Inset Cabinet Door Hinges Concealed: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for inset cabinet door hinges concealed

In the competitive landscape of global hardware sourcing, finding reliable and high-quality inset cabinet door hinges concealed can be a daunting challenge for B2B buyers. With the rising demand for aesthetically pleasing and functional cabinetry across various markets, including Africa, South America, the Middle East, and Europe, understanding the nuances of these hinges is essential for making informed purchasing decisions. This guide serves as a comprehensive resource, delving into the diverse types of concealed hinges available, their specific applications, and critical considerations for supplier vetting.

International buyers will benefit from insights on cost factors, quality standards, and the latest trends in hinge technology, ensuring they can navigate the complexities of this sector with confidence. By addressing key challenges, such as compatibility with different cabinet designs and regulatory requirements in various regions, this guide empowers buyers to select the best products for their needs. Furthermore, we will explore how to establish strong partnerships with suppliers, equipping businesses with the tools necessary to enhance their procurement strategies.

Whether you are a retailer, manufacturer, or contractor, this guide will illuminate the path to sourcing top-notch concealed hinges, fostering an efficient and effective purchasing process tailored to the specific demands of your market.

Understanding inset cabinet door hinges concealed Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Inset Hinges | Doors fit flush with cabinet frame, concealed hinge | High-end cabinetry, custom furniture | Pros: Sleek appearance, maximizes space. Cons: More complex installation. |

| Half Inset Hinges | Partial overlay, door partially covers frame | Residential kitchens, office furniture | Pros: Easier to install, less expensive. Cons: Less aesthetic appeal than full inset. |

| Soft Close Inset Hinges | Integrated damping mechanism to prevent slamming | High-end cabinetry, luxury furniture | Pros: Quiet operation, reduces wear. Cons: Higher cost, may require more maintenance. |

| Self-Closing Inset Hinges | Automatically closes door when within a certain range | Commercial spaces, heavy-use cabinets | Pros: Enhances convenience, improves safety. Cons: Can be less durable under heavy use. |

| Demountable Inset Hinges | Allows for easy removal of doors without tools | Modular cabinetry, repair applications | Pros: Simplifies maintenance, flexible designs. Cons: May compromise structural integrity if not used correctly. |

What are Full Inset Hinges and Their Suitability for B2B Buyers?

Full inset hinges are designed so that cabinet doors fit flush against the cabinet frame, providing a seamless look. This type is particularly suitable for high-end cabinetry and custom furniture where aesthetics are paramount. B2B buyers should consider the complexity of installation and the potential need for specialized tools, which may increase labor costs. However, the sleek appearance and maximization of space often justify the investment for upscale projects.

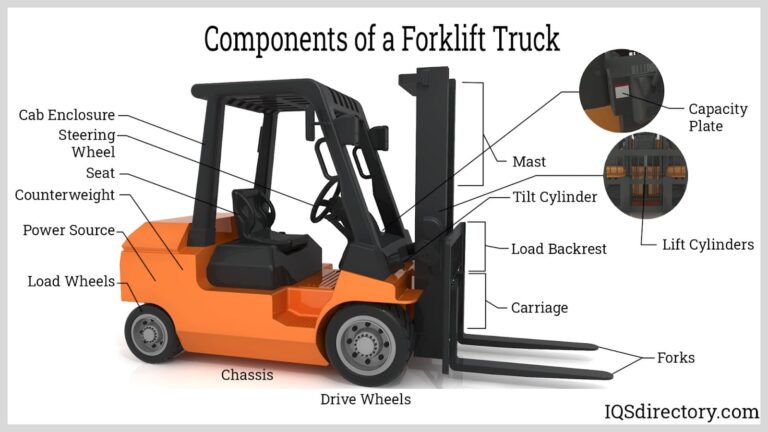

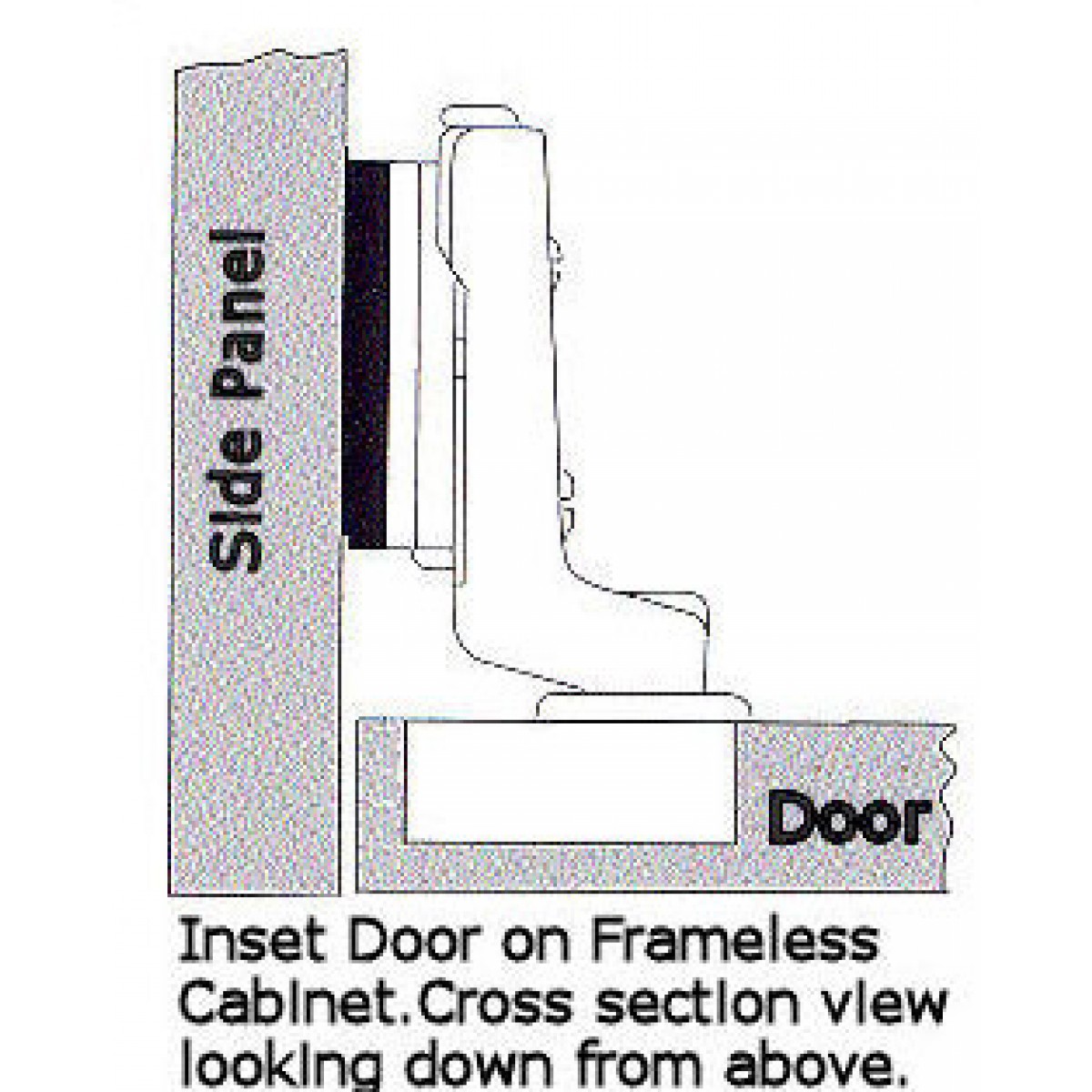

Illustrative image related to inset cabinet door hinges concealed

How Do Half Inset Hinges Compare to Other Types?

Half inset hinges allow the door to partially cover the cabinet frame, making them easier to install compared to full inset options. They are commonly used in residential kitchens and office furniture applications. Buyers should weigh the cost-effectiveness and simpler installation against the slightly less polished appearance. For businesses looking for a balance between budget and aesthetics, half inset hinges can be an appealing choice.

Why Choose Soft Close Inset Hinges for Luxury Projects?

Soft close inset hinges feature a damping mechanism that ensures doors close quietly and gently, making them ideal for luxury cabinetry. These hinges are often specified in high-end residential and commercial projects where user experience is critical. While they provide significant advantages in terms of noise reduction and durability, buyers should anticipate a higher upfront cost and potential maintenance requirements, which are essential to factor into project budgets.

What Are the Advantages of Self-Closing Inset Hinges in Commercial Spaces?

Self-closing inset hinges automatically close cabinet doors when they are within a certain range, making them highly beneficial in commercial environments where convenience and safety are priorities. They are commonly used in heavy-use cabinets, such as those found in kitchens and storage areas. While they enhance operational efficiency, buyers should consider the potential for wear over time, especially in high-traffic areas.

How Do Demountable Inset Hinges Facilitate Maintenance?

Demountable inset hinges allow for the easy removal of cabinet doors without the need for tools, making them an excellent choice for modular cabinetry and repair applications. This feature is particularly advantageous for businesses that require frequent maintenance or updates to their cabinetry. However, buyers must ensure that the hinges are installed correctly to maintain structural integrity, as improper use can lead to complications.

Key Industrial Applications of inset cabinet door hinges concealed

| Industry/Sector | Specific Application of Inset Cabinet Door Hinges Concealed | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Used in high-end cabinetry for residential and commercial furniture. | Enhances aesthetic appeal and functionality of products. | Quality of materials, hinge durability, and design compatibility. |

| Hospitality | Implemented in hotel room cabinetry and restaurant furniture. | Contributes to a sleek, modern design while ensuring ease of use. | Compliance with safety standards, availability of soft-close features. |

| Retail Fixtures | Integrated into display units and shelving in retail environments. | Improves customer experience by providing seamless access to products. | Customization options, weight capacity, and finish variety. |

| Architectural Design | Utilized in custom-built homes and commercial buildings. | Adds value through enhanced design flexibility and space efficiency. | Compatibility with architectural specifications, ease of installation. |

| Healthcare Facilities | Applied in cabinetry for medical storage and patient rooms. | Ensures safety and hygiene while maintaining a clean look. | Compliance with health regulations, ease of cleaning, and durability. |

How Are Inset Cabinet Door Hinges Concealed Used in Furniture Manufacturing?

In the furniture manufacturing sector, inset cabinet door hinges concealed are integral to creating high-end cabinetry that emphasizes both aesthetics and functionality. These hinges allow for flush mounting of doors, resulting in a seamless look that appeals to discerning consumers. For international buyers, particularly in regions like Africa and Europe, sourcing hinges that offer durability and compatibility with various wood types is essential. Additionally, manufacturers should consider the hinge’s weight capacity and ease of installation to ensure a smooth production process.

What Role Do Inset Cabinet Door Hinges Concealed Play in the Hospitality Industry?

In the hospitality industry, inset cabinet door hinges concealed are commonly found in hotel room cabinetry and restaurant furniture. These hinges contribute to a sleek, modern design that enhances the overall guest experience while ensuring easy access to storage spaces. For B2B buyers in the Middle East and South America, sourcing hinges that comply with local safety standards and offer features like soft-close mechanisms can significantly improve the usability of hospitality furniture. Additionally, durability is key, given the high usage rates in these environments.

How Are Inset Cabinet Door Hinges Concealed Beneficial for Retail Fixtures?

In retail environments, inset cabinet door hinges concealed are utilized in display units and shelving, providing customers with seamless access to products. This not only enhances the shopping experience but also contributes to the overall aesthetic of the store. For international retail buyers, especially in Brazil and Europe, it’s crucial to consider customization options to match the store’s branding, along with the hinge’s weight capacity to support various product displays. The finish variety also plays a significant role in aligning with the store’s design theme.

Why Are Inset Cabinet Door Hinges Concealed Important in Architectural Design?

Within architectural design, inset cabinet door hinges concealed are used in custom-built homes and commercial buildings to add value through enhanced design flexibility and space efficiency. These hinges allow architects and builders to create clean lines and maximize storage solutions without compromising aesthetics. Buyers from regions like Africa and the Middle East should prioritize sourcing hinges that meet specific architectural specifications and are easy to install. The ability to provide a variety of finishes is also essential to meet diverse design preferences.

How Do Inset Cabinet Door Hinges Concealed Serve Healthcare Facilities?

In healthcare facilities, inset cabinet door hinges concealed are crucial for cabinetry used in medical storage and patient rooms. They ensure a clean, professional appearance while supporting safety and hygiene standards. For B2B buyers in this sector, particularly in regions with strict health regulations, it’s vital to source hinges that are easy to clean and highly durable. Additionally, features such as soft-close mechanisms can enhance usability, making it easier for staff to access essential supplies without disturbing patients.

3 Common User Pain Points for ‘inset cabinet door hinges concealed’ & Their Solutions

Scenario 1: Difficulty in Matching Hinge Specifications with Cabinet Designs

The Problem: B2B buyers often face challenges when trying to match concealed inset cabinet door hinges with specific cabinet designs. This may arise from a lack of detailed product specifications or an understanding of hinge types. For instance, a buyer might order hinges based on a general description, only to find that the measurements do not align with the cabinet frames they are working with. This misalignment can lead to costly returns, delays in project timelines, and ultimately impact customer satisfaction.

The Solution: To avoid this pitfall, it’s essential for buyers to invest time in understanding the specifications of the hinges they intend to purchase. Start by measuring the cabinet frame’s thickness and the overlay of the doors accurately. Utilize resources like hinge guides available on manufacturer websites to comprehend different hinge types and their specific applications. When sourcing hinges, opt for suppliers who provide comprehensive technical data, including detailed dimensional drawings and installation instructions. Consider also consulting with hinge manufacturers for recommendations tailored to your specific cabinet design needs, ensuring a proper fit and seamless integration.

Scenario 2: Issues with Hinge Durability and Performance

The Problem: Another common issue is the durability and performance of concealed hinges over time. Buyers may encounter hinges that fail prematurely, resulting in doors that sag or do not close properly. This not only affects the aesthetics of the cabinetry but can also lead to increased maintenance costs and diminished product reputation. In regions with varying humidity and temperature, the quality of the hinge material becomes even more critical, as subpar materials can corrode or warp.

The Solution: To address durability concerns, it’s advisable to prioritize high-quality hinges made from robust materials such as stainless steel or brass, which offer greater resistance to wear and environmental factors. When selecting hinges, look for those with features like soft-close mechanisms or self-closing functionalities that enhance performance. Additionally, engage with suppliers who provide performance warranties or guarantees, giving you peace of mind regarding the longevity of the product. Regular maintenance checks on installed hinges can also extend their lifespan; ensure that your installation teams are trained to perform these checks during routine inspections.

Scenario 3: Complications in Installation and Alignment

The Problem: Installation of concealed inset cabinet door hinges can be complex, particularly for buyers who are not experienced in carpentry or cabinetry work. Incorrect installation can lead to misalignment, which affects how doors open and close, and can also lead to premature wear on the hinges themselves. This is a frequent issue for companies taking on new projects without adequate training or guidance for their installation teams.

The Solution: To streamline the installation process, provide comprehensive training for your installation teams, focusing on best practices for hinge installation. Make use of detailed installation guides and videos from manufacturers that demonstrate proper techniques. Additionally, consider investing in specialized tools that facilitate accurate measurements and alignments, such as hinge jigs or template guides. For larger projects, it may be beneficial to partner with experienced installers or consultants who can provide on-site training or oversee the installation process. This proactive approach not only minimizes errors but also enhances the overall quality of the finished product, leading to higher customer satisfaction and potential repeat business.

Strategic Material Selection Guide for inset cabinet door hinges concealed

What Are the Key Materials Used for Inset Cabinet Door Hinges Concealed?

When selecting materials for inset cabinet door hinges concealed, it is crucial to consider their properties, advantages, disadvantages, and suitability for specific applications. Here, we analyze four common materials: stainless steel, brass, zinc alloy, and plastic.

Illustrative image related to inset cabinet door hinges concealed

How Does Stainless Steel Perform in Inset Cabinet Door Hinges?

Stainless steel is a popular choice for concealed hinges due to its exceptional corrosion resistance and mechanical strength. It can withstand high temperatures and pressures, making it suitable for various environments, including humid or coastal areas. The primary advantage of stainless steel hinges is their durability and longevity, which translates into lower replacement costs over time.

However, stainless steel can be more expensive than other materials, which may impact budget-sensitive projects. Additionally, the manufacturing complexity can be higher, requiring advanced machining techniques. For international buyers, compliance with standards such as ASTM A240 (for stainless steel) is essential, especially in regions like Europe and the Middle East, where quality assurance is paramount.

What Are the Benefits of Using Brass for Concealed Hinges?

Brass is favored for its aesthetic appeal and excellent corrosion resistance. It is often used in high-end cabinetry where appearance matters, as it can be polished to a bright finish. Brass hinges are also relatively durable and can handle moderate weight loads effectively.

Illustrative image related to inset cabinet door hinges concealed

On the downside, brass is softer than stainless steel, which may lead to wear and tear over time, particularly in high-use applications. The cost of brass can also be higher, making it less suitable for large-scale projects where budget constraints exist. Buyers from regions like South America may appreciate the aesthetic value, but they should also consider the potential need for regular maintenance to keep the hinges looking their best.

Why Choose Zinc Alloy for Inset Cabinet Door Hinges?

Zinc alloy is often selected for its cost-effectiveness and versatility. It offers decent corrosion resistance and can be easily molded into intricate designs, making it suitable for decorative applications. Zinc alloy hinges are lightweight, which can be advantageous in reducing the overall weight of cabinet doors.

However, zinc alloy does not offer the same level of durability as stainless steel or brass. It may not perform well in high-humidity environments, leading to potential corrosion issues. International buyers should consider local climate conditions when selecting zinc alloy hinges, especially in regions like Africa, where humidity and temperature variations can be significant.

What Role Does Plastic Play in Concealed Hinges?

Plastic hinges are gaining traction due to their lightweight nature and resistance to corrosion. They are often used in applications where weight is a critical factor, such as in mobile or modular furniture. Plastic hinges can also be produced in various colors and styles, allowing for customization.

The primary limitation of plastic hinges is their lower mechanical strength compared to metal options. They may not be suitable for heavy cabinet doors or high-traffic environments. For buyers in the Middle East, where extreme temperatures can affect material performance, it’s crucial to ensure that the selected plastic can withstand local conditions.

Summary Table of Material Selection for Inset Cabinet Door Hinges Concealed

| Material | Typical Use Case for inset cabinet door hinges concealed | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-end cabinetry, humid environments | Exceptional durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Brass | Decorative cabinetry, aesthetic applications | Attractive finish and corrosion resistance | Softer material, may wear over time | Med |

| Zinc Alloy | Budget-friendly projects, decorative applications | Cost-effective and versatile | Lower durability in humid conditions | Low |

| Plastic | Lightweight applications, modular furniture | Lightweight and corrosion-resistant | Lower strength, not suitable for heavy use | Low |

This strategic material selection guide provides B2B buyers with a comprehensive understanding of the materials available for concealed hinges, enabling informed decisions tailored to specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for inset cabinet door hinges concealed

What Are the Key Manufacturing Processes for Inset Cabinet Door Hinges?

Manufacturing inset cabinet door hinges concealed involves a series of meticulous processes designed to ensure precision, durability, and aesthetic appeal. Understanding these processes is crucial for B2B buyers who prioritize quality and reliability in their sourcing decisions.

Illustrative image related to inset cabinet door hinges concealed

How Are Materials Prepared for Manufacturing Cabinet Hinges?

The manufacturing process begins with the careful selection of raw materials, typically high-grade steel, brass, or stainless steel, depending on the desired strength and finish. Material preparation involves cutting sheets or bars to specific dimensions, followed by treatment processes such as annealing or galvanizing to enhance corrosion resistance and durability.

Advanced techniques such as laser cutting or water jet cutting are often employed to achieve precise dimensions and minimize waste. This initial stage is critical, as the quality of the raw materials directly influences the final product’s performance and lifespan.

What Forming Techniques Are Used in Hinge Production?

Once the materials are prepared, the next step is forming. This stage usually includes processes like stamping, bending, and machining.

-

Stamping: This is a common method where the material is placed in a die and pressed to create the basic hinge shape. Stamping is efficient and allows for high-volume production while maintaining consistency in dimensions.

-

Bending: After stamping, the hinge components may require bending to achieve the desired angles. CNC (Computer Numerical Control) machines are frequently used for this purpose, ensuring high precision and repeatability.

-

Machining: For more complex designs, machining processes like milling and drilling are employed to create features such as mounting holes and slots. This stage is critical for ensuring that the hinge aligns perfectly with the cabinet door and frame.

How Is the Assembly of Inset Cabinet Door Hinges Conducted?

The assembly process involves bringing together the various components—hinge plates, pins, and springs—into a finished product. Depending on the design, assembly can be manual or automated.

-

Automated Assembly: For high-volume production, automated assembly lines are utilized, where robotic systems accurately and quickly assemble the hinges, reducing labor costs and minimizing human error.

-

Manual Assembly: In cases where customization or intricate designs are involved, skilled workers may assemble hinges by hand, ensuring that each component fits perfectly and functions smoothly.

Quality checks during assembly are essential, as they help identify any defects early in the production cycle. This proactive approach reduces waste and enhances overall product quality.

What Finishing Processes Are Commonly Used for Hinges?

Finishing is the final stage of hinge manufacturing, where aesthetic and protective coatings are applied. Common finishing processes include:

-

Electroplating: This process involves coating the hinge with a thin layer of metal (like nickel or chrome) to enhance corrosion resistance and provide a polished appearance.

-

Powder Coating: An environmentally friendly alternative, powder coating provides a durable finish that can be applied in various colors. This method is particularly beneficial for meeting specific design requirements of clients.

-

Anodizing: For aluminum hinges, anodizing is a common finishing technique that increases corrosion resistance and wear properties while allowing for a range of color finishes.

These finishing processes not only improve the aesthetic appeal of the hinges but also contribute to their longevity and performance in various environments.

What Quality Assurance Standards Are Relevant to Inset Cabinet Door Hinges?

For B2B buyers, understanding the quality assurance (QA) processes in hinge manufacturing is vital to ensure product reliability and compliance with international standards.

Which International Standards Should Buyers Be Aware Of?

ISO 9001 is a widely recognized standard that outlines the requirements for a quality management system (QMS). Manufacturers adhering to this standard demonstrate their commitment to consistent quality and customer satisfaction. Additionally, industry-specific certifications such as CE marking in Europe signify compliance with safety and environmental standards, which can be crucial for international trade.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter production. Inspections may include testing material properties and verifying supplier certifications.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections ensure that each stage meets specified standards. Techniques such as visual inspections, measurements, and functional testing are commonly employed.

-

Final Quality Control (FQC): Before shipment, a comprehensive inspection of the finished hinges is conducted. This includes testing for functionality, durability, and adherence to design specifications.

How Can Buyers Verify Supplier Quality Control Practices?

B2B buyers should implement robust verification processes to ensure their suppliers maintain high-quality standards. Key strategies include:

-

Supplier Audits: Conducting regular audits of suppliers’ facilities can provide insights into their production practices, quality control measures, and compliance with international standards.

-

Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including inspection reports and certifications. These documents are essential for verifying compliance with standards like ISO 9001 and CE marking.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices and product reliability. This is especially useful for buyers from diverse regions, ensuring that products meet local and international standards.

What Are the Unique Quality Control Considerations for International Buyers?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, navigating quality control nuances can be complex.

-

Cultural and Regulatory Differences: Understanding local regulations and cultural expectations around quality can help buyers make informed decisions. For instance, buyers in the Middle East may prioritize specific certifications that align with regional standards.

-

Logistical Challenges: Transportation and customs regulations can impact the quality and safety of products during shipment. Ensuring that suppliers are aware of these challenges and have protocols in place can mitigate risks.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing inset cabinet door hinges concealed, ensuring they receive products that meet their expectations for quality and performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘inset cabinet door hinges concealed’

To assist B2B buyers in procuring inset cabinet door hinges concealed effectively, this guide provides a step-by-step checklist. Each step is designed to streamline the sourcing process, ensuring that you select high-quality products that meet your specific needs.

Step 1: Define Your Technical Specifications

Begin by outlining the specific technical requirements for the hinges you need. Consider factors such as the door type, weight, and the desired finish. This clarity helps in narrowing down options and ensures compatibility with your cabinet designs.

- Door Type: Identify whether you need hinges for face frame or frameless cabinets.

- Weight Capacity: Ensure the hinges can support the weight of the doors without sagging or malfunctioning.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in concealed hinges. Look for manufacturers with a strong reputation in the industry and positive reviews from other B2B buyers.

Illustrative image related to inset cabinet door hinges concealed

- Supplier Reputation: Utilize platforms like trade shows or industry publications to gather insights.

- Market Presence: Prioritize suppliers with a global presence, especially those familiar with your target regions like Africa, South America, the Middle East, and Europe.

Step 3: Evaluate Supplier Certifications

Verify the certifications and standards adhered to by potential suppliers. This step is critical to ensure that the hinges meet international quality and safety standards.

- Quality Standards: Look for certifications such as ISO, CE, or any regional standards relevant to your market.

- Sustainability Practices: Consider suppliers who adhere to environmental regulations, which can be a significant factor in many regions.

Step 4: Request Samples for Testing

Before making a bulk order, request samples of the hinges to assess their quality and functionality. Testing samples helps prevent costly mistakes later.

- Functionality Check: Ensure the hinges operate smoothly and meet your design expectations.

- Durability Assessment: Evaluate the materials used and their resistance to wear over time.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers and compare their pricing structures, payment terms, and delivery timelines. This step is crucial for budgeting and securing the best deal.

- Transparent Pricing: Ensure all costs are outlined, including shipping and potential tariffs, especially for international purchases.

- Negotiation Opportunities: Look for suppliers willing to negotiate terms, especially for bulk orders.

Step 6: Confirm After-Sales Support

Assess the level of after-sales support offered by the supplier. This can be pivotal in resolving issues that may arise post-purchase.

- Warranty and Returns Policy: Understand the warranty period and the process for returns or replacements.

- Customer Service Availability: Ensure there is reliable support for any inquiries or issues that may arise during installation.

Step 7: Finalize and Place Your Order

Once you have completed the evaluation and are satisfied with your chosen supplier, finalize your order. Ensure that all specifications, quantities, and delivery details are clearly documented.

- Order Confirmation: Double-check that the order confirmation reflects your requirements accurately.

- Follow-Up Communication: Maintain communication with the supplier throughout the order process to ensure timely delivery.

By following this checklist, B2B buyers can confidently navigate the procurement of concealed inset cabinet door hinges, ensuring they make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for inset cabinet door hinges concealed Sourcing

What Are the Key Cost Components for Sourcing Inset Cabinet Door Hinges?

When analyzing the cost structure for inset cabinet door hinges concealed, several components come into play. The primary cost components include:

-

Materials: The choice of materials significantly affects the overall cost. Common materials for hinges include stainless steel, brass, and zinc alloy, each varying in price due to their durability and resistance to corrosion. Higher-quality materials typically lead to longer-lasting products, justifying a higher price point.

-

Labor: Labor costs encompass the wages of workers involved in the manufacturing process. Depending on the region, labor costs can vary significantly. For instance, manufacturing in countries with lower wage standards can reduce overall expenses, making it crucial for buyers to consider the location of their suppliers.

-

Manufacturing Overhead: This includes the costs associated with running the factory, such as utilities, rent, and machinery maintenance. Efficient manufacturing processes can help lower these costs, which can be passed on to the buyer.

-

Tooling: The initial investment in tooling is essential for production. Custom designs may require specialized tooling, which can increase upfront costs but may be amortized over larger production runs.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes is vital for maintaining standards. While this adds to the cost, it ultimately reduces the risk of returns and defects, benefiting buyers in the long run.

-

Logistics: Shipping and handling costs must also be factored in, especially for international buyers. Costs can vary based on shipping methods, distances, and freight charges, which are influenced by current fuel prices and regional trade agreements.

-

Margin: Finally, suppliers will add their margin to cover overhead and profit. This can vary by supplier and market conditions.

How Do Price Influencers Impact Inset Cabinet Door Hinge Sourcing?

Understanding the factors that influence pricing is essential for B2B buyers looking to optimize their procurement strategies:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to discounts. Suppliers are more willing to negotiate prices for larger orders, which can significantly reduce the unit cost.

-

Specifications and Customization: Customized hinges that meet specific design requirements may incur additional costs. Buyers should weigh the benefits of customization against the potential increase in price.

-

Material Quality and Certifications: The level of quality and any necessary certifications (e.g., ISO, CE) can influence pricing. Products that meet stringent quality standards may come at a premium but are often worth the investment for their reliability.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a proven track record may charge more, but their quality assurance and service can justify the higher price.

-

Incoterms: The chosen Incoterms can affect overall costs. Terms like CIF (Cost, Insurance, Freight) include shipping costs in the price, whereas FOB (Free on Board) requires buyers to manage shipping, impacting total expenses.

What Are the Key Tips for Buyers to Optimize Their Sourcing Costs?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Engage in proactive negotiations with suppliers. Understanding the cost breakdown can empower buyers to negotiate better terms and prices.

-

Total Cost of Ownership (TCO): Consider the TCO rather than just the purchase price. This includes maintenance, replacement, and potential downtime costs associated with lower-quality products.

-

Market Research: Conduct thorough market research to understand price trends and supplier offerings in different regions. This knowledge can provide leverage during negotiations.

-

Long-Term Relationships: Building long-term relationships with suppliers can lead to better pricing and service as suppliers may offer loyalty discounts or preferential treatment.

-

Stay Informed on Regulations: Awareness of import duties and regulations can prevent unexpected costs. Buyers should factor these into their budgeting to avoid surprises.

Disclaimer on Pricing

Prices for inset cabinet door hinges concealed can vary widely based on the factors mentioned above. The prices provided by suppliers should be regarded as indicative and subject to change due to market fluctuations, material costs, and supplier negotiations. Always request a detailed quote before finalizing purchases.

Alternatives Analysis: Comparing inset cabinet door hinges concealed With Other Solutions

Introduction

In the realm of cabinet hardware, selecting the right hinge system is pivotal for both functionality and aesthetic appeal. While inset cabinet door hinges concealed are a popular choice for their sleek design and effective space management, there are alternative solutions available that may better suit specific needs. This section explores viable alternatives, comparing their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Inset Cabinet Door Hinges Concealed | European Style Hinges | Overlay Hinges |

|---|---|---|---|

| Performance | Excellent for a clean, flush look | Good adjustability; versatile | Good for overlay cabinets; easy to install |

| Cost | Moderate to high | Moderate | Low to moderate |

| Ease of Implementation | Requires precise installation | Relatively easy; adjustable | Simple installation, suitable for DIY |

| Maintenance | Low maintenance; durable | Moderate; requires adjustments | Low maintenance; easy to replace |

| Best Use Case | High-end cabinetry and custom designs | General cabinetry; versatile applications | Budget-friendly projects; standard cabinets |

What Are the Pros and Cons of European Style Hinges?

European style hinges, commonly known as concealed hinges, offer a balance between aesthetics and functionality. One of their standout features is adjustability, allowing for fine-tuning once installed. This can be particularly advantageous in environments where doors may warp or shift over time. However, the installation process can be somewhat complex, requiring precise drilling and alignment, which may not be ideal for all users. Despite their moderate cost, the need for adjustments might deter some buyers seeking a more straightforward solution.

How Do Overlay Hinges Compare in Terms of Usability and Cost?

Overlay hinges provide a cost-effective alternative, especially for standard cabinetry. Their design allows them to sit on the exterior of the cabinet frame, making installation relatively easy and often suitable for DIY projects. This is particularly appealing for budget-conscious buyers or those managing larger projects where labor costs can escalate. However, they do not provide the same sleek, flush appearance that inset hinges offer, which can be a drawback in high-end cabinetry applications. While maintenance is minimal, the aesthetic compromise may not align with all design goals.

Illustrative image related to inset cabinet door hinges concealed

Conclusion

Choosing the right hinge solution is crucial for meeting both functional and aesthetic requirements. For B2B buyers, the decision should be guided by the specific needs of their projects, considering factors such as budget, ease of installation, and desired appearance. While inset cabinet door hinges concealed provide a premium finish and durability, alternatives like European style hinges and overlay hinges offer varying benefits that may suit different applications. Ultimately, understanding these options allows buyers to make informed decisions that align with their project goals and client expectations.

Essential Technical Properties and Trade Terminology for inset cabinet door hinges concealed

What Are the Key Technical Properties of Inset Cabinet Door Hinges Concealed?

When evaluating inset cabinet door hinges concealed for B2B procurement, understanding critical specifications is essential for ensuring compatibility and functionality. Below are some key properties to consider:

-

Material Grade

The material used for hinges typically ranges from stainless steel to zinc alloy, with stainless steel being preferred for its corrosion resistance and durability. High-quality materials are crucial for ensuring longevity, especially in humid environments. Choosing the right material can reduce maintenance costs and extend the lifespan of the hinges, making it a vital consideration for B2B buyers. -

Load Capacity

This specification indicates the maximum weight the hinge can support. It is essential to match the load capacity to the weight of the cabinet door. An insufficient load capacity can lead to hinge failure, resulting in costly repairs and potential safety hazards. Understanding the load capacity helps businesses select appropriate hinges for their specific applications. -

Hinge Type

Inset hinges come in different types, such as self-closing and soft-close. Self-closing hinges automatically pull the door shut, while soft-close hinges provide a gentle, controlled closing action. The choice between these types can influence user experience and functionality, making it a critical decision for businesses aiming to enhance customer satisfaction. -

Adjustability

Some hinges offer features like vertical and lateral adjustment capabilities. This adjustability allows for fine-tuning after installation, accommodating slight misalignments that might occur. For B2B buyers, investing in adjustable hinges can streamline installation processes and reduce the need for additional labor. -

Finish Options

The finish of the hinge affects not only aesthetic appeal but also corrosion resistance. Options such as matte, polished, or oil-rubbed finishes can complement various cabinet styles. For businesses, selecting the right finish can enhance product offerings and meet customer preferences. -

Tolerance

Tolerance refers to the allowable deviation in dimensions for hinge parts. Precise tolerances are critical in ensuring that hinges fit correctly and operate smoothly. For B2B buyers, understanding tolerance levels is essential to avoid compatibility issues in assembly and function.

What Are Common Trade Terms Related to Inset Cabinet Door Hinges?

Familiarity with industry jargon can significantly enhance communication and negotiation in the B2B space. Here are some common terms relevant to inset cabinet door hinges concealed:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers seeking reliable suppliers of quality hinges that meet specific design criteria. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest number of units a supplier is willing to sell. This term is vital for B2B buyers to know, as it can impact inventory levels and cash flow. Being aware of MOQ can help businesses plan their purchases effectively. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products. For buyers, issuing an RFQ can facilitate competitive pricing and help in selecting the best supplier based on quality and cost. -

Incoterms (International Commercial Terms)

These are a set of predefined commercial terms published by the International Chamber of Commerce, defining responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers to navigate shipping and delivery logistics effectively. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until it is fulfilled. For B2B transactions, knowing the lead time is important for inventory management and project planning. -

Certification Standards

These are industry standards that ensure product safety and quality, such as ISO or ANSI certifications. Familiarity with these standards can help businesses ensure compliance and enhance their product offerings in competitive markets.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, streamline procurement processes, and enhance overall operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the inset cabinet door hinges concealed Sector

What are the Key Trends Driving the Inset Cabinet Door Hinges Concealed Market?

The global market for inset cabinet door hinges concealed is currently experiencing significant growth, driven by several factors. Firstly, the rising demand for aesthetically pleasing furniture designs, particularly in residential and commercial sectors, is pushing manufacturers to innovate with concealed hinges that offer seamless integration. Countries in Africa, South America, the Middle East, and Europe are witnessing a surge in housing and commercial construction, bolstering the demand for high-quality cabinet hardware.

Illustrative image related to inset cabinet door hinges concealed

Emerging technologies such as smart home integrations are influencing sourcing trends. Manufacturers are beginning to produce hinges that can be incorporated into smart furniture systems, providing added functionality and appeal. Additionally, there is a growing interest in customizable solutions, allowing buyers to select finishes and features that align with their unique design requirements.

Market dynamics indicate a shift towards online sourcing platforms, enabling international buyers to access a wider range of products and suppliers. This trend is particularly prevalent in regions like Brazil and Saudi Arabia, where e-commerce is rapidly expanding. As buyers increasingly prioritize convenience and efficiency, the ability to compare products and prices online will continue to shape sourcing decisions.

How is Sustainability Influencing Sourcing Decisions for Inset Cabinet Door Hinges Concealed?

Sustainability has become a pivotal consideration in B2B sourcing, particularly in the inset cabinet door hinges concealed sector. The environmental impact of manufacturing processes, including material extraction and production, is under scrutiny. As a result, buyers are seeking suppliers that demonstrate a commitment to sustainable practices, which can include using responsibly sourced materials and minimizing waste.

Ethical supply chains are gaining importance, with businesses favoring manufacturers that adhere to fair labor practices and environmental regulations. Certifications such as FSC (Forest Stewardship Council) for wood products and ISO 14001 for environmental management systems are increasingly sought after. These certifications not only enhance brand reputation but also provide buyers with assurance regarding the sustainability of their purchases.

Illustrative image related to inset cabinet door hinges concealed

Additionally, the market is witnessing a rise in the use of eco-friendly materials, such as recycled metals and sustainable wood options for hinges. This shift is not only driven by regulatory pressures but also by consumer demand for greener products, further influencing B2B sourcing strategies.

What is the Historical Context Behind the Evolution of Inset Cabinet Door Hinges Concealed?

The evolution of inset cabinet door hinges concealed dates back to the late 20th century when furniture design began to prioritize minimalism and clean lines. Initially, visible hinges were standard; however, as aesthetic preferences shifted, the need for concealed options became evident. Manufacturers responded by developing hinges that could be hidden within the cabinet frame, allowing for a more streamlined appearance.

Over the years, advancements in manufacturing technology have improved the functionality and durability of these hinges, leading to the introduction of features such as soft-close mechanisms and adjustable settings. Today, inset cabinet door hinges concealed are not only a design choice but also a critical component in enhancing the overall user experience in both residential and commercial applications. This evolution reflects broader trends in furniture design and consumer preferences, emphasizing the importance of both form and function in hardware solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of inset cabinet door hinges concealed

-

How do I choose the right concealed inset cabinet door hinges for my project?

Selecting the appropriate concealed inset cabinet door hinges involves assessing the specific requirements of your cabinetry. Consider factors such as the cabinet style, door weight, and desired functionality (e.g., soft-close features). It’s essential to measure the overlay and inset dimensions accurately. Engaging with a reliable supplier who can provide product samples and technical support can greatly assist in making an informed decision. -

What are the advantages of using concealed hinges in cabinet design?

Concealed hinges offer a sleek, modern aesthetic by keeping the hinge mechanism hidden when the cabinet door is closed. They provide smooth operation and can enhance the overall durability of the cabinetry. Additionally, many concealed hinges come with features like soft-close mechanisms, preventing slamming and ensuring quieter operation, which is especially valuable in residential and commercial environments. -

What is the minimum order quantity (MOQ) for concealed cabinet door hinges?

MOQs for concealed cabinet door hinges can vary widely among suppliers, typically ranging from 100 to 1,000 units. When negotiating with potential suppliers, clarify the MOQ to ensure it aligns with your project needs. Some suppliers may offer flexibility for larger orders or long-term partnerships, which can be advantageous for ongoing projects. -

How do I verify the quality of concealed cabinet door hinges from suppliers?

To ensure quality, request samples before placing bulk orders. Look for certifications that indicate compliance with international standards, such as ISO or CE markings. Additionally, check customer reviews and case studies to assess the supplier’s reputation. Establishing a clear quality assurance process, including inspection protocols upon receipt, will further safeguard your investment. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary significantly based on the supplier’s location and your negotiation skills. Common arrangements include a deposit (typically 30-50%) upfront, with the balance due upon delivery or prior to shipping. Some suppliers may offer letters of credit or escrow services for added security. Always confirm the payment methods accepted, including bank transfers, credit cards, or other digital payment platforms. -

What logistics considerations should I keep in mind when importing hinges?

When importing concealed cabinet door hinges, consider shipping costs, customs duties, and lead times. It’s vital to work with logistics partners experienced in international trade who can help navigate customs regulations. Ensure that the supplier provides the necessary documentation, such as invoices and packing lists, to facilitate a smooth customs clearance process. Additionally, consider insurance options to protect against potential damage during transit. -

Can I customize the hinges to fit my specific design requirements?

Many suppliers offer customization options for concealed cabinet door hinges, including variations in size, finish, and special features like soft-close mechanisms. Discuss your specific needs with potential suppliers to determine their capabilities. Customization may affect lead times and pricing, so be sure to request detailed quotes and timelines for any bespoke orders. -

What should I do if I encounter issues with the hinges after purchase?

If you experience issues with concealed cabinet door hinges after purchase, first contact the supplier to report the problem. A reputable supplier will typically have a return policy or warranty that covers defective products. Document the issue with photos and provide detailed descriptions when communicating with the supplier. This proactive approach can facilitate quicker resolutions, whether through replacements, repairs, or refunds.

Top 5 Inset Cabinet Door Hinges Concealed Manufacturers & Suppliers List

1. HingeOutlet – Full Inset Cabinet Hinges

Domain: hingeoutlet.com

Registered: 2004 (21 years)

Introduction: Full Inset Cabinet Hinges available at HingeOutlet. Free shipping on orders over $160. Wide variety of cabinet hinges for residential and commercial applications including concealed, demountable, European, frameless, overlay, self-closing, soft close, and more. Expert support available at 888-250-8133. Additional resources include guides for cabinet hinge installation and selection.

2. The Knob Shop – Inset Cabinet Hinges

Domain: theknobshop.net

Registered: 2014 (11 years)

Introduction: Inset Cabinet Hinges available at The Knob Shop. Commonly referred to as offset cabinet hinges, these hinges sit inside the frame while the cabinet door offsets the frame. Assistance is available for identifying the correct hinge.

3. WoodWeb – Inset Door Hinges

Domain: woodweb.com

Registered: 1995 (30 years)

Introduction: Inset door hinge that allows a 7/8″ thick inset door to open completely clear of the door opening. Options discussed include Blum’s 155° no protrusion hinge, 175 degree euro hinge, and the straight arm 71B9550 euro hinge with the 173H7100 zero plate in a reverse configuration. Alternative hinges mentioned are Sugatsune mortised adjustable concealed hinges like the HES3D-70DC.

4. Grass – Inset Hinges for Thick Doors

Domain: finewoodworking.com

Introduction: Grass inset hinge for thick doors, suitable for 3/4″ thick doors, may only handle 1″ thick doors with wider gaps; Soss heavy-duty concealed hinges; Grass 3303 VZ & G3/RZ 4.3 mounts for blind panel hinges, suitable for doors less than 3/4″ thick.

5. Woodworker Express – Semi-Concealed Hinges

Domain: woodworkerexpress.com

Registered: 2013 (12 years)

Introduction: This company, Woodworker Express – Semi-Concealed Hinges, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for inset cabinet door hinges concealed

In the ever-evolving landscape of cabinetry hardware, the strategic sourcing of concealed inset cabinet door hinges emerges as a pivotal consideration for international B2B buyers. Understanding the diverse range of hinge types, features, and finishes available is essential for making informed procurement decisions that align with market demands and consumer preferences. Emphasizing quality and reliability not only enhances product performance but also strengthens brand reputation in competitive markets across Africa, South America, the Middle East, and Europe.

As buyers increasingly prioritize sustainability and cost-effectiveness, establishing strong relationships with suppliers who offer innovative solutions and responsive service is crucial. Leveraging technology to streamline sourcing processes can yield significant benefits, including reduced lead times and improved inventory management.

Looking ahead, the market for concealed hinges is poised for growth, driven by trends in minimalist design and custom cabinetry. International buyers should stay abreast of emerging technologies and evolving consumer expectations to capitalize on these opportunities. Engaging with trusted suppliers and exploring new product lines will be instrumental in positioning businesses for success in this dynamic industry. Embrace the future of cabinetry hardware by making strategic sourcing a cornerstone of your operational strategy.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.