 6: Confirm Production Timeline

Understanding the production timeline is crucial for planning your inventory and sales strategy. Confirm the estimated lead times for production and shipping to avoid any supply chain disruptions.

- Production Speed: Suppliers should provide a clear timeline for how long it will take to produce your order after approval.

- Shipping Options: Evaluate the shipping methods available and their corresponding timelines to ensure timely delivery.

Step 7: Review and Finalize Your Order

Before finalizing your order, review all details including product specifications, quantities, and delivery dates. Confirm that all agreed terms are documented to avoid any misunderstandings later.

- Proof Approval: Ensure that you receive a proof of your design before production begins, allowing for any last-minute changes.

- Contractual Agreement: If necessary, draft a contract outlining all terms, including quality expectations and delivery timelines, to protect your interests.

By following this comprehensive checklist, B2B buyers can streamline the sourcing process for acrylic character carabiners, ensuring a successful procurement that meets their business needs.

Comprehensive Cost and Pricing Analysis for acrylic character carabiner Sourcing

When sourcing acrylic character carabiners, understanding the cost structure and pricing dynamics is crucial for B2B buyers, particularly those operating in diverse international markets such as Africa, South America, the Middle East, and Europe.

Illustrative image related to acrylic character carabiner

What Are the Key Cost Components of Acrylic Character Carabiners?

The cost structure for acrylic character carabiners typically includes several critical components:

-

Materials: The primary cost driver is the acrylic itself, which varies based on quality and type. High-grade acrylic may command higher prices but offers better durability and visual appeal.

-

Labor: The manufacturing process often involves skilled labor for tasks like laser cutting, printing, and assembly. Labor costs can fluctuate based on the supplier’s location, affecting overall pricing.

-

Manufacturing Overhead: This includes utilities, facility costs, and equipment depreciation. Suppliers may pass these costs onto buyers, especially if production is located in regions with higher operational expenses.

-

Tooling: Initial setup costs for custom designs can be significant, particularly for molds and cutting tools. These costs are often amortized over larger orders, making them less impactful per unit when purchasing at scale.

-

Quality Control (QC): Ensuring that each carabiner meets quality standards involves testing and inspection, which can add to the cost. Buyers should consider suppliers with robust QC processes to minimize defects.

-

Logistics: Shipping costs can vary widely based on the origin and destination. Factors like freight options, packaging, and potential customs duties must be considered, particularly for international orders.

-

Margin: Suppliers typically apply a markup on their costs, which can vary based on competition, brand positioning, and perceived value. Understanding this margin is vital for effective negotiation.

How Do Price Influencers Affect Sourcing Decisions?

Several factors influence the pricing of acrylic character carabiners:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly impact pricing. Larger orders often lead to lower per-unit costs due to economies of scale.

-

Specifications and Customization: Custom designs, special finishes, or advanced features can increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials: Different grades of acrylic or the inclusion of additional materials for enhanced durability can affect pricing. Buyers should weigh the benefits against costs.

-

Quality and Certifications: Suppliers offering certifications (e.g., ISO) or those known for high-quality products may charge a premium. However, this can lead to better long-term value.

-

Supplier Factors: The supplier’s reputation, reliability, and service level can influence pricing. Established suppliers may charge more but often provide better support and consistency.

-

Incoterms: Understanding shipping terms (Incoterms) is essential for calculating total landed costs. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can significantly impact overall expenses.

What Negotiation Strategies Can Buyers Use for Cost-Efficiency?

To maximize cost-efficiency when sourcing acrylic character carabiners, buyers can adopt the following strategies:

-

Leverage Volume: Consider consolidating orders to meet higher MOQs, which may lead to better pricing.

-

Request Detailed Quotes: Ask for itemized pricing to understand the breakdown of costs. This transparency can aid in negotiations.

-

Explore Multiple Suppliers: Getting quotes from several suppliers can help identify competitive pricing and service offerings.

-

Negotiate Terms: Discuss payment terms and delivery schedules. Flexible arrangements can sometimes yield discounts.

-

Calculate Total Cost of Ownership (TCO): Beyond initial pricing, consider factors like durability, maintenance, and logistics costs to make informed decisions.

Conclusion: Why Understanding Pricing Nuances Matters for International Buyers

For international B2B buyers, particularly those in diverse markets, understanding the nuances of acrylic character carabiner pricing is essential. Factors such as local market conditions, supplier reliability, and logistics can significantly affect total costs. As prices can vary widely based on the aforementioned components and influencers, thorough research and strategic negotiation are vital for securing the best deals.

Disclaimer: Prices mentioned in this analysis are indicative and may vary based on supplier, region, and market conditions. Always request up-to-date quotes from suppliers.

Alternatives Analysis: Comparing acrylic character carabiner With Other Solutions

When considering the purchase of acrylic character carabiners, it’s essential to evaluate alternative solutions that may serve similar purposes. This analysis will provide insights into the strengths and weaknesses of the acrylic character carabiner compared to other options, helping B2B buyers make informed decisions.

| Comparison Aspect | Acrylic Character Carabiner | Metal Carabiner | Plastic Keychain Clip |

|---|---|---|---|

| Performance | Lightweight and durable, suitable for promotional use | High strength and durability, ideal for heavy-duty applications | Moderate strength, best for light items |

| Cost | $1.80 – $3.99 per unit | $0.50 – $5.00 per unit | $0.10 – $2.00 per unit |

| Ease of Implementation | Customizable designs available, easy to order | Limited customization, more rigid production processes | Simple production, minimal customization options |

| Maintenance | Low maintenance, resistant to fading | Low maintenance, corrosion-resistant | Moderate maintenance, can become brittle over time |

| Best Use Case | Promotional giveaways, events, light usage | Outdoor activities, climbing, heavy loads | Everyday use, casual applications |

What are the Pros and Cons of Using Metal Carabiners as an Alternative?

Metal carabiners are renowned for their strength and durability, making them suitable for more demanding applications, such as climbing or securing heavy loads. They often come in various designs, allowing for some customization, though options are limited compared to acrylic counterparts. On the downside, metal carabiners can be significantly heavier and may not be as visually appealing for promotional purposes. Their cost can vary widely depending on the material and brand, making them less attractive for bulk promotional orders.

How Do Plastic Keychain Clips Compare to Acrylic Character Carabiners?

Plastic keychain clips are an economical alternative, particularly for everyday use. They are lightweight and easy to produce, with lower costs per unit. However, their strength is limited, making them unsuitable for heavy-duty applications. While they can be printed with basic designs, customization options are often minimal. Additionally, plastic clips may degrade over time due to exposure to sunlight and other environmental factors, which can affect their longevity and appearance.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting a carabiner solution, B2B buyers should consider their specific use cases, budget constraints, and desired aesthetic. Acrylic character carabiners excel in promotional settings where customization and visual appeal are paramount, while metal carabiners are better suited for high-strength applications. Plastic keychain clips offer a cost-effective solution for everyday use but may lack durability. By understanding the distinct advantages and limitations of each option, businesses can make strategic decisions that align with their operational requirements and branding goals.

Essential Technical Properties and Trade Terminology for acrylic character carabiner

What Are the Key Technical Properties of Acrylic Character Carabiners?

Acrylic character carabiners are specialized products that combine functionality with aesthetic appeal. Understanding their technical properties is essential for B2B buyers to make informed purchasing decisions. Here are some critical specifications to consider:

-

Material Grade

Acrylic carabiners are primarily made from high-quality acrylic, which is known for its clarity and durability. The material grade affects the carabiner’s strength, transparency, and resistance to UV light. Higher-grade acrylic typically results in better longevity and visual appeal, making it an important factor for buyers focused on quality. -

Size and Dimensions

These carabiners come in various sizes, commonly ranging from 50.8mm (2 inches) to 101.6mm (4 inches). The size is crucial for their intended use, whether for keychains, promotional items, or functional applications. Buyers should consider the dimensions that best fit their branding or functional requirements, as it influences both aesthetics and usability. -

Printing Techniques

Customization options such as CMYK printing and double-sided designs allow businesses to add their logos or artwork. The choice of printing technique can significantly impact the final product’s appearance and brand representation. Understanding the capabilities and limitations of different printing methods is vital for ensuring that the final product meets expectations. -

Production Tolerance

Tolerance refers to the allowable deviation from specified dimensions during manufacturing. A tighter tolerance ensures that the final product meets precise specifications, which is particularly important for businesses that require uniformity in bulk orders. Buyers should inquire about the production tolerances to ensure that their needs are met, especially when precision is critical. -

Finish Options

The finish of acrylic carabiners can vary, including options for full bleed printing and smooth edges. The finish affects both the aesthetic quality and the tactile experience of the product. A well-finished product enhances brand perception and can influence customer satisfaction, making this an important specification for B2B buyers. -

Load Capacity

Although primarily decorative, acrylic carabiners can still have load limits based on their design and material properties. Understanding the load capacity is crucial for businesses that intend to use these carabiners for functional purposes, such as attaching items to bags or belts.

What Are Common Trade Terms Related to Acrylic Character Carabiners?

Familiarity with industry terminology can streamline the purchasing process and improve communication with suppliers. Here are several key terms:

Illustrative image related to acrylic character carabiner

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are sold under another company’s brand. For acrylic carabiners, buyers might engage with OEMs to create custom designs or branding, ensuring that their products meet specific market needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell in a single order. Understanding MOQs is essential for B2B buyers as it impacts inventory management and cash flow. Suppliers often set MOQs based on production costs and materials, so it’s crucial to negotiate terms that align with your business needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products. When sourcing acrylic carabiners, buyers should prepare a detailed RFQ to ensure they receive accurate quotes, including specifications like size, printing options, and delivery timelines. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Understanding these terms is vital for B2B transactions involving acrylic carabiners, as they dictate shipping costs, insurance, and risk transfer, ensuring both parties are clear on their obligations. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. For B2B buyers, understanding lead times is crucial for inventory planning and meeting customer demands. It’s advisable to clarify lead times with suppliers to avoid delays in product availability. -

Customization Options

This term encompasses various ways to personalize the acrylic carabiners, including size, design, color, and printing methods. Knowing the available customization options allows businesses to align their promotional products with their branding strategies effectively.

By mastering these technical properties and trade terms, international B2B buyers can navigate the acrylic character carabiner market more effectively, ensuring they make informed decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the acrylic character carabiner Sector

Market Overview & Key Trends: What Are the Current Dynamics in the Acrylic Character Carabiner Sector?

The acrylic character carabiner market is experiencing robust growth, driven primarily by the increasing demand for customized promotional products and accessories. This surge is attributed to a growing trend among businesses to enhance brand visibility through unique and personalized items. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly sourcing these products as they look to differentiate themselves in competitive markets.

Emerging technologies in production, such as advanced laser cutting and CMYK printing, allow for high-quality customization at scale. These innovations not only reduce lead times but also enable businesses to offer a wider range of designs and sizes, catering to diverse customer preferences. Additionally, platforms providing online ordering and proofing systems streamline the procurement process, making it easier for international buyers to manage bulk orders efficiently.

Market dynamics are also influenced by shifts in consumer behavior towards more sustainable and ethically sourced products. As awareness of environmental issues grows, businesses that prioritize sustainability in their sourcing strategies are likely to gain a competitive edge. This shift is particularly pronounced in Europe, where eco-conscious purchasing is becoming a standard practice among consumers and businesses alike.

How Are Sustainability and Ethical Sourcing Shaping the Acrylic Character Carabiner Market?

Sustainability is increasingly becoming a non-negotiable aspect of the B2B procurement process. For the acrylic character carabiner sector, the environmental impact of acrylic production and disposal is a significant concern. Buyers are now more inclined to partner with suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials or implementing eco-friendly manufacturing processes.

Illustrative image related to acrylic character carabiner

Ethical sourcing goes hand in hand with sustainability. It is essential for suppliers to maintain transparency in their supply chains, ensuring fair labor practices and minimizing environmental impact. Certifications like ISO 14001 for environmental management and Fair Trade can enhance credibility and appeal to conscientious buyers. Furthermore, the demand for ‘green’ materials is rising, with businesses seeking alternatives that reduce their carbon footprint while still delivering quality products.

As a result, international buyers are advised to conduct thorough due diligence on potential suppliers, focusing on their sustainability credentials and ethical practices. This not only aligns with corporate social responsibility goals but also resonates well with an increasingly eco-aware customer base.

What Is the Evolution of the Acrylic Character Carabiner Market?

The acrylic character carabiner has evolved significantly over the years, transitioning from a simple utility tool to a versatile promotional item. Initially popular in outdoor and adventure contexts, the product’s appeal expanded as customization options became available.

Illustrative image related to acrylic character carabiner

The rise of digital printing technologies and laser cutting has allowed for intricate designs and vibrant colors, making these carabiners not just functional but also stylish accessories. This evolution has been particularly impactful for businesses looking to leverage promotional products for marketing campaigns. Today, acrylic character carabiners are used across various sectors, from retail to events, reflecting their adaptability and enduring popularity in the B2B space.

As the market continues to evolve, staying attuned to consumer preferences and technological advancements will be crucial for businesses aiming to thrive in the acrylic character carabiner sector.

Frequently Asked Questions (FAQs) for B2B Buyers of acrylic character carabiner

-

How do I ensure the quality of acrylic character carabiners from suppliers?

To ensure quality when sourcing acrylic character carabiners, request samples before placing a bulk order. Evaluate the samples for clarity, durability, and finish. Additionally, inquire about the supplier’s quality assurance processes, such as inspections during production and final checks. It’s also beneficial to read customer reviews and testimonials to gauge past performance. Lastly, consider suppliers that offer warranties or guarantees on their products, as this can indicate confidence in quality. -

What is the best way to customize acrylic character carabiners for my brand?

The best way to customize acrylic character carabiners is to work closely with suppliers who specialize in custom designs. Look for suppliers that offer various printing methods, such as CMYK printing or full bleed options, to ensure vibrant and detailed designs. When submitting your design, ensure it’s high resolution and meets the supplier’s specifications. Discuss options for size, shape, and additional features like key rings or clips that align with your branding strategy. -

What are the typical minimum order quantities (MOQs) for acrylic character carabiners?

Minimum order quantities for acrylic character carabiners can vary significantly by supplier. Many suppliers offer flexible MOQs, sometimes allowing orders as low as one piece for custom designs. However, for bulk pricing and better rates, it’s common to see MOQs range from 100 to 500 units. Always confirm the MOQ with your chosen supplier to align with your budget and inventory needs. -

What payment terms should I expect when sourcing acrylic character carabiners internationally?

When sourcing internationally, payment terms can vary widely based on the supplier and your negotiation. Common terms include a 30% deposit upfront with the remaining balance due upon shipment or delivery. Some suppliers may offer net payment terms (e.g., net 30 or net 60 days) for established relationships. Always clarify payment methods accepted, such as bank transfers, PayPal, or credit cards, and ensure you understand any additional fees related to currency conversion or international transactions. -

How can I vet suppliers of acrylic character carabiners effectively?

To effectively vet suppliers, start by checking their business credentials, such as registration and certifications. Look for reviews and ratings on platforms like Alibaba, Global Sources, or trade forums. Request references from previous clients, particularly those in your industry. Additionally, consider conducting a factory audit or visiting their premises if feasible. This due diligence can help you assess their production capabilities, quality control measures, and overall reliability. -

What logistics considerations should I keep in mind when importing acrylic character carabiners?

When importing acrylic character carabiners, consider shipping methods, customs duties, and lead times. Determine whether air freight or sea freight is more cost-effective for your order size and urgency. Be aware of the customs regulations in your country, as these can affect delivery times and costs. Partnering with a freight forwarder can simplify the logistics process, helping you navigate documentation and compliance issues, ensuring smoother delivery. -

What are common design limitations for acrylic character carabiners?

Common design limitations for acrylic character carabiners include the size of intricate designs and the clarity of printed text. Complex designs may lose detail when scaled down, so it’s crucial to work within the supplier’s design guidelines. Additionally, if your design includes text, ensure it’s legible on the carabiner’s surface. Discuss any specific requirements with your supplier to optimize your design for the best possible outcome. -

How long does production and shipping typically take for acrylic character carabiners?

Production time for acrylic character carabiners typically ranges from 5 to 14 business days, depending on customization options and order size. After production, shipping times can vary based on the method chosen—standard delivery may take 8-13 business days, while expedited options can reduce this to 3-5 business days. Always confirm these timelines with your supplier to manage your expectations and plan your inventory accordingly.

Top 8 Acrylic Character Carabiner Manufacturers & Suppliers List

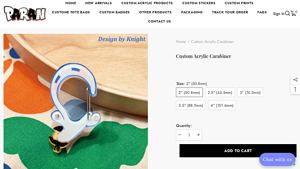

1. Lollipop Ins – Custom Acrylic Carabiner

Domain: lollipopins.com

Registered: 2022 (3 years)

Introduction: Custom acrylic carabiner, available in various colors, lightweight and durable, ideal for promotional use, customizable with logos or designs, suitable for outdoor activities, dimensions and weight not specified.

2. Vograce – Custom Acrylic Carabiner

Domain: vograce.com

Registered: 2016 (9 years)

Introduction: {“product_name”:”Custom Acrylic Carabiner”,”regular_price”:”$2.28″,”sizes”:[“1.5”(38.1mm)”,”2”(50.8mm)”,”2.5”(63.5mm)”,”3”(76.2mm)”,”3.5”(88.9mm)”,”4”(101.6mm)”,”4.5”(114.3mm)”,”5”(127mm)”],”printing_options”:[“Double sided same design”,”Double sided different design”],”accessories_options”:[“Ball Bead Chain”,”NO-Accessories”],”minimum_order_quantity”:1,”bulk_discount”:{“6+”:”10% off”,”16+…

3. Etsy – Acrylic Carabiners

Domain: etsy.com

Introduction: Acrylic carabiners available in various designs and price ranges. Prices range from $10.00 to $98.95. Notable products include: Anime Tactical/Military Gun Waifu Acrylic Charm Keychain ($10.00), KYLIHNK Ti-Drone Carabiner/Swivel Piston Skull Bob Keychain ($98.95), Tempura Fried Shrimp Acrylic Carabiner Trinket Keychain Holder ($10.00), Sea Creature Carabiner featuring designs like fish, octopus, s…

4. Zoartix – Custom Full Bleed Acrylic Carabiner

Domain: zoartix.com

Registered: 2024 (1 years)

Introduction: {“product_name”:”Custom Full Bleed Acrylic Carabiner”,”price”:”$3.99 USD”,”size”:”70mm wide”,”print”:”double-sided same design”,”finish”:”full bleed (2.5mm bleed cutting)”,”shipping_info”:{“processing_time”:”5-10 days”,”standard_delivery”:”8-13 business days”,”fast_delivery”:”6-10 business days”,”expedited_delivery”:”3-5 business days”},”availability”:”In stock, ready to ship”}

5. ScrapingDog – Instagram Scraping Services

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: Contact us at [email protected] for scraping Instagram. Let us know how many pages you want to scrape per month.

6. Pacific Omega – Acrylic Carabiner Manufacturer

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Acrylic carabiner, looking for a manufacturer, specific size not mentioned, reference to a previous manufacturer (Pacific Omega) that is no longer in operation.

7. Paran Crafts – Custom Acrylic Carabiner

Domain: parancrafts.com

Introduction: Custom acrylic carabiner, available in various colors, ideal for promotional use, lightweight and durable, customizable with logos or designs, suitable for outdoor activities and everyday use.

8. Jean A Draws – Whale Acrylic Carabiner

Domain: jeanadraws.com

Registered: 2020 (5 years)

Introduction: {“product_name”: “Whale Acrylic Carabiner”, “regular_price”: “$15.00”, “sale_price”: “$15.00”, “description”: “A carabiner for your bag to hold more of your favorite trinkets and keychains!”, “features”: [“Acrylic carabiner with double sided print”, “Metal clasp hardware”], “dimensions”: “Approx 3.4 inches large”}

Strategic Sourcing Conclusion and Outlook for acrylic character carabiner

The acrylic character carabiner market presents a wealth of opportunities for international B2B buyers, particularly those based in Africa, South America, the Middle East, and Europe. The customization potential, vibrant aesthetics, and practical applications of these products make them ideal for promotional items, merchandise, and unique branding solutions. Strategic sourcing is paramount; leveraging suppliers who prioritize quality and customer service can significantly enhance your product offerings.

As buyers consider their sourcing strategies, understanding production timelines, minimum order quantities, and available customization options is essential. Engaging with manufacturers who demonstrate flexibility in design and production methods can lead to innovative solutions tailored to specific market needs.

Looking ahead, the acrylic carabiner market is poised for growth, driven by increasing demand for personalized promotional products. International buyers are encouraged to explore partnerships with reliable suppliers that can deliver not just products, but also value-added services. By doing so, you can position your business to capitalize on this trend, ensuring a competitive edge in a dynamic marketplace. Connect with suppliers today to discover how acrylic character carabiners can enhance your product line and drive your brand forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.