Is Your Abrasive Machining Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for abrasive machining

In today’s competitive manufacturing landscape, sourcing the right abrasive machining solutions can be a daunting task for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. With an array of options available, from grinding to superfinishing, understanding the nuances of abrasive machining processes is essential for optimizing production and achieving superior product quality. This comprehensive guide aims to demystify abrasive machining, exploring its various types, applications, and the critical parameters that influence outcomes.

Buyers will find valuable insights on how to effectively vet suppliers, assess costs, and make informed decisions that align with their operational needs. Additionally, we will address key challenges such as identifying suitable abrasive materials, ensuring compliance with safety standards, and understanding the environmental impacts of different machining processes. Whether you’re in Brazil seeking advanced grinding solutions or in Germany exploring the latest innovations in water-jet cutting, this guide is designed to empower your purchasing decisions. By navigating the complexities of the global abrasive machining market with confidence, you can enhance your manufacturing capabilities and drive competitive advantage.

Understanding abrasive machining Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Grinding | Utilizes a rotating grinding wheel for material removal | Automotive, Aerospace, Toolmaking | Pros: High precision, versatile. Cons: Can generate heat, requires cooling. |

| Honing | Focuses on achieving precise dimensions and finishes | Engine components, Hydraulic cylinders | Pros: Enhances surface finish, tight tolerances. Cons: Slower process, limited to specific applications. |

| Superfinishing | Achieves ultra-smooth surface finishes | Bearings, Gears, Precision components | Pros: Exceptional finish quality, reduces wear. Cons: More expensive, specialized equipment needed. |

| Abrasive Belt Machining | Employs a continuous belt of abrasive material | Metal fabrication, Woodworking | Pros: Efficient for large surfaces, consistent results. Cons: Belt wear can increase costs. |

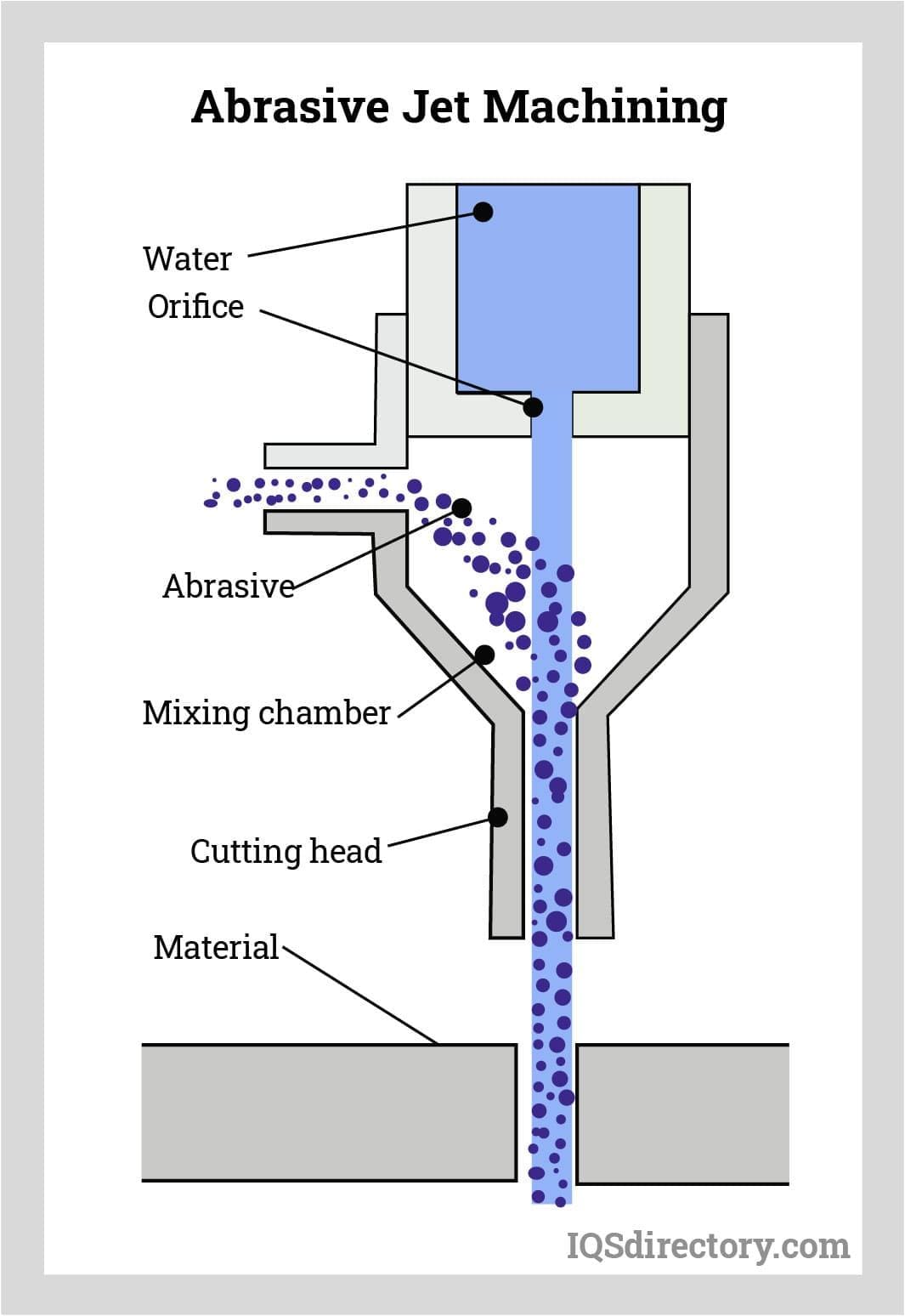

| Water-Jet Cutting | Uses high-pressure water mixed with abrasives | Aerospace, Automotive, Art | Pros: No heat-affected zones, versatile materials. Cons: Higher operational costs, slower than some traditional methods. |

What are the Characteristics of Grinding in Abrasive Machining?

Grinding is one of the most common forms of abrasive machining, characterized by its use of a rotating grinding wheel that removes material from a workpiece. This method is highly versatile and can accommodate various materials, making it ideal for industries such as automotive and aerospace. When purchasing grinding equipment, buyers should consider wheel composition, machine precision, and the ability to manage heat generation, which can affect material integrity.

How Does Honing Enhance Surface Quality?

Honing is primarily utilized for achieving precise dimensions and superior surface finishes, particularly in cylindrical components like engine parts and hydraulic cylinders. This process involves a honing stone that gently abrades the workpiece, allowing for very tight tolerances. B2B buyers should evaluate the type of honing stones used and the machine’s capability to handle specific materials to ensure optimal results in their applications.

What Makes Superfinishing Essential for Precision Components?

Superfinishing stands out in abrasive machining for its ability to deliver ultra-smooth surface finishes, making it crucial for components like bearings and gears that demand minimal friction. This process often employs specialized stones or tapes and requires a significant investment in equipment. Buyers should assess the cost-benefit ratio, as the initial expenditure can lead to improved product performance and longevity.

Why Choose Abrasive Belt Machining for Large Surface Areas?

Abrasive belt machining is favored for its efficiency in processing large, flat surfaces. This method uses a continuous belt of abrasive material, making it ideal for industries such as metal fabrication and woodworking. When considering abrasive belt machines, buyers should focus on belt durability, grit size options, and the machine’s throughput capabilities to maximize productivity while minimizing operational costs.

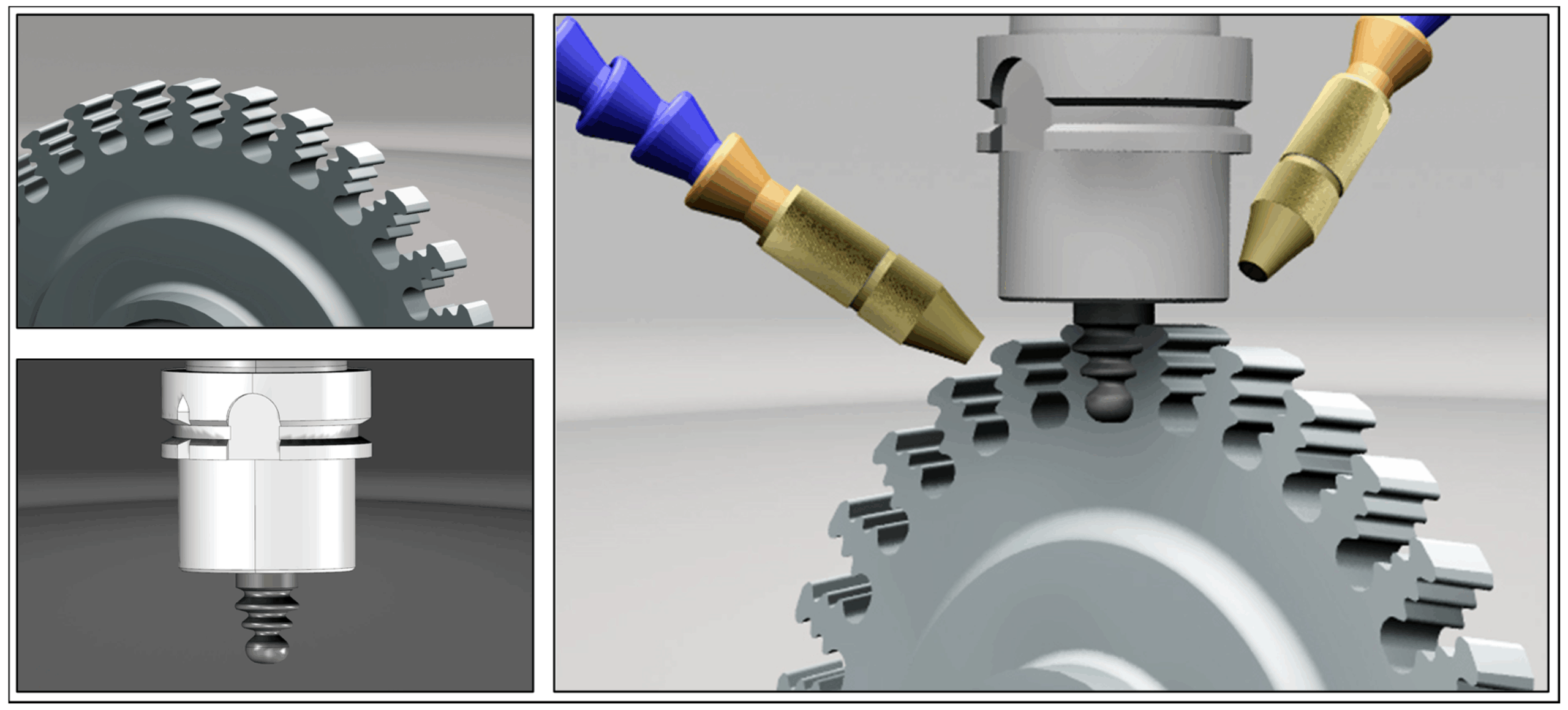

Illustrative image related to abrasive machining

How Does Water-Jet Cutting Offer Versatility in Material Processing?

Water-jet cutting utilizes high-pressure water mixed with abrasive materials to achieve precise cuts without generating heat that can alter material properties. This versatility makes it suitable for a wide range of applications, including aerospace and artistic endeavors. Buyers should consider the operational costs and the types of materials their projects require, as water-jet cutting can be more expensive than traditional methods but offers unique advantages in precision and finish.

Key Industrial Applications of abrasive machining

| Industry/Sector | Specific Application of Abrasive Machining | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision component manufacturing | Enhanced accuracy and weight reduction | Need for certified suppliers with aerospace-grade materials |

| Automotive | Engine component finishing | Improved performance and durability | High-quality abrasives and advanced machining technologies |

| Metal Fabrication | Surface preparation and finishing | Increased lifespan of components | Availability of various grit sizes and types of abrasives |

| Medical Devices | Custom implant manufacturing | Biocompatibility and precision in fit | Regulatory compliance and quality assurance certifications |

| Electronics | PCB surface preparation | Enhanced conductivity and reliability | Sourcing from suppliers with expertise in fine abrasive processes |

How is Abrasive Machining Used in the Aerospace Industry?

In the aerospace sector, abrasive machining is critical for manufacturing precision components such as turbine blades and structural parts. These applications require exacting tolerances and a lightweight finish to enhance fuel efficiency and performance. International buyers must prioritize suppliers who meet stringent aerospace standards, ensuring that materials are sourced from certified manufacturers capable of providing traceability and quality assurance documentation.

What Role Does Abrasive Machining Play in Automotive Applications?

Abrasive machining is extensively used in finishing engine components, such as crankshafts and camshafts, where precision and surface integrity are paramount. This process improves the performance and durability of automotive parts, reducing friction and wear. Buyers from regions like South America and Europe should seek suppliers who can offer advanced grinding technologies and high-quality abrasives that comply with automotive industry standards.

Why is Abrasive Machining Important in Metal Fabrication?

In metal fabrication, abrasive machining is employed for surface preparation and finishing, ensuring that metal parts are free from defects and ready for subsequent processes like coating or welding. This enhances the longevity and performance of the components. Buyers should consider suppliers who can provide a range of abrasive options, including various grit sizes and types, to suit specific metal types and desired finishes.

How Does Abrasive Machining Benefit the Medical Device Industry?

For the medical device industry, abrasive machining is essential in the custom manufacturing of implants and surgical instruments. Precision is critical, as is the biocompatibility of the materials used. International buyers must ensure that their suppliers adhere to strict regulatory compliance and quality assurance processes, as any deviation can lead to significant safety issues.

Illustrative image related to abrasive machining

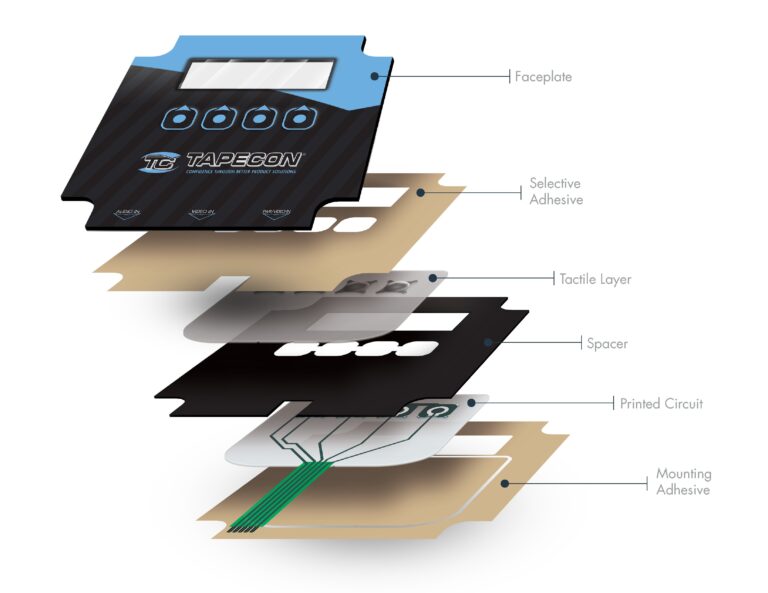

What is the Significance of Abrasive Machining in Electronics Manufacturing?

In the electronics sector, abrasive machining is used for surface preparation of printed circuit boards (PCBs), enhancing their conductivity and reliability. This process is vital for ensuring that electronic components function effectively and meet performance standards. Buyers should focus on sourcing from suppliers who specialize in fine abrasive processes and have a deep understanding of the unique requirements of electronic manufacturing.

3 Common User Pain Points for ‘abrasive machining’ & Their Solutions

Scenario 1: Struggling with Surface Finish Quality Issues in Abrasive Machining

The Problem: B2B buyers often face the challenge of achieving a consistent and high-quality surface finish on machined parts. Variations in abrasive grain sizes, wheel composition, and machining parameters can lead to defects such as scratches, uneven textures, or insufficient smoothness. These quality issues not only affect the aesthetic appeal of the products but can also impact their functionality, leading to increased rejection rates and costly rework. Manufacturers in industries like automotive and aerospace, where precision is paramount, find these challenges particularly pressing.

The Solution: To mitigate surface finish issues, it is crucial to conduct a thorough analysis of the abrasive materials and machining parameters being utilized. Buyers should start by selecting the right type of grinding wheel based on the specific material being processed. For instance, using wheels with aluminum oxide for ferrous materials and silicon carbide for non-ferrous materials can yield better results. Additionally, investing in advanced wheel dressing tools can maintain the wheel’s shape and cutting efficiency over time, reducing the likelihood of surface defects. Regular monitoring and adjustment of parameters such as feed rate, wheel speed, and coolant application can further enhance surface quality. Implementing a quality control process that includes surface roughness testing can help ensure that the finished parts meet the required specifications.

Scenario 2: Overcoming Excessive Heat Generation During Machining

The Problem: Excessive heat generation during abrasive machining can lead to material degradation, altered properties, and even tool wear. B2B buyers in sectors like metal fabrication and precision engineering often experience challenges related to overheating, which can compromise the integrity of the workpiece and reduce the lifespan of the grinding wheel. This not only affects production efficiency but can also lead to costly downtime and repairs.

The Solution: To combat overheating, it is essential to optimize the cooling and lubrication processes. Buyers should consider employing high-quality coolants that not only reduce friction but also dissipate heat effectively. Implementing flood cooling or mist cooling systems can ensure that the workpiece and the grinding wheel maintain optimal temperatures throughout the machining process. Additionally, selecting abrasives designed for high-speed operations can help mitigate heat generation. Regular maintenance of the grinding machine, including checking for proper alignment and wear, can also contribute to more efficient heat management. It may be beneficial to conduct thermal imaging inspections periodically to identify hotspots and adjust machining parameters accordingly.

Scenario 3: Difficulty in Sourcing the Right Abrasive Materials

The Problem: Sourcing suitable abrasive materials can be a significant hurdle for B2B buyers, especially in regions with limited access to specialized suppliers. Buyers often struggle to find abrasives that meet specific application requirements, such as grain size, bonding agents, and hardness. This challenge can result in delays in production schedules and increased costs due to trial-and-error approaches in material selection.

The Solution: To effectively source the right abrasive materials, buyers should establish relationships with reputable suppliers who specialize in abrasive products. Engaging with suppliers that offer a diverse range of abrasives can provide access to tailored solutions that fit specific applications. It is advisable to conduct thorough market research and request samples to evaluate the performance of different abrasives before making bulk purchases. Buyers should also leverage industry networks and online platforms to connect with other manufacturers who can share their experiences with various abrasive materials. Implementing a systematic approach to evaluate and compare suppliers based on quality, availability, and cost can streamline the procurement process and ensure that the right materials are sourced efficiently.

Strategic Material Selection Guide for abrasive machining

What Materials Are Commonly Used in Abrasive Machining and Their Key Properties?

When selecting materials for abrasive machining, it’s essential to consider their properties and how they align with specific applications. Below are analyses of four common materials used in this process, focusing on their performance characteristics, advantages, limitations, and considerations for international B2B buyers.

Aluminum Oxide: A Versatile Abrasive Material

Aluminum oxide is one of the most widely used abrasives in the machining industry. Its hardness and durability make it suitable for various applications, including grinding and honing. The material has a high-temperature rating, allowing it to withstand significant heat generated during machining. Additionally, it exhibits good corrosion resistance, making it ideal for use in environments where moisture or chemicals are present.

Pros: Aluminum oxide is cost-effective and readily available, making it a popular choice among manufacturers. Its durability ensures a longer lifespan for grinding wheels, reducing the frequency of replacements.

Illustrative image related to abrasive machining

Cons: While it performs well on ferrous materials, it may not be as effective on harder metals like titanium or carbide. Moreover, the production of aluminum oxide can be energy-intensive, impacting overall manufacturing costs.

Impact on Application: Aluminum oxide is compatible with various media, making it suitable for diverse machining operations. However, buyers should ensure that the specific type of aluminum oxide aligns with their intended application.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is crucial. Buyers from regions like Africa and South America should also consider local sourcing to minimize costs and ensure timely deliveries.

Silicon Carbide: The Choice for Harder Materials

Silicon carbide is another prominent abrasive material, particularly effective for machining hard materials such as ceramics and glass. It boasts a high thermal conductivity and is resistant to thermal shock, making it suitable for high-pressure applications.

Pros: Silicon carbide’s sharpness allows for efficient cutting and grinding, resulting in superior surface finishes. It is also less likely to wear down quickly, providing longevity in demanding applications.

Cons: This material is generally more expensive than aluminum oxide and may not be as readily available in all markets. Its brittleness can also lead to chipping under certain conditions.

Impact on Application: Silicon carbide is particularly effective in applications requiring a fine finish, such as in the aerospace and automotive industries. Its compatibility with various media enhances its versatility.

Considerations for International Buyers: Buyers should be aware of regional standards and certifications, especially in Europe, where stringent regulations may apply. Understanding local market dynamics can also aid in sourcing and pricing strategies.

Diamond Abrasives: The Premium Option for Precision

Diamond abrasives are the hardest known materials, making them ideal for precision machining tasks. They excel in cutting and grinding hard materials, including composites and ceramics, and can operate at high temperatures without degrading.

Pros: The exceptional hardness of diamond abrasives allows for superior cutting performance and extended tool life. This can lead to significant cost savings over time, especially in high-volume production environments.

Cons: The primary drawback is the high cost of diamond abrasives, which can be prohibitive for smaller manufacturers. Additionally, their fragility means they require careful handling and specific operating conditions.

Impact on Application: Diamond abrasives are particularly suited for applications requiring extreme precision, such as in the semiconductor and aerospace industries. Their compatibility with various media makes them versatile, but they require specialized equipment.

Considerations for International Buyers: Buyers should ensure compliance with international standards and consider the availability of diamond abrasives in their region. Understanding local supply chains is vital for cost management.

Illustrative image related to abrasive machining

Ceramic Abrasives: A Cost-Effective Alternative

Ceramic abrasives are increasingly popular due to their balance of performance and cost. They are suitable for a wide range of applications, including grinding and finishing operations.

Pros: Ceramic abrasives offer good durability and can maintain their cutting efficiency over time. They are also less expensive than diamond abrasives, making them an attractive option for budget-conscious buyers.

Cons: While ceramic abrasives perform well on various materials, they may not achieve the same level of precision as diamond abrasives. Their performance can also vary significantly depending on the specific formulation.

Illustrative image related to abrasive machining

Impact on Application: Ceramic abrasives are versatile and can be used in various industries, including automotive and metalworking. Their adaptability makes them suitable for different machining processes.

Considerations for International Buyers: Buyers should verify compliance with local standards and consider the specific needs of their operations. Understanding the regional market can help in selecting the right abrasive for their applications.

Summary Table of Abrasive Materials

| Material | Typical Use Case for abrasive machining | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Oxide | Grinding and honing | Cost-effective and durable | Less effective on harder metals | Low |

| Silicon Carbide | Machining hard materials | Sharpness for efficient cutting | Higher cost and brittleness | Med |

| Diamond Abrasives | Precision machining | Exceptional hardness and longevity | High cost and fragile | High |

| Ceramic Abrasives | General grinding and finishing | Good balance of performance and cost | Varies in precision performance | Med |

This strategic material selection guide serves as a comprehensive resource for international B2B buyers, providing insights into the properties and applications of various abrasive materials used in machining. Understanding these factors can significantly enhance decision-making processes and optimize manufacturing outcomes.

In-depth Look: Manufacturing Processes and Quality Assurance for abrasive machining

What Are the Key Stages of the Manufacturing Process in Abrasive Machining?

Abrasive machining is a sophisticated process that requires meticulous attention to detail at every stage of manufacturing. This ensures that the final product meets the stringent requirements of various industries. The key stages in the manufacturing process include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Abrasive Machining?

The first step in the abrasive machining process is material preparation. This involves selecting the appropriate workpiece material based on the desired properties and end-use. Common materials include metals, ceramics, and composites.

Once the material is selected, it must be cut to size and shaped according to the specifications of the project. This may involve initial machining processes such as turning or milling to create a rough shape. Proper handling and storage of materials are critical to prevent contamination or damage, which can affect the final product’s quality.

What Forming Techniques Are Used in Abrasive Machining?

After material preparation, the next stage is forming, where the actual abrasive machining takes place. This can involve various techniques, including:

-

Grinding: Utilizing grinding wheels made of bonded abrasive grains, this technique removes material through a combination of abrasive action and mechanical force. It is commonly used for achieving precise dimensions and surface finishes.

-

Honing: This process focuses on refining the internal surfaces of cylindrical parts. Honing stones, which are softer than grinding wheels, are used to achieve a high-quality finish and accurate dimensions.

-

Superfinishing: Employed for components requiring ultra-smooth surfaces, superfinishing uses fine abrasive stones or tapes to polish the surface, significantly reducing roughness.

-

Abrasive Belt Machining: This method involves moving a continuous belt covered in abrasive material over the workpiece, allowing for efficient processing of large flat surfaces.

These forming techniques are chosen based on factors such as the desired surface finish, tolerances, and the material’s properties.

Illustrative image related to abrasive machining

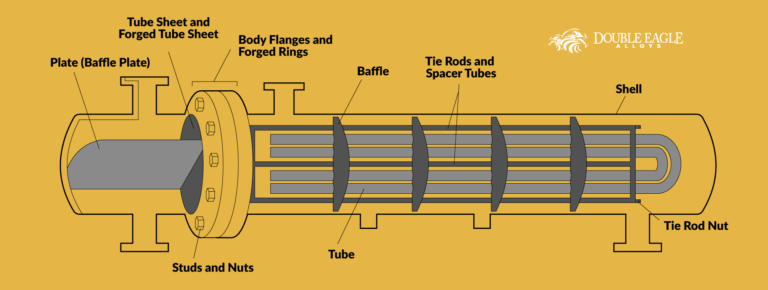

How Is the Assembly Process Handled in Abrasive Machining?

In many cases, abrasive machining is part of a larger assembly process. After parts have been machined to specifications, they may require additional assembly with other components. This stage may include welding, fastening, or integrating electronic parts, depending on the end product.

The assembly process must be carefully controlled to maintain dimensional accuracy and ensure that all components fit together correctly. Quality checks during this stage are crucial to prevent defects that could compromise the product’s functionality.

What Finishing Techniques Are Commonly Used in Abrasive Machining?

Finishing is the final stage in the manufacturing process of abrasive machining. This stage aims to enhance the aesthetic and functional qualities of the workpiece. Common finishing techniques include:

-

Polishing: Achieving a high-gloss surface finish through the use of loose abrasive particles mixed with a liquid. This technique is often used in decorative applications or where a reflective surface is required.

-

Buffing: A process similar to polishing but typically employs softer materials to achieve a higher luster. Buffing is often the final step in creating a visually appealing product.

-

Coating: In some applications, a protective coating may be applied after machining to enhance durability and resistance to environmental factors.

What Quality Assurance Practices Are Essential for Abrasive Machining?

Quality assurance (QA) is critical in the abrasive machining process, ensuring that products meet international standards and customer specifications. The primary QA practices include adherence to relevant standards, implementation of quality checkpoints, and common testing methods.

Illustrative image related to abrasive machining

Which International Standards Should B2B Buyers Be Aware Of?

For B2B buyers, understanding quality standards is essential. The most widely recognized international standard is ISO 9001, which outlines criteria for a quality management system. Companies in the abrasive machining sector may also comply with industry-specific standards such as:

- CE Marking: Required for products sold in the European Economic Area, ensuring they meet safety and environmental protection standards.

- API Standards: Relevant for products used in the oil and gas sector, ensuring that materials and processes meet stringent safety and performance requirements.

What Are the Key Quality Control Checkpoints in Abrasive Machining?

Quality control (QC) involves systematic processes to monitor and ensure the quality of products throughout the manufacturing stages. Key checkpoints in abrasive machining include:

-

Incoming Quality Control (IQC): Verification of raw materials and components upon arrival. This ensures that only materials meeting specified standards are used in production.

-

In-Process Quality Control (IPQC): Monitoring the manufacturing process in real-time to detect any deviations from established parameters. This may involve measuring dimensions, surface finish, and other critical characteristics.

-

Final Quality Control (FQC): Comprehensive testing of the finished product to ensure it meets all specifications and standards. This may include functional testing, dimensional checks, and visual inspections.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control processes of their suppliers. Key methods include:

-

Supplier Audits: Conducting on-site audits to assess the supplier’s quality management system, manufacturing processes, and adherence to standards.

-

Reviewing QC Reports: Requesting detailed quality control reports that outline testing methods, results, and any corrective actions taken.

-

Third-Party Inspections: Engaging independent inspection agencies to evaluate the supplier’s processes and products. This adds an extra layer of assurance regarding quality.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding regional nuances in quality control is vital. Factors such as differing regulations, cultural attitudes towards quality, and varying levels of technological advancement can impact the manufacturing processes.

Buyers should be aware of local standards and certifications that may differ from international norms. Establishing clear communication with suppliers regarding quality expectations and compliance can help mitigate risks associated with cross-border transactions.

Illustrative image related to abrasive machining

Conclusion

A comprehensive understanding of the manufacturing processes and quality assurance practices in abrasive machining is crucial for B2B buyers. By focusing on critical stages like material preparation, forming, assembly, and finishing, along with rigorous quality control measures, buyers can ensure they partner with reliable suppliers that meet their specifications and industry standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘abrasive machining’

Introduction

This practical sourcing guide is designed to assist B2B buyers in effectively procuring abrasive machining services and equipment. With the increasing demand for precision and efficiency in manufacturing, understanding the key steps in the sourcing process is essential for ensuring quality outcomes and long-term partnerships.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is the foundation of a successful procurement process. This includes identifying the type of abrasive machining required, such as grinding, honing, or superfinishing, as well as material types and tolerances. Providing detailed specifications will help potential suppliers to understand your needs and offer tailored solutions.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in abrasive machining. Look for companies with a proven track record in your industry and assess their capabilities through online reviews, industry publications, and trade shows. Focus on suppliers who can demonstrate experience with the specific materials and processes relevant to your projects.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify the certifications and compliance of potential suppliers. Key certifications to look for include ISO 9001 for quality management and any industry-specific standards that may apply. Certifications provide assurance that the supplier adheres to established quality and safety protocols.

Step 4: Request Samples and Case Studies

Request samples of previous work and relevant case studies to evaluate the supplier’s capabilities and quality of output. Analyzing case studies can provide insights into the supplier’s problem-solving abilities and their approach to meeting specific client requirements. Pay attention to the success stories of businesses similar to yours.

Step 5: Assess Production Capacity and Lead Times

Understanding the production capacity and lead times of your potential suppliers is crucial for meeting your project timelines. Inquire about their manufacturing processes and any potential bottlenecks that could affect delivery. Suppliers should be transparent about their capabilities and willing to work with you to accommodate your schedule.

Illustrative image related to abrasive machining

Step 6: Discuss Pricing and Payment Terms

Engage in discussions regarding pricing structures and payment terms before finalizing any contracts. Ensure that you have a clear understanding of the cost breakdown, including material, labor, and any additional fees. Favor suppliers who offer flexible payment options and transparent pricing, as this fosters a stronger business relationship.

Step 7: Establish Communication and Support Channels

Finally, ensure that there are clear communication channels in place for ongoing support and updates throughout the project. Effective communication can significantly reduce misunderstandings and delays. Confirm the availability of dedicated account managers or customer service representatives who can assist with any concerns that arise during the production process.

By following these steps, B2B buyers can streamline their sourcing process for abrasive machining, ensuring they select the right suppliers that meet their technical and operational needs while fostering successful partnerships.

Comprehensive Cost and Pricing Analysis for abrasive machining Sourcing

What Are the Key Cost Components in Abrasive Machining Sourcing?

When sourcing abrasive machining services, several cost components must be considered to develop a comprehensive understanding of the pricing structure. These components include:

-

Materials: The type and quality of abrasives used significantly influence costs. Common materials such as aluminum oxide and silicon carbide vary in price based on their purity and sourcing. Additionally, the choice between fixed and loose abrasives can affect material costs.

-

Labor: Skilled labor is crucial in abrasive machining processes. Labor costs can fluctuate based on regional wage standards, the complexity of the machining operations, and the level of expertise required.

-

Manufacturing Overhead: This encompasses the indirect costs associated with running a machining facility, including utilities, maintenance, and equipment depreciation. Efficient operations can help mitigate these costs.

-

Tooling: The initial investment in grinding wheels, honing stones, and other tools is significant. Tooling costs vary based on the complexity of the tooling required and the frequency of replacement due to wear and tear.

-

Quality Control (QC): Ensuring that the finished products meet specified quality standards involves additional costs. Investing in QC processes and certifications can enhance product reliability but will increase overall sourcing costs.

-

Logistics: Shipping and handling fees, especially for international transactions, can add substantial costs. Factors such as distance, weight, and chosen Incoterms can significantly influence logistics expenses.

-

Margin: Suppliers will typically include a profit margin in their pricing, which can vary based on market conditions and competition.

What Factors Influence Pricing for Abrasive Machining Services?

Several key factors influence the pricing of abrasive machining services, making it essential for buyers to understand these nuances:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs. Suppliers may provide discounts based on the quantity ordered, making it beneficial for buyers to consolidate orders.

-

Specifications and Customization: Customized solutions tailored to specific applications typically incur higher costs. The more specialized the requirements, the more expensive the machining process may become.

-

Materials: The choice of materials directly impacts pricing. Higher-quality abrasives may offer better performance but come at a premium price.

-

Quality and Certifications: Suppliers with industry certifications (e.g., ISO standards) may charge more due to the assurance of quality and reliability. Buyers should consider whether these certifications are critical for their applications.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may command higher prices but often provide better service and assurance of quality.

-

Incoterms: The chosen Incoterms affect shipping costs and responsibilities. Understanding terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for calculating total landed costs.

What Are Some Essential Buyer Tips for Cost Efficiency in Abrasive Machining Sourcing?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, the following tips can help maximize cost efficiency:

-

Negotiation: Always negotiate pricing and terms. Suppliers often have room to maneuver, especially for larger orders or long-term contracts.

-

Focus on Total Cost of Ownership (TCO): Rather than just evaluating the initial purchase price, consider the TCO, which includes maintenance, operational costs, and potential downtime. This holistic view will provide a clearer picture of overall expenses.

-

Research Local Suppliers: Local suppliers may offer competitive pricing and reduced logistics costs. It’s beneficial to explore regional options, especially in emerging markets.

-

Evaluate Quality vs. Cost: While it may be tempting to choose the lowest price, consider the quality implications. Poor-quality machining can lead to increased costs in the long run due to rework or failure.

-

Understand Pricing Nuances: Familiarize yourself with the pricing structures specific to different regions. For example, European suppliers may have different cost considerations compared to those in South America or Africa.

Disclaimer on Indicative Prices

Prices for abrasive machining services can vary widely based on numerous factors, including material types, order volumes, and supplier capabilities. It is essential to obtain quotes from multiple suppliers to ensure a competitive and fair pricing strategy tailored to your specific needs.

Alternatives Analysis: Comparing abrasive machining With Other Solutions

Exploring Alternatives to Abrasive Machining

In the manufacturing landscape, selecting the most effective machining solution is crucial for achieving desired outcomes. While abrasive machining is a well-established method known for its precision and surface finish capabilities, several alternative solutions can also meet similar objectives. This analysis compares abrasive machining with two viable alternatives: CNC Machining and Laser Cutting.

| Comparison Aspect | Abrasive Machining | CNC Machining | Laser Cutting |

|---|---|---|---|

| Performance | High precision and excellent surface finish | Very high precision, capable of complex geometries | High speed, precise cuts, but may require post-processing |

| Cost | Moderate to high, depending on abrasives used | Can be high due to machine cost and programming | Generally lower operating costs but high initial investment |

| Ease of Implementation | Requires skilled operators; setup can be complex | Requires programming knowledge; setup time can vary | User-friendly software; quick setup for most materials |

| Maintenance | Moderate; grinding wheels need regular dressing | High; regular calibration and tool changes necessary | Low; minimal maintenance required for laser systems |

| Best Use Case | Ideal for hard materials and achieving fine finishes | Versatile; suitable for a wide range of materials and intricate designs | Best for thin materials and quick prototyping |

Detailed Breakdown of Alternatives

CNC Machining

CNC (Computer Numerical Control) machining is a widely used method that automates the control of machining tools via computer programming. This process is particularly beneficial for creating complex shapes and parts with high precision. Pros include its versatility across various materials, such as metals, plastics, and composites. Additionally, CNC machines can achieve intricate designs that might be challenging for abrasive machining. However, the cons are significant initial investments in machinery and programming expertise, which can be a barrier for smaller operations.

Laser Cutting

Laser cutting utilizes a focused laser beam to cut through materials with high precision. It is especially effective for sheet metal and other thin materials. One of the primary advantages of laser cutting is its speed and the ability to produce intricate designs without the need for tooling. This method also results in minimal material waste. However, the disadvantages include limitations on the thickness of materials that can be cut and the potential need for additional finishing processes to achieve the desired surface quality.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating the best machining solution, B2B buyers should consider their specific requirements, including the material type, desired precision, production volume, and budget constraints. Abrasive machining excels in delivering high-quality finishes on hard materials, while CNC machining offers versatility for complex designs. Laser cutting, on the other hand, is ideal for quick and precise cuts in thinner materials. By understanding the strengths and weaknesses of each method, buyers can make informed decisions that align with their operational goals and enhance their manufacturing capabilities.

Essential Technical Properties and Trade Terminology for abrasive machining

What Are the Key Technical Properties of Abrasive Machining?

In abrasive machining, understanding critical specifications can significantly influence the purchasing decisions of B2B buyers. Here are some essential technical properties:

-

Material Grade

– Material grade refers to the specific type of abrasive used in the machining process, such as aluminum oxide or silicon carbide. Each type has unique characteristics, impacting performance, durability, and cost. For B2B buyers, selecting the right material grade ensures optimal machining efficiency and product quality. -

Tolerance

– Tolerance defines the allowable deviation from a specified dimension or characteristic of the workpiece. In abrasive machining, tight tolerances are often crucial for applications in industries like aerospace and automotive. Understanding tolerances helps buyers assess whether a supplier can meet their exacting standards, directly influencing product reliability and performance. -

Grain Size

– The grain size of the abrasive material affects the surface finish and the material removal rate during machining. Finer grains provide a smoother finish but may remove material more slowly, while coarser grains remove material quickly but produce a rougher surface. Buyers must consider the desired surface quality and machining speed when evaluating grain sizes. -

Bonding Material

– The type of bonding material used to hold abrasive grains together is pivotal in determining the wheel’s performance and durability. Common bonding materials include resin and metal. Understanding the bonding type helps buyers select products that can withstand specific operational conditions, ensuring longevity and effectiveness. -

Wheel Speed

– The speed at which the grinding wheel operates can significantly impact both the efficiency of the machining process and the quality of the finish. Higher speeds can lead to faster material removal but may also increase heat generation. Buyers need to assess the compatibility of wheel speed with their machinery to optimize performance and prevent damage.

What Are Common Trade Terminology and Jargon in Abrasive Machining?

Familiarity with industry-specific terminology is essential for effective communication and negotiation. Here are some common terms used in abrasive machining:

Illustrative image related to abrasive machining

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that manufactures products or components that are purchased by another company and sold under that company’s brand name. Understanding OEM relationships can help buyers identify reliable suppliers and ensure product quality. -

MOQ (Minimum Order Quantity)

– MOQ represents the smallest quantity of a product that a supplier is willing to sell. This term is critical for buyers to understand, as it affects inventory management and cost-efficiency. Knowing the MOQ helps businesses plan their purchases and avoid overstocking. -

RFQ (Request for Quotation)

– An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It outlines specific requirements, including technical specifications and quantities. For buyers, issuing an RFQ streamlines the procurement process and facilitates comparisons among suppliers. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. These terms define aspects such as shipping costs, risk transfer, and delivery timelines. Understanding Incoterms is crucial for B2B buyers to ensure smooth transactions and mitigate potential disputes. -

Dressing

– Dressing refers to the process of reshaping and cleaning the grinding wheel to maintain its cutting efficiency. This term is vital for buyers to understand, as proper dressing can enhance the lifespan of grinding wheels and improve machining outcomes.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions in the abrasive machining market, ensuring they select the right tools and suppliers for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the abrasive machining Sector

What Are the Key Trends Shaping the Global Abrasive Machining Market?

The global abrasive machining market is experiencing robust growth driven by several factors. The rising demand for precision-engineered components across industries such as aerospace, automotive, and manufacturing is a primary driver. As international B2B buyers seek higher efficiency and accuracy, technologies like CNC grinding and waterjet cutting are becoming increasingly relevant. Additionally, advancements in abrasives technology, including the development of superabrasives, are enabling manufacturers to achieve superior finishes and faster material removal rates.

Emerging trends in sourcing for abrasive machining materials reflect a shift towards digitalization. E-commerce platforms and online sourcing tools are becoming essential for B2B buyers in regions like Africa and South America, where traditional supply chains may be less developed. Moreover, the integration of Industry 4.0 technologies is facilitating real-time monitoring and predictive maintenance, enhancing operational efficiency and reducing downtime.

In terms of regional dynamics, markets in Europe, particularly Germany, are at the forefront of adopting sustainable practices and innovative technologies. Meanwhile, African and South American markets are witnessing increased foreign investment, leading to an uptick in local manufacturing capabilities. As a result, international buyers are presented with a dual opportunity: to source high-quality abrasive machining products while simultaneously contributing to the development of local economies.

How Is Sustainability Influencing Sourcing Trends in Abrasive Machining?

Sustainability is becoming a cornerstone of sourcing strategies in the abrasive machining sector. The environmental impact of traditional abrasive processes, including waste generation and resource consumption, is prompting companies to adopt more sustainable practices. B2B buyers are increasingly prioritizing suppliers who demonstrate commitment to eco-friendly operations and materials.

The importance of ethical supply chains cannot be overstated. Buyers are looking for partners who ensure traceability of materials and compliance with international environmental standards. This trend has led to the rise of ‘green’ certifications and materials, such as recycled abrasives and eco-friendly bonding agents, which minimize the ecological footprint of abrasive machining processes.

Moreover, many companies are adopting circular economy principles, focusing on reusing and recycling abrasive materials. This shift not only reduces waste but also lowers operational costs, making it an attractive option for businesses looking to enhance their bottom line while being environmentally responsible. As a result, international buyers, especially in Europe and the Middle East, are increasingly aligning their purchasing decisions with sustainability goals.

What Is the Historical Context of Abrasive Machining for B2B Buyers?

Abrasive machining has a rich history that dates back to ancient civilizations, where natural materials were used for shaping and finishing tools. The evolution of this process accelerated in the 19th century with the advent of powered grinding machines, which revolutionized manufacturing by allowing for greater precision and efficiency.

In the 20th century, advancements in synthetic abrasives and bonding technologies further transformed the landscape of abrasive machining. This period also saw the introduction of new methods, such as waterjet cutting and CNC grinding, which catered to the growing demand for high-quality finishes and complex geometries.

For B2B buyers, understanding this historical context is essential, as it highlights the technological advancements that have shaped current practices and standards. As the sector continues to evolve, buyers can leverage this knowledge to make informed decisions about sourcing and adopting the latest technologies that align with their operational needs and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of abrasive machining

-

How do I choose the right type of abrasive machining for my project?

Selecting the appropriate type of abrasive machining depends on your specific project requirements, including material type, desired finish, and dimensional tolerances. For instance, if precision is critical, consider precision grinding or honing. If you need to achieve a super-smooth surface, superfinishing may be ideal. Always assess the materials you are working with, as different abrasives like aluminum oxide or silicon carbide may yield different results. Consulting with suppliers about your objectives can provide additional insights into the most effective machining method. -

What are the advantages of using abrasive machining in manufacturing?

Abrasive machining offers several advantages, including superior surface finishes, high precision, and the ability to machine hard materials. It is particularly effective for achieving tight tolerances and intricate shapes that other machining methods may struggle with. Additionally, abrasive processes can be cost-effective for high-volume production as they often require fewer steps and less time to achieve the desired results. This can lead to reduced operational costs and improved product quality in competitive markets. -

What should I consider when vetting suppliers for abrasive machining services?

When vetting suppliers, evaluate their experience, certifications, and quality control processes. Look for suppliers with a proven track record in your industry and ask for case studies or references. Assess their production capabilities, including the types of machines they use and their ability to handle your specific materials. Additionally, inquire about their lead times, scalability, and flexibility to accommodate custom requirements. Conducting site visits or audits can also provide deeper insights into their operational standards. -

What are typical payment terms for international abrasive machining orders?

Payment terms can vary significantly based on the supplier and the complexity of the order. Common terms include 30% upfront payment with the balance due upon completion, or payment upon delivery. For larger orders, consider negotiating letters of credit or escrow services to ensure security for both parties. Always clarify payment methods, currency, and any potential additional costs such as tariffs or taxes that may apply to international transactions. -

What is the minimum order quantity (MOQ) for abrasive machining products?

Minimum order quantities (MOQs) for abrasive machining can vary widely depending on the supplier and the specific machining process. Some suppliers may offer flexible MOQs for custom projects, while others may require larger quantities to justify production setup costs. It’s essential to discuss your needs with potential suppliers to determine if they can accommodate smaller orders, especially if you are testing new designs or materials. Always factor in the cost implications of MOQs when budgeting for your projects. -

How can I ensure quality assurance in abrasive machining processes?

To ensure quality assurance, work with suppliers who have established quality control systems, including regular inspections and certifications like ISO 9001. Request detailed documentation of their quality assurance processes and ask about their testing methods for finished products. Involve your quality control team in the early stages to set clear specifications and standards. Consider conducting periodic audits or quality checks during production to ensure that the final output meets your expectations. -

What logistics considerations should I be aware of when importing abrasive machining products?

Logistics for importing abrasive machining products involve several key considerations. First, understand the shipping methods and transit times associated with your chosen supplier. Ensure compliance with local regulations regarding the import of machinery and materials, which may include tariffs or safety standards. Coordinate with freight forwarders who specialize in industrial equipment to navigate customs clearance efficiently. Lastly, plan for potential delays and ensure that your supply chain has contingency measures in place. -

What are the environmental impacts of abrasive machining, and how can they be mitigated?

Abrasive machining can have environmental impacts, such as dust generation and wastewater from coolant use. To mitigate these effects, consider suppliers who use eco-friendly abrasives and lubricants. Implementing dust collection systems and proper waste disposal protocols can significantly reduce pollution. Additionally, explore technologies like waterjet cutting, which minimizes heat generation and waste. Engaging in sustainable practices not only complies with regulations but also enhances your brand’s reputation in increasingly eco-conscious markets.

Top 1 Abrasive Machining Manufacturers & Suppliers List

1. Slabe Machine – Abrasive Machining Solutions

Domain: slabemachine.com

Registered: 1998 (27 years)

Introduction: Abrasive machining is a material removal process using abrasives like aluminum oxide, silicon carbide, and resin bond. Common processes include Grinding, Honing, Sanding, Polishing, Buffing, Lapping, Abrasive Waterjet Cutting, Sand Blasting, and Glass Blasting. Grinding uses grinding wheels or belts for outer and inner diameter finishing, with grit ranging from 24 to 100. Honing uses honing stones…

Strategic Sourcing Conclusion and Outlook for abrasive machining

Abrasive machining stands as a critical component in modern manufacturing, enabling precision, efficiency, and quality across various industries. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the nuances of this process is vital. Strategic sourcing can significantly enhance supply chain resilience, ensuring access to advanced abrasive technologies and materials that meet specific operational needs. By prioritizing partnerships with suppliers that offer innovative solutions, buyers can achieve superior surface finishes and improved product performance.

Furthermore, as industries evolve and embrace technological advancements, the demand for tailored abrasive machining solutions will only increase. Buyers should remain vigilant in exploring new methods, such as water-jet cutting and abrasive flow machining, which promise enhanced capabilities and efficiencies. The future of abrasive machining is bright, with opportunities for growth in emerging markets and sectors.

Investing in strategic sourcing not only streamlines operations but also positions companies to adapt to changing market dynamics. Take the next step in optimizing your manufacturing processes—engage with trusted suppliers today to unlock the full potential of abrasive machining for your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.