Is Your 2005 Toyota Camry Transmission U250 Torque Converter Senor Sourcing Strategy…

Introduction: Navigating the Global Market for 2005 toyota camry transmission u250 torque converter senor

In the dynamic landscape of the automotive parts market, sourcing high-quality components like the 2005 Toyota Camry transmission U250 torque converter sensor presents a significant challenge for international B2B buyers. The complexity of supply chains, varying regional regulations, and the necessity for precise compatibility can make procurement daunting, particularly for businesses operating in diverse markets such as Africa, South America, the Middle East, and Europe, including Brazil and Nigeria. This guide aims to demystify the process of acquiring this critical component by providing a comprehensive overview of types, applications, supplier vetting strategies, and cost considerations.

Understanding the nuances of torque converter sensors, including their essential role in optimizing vehicle performance and fuel efficiency, is vital for informed purchasing decisions. This guide equips B2B buyers with actionable insights to navigate the global market effectively. By highlighting key factors such as product specifications, supplier reliability, and price competitiveness, buyers will be empowered to identify the best sourcing options tailored to their specific needs. Additionally, the guide addresses potential pitfalls and offers recommendations for ensuring quality assurance and compliance with local standards.

In a competitive environment where timely access to reliable automotive parts can influence business success, leveraging the information in this guide will enable buyers to make strategic, informed choices that enhance their operational efficiency and drive growth.

Understanding 2005 toyota camry transmission u250 torque converter senor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| TC Remanufacturing TO42-9 | 9″ bolt circle, fits U151E and U250E, lock-up feature, core deposit required | Automotive repair shops, parts distributors | Pros: Cost-effective; Cons: Core deposit adds to initial cost. |

| Pro-King TO55L | 11.150″ overall diameter, very low stall, multiple transmission codes compatibility | Vehicle service centers, fleet maintenance | Pros: Versatile; Cons: Slightly higher price point. |

| TC Remanufacturing TO82 | Designed specifically for U250E, simpler installation, lower overall diameter | Small garages, DIY mechanics | Pros: Easy to install; Cons: Limited to U250E compatibility. |

| Pro-King TO42 | 10.30″ overall diameter, slotted/flanged hub, compatible with multiple models | Independent repair shops, OEM suppliers | Pros: Multi-vehicle applicability; Cons: May require adaptation. |

| OEM Original Equipment | Factory-fitted torque converter, optimal performance, warranty included | Dealerships, high-end auto repair shops | Pros: Guaranteed fit and performance; Cons: Higher cost. |

What Are the Key Characteristics of TC Remanufacturing TO42-9 Torque Converters?

The TC Remanufacturing TO42-9 is designed for the 2005 Toyota Camry’s U250E transmission, featuring a 9″ bolt circle and a lock-up mechanism for enhanced fuel efficiency. This type is ideal for automotive repair shops looking to provide a reliable replacement option. The initial cost may be offset by the potential for lower labor costs due to its straightforward installation. However, buyers should be aware of the core deposit that adds to the upfront expense.

How Does Pro-King TO55L Stand Out in the Market?

The Pro-King TO55L torque converter is notable for its larger 11.150″ diameter and compatibility with various transmission codes. This versatility makes it a preferred choice for vehicle service centers and fleet maintenance providers. Its design focuses on low stall speeds, which can improve vehicle responsiveness. However, the slightly higher price point may be a consideration for budget-conscious buyers.

Why Choose TC Remanufacturing TO82 for Your Inventory?

The TC Remanufacturing TO82 is tailored specifically for the U250E model, making it an excellent choice for smaller garages and DIY enthusiasts. Its lower overall diameter simplifies installation, which can lead to reduced labor costs. However, its limitation to U250E compatibility means buyers should ensure it meets their specific inventory needs.

What Benefits Does Pro-King TO42 Offer to Repair Shops?

The Pro-King TO42 torque converter is characterized by its slotted/flanged hub and compatibility with multiple Toyota models, making it suitable for independent repair shops and OEM suppliers. Its adaptability can help shops maintain a diverse inventory. However, some installations may require additional adaptation, which could increase labor time.

Why Consider OEM Original Equipment Torque Converters?

OEM original equipment torque converters are factory-fitted, ensuring optimal performance and compatibility with the 2005 Toyota Camry. This type is often sought after by dealerships and high-end auto repair shops for its reliability and warranty coverage. While they provide peace of mind, the higher cost may deter some buyers looking for more economical options.

Key Industrial Applications of 2005 toyota camry transmission u250 torque converter senor

| Industry/Sector | Specific Application of 2005 Toyota Camry Transmission U250 Torque Converter Sensor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Used in diagnosing and repairing automatic transmission issues in Toyota Camry models | Improved repair accuracy and reduced labor costs | Ensure compatibility with specific Toyota models and transmission codes |

| Fleet Management | Monitoring and maintaining the performance of fleet vehicles equipped with U250E transmissions | Enhanced vehicle reliability and reduced downtime | Source from reliable suppliers with warranty and support services |

| Export and Import | Replacement parts for international markets where the 2005 Camry is still in use | Cost-effective solutions for maintaining older vehicle fleets | Consider shipping logistics and customs regulations for international trade |

| Automotive Parts Retail | Retailing torque converter sensors for DIY mechanics and small repair shops | Increased sales through diverse product offerings | Assess local demand, stock levels, and supplier reliability |

| Vehicle Manufacturing | Integration in remanufactured or refurbished vehicles for resale | Competitive pricing and quality assurance for refurbished models | Focus on quality control and certification of parts to ensure reliability |

How is the 2005 Toyota Camry Transmission U250 Torque Converter Sensor Used in Automotive Repair?

In the automotive repair industry, the 2005 Toyota Camry transmission U250 torque converter sensor plays a crucial role in diagnosing transmission performance issues. Technicians utilize the sensor to monitor the torque converter’s functionality, which is essential for efficient vehicle operation. Problems such as slipping or overheating can be identified early, allowing for timely interventions. For international buyers, particularly in regions like Africa and South America, sourcing this sensor ensures they can maintain older Camry models effectively, reducing repair costs and improving customer satisfaction.

What Benefits Does the Torque Converter Sensor Provide for Fleet Management?

Fleet management companies rely on the torque converter sensor to maintain the performance of their vehicles, particularly those equipped with U250E transmissions. By monitoring transmission behavior, fleet managers can proactively address issues, minimizing vehicle downtime and extending the lifespan of their fleet. This is particularly beneficial in regions with challenging driving conditions, such as Nigeria or Brazil, where vehicle reliability is paramount. Sourcing high-quality sensors can enhance fleet performance and reduce long-term operational costs.

How Does the 2005 Camry Torque Converter Sensor Support Export and Import Businesses?

For businesses engaged in the export and import of automotive parts, the 2005 Toyota Camry transmission U250 torque converter sensor represents a valuable component for markets where older vehicles are prevalent. The sensor provides a cost-effective solution for maintaining these vehicles, appealing to budget-conscious consumers. International buyers need to consider shipping logistics and customs regulations when sourcing these parts, ensuring compliance to facilitate smooth transactions.

Why is the Torque Converter Sensor Important for Automotive Parts Retailers?

Automotive parts retailers can benefit significantly from offering the 2005 Toyota Camry transmission U250 torque converter sensor. This sensor meets the needs of DIY mechanics and small repair shops looking for reliable replacement parts. By stocking this sensor, retailers can increase sales and attract a diverse customer base. It is essential for retailers to assess local demand and establish relationships with reliable suppliers to ensure consistent stock levels and product availability.

How Can Vehicle Manufacturers Utilize the Torque Converter Sensor?

Vehicle manufacturers engaged in remanufacturing or refurbishing older models can integrate the 2005 Toyota Camry transmission U250 torque converter sensor to enhance the quality of their offerings. By using certified parts, manufacturers can assure customers of the reliability and performance of their refurbished vehicles. This approach is particularly relevant in European markets, where consumers often seek quality assurance in used vehicles. Manufacturers should focus on quality control and certification processes to maintain high standards in their products.

3 Common User Pain Points for ‘2005 toyota camry transmission u250 torque converter senor’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Torque Converter Sensors

The Problem: B2B buyers often struggle to find reliable suppliers for the 2005 Toyota Camry transmission U250 torque converter sensor. Many vendors may offer parts that are either low quality or not compatible, leading to potential failures in the transmission system. This can result in costly repairs and downtime, impacting the overall efficiency of operations, especially for businesses involved in automotive repairs or parts distribution.

The Solution: To mitigate sourcing challenges, buyers should establish relationships with reputable distributors who specialize in Toyota parts. Conduct thorough market research to identify suppliers that have a proven track record for quality and reliability. Utilize platforms that allow for reviews and ratings from other businesses to gauge supplier performance. When ordering, ensure to specify the exact part number and compatibility requirements, as well as inquire about warranty policies. It’s also beneficial to request samples or detailed product specifications to verify quality before making bulk purchases. Establishing a consistent communication channel with suppliers can help in timely updates on inventory and new product releases.

Scenario 2: Misalignment of Technical Specifications

The Problem: Another common issue for B2B buyers is the misalignment of technical specifications when ordering the torque converter sensor. The U250 transmission may have varying specifications based on production year or model variations, leading to the wrong parts being purchased. This not only wastes time but also leads to increased costs due to returns and reorders.

The Solution: To avoid specification mismatches, buyers should invest in detailed technical training for their procurement teams to understand the specific requirements of the U250 transmission. Detailed documentation, including specifications and diagrams, should be kept readily accessible. When placing orders, always cross-reference the part number with the manufacturer’s catalog or reliable automotive databases. Implementing a robust inventory management system can also help track parts and specifications, ensuring that all orders are accurate and meet the necessary requirements. Additionally, consider setting up a direct line of communication with manufacturers to clarify specifications before purchase.

Scenario 3: Integration Challenges with Existing Systems

The Problem: Buyers may encounter integration challenges when installing new torque converter sensors into existing systems. If the sensors are not compatible with other transmission components or the vehicle’s electronic systems, this can lead to malfunctioning systems and additional troubleshooting costs. This is particularly concerning for businesses that rely on efficient turnaround times for repairs.

The Solution: To ensure seamless integration, buyers should conduct comprehensive compatibility checks before installation. This includes verifying that the sensor is compatible not only with the U250 transmission but also with the vehicle’s ECU (Engine Control Unit) and other related components. Utilizing diagnostic tools to assess the vehicle’s current systems can identify potential compatibility issues before installation. Furthermore, consider collaborating with experienced automotive technicians who can provide insights during the installation process. Offering training sessions for your team on how to properly integrate and troubleshoot new parts can also save time and reduce the risk of errors. Establishing a feedback loop with technicians after installations can help refine future procurement processes, ensuring that the right parts are sourced for optimal integration.

Strategic Material Selection Guide for 2005 toyota camry transmission u250 torque converter senor

What Are the Key Materials for the 2005 Toyota Camry Transmission U250 Torque Converter Sensor?

When selecting materials for the torque converter sensor in the 2005 Toyota Camry U250 transmission, several factors must be considered, including performance characteristics, durability, and cost. Below are analyses of four common materials used in this application.

1. Aluminum

Key Properties: Aluminum is lightweight, has good thermal conductivity, and offers decent corrosion resistance. It can operate effectively at temperatures up to approximately 150°C (302°F) and withstand moderate pressure levels.

Pros & Cons: The primary advantages of aluminum include its low weight, which contributes to overall vehicle efficiency, and its resistance to corrosion, making it suitable for various environments. However, aluminum can be more expensive than some alternatives and may require more complex manufacturing processes, particularly in forming and machining.

Impact on Application: Aluminum’s compatibility with various media, including automotive fluids, makes it a suitable choice for the torque converter sensor. However, it may not be ideal for high-pressure applications without additional reinforcement.

International Considerations: Buyers in regions like Africa and South America should ensure compliance with local standards, as aluminum components may be subject to specific regulations regarding recycling and environmental impact.

2. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance and high strength, withstanding temperatures up to 800°C (1472°F) and high-pressure environments.

Pros & Cons: The key advantages of stainless steel are its durability and resistance to rust and corrosion, making it ideal for harsh operating conditions. However, it is heavier than aluminum and can be more costly, impacting overall manufacturing expenses.

Impact on Application: Stainless steel’s robustness makes it suitable for environments with exposure to aggressive fluids or extreme temperatures. It is compatible with various automotive fluids, ensuring long-term performance.

International Considerations: Compliance with ASTM and ISO standards is crucial for international buyers, particularly in Europe and the Middle East, where stringent regulations on material quality and environmental impact are enforced.

3. Plastic Composites

Key Properties: Plastic composites are lightweight and can be engineered for specific thermal and chemical resistance properties, typically handling temperatures up to 120°C (248°F).

Pros & Cons: These materials are cost-effective and allow for complex shapes, reducing manufacturing complexity. However, they may not offer the same level of durability as metals and can be susceptible to degradation over time, especially under high heat or pressure.

Impact on Application: Plastic composites can be suitable for non-structural components of the sensor, particularly in environments where weight savings are critical. However, they may not be suitable for high-pressure applications.

International Considerations: Buyers should be aware of the varying standards for plastics in different regions, especially in Europe, where regulations on plastic recyclability and safety are stringent.

4. Copper Alloys

Key Properties: Copper alloys exhibit excellent electrical conductivity and moderate corrosion resistance, performing well at temperatures up to 200°C (392°F).

Pros & Cons: The primary advantage of copper alloys is their superior conductivity, making them ideal for electronic components. However, they can be more expensive and may require protective coatings to enhance corrosion resistance.

Impact on Application: Copper alloys are particularly effective in sensor applications where electrical performance is critical. Their compatibility with automotive fluids is generally good, but they may require careful consideration in corrosive environments.

International Considerations: Compliance with local regulations regarding copper usage, particularly in Europe and the Middle East, is essential due to environmental concerns surrounding heavy metals.

Summary Table of Material Selection

| Material | Typical Use Case for 2005 Toyota Camry Transmission U250 Torque Converter Sensor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housing and structural components | Lightweight and corrosion-resistant | Higher manufacturing complexity | Medium |

| Stainless Steel | High-stress components and sensor housings | Excellent durability and strength | Heavier and more expensive | High |

| Plastic Composites | Non-structural sensor components | Cost-effective and lightweight | Less durable under extreme conditions | Low |

| Copper Alloys | Electrical connections and sensor components | Superior electrical conductivity | Requires protective coatings | Medium |

This material selection guide provides a comprehensive overview for international B2B buyers, ensuring informed decisions that align with performance requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 2005 toyota camry transmission u250 torque converter senor

What Are the Key Manufacturing Processes for the 2005 Toyota Camry U250 Torque Converter Sensor?

The manufacturing of the 2005 Toyota Camry U250 torque converter sensor involves several critical stages that ensure high performance and reliability. Understanding these processes can help B2B buyers make informed decisions when sourcing parts.

Material Preparation: What Raw Materials Are Used?

The first step in manufacturing the torque converter sensor is the selection and preparation of raw materials. Typically, high-quality metals such as aluminum and steel are used due to their durability and resistance to wear. These materials undergo processes like alloying and heat treatment to enhance their mechanical properties. Additionally, specialized electronic components are sourced for the sensor, ensuring they meet the required specifications for performance and longevity.

How Is the Forming Process Conducted?

Once the materials are prepared, the forming process begins. This can involve techniques such as die casting for metal components and injection molding for plastic parts. These methods allow for precise shaping and consistency in the parts produced. The use of advanced machinery, like CNC (Computer Numerical Control) machines, ensures that the components meet exact tolerances, which is critical for the functionality of the torque converter sensor.

What Are the Assembly Techniques Employed?

After forming, the next stage is assembly. This process involves integrating the sensor with the torque converter components. Automated assembly lines are often utilized, which can significantly enhance efficiency and reduce human error. Each assembly line is typically equipped with robotic arms for tasks such as soldering and fastening, ensuring a high degree of precision. Quality checks are embedded within the assembly line to catch any defects early in the process.

How Is the Finishing Process Handled?

The finishing stage involves several treatments to ensure the final product meets aesthetic and functional standards. This includes processes like polishing, coating, and painting. For the torque converter sensor, protective coatings may be applied to prevent corrosion and enhance durability. This stage is crucial, as it not only affects the appearance but also the performance and lifespan of the component.

What Quality Assurance Practices Are Followed in Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process for the torque converter sensor. B2B buyers should be aware of the various standards and practices that ensure the product’s reliability and safety.

Which International Standards Are Relevant for Quality Assurance?

Manufacturers of automotive parts, including the torque converter sensor, often adhere to international standards such as ISO 9001. This standard outlines a framework for quality management systems, ensuring consistent quality in products and services. Additionally, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, depending on the markets served. These certifications signify compliance with safety and performance standards recognized globally.

What Quality Control Checkpoints Are Essential?

Quality control (QC) checkpoints are critical throughout the manufacturing process. Typical checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, inspections are conducted at various stages to ensure that processes are being followed correctly and that products are within tolerance limits.

-

Final Quality Control (FQC): This final inspection ensures that the finished torque converter sensor meets all specifications before it is packaged and shipped.

What Common Testing Methods Are Used?

Various testing methods are employed to validate the quality of the torque converter sensor. These can include:

- Functional Testing: Ensures the sensor operates correctly within the torque converter system.

- Durability Testing: Simulates long-term usage to assess wear and tear.

- Environmental Testing: Evaluates the sensor’s performance under different temperature and humidity conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control practices is essential to ensure reliability and compliance with standards. Here are several strategies to achieve this:

What Auditing Practices Should Be Considered?

Conducting supplier audits is a practical way for B2B buyers to assess a manufacturer’s quality control processes. Audits can include on-site inspections and reviews of quality management systems. Buyers should request documentation of past audits and any relevant certifications to gain insight into the supplier’s commitment to quality.

How Can Reports and Third-Party Inspections Assist Buyers?

Requesting reports from suppliers that detail their quality control processes can be beneficial. Additionally, engaging third-party inspection services can provide an unbiased assessment of the manufacturing facility and its adherence to quality standards. These inspections can be particularly important for buyers from regions with varying levels of regulatory oversight.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing the torque converter sensor from international suppliers, it’s essential to understand regional quality control nuances. For instance, buyers from Africa, South America, the Middle East, and Europe may face different compliance requirements.

How Do Regional Regulations Impact Quality Assurance?

Certain regions may have specific regulations that impact product standards, such as environmental compliance or safety certifications. Buyers should familiarize themselves with these regulations to ensure that the products they source not only meet their local requirements but also international standards.

What Role Do Cultural Differences Play in Quality Expectations?

Cultural differences can also influence quality expectations and communication styles. Building a strong relationship with suppliers through clear communication can help mitigate misunderstandings regarding quality requirements. Establishing trust can lead to better collaboration and adherence to quality standards.

In conclusion, understanding the manufacturing processes and quality assurance practices for the 2005 Toyota Camry U250 torque converter sensor is crucial for B2B buyers. By focusing on the key manufacturing stages, quality standards, and verification practices, buyers can ensure they are sourcing high-quality components that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘2005 toyota camry transmission u250 torque converter senor’

In the competitive landscape of automotive parts sourcing, particularly for components like the 2005 Toyota Camry transmission U250 torque converter sensor, a structured approach is essential. This guide provides a comprehensive checklist designed to assist international B2B buyers in navigating the procurement process effectively.

Step 1: Define Your Technical Specifications

Clearly outline the specifications needed for the torque converter sensor. Understanding the exact requirements, including dimensions, compatibility with the U250 transmission code, and performance characteristics, is crucial. This ensures that you procure the correct part that fits seamlessly into your operations and avoids costly mistakes.

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to identify reliable suppliers. Look for manufacturers or distributors with a solid reputation in the automotive parts industry. Consider factors such as their market presence, years of operation, and feedback from previous clients. Utilize platforms like industry forums, trade shows, and online reviews to gather insights about potential suppliers.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This step helps you gauge their reliability and the quality of their products. Look for suppliers that specialize in Toyota parts or have specific experience with torque converters.

- Check for certifications: Ensure that the suppliers have necessary industry certifications, which can signify adherence to quality standards.

- Assess technical support availability: Suppliers that offer robust technical support can be invaluable, especially for complex components like torque converter sensors.

Step 4: Request Quotes and Compare Pricing

Gather quotes from multiple suppliers to compare pricing structures. This not only helps you identify competitive pricing but also allows you to assess the value offered by each supplier. Pay attention to shipping costs, core deposits, and potential discounts for bulk orders, as these can significantly impact your overall expenditure.

Step 5: Verify Warranty and Return Policies

Review the warranty and return policies offered by suppliers. A strong warranty can provide peace of mind, ensuring that you are covered in case of defects or failures. Familiarize yourself with the terms of the warranty, including what components are covered and the duration of coverage.

- Understand the return process: Knowing how to handle returns can save time and money if the wrong part is delivered or if there are quality issues.

Step 6: Place the Order and Confirm Details

Once you’ve selected a supplier, place your order with clear specifications. Confirm all details, including part numbers, quantities, and shipping instructions. It’s vital to maintain open communication with the supplier during this stage to ensure that your order is processed accurately and promptly.

Step 7: Inspect Upon Arrival

Upon receiving the torque converter sensor, conduct a thorough inspection. Check for any visible damage and verify that the part matches the specifications outlined in your order. This step is crucial to ensure that the component meets your requirements before installation.

By following this checklist, B2B buyers can streamline their sourcing process for the 2005 Toyota Camry transmission U250 torque converter sensor, ensuring they make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for 2005 toyota camry transmission u250 torque converter senor Sourcing

What Are the Key Cost Components for Sourcing the 2005 Toyota Camry U250 Torque Converter Sensor?

When evaluating the cost structure for sourcing the 2005 Toyota Camry transmission U250 torque converter sensor, several cost components must be considered. These include:

-

Materials: The primary material costs involve high-grade steel and various alloys used in the production of the torque converter and its sensor. Quality materials are essential for durability and performance, which directly influence the product’s lifecycle and warranty claims.

-

Labor: Labor costs encompass the wages of skilled workers involved in the manufacturing process. This includes assembly, quality control, and testing personnel. In regions with higher labor costs, such as parts of Europe, the overall price may be elevated compared to regions with lower labor costs.

-

Manufacturing Overhead: This includes indirect costs associated with the production process, such as utilities, maintenance of machinery, and factory rent. Efficient manufacturing practices can help mitigate these costs.

-

Tooling: The initial setup for producing torque converters requires specialized tooling and equipment, which can be a significant upfront investment. This cost is typically amortized over the production volume.

-

Quality Control (QC): Implementing stringent QC measures ensures that each torque converter sensor meets industry standards. This may involve additional testing and certification processes, which contribute to the overall cost.

-

Logistics: Shipping and handling costs can vary significantly based on the mode of transport, distance, and Incoterms used. For international buyers, understanding these logistics costs is crucial for accurate budgeting.

-

Margin: Suppliers typically add a profit margin to cover their expenses and ensure profitability. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Impact the Sourcing of Torque Converter Sensors?

Several factors influence the pricing of the torque converter sensors, particularly for international B2B buyers:

-

Volume/MOQ: Bulk purchases often lead to lower unit prices due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their inventory and demand forecasts to maximize cost efficiency.

-

Specifications and Customization: Custom specifications or unique features can increase costs. Buyers must assess whether the additional features are necessary for their applications or if standard products suffice.

-

Materials and Quality Certifications: Sensors made from superior materials with relevant quality certifications (such as ISO standards) may command higher prices. Buyers should weigh the long-term benefits of quality against initial costs.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers in shipping, which can influence overall costs.

What Are Essential Buyer Tips for Cost-Efficiency in Sourcing?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following tips:

-

Negotiation: Engage suppliers in negotiations to secure better pricing, especially for larger orders. Establishing long-term relationships can also result in favorable terms and discounts.

-

Total Cost of Ownership (TCO): Evaluate the total cost of ownership, which includes purchase price, shipping, maintenance, and potential warranty claims. A lower initial cost may lead to higher long-term expenses if quality is compromised.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties that can affect total costs. It’s advisable to work with suppliers who have experience in your region to navigate these complexities effectively.

-

Market Research: Conduct thorough market research to understand prevailing prices and trends in different regions. This knowledge can empower buyers during negotiations and sourcing strategies.

-

Warranty and Support: Assess the warranty terms and after-sales support offered by suppliers. A robust warranty can mitigate the risks associated with defects, enhancing the overall value of the purchase.

Conclusion

In summary, sourcing the 2005 Toyota Camry U250 torque converter sensor involves a multifaceted approach to understanding costs and pricing. By considering the cost components, price influencers, and strategic buyer tips, international B2B buyers can make informed decisions that enhance their procurement processes and optimize their supply chains. Always remember that indicative prices may vary, and thorough due diligence is essential for successful sourcing.

Alternatives Analysis: Comparing 2005 toyota camry transmission u250 torque converter senor With Other Solutions

Introduction: Exploring Alternative Solutions for Torque Converter Sensors

In the automotive industry, particularly for businesses involved in vehicle maintenance and repair, understanding the various options available for components like the torque converter sensor is crucial. The 2005 Toyota Camry transmission U250 torque converter sensor is a specific solution, but there are alternative technologies and methods that may offer similar benefits or cater to different operational needs. This analysis aims to provide a clear comparison of the U250 sensor with alternative products and approaches to help B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | 2005 Toyota Camry Transmission U250 Torque Converter Sensor | TC Remanufacturing Torque Converter | Pro-King Automatic Torque Converter |

|---|---|---|---|

| Performance | Reliable performance with OEM specifications | Comparable performance, remanufactured for quality | High performance, designed for heavy-duty applications |

| Cost | Approximately $200-$300 | $199.99 + core deposit | $287.99 + core deposit |

| Ease of Implementation | Direct replacement, straightforward installation | Requires skilled labor for installation | Requires skilled labor for installation |

| Maintenance | Minimal maintenance required, typically long-lasting | Remanufactured, may need future servicing | Durable, but may need periodic checks |

| Best Use Case | Ideal for standard replacement in Toyota vehicles | Cost-effective for budget-conscious repairs | Suitable for performance upgrades in heavier vehicles |

Detailed Breakdown of Alternatives

TC Remanufacturing Torque Converter

The TC Remanufacturing torque converter is a viable alternative for businesses looking for a cost-effective solution. Priced around $199.99, this remanufactured option provides performance comparable to the OEM sensor. While it requires a core deposit, which is refundable, the main consideration is the need for skilled labor during installation. Its reliability makes it suitable for standard applications, but buyers should be aware that remanufactured components can sometimes require more frequent maintenance.

Pro-King Automatic Torque Converter

The Pro-King Automatic torque converter, priced at $287.99, is designed for heavier-duty applications and offers high performance. This option is ideal for businesses that require enhanced power and efficiency, particularly in vehicles that undergo more demanding usage. While it also necessitates professional installation, its durability and performance capabilities may justify the higher cost for those needing robust solutions. However, it may not be the best choice for standard use cases where budget constraints are a concern.

Conclusion: Choosing the Right Torque Converter Sensor for Your Needs

When selecting a torque converter sensor or related component for the 2005 Toyota Camry, B2B buyers must consider various factors such as performance requirements, budget constraints, and installation capabilities. The original U250 sensor provides reliable performance and ease of installation, making it an excellent choice for standard replacements. However, alternatives like TC Remanufacturing and Pro-King torque converters can cater to specific needs, such as cost-effectiveness or high-performance applications. Ultimately, understanding the unique demands of your business and vehicle usage will guide you in selecting the most suitable solution.

Essential Technical Properties and Trade Terminology for 2005 toyota camry transmission u250 torque converter senor

What Are the Key Technical Properties of the 2005 Toyota Camry U250 Torque Converter Sensor?

When sourcing components like the torque converter sensor for the 2005 Toyota Camry, understanding the critical specifications is essential for ensuring compatibility, performance, and longevity. Here are some of the vital technical properties to consider:

-

Material Grade

The materials used in the torque converter sensor, typically high-grade metals and durable plastics, impact its performance and lifespan. For example, stainless steel is often preferred for its resistance to corrosion and high temperature, ensuring that the sensor remains functional in various conditions. Buyers should prioritize sensors made with robust materials to minimize the risk of premature failure. -

Electrical Resistance

This property is crucial for sensors, as it determines their ability to transmit signals accurately. A lower resistance typically indicates better conductivity, which is vital for the sensor’s responsiveness. In the B2B context, understanding electrical resistance can help buyers ensure that the sensor will perform optimally within the vehicle’s electrical system. -

Tolerance Levels

Tolerance refers to the allowable deviation in dimensions during manufacturing. For torque converter sensors, tight tolerances are critical to ensure proper fit and function. High tolerance levels can lead to increased efficiency and reduced wear, making it a significant factor for buyers looking to maintain vehicle performance. -

Temperature Range

The operational temperature range indicates the extremes within which the sensor can function effectively. For automotive applications, especially in regions with varying climates, a broader temperature range can enhance reliability. Buyers should ensure the sensor meets the specific temperature requirements of the 2005 Toyota Camry. -

Response Time

This metric refers to how quickly the sensor can react to changes in engine conditions. A faster response time can lead to improved performance and fuel efficiency. In the B2B environment, understanding response time is essential for sourcing sensors that enhance vehicle performance. -

Lock-Up Mechanism

This feature is crucial for torque converters as it allows for direct coupling between the engine and transmission, improving efficiency. The lock-up mechanism’s design and functionality can significantly influence the vehicle’s performance, making it an important aspect for buyers to consider.

What Trade Terminology Should B2B Buyers Know When Sourcing Torque Converter Sensors?

Navigating the world of automotive components requires familiarity with specific trade terms. Here are some essential terms relevant to the 2005 Toyota Camry torque converter sensor:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the vehicle’s original manufacturer, ensuring compatibility and quality. When sourcing parts like torque converter sensors, buyers should consider OEM options to guarantee that they meet the same standards as the original components. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding this term is vital for B2B buyers, as it can affect inventory management and overall costs. Buyers should negotiate MOQs that align with their purchasing capabilities. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. Utilizing RFQs can help buyers compare prices and terms from multiple suppliers, ensuring they get the best deal for torque converter sensors. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Familiarity with these terms is crucial for B2B transactions, as they dictate shipping costs, risks, and responsibilities. Buyers should ensure they understand which Incoterms apply to their purchases. -

Lead Time

This term refers to the time it takes from placing an order to receiving the product. Understanding lead times is critical for inventory planning and ensuring that supply chains remain uninterrupted. -

Warranty Period

The warranty period outlines the timeframe during which the manufacturer will cover defects in the product. For B2B buyers, knowing the warranty details can provide peace of mind and a safeguard against potential losses due to faulty components.

In summary, a comprehensive understanding of the technical properties and trade terminology associated with the 2005 Toyota Camry U250 torque converter sensor is essential for B2B buyers. This knowledge not only aids in making informed purchasing decisions but also enhances the overall efficiency and effectiveness of the supply chain.

Navigating Market Dynamics and Sourcing Trends in the 2005 toyota camry transmission u250 torque converter senor Sector

What Are the Key Market Dynamics and Trends Affecting the 2005 Toyota Camry Transmission U250 Torque Converter Sector?

The market for the 2005 Toyota Camry transmission U250 torque converter sensor is experiencing notable shifts driven by various global factors. The surge in demand for reliable automotive parts, particularly in regions like Africa, South America, the Middle East, and Europe, is propelled by an increasing number of vehicles on the road and a growing focus on vehicle maintenance. Additionally, the rise of e-commerce platforms has transformed sourcing strategies, enabling B2B buyers to access a wider range of suppliers and products globally.

Emerging technologies such as predictive analytics and AI-driven inventory management are enhancing supply chain efficiency, allowing buyers to forecast demand accurately and optimize stock levels. Furthermore, the push for aftermarket parts, including remanufactured components, is gaining traction as businesses seek cost-effective solutions without compromising quality. This trend is particularly relevant in developing markets, where affordability is a critical factor.

Moreover, the regulatory landscape is evolving, with stricter emissions and safety standards influencing product offerings. B2B buyers must stay informed about compliance requirements to ensure that the parts sourced meet the necessary specifications. Understanding these dynamics is crucial for international buyers to navigate the complexities of the supply chain effectively.

How Can Sustainability and Ethical Sourcing Impact the 2005 Toyota Camry Transmission U250 Torque Converter Sector?

Sustainability and ethical sourcing have become imperative in the automotive parts industry, including the market for the 2005 Toyota Camry transmission U250 torque converter sensor. The environmental impact of manufacturing processes has prompted businesses to adopt greener practices. This includes utilizing recycled materials and minimizing waste, which not only helps in reducing the carbon footprint but also appeals to environmentally conscious consumers.

Ethical supply chains are increasingly prioritized, with buyers seeking suppliers who adhere to fair labor practices and transparent sourcing methods. Certifications such as ISO 14001 for environmental management and ISO 26000 for social responsibility are becoming essential for suppliers aiming to demonstrate their commitment to sustainability. B2B buyers can enhance their brand reputation by sourcing from suppliers that hold these certifications, thereby aligning with the growing consumer demand for corporate social responsibility.

Moreover, as sustainability becomes a key differentiator in the automotive sector, businesses that incorporate ‘green’ materials and processes into their supply chains are likely to gain a competitive advantage. This trend is particularly relevant for international buyers from regions like Brazil and Nigeria, where there is a burgeoning interest in sustainable practices.

What Is the Historical Context of the 2005 Toyota Camry Transmission U250 Torque Converter Sector?

The evolution of the 2005 Toyota Camry transmission U250 torque converter sector is rooted in advancements in automotive technology and changing consumer needs. Since its introduction, the Toyota Camry has been a popular choice for consumers due to its reliability and efficiency. The U250 transmission, featuring improved torque converter designs, was developed to enhance performance and fuel efficiency.

Over the years, the demand for aftermarket components has grown, driven by the need for cost-effective repair solutions. This shift has led to an increase in remanufactured and refurbished parts, providing an alternative to original equipment manufacturer (OEM) components. As the automotive industry continues to evolve, understanding this historical context allows B2B buyers to make informed decisions regarding sourcing and procurement strategies, ensuring they select the best options for their market needs.

In summary, the dynamics of the 2005 Toyota Camry transmission U250 torque converter sensor sector are shaped by market trends, sustainability considerations, and historical developments, all of which are vital for international B2B buyers to consider in their sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of 2005 toyota camry transmission u250 torque converter senor

-

How do I troubleshoot issues with the 2005 Toyota Camry U250 torque converter sensor?

To troubleshoot problems with the torque converter sensor in a 2005 Toyota Camry, start by checking for any diagnostic trouble codes (DTCs) using an OBD-II scanner. Look for codes related to the torque converter or transmission performance. Inspect the wiring and connectors for damage or corrosion, as these can lead to sensor failures. If necessary, test the sensor’s resistance and voltage output to ensure it is functioning correctly. If problems persist, consider consulting a certified mechanic or technician for a thorough diagnosis and repair. -

What is the best replacement option for the 2005 Toyota Camry U250 torque converter sensor?

The best replacement option for the 2005 Toyota Camry U250 torque converter sensor depends on factors such as budget, availability, and warranty. OEM (Original Equipment Manufacturer) parts are often recommended for their reliability and fitment accuracy, but high-quality aftermarket sensors can also perform well. Ensure that the selected part meets or exceeds OEM specifications. Verify the supplier’s reputation and check for warranty options to ensure peace of mind with your purchase. -

What are the key factors to consider when sourcing U250 torque converter sensors internationally?

When sourcing U250 torque converter sensors internationally, consider factors such as supplier reliability, product quality, and compliance with local regulations. Verify the supplier’s credentials, including certifications and reviews from previous clients. Additionally, assess the shipping costs and delivery timelines to avoid unexpected delays. Understand the payment terms and ensure that they align with your financial policies, while also confirming the warranty and return policies for the products. -

How can I ensure the quality of the torque converter sensor before purchasing?

To ensure the quality of the torque converter sensor, request samples or detailed product specifications from the supplier. Look for third-party quality certifications, such as ISO standards, which indicate adherence to manufacturing best practices. Conduct a background check on the supplier to assess their history and reputation in the industry. Additionally, consider reading customer reviews and testimonials to gauge the experiences of other buyers regarding the product’s performance and durability. -

What is the minimum order quantity (MOQ) for the 2005 Toyota Camry U250 torque converter sensor?

Minimum order quantities (MOQs) for the 2005 Toyota Camry U250 torque converter sensor can vary significantly between suppliers. Some may offer flexible MOQs for B2B buyers, while others may have strict requirements based on their production capabilities. It’s advisable to inquire directly with potential suppliers about their MOQ policies. If your purchase volume is lower than the MOQ, consider negotiating or joining with other buyers to meet the required quantity. -

What payment terms should I consider when purchasing internationally?

When purchasing torque converter sensors internationally, consider payment terms that provide security and flexibility. Common options include letters of credit, PayPal, or escrow services, which protect both the buyer and seller. Negotiate terms such as payment in advance, partial payments, or payment upon delivery based on your level of trust with the supplier. Always ensure that the payment method aligns with your financial policies and provides recourse in case of disputes. -

How can I manage logistics and shipping for international orders of torque converter sensors?

To manage logistics and shipping for international orders of torque converter sensors, establish clear communication with your supplier regarding shipping options and timelines. Choose a reliable freight forwarder who can navigate customs regulations and ensure timely delivery. Evaluate different shipping methods—air freight for speed, sea freight for cost-effectiveness—and choose based on your urgency and budget. Track shipments closely and maintain contact with the carrier to address any potential delays or issues during transit. -

What should I do if my torque converter sensor is defective upon arrival?

If your torque converter sensor arrives defective, promptly document the issue with photographs and detailed descriptions. Review the supplier’s return and warranty policy to understand your options. Contact the supplier immediately to report the defect and initiate a return or replacement process. Ensure that you follow their instructions for returning the item, including shipping methods and timelines, to avoid complications. Keep records of all communications and transactions for reference in case of disputes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 2005 Toyota Camry Transmission U250 Torque Converter Senor Manufacturers & Suppliers List

1. U250E – Auto Transmission Repair Torque Converter

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“product_name”:”U250E U250 Auto Transmission Repair Torque Converter”,”compatible_vehicle”:”TOYOTA CAMRY 05-ON”,”condition”:”Remanufactured”,”price”:”$236.80 or Best Offer”,”shipping_cost”:”$25.00″,”estimated_delivery”:”Mon, Sep 22 – Thu, Sep 25″,”seller_feedback”:”96.2% positive feedback”,”payment_options”:”As low as $41.09/mo with Klarna”,”additional_service”:”1-year protection plan from Allsta…

2. JDM Engine Depot – 2005-2006 Toyota Camry Automatic Transmission

Domain: jdmenginedepotinc.com

Registered: 2017 (8 years)

Introduction: Product: 2005-2006 Toyota Camry 2.4L 4CYL Automatic Transmission 2AZ U250

Price: $699.00

Stock: 1 in stock

SKU: PROD_NUM_20432-3448-4201-2

Description: Used automatic transmission (2.4L, AT, 5-Speed). Attached engine not included. Transmission comes with external accessories as shown in photos (not covered under warranty).

Warranty: 90-Day start up warranty on internal moving components of transmi…

3. Toyota – Automatic Transmission Parts

Domain: rockauto.com

Registered: 1999 (26 years)

Introduction: This company, Toyota – Automatic Transmission Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Toyota – Automatic Transmission Torque Converter

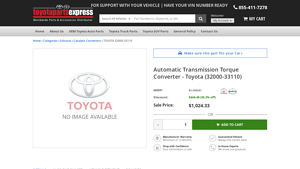

Domain: toyotaparts.lakelandtoyota.com

Registered: 1996 (29 years)

Introduction: {“part_name”:”Automatic Transmission Torque Converter”,”part_number”:”32000-33110″,”compatible_models”:[{“year”:”2005″,”make”:”Toyota”,”model”:”Camry”},{“year”:”2006″,”make”:”Toyota”,”model”:”Camry”}],”msrp”:”$1,468.81″,”discount”:”$444.48 (30.3% off)”,”sale_price”:”$1,024.33″,”condition”:”New”,”brand”:”Toyota”,”origin”:”Japan Built Part”,”warranty”:”Minimum of 12 Months”,”warning”:”California Pro…

5. Carquest – Automatic Transmission Torque Converter Clutch Solenoids

Domain: shop.advanceautoparts.com

Registered: 1997 (28 years)

Introduction: Toyota Camry Automatic Transmission Torque Converter Clutch Solenoids available at Advance Auto Parts. Two different solenoids offered: 1) Carquest Premium Automatic Transmission Torque Converter Clutch Solenoid (Part No.SBA6036) starting from $399.99 and 2) Carquest Premium Automatic Transmission Torque Converter Clutch Solenoid (Part No.SBA6037) starting from $312.99. Features include: construct…

Strategic Sourcing Conclusion and Outlook for 2005 toyota camry transmission u250 torque converter senor

In conclusion, effective strategic sourcing of the 2005 Toyota Camry transmission U250 torque converter sensor is critical for international B2B buyers seeking to enhance their inventory and operational efficiency. By understanding the nuances of the U250E transmission and its components, including the torque converter, businesses can make informed purchasing decisions that ensure compatibility and performance reliability.

The current market landscape emphasizes the importance of sourcing from reputable suppliers who can provide quality parts, such as TC Remanufacturing and Pro-King, ensuring that buyers receive components that meet stringent standards. This not only minimizes downtime but also optimizes the overall performance of the vehicles in question.

Looking ahead, B2B buyers from regions like Africa, South America, the Middle East, and Europe should capitalize on the growing demand for reliable automotive parts. By fostering strong relationships with suppliers and leveraging strategic sourcing practices, businesses can position themselves competitively in the market. Consider exploring new partnerships and investing in quality components to drive your business forward in the automotive sector.