Is Your 3 Prong Plugs Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for 3 prong plugs

In today’s interconnected world, sourcing high-quality 3 prong plugs can be a daunting challenge for international B2B buyers. The complexities of varying standards and regulations across regions, particularly in Africa, South America, the Middle East, and Europe, necessitate a comprehensive understanding of product specifications and safety requirements. This guide is designed to navigate the intricate landscape of 3 prong plugs, covering critical aspects such as types, applications, supplier vetting processes, and cost considerations.

With an emphasis on empowering informed purchasing decisions, this resource will delve into the nuances that influence the selection of the right plugs for your specific business needs. From understanding the differences between thermoplastic and other materials to recognizing the importance of compliance with local electrical codes, buyers will gain insights that can significantly impact operational safety and efficiency.

Moreover, the guide addresses the best practices for evaluating suppliers, ensuring you partner with reputable manufacturers who can deliver reliable products that meet international standards. Whether you are based in Germany, Saudi Arabia, or any other market, this comprehensive resource equips you with the knowledge necessary to make strategic procurement choices, ultimately enhancing your business’s operational capabilities and safety standards.

Understanding 3 prong plugs Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| NEMA 5-15 | Standard 3-prong plug in North America; rated for 15A | Consumer electronics, appliances | Pros: Widely available; Cons: Limited to 15A |

| IEC 60320 C13 | Commonly used for computer and server equipment; 3-pin | IT and data centers, telecommunications | Pros: Standardized; Cons: Requires compatible sockets |

| BS 1363 (UK Plug) | Rectangular prongs; includes fuse for safety | Home appliances, office equipment | Pros: Enhanced safety; Cons: Size may not fit all outlets |

| Schuko Plug (Type F) | Round prongs; earth contact on the side | Industrial machinery, power tools | Pros: High current rating; Cons: May not fit non-European sockets |

| Australian/New Zealand Plug | Flat angled prongs; often includes safety switch | Appliances, power tools | Pros: Safe design; Cons: Limited international compatibility |

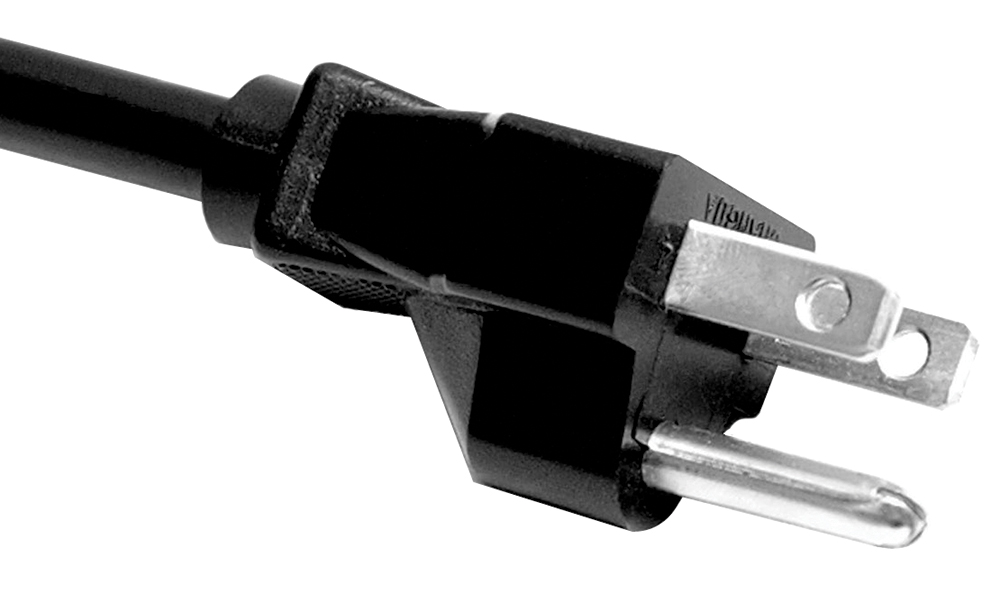

What are the Characteristics and Suitability of NEMA 5-15 Plugs?

The NEMA 5-15 plug is the standard three-prong plug used in North America. It features two flat parallel blades and a round grounding pin. This type is suitable for a wide range of consumer electronics and appliances, making it a staple in both residential and commercial settings. B2B buyers should consider its widespread availability and compatibility with existing infrastructure, although it’s limited to a maximum current of 15A, which may not suffice for heavy-duty applications.

Illustrative image related to 3 prong plugs

How Does the IEC 60320 C13 Plug Serve B2B Needs?

The IEC 60320 C13 plug is recognized globally, particularly in IT and telecommunications. It is designed for devices such as computers and servers, featuring a three-pin configuration that ensures a secure connection. This plug’s standardization across multiple countries makes it an appealing choice for B2B buyers looking to equip facilities with compatible equipment. However, it requires specific sockets, which may necessitate additional investment in infrastructure.

What Safety Features Does the BS 1363 Plug Offer?

The BS 1363 plug, commonly used in the UK, is characterized by its rectangular prongs and built-in fuse, which enhances safety by preventing overloads. This plug is ideal for a wide range of applications, including home appliances and office equipment. B2B buyers benefit from its robust safety features, although they must consider the plug’s size, which may not fit all international outlets, potentially complicating global operations.

Why Choose the Schuko Plug for Industrial Applications?

The Schuko plug (Type F) is popular in Europe for its round prongs and side grounding contacts. It is engineered for high current ratings, making it suitable for industrial machinery and power tools. For B2B buyers, its durability and safety features are significant advantages. However, compatibility with non-European sockets may limit its use in international operations, requiring careful consideration of electrical infrastructure.

What Makes the Australian/New Zealand Plug Unique?

The Australian/New Zealand plug features flat angled prongs and is often designed with safety switches to prevent accidental disconnection. This plug is commonly used for various appliances and power tools. B2B buyers should appreciate its safety-oriented design, though they must also be aware of its limited compatibility with international sockets, which could impact global sourcing strategies.

Key Industrial Applications of 3 prong plugs

| Industry/Sector | Specific Application of 3 Prong Plugs | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering Heavy Machinery | Ensures reliable operation and safety of equipment | Compliance with local electrical standards and load ratings |

| Construction | Electrical Tools and Equipment | Enhances safety protocols on job sites | Durability and weather resistance for outdoor use |

| Healthcare | Medical Equipment and Devices | Protects patients and staff from electrical hazards | UL certification and compatibility with medical standards |

| Hospitality | Appliances in Commercial Kitchens | Supports efficient operations and safety compliance | Voltage requirements and compatibility with local outlets |

| Agriculture | Equipment for Irrigation and Processing | Increases productivity and reliability | Resistance to environmental factors and electrical load capacity |

How Are 3 Prong Plugs Used in the Manufacturing Sector?

In the manufacturing industry, 3 prong plugs are essential for powering heavy machinery and equipment. These plugs provide a secure connection that includes a ground for safety, significantly reducing the risk of electrical shock. For international buyers, particularly in regions like Africa and South America, sourcing plugs that comply with local electrical standards is crucial. They must ensure that the plugs can handle the specific load requirements of their machinery to maintain operational efficiency and safety.

What Role Do 3 Prong Plugs Play in Construction?

3 prong plugs are widely used to power electrical tools and equipment on construction sites. They enhance safety protocols by ensuring that tools are properly grounded, which minimizes the risk of electrical hazards. For B2B buyers in the construction sector, especially in the Middle East and Europe, sourcing durable plugs that can withstand harsh conditions is vital. Considerations should include weather resistance and the ability to handle high voltage and current loads.

Why Are 3 Prong Plugs Critical in Healthcare Settings?

In healthcare facilities, 3 prong plugs are used for medical equipment and devices, ensuring a safe operational environment for both patients and staff. These plugs help prevent electrical shocks, which is crucial in settings where equipment is used in close proximity to individuals. Buyers in this sector, particularly in Europe and the Middle East, must prioritize sourcing UL-certified plugs that meet strict medical safety standards, ensuring compatibility with various medical devices.

How Do 3 Prong Plugs Support Hospitality Operations?

In the hospitality industry, 3 prong plugs are commonly used for powering appliances in commercial kitchens, such as ovens, refrigerators, and dishwashers. These plugs not only ensure efficient operations but also help establishments comply with safety regulations. For B2B buyers in Africa and South America, it’s important to consider the voltage requirements and ensure that the plugs are compatible with local outlet configurations to avoid operational disruptions.

What Benefits Do 3 Prong Plugs Offer in Agriculture?

In agriculture, 3 prong plugs are utilized for powering irrigation systems and processing equipment. These plugs enhance productivity by providing reliable electrical connections necessary for the operation of essential machinery. Buyers in regions like Africa and South America should focus on sourcing plugs that are resistant to environmental factors, such as moisture and dust, and that can support the electrical load required by agricultural equipment.

3 Common User Pain Points for ‘3 prong plugs’ & Their Solutions

Scenario 1: Sourcing Compatible 3-Prong Plugs for Diverse Electrical Systems

The Problem: B2B buyers, especially those operating in regions like Africa and the Middle East, often face challenges in sourcing 3-prong plugs that are compatible with local electrical systems. Variations in voltage, frequency, and plug specifications can lead to significant operational issues, such as equipment damage or increased safety risks. Buyers may find themselves with products that do not meet local standards, resulting in delays and added costs due to returns or replacements.

The Solution: To effectively source compatible 3-prong plugs, buyers should engage with local suppliers who understand regional electrical codes and standards. It’s crucial to conduct thorough research on the specific electrical requirements of the countries in which they operate. Collaborating with manufacturers that provide detailed specifications, including voltage ratings and wire gauge compatibility, can ensure that the plugs are suitable for local use. Additionally, establishing partnerships with distributors that offer a range of plug types can help buyers maintain a versatile inventory, minimizing the risk of encountering compatibility issues.

Scenario 2: Ensuring Safety and Compliance in Electrical Installations

The Problem: Safety compliance is a critical concern for businesses that utilize 3-prong plugs in their operations. Inadequate grounding or improper installation can lead to electrical hazards, posing risks to personnel and equipment. Buyers often struggle with ensuring that all electrical installations comply with local and international safety standards, which can result in legal repercussions and damage to their reputation.

The Solution: To mitigate safety risks, buyers should prioritize working with certified electricians who are well-versed in local electrical codes. Implementing a rigorous quality assurance process when sourcing 3-prong plugs is essential. This includes verifying that plugs meet industry standards such as UL certification. Additionally, providing comprehensive training for staff on proper installation and maintenance practices can enhance safety compliance. Regular audits of electrical systems and equipment can also help identify potential issues before they escalate, ensuring ongoing compliance and safety.

Scenario 3: Managing Supply Chain Disruptions for Consistent Availability

The Problem: Global supply chain disruptions can significantly impact the availability of 3-prong plugs, leading to delays in projects and increased operational costs. B2B buyers may experience difficulties in obtaining the necessary components for their electrical systems, which can halt production and result in financial losses. The unpredictability of lead times can complicate inventory management and planning.

The Solution: To effectively manage supply chain disruptions, buyers should adopt a proactive approach by diversifying their supplier base. Engaging multiple suppliers across different regions can provide a buffer against localized disruptions. Additionally, establishing long-term contracts with reliable manufacturers can ensure a consistent supply of 3-prong plugs. Implementing inventory management software that tracks usage patterns and forecasts demand can help maintain optimal stock levels. Lastly, developing contingency plans, such as identifying alternative products or temporary solutions, can keep operations running smoothly in the face of unexpected shortages.

Strategic Material Selection Guide for 3 prong plugs

What Are the Key Materials Used in Manufacturing 3 Prong Plugs?

When selecting materials for 3 prong plugs, it is crucial to consider the performance characteristics, environmental factors, and compliance with international standards. Below are four common materials used in the production of 3 prong plugs, along with their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Thermoplastic Material Perform in 3 Prong Plugs?

Thermoplastics, such as polyvinyl chloride (PVC) and nylon, are widely used in the manufacturing of 3 prong plugs due to their excellent electrical insulation properties and durability. These materials can withstand a range of temperatures, typically up to 85°C (185°F), making them suitable for various applications.

Pros: Thermoplastics are lightweight, cost-effective, and easy to mold, which simplifies the manufacturing process. They also offer good resistance to chemicals and moisture, enhancing their longevity.

Cons: However, thermoplastics may not be as durable as some metals, especially in high-temperature or high-stress environments. They can also be less effective in grounding applications compared to metal components.

Impact on Application: Thermoplastics are compatible with low to medium voltage applications, making them suitable for household appliances and light industrial equipment.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards such as IEC 60884-1 and UL 498. Additionally, thermoplastics may not be ideal for regions with extreme temperatures, necessitating careful selection based on local conditions.

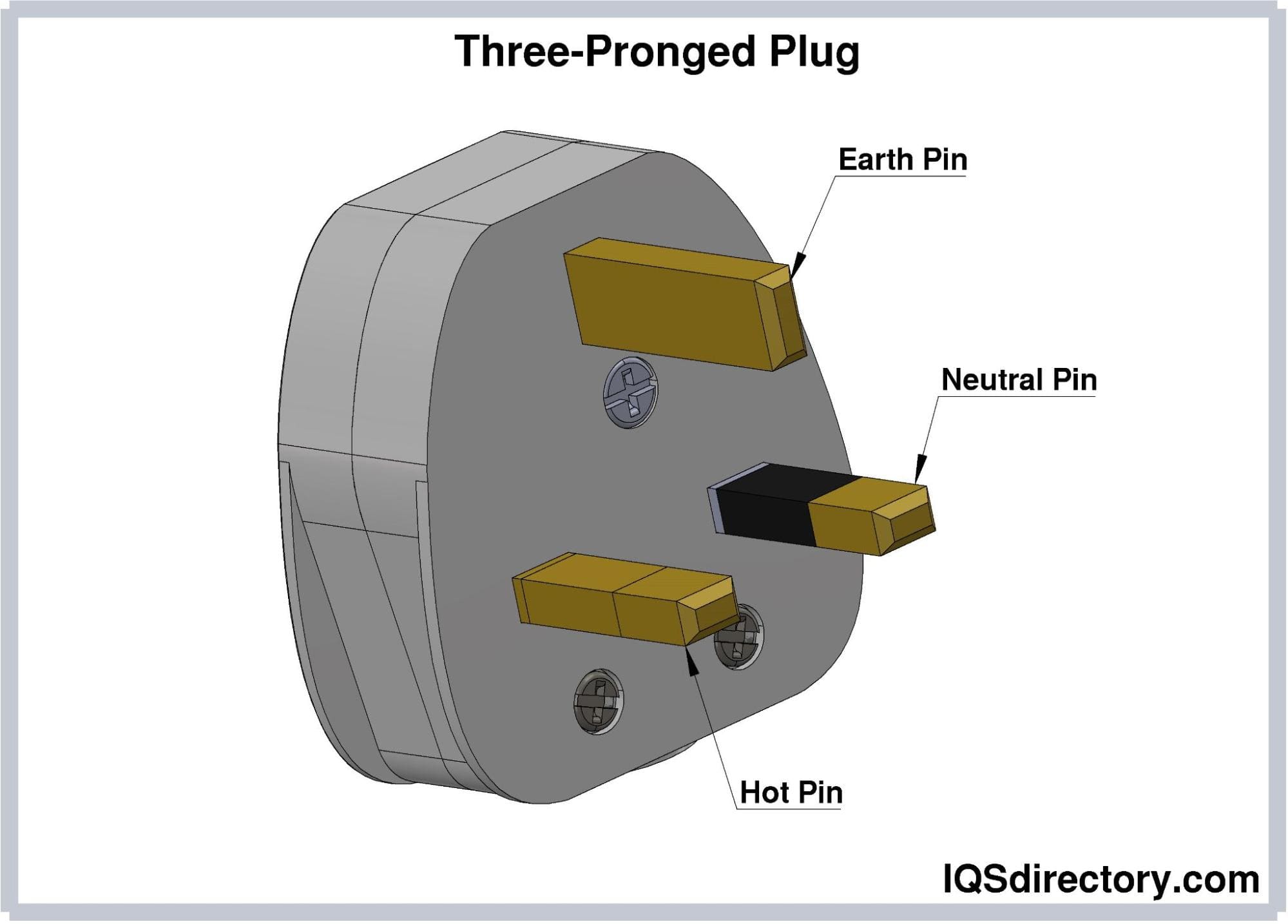

Illustrative image related to 3 prong plugs

What Role Does Metal Play in 3 Prong Plug Construction?

Metal components, particularly brass and copper, are essential in 3 prong plugs for their conductive properties. Brass, often used for prongs, offers excellent corrosion resistance and can handle higher electrical loads, typically rated for 15A at 125V.

Pros: Metals like brass provide superior conductivity and grounding capabilities, enhancing safety in electrical applications. They are also highly durable, ensuring a longer lifespan for the plug.

Cons: The primary disadvantage is the higher cost of metal components compared to thermoplastics. Additionally, metal parts may be prone to corrosion if not properly treated or coated.

Illustrative image related to 3 prong plugs

Impact on Application: Metal prongs are crucial for applications requiring reliable electrical connections, such as industrial machinery and heavy-duty appliances.

Considerations for International Buyers: Compliance with standards such as ASTM B16 for brass and DIN EN 60529 for ingress protection is essential. Buyers in humid or coastal regions should consider corrosion-resistant finishes to ensure longevity.

How Do Silicone Materials Enhance 3 Prong Plug Functionality?

Silicone is increasingly being used in the insulation of 3 prong plugs due to its excellent thermal stability and flexibility. It can withstand temperatures ranging from -60°C to 200°C (-76°F to 392°F), making it suitable for extreme environments.

Illustrative image related to 3 prong plugs

Pros: Silicone’s flexibility allows for easier handling and installation. Its high-temperature resistance makes it ideal for applications involving heat-generating devices.

Cons: The primary limitation is the higher cost of silicone compared to traditional thermoplastics. Additionally, silicone may not provide the same level of rigidity, which can be a concern in certain applications.

Impact on Application: Silicone-insulated plugs are particularly effective in high-temperature environments, such as industrial ovens and heating equipment.

Considerations for International Buyers: Buyers should look for compliance with international standards like IEC 60695 for fire safety. The higher cost may be justified in applications where temperature extremes are a concern.

Why Is Rubber a Viable Option for 3 Prong Plugs?

Rubber is another material option for 3 prong plugs, particularly in the form of thermoset rubber. It is known for its excellent flexibility and resistance to wear and tear.

Pros: Rubber provides good electrical insulation and is highly resistant to abrasion, making it suitable for rugged environments. It also remains flexible at low temperatures.

Cons: However, rubber can degrade over time when exposed to UV light and certain chemicals. Additionally, it is generally less heat-resistant than silicone.

Impact on Application: Rubber plugs are often used in outdoor applications where flexibility and durability are paramount, such as in extension cords and portable power tools.

Illustrative image related to 3 prong plugs

Considerations for International Buyers: Compliance with standards like IEC 60335 for household and similar electrical appliances is critical. Buyers should also consider the local climate and environmental conditions when selecting rubber materials.

Summary Table of Material Selection for 3 Prong Plugs

| Material | Typical Use Case for 3 Prong Plugs | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic | Household appliances | Lightweight and cost-effective | Less durable under high stress | Low |

| Metal (Brass) | Industrial machinery | Superior conductivity and durability | Higher cost, prone to corrosion | High |

| Silicone | High-temperature applications | Excellent thermal stability | Higher cost, less rigidity | Med |

| Rubber | Outdoor power tools | Good flexibility and abrasion resistance | Degrades under UV exposure | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on performance, cost, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 3 prong plugs

What Are the Key Stages in the Manufacturing Process of 3 Prong Plugs?

The manufacturing of 3 prong plugs involves several critical stages, each contributing to the overall functionality and safety of the final product. Understanding these stages can help B2B buyers ensure they are sourcing quality components.

How Is Material Prepared for 3 Prong Plugs?

The first stage of production involves the careful selection and preparation of materials. Typically, thermoplastic or thermosetting plastics are used for the housing of plugs due to their durability and insulating properties. Copper is commonly selected for the prongs because of its excellent conductivity. Suppliers must ensure that materials meet specific industry standards, such as UL (Underwriters Laboratories) or CE (Conformité Européenne) certifications, to guarantee safety and reliability.

What Techniques Are Used for Forming 3 Prong Plugs?

Once materials are prepared, the forming process begins. This usually involves injection molding for the plastic components, where heated plastic is injected into molds to create the plug casing. For the metal prongs, stamping or forging techniques are often used. These processes require precision to ensure that prongs fit securely into outlets and maintain electrical integrity. Advanced manufacturing techniques like CNC machining may also be employed for higher accuracy in prong dimensions.

How Are 3 Prong Plugs Assembled?

After forming, the next step is assembly. This typically occurs in a controlled environment to minimize contamination. During assembly, the prongs are inserted into the plastic housing, and the components are secured, often using ultrasonic welding or mechanical fastening methods. The use of automated assembly lines is common, which helps in maintaining consistency and efficiency.

What Finishing Processes Are Essential for 3 Prong Plugs?

Finishing processes are crucial for enhancing the durability and aesthetics of 3 prong plugs. These processes can include surface treatments such as plating or coating to improve corrosion resistance for the metal prongs. Additionally, quality checks are performed to ensure that there are no sharp edges or defects that could compromise safety. A final inspection ensures that the plugs are visually and functionally compliant with standards before packaging.

What Quality Assurance Practices Are Essential for 3 Prong Plugs?

Quality assurance (QA) is a pivotal aspect of the manufacturing process for 3 prong plugs, ensuring that they meet international and industry-specific standards. This section outlines the key QA practices relevant to B2B buyers.

Illustrative image related to 3 prong plugs

Which International Standards Should B2B Buyers Consider?

B2B buyers should be aware of several international standards when assessing potential suppliers. ISO 9001 is a widely recognized quality management system standard that applies to manufacturing processes across various industries, ensuring consistent quality in products. Additionally, the CE mark is essential for products sold in Europe, indicating compliance with health, safety, and environmental protection standards. In regions like Africa and South America, buyers should also consider local certifications that may apply.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are critical for identifying defects and ensuring compliance throughout the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC involves monitoring various stages of production to catch defects early.

-

Final Quality Control (FQC): This is the last stage where finished products undergo comprehensive testing for functionality and safety before shipment.

These checkpoints help maintain a high level of quality and reliability in the final product.

What Testing Methods Are Commonly Used for 3 Prong Plugs?

Several testing methods are utilized to ensure that 3 prong plugs meet safety and performance criteria. Common tests include:

-

Electrical Testing: To check for proper conductivity and insulation resistance.

-

Mechanical Testing: Assessing the durability of the prongs and housing through stress tests.

-

Environmental Testing: Evaluating how the plugs perform under different environmental conditions, such as temperature and humidity extremes.

Conducting these tests can help prevent failures in the field, which is essential for maintaining customer trust and satisfaction.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to verify the quality control processes of potential suppliers. This can be achieved through several strategies:

Illustrative image related to 3 prong plugs

What Auditing Practices Should Buyers Implement?

Conducting audits of suppliers is a crucial step in verifying quality control processes. Buyers should request audits of the supplier’s manufacturing facilities to assess compliance with international standards like ISO 9001. Additionally, third-party audits can provide an unbiased assessment of the supplier’s adherence to quality practices.

How Can Buyers Access Quality Reports and Inspection Results?

Buyers should require suppliers to provide quality reports and inspection results as part of the procurement process. These documents should detail the outcomes of various QC checkpoints, testing methods, and compliance with relevant standards. Transparency in reporting will help buyers make informed decisions.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can provide additional assurance of product quality. These services can perform unannounced inspections during production, ensuring that suppliers maintain high-quality standards consistently. For international transactions, third-party inspectors can also help navigate local compliance requirements.

Illustrative image related to 3 prong plugs

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control.

How Do Regional Standards Impact Quality Assurance?

Different regions may have varying standards and regulations regarding electrical components. For example, the European Union has stringent CE marking requirements, while other regions may prioritize different certifications. Understanding these regional standards is crucial for ensuring compliance and avoiding costly penalties.

What Should Buyers Know About Local Compliance and Safety Regulations?

Buyers should familiarize themselves with local compliance and safety regulations that may apply to 3 prong plugs in their respective markets. This includes understanding local electrical codes and safety standards, which can differ significantly from international standards. Engaging with local experts can provide valuable insights into these requirements.

By understanding the manufacturing processes and quality assurance practices associated with 3 prong plugs, B2B buyers can make informed decisions, ensuring they source safe, reliable, and high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3 prong plugs’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure 3-prong plugs. Sourcing these electrical components requires careful consideration of technical specifications, supplier reliability, and compliance with international standards. By following these steps, you can ensure that your procurement process is efficient and results in high-quality products that meet your operational needs.

1. Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the 3-prong plugs you need. This includes voltage ratings, current ratings, and material specifications (e.g., thermoplastic vs. thermoset materials). Understanding these specifications is crucial to ensure compatibility with your existing electrical systems and to meet safety standards.

- Voltage and current ratings should match your application needs.

- Consider environmental factors like temperature and moisture resistance.

2. Research International Standards and Compliance

Ensure that the plugs you intend to purchase comply with relevant international standards such as IEC, UL, or CE. Compliance with these standards not only ensures safety but also facilitates easier trade across borders, particularly in regions like Africa, South America, the Middle East, and Europe.

- Request documentation or certification from suppliers to verify compliance.

- Stay updated on regional regulations that may affect your procurement.

3. Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Look for suppliers with established reputations in the industry. Request company profiles, case studies, and references from buyers in similar industries or regions to gauge their reliability and quality of service.

- Check for customer reviews and testimonials.

- Assess their ability to meet your volume and delivery timelines.

4. Verify Supplier Certifications

Confirm that your chosen suppliers hold relevant certifications that demonstrate their commitment to quality and safety. Certifications such as ISO 9001 can indicate a standardized approach to quality management, which is crucial for electrical components.

- Ask for copies of certifications and audit reports.

- Ensure certifications are current and applicable to the products you are sourcing.

5. Assess Pricing and Payment Terms

Analyze the pricing structures offered by potential suppliers, ensuring that the costs align with your budget. Consider not only the unit price but also shipping and handling fees, as these can significantly impact the overall cost. Additionally, review payment terms to ensure they are favorable and manageable for your business.

- Request quotes from multiple suppliers for comparison.

- Negotiate terms that allow for flexibility in payment and potential discounts for bulk purchases.

6. Request Samples for Testing

Before placing a large order, request samples of the 3-prong plugs for quality testing. This step allows you to evaluate the product’s performance, durability, and compatibility with your applications. Testing samples can help prevent costly mistakes in your procurement.

- Check for functionality and safety features, such as grounding.

- Conduct stress tests to ensure they meet your operational demands.

7. Establish a Clear Communication Channel

Finally, set up a communication channel with your supplier to facilitate ongoing discussions regarding order statuses, potential issues, and future needs. Effective communication can help build a strong partnership and ensure that any challenges are addressed promptly.

- Utilize email, phone, or dedicated platforms for regular updates.

- Establish points of contact for both parties to streamline communication.

By following this checklist, B2B buyers can navigate the complexities of sourcing 3-prong plugs effectively, ensuring that they secure high-quality products that meet their operational needs while adhering to safety standards.

Comprehensive Cost and Pricing Analysis for 3 prong plugs Sourcing

What Are the Key Cost Components in Sourcing 3 Prong Plugs?

When evaluating the cost structure for sourcing 3 prong plugs, several components play a significant role. These include:

-

Materials: The primary materials for 3 prong plugs typically consist of thermoplastic or thermoset plastic for the casing, copper for the prongs, and sometimes additional materials for insulation. The choice of materials directly impacts the durability, safety, and regulatory compliance of the product, influencing overall costs.

-

Labor: Labor costs can vary significantly based on the manufacturing location. Regions with higher labor costs, such as parts of Europe, will yield higher overall costs compared to regions with lower labor costs, like parts of Africa or South America.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, equipment depreciation, and factory maintenance. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Initial tooling costs can be substantial, especially if custom molds are required for specific plug designs. For large orders, these costs can be amortized over a greater number of units, reducing the per-unit price.

-

Quality Control (QC): Ensuring that plugs meet international safety standards (like UL certification) incurs additional costs. A robust QC process minimizes defects and enhances product reliability, which is crucial for B2B buyers concerned about safety.

-

Logistics: Shipping and handling costs are significant, particularly for international buyers. Factors such as shipping distance, mode of transport, and customs duties can greatly affect the total cost.

-

Margin: Suppliers will typically include a profit margin in their pricing, which can vary based on competition, market demand, and the buyer’s negotiating power.

How Do Price Influencers Affect the Cost of 3 Prong Plugs?

Several factors can influence the pricing of 3 prong plugs, and understanding these can help buyers make more informed purchasing decisions:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for bulk pricing discounts. Buyers should negotiate to reach optimal order quantities that balance cost and inventory needs.

-

Specifications and Customization: Custom designs or specifications (e.g., specific color or prong configurations) can increase costs. Buyers should assess whether customization is necessary or if standard options will suffice.

-

Material Quality and Certifications: Higher-quality materials and certifications (like UL or CE) typically lead to higher prices. Buyers must weigh the importance of certifications against their budget constraints.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can impact pricing. Established suppliers may command higher prices due to perceived quality and reliability.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) affect who bears costs and responsibilities during transport, influencing the overall price.

What Are the Best Buyer Tips for Cost-Efficiency in 3 Prong Plug Sourcing?

To achieve cost-efficiency while sourcing 3 prong plugs, buyers should consider the following tips:

-

Negotiate Effectively: Always negotiate pricing, especially for larger orders. Suppliers may be willing to adjust pricing based on volume or long-term commitments.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the total cost of ownership, which includes shipping, installation, maintenance, and potential downtime costs due to product failures.

-

Understand Pricing Nuances in Different Regions: Price sensitivity can vary by region. For instance, buyers in Europe may prioritize safety certifications more than buyers in other regions, affecting overall pricing structures.

-

Research Local and Regional Suppliers: Local suppliers may offer reduced shipping costs and faster delivery times. Establishing relationships with regional suppliers can also enhance supply chain reliability.

-

Stay Informed on Market Trends: Keep abreast of changes in material costs, labor rates, and regulatory requirements that could impact pricing. This knowledge can empower buyers to make timely purchasing decisions.

Disclaimer on Indicative Prices

Prices for 3 prong plugs can fluctuate based on market conditions, supplier availability, and changes in material costs. It is advisable for buyers to obtain quotes from multiple suppliers to ensure competitive pricing and to verify that the prices reflect current market conditions.

Illustrative image related to 3 prong plugs

Alternatives Analysis: Comparing 3 prong plugs With Other Solutions

Exploring Alternatives to 3 Prong Plugs: A Comprehensive Comparison

In the electrical connectivity sector, 3 prong plugs are widely recognized for their safety and effectiveness. However, various alternative solutions exist that can meet specific needs depending on the application, environment, and budget. This section compares 3 prong plugs with two viable alternatives: 2 prong plugs and smart plugs.

Comparison Table

| Comparison Aspect | 3 Prong Plugs | 2 Prong Plugs | Smart Plugs |

|---|---|---|---|

| Performance | High, with grounding for safety | Moderate, lacks grounding | Variable, depends on device |

| Cost | Moderate ($3-$20) | Low ($1-$10) | Higher ($15-$50) |

| Ease of Implementation | Simple, requires standard outlet | Very simple, standard outlet | Requires Wi-Fi setup |

| Maintenance | Low, durable materials | Low, fewer components | Moderate, software updates needed |

| Best Use Case | Heavy-duty appliances, safety needs | Light-duty devices, basic use | Smart home integration, automation |

Detailed Breakdown of Alternatives

2 Prong Plugs

2 prong plugs are simpler and typically less expensive than their 3 prong counterparts. They are suitable for light-duty appliances and devices that do not require grounding. However, the lack of a grounding feature increases the risk of electrical shock, especially for metal-encased devices. This makes them less ideal for safety-critical applications. They are easy to implement and widely available, making them a go-to choice for basic needs.

Smart Plugs

Smart plugs represent a modern approach to electrical connectivity, allowing users to control devices remotely via smartphone applications. They provide flexibility and can integrate into smart home systems, enabling automation and energy monitoring. However, smart plugs often come at a higher cost and require a stable Wi-Fi connection for optimal functionality. Maintenance involves occasional software updates and troubleshooting connectivity issues, which may not be ideal for all businesses, particularly those in regions with unstable internet access.

Conclusion: Making the Right Choice for Your Business Needs

When evaluating electrical solutions, B2B buyers should consider their specific requirements, including safety, budget, and the nature of the devices being powered. While 3 prong plugs offer enhanced safety for high-demand applications, 2 prong plugs serve well for simpler tasks without significant safety concerns. Smart plugs, although more expensive, provide advanced functionality and convenience for businesses looking to embrace automation. Ultimately, the right choice will align with the operational needs and safety standards of the organization, ensuring both efficiency and reliability in electrical connectivity.

Essential Technical Properties and Trade Terminology for 3 prong plugs

What are the Key Technical Properties of 3 Prong Plugs?

Understanding the technical properties of 3 prong plugs is essential for B2B buyers to ensure compliance, safety, and reliability in electrical applications. Here are some critical specifications to consider:

1. Material Grade

3 prong plugs are typically made from thermoplastic or thermoset materials. Thermoplastic plugs offer flexibility and are often less expensive, while thermoset materials provide superior heat resistance and durability. Selecting the appropriate material is crucial for applications that may expose the plug to high temperatures or mechanical stress, ensuring longevity and performance.

2. Current Rating (Amperage)

The current rating indicates the maximum amperage that a plug can safely handle, commonly rated at 15A for standard plugs. This specification is vital for B2B buyers as it determines the plug’s suitability for various devices. Using a plug with a lower amperage rating than required can lead to overheating and potentially cause electrical fires.

3. Voltage Rating

Voltage ratings for 3 prong plugs can vary, with common ratings being 125V or 250V. Understanding the voltage rating is essential for ensuring compatibility with electrical systems in different regions, especially when dealing with international suppliers. This knowledge helps prevent equipment damage and ensures compliance with local electrical standards.

4. Wire Opening Diameter

The wire opening diameter is the size of the hole in the plug where the electrical wires are inserted. A standard diameter for 3 prong plugs is approximately 9.5 mm (3/8″). This specification is crucial for ensuring that the plug can accommodate the appropriate gauge of wire, which directly impacts safety and performance.

5. UL Certification

A UL (Underwriters Laboratories) certification indicates that the plug has been tested for safety and performance standards. For B2B buyers, this certification is important as it assures compliance with safety regulations and reduces liability risks. Products without UL certification may not meet local electrical codes, which can be particularly relevant in international markets.

What Common Trade Terms Should B2B Buyers Know for 3 Prong Plugs?

Familiarity with industry terminology can streamline procurement processes and enhance communication with suppliers. Here are some common trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of 3 prong plugs, understanding whether a supplier is an OEM can influence pricing, quality, and warranty conditions.

Illustrative image related to 3 prong plugs

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is critical for budgeting and inventory management, especially when purchasing in bulk. Suppliers may have different MOQs based on production costs and logistics.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing and terms from suppliers for specific products. Issuing an RFQ for 3 prong plugs can help B2B buyers compare costs, lead times, and terms from various manufacturers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B buyers to clarify delivery terms and avoid unexpected costs, particularly when sourcing products from international suppliers.

5. CE Marking

CE marking indicates that a product meets European safety, health, and environmental protection standards. For companies operating in Europe or importing products into the region, ensuring that 3 prong plugs have CE marking is essential for compliance with EU regulations.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing 3 prong plugs, ensuring safety, compliance, and efficiency in their operations.

Navigating Market Dynamics and Sourcing Trends in the 3 prong plugs Sector

In the evolving landscape of the 3-prong plug market, several key trends are shaping the sourcing dynamics for international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe.

What Are the Global Drivers Influencing the 3-Prong Plug Market?

The demand for 3-prong plugs is driven by the increasing emphasis on electrical safety and compliance with international standards. As markets in Africa and South America develop, the need for reliable electrical components becomes paramount, particularly in burgeoning industries such as construction, manufacturing, and electronics. Additionally, the rise of smart home technologies is prompting a shift towards more sophisticated electrical solutions, thereby increasing the demand for quality plugs that ensure safety and efficiency.

Emerging technologies are also influencing sourcing trends. The integration of IoT (Internet of Things) in electrical systems is leading to a demand for plugs that can support smart devices. B2B buyers are increasingly looking for suppliers who can provide innovative solutions that integrate seamlessly with modern technology. Furthermore, the trend towards e-commerce is reshaping how businesses source their products, with a growing reliance on online platforms for procurement.

How Is Sustainability Shaping the Sourcing of 3-Prong Plugs?

Sustainability has become a crucial consideration in the sourcing of electrical components, including 3-prong plugs. The environmental impact of manufacturing processes and materials used in plugs is under scrutiny, leading to a demand for eco-friendly alternatives. B2B buyers are increasingly prioritizing suppliers who utilize sustainable practices, such as reducing waste and energy consumption during production.

Illustrative image related to 3 prong plugs

Ethical sourcing is equally important, with buyers seeking suppliers who adhere to fair labor practices and responsible sourcing of materials. Certifications such as RoHS (Restriction of Hazardous Substances) and energy efficiency ratings are becoming essential criteria in the decision-making process. By prioritizing suppliers with ‘green’ certifications, businesses not only mitigate their environmental footprint but also enhance their brand reputation in an increasingly eco-conscious market.

What Historical Developments Have Influenced Current Trends in the 3-Prong Plug Market?

The evolution of the 3-prong plug can be traced back to safety concerns regarding electrical equipment. Initially, two-prong plugs were the standard; however, the introduction of the ground prong significantly improved safety by providing a path for stray electricity, thereby reducing the risk of electric shock. This change was particularly crucial as electrical appliances became more prevalent in homes and industries.

Over the years, the design and materials used in 3-prong plugs have evolved to enhance durability and safety. The introduction of thermoplastic materials has allowed for better insulation and resistance to heat, making plugs more reliable in various environments. Today, as the global market continues to expand, the focus is not only on functionality but also on sustainability and compliance with international standards, guiding B2B buyers in their sourcing decisions.

Conclusion

In summary, the 3-prong plug market is shaped by a combination of safety regulations, technological advancements, and a growing emphasis on sustainability. For international B2B buyers, particularly those from emerging markets, understanding these dynamics is crucial for making informed sourcing decisions. By aligning procurement strategies with current trends and ethical considerations, businesses can not only ensure compliance but also enhance their competitive edge in the marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of 3 prong plugs

-

How do I ensure the quality and safety of 3 prong plugs when sourcing?

To ensure quality and safety, always verify that the 3 prong plugs meet international safety standards, such as UL (Underwriters Laboratories) or CE (Conformité Européenne) markings. Request samples from potential suppliers and conduct independent testing for electrical performance and durability. Additionally, consider suppliers who provide detailed product specifications and certifications. Establishing clear communication about quality expectations upfront can help minimize risks in your supply chain. -

What is the best way to evaluate suppliers of 3 prong plugs?

When evaluating suppliers, prioritize those with a solid reputation and proven experience in manufacturing electrical components. Check for customer reviews, industry certifications, and their compliance with international standards. Conduct background checks, including financial stability assessments and previous export records. Engaging in direct communication to gauge responsiveness and support can also provide insights into their reliability. -

What customization options are available for 3 prong plugs?

Many manufacturers offer customization options for 3 prong plugs, including variations in materials, colors, and specifications. Common customizations include different prong configurations, wire lengths, and insulation types. When requesting customization, provide detailed specifications and inquire about the minimum order quantities (MOQs) that apply. Ensure that the supplier can accommodate your requirements while maintaining compliance with safety standards. -

What are the typical minimum order quantities (MOQs) for 3 prong plugs?

MOQs for 3 prong plugs can vary significantly depending on the manufacturer and the level of customization required. Standard orders might start at 500 to 1,000 units, while customized plugs may require higher MOQs due to production setup costs. Always clarify MOQs during initial discussions with suppliers, as this will impact your procurement strategy and inventory management. -

What payment terms should I expect when sourcing 3 prong plugs internationally?

Payment terms can vary widely among suppliers. Common practices include full payment upfront, a 30% deposit with the balance due before shipment, or payment upon delivery. It is crucial to negotiate terms that align with your cash flow needs while ensuring security for both parties. Using secure payment methods like letters of credit or escrow services can mitigate risks in international transactions. -

How can I manage logistics for importing 3 prong plugs?

To manage logistics effectively, partner with a freight forwarder experienced in handling electrical components. They can assist with customs documentation, tariffs, and shipping regulations specific to your target market. Plan for lead times by factoring in production, shipping, and customs clearance durations. Ensure that you have a reliable tracking system in place to monitor shipments and address any potential delays promptly. -

What are the key safety standards for 3 prong plugs in different regions?

Safety standards for 3 prong plugs can vary by region. In the U.S., look for UL certification, while in Europe, CE marking is essential. For markets in Africa and the Middle East, compliance with local standards such as SANS (South African National Standards) or GCC (Gulf Cooperation Council) regulations may be required. Always verify that your supplier’s products comply with the relevant standards in the regions you plan to sell. -

How do I handle quality assurance (QA) for 3 prong plugs?

Implement a robust quality assurance process by conducting inspections at various stages of production. This includes initial sample inspections, in-process monitoring, and final product testing. Collaborate with your supplier to establish quality benchmarks and testing protocols. Consider third-party inspection services for impartial quality assessments, ensuring that the products meet your specifications before shipment.

Top 6 3 Prong Plugs Manufacturers & Suppliers List

1. Sundial Wire – 3-Prong Thermoplastic Plug

Domain: sundialwire.com

Registered: 2002 (23 years)

Introduction: Product Name: 3-Prong Thermoplastic Plug

Price: $3.00

Available Colors: Black, Brown, White

SKU: PN3THERMOBK

Stock: 23 in stock

Material: Thermoplastic

UL Certification: UL-Recognized, 15A-125V

Wire Opening Diameter: 9.5 mm (3/8″)

Polarity: Not polarized

Usage Note: Should only be used with 3-conductor wire (e.g., 3-conductor pulley cords or overbraid wires). Consult a qualified electrician for sa…

2. Creative Cables – 3-Prong Plug

Domain: creative-cables.us

Registered: 2015 (10 years)

Introduction: {“name”:”3-prong plug”,”price”:”$12.00″,”sku”:”LV3PPW”,”ean13″:”8057730852883″,”finish”:[“White”,”Black”],”characteristics”:{“hinged_design”:”provides fast, easy assembly”,”ideal_for”:”replacement of plugs on tools, appliances and extension cords”,”accepts”:”AWG SJ 16/3 NEMA 5-15P cULus, NOM”,”unique_body”:”dimpled body provides a secure hinge grip”,”built_in_cord_grip”:”adjusts automatically for …

3. HowStuffWorks – Electrical Safety Essentials

Domain: electronics.howstuffworks.com

Registered: 1998 (27 years)

Introduction: Two-pronged plugs have two vertical slots: one for neutral (left, slightly larger) and one for hot (right). Three-pronged plugs include a ground prong (round hole below the slots) that protects against electric shock by grounding the appliance’s metal casing. The ground prong is crucial for safety, especially for metal-encased appliances. Existing two-prong outlets are legal but can be replaced wi…

4. Wadsworth City – Three-Prong Plug Safety

Domain: wadsworthcity.com

Registered: 1997 (28 years)

Introduction: The three-prong plug features a third prong that provides a path to ground for electricity that is straying or leaking from a product, helping to protect equipment and prevent electric shock. It is advised not to remove or bend the third prong to fit a two-slot outlet, and an adapter should only be used if the grounding wire or tab is physically connected to an electrical ground. The recommended s…

5. Reddit – 3-Prong Plug Safety

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Replacement 3-prong plugs cost about $4 at places like Home Depot. The ground connection is a safety feature.

6. Landis Electric – 3 Prong Outlets Guide

Domain: landiselectrickc.com

Registered: 2019 (6 years)

Introduction: Types of 3 Prong Outlets: 1. Standard 3 Prong Outlet: 15A, 120V, suitable for small to medium powered devices. 20A, 120V variant supports larger appliances. 2. Ground Fault Circuit Interrupter (GFCI) Outlet: Protects against electrical shock, used in wet areas, monitors electricity flow, cuts off power if imbalance detected. 3. Arc Fault Circuit Interrupter (AFCI) Outlet: Prevents arcing and poten…

Strategic Sourcing Conclusion and Outlook for 3 prong plugs

In navigating the dynamic landscape of international sourcing for three-prong plugs, B2B buyers must prioritize quality, compliance, and cost-effectiveness. Understanding the technical specifications, such as the importance of grounding and the appropriate use of thermoplastic materials, is essential for ensuring safety and reliability in electrical applications. Moreover, leveraging supplier relationships and local market knowledge can enhance procurement strategies, particularly in regions like Africa, South America, the Middle East, and Europe, where standards may vary.

Strategic sourcing not only optimizes costs but also mitigates risks associated with supply chain disruptions. By diversifying suppliers and focusing on those who comply with international safety standards, businesses can secure a competitive edge. As the demand for reliable electrical components continues to grow, aligning sourcing strategies with market trends will be vital.

Looking ahead, international buyers are encouraged to stay abreast of innovations in plug design and materials. Engaging with suppliers who demonstrate adaptability and foresight will be crucial in meeting evolving consumer needs. Now is the time to strengthen your sourcing strategy for three-prong plugs, ensuring your business remains at the forefront of safety and efficiency in electrical solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.