Is Your 80 White Jpt Fiber Laser Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for 80 white jpt fiber laser

In today’s competitive landscape, sourcing the right 80 white JPT fiber laser can be a daunting challenge for international B2B buyers. With a plethora of options available, understanding the distinct features, applications, and potential cost implications is essential for making informed purchasing decisions. This comprehensive guide delves into the intricacies of the 80 white JPT fiber laser market, providing insights into various types of lasers, their applications in industries ranging from manufacturing to artistic endeavors, and best practices for supplier vetting.

As buyers from regions such as Africa, South America, the Middle East, and Europe—specifically Brazil and Vietnam—navigate this complex marketplace, it becomes crucial to identify reliable suppliers that offer not only quality products but also robust customer support. This guide is designed to empower you with actionable insights, equipping you to evaluate options effectively and negotiate favorable terms. By understanding the unique capabilities of different fiber laser models, such as the MOPA technology for enhanced color marking and precision cutting, you can confidently select a solution that meets your operational needs and budget constraints.

Whether you are looking for a machine to fulfill industrial tasks or to create intricate decorative designs, this guide serves as a valuable resource to streamline your decision-making process, ultimately driving your business success in the global market.

Understanding 80 white jpt fiber laser Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 80W MOPA JPT Fiber Laser M7 | High power output, MOPA technology for color marking | Industrial engraving, decorative work | Pros: Versatile, durable, high precision. Cons: Higher initial cost. |

| OMTech 80W MOPA Split Fiber Laser | Split design, two working areas, user-friendly control panel | Personalized gifts, industrial engravings | Pros: Space-efficient, easy to use. Cons: Limited to specific workspace sizes. |

| Pre-Owned 80W MOPA Fiber Laser | Certified pre-owned, functional with minor cosmetic wear | Cost-effective industrial applications | Pros: Lower price, fully operational. Cons: Potential for wear-related issues. |

| 80W JPT M8 MOPA Fiber Laser | Compact design, adjustable pulse frequency | Small to medium project engraving | Pros: Space-saving, precise. Cons: Limited power for heavy-duty tasks. |

| 80W JPT MOPA Fiber Laser 200W | Higher power output, suitable for thicker materials | Heavy-duty cutting and engraving | Pros: Excellent for tough materials. Cons: Larger footprint, higher cost. |

What are the Key Characteristics of the 80W MOPA JPT Fiber Laser M7?

The 80W MOPA JPT Fiber Laser M7 is renowned for its robust build and exceptional power output. It utilizes MOPA technology, which allows for detailed color markings, making it ideal for both industrial and artistic applications. This model is particularly suitable for deep engraving and cutting of thin metals, ensuring high efficiency and durability for long-term use. B2B buyers should consider its versatility in handling various metal types, making it a strong investment for businesses looking to diversify their offerings.

How Does the OMTech 80W MOPA Split Fiber Laser Stand Out?

The OMTech 80W MOPA Split Fiber Laser features a unique split design that provides two working areas, catering to a range of project sizes. Its user-friendly control panel and compatibility with popular software like LightBurn make it accessible for both novices and experienced users. This model excels in creating personalized gifts and industrial engravings, making it a valuable asset for businesses focused on customization. Buyers should evaluate their workspace constraints, as its design is optimized for efficiency in smaller environments.

What Should Buyers Know About Pre-Owned 80W MOPA Fiber Lasers?

Pre-owned 80W MOPA Fiber Lasers, such as those certified by OMTech, offer a cost-effective solution for businesses. These machines have undergone rigorous testing and repairs, ensuring full operational capacity despite minor cosmetic wear. Ideal for industrial applications, they present an attractive option for budget-conscious buyers. However, potential purchasers should be aware of the risk of wear-related issues and ensure they understand the warranty and support options available for pre-owned units.

Why Choose the Compact 80W JPT M8 MOPA Fiber Laser?

The 80W JPT M8 MOPA Fiber Laser is designed with compactness in mind, making it suitable for small to medium project engraving. Its adjustable pulse frequency enhances precision, allowing users to achieve fine details in their work. While it is an excellent choice for businesses with limited space, potential buyers should consider its lower power output compared to larger models, which may restrict its use for heavy-duty tasks.

What Advantages Does the 80W JPT MOPA Fiber Laser 200W Provide?

For businesses requiring more power, the 80W JPT MOPA Fiber Laser 200W is an ideal solution. It can handle thicker materials and is well-suited for heavy-duty cutting and engraving tasks. While its higher price point and larger footprint may deter some buyers, the investment is justified for companies focused on robust manufacturing capabilities. Buyers should assess their specific needs, particularly if they frequently work with tougher materials, to determine if this model aligns with their operational goals.

Key Industrial Applications of 80 white jpt fiber laser

| Industry/Sector | Specific Application of 80 white jpt fiber laser | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Precision metal engraving and cutting for component parts | Enhances product quality and reduces material waste | Ensure compatibility with existing machinery and materials |

| Jewelry | Detailed engraving on metals and gemstones | Adds unique value to products, catering to customer desires | Consider customization options and design software support |

| Automotive | Marking and engraving vehicle identification numbers (VINs) | Improves traceability and compliance with regulations | Look for machines that support high-speed operations |

| Electronics | Marking circuit boards and components | Increases production efficiency and accuracy | Focus on precision and durability for long-term use |

| Arts and Crafts | Creating intricate designs on various materials | Expands creative possibilities and market offerings | Assess the versatility in handling different materials |

How is the 80 white jpt fiber laser Used in Manufacturing?

In the manufacturing sector, the 80 white JPT fiber laser is utilized for precision metal engraving and cutting of component parts. This application is vital for enhancing product quality and reducing material waste, as the laser can execute intricate designs with high accuracy. Buyers in this sector must ensure that the chosen laser machine is compatible with their existing machinery and materials, particularly when scaling up production in regions like Africa and South America, where manufacturing capabilities are expanding rapidly.

What Role Does the 80 white jpt Fiber Laser Play in Jewelry Production?

In the jewelry industry, the 80 white JPT fiber laser is employed for detailed engraving on metals and gemstones, allowing artisans to create unique and personalized items. This capability adds significant value to jewelry products, catering to customer desires for customization. International buyers should consider customization options and the availability of design software support to facilitate the engraving process, especially in markets like Europe and the Middle East, where personalized jewelry is increasingly popular.

How Does the 80 white JPT Fiber Laser Improve Automotive Applications?

The automotive industry leverages the 80 white JPT fiber laser for marking and engraving vehicle identification numbers (VINs) on various components. This application enhances traceability and compliance with regulatory standards, ensuring that manufacturers can efficiently track vehicle history. When sourcing this technology, businesses should focus on machines that support high-speed operations, as the automotive sector often requires rapid production cycles to meet demand in regions like Brazil and Vietnam.

Why is the 80 white JPT Fiber Laser Essential for Electronics?

In the electronics sector, the 80 white JPT fiber laser is crucial for marking circuit boards and components, significantly increasing production efficiency and accuracy. This application is particularly important as the industry moves toward more compact and intricate designs. Buyers need to focus on precision and durability to ensure long-term use, particularly in fast-growing markets in Africa and South America, where the demand for electronic products is rising.

How Can Arts and Crafts Benefit from the 80 white JPT Fiber Laser?

The arts and crafts sector utilizes the 80 white JPT fiber laser to create intricate designs on various materials, expanding creative possibilities and product offerings. This versatility allows artisans to cater to diverse markets and customer preferences. Buyers should assess the machine’s capability to handle different materials effectively, ensuring it can adapt to the creative demands of international markets, particularly in Europe and the Middle East, where artistic expression is highly valued.

3 Common User Pain Points for ’80 white jpt fiber laser’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Quality in Metal Engravings

The Problem: Many B2B buyers, particularly those in the manufacturing and decorative sectors, struggle with achieving consistent quality in their metal engraving projects. This inconsistency can arise from varying material thicknesses, different types of metals, or even fluctuations in environmental conditions. Such challenges can lead to increased waste, customer dissatisfaction, and ultimately, a negative impact on the bottom line. Buyers may find themselves spending excessive time recalibrating or experimenting with settings to achieve the desired results.

The Solution: To overcome this problem, buyers should leverage the advanced MOPA (Master Oscillator Power Amplifier) technology of the 80W JPT fiber laser. This system allows for independent adjustments of pulse frequency and width, enabling users to fine-tune the laser parameters for different materials and thicknesses. It is advisable to conduct a series of test engravings on scrap material to establish baseline settings before moving to production. Additionally, utilizing software like EzCad2, which is compatible with the fiber laser, can simplify the process of creating consistent designs. By implementing a quality control checklist and maintaining a controlled environment (temperature and humidity), users can significantly enhance the consistency of their output.

Scenario 2: High Operational Costs Due to Inefficient Use of Resources

The Problem: B2B buyers often face high operational costs stemming from inefficient use of resources and energy when operating laser engraving machines. These inefficiencies can be attributed to factors such as improper machine settings, inadequate training of operators, and suboptimal material handling processes. Such issues not only inflate costs but also diminish the overall productivity of the engraving operations, leading to reduced profitability.

The Solution: To combat high operational costs, buyers should focus on optimizing the operational efficiency of the 80W JPT fiber laser. First, investing in comprehensive training for operators is crucial. This training should encompass the machine’s capabilities, maintenance procedures, and optimal settings for various materials. Second, buyers should implement a systematic approach to material handling by using properly sized work areas and ensuring that the materials are securely positioned during engraving. Utilizing the machine’s advanced features, such as adjustable pulse settings, can also minimize energy consumption while maximizing output quality. Regular maintenance checks will ensure that the machine operates at peak performance, reducing the likelihood of costly breakdowns and enhancing overall efficiency.

Scenario 3: Limited Technical Support and Maintenance Challenges

The Problem: One significant pain point for B2B buyers is the lack of reliable technical support and maintenance options for their laser engraving machines. This issue can lead to extended downtime during critical production periods, resulting in lost revenue and delayed project timelines. Buyers may struggle to find prompt assistance or spare parts, especially in regions with less access to advanced manufacturing technology.

The Solution: To alleviate this challenge, buyers should prioritize sourcing their 80W JPT fiber laser from suppliers that offer robust technical support and warranty options. A comprehensive warranty, such as a three-year warranty with lifetime technical support, is essential for ensuring long-term machine performance. Buyers should establish a relationship with the supplier for quick access to replacement parts and technical assistance. Additionally, maintaining an inventory of commonly needed spare parts can prevent prolonged downtime. Implementing a proactive maintenance schedule based on the manufacturer’s recommendations will also help identify potential issues before they escalate, ensuring that the machine remains operational and efficient. This proactive approach will help secure a competitive edge in the market while fostering trust with clients.

Strategic Material Selection Guide for 80 white jpt fiber laser

What Materials Are Best for Use with the 80W JPT Fiber Laser?

When selecting materials for processing with the 80W JPT fiber laser, it is essential to consider the unique properties and applications of each material type. This guide analyzes four common materials—stainless steel, aluminum, brass, and acrylic—focusing on their performance characteristics, advantages, disadvantages, and specific considerations for international buyers.

How Does Stainless Steel Perform with the 80W JPT Fiber Laser?

Key Properties: Stainless steel is known for its excellent corrosion resistance and high tensile strength. It can withstand temperatures up to 800°C, making it suitable for various industrial applications.

Pros & Cons: The durability of stainless steel makes it ideal for products requiring longevity and resistance to harsh environments. However, the cost can be relatively high compared to other metals, and its manufacturing complexity may require specialized tools for cutting and shaping.

Impact on Application: Stainless steel is widely used in industries such as automotive, aerospace, and medical devices. The 80W JPT fiber laser excels at engraving and cutting intricate designs on stainless steel, enhancing both functionality and aesthetics.

Considerations for International Buyers: Compliance with international standards such as ASTM A240 or DIN 1.4301 is crucial. Buyers from regions like Europe and the Middle East should ensure that the stainless steel grades meet local regulations regarding corrosion resistance and mechanical properties.

What Are the Benefits of Using Aluminum with the 80W JPT Fiber Laser?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has a melting point of about 660°C. Its thermal conductivity is significantly higher than that of steel, allowing for efficient heat dissipation during laser processing.

Pros & Cons: The advantages of aluminum include its low weight and ease of machining, making it suitable for a wide range of applications from automotive parts to consumer goods. However, its lower strength compared to steel may limit its use in heavy-duty applications.

Impact on Application: Aluminum’s compatibility with the 80W JPT fiber laser allows for high-speed engraving and cutting, particularly for decorative applications. The MOPA technology enables vibrant color markings on anodized aluminum, enhancing product appeal.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM B221 for aluminum extrusions. In regions like South America, the availability of specific aluminum grades may vary, impacting project timelines.

How Does Brass Compare When Using the 80W JPT Fiber Laser?

Key Properties: Brass is an alloy of copper and zinc, known for its excellent machinability and corrosion resistance. It has a melting point around 900°C, making it suitable for various applications.

Pros & Cons: The aesthetic appeal of brass, combined with its workability, makes it popular for decorative items and fittings. However, brass can be more expensive than other metals, and its softer nature may lead to wear in high-friction applications.

Impact on Application: The 80W JPT fiber laser can effectively engrave and cut brass, producing detailed designs and high-quality finishes. Its ability to create color markings further enhances its use in artistic applications.

Considerations for International Buyers: Compliance with standards such as ASTM B36 is essential for ensuring material quality. Buyers in regions like Africa should consider the availability of brass alloys and their specific properties.

What Advantages Does Acrylic Offer for the 80W JPT Fiber Laser?

Key Properties: Acrylic is a lightweight, shatter-resistant plastic with excellent optical clarity. It can withstand temperatures up to 80°C and is easy to cut and engrave.

Pros & Cons: Acrylic is cost-effective and versatile, making it suitable for signage, displays, and decorative items. However, it can be prone to scratching and may not be suitable for high-temperature applications.

Impact on Application: The 80W JPT fiber laser can cut and engrave acrylic with precision, allowing for intricate designs and clean edges. The ability to create depth and texture enhances its visual appeal.

Considerations for International Buyers: Buyers should ensure compliance with local standards for plastics, such as ISO 7823. In regions like Europe, environmental regulations regarding plastic use may impact sourcing decisions.

Summary Table of Material Selection for 80W JPT Fiber Laser

| Material | Typical Use Case for 80 white jpt fiber laser | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Automotive parts, medical devices | Excellent durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Consumer goods, automotive components | Lightweight and easy to machine | Lower strength compared to steel | Medium |

| Brass | Decorative items, fittings | Aesthetic appeal and machinability | Higher cost and softer nature | Medium |

| Acrylic | Signage, displays | Cost-effective and versatile | Prone to scratching | Low |

This guide provides a comprehensive overview of material selection for the 80W JPT fiber laser, enabling international B2B buyers to make informed decisions based on performance characteristics and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 80 white jpt fiber laser

What Are the Key Stages in the Manufacturing Process of 80W JPT Fiber Lasers?

The manufacturing process for 80W JPT fiber lasers involves several critical stages that ensure high-quality output. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with sourcing high-grade materials, particularly for the laser source, optics, and structural components. These materials must meet specific standards to ensure performance. For instance, the fiber laser’s core is typically made from specialized glass, while the casing is often constructed from robust metals to withstand operational stresses.

-

Forming: In this stage, the prepared materials undergo various shaping processes. Advanced techniques such as CNC machining and laser cutting are utilized to achieve precise dimensions and tolerances. The fiber optic components are also formed with high precision to ensure optimal light transmission and focus.

-

Assembly: Once the individual components are prepared, they are assembled into a complete unit. This stage requires meticulous attention to detail, as any misalignment can affect performance. The assembly process often includes integrating the laser source, optics, and cooling systems, ensuring that all components work harmoniously.

-

Finishing: The final stage involves polishing and coating the laser components to enhance durability and performance. A thorough cleaning process is also performed to eliminate any contaminants that could interfere with the laser’s operation. The product is then subjected to aesthetic checks to ensure it meets the branding and quality standards.

How Is Quality Assurance Implemented in the Manufacturing of 80W JPT Fiber Lasers?

Quality assurance (QA) is a fundamental aspect of the manufacturing process, particularly for high-precision equipment like fiber lasers. Several international standards and industry-specific certifications guide the QA process.

-

International Standards: Compliance with ISO 9001 is essential for manufacturers, as this standard outlines requirements for a quality management system. Adherence to this standard ensures that processes are consistent and customer satisfaction is prioritized. Additionally, CE certification is crucial for products sold in Europe, indicating compliance with safety and health regulations.

-

Quality Control Checkpoints: Various checkpoints are established throughout the manufacturing process to ensure quality. These typically include:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for compliance with specifications before they enter the production line.

– In-Process Quality Control (IPQC): This stage monitors the manufacturing process itself, ensuring that all operations meet quality standards. Regular inspections and tests are performed to catch any discrepancies early.

– Final Quality Control (FQC): Once the assembly is complete, the final product undergoes rigorous testing to ensure it functions correctly and meets all specifications. This includes performance testing, safety checks, and aesthetic evaluations.

What Testing Methods Are Commonly Used for 80W JPT Fiber Lasers?

Testing methods play a crucial role in verifying the performance and safety of fiber lasers. Common techniques include:

- Performance Testing: This assesses the laser’s output power, beam quality, and marking speed. It ensures that the machine meets the specified operational parameters.

- Durability Testing: This involves subjecting the laser to extended operational periods to evaluate its reliability and longevity. Manufacturers often simulate real-world conditions to ensure the product can withstand typical usage.

- Safety Testing: Compliance with safety regulations is essential. This testing examines potential hazards, such as electrical safety and optical safety, to ensure the product is safe for end-users.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is vital for ensuring product reliability and compliance.

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality control measures firsthand. This provides insights into the supplier’s adherence to international standards and the effectiveness of their QA systems.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s performance history. These reports should include data on defect rates, compliance with standards, and results from various testing phases.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections often include a thorough review of manufacturing practices and product testing results.

What Are the Quality Certification Nuances for International Buyers?

Understanding quality certification nuances is essential for international buyers. Each region may have different requirements and standards, which can affect product acceptance in the market.

-

Regional Certifications: Buyers should familiarize themselves with the certifications required in their target markets. For instance, products sold in Europe must be CE certified, while those in the United States may need to comply with FDA regulations if applicable.

-

Documentation: Ensure that all quality certifications and compliance documents are available and up-to-date. This documentation serves as proof of the supplier’s commitment to quality and safety standards.

-

Cultural and Regulatory Differences: International buyers must be aware of cultural and regulatory differences that may influence quality perceptions. For example, certain regions may place a higher emphasis on specific certifications or testing methods.

Conclusion: Ensuring Quality in the Purchase of 80W JPT Fiber Lasers

For B2B buyers, understanding the manufacturing processes and quality assurance practices associated with 80W JPT fiber lasers is crucial for making informed purchasing decisions. By focusing on supplier audits, quality reports, and regional certification nuances, buyers can ensure they partner with reputable manufacturers who prioritize quality and compliance. This not only mitigates risks but also enhances overall satisfaction with the purchased equipment.

Practical Sourcing Guide: A Step-by-Step Checklist for ’80 white jpt fiber laser’

This guide provides a comprehensive checklist for B2B buyers looking to procure an 80W JPT fiber laser. It will help streamline your sourcing process, ensuring you make informed decisions based on technical specifications, supplier reliability, and long-term support.

Step 1: Define Your Technical Specifications

Before beginning your search, clearly outline your technical requirements. Consider the materials you will be working with, such as metals or plastics, and the types of applications—marking, engraving, or cutting.

– Determine the power output needed (80W is standard for many applications).

– Assess the importance of features like color marking capabilities, pulse frequency adjustments, and engraving depth.

Step 2: Research Potential Suppliers

Conduct thorough research on suppliers who offer the 80W JPT fiber laser. Look for companies with a strong reputation in the market and extensive experience in the field.

– Check online reviews and testimonials to gauge customer satisfaction.

– Review their product range to ensure they have the specific model you need.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold the necessary certifications, such as ISO or CE, indicating compliance with international quality and safety standards.

– Certifications not only assure product reliability but also indicate a commitment to quality management.

– Inquire about warranty terms and the extent of customer support services, which are crucial for maintenance and repairs.

Step 4: Request Product Demos or Samples

Whenever possible, request a demonstration or sample of the 80W JPT fiber laser. This allows you to evaluate the machine’s performance firsthand and assess its suitability for your applications.

– Pay attention to the ease of operation, speed, and precision of the engraving or cutting.

– Consider reaching out to current users for their feedback on performance and usability.

Step 5: Compare Pricing and Payment Options

Gather quotes from multiple suppliers and compare pricing structures. Look beyond just the initial cost; factor in shipping fees, installation, and any additional accessories required.

– Assess the total cost of ownership, including maintenance and operational costs.

– Explore available payment options, including financing plans, which may ease budget constraints.

Step 6: Confirm After-Sales Support and Warranty

Review the after-sales support offered by the supplier. A robust support system can save you time and resources in the long run, especially if issues arise after purchase.

– Ensure there is a clear warranty policy that covers parts and service for a reasonable duration.

– Inquire about the availability of replacement parts and technical support, especially if you operate in regions with limited access to service technicians.

Step 7: Finalize the Purchase Agreement

Once you’ve selected a supplier, carefully review and finalize the purchase agreement. Ensure that all terms, including delivery timelines, warranty coverage, and support services, are clearly outlined.

– Maintain open communication with the supplier to clarify any doubts before signing.

– Document all agreements and communications to protect your interests in case of disputes.

By following this checklist, you can confidently navigate the procurement process for an 80W JPT fiber laser, ensuring that you choose a product and supplier that meet your operational needs and expectations.

Comprehensive Cost and Pricing Analysis for 80 white jpt fiber laser Sourcing

What Are the Key Cost Components in Sourcing an 80W JPT Fiber Laser?

When sourcing an 80W JPT fiber laser, various cost components must be considered to fully understand the financial implications. These components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The primary material for fiber lasers is high-grade optical components and metals. The choice of materials directly affects performance and durability. For example, lasers using MOPA technology may require more specialized materials, impacting the overall cost.

-

Labor: Skilled labor is essential for assembling and testing the laser equipment. Labor costs can vary significantly depending on the region, which is crucial for international buyers. Countries with higher labor costs may result in higher prices, whereas sourcing from regions with lower labor expenses could provide cost savings.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and maintenance. Efficient manufacturing processes can lower overhead costs, which may be reflected in the pricing.

-

Tooling: Specialized tools and machinery for producing fiber lasers can entail significant initial investments. This cost is often amortized over the production volume, meaning larger orders may benefit from lower per-unit costs.

-

Quality Control: Rigorous QC processes are essential for ensuring the reliability and performance of fiber lasers. This may involve testing each unit, which can add to costs but is vital for maintaining product standards.

-

Logistics: Shipping and handling costs can be substantial, particularly for international orders. Factors such as distance, shipping method, and customs duties can influence overall logistics expenses.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market conditions, competition, and the perceived value of the product.

How Do Price Influencers Affect the Cost of an 80W JPT Fiber Laser?

Several price influencers can impact the overall cost of sourcing an 80W JPT fiber laser:

-

Volume/MOQ: Bulk purchases often lead to lower per-unit costs. Suppliers may offer discounts for minimum order quantities (MOQ), making it advantageous for buyers to negotiate larger orders.

-

Specifications/Customization: Customized features or specifications can increase costs. Buyers should assess whether they need unique functionalities or if standard options suffice, as this could lead to significant savings.

-

Materials: The choice of materials not only affects performance but also cost. For instance, higher-quality optical components may come at a premium but could enhance the laser’s lifespan and functionality.

-

Quality/Certifications: Certifications such as CE or ISO can add to costs but are essential for compliance in many regions. Buyers should evaluate the necessity of these certifications based on their market requirements.

-

Supplier Factors: Reputation, reliability, and service quality of the supplier can influence pricing. Established suppliers may charge more but offer better support and warranty services, which can be invaluable.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) used in the contract is crucial for managing logistics costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact the total cost of ownership.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, strategic sourcing can lead to better cost-efficiency:

-

Negotiation: Engaging in negotiations can yield better pricing. Buyers should be prepared to discuss volume discounts and payment terms to achieve favorable outcomes.

-

Total Cost of Ownership (TCO): Consider not just the initial purchase price but the TCO, which includes maintenance, operation, and potential downtime. A cheaper machine may incur higher long-term costs.

-

Pricing Nuances for International Markets: Be aware of currency fluctuations, import duties, and taxes that could affect pricing. Researching local market conditions can also provide leverage during negotiations.

In conclusion, a comprehensive understanding of the cost structure and pricing dynamics of 80W JPT fiber lasers is essential for informed purchasing decisions. By considering these factors, international B2B buyers can optimize their sourcing strategies and achieve better value for their investments.

Alternatives Analysis: Comparing 80 white jpt fiber laser With Other Solutions

When evaluating the best laser engraving solutions, it’s essential to consider various alternatives that can meet similar needs as the 80 White JPT Fiber Laser. This analysis will compare the 80 White JPT Fiber Laser with two viable alternatives: the OMTech MOPA 80W Split Fiber Laser and the CO2 Laser Engraving Machine. Each option has distinct advantages and limitations that can influence a B2B buyer’s decision based on their specific operational requirements.

| Comparison Aspect | 80 White JPT Fiber Laser | OMTech MOPA 80W Split Fiber Laser | CO2 Laser Engraving Machine |

|---|---|---|---|

| Performance | High precision and speed; ideal for metals and color marking | High precision with adjustable pulse; versatile for various materials | Good for non-metallic materials; slower than fiber lasers |

| Cost | $6,500 | $6,999 (on sale from $9,999) | $3,000 – $5,000, depending on power and features |

| Ease of Implementation | Moderate; requires setup and calibration | User-friendly; compatible with popular software | Typically easier to set up; familiar to many users |

| Maintenance | Low; durable with long service life (MTTF of 100,000 hours) | Moderate; routine maintenance needed | Moderate; tube replacement every 1-2 years |

| Best Use Case | Industrial applications requiring deep engraving and color marking | Versatile for both industrial and artistic applications | Ideal for wood, acrylic, and leather engraving |

What Are the Advantages and Disadvantages of the OMTech MOPA 80W Split Fiber Laser?

The OMTech MOPA 80W Split Fiber Laser offers a powerful alternative to the 80 White JPT Fiber Laser. It excels in versatility, handling a variety of materials including metals and plastics with ease. Its adjustable pulse frequency allows for vibrant color markings, making it suitable for both decorative and functional applications. However, it comes at a slightly higher price point, which may deter cost-sensitive buyers. Additionally, while it is user-friendly, the split design may require more space than traditional laser systems, which could be a limitation for smaller workshops.

How Does the CO2 Laser Engraving Machine Compare?

The CO2 Laser Engraving Machine is a more budget-friendly option, making it attractive for businesses looking to minimize upfront costs. It works exceptionally well with non-metal materials such as wood, acrylic, and leather, making it a preferred choice for crafts and signage. However, its performance on metals is limited compared to fiber lasers, and it typically operates at a slower speed. Maintenance can also be a consideration, as CO2 lasers require tube replacements every few years, which can add to long-term operational costs.

How to Choose the Right Laser Solution for Your Business Needs?

In conclusion, selecting the right laser engraving solution depends on your specific requirements, such as the materials you plan to work with, your budget, and the scale of your operations. If high precision and the ability to mark metals with vibrant colors are essential, the 80 White JPT Fiber Laser stands out as a top choice. Conversely, if you are focusing primarily on non-metal applications and require a lower initial investment, the CO2 Laser may be the better fit. For businesses needing versatility across multiple materials, the OMTech MOPA 80W Split Fiber Laser presents a compelling option. Assessing these factors will guide B2B buyers toward the optimal laser technology for their needs.

Essential Technical Properties and Trade Terminology for 80 white jpt fiber laser

What Are the Key Technical Properties of the 80W JPT Fiber Laser?

Understanding the essential technical properties of the 80W JPT fiber laser is crucial for B2B buyers seeking to optimize their operations. Here are several critical specifications that should be considered:

-

Output Power (80W)

The output power of 80W indicates the laser’s ability to perform tasks such as engraving, cutting, and marking with precision and speed. This power level is optimal for handling a variety of materials, including metals and plastics, making it suitable for both industrial applications and intricate artistic designs. For businesses, selecting the right output power can enhance productivity and reduce operational costs. -

Laser Wavelength (1064 nm)

The 1064 nm wavelength is standard for fiber lasers and is particularly effective for marking and engraving metals. This wavelength allows for deep penetration into the material, resulting in high-quality markings. B2B buyers should consider the wavelength when selecting lasers, as it affects the types of materials that can be processed and the quality of the results. -

Marking Speed (up to 394 ips)

The marking speed, measured in inches per second (ips), indicates how quickly the laser can engrave or mark materials. A higher marking speed translates to increased efficiency and productivity, which is vital for businesses with high-volume production needs. Understanding marking speed helps buyers assess whether the laser can meet their operational requirements. -

Pulse Width (2-500 ns)

The adjustable pulse width allows for greater control over the engraving process, enabling businesses to achieve various effects, from deep engravings to fine details. This flexibility is particularly beneficial for applications that require intricate designs or different surface finishes. Buyers should evaluate this specification to ensure the laser can meet their specific engraving needs. -

Mean Time to Failure (MTTF) (100,000 hours)

A high MTTF indicates durability and reliability, essential factors for minimizing downtime and maintenance costs. For B2B buyers, investing in equipment with a long operational lifespan can lead to significant savings and enhance overall productivity. This specification is critical for businesses planning long-term investments in laser technology.

What Are Common Trade Terms Related to the 80W JPT Fiber Laser?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers who wish to source reliable components or equipment, ensuring compatibility and quality in their production processes. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it can impact inventory management and cash flow. Knowing the MOQ helps businesses plan their purchases effectively and avoid excess inventory. -

RFQ (Request for Quotation)

An RFQ is a formal request for pricing and terms from suppliers. It is a vital tool for buyers looking to compare offers and negotiate the best deal. Understanding how to prepare and respond to RFQs can lead to better purchasing decisions and cost savings. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. They specify who is responsible for shipping, insurance, and tariffs. Knowledge of Incoterms is essential for B2B buyers engaged in international transactions to ensure clear agreements and minimize disputes. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and performance of the product. In the context of the 80W JPT fiber laser, understanding warranty terms can help buyers assess the risk associated with their investment and ensure they receive support in case of equipment failure.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring they select the right equipment and engage effectively with suppliers.

Navigating Market Dynamics and Sourcing Trends in the 80 white jpt fiber laser Sector

What Are the Current Market Trends for 80W JPT Fiber Lasers?

The global market for 80W JPT fiber lasers is experiencing significant growth, driven by advancements in manufacturing technologies and increasing demand for precision engraving and marking across various industries. Key sectors include automotive, electronics, and jewelry, where the ability to mark and engrave intricate designs on metals is essential. Notably, the MOPA (Master Oscillator Power Amplifier) technology is gaining traction for its capability to create detailed color markings and deep engravings, making it a preferred choice for both artistic and industrial applications.

In regions such as Africa, South America, the Middle East, and Europe, international B2B buyers are increasingly focused on sourcing high-quality, durable laser machines that offer versatility in handling diverse materials. The rise of e-commerce platforms and online marketplaces is also facilitating easier access to suppliers, allowing buyers to compare products and prices more effectively. Additionally, there is a growing emphasis on local sourcing and partnerships that can provide quicker delivery times and reduced shipping costs, which is particularly advantageous for businesses in emerging markets like Brazil and Vietnam.

How Is Sustainability Impacting the Sourcing of 80W JPT Fiber Lasers?

Sustainability is becoming a critical consideration in the sourcing of 80W JPT fiber lasers. Environmental impacts associated with manufacturing processes are under scrutiny, leading companies to seek suppliers that prioritize eco-friendly practices. This includes minimizing waste, reducing energy consumption, and using materials with lower environmental footprints.

Ethical supply chains are increasingly important for international buyers who are keen on aligning their procurement strategies with corporate social responsibility (CSR) goals. Certifications such as ISO 14001 for environmental management and RoHS compliance for hazardous substances can serve as indicators of a supplier’s commitment to sustainable practices. Buyers are also looking for manufacturers that utilize recyclable materials and offer products with longer lifespans, thus reducing the frequency of replacements. By prioritizing sustainability, companies not only enhance their brand reputation but also cater to the growing consumer demand for environmentally responsible products.

What Is the Historical Context of 80W JPT Fiber Lasers in B2B Markets?

The evolution of fiber laser technology has significantly shaped the B2B landscape over the past two decades. Initially, laser marking and engraving systems were bulky and limited in functionality. However, advancements in fiber laser technology, particularly the introduction of JPT sources and MOPA configurations, have enabled machines to become more compact, efficient, and versatile.

As industries began to recognize the advantages of fiber lasers—such as speed, precision, and the ability to work with various materials—their adoption became widespread. Over time, the 80W JPT fiber laser emerged as a popular choice for businesses looking for a balance between power and affordability. This trend has been particularly pronounced in developing regions, where manufacturers seek cost-effective solutions that do not compromise on quality. The ongoing innovation in this field ensures that the 80W JPT fiber laser will continue to meet the evolving needs of international B2B buyers in diverse markets.

Frequently Asked Questions (FAQs) for B2B Buyers of 80 white jpt fiber laser

-

How can I ensure the quality of the 80W JPT fiber laser before purchasing?

To ensure quality, request detailed specifications and quality assurance documentation from the supplier. Look for machines that come with a warranty and consider suppliers that offer lifetime technical support. Additionally, ask for references or testimonials from previous customers, particularly those in your region, to assess the reliability and performance of the equipment in real-world applications. A pre-purchase inspection or a factory visit can also be beneficial in verifying the machine’s quality and capabilities. -

What are the key features to look for in an 80W fiber laser machine?

When sourcing an 80W fiber laser, focus on features such as MOPA technology for enhanced color marking capabilities, pulse frequency adjustments, and a robust cooling system. The machine’s marking area size and speed are also crucial, as they affect production efficiency. Additionally, ensure compatibility with various materials, such as metals and plastics, to maximize versatility in your projects. Lastly, consider the support and warranty offered by the manufacturer for long-term operational assurance. -

What is the typical lead time for shipping an 80W fiber laser internationally?

Lead times can vary based on the supplier and the destination country. Generally, expect a shipping timeframe of 4 to 8 weeks for international orders, including customs clearance. It’s advisable to discuss shipping options with your supplier, as they may offer expedited shipping for an additional fee. Ensure that you also account for potential delays due to customs regulations in your country, which can affect the final delivery date. -

What are the minimum order quantities (MOQs) for purchasing fiber lasers?

Minimum order quantities can differ significantly among suppliers. Some manufacturers may allow single-unit purchases, while others might require bulk orders to achieve competitive pricing. It’s essential to inquire about MOQs upfront to align your purchasing strategy with your operational needs. If you are looking to test the market, consider negotiating with suppliers for a trial purchase or smaller order to assess the product’s suitability before committing to larger quantities. -

What payment terms are typically offered for B2B laser machine purchases?

Payment terms vary widely between suppliers, but common arrangements include a 30% deposit upfront with the balance due upon shipment or delivery. Some suppliers may offer financing options or extended payment plans, especially for larger orders. Always clarify the payment terms before finalizing your purchase and consider using secure payment methods to protect your transaction. Negotiating favorable terms can also be advantageous for cash flow management in your business. -

How can I vet suppliers when sourcing an 80W fiber laser?

To vet suppliers, conduct thorough research by checking their industry reputation, certifications, and customer reviews. Look for suppliers who have been in the market for several years and have a track record of serving international clients. Verify their manufacturing capabilities and quality control processes. Engaging in direct communication to discuss your specific needs and asking for samples or product demonstrations can also help assess their reliability and responsiveness. -

What kind of after-sales support should I expect after purchasing a fiber laser?

After-sales support is critical for ensuring operational efficiency. Look for suppliers that provide comprehensive support, including technical assistance, maintenance services, and access to replacement parts. A warranty period of at least two years is standard, but some suppliers offer extended warranties or service contracts. Additionally, inquire about training programs for your staff to maximize the use of the machine and ensure they are well-versed in its operation and maintenance. -

What logistics considerations should I keep in mind when importing fiber lasers?

When importing fiber lasers, consider logistics factors such as shipping costs, customs duties, and import regulations specific to your country. Collaborate with a freight forwarder experienced in handling machinery imports to streamline the process. Ensure that the machine is adequately packaged to prevent damage during transit. Additionally, familiarize yourself with local regulations regarding laser machinery to avoid compliance issues upon arrival. Proper logistics planning can save time and reduce unexpected costs in the import process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 80 White Jpt Fiber Laser Manufacturers & Suppliers List

1. OMTech – MP6969 80W MOPA Fiber Laser Marking & Engraving Machine

Domain: omtech.com

Registered: 2023 (2 years)

Introduction: {“product_name”: “MP6969 80W MOPA Fiber Laser Marking & Engraving Machine”, “working_area”: “6.9 x 6.9 inches”, “laser_type”: “MOPA Fiber Laser”, “power”: “80W”, “features”: [“High precision”, “Versatile applications”, “User-friendly interface”, “Durable construction”], “applications”: [“Metal marking”, “Plastic engraving”, “Jewelry engraving”, “Industrial marking”]}

2. SFX – Auto Focus 80W Mopa Fiber Laser Engraver

Domain: sfxlyxc.com

Registered: 2019 (6 years)

Introduction: {“Name”:”SFX Auto Focus 80W Mopa Fiber Laser Engraver”,”Model”:”SFX-80GS”,”Laser Power”:”80W”,”Laser Source”:”JPT MOPA M7 (YDFLP-E-M7-M-R)”,”Frequency”:”1-4000kHz”,”Maximum Pulse Energy”:”1.5mJ”,”Pulse Duration”:”22-500ns”,”Lens Options”:”70x70mm, 110x110mm, 150x150mm, 175x175mm, 220x220mm, 300x300mm”,”Wavelength”:”1064nm”,”Rotary Axis Options”:”D69mm, D80mm, D100mm, D125mm”,”Marking Speed”:”≤7000…

3. ComMarker – B6 JPT MOPA Fiber Laser Engraver

Domain: commarker.com

Registered: 2022 (3 years)

Introduction: ComMarker B6 JPT MOPA Fiber Laser Engraver

– Price: $3,599 (Discounted to $3,059)

– Save: $540

– Features:

– World’s smallest flagship auto-focus laser engraver

– Color marking ability

– Super 3D engraving and cutting ability

– 2-in-1 design (integrated or split setup)

– Auto-focus technology

– Speed: 15,000mm/s SpeedMax™ engraving

– 8K HD accuracy

– Weight: 13.5 kg (29.7 lbs)

– …

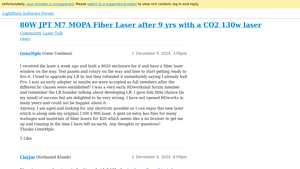

4. LightBurn – 80W JPT M7 MOPA Fiber Laser

Domain: forum.lightburnsoftware.com

Registered: 2017 (8 years)

Introduction: 80W JPT M7 MOPA Fiber Laser

Strategic Sourcing Conclusion and Outlook for 80 white jpt fiber laser

The strategic sourcing of the 80W JPT fiber laser presents numerous advantages for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. These high-performance machines, equipped with MOPA technology, offer exceptional versatility, enabling applications from intricate engraving to robust cutting across various materials. The ability to create vibrant color markings on metals enhances product differentiation, appealing to businesses aiming for innovation and quality in their offerings.

Moreover, the competitive pricing, coupled with warranties and lifetime technical support, underscores the value proposition of these fiber lasers. Sourcing these machines strategically not only ensures access to reliable technology but also fosters long-term partnerships with suppliers who prioritize customer satisfaction and operational efficiency.

As the demand for advanced manufacturing technologies grows globally, now is the opportune moment for businesses to invest in high-quality fiber laser solutions. By leveraging the capabilities of the 80W JPT fiber laser, companies can enhance their productivity and creativity, positioning themselves favorably in competitive markets. Engage with suppliers today to explore tailored solutions that meet your specific needs and drive your business forward.