Is Your 3 Pin Connector Socket Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for 3 pin connector socket

In the rapidly evolving landscape of global trade, sourcing high-quality 3 pin connector sockets presents a significant challenge for B2B buyers. With diverse applications ranging from automotive to consumer electronics, understanding the intricacies of these connectors is vital for making informed purchasing decisions. This comprehensive guide delves into the various types of 3 pin connectors, their specific applications, and essential criteria for evaluating potential suppliers.

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Germany—face unique challenges in navigating supplier landscapes, pricing structures, and regulatory standards. By equipping buyers with actionable insights into product specifications, market trends, and cost considerations, this guide empowers them to make strategic decisions that align with their operational needs and budget constraints.

Furthermore, we will explore best practices for supplier vetting, ensuring that buyers can identify reliable partners who meet quality and compliance standards. With the right knowledge and tools, businesses can streamline their procurement processes, mitigate risks, and enhance their competitive edge in the global marketplace. Embrace this opportunity to optimize your sourcing strategy for 3 pin connector sockets, and position your business for success in a dynamic and interconnected world.

Understanding 3 pin connector socket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| JST PH Series | Compact design, three-pin configuration, color-coded | Consumer electronics, small appliances | Pros: Space-efficient, widely available. Cons: Limited to low-power applications. |

| DTM Style Connector | Durable thermoplastic housing, often weatherproof | Automotive, industrial equipment | Pros: Robust, suitable for harsh environments. Cons: Higher cost compared to basic options. |

| Molex KK Connector | Similar to 3-pin connectors, but with a 4-pin option | Power distribution in electronics | Pros: Versatile, supports higher current. Cons: Bulkier design may not fit all applications. |

| AMP MTA Connector | Available in various pin configurations, good for PCB | Telecommunications, computer hardware | Pros: Reliable, easy to solder. Cons: Requires specific tools for assembly. |

| Automotive Connectors | Designed for automotive use, often with locking features | Vehicle wiring, automotive sensors | Pros: Secure connections, designed for vibration resistance. Cons: May require specialized knowledge for installation. |

What are the Characteristics of JST PH Series Connectors?

JST PH Series connectors are compact and lightweight, making them ideal for applications where space is limited. They typically feature a three-pin configuration with color-coded wires that simplify installation and maintenance. These connectors are widely used in consumer electronics and small appliances, offering a reliable connection for low-power applications. Buyers should consider the voltage and current ratings to ensure compatibility with their devices.

How Do DTM Style Connectors Stand Out?

DTM Style connectors are known for their robust design, often featuring weatherproof thermoplastic housings that protect against moisture and dust. This makes them particularly suitable for automotive and industrial applications where durability is essential. While they may come at a higher cost, their reliability in harsh environments justifies the investment. B2B buyers should evaluate the environmental conditions of their application when considering DTM connectors.

What Makes Molex KK Connectors Versatile?

Molex KK connectors offer a versatile solution with configurations that can accommodate multiple pins, including a common 4-pin variant. This flexibility allows them to support higher current loads, making them suitable for power distribution in electronic devices. However, their bulkier design may limit their application in tight spaces. Buyers should weigh the need for higher current capacity against the physical constraints of their projects.

Why Choose AMP MTA Connectors for PCB Applications?

AMP MTA connectors are designed for easy soldering onto printed circuit boards (PCBs), making them a preferred choice for telecommunications and computer hardware applications. Their reliability and ease of use are significant advantages, especially in high-volume manufacturing. However, buyers should consider the need for specific assembly tools and processes when integrating these connectors into their systems.

What are the Benefits of Automotive Connectors?

Automotive connectors are specifically designed to withstand the vibrations and environmental challenges found in vehicle applications. They often feature locking mechanisms that ensure secure connections, which is crucial for automotive sensors and wiring systems. While they may require specialized knowledge for installation, their reliability and security make them a valuable investment for automotive manufacturers and suppliers. Buyers should assess the specific requirements of their automotive applications to select the appropriate connector type.

Key Industrial Applications of 3 pin connector socket

| Industry/Sector | Specific Application of 3 Pin Connector Socket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine control units and sensor connections | Reliable performance in high-vibration environments | Quality certifications (ISO, TS), compatibility with OEM standards |

| Consumer Electronics | Power supply connections for small appliances | Cost-effective and easy-to-replace components | Availability of various pin configurations and materials |

| Industrial Automation | Signal transmission in control panels | Enhanced operational efficiency and reduced downtime | Temperature ratings and environmental resistance |

| Renewable Energy | Connections in solar panel systems | Improved energy efficiency and reliability | Compliance with international standards for safety and performance |

| Telecommunications | Data transfer in networking equipment | High-speed connectivity and minimal signal loss | Sourcing from trusted manufacturers with a proven track record |

How is the 3 Pin Connector Socket Used in Automotive Applications?

In the automotive sector, 3 pin connector sockets are essential for connecting engine control units and various sensors, such as throttle position and crankshaft sensors. These connectors ensure reliable electrical connections in high-vibration environments typical of vehicles. For international buyers, sourcing connectors that meet strict quality certifications (like ISO and TS) is crucial to ensure compatibility with original equipment manufacturer (OEM) standards, enhancing vehicle performance and safety.

What Role Does the 3 Pin Connector Socket Play in Consumer Electronics?

In consumer electronics, 3 pin connector sockets are commonly used for power supply connections in small appliances, including fans and kitchen gadgets. Their simplicity and cost-effectiveness make them ideal for manufacturers looking to streamline production and facilitate easy replacements. B2B buyers should consider the availability of various pin configurations and materials to meet specific product requirements, ensuring durability and safety compliance.

How Does the 3 Pin Connector Socket Enhance Industrial Automation?

In industrial automation, 3 pin connector sockets are pivotal for signal transmission in control panels. They provide a robust solution for connecting various components, improving operational efficiency and reducing downtime. Buyers in this sector should prioritize sourcing connectors that meet specific temperature ratings and environmental resistance standards, ensuring they can withstand the rigors of industrial settings while maintaining performance.

In What Ways are 3 Pin Connector Sockets Utilized in Renewable Energy?

The renewable energy sector employs 3 pin connector sockets for connections in solar panel systems, where reliability and efficiency are paramount. These connectors facilitate the safe transmission of electricity generated from solar energy, contributing to improved energy efficiency. For international buyers, ensuring compliance with international safety and performance standards is essential to guarantee the long-term viability of these systems, particularly in diverse environmental conditions.

How are 3 Pin Connector Sockets Important in Telecommunications?

In telecommunications, 3 pin connector sockets are integral for data transfer in networking equipment. They enable high-speed connectivity with minimal signal loss, which is vital for maintaining the integrity of data communications. When sourcing these connectors, businesses should focus on suppliers with a proven track record in quality and reliability, ensuring that the components can support the increasing demands for bandwidth and data transmission speeds.

3 Common User Pain Points for ‘3 pin connector socket’ & Their Solutions

Scenario 1: Compatibility Issues with Existing Systems

The Problem: B2B buyers often encounter compatibility issues when integrating new 3 pin connector sockets into existing systems. This is especially common in sectors like automotive and electronics, where various manufacturers use different standards and specifications. The lack of standardization can lead to mismatches in pin configurations, resulting in operational failures or inefficiencies. Such compatibility challenges can cause delays in project timelines and increase overall costs, as businesses may need to source additional adapters or new equipment to make the connections work.

The Solution: To mitigate compatibility issues, buyers should conduct thorough compatibility assessments before sourcing 3 pin connector sockets. Begin by documenting the specifications of existing connectors and identifying the required pin configurations. Engaging with manufacturers that provide customizable solutions can also be beneficial. Some suppliers offer 3 pin connector sockets with adjustable pin layouts or even the ability to create bespoke connectors that align perfectly with your existing systems. Additionally, consider investing in quality connectors from reputable manufacturers known for adhering to international standards. This proactive approach minimizes risks and ensures that the new connectors will integrate seamlessly into your operations.

Scenario 2: Poor Durability and Reliability in Harsh Environments

The Problem: Many businesses in sectors such as manufacturing, construction, and transportation require connectors that can withstand harsh environmental conditions. Buyers often discover that standard 3 pin connector sockets are not designed for extreme temperatures, moisture, or exposure to chemicals, leading to premature failures. Such durability issues can result in costly downtime and maintenance, as well as potential safety hazards for workers.

The Solution: When sourcing 3 pin connector sockets for challenging environments, prioritize products that are specifically designed for durability. Look for connectors with robust materials such as high-temperature plastics and corrosion-resistant metals. Additionally, consider connectors that have been tested to meet or exceed industry standards for environmental resistance, such as IP67 or IP68 ratings, which indicate protection against dust and water ingress. Engaging with suppliers who specialize in rugged connectors can provide insights into the best options available for your specific applications. By investing in high-quality, environment-specific connectors, businesses can significantly enhance reliability and reduce maintenance costs.

Scenario 3: Difficulty in Installation and Maintenance

The Problem: B2B buyers frequently face challenges related to the installation and maintenance of 3 pin connector sockets, particularly when dealing with complex wiring systems. Inadequate instructions, non-intuitive designs, or insufficient training can lead to installation errors that complicate electrical systems. This not only causes immediate operational setbacks but can also lead to long-term inefficiencies and increased labor costs.

The Solution: To streamline the installation process, buyers should seek out 3 pin connector sockets that come with comprehensive installation guides, including clear diagrams and step-by-step instructions. Additionally, consider connectors that feature user-friendly designs, such as color-coded wires or easy-to-use locking mechanisms that ensure a secure connection without specialized tools. Training personnel on proper installation techniques can further enhance efficiency. Many manufacturers offer training resources or workshops for their products; taking advantage of these can empower your team and reduce installation errors. By focusing on ease of use and providing adequate training, businesses can enhance operational efficiency and reduce costs associated with installation and maintenance.

Strategic Material Selection Guide for 3 pin connector socket

What Are the Common Materials Used for 3 Pin Connector Sockets?

When selecting materials for 3 pin connector sockets, it is crucial to consider their properties, advantages, disadvantages, and suitability for specific applications. Below, we analyze four common materials used in the manufacturing of these connectors: nylon, thermoplastic elastomers (TPE), metal alloys, and polycarbonate.

How Does Nylon Perform in 3 Pin Connector Sockets?

Nylon is a widely used material for 3 pin connector sockets due to its excellent mechanical properties. It offers a temperature range of -40°C to 120°C and is known for its good chemical resistance, particularly against oils and fuels. The durability of nylon makes it suitable for automotive and industrial applications.

Pros: Nylon connectors are lightweight, cost-effective, and exhibit good wear resistance. They can also be produced in various colors, aiding in identification.

Cons: However, nylon can absorb moisture, which may lead to dimensional changes over time. It is also less effective in high-temperature applications compared to some alternatives.

Impact on Application: Nylon’s compatibility with various media makes it suitable for automotive and electronic applications. However, moisture absorption can affect performance in humid environments, which is a consideration for buyers in tropical regions like parts of Africa and South America.

What Are the Benefits of Using Thermoplastic Elastomers (TPE)?

Thermoplastic elastomers (TPE) are increasingly popular for 3 pin connector sockets due to their flexibility and resilience. TPE can withstand temperatures ranging from -50°C to 100°C and offers excellent resistance to UV light and ozone.

Pros: TPE connectors are highly durable, providing excellent resistance to wear and tear. They are also flexible, which can be advantageous in applications requiring bending or movement.

Cons: The manufacturing process for TPE can be more complex and costly compared to nylon. Additionally, TPE may not be suitable for high-temperature applications.

Impact on Application: TPE’s flexibility makes it ideal for automotive and consumer electronics. Buyers in regions with high UV exposure, such as the Middle East, may prefer TPE for its durability against environmental factors.

Why Choose Metal Alloys for 3 Pin Connector Sockets?

Metal alloys, particularly those made from copper or aluminum, are often used for the pins and contacts in 3 pin connectors. These materials provide excellent conductivity and strength, with temperature ratings often exceeding 150°C.

Pros: Metal connectors are highly durable and resistant to corrosion, making them suitable for harsh environments. They also provide superior electrical performance.

Cons: The primary drawback is the higher cost of metal alloys compared to plastics. Additionally, metal connectors can be heavier, which may be a concern in weight-sensitive applications.

Impact on Application: Metal connectors are ideal for high-power applications, such as in industrial machinery. Buyers from Europe, particularly Germany, may prefer metal connectors for their reliability and compliance with stringent standards.

What Advantages Does Polycarbonate Offer for 3 Pin Connectors?

Polycarbonate is another material used in the manufacturing of 3 pin connector housings. It is known for its high impact resistance and clarity, with temperature ratings typically around -40°C to 120°C.

Pros: Polycarbonate is lightweight and offers excellent strength-to-weight ratios. It is also resistant to UV light, making it suitable for outdoor applications.

Cons: Polycarbonate can be more expensive than nylon and may not offer the same level of chemical resistance as other materials.

Impact on Application: Polycarbonate’s impact resistance makes it suitable for consumer electronics and outdoor applications. Buyers in regions with varying climates may find polycarbonate advantageous due to its durability.

Summary Table of Material Selection for 3 Pin Connector Sockets

| Material | Typical Use Case for 3 pin connector socket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Automotive, industrial applications | Lightweight and cost-effective | Moisture absorption can affect performance | Low |

| Thermoplastic Elastomers | Consumer electronics, automotive | Excellent flexibility and durability | Higher manufacturing complexity | Medium |

| Metal Alloys | High-power industrial machinery | Superior conductivity and strength | Higher cost and weight | High |

| Polycarbonate | Outdoor applications, consumer electronics | High impact resistance | More expensive, less chemical resistance | Medium |

This strategic material selection guide provides essential insights for international B2B buyers, enabling them to make informed decisions based on their specific application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 3 pin connector socket

What are the Main Stages of Manufacturing for a 3 Pin Connector Socket?

The manufacturing process for 3 pin connector sockets involves several critical stages, each designed to ensure that the final product meets the required specifications for performance, durability, and safety. These stages typically include material preparation, forming, assembly, and finishing.

How is Material Prepared for 3 Pin Connector Socket Production?

Material preparation is the foundational step in the manufacturing process. It typically involves selecting high-quality materials such as nylon for housings and copper for contacts. The materials are often sourced from certified suppliers to ensure they meet industry standards. Buyers should verify that materials are compliant with international regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), particularly when sourcing from regions with stringent environmental regulations like Europe.

Once the materials are sourced, they undergo initial quality checks to confirm their specifications. This includes testing for electrical conductivity, tensile strength, and thermal resistance. For B2B buyers, understanding the material specifications can help in assessing a supplier’s capability to deliver products that can withstand specific environmental conditions.

What Techniques are Used in the Forming Process?

The forming stage involves shaping the prepared materials into the desired configurations. Techniques such as injection molding are commonly used for creating the housing of the connector. This method allows for high precision and repeatability, which is crucial for ensuring that each connector fits seamlessly with its counterpart.

For the metal contacts, processes such as stamping or machining are employed. Stamping involves cutting the metal sheets into the required shapes, while machining may be used for more complex designs. Each technique has its advantages in terms of cost-effectiveness and precision, and buyers should discuss these with potential suppliers to ensure they align with their quality expectations.

How is Assembly Conducted for 3 Pin Connector Sockets?

The assembly stage is where the individual components are brought together to form the complete connector. This involves several sub-steps, including inserting the metal contacts into the plastic housing and securing them with locking mechanisms. Automated assembly lines are often used to enhance efficiency and minimize the risk of human error.

For B2B buyers, it’s important to inquire about the assembly process and any automation technologies employed. Automated assembly can lead to greater consistency in product quality, reducing the likelihood of defects that may arise from manual assembly.

What Finishing Processes are Applied to Ensure Quality?

Finishing processes include cleaning, coating, and packaging the connectors. Cleaning is essential to remove any contaminants that may affect performance. Coating processes, such as applying a layer of gold or tin, are used to enhance conductivity and prevent corrosion. Finally, packaging must be done in a way that protects the connectors during transport and storage.

Buyers should look for suppliers that implement robust finishing processes and inquire about their practices to ensure that the connectors will perform reliably in their applications.

What Quality Assurance Practices are Essential for 3 Pin Connectors?

Quality assurance (QA) is a critical aspect of the manufacturing process for 3 pin connector sockets. It ensures that products meet the required specifications and standards, thus safeguarding the interests of B2B buyers.

Which International Standards Should Buyers Be Aware Of?

International standards such as ISO 9001 are crucial for ensuring consistent quality management systems. Suppliers that adhere to ISO 9001 demonstrate their commitment to quality and customer satisfaction. Additionally, industry-specific certifications, such as CE marking for products sold in Europe and API standards for connectors used in industrial applications, are also essential. Buyers should request documentation proving compliance with these standards to ensure product quality.

What are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to the manufacturing process. These typically include:

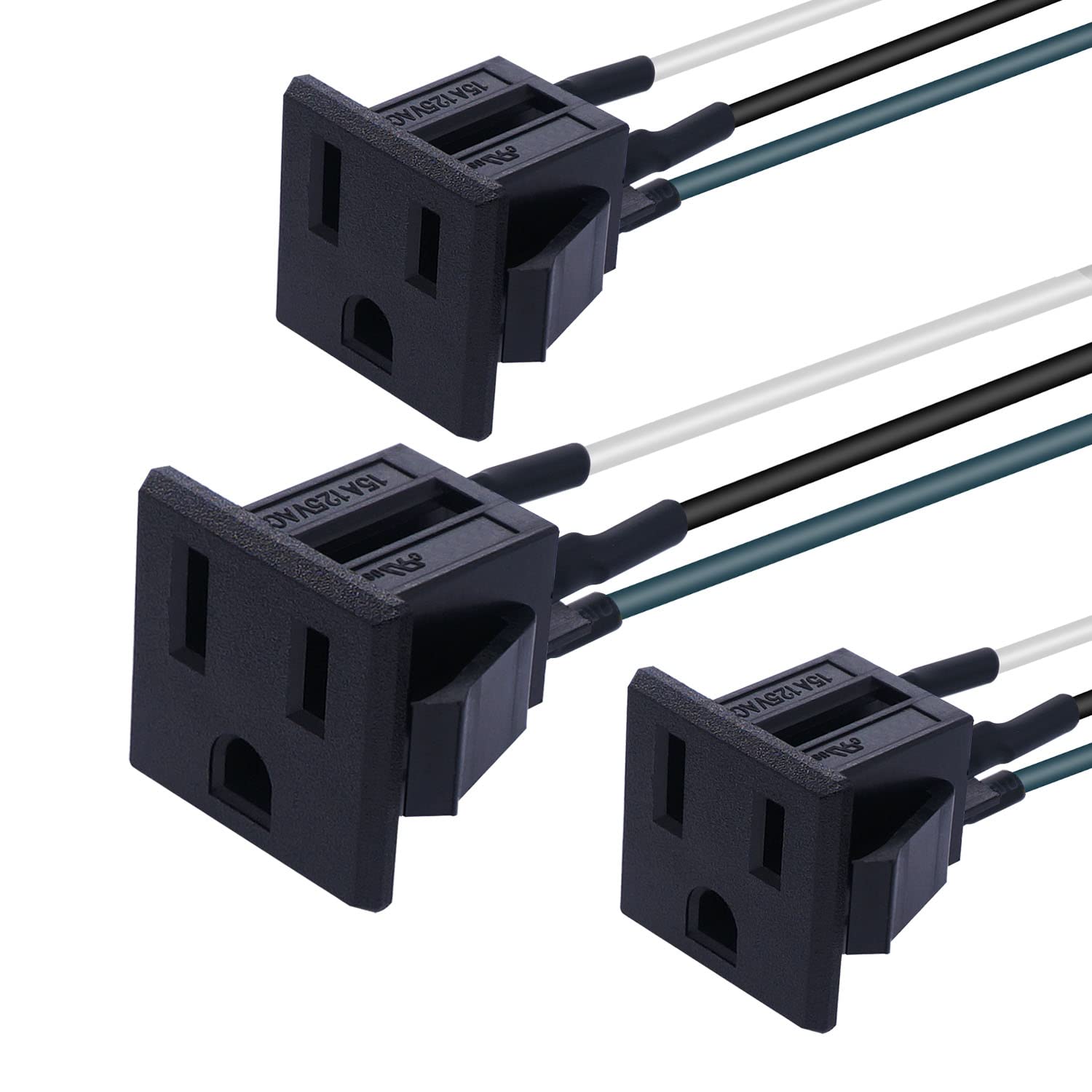

Illustrative image related to 3 pin connector socket

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials before they enter the production line. Buyers should verify that suppliers have robust IQC processes in place to catch defects early.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC ensures that products are being made according to specifications. This includes regular checks at different production stages.

-

Final Quality Control (FQC): At this stage, finished products undergo rigorous testing to ensure they meet all quality standards before shipping. Buyers should inquire about the types of tests conducted, such as electrical testing, mechanical testing, and environmental testing.

What Common Testing Methods are Employed for Quality Assurance?

Common testing methods for 3 pin connectors include:

- Electrical Testing: Verifying that the connectors meet specified current and voltage ratings.

- Mechanical Testing: Assessing the durability of the connectors under stress or strain.

- Environmental Testing: Evaluating performance under various temperature and humidity conditions.

Understanding these testing methods allows B2B buyers to gauge the reliability of the connectors they intend to purchase.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is crucial for B2B buyers, particularly when sourcing from international markets. Here are several strategies:

-

Conducting Audits: Buyers should consider conducting on-site audits to assess the manufacturing facilities and quality control processes firsthand. This can help build trust and ensure that the supplier adheres to required standards.

-

Requesting Quality Reports: Suppliers should provide detailed quality reports that outline their QC processes and test results. This documentation is vital for understanding the reliability of the products.

-

Utilizing Third-Party Inspections: Employing third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. This can be particularly beneficial for buyers from regions like Africa and South America, where local supplier evaluations may be challenging.

What are the Quality Control and Certification Nuances for International Buyers?

For international buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is essential. Different regions may have varying standards and regulations, which can affect product compliance and acceptance in local markets.

Illustrative image related to 3 pin connector socket

Buyers should familiarize themselves with the specific regulatory requirements in their region. For instance, European buyers must ensure compliance with CE marking, while buyers in the Middle East may need to adhere to local safety standards. Engaging with local regulatory bodies or consultants can provide valuable insights into these requirements.

In conclusion, the manufacturing and quality assurance processes for 3 pin connector sockets are intricate and vital for ensuring product reliability. B2B buyers must conduct thorough due diligence when selecting suppliers, focusing on material quality, manufacturing techniques, and compliance with international standards to ensure they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3 pin connector socket’

In the competitive landscape of B2B procurement, sourcing the right components such as 3 pin connector sockets requires a systematic approach. This checklist is designed to guide international buyers through the essential steps to ensure they make informed purchasing decisions.

Illustrative image related to 3 pin connector socket

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for your 3 pin connector sockets, including voltage, current rating, and environmental factors. This step is crucial as it helps you identify connectors that meet your project’s specific needs. Consider factors like temperature range and material composition, which can affect performance in different applications.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers of 3 pin connector sockets. Look for manufacturers with a proven track record in your industry and region. Resources like industry directories, trade shows, and online marketplaces can provide valuable insights into reputable suppliers.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Pay attention to their production capacity, lead times, and customer service reputation, as these factors can significantly impact your procurement experience.

Illustrative image related to 3 pin connector socket

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers possess the necessary certifications and compliance standards relevant to your industry. Certifications such as ISO 9001, CE, or UL can indicate quality assurance and adherence to international safety standards. This step mitigates the risk of sourcing subpar products that may lead to operational failures.

Step 5: Request Samples for Testing

Before placing a bulk order, request samples of the 3 pin connector sockets to evaluate their quality and compatibility with your applications. Testing samples allows you to assess the performance and durability of the connectors under real-world conditions. Look for consistency in manufacturing and ensure that the connectors meet your specifications.

Step 6: Negotiate Pricing and Terms

Engage in negotiations to secure competitive pricing and favorable terms of purchase. Consider factors such as payment terms, shipping costs, and bulk discounts. Establish clear agreements regarding returns, warranties, and after-sales support to protect your investment and ensure a smooth transaction.

Step 7: Establish a Long-term Partnership

After successful procurement, aim to build a long-term relationship with your suppliers. Regular communication can foster collaboration and allow you to stay informed about new products or innovations. A solid partnership can lead to better pricing, priority service, and tailored solutions for future projects.

Illustrative image related to 3 pin connector socket

By following this checklist, B2B buyers can streamline their sourcing process for 3 pin connector sockets, ensuring they make well-informed decisions that align with their technical needs and business goals.

Comprehensive Cost and Pricing Analysis for 3 pin connector socket Sourcing

What Are the Key Cost Components for 3-Pin Connector Socket Manufacturing?

Understanding the cost structure of 3-pin connector sockets is crucial for B2B buyers looking to optimize their sourcing strategies. The primary cost components include:

-

Materials: The choice of materials significantly influences the cost. Common materials such as nylon and polyester are standard, but higher-quality options that offer better durability and resistance to environmental factors can increase expenses.

-

Labor: Labor costs can vary widely based on geographic location and the skill level required for assembly. Countries with lower labor costs can provide a competitive advantage, but this must be weighed against the quality of workmanship.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient production processes can lower overhead costs, impacting the overall pricing of connectors.

-

Tooling: Initial tooling costs for molds and dies can be substantial, especially for custom designs. However, these costs are amortized over larger production runs, making high-volume orders more cost-effective.

-

Quality Control (QC): Implementing rigorous QC processes ensures that products meet required standards, which can add to the overall cost. However, these costs are justified by the reduction in returns and increased customer satisfaction.

-

Logistics: Shipping costs, including freight, insurance, and handling, can vary significantly based on the destination and shipping method. B2B buyers must consider these costs when calculating total expenses.

-

Margin: Suppliers typically include a margin to cover their operational costs and profit. Understanding the supplier’s pricing model is essential for effective negotiation.

How Do Price Influencers Affect 3-Pin Connector Socket Pricing?

Several factors influence the pricing of 3-pin connector sockets:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to discounted rates. Suppliers may impose MOQs that can affect smaller buyers, making it essential to align purchasing strategies with supplier capabilities.

-

Specifications and Customization: Customized connectors tailored to specific applications may incur higher costs due to additional design and manufacturing processes. Standardized products are generally more cost-effective.

-

Material Quality and Certifications: Connectors that meet specific industry certifications (e.g., UL, TUV) tend to be more expensive. Buyers should evaluate whether these certifications are necessary for their applications.

-

Supplier Factors: Supplier reputation, reliability, and production capacity can impact pricing. Established suppliers may charge a premium for their reputation and quality assurance.

-

Incoterms: The terms of delivery significantly affect logistics costs. Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate responsibility for shipping costs and risks, influencing the overall pricing structure.

What Negotiation Strategies Can B2B Buyers Use to Optimize Costs?

B2B buyers can employ various strategies to negotiate better pricing for 3-pin connector sockets:

-

Leverage Volume Discounts: Consolidating orders can lead to better pricing. Discussing future orders can also secure favorable terms.

-

Request Cost Breakdowns: Understanding the cost components allows buyers to identify areas where they can negotiate, such as material choices or QC processes.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also installation, maintenance, and potential failure costs. This comprehensive view can justify higher upfront costs for more reliable connectors.

-

Consider Local Suppliers: For buyers in regions like Africa or South America, sourcing from local suppliers can reduce logistics costs and delivery times, potentially offsetting higher product prices.

-

Stay Informed About Market Trends: Awareness of global supply chain issues, material shortages, and changing regulations can empower buyers in negotiations, allowing them to leverage market conditions for better pricing.

Final Thoughts

When sourcing 3-pin connector sockets, a thorough understanding of cost structures and pricing influencers is essential for making informed purchasing decisions. By employing strategic negotiation tactics and considering the total cost of ownership, B2B buyers can optimize their sourcing processes and achieve significant savings. Always remember that the indicative prices available may vary based on market conditions and should be confirmed with suppliers.

Illustrative image related to 3 pin connector socket

Alternatives Analysis: Comparing 3 pin connector socket With Other Solutions

Exploring Alternatives: How Does the 3 Pin Connector Socket Stack Up?

In the world of connectivity solutions, the 3 pin connector socket is a popular choice for various applications, particularly in automotive and electronic devices. However, buyers often face multiple options that may better suit their specific needs. This analysis provides a comparative overview of the 3 pin connector socket against two viable alternatives: the 4 pin connector socket and the Molex connector.

Comparison Table

| Comparison Aspect | 3 Pin Connector Socket | 4 Pin Connector Socket | Molex Connector |

|---|---|---|---|

| Performance | Good for low-power applications | Enhanced performance with PWM control | Versatile with high current capacity |

| Cost | Generally low-cost | Slightly higher than 3 pin | Mid-range cost |

| Ease of Implementation | Simple to install | Requires precise alignment | Moderate installation complexity |

| Maintenance | Low maintenance | Low maintenance | Moderate maintenance due to larger size |

| Best Use Case | Small electronics, automotive | Computer fans, lighting | High-power applications, consumer electronics |

What Are the Advantages and Disadvantages of a 4 Pin Connector Socket?

The 4 pin connector socket is an evolution of the 3 pin design, adding an extra pin for PWM (Pulse Width Modulation) control, making it ideal for applications requiring variable power. This additional control enhances the performance of devices like computer fans, allowing for more efficient energy use and quieter operation. However, the complexity of installation increases slightly due to the need for precise alignment and compatibility with specific devices. Furthermore, the cost is typically higher than that of a 3 pin connector, which could be a consideration for budget-conscious buyers.

Why Consider a Molex Connector?

Molex connectors are renowned for their versatility and ability to handle higher current loads compared to the 3 pin connector. This makes them suitable for high-power applications such as consumer electronics and automotive systems. They offer reliable connections and are widely used across various industries. However, the installation process can be more complex, and the maintenance might require additional attention due to their larger size and varied configurations. The cost is generally mid-range, making them a balanced choice for businesses looking for reliability without breaking the bank.

How Can B2B Buyers Choose the Right Solution?

When selecting the appropriate connector, B2B buyers should consider the specific requirements of their applications. The 3 pin connector socket is a solid choice for low-power, straightforward applications where cost and simplicity are paramount. In contrast, if the application demands more control and efficiency, the 4 pin connector would be advantageous. For high-power needs, the Molex connector is the preferred option, offering robustness and flexibility. Understanding the unique needs of your project, including power requirements, installation capabilities, and budget constraints, will guide buyers in making an informed decision that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for 3 pin connector socket

What Are the Essential Technical Properties of a 3-Pin Connector Socket?

When evaluating a 3-pin connector socket for procurement, understanding its technical specifications is crucial for ensuring compatibility and performance. Below are some key properties to consider:

Illustrative image related to 3 pin connector socket

1. Material Grade

The material used in the construction of a 3-pin connector socket significantly influences its durability and performance. Common materials include nylon, polyester, and metal alloys. These materials are selected based on factors like resistance to corrosion, temperature stability, and mechanical strength. For instance, nylon connectors can withstand a temperature range of -25 °C to 85 °C, making them suitable for various applications, from automotive to consumer electronics. Selecting the right material is essential for ensuring longevity and reliability in the intended environment.

2. Current Rating

The current rating indicates the maximum amount of electrical current a connector can safely carry without overheating. Standard ratings for 3-pin connectors typically range from 2 to 10 Amps. Buyers should match the current rating to their application requirements to prevent potential failure or damage. This specification is vital for ensuring that the connector can handle the electrical load without compromising safety or performance.

3. Voltage Rating

Voltage rating defines the maximum voltage that can be applied across the connector without the risk of breakdown. This rating is critical, especially in high-voltage applications, as exceeding it can lead to arcing or connector failure. Typical voltage ratings for 3-pin connectors can range from 12V to 240V, depending on the design and intended use. Ensuring the connector meets the required voltage specifications is essential for safety and operational efficiency.

Illustrative image related to 3 pin connector socket

4. Pin Configuration

The pin configuration of a 3-pin connector socket determines how it connects to other components. Common configurations include power, ground, and signal pins. Understanding the pin layout is crucial for compatibility with existing systems. Mismatched configurations can lead to operational failures or damage to connected devices. Buyers must verify that the pin configuration aligns with their specific application needs.

5. Temperature Range

The operational temperature range specifies the conditions under which the connector can function effectively. Some connectors are designed for extreme environments, while others are suitable for standard indoor use. A connector rated for a wider temperature range ensures reliability in various climates, which is particularly important for international buyers operating in diverse environments.

What Are Common Trade Terms Related to 3-Pin Connector Sockets?

Understanding industry jargon is critical for effective communication and negotiation in B2B transactions. Here are some common terms related to 3-pin connector sockets:

Illustrative image related to 3 pin connector socket

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of connectors, an OEM might design a unique 3-pin connector for a specific application, which can be crucial for buyers looking for specialized solutions.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management. Buyers should negotiate MOQs that align with their operational needs, especially when dealing with specialized components like 3-pin connectors.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. In the context of 3-pin connectors, an RFQ can help buyers compare prices and terms from multiple suppliers, facilitating better purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers for the delivery of goods under sales contracts. Understanding these terms is crucial for international transactions, as they clarify shipping responsibilities, risk management, and cost distribution between parties.

5. Tolerances

Tolerances refer to the allowable limits of variation in a physical dimension of the connector. These specifications ensure that the connectors fit properly within their intended applications. Buyers should confirm that the tolerances meet their design requirements to avoid compatibility issues.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions regarding 3-pin connector sockets, ensuring they select the right products for their needs.

Navigating Market Dynamics and Sourcing Trends in the 3 pin connector socket Sector

What Are the Current Market Dynamics and Key Trends in the 3-Pin Connector Socket Sector?

The global market for 3-pin connector sockets is witnessing significant growth, driven by the increasing demand for reliable connectivity solutions across various industries, including automotive, consumer electronics, and industrial automation. In emerging markets such as Africa and South America, infrastructure development and rising mobile device usage are propelling the demand for efficient electrical connections. Additionally, the European market is focused on high-quality, durable connectors, reflecting a trend towards increased safety and performance standards.

Technological advancements are also reshaping the sector, with manufacturers increasingly adopting automation and smart manufacturing practices to enhance production efficiency. The rise of the Internet of Things (IoT) is further driving innovation, as more devices require compact and reliable connectors for seamless communication. For international B2B buyers, understanding these dynamics is crucial for making informed sourcing decisions. Buyers should consider suppliers who not only offer a diverse range of products but also demonstrate adaptability to changing market conditions.

How Is Sustainability and Ethical Sourcing Affecting the 3-Pin Connector Socket Industry?

Sustainability has emerged as a central theme in the B2B marketplace, influencing purchasing decisions and supplier relationships. For 3-pin connector sockets, this means a growing emphasis on sourcing materials that are environmentally friendly and reducing the overall carbon footprint of manufacturing processes. Buyers are increasingly looking for suppliers who prioritize ethical sourcing, ensuring that materials are obtained from sustainable sources and that labor practices are fair and transparent.

The introduction of ‘green’ certifications, such as RoHS and REACH, is becoming more common as buyers seek assurance that products meet environmental standards. Additionally, the use of recyclable and low-hazard materials is becoming a competitive advantage for manufacturers. For international buyers, particularly those in regions with stringent environmental regulations, aligning with suppliers who prioritize sustainability can enhance brand reputation and compliance with local laws.

What Is the Evolution of 3-Pin Connectors and Their Relevance in Today’s Market?

The 3-pin connector has evolved significantly since its inception in the mid-20th century. Originally designed for simple applications, these connectors have expanded in functionality and design to meet the demands of modern electronics. The shift towards miniaturization in devices has led to the development of more compact and efficient connector designs, catering to a wide array of applications from automotive to consumer electronics.

As technology continues to advance, the importance of 3-pin connectors is expected to grow, particularly in applications involving automation and smart technologies. Their versatility and reliability make them essential components in various sectors, ensuring that they remain relevant in the ever-evolving landscape of electrical connectivity solutions. For B2B buyers, recognizing the historical context and technological advancements in 3-pin connectors can provide valuable insights for future sourcing strategies and investments.

Frequently Asked Questions (FAQs) for B2B Buyers of 3 pin connector socket

-

How do I choose the right 3-pin connector socket for my application?

When selecting a 3-pin connector socket, consider the specific requirements of your application, including voltage, current ratings, and environmental conditions. Assess whether you need waterproof or dustproof features, especially for outdoor or industrial uses. Additionally, compatibility with existing equipment is crucial, so verify pin configuration and dimensions. If customization is needed, consult with suppliers who can provide tailored solutions to ensure optimal performance and reliability. -

What are the common applications of 3-pin connector sockets?

3-pin connector sockets are widely used in various applications, including automotive wiring, consumer electronics, and industrial machinery. They are particularly prevalent in connecting fans, sensors, and other low-power devices. In automotive applications, these connectors facilitate communication between components, ensuring efficient operation. Understanding your specific application will help determine the best type of connector to meet your needs. -

What is the minimum order quantity (MOQ) for 3-pin connector sockets?

MOQs for 3-pin connector sockets can vary significantly based on the supplier and the customization required. Typically, standard products may have a MOQ of 100 to 500 units, while customized connectors could require larger orders. It is essential to discuss your project requirements with suppliers to find flexible options that suit your budget and project timeline, especially if you are sourcing from international markets. -

How can I verify the quality of 3-pin connector sockets from suppliers?

To ensure the quality of 3-pin connector sockets, request certifications such as ISO, CE, or UL, which indicate compliance with industry standards. Conducting supplier audits and checking for customer reviews can provide insights into reliability and performance. Additionally, asking for samples allows you to test the connectors in your application before making a larger commitment. Establishing a strong quality assurance process is crucial, especially for international sourcing. -

What payment terms should I expect when purchasing 3-pin connector sockets internationally?

Payment terms for international purchases of 3-pin connector sockets can vary by supplier and region. Common terms include upfront payment, partial payment upon order confirmation, and the balance before shipment. It is advisable to use secure payment methods, such as letters of credit or escrow services, to protect your transaction. Negotiating favorable terms that align with your cash flow needs is essential for maintaining a smooth procurement process. -

What are the logistics considerations when importing 3-pin connector sockets?

When importing 3-pin connector sockets, consider shipping methods, lead times, and customs regulations. Air freight is faster but more expensive, while sea freight is cost-effective for larger orders but takes longer. Ensure compliance with import regulations in your country, including tariffs and duties, to avoid unexpected costs. Partnering with a reliable logistics provider can help streamline the process and ensure timely delivery of your components. -

Can I customize 3-pin connector sockets to fit specific requirements?

Yes, many suppliers offer customization options for 3-pin connector sockets. You can specify dimensions, materials, pin configurations, and even color-coding to suit your application needs. When engaging with suppliers, provide detailed specifications and any relevant industry standards to ensure they understand your requirements. Custom solutions may have longer lead times, so it’s important to plan accordingly. -

What should I consider when vetting suppliers for 3-pin connector sockets?

When vetting suppliers, assess their experience in the connector industry, production capacity, and delivery track record. Look for suppliers with positive reviews and testimonials from previous clients, especially in your target market. Verify their certifications and quality assurance processes to ensure they meet international standards. Engaging in direct communication can also provide insights into their responsiveness and willingness to accommodate your specific needs.

Top 5 3 Pin Connector Socket Manufacturers & Suppliers List

1. Custom Connector Kits – DEUTSCH DT 3 Way Gray J1939 Terminating Plug Connector

Domain: customconnectorkits.com

Registered: 2016 (9 years)

Introduction: This company, Custom Connector Kits – DEUTSCH DT 3 Way Gray J1939 Terminating Plug Connector, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. McMaster – 3 Pole Pin Connectors

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – 3 Pole Pin Connectors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Wiring Specialties – 3 Pin Connectors

Domain: wiringspecialties.com

Registered: 2005 (20 years)

Introduction: 3 Pin Connectors include various types such as: 1. LS1 / LS6 TPS (Throttle Position) Connector – MSRP: $9.95 2. 3 Pin DTM Style Male Connector – MSRP: $13.00 3. Supra MK4 Fuse Box Connector (5-pin) – MSRP: $14.00 4. Supra MK4 and SC300/400 Fuse Box Connector (3-pin) – MSRP: $11.00 5. LS2 24x Crank Sensor Connector Male Sensor side – MSRP: $9.95 6. K-Series Crank Sensor Connector – MSRP: $13.00 7. …

4. Connector Experts – 3-Pin Connectors

Domain: connectorexperts.com

Registered: 2009 (16 years)

Introduction: 3-Pin Connectors | 3-Wire Electrical Connectors that fit up to 3 wires.

5. Kabasi – Three-Pin Connector Plug

Domain: kabasi-connector.com

Registered: 2020 (5 years)

Introduction: A three-pin connector plug refers to any connector plug with three pins, providing a safe choice by including a third neutral pin to lead out leakage voltage. The three pins are designed to carry different wires: the red or brown wire represents the live wire, the blue or black wire represents the neutral wire, and the green or yellow wire represents the earth. The housing is typically made of tou…

Strategic Sourcing Conclusion and Outlook for 3 pin connector socket

As the demand for 3 pin connector sockets continues to grow across various industries, strategic sourcing emerges as a critical factor for B2B buyers aiming to optimize their supply chains. By focusing on reliable suppliers, understanding regional market nuances, and leveraging economies of scale, businesses can secure high-quality components that enhance product performance while reducing costs.

International buyers, particularly from Africa, South America, the Middle East, and Europe, should prioritize partnerships with manufacturers that offer not only competitive pricing but also compliance with global standards and certifications. This will ensure that the connectors meet rigorous safety and quality benchmarks, which are essential in today’s competitive landscape.

Looking ahead, the evolution of technology and increased connectivity demands will drive further innovation in the 3 pin connector market. As you navigate your sourcing strategies, consider embracing digital platforms and trade shows to connect with potential suppliers. By doing so, you position your business to capitalize on emerging trends and technologies, ensuring that you remain at the forefront of your industry. Explore your sourcing options today and build a robust foundation for future success.

Illustrative image related to 3 pin connector socket

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.