Hydraulic Pump Parts Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for hydraulic pump parts

In the competitive landscape of global manufacturing, sourcing high-quality hydraulic pump parts is a critical challenge for B2B buyers. As industries across Africa, South America, the Middle East, and Europe increasingly rely on hydraulic systems for their operations, the demand for reliable and efficient hydraulic pump components has surged. This guide serves as a comprehensive resource, addressing various aspects of hydraulic pump parts, including types, applications, supplier vetting processes, and cost considerations.

By navigating the intricacies of this market, international buyers can enhance their procurement strategies and ensure they select the right components for their specific needs. From understanding the differences between piston pumps and gear pumps to evaluating the benefits of OEM versus aftermarket parts, this guide provides actionable insights that empower informed purchasing decisions.

Moreover, as the market evolves, being equipped with knowledge about current trends and best practices in sourcing can significantly impact operational efficiency and cost-effectiveness. Whether you are based in bustling cities like Ho Chi Minh or Riyadh, this guide aims to streamline your sourcing process, ensuring that you not only find the right parts but also establish strong partnerships with reputable suppliers. In an era where every decision counts, let this guide be your trusted companion in the journey of sourcing hydraulic pump parts effectively.

Understanding hydraulic pump parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gear Pumps | Simple design, high efficiency, low cost | Construction, agriculture, manufacturing | Pros: Durable, low maintenance; Cons: Limited flow rate compared to others. |

| Vane Pumps | Adjustable displacement, compact design | Mobile machinery, automotive, industrial | Pros: Versatile, quiet operation; Cons: Sensitive to fluid contamination. |

| Piston Pumps | High pressure capability, variable displacement | Oil & gas, mining, heavy machinery | Pros: High efficiency, suitable for high-pressure systems; Cons: More complex, higher cost. |

| Screw Pumps | Continuous flow, low pulsation | Marine, chemical processing, food industry | Pros: Smooth operation, self-priming; Cons: Higher initial cost, specific fluid compatibility needed. |

| Hydraulic Motors | Converts hydraulic energy to mechanical energy | Automotive, robotics, construction equipment | Pros: High torque, efficient; Cons: Requires precise control systems. |

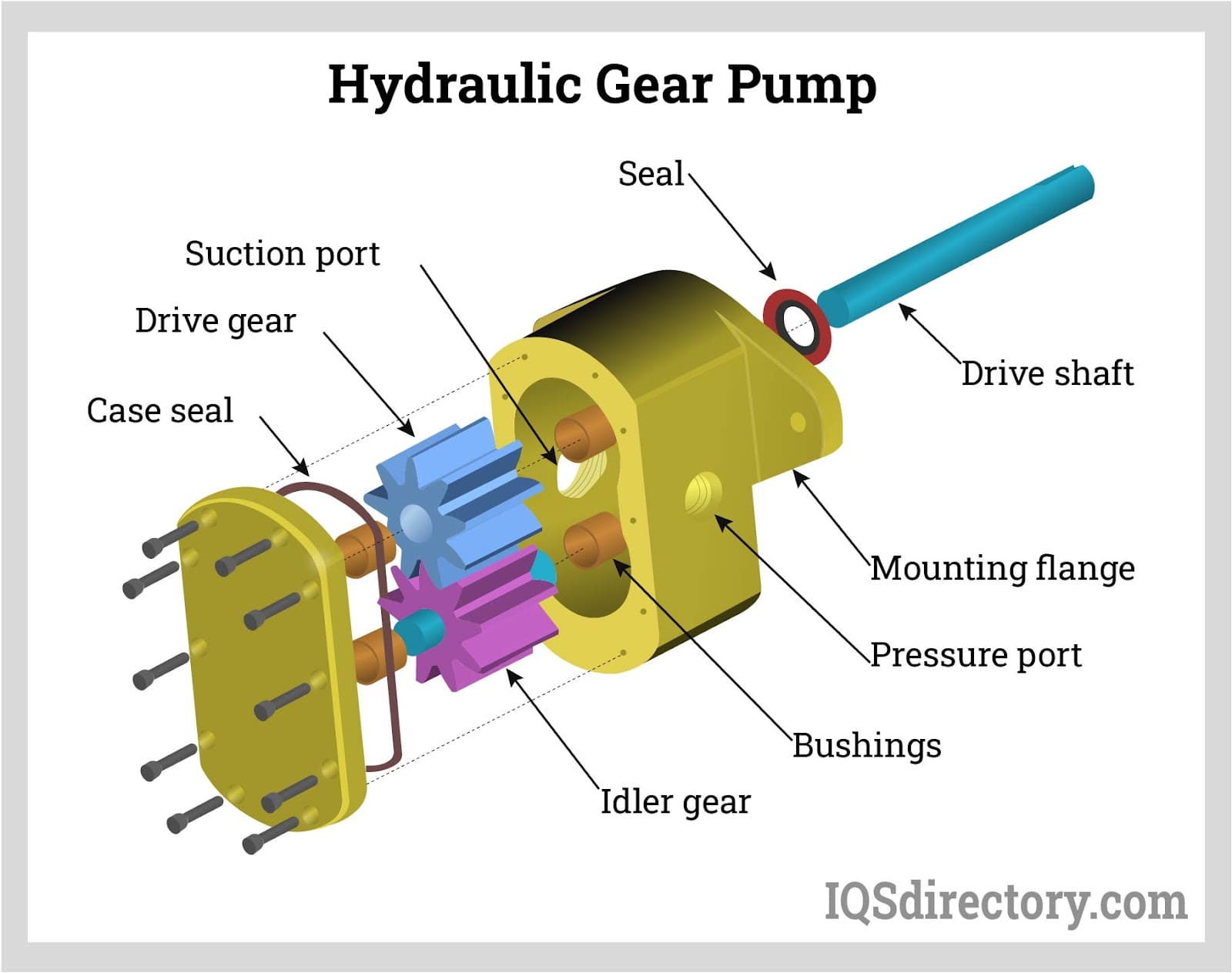

What Are Gear Pumps and Their B2B Relevance?

Gear pumps are characterized by their straightforward construction, typically comprising two or more gears that create a pumping action. They are favored in industries like construction and agriculture due to their reliability and low maintenance requirements. When considering a gear pump, B2B buyers should assess the required flow rate and pressure, as these pumps may not be suitable for high-flow applications.

How Do Vane Pumps Stand Out for B2B Buyers?

Vane pumps utilize a rotating mechanism with adjustable vanes to manage fluid displacement, making them compact and efficient. Their versatility allows them to cater to various applications, particularly in mobile machinery and automotive sectors. Buyers should consider the potential for fluid contamination, as vane pumps can be sensitive to impurities, which may affect their operational lifespan.

What Makes Piston Pumps Ideal for High-Pressure Applications?

Piston pumps are known for their ability to handle high pressures, making them essential in oil and gas extraction, mining, and heavy machinery operations. Their variable displacement feature allows for greater efficiency. However, B2B buyers must weigh the complexity and cost of these pumps against their performance needs, especially in demanding environments.

Why Choose Screw Pumps for Specific Industries?

Screw pumps are designed for continuous flow with minimal pulsation, making them suitable for applications in marine, chemical processing, and food industries. Their self-priming ability is a significant advantage, but buyers should be aware of the higher initial costs and ensure compatibility with the fluids they intend to pump.

How Do Hydraulic Motors Function in Industrial Applications?

Hydraulic motors convert hydraulic energy into mechanical energy, providing high torque, particularly in automotive and robotics applications. They are efficient and can be integrated into various control systems. B2B buyers should consider the complexity of control systems required for these motors, as precise control is crucial for optimal performance.

Key Industrial Applications of hydraulic pump parts

| Industry/Sector | Specific Application of Hydraulic Pump Parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Excavators and Loaders | Enhanced operational efficiency and productivity | Ensure compatibility with existing machinery and OEM standards. |

| Agriculture | Tractors and Harvesters | Increased reliability and reduced downtime | Look for durable parts that can withstand harsh environments. |

| Manufacturing | CNC Machines and Automation Systems | Improved precision and reduced operational costs | Source parts that meet stringent quality and safety standards. |

| Oil & Gas | Drilling Rigs and Hydraulic Fracturing | Maximized extraction efficiency and safety | Verify certifications and compliance with industry regulations. |

| Mining | Haul Trucks and Conveyors | Enhanced performance and reduced maintenance costs | Consider local sourcing for quicker delivery and support. |

How Are Hydraulic Pump Parts Used in Key Industries?

In the construction industry, hydraulic pump parts are integral to the operation of excavators and loaders, enabling powerful lifting and digging capabilities. These components ensure that machinery operates efficiently under heavy loads, thereby enhancing productivity on job sites. For international buyers, sourcing parts that comply with OEM specifications is crucial to maintain machinery integrity and performance.

In agriculture, hydraulic pump parts are vital for tractors and harvesters, providing the necessary power for various farming operations such as plowing, planting, and harvesting. The reliability of these parts directly impacts operational uptime, which is critical during planting and harvest seasons. Buyers must consider the durability of components, as agricultural machinery often operates in rugged conditions.

The manufacturing sector utilizes hydraulic pump parts in CNC machines and automation systems to improve precision in cutting and shaping materials. The efficiency of these machines can significantly affect production costs. B2B buyers should prioritize sourcing high-quality parts that adhere to strict quality and safety standards to ensure smooth operations and minimize downtime.

In the oil and gas industry, hydraulic pump parts are essential for drilling rigs and hydraulic fracturing operations. These components facilitate the extraction of resources by managing high-pressure systems safely and efficiently. Buyers in this sector must verify that parts meet industry regulations and certifications to ensure safety and compliance during operations.

The mining industry relies on hydraulic pump parts for haul trucks and conveyor systems, which are crucial for transporting materials across vast sites. The performance of these hydraulic systems directly influences operational efficiency and maintenance costs. International buyers should consider local sourcing options to reduce lead times and ensure timely support, which is critical in remote mining operations.

3 Common User Pain Points for ‘hydraulic pump parts’ & Their Solutions

Scenario 1: Sourcing Compatible Hydraulic Pump Parts for Diverse Applications

The Problem: B2B buyers often face difficulties in sourcing hydraulic pump parts that are compatible with a wide range of machinery and systems. This challenge is particularly acute in international markets where different manufacturers may use unique specifications. Buyers can struggle with mismatched parts, leading to operational downtime and increased repair costs. The lack of clear compatibility information can make it daunting to make informed purchasing decisions.

The Solution: To navigate this challenge, B2B buyers should implement a systematic approach to sourcing hydraulic pump parts. Start by compiling a comprehensive list of the machinery and equipment in use, along with their specific requirements. Engage with suppliers who offer detailed catalogs and specification sheets, ensuring they provide information on compatibility and application. It is also beneficial to establish relationships with multiple suppliers who specialize in various brands and parts. Utilizing online databases and resources that list cross-referenced parts can further assist in identifying compatible components. Additionally, consider investing in training for procurement teams to enhance their understanding of hydraulic systems, which will facilitate better decision-making.

Scenario 2: Managing Lead Times and Delivery Delays in Parts Procurement

The Problem: International buyers frequently experience lead times and delivery delays when procuring hydraulic pump parts, which can significantly disrupt operations. These delays may arise from supply chain bottlenecks, customs regulations, or inadequate inventory management practices among suppliers. Such interruptions can lead to extended downtimes and financial losses, especially in critical industries like construction and manufacturing.

Illustrative image related to hydraulic pump parts

The Solution: To mitigate lead time issues, B2B buyers should adopt a proactive procurement strategy. Establishing long-term contracts with suppliers who demonstrate reliability in timely deliveries can create a buffer against unexpected delays. Additionally, consider using suppliers who offer real-time tracking and updates on order status, which can help manage expectations and plan accordingly. Implementing an inventory management system that forecasts demand and maintains optimal stock levels can also reduce reliance on last-minute orders. For urgent needs, explore local distributors or service centers that can provide expedited shipping options. Building a network of alternative suppliers can serve as a contingency plan in case of unforeseen delays, ensuring that operations remain uninterrupted.

Scenario 3: Ensuring Quality and Performance of Hydraulic Pump Parts

The Problem: Buyers often grapple with the challenge of ensuring that the hydraulic pump parts they purchase meet quality standards and performance expectations. With numerous aftermarket options available, distinguishing between high-quality parts and subpar alternatives can be difficult. Poor-quality components can lead to equipment failures, safety hazards, and costly repairs, compromising overall operational efficiency.

The Solution: To ensure quality and performance, B2B buyers should prioritize sourcing hydraulic pump parts from reputable suppliers who provide guarantees and warranties. Request certifications that verify compliance with industry standards, such as ISO or OEM specifications. It’s also wise to conduct thorough research on suppliers, including reading reviews and case studies from other businesses that have sourced from them. Establishing a robust quality control process for incoming parts can further safeguard against low-quality components. This may involve performing regular inspections and tests on new parts to ensure they function as intended. Additionally, maintaining open lines of communication with suppliers can help address any quality concerns promptly, leading to better overall outcomes in performance and reliability.

Strategic Material Selection Guide for hydraulic pump parts

What Are the Key Materials Used in Hydraulic Pump Parts?

When selecting materials for hydraulic pump parts, it’s essential to consider properties such as durability, corrosion resistance, and compatibility with specific media. Here, we analyze four common materials used in hydraulic pump parts: cast iron, aluminum, stainless steel, and composite materials.

How Does Cast Iron Perform in Hydraulic Pump Applications?

Cast iron is widely used in hydraulic pump components due to its excellent wear resistance and ability to withstand high pressures. It typically has a temperature rating of up to 300°F (150°C) and can handle substantial mechanical stress.

Pros: Cast iron is cost-effective and offers good machinability, making it suitable for mass production. Its durability ensures a long service life, reducing replacement frequency.

Cons: However, cast iron is prone to corrosion, particularly in humid environments, and can be brittle under extreme conditions. This limits its use in applications involving aggressive fluids.

Impact on Application: Cast iron is ideal for hydraulic systems that operate with non-corrosive fluids, but buyers in regions with high humidity or corrosive environments should consider protective coatings or alternative materials.

What Are the Advantages of Aluminum in Hydraulic Pump Parts?

Aluminum is increasingly favored for hydraulic pump parts due to its lightweight nature and excellent corrosion resistance. It can withstand temperatures up to 400°F (204°C) and offers good pressure ratings.

Pros: The lightweight property of aluminum enhances the efficiency of hydraulic systems, leading to reduced energy consumption. Additionally, it is highly resistant to corrosion, making it suitable for diverse environments.

Illustrative image related to hydraulic pump parts

Cons: The main drawback is its lower strength compared to cast iron and stainless steel, which may limit its use in high-stress applications. Aluminum can also be more expensive to manufacture due to the complexities involved in machining.

Impact on Application: Aluminum is particularly suitable for hydraulic systems in marine or coastal environments where corrosion resistance is paramount. Buyers should ensure compliance with relevant standards, such as ASTM B221 for aluminum alloys.

How Does Stainless Steel Compare in Hydraulic Pump Applications?

Stainless steel is renowned for its exceptional corrosion resistance and strength, making it a preferred choice for hydraulic pump parts exposed to harsh environments. It can handle temperatures up to 800°F (427°C) and high-pressure applications.

Pros: Its durability and resistance to oxidation extend the lifespan of hydraulic components, making it a reliable choice for critical applications. Stainless steel also meets various international standards, ensuring compatibility across different markets.

Illustrative image related to hydraulic pump parts

Cons: The primary disadvantage is its higher cost compared to cast iron and aluminum. Additionally, machining stainless steel can be more challenging, leading to increased manufacturing complexity.

Impact on Application: Stainless steel is ideal for hydraulic systems in industries such as oil and gas, where exposure to corrosive substances is common. Buyers should verify compliance with standards like ASTM A276 for stainless steel grades.

What Role Do Composite Materials Play in Hydraulic Pump Parts?

Composite materials, often a blend of polymers and fibers, are gaining traction in hydraulic pump applications due to their lightweight and customizable properties. They can be engineered to withstand specific pressures and temperatures depending on the formulation.

Illustrative image related to hydraulic pump parts

Pros: Composites offer excellent corrosion resistance and can be tailored for specific applications, providing versatility. They are also lightweight, which can enhance overall system efficiency.

Cons: However, composites may not match the strength of metals, limiting their use in high-stress applications. They can also be more expensive to produce and may require specialized manufacturing processes.

Impact on Application: Composites are suitable for hydraulic systems in industries where weight reduction is critical, such as aerospace and automotive. International buyers should consider certifications that ensure quality and performance, such as ISO 9001.

Summary of Material Selection for Hydraulic Pump Parts

| Material | Typical Use Case for Hydraulic Pump Parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | General hydraulic components | Cost-effective and durable | Prone to corrosion and brittleness | Low |

| Aluminum | Lightweight hydraulic systems | Excellent corrosion resistance | Lower strength than metals | Medium |

| Stainless Steel | High-stress, corrosive environments | Exceptional durability and strength | Higher manufacturing complexity | High |

| Composite | Specialized applications (e.g., aerospace) | Lightweight and customizable | May lack strength in high-stress | Medium to High |

This guide provides a comprehensive overview of material selection for hydraulic pump parts, aiding international B2B buyers in making informed decisions tailored to their specific needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for hydraulic pump parts

What Are the Main Stages of Manufacturing Hydraulic Pump Parts?

The manufacturing process for hydraulic pump parts is intricate and involves several key stages that ensure the final product meets the necessary performance and reliability standards. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

-

Material Preparation: The manufacturing process begins with the careful selection of raw materials, which typically include various metals such as steel, aluminum, and specialized alloys. Suppliers often conduct a thorough analysis of the material properties, such as tensile strength and corrosion resistance, to ensure they meet specifications. This stage may involve cutting materials to size and removing any impurities to prepare for forming.

-

Forming Techniques: Once materials are prepared, forming techniques such as casting, forging, or machining are employed to create the desired shapes of pump components. For instance, casting is commonly used for producing complex geometries like pump housings, while machining is utilized for precision parts such as shafts and gears. Advanced technologies, including CNC (Computer Numerical Control) machining, are often employed to enhance accuracy and repeatability.

-

Assembly Processes: After forming, the components undergo assembly, which may involve fitting various parts together, such as seals, pistons, and valves. This step is crucial, as proper alignment and assembly are vital for the operational efficiency of hydraulic pumps. Skilled technicians often oversee this process to ensure that tolerances are met and that any necessary adjustments are made.

-

Finishing Operations: The final stage in the manufacturing process involves finishing operations, which may include surface treatments, painting, or plating to enhance durability and corrosion resistance. These treatments not only improve the aesthetic quality of the parts but also increase their lifespan in harsh operating conditions.

How Is Quality Assurance Implemented in Hydraulic Pump Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process for hydraulic pump parts, ensuring that products meet both international standards and specific customer requirements. B2B buyers should be familiar with the various QA processes and standards to assess supplier capabilities effectively.

-

International Standards and Certifications: Many manufacturers comply with international quality management standards such as ISO 9001, which provides a framework for consistent quality in production and service. In addition, industry-specific certifications like CE marking for European markets and API (American Petroleum Institute) standards for oil and gas applications are crucial for ensuring that products are safe and reliable.

-

Quality Control Checkpoints: The quality assurance process typically involves several checkpoints:

– Incoming Quality Control (IQC): This initial phase assesses the quality of raw materials before they enter the manufacturing process. Inspections may include material certifications and physical testing to confirm compliance with specifications.

– In-Process Quality Control (IPQC): During production, IPQC is implemented to monitor the manufacturing process in real-time. This may include dimensional checks and process audits to ensure that manufacturing parameters are being followed.

– Final Quality Control (FQC): Once assembly is completed, FQC involves a comprehensive inspection of the finished products. This may include functional testing, performance evaluations, and visual inspections to detect any defects. -

Common Testing Methods for Hydraulic Pump Parts: Various testing methods are employed to ensure the integrity and performance of hydraulic pump parts. These methods may include:

– Pressure Testing: To ensure that components can withstand operational pressures without leaking.

– Flow Testing: To verify that pumps operate at the specified flow rates.

– Fatigue Testing: To assess the durability of components under cyclic loading conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to mitigate risks associated with product quality and compliance. Here are several strategies to ensure that suppliers meet quality standards.

-

Supplier Audits: Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality control systems. This can include reviewing their quality manuals, process documentation, and records of previous inspections and tests.

-

Requesting Quality Reports: B2B buyers should request detailed quality reports from suppliers, including data on previous testing outcomes, non-conformance reports, and corrective action plans. This information can provide assurance that the supplier is proactive in maintaining quality standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control processes. These organizations can conduct inspections and tests on behalf of the buyer, ensuring that the products meet specified standards before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must be aware of specific quality control nuances that may affect their procurement strategies.

-

Cultural and Regional Differences: Quality expectations can vary significantly across regions. Buyers should be cognizant of these differences and communicate their quality requirements clearly to avoid misunderstandings.

-

Regulatory Compliance: Different countries may have unique regulations regarding hydraulic pump parts, especially in safety-critical industries such as oil and gas. Buyers should ensure that suppliers are compliant with local regulations to avoid legal issues.

-

Supply Chain Considerations: The complexity of international logistics can introduce risks related to product quality. B2B buyers should consider how transportation and handling might affect the quality of hydraulic pump parts during shipping.

In summary, understanding the manufacturing processes and quality assurance measures for hydraulic pump parts is critical for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring that they source high-quality components that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hydraulic pump parts’

Introduction

In the competitive landscape of hydraulic pump parts procurement, making informed decisions is crucial for B2B buyers. This checklist serves as a practical guide to streamline your sourcing process, ensuring you select the right components from reliable suppliers while adhering to your operational requirements. By following these steps, you can minimize risks, enhance efficiency, and secure quality parts that meet your specifications.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for the hydraulic pump parts you need. This includes specifications such as dimensions, materials, pressure ratings, and compatibility with existing equipment. A detailed specification will not only help you communicate your needs effectively to suppliers but also ensure that the parts you procure will function optimally within your systems.

- Considerations: Identify any unique features or requirements specific to your application, such as environmental conditions or operational loads.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in hydraulic pump parts. Look for manufacturers and distributors with a solid reputation in the industry, particularly those with experience in your geographical region.

Illustrative image related to hydraulic pump parts

- Key Actions: Review online platforms, industry forums, and trade directories to compile a list of candidates. Focus on suppliers who have a track record of serving businesses similar to yours.

Step 3: Evaluate Supplier Certifications

Before moving forward with any supplier, verify their certifications and compliance with industry standards. Certifications such as ISO 9001 can indicate a commitment to quality management systems, which is essential in the hydraulic parts industry.

- Why It Matters: Certified suppliers are more likely to adhere to quality standards and deliver reliable products, reducing the risk of operational failures.

Step 4: Request Samples or Prototype Parts

Once you have shortlisted suppliers, request samples or prototype parts to evaluate their quality. This step allows you to assess the craftsmanship, material durability, and overall performance of the parts before making a bulk order.

- What to Look For: Ensure that the samples meet your specifications and consider conducting tests to verify performance under operational conditions.

Step 5: Negotiate Pricing and Terms

Engage in discussions with potential suppliers to negotiate pricing, payment terms, and delivery schedules. Be clear about your budget constraints and timelines, as this can help in securing better deals.

- Considerations: Inquire about bulk order discounts, warranty terms, and return policies to ensure you are protected in case of discrepancies.

Step 6: Assess After-Sales Support and Services

Evaluate the after-sales support offered by suppliers, including warranty terms, repair services, and customer support availability. Reliable after-sales service can save you time and money in the long run.

- Importance: A supplier that offers robust support will help you address any issues quickly, ensuring minimal downtime in your operations.

Step 7: Finalize Your Order and Establish a Relationship

After selecting a supplier, finalize your order and establish a long-term relationship. Consider setting up regular communication to keep abreast of new products and services that may benefit your operations.

Illustrative image related to hydraulic pump parts

- Benefits: A strong supplier relationship can lead to better pricing, priority service, and tailored solutions that align with your evolving needs.

By following this checklist, B2B buyers can enhance their sourcing strategy for hydraulic pump parts, ensuring quality, reliability, and operational efficiency in their procurement processes.

Comprehensive Cost and Pricing Analysis for hydraulic pump parts Sourcing

What Are the Key Cost Components in Hydraulic Pump Parts Sourcing?

When sourcing hydraulic pump parts, understanding the cost structure is crucial for effective budgeting and procurement strategies. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality metals such as steel or aluminum, as well as specialized composites for seals and gaskets, can drive up expenses. Additionally, sourcing materials from different regions may influence prices due to local availability and market demand.

-

Labor: Labor costs encompass the wages paid to workers involved in manufacturing, assembly, and quality control. Regions with higher labor costs, such as parts of Europe, may see increased prices compared to countries in Africa or South America where labor might be more affordable.

-

Manufacturing Overhead: This includes indirect costs such as utilities, facility maintenance, and administrative expenses that are allocated to the production of hydraulic parts. Efficient manufacturing processes can reduce overhead costs, allowing for more competitive pricing.

-

Tooling: Tooling costs are associated with the creation of molds and dies necessary for the production of specific parts. Custom tooling can be expensive, but is essential for high-volume production runs of specialized components.

-

Quality Control (QC): Ensuring that each part meets industry standards requires investment in quality assurance processes. This may include testing, inspections, and certifications, which can add to the overall cost but are critical for reliability and compliance.

-

Logistics: Transportation costs, including shipping and handling, play a significant role in the final price. International shipping can incur additional fees, particularly if using expedited services or dealing with customs.

-

Margin: Suppliers typically add a margin to cover their operational costs and generate profit. This margin can vary widely depending on the supplier’s market position, the competitiveness of their offerings, and their relationship with buyers.

How Do Price Influencers Affect Hydraulic Pump Parts Costs?

Several factors can influence the pricing of hydraulic pump parts, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for volume discounts. Establishing long-term contracts or consistently high order volumes can lead to better pricing arrangements.

-

Specifications and Customization: Custom parts designed to meet specific requirements will typically cost more than standard components. Suppliers may charge additional fees for modifications or unique designs.

-

Materials and Quality Certifications: Parts made from higher-grade materials or those that have undergone rigorous testing and certification processes (e.g., ISO, CE) will command a premium price. Buyers should weigh the benefits of quality against the potential cost savings of lower-grade options.

-

Supplier Factors: The reputation, reliability, and location of the supplier can significantly impact pricing. Established suppliers with a history of quality and service may charge higher prices but offer better assurance of performance.

-

Incoterms: The agreed-upon shipping terms (such as FOB, CIF) can influence the total landed cost of parts. Understanding these terms is vital for international buyers to avoid unexpected charges.

What Buyer Tips Can Help Optimize Costs and Pricing for Hydraulic Pump Parts?

To navigate the complexities of sourcing hydraulic pump parts effectively, buyers should consider the following tips:

-

Negotiation: Don’t hesitate to negotiate prices with suppliers. Building a relationship can lead to better terms and discounts over time. Transparency about your purchasing needs can also foster goodwill.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO), which includes not only the purchase price but also maintenance, operational, and disposal costs. Opt for suppliers who provide comprehensive support and warranties.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and taxes that can affect pricing when sourcing from different regions. Understanding local market conditions can also provide leverage in negotiations.

-

Research and Compare: Conduct thorough market research to compare pricing from multiple suppliers. Utilize platforms that provide insights into industry standards and average pricing to ensure you’re getting a fair deal.

By understanding these cost components and price influencers, international B2B buyers can make informed decisions that enhance their procurement strategies for hydraulic pump parts, ultimately leading to better performance and cost savings in their operations.

Alternatives Analysis: Comparing hydraulic pump parts With Other Solutions

Understanding Alternatives to Hydraulic Pump Parts

In the realm of industrial machinery, hydraulic pump parts are critical for ensuring operational efficiency and reliability. However, businesses often seek alternative solutions that can either complement or replace traditional hydraulic systems. By comparing hydraulic pump parts with other viable options, B2B buyers can make informed decisions that align with their operational needs and budget constraints.

Comparison of Hydraulic Pump Parts and Alternative Solutions

| Comparison Aspect | Hydraulic Pump Parts | Electric Motor Systems | Pneumatic Systems |

|---|---|---|---|

| Performance | High power density, ideal for heavy-duty applications | Excellent for precise control and speed variations | Suitable for applications requiring quick action and high speed |

| Cost | Moderate initial cost, but higher maintenance expenses | Higher upfront costs, lower operational costs | Generally lower initial cost but may incur high energy costs |

| Ease of Implementation | Requires specialized knowledge for installation | Can be complex depending on application | Easy to implement, often with off-the-shelf components |

| Maintenance | Regular maintenance needed to prevent leaks and wear | Minimal maintenance, primarily electrical checks | Regular maintenance needed, but simpler than hydraulic systems |

| Best Use Case | Heavy machinery, construction, and industrial applications | Robotics, conveyor systems, and applications requiring precision | Packaging, automotive assembly, and applications needing rapid actuation |

Analyzing Electric Motor Systems as an Alternative

Electric motor systems are increasingly popular in industrial applications due to their precise control capabilities and lower maintenance requirements. They excel in environments where speed variation and accuracy are paramount, such as in robotics and conveyor systems. However, the initial investment can be substantial, and they may not provide the same power density as hydraulic systems. Additionally, electric motors are less effective in high-load scenarios compared to hydraulic pumps, making them less ideal for heavy machinery.

Evaluating Pneumatic Systems for Specific Applications

Pneumatic systems utilize compressed air to generate movement and are known for their quick action and responsiveness. They are particularly advantageous in applications that require rapid actuation, such as packaging and assembly lines. The initial setup costs are typically lower than hydraulic systems, and they are easier to implement. However, pneumatic systems can incur higher operational costs due to energy consumption, and they may lack the power and efficiency of hydraulic systems in heavy-duty applications.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between hydraulic pump parts and alternative solutions like electric motors or pneumatic systems, B2B buyers must consider their specific operational requirements, budget constraints, and maintenance capabilities. Hydraulic systems are well-suited for high-load applications, while electric motors offer precision and lower long-term costs. Pneumatic systems provide quick response times and ease of implementation, making them ideal for certain automated processes. Ultimately, the decision should be guided by a thorough assessment of the business’s unique needs, ensuring optimal performance and cost-effectiveness in the long run.

Essential Technical Properties and Trade Terminology for hydraulic pump parts

Understanding the technical properties and trade terminology associated with hydraulic pump parts is essential for B2B buyers looking to make informed purchasing decisions. This guide provides a clear overview of critical specifications and common industry jargon that can impact procurement, operational efficiency, and cost management.

What Are the Key Technical Properties of Hydraulic Pump Parts?

1. Material Grade

The material grade of hydraulic pump components, such as aluminum, steel, or composite materials, significantly influences durability and performance. High-grade materials resist corrosion and wear, leading to longer service life and lower replacement costs. For B2B buyers, selecting the appropriate material can ensure compatibility with specific applications and environmental conditions.

2. Tolerance

Tolerance refers to the allowable variation in dimensions and shapes of hydraulic pump parts. Tight tolerances are critical in ensuring proper assembly and function, particularly in high-pressure systems. Understanding tolerance levels helps buyers assess the quality and precision of components, which is vital for maintaining operational efficiency and preventing costly downtime.

3. Pressure Rating

The pressure rating indicates the maximum pressure a hydraulic pump component can withstand during operation. This specification is crucial for ensuring safety and reliability in hydraulic systems. Buyers must match the pressure rating with their system requirements to avoid failures, which can lead to significant operational disruptions and financial losses.

4. Flow Rate

Flow rate measures the volume of fluid that passes through a hydraulic pump in a given time, typically expressed in liters per minute (LPM) or gallons per minute (GPM). It directly impacts the efficiency of hydraulic systems. For B2B buyers, understanding flow rates helps in selecting the right pump size and type to meet their operational demands without incurring unnecessary energy costs.

5. Efficiency Rating

Efficiency ratings describe how effectively a hydraulic pump converts input power into hydraulic energy. Higher efficiency translates into lower energy consumption and reduced operational costs. B2B buyers should prioritize pumps with high efficiency ratings to maximize productivity and minimize expenses over the product’s lifecycle.

What Are Common Trade Terms Used in Hydraulic Pump Parts?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that may be marketed by another manufacturer. Understanding the distinction between OEM and aftermarket parts is crucial for buyers looking for quality and compatibility. OEM parts generally offer higher reliability and performance, making them a preferred choice for many businesses.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier requires a buyer to purchase in a single order. This term is vital for budgeting and inventory management. Buyers should negotiate MOQs that align with their operational needs to avoid excess inventory and associated carrying costs.

3. RFQ (Request for Quotation)

An RFQ is a formal document issued by a buyer to solicit price quotes from suppliers. It typically outlines specifications, quantities, and delivery requirements. Understanding how to prepare and respond to RFQs can streamline the procurement process and facilitate better pricing negotiations.

Illustrative image related to hydraulic pump parts

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms is essential for B2B transactions, especially in international trade, as they clarify shipping costs, risks, and responsibilities.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is crucial for effective project planning and inventory management. Buyers should consider lead times when sourcing hydraulic pump parts to ensure timely delivery and avoid operational delays.

In summary, a solid grasp of technical specifications and trade terminology related to hydraulic pump parts equips B2B buyers with the knowledge necessary to make informed purchasing decisions, ultimately leading to enhanced operational efficiency and cost savings.

Navigating Market Dynamics and Sourcing Trends in the hydraulic pump parts Sector

What Are the Current Market Trends Affecting Hydraulic Pump Parts Procurement?

The hydraulic pump parts market is experiencing significant transformation driven by several global factors. The rise in industrial automation, particularly in sectors such as construction, agriculture, and manufacturing, is propelling the demand for hydraulic systems. As industries seek to enhance efficiency and reduce operational costs, the need for reliable and durable hydraulic pump parts has surged. Additionally, international buyers from regions like Africa, South America, the Middle East, and Europe are increasingly focusing on suppliers that offer quick turnaround times and competitive pricing.

Emerging technologies such as IoT and predictive maintenance are reshaping sourcing strategies. These innovations allow for real-time monitoring of hydraulic systems, enabling companies to anticipate failures before they occur and reduce downtime. Furthermore, e-commerce platforms are facilitating easier access to suppliers across borders, making it simpler for buyers in developing markets to procure high-quality hydraulic pump parts without geographical constraints.

Additionally, the emphasis on customization is growing; buyers are now looking for suppliers who can offer tailored solutions that meet specific operational requirements. This shift towards personalized service is becoming a key differentiator in the competitive landscape of hydraulic pump parts sourcing.

How Is Sustainability Shaping the Sourcing of Hydraulic Pump Parts?

As environmental concerns intensify globally, sustainability has emerged as a pivotal factor in the sourcing of hydraulic pump parts. The hydraulic industry is under pressure to minimize its environmental impact, prompting buyers to prioritize suppliers who demonstrate a commitment to sustainable practices. This includes sourcing materials that are recyclable or derived from renewable resources, as well as adopting manufacturing processes that reduce waste and energy consumption.

Ethical supply chains are also gaining traction. Buyers are increasingly scrutinizing their suppliers to ensure they adhere to labor rights and fair trade practices. Certifications such as ISO 14001, which focuses on effective environmental management systems, are becoming essential in supplier evaluations. Additionally, more companies are seeking partnerships with suppliers who can provide ‘green’ certifications for their hydraulic pump parts, ensuring that their sourcing decisions align with their corporate social responsibility goals.

This shift not only enhances brand reputation but also meets the growing consumer demand for environmentally friendly products. As a result, companies that integrate sustainability into their sourcing strategies will likely gain a competitive edge in the hydraulic pump parts market.

What Is the Historical Context of Hydraulic Pump Parts in the B2B Landscape?

The hydraulic pump parts industry has evolved significantly over the past few decades. Initially, hydraulic systems were primarily used in heavy machinery, but advancements in technology have broadened their application across various sectors, including automotive, aerospace, and even renewable energy. The introduction of automated manufacturing processes in the late 20th century enhanced the precision and quality of hydraulic components, making them more reliable and efficient.

As globalization took hold in the early 21st century, international trade in hydraulic pump parts flourished. This expansion allowed for greater collaboration between manufacturers and buyers across different continents, fostering innovation and competition. The rise of digital platforms for sourcing and procurement has further transformed the landscape, making it easier for B2B buyers to access diverse suppliers and products, ultimately shaping the current dynamics of the hydraulic pump parts market.

In summary, understanding these market trends, sustainability considerations, and historical context is crucial for international B2B buyers looking to navigate the complexities of sourcing hydraulic pump parts effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of hydraulic pump parts

-

How do I select the right hydraulic pump parts for my application?

Choosing the right hydraulic pump parts involves understanding your system’s specifications, including pressure requirements, flow rates, and compatibility with existing components. Begin by reviewing the manufacturer’s guidelines for your hydraulic system. If you’re sourcing parts from international suppliers, ensure they provide detailed specifications and compatibility information. Additionally, consider the material and environmental conditions the parts will be exposed to, as this can affect durability and performance. -

What are the most common types of hydraulic pump parts I should be aware of?

Key hydraulic pump parts include gears, pistons, valves, seals, and filters. Each component plays a crucial role in the pump’s operation, affecting efficiency and reliability. Gears and pistons are essential for generating hydraulic pressure, while valves control flow and direction. Seals prevent leaks, and filters maintain fluid cleanliness. Understanding these components will help you make informed purchasing decisions and ensure system performance. -

What should I consider when vetting international suppliers for hydraulic pump parts?

When vetting suppliers, assess their industry reputation, certifications, and compliance with international quality standards. Request samples and evaluate their product quality and responsiveness. Check for customer testimonials or case studies, and inquire about their supply chain capabilities, including lead times and logistics. Additionally, ensure they offer support in your preferred language and understand the local regulations regarding hydraulic equipment. -

Are there minimum order quantities (MOQs) for hydraulic pump parts when sourcing internationally?

MOQs can vary significantly between suppliers and depend on the type of parts you are ordering. While some suppliers may have low or no MOQs, others, especially for specialized components, might require larger orders to justify production costs. Always clarify MOQs upfront and consider negotiating terms that align with your purchasing strategy, particularly if you are a smaller business or testing new products. -

What payment terms are typically offered by international suppliers of hydraulic pump parts?

Payment terms can vary widely, but common options include advance payment, net 30/60/90 days, and letter of credit. When dealing with international transactions, consider using secure payment methods such as escrow services to protect both parties. Always review the supplier’s payment policies and negotiate terms that are favorable to your cash flow while ensuring you maintain a good relationship with the supplier. -

How do I ensure the quality of hydraulic pump parts when sourcing from abroad?

To ensure quality, request certifications such as ISO 9001 or other relevant industry standards from your suppliers. Consider conducting factory audits or using third-party inspection services to verify product quality before shipment. Additionally, establish a clear quality assurance process, including testing samples upon receipt. Creating a partnership with suppliers who prioritize quality will also enhance your confidence in the parts you receive. -

What logistics considerations should I keep in mind when importing hydraulic pump parts?

Logistics considerations include shipping methods, lead times, customs clearance, and potential tariffs. Choose a reliable freight forwarder experienced in handling hydraulic components to navigate international shipping complexities. Ensure that all documentation is in order to avoid delays at customs. Additionally, factor in delivery times and costs into your overall procurement strategy to maintain project schedules. -

Can I customize hydraulic pump parts to meet specific application requirements?

Many suppliers offer customization options for hydraulic pump parts to meet unique application needs. This can include alterations in size, material, or design features. When considering customization, communicate your specific requirements clearly to the supplier and inquire about the feasibility, cost implications, and lead times for customized parts. Engaging with manufacturers that have design capabilities will help ensure the parts meet your precise specifications.

Top 8 Hydraulic Pump Parts Manufacturers & Suppliers List

1. Surplus Center – Hydraulic Pump Seal Kits

Domain: surpluscenter.com

Registered: 1996 (29 years)

Introduction: Pump Parts & Accessories for Hydraulic Pumps including various seal kits and replacement parts. Key products include: 1. Dynamic Side Port PTO Seal Kit 70722 – $47.40 2. GP-F10 Dynamic Pump Seal Kit 70905 – $34.30 3. GP-F20 Dynamic Pump Seal Kit 70904 + 70305 – $36.50 4. Plastic Seal Pick Tool – $1.95 5. Replacement Parts Kit For Wolverine Hand Pumps – $37.50 6. Seal Kit for Dynamic 22 GPM 2-Stage…

2. HPS – Hydraulic Pumps and Parts

Domain: hydparts.com

Registered: 1998 (27 years)

Introduction: HPS offers remanufactured hydraulic pumps, valves, motors, parts, and repair services. Key product categories include: Directional Valve, Piston Pump, Pressure Control Valve, Vane Motor, Vane Pump, Accessories, Cartridge Valve, Check Valve, Control Panel, Deceleration Valve, Electronics, Filter, Flow Control Valve, Pilot Operated Check Valve, Piston Motor, Power Pack, Servo Proportional Valve, Rel…

3. Load Trail – Hydraulic Products

Domain: loadtrailparts.com

Registered: 2011 (14 years)

Introduction: Hydraulics products include: 1. Starter Solenoid for Dump Pump – MSRP: $41.99 2. O-Ring Kit for Hydraulic Reservoir (Q2-411) – MSRP: $2.10 3. 3 Quart Plastic Reservoir (8181-35) – MSRP: $27.99, dimensions: 7″ wide x 8″ tall, opening dimensions: 4-5/8″, bolt hole center to center: 4″, bolt hole measurements: 1/4″ 4. KTI Hydraulics 2 Button Remote – MSRP: $38.99 5. 10 Volt Coil for Use on Down Valve…

4. Motion – Hydraulic Pump Accessories

Domain: motion.com

Registered: 1994 (31 years)

Introduction: Motion offers a comprehensive range of hydraulic pump accessories and replacement parts. These parts convert mechanical energy into hydraulic energy by drawing fluid from a reservoir and delivering it under pressure to power various actuators and components within a hydraulic system. Key brands include VICKERS BY DANFOSS, Lovejoy, Danfoss Hydrostatic, Festo, SKF, FAG (Schaeffler), Char-Lynn (Danfo…

5. Magister Hyd – Hydraulic Cylinders & Power Units

Domain: magisterhyd.com

Registered: 2014 (11 years)

Introduction: Hydraulic cylinders: AG Clevis, Clevis End, Cross Tube, Dump Trailer, Loader, Log Splitter, Pin Eye, Snow Plow, Swivel Ball, Swivel Eye, Tang, Tie Rod, Universal, Rephasing, Stroke Control, Top link cylinders. Hydraulic Power Units: Dump Trailer, Snow Plow, Hydraulic Lift Gate, Hydraulic Wheelchair Lift, Bi-Directional, 12 Volt, 24 Volt, Single Acting, Double Acting, with Plastic Tank, with Steel …

6. Panagon Systems – Hydraulic Pump & Motor Parts

Domain: panagonsystems.com

Registered: 2000 (25 years)

Introduction: Panagon Systems specializes in replacement hydraulic pump and motor parts, offering a wide range of components for various series including PVM, PVB, PFB, PVE, PVH, PVQ, TA, TDV, A10V, 54 Series, and Caterpillar pumps. They provide aftermarket parts for hydraulic pumps and motors, including legacy and discontinued models. Key components available include adapters, adjustment rods, bearings, compen…

7. Loader Parts Source – Hydraulic Pumps & Parts

Domain: loaderpartssource.com

Registered: 2008 (17 years)

Introduction: Case Hydraulic Pumps Parts, Case Hydraulic Pump Parts, Case Hydraulic Motors, Hydraulic Motor Parts, Belts, Filters & Maintenance, Engine Compartment, Glass, Cylinders & Seal Kits, Electrical Components, Cab Parts & Controls, Axle, Chain & Brake Parts, Lift Arm & Coupler Plates, Undercarriage & Wheel, Tools & Miscellaneous.

8. Permco – Hydraulic Components & Accessories

Domain: permco.com

Registered: 1998 (27 years)

Introduction: Parts & Accessories include:

– In-Line and Pilot Relief Valves

– Filters: Spin-on filters with adapters/heads for various applications, maximum working pressure 100 PSI, burst pressure 300 PSI.

– Thrust Plates: Made from high density bronze alloy.

– Gears and Shafts: Cut to close tolerances in-house for pumps and motors.

– Castings: Housings, port-end covers, shaft-end covers.

– Valves…

Strategic Sourcing Conclusion and Outlook for hydraulic pump parts

In the rapidly evolving landscape of hydraulic pump parts sourcing, strategic procurement remains essential for international B2B buyers. By focusing on quality, reliability, and timely delivery, businesses can enhance operational efficiency and reduce downtime. Establishing relationships with reputable suppliers, particularly those that offer OEM-grade components and prompt service, can lead to significant cost savings and improved performance.

Illustrative image related to hydraulic pump parts

As markets in Africa, South America, the Middle East, and Europe continue to expand, the demand for high-quality hydraulic pump parts will only increase. Buyers should prioritize partnerships with suppliers that provide comprehensive support, including rapid response times and customization options. Emphasizing sustainability and local sourcing can also yield competitive advantages in today’s environmentally conscious marketplace.

Looking ahead, embracing digital platforms for sourcing and procurement will empower businesses to streamline operations and enhance transparency. As the hydraulic industry evolves, staying informed about emerging technologies and market trends will be critical. International buyers are encouraged to leverage these insights to make informed decisions, ensuring their hydraulic systems remain robust and efficient. Engage with trusted suppliers today to secure your competitive edge in this dynamic sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.