Hvac High Pressure Switch Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for hvac high pressure switch

Navigating the global market for HVAC high-pressure switches presents a significant challenge for international B2B buyers, particularly in diverse regions such as Africa, South America, the Middle East, and Europe. Sourcing reliable high-pressure switches that ensure the safety and efficiency of HVAC systems is crucial, yet can be complicated by varying supplier standards and regional regulations. This comprehensive guide delves into the intricacies of HVAC high-pressure switches, providing insights into their types, applications, and the critical role they play in system performance.

In addition to exploring the diverse varieties of high-pressure switches—from manual reset to advanced electronic options—the guide also outlines essential supplier vetting processes to help buyers identify trustworthy manufacturers. Cost considerations are meticulously examined, equipping decision-makers with the knowledge to make informed purchases that align with budgetary constraints.

Furthermore, this guide empowers B2B buyers by offering actionable insights into maintenance practices and replacement strategies, thereby enhancing operational efficiency and longevity of HVAC systems. By addressing the unique challenges faced by businesses in Brazil, Saudi Arabia, and beyond, this resource serves as a vital tool for optimizing procurement strategies and ensuring the seamless operation of HVAC installations across various climates and markets.

Understanding hvac high pressure switch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Reset Switch | Requires manual intervention to reset after activation | Industrial HVAC systems, refrigeration units | Pros: Ensures user checks for issues; Cons: Less convenient, can lead to downtime. |

| Automatic Reset Switch | Automatically resets once pressure drops below a set level | Commercial air conditioning systems | Pros: Convenient for continuous operation; Cons: May allow undetected issues to persist. |

| Electronic Pressure Switch | Utilizes electronic sensors for precise pressure readings | High-efficiency HVAC systems | Pros: High accuracy, less prone to failure; Cons: Higher cost compared to mechanical switches. |

| Mechanical Pressure Switch | Relies on mechanical components for operation | Older HVAC systems, budget-friendly options | Pros: Simple design, cost-effective; Cons: Less accurate, more prone to wear and tear. |

| Dual Pressure Switch | Monitors both high and low pressure conditions | Complex HVAC systems, industrial applications | Pros: Comprehensive monitoring; Cons: More complex installation and maintenance. |

What are the Characteristics of a Manual Reset Switch in HVAC Systems?

Manual reset switches are safety devices that require user intervention to reset the system after it has shut down due to high pressure. This feature ensures that the user checks for underlying issues, making it particularly suitable for industrial HVAC systems and refrigeration units where operational reliability is critical. B2B buyers should consider the potential downtime and maintenance implications associated with manual reset switches, as they can lead to delays in operations if not promptly addressed.

How Does an Automatic Reset Switch Benefit Commercial Applications?

Automatic reset switches are designed to reset themselves once the pressure falls below a predetermined threshold. This functionality is advantageous for commercial air conditioning systems, where continuous operation is essential. While they offer convenience, B2B buyers should be cautious, as these switches may allow undetected issues to persist, leading to potential system failures. Thus, regular monitoring and maintenance are recommended to ensure optimal performance.

What Makes Electronic Pressure Switches Ideal for High-Efficiency HVAC Systems?

Electronic pressure switches employ advanced electronic sensors to provide precise pressure readings, making them ideal for high-efficiency HVAC systems. Their accuracy minimizes the risk of malfunctions, which can be crucial for businesses focused on energy efficiency and sustainability. While they come at a higher initial cost, the long-term savings in energy consumption and reduced maintenance needs can make them a worthwhile investment for B2B buyers.

Why Choose Mechanical Pressure Switches for Budget-Friendly Options?

Mechanical pressure switches operate using simple mechanical components, making them a cost-effective solution for older HVAC systems or budget-conscious buyers. Although they are straightforward and less expensive, they are more prone to wear and tear, leading to potential inaccuracies over time. B2B buyers should weigh the lower upfront costs against the potential for increased maintenance and replacement needs.

What Are the Advantages of Using a Dual Pressure Switch in Complex HVAC Systems?

Dual pressure switches monitor both high and low pressure conditions, providing comprehensive oversight for complex HVAC systems, particularly in industrial applications. This feature enhances system reliability by allowing for more precise control and early detection of potential issues. However, B2B buyers should consider the complexity of installation and maintenance, as dual pressure switches may require more expertise to manage effectively.

Key Industrial Applications of hvac high pressure switch

| Industry/Sector | Specific Application of HVAC High Pressure Switch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Monitoring refrigerant pressure in industrial chillers | Protects equipment from damage, reducing repair costs | Ensure compatibility with existing systems and local regulations |

| Food and Beverage | Maintaining optimal temperatures in refrigeration units | Enhances product quality and shelf life, ensuring safety | Look for switches that meet food safety standards |

| Commercial Buildings | Regulating HVAC systems in large office complexes | Improves energy efficiency, lowering operational costs | Prioritize energy-efficient models and reliable suppliers |

| Data Centers | Protecting cooling systems for servers | Prevents overheating, ensuring system reliability and uptime | Seek switches with fast response times and robust designs |

| Pharmaceuticals | Controlling temperature in storage facilities | Ensures compliance with strict temperature regulations | Consider certifications and reliability under varying conditions |

How is HVAC High Pressure Switch Used in Manufacturing?

In the manufacturing sector, HVAC high-pressure switches are critical in monitoring refrigerant pressure within industrial chillers. By preventing excessive pressure build-up, these switches protect essential equipment from potential damage, thus reducing maintenance and repair costs. For international buyers, especially in regions like Africa and South America, sourcing switches that comply with local standards and are compatible with existing systems is crucial to ensure seamless integration and operational efficiency.

What Role Does HVAC High Pressure Switch Play in Food and Beverage Industry?

In the food and beverage industry, HVAC high-pressure switches maintain optimal temperatures in refrigeration units. These switches ensure that the temperature remains within safe limits, which is vital for preserving product quality and extending shelf life. Compliance with food safety standards is paramount for buyers in this sector, particularly in the Middle East and Europe, where regulations are stringent. Selecting high-quality switches that can withstand varying environmental conditions is essential to avoid costly product losses.

How Do HVAC High Pressure Switches Enhance Commercial Building Operations?

For commercial buildings, HVAC high-pressure switches regulate the HVAC systems in large office complexes. By maintaining optimal refrigerant pressures, these switches contribute to improved energy efficiency, which can significantly lower operational costs. B2B buyers in Europe and the Middle East should prioritize energy-efficient models that offer reliable performance to meet sustainability goals. Additionally, sourcing from reputable suppliers who provide robust support and warranties can enhance long-term operational reliability.

What Importance Does HVAC High Pressure Switch Hold in Data Centers?

In data centers, HVAC high-pressure switches are vital for protecting cooling systems that prevent server overheating. These switches ensure that refrigerant pressure remains within safe limits, which is crucial for maintaining system reliability and uptime. Buyers in regions like Africa and South America should seek switches with fast response times and robust designs to handle the demands of high-performance cooling systems. Partnering with suppliers who understand the specific needs of data center operations can lead to better performance and reliability.

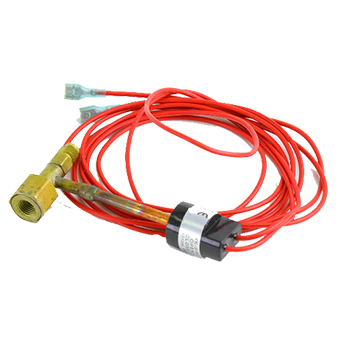

Illustrative image related to hvac high pressure switch

How is HVAC High Pressure Switch Used in Pharmaceutical Storage?

In the pharmaceutical sector, HVAC high-pressure switches are used to control temperatures in storage facilities, ensuring compliance with strict temperature regulations. This is crucial for maintaining the efficacy and safety of pharmaceutical products. Buyers should consider sourcing switches that come with appropriate certifications and can perform reliably under varying conditions. Ensuring compatibility with existing systems and understanding local regulatory requirements will be key for international buyers, particularly in regions with stringent health regulations.

3 Common User Pain Points for ‘hvac high pressure switch’ & Their Solutions

Scenario 1: Frequent System Shutdowns Due to High-Pressure Switch Failure

The Problem: Many B2B buyers managing HVAC systems encounter the frustrating issue of frequent system shutdowns triggered by high-pressure switches. This problem often arises from improper refrigerant charging or clogged condenser coils, leading to unsafe pressure levels. The unpredictability of sudden shutdowns not only disrupts operational efficiency but also creates discomfort for occupants and potential loss of productivity for businesses relying on climate control. For buyers in regions with extreme weather conditions, this issue can be particularly detrimental, emphasizing the need for reliable HVAC functionality.

The Solution: To mitigate this challenge, it is crucial to implement a comprehensive maintenance plan that includes regular inspections and servicing of the HVAC system. Start by training your maintenance staff to recognize the symptoms of a failing high-pressure switch, such as frequent system shutdowns or unusual sounds. Additionally, ensure that the refrigerant levels are maintained within manufacturer specifications to prevent overcharging. When sourcing high-pressure switches, opt for OEM parts to guarantee compatibility and reliability. Establish a routine for cleaning condenser coils and checking for airflow obstructions. By proactively addressing these areas, you can enhance system reliability and minimize operational disruptions.

Scenario 2: Difficulty in Sourcing the Right High-Pressure Switch

The Problem: B2B buyers often face challenges in sourcing high-pressure switches that meet their specific HVAC system requirements. With numerous brands and specifications available, the risk of purchasing incompatible or substandard parts can lead to increased downtime and repair costs. This scenario is particularly common in international markets where local suppliers may not stock the necessary components, forcing buyers to navigate complex logistics or rely on less reputable sources.

The Solution: To streamline the sourcing process, develop a standardized parts list that includes the exact specifications and compatible brands of high-pressure switches for your HVAC systems. Collaborate with reputable suppliers who can guarantee the availability of OEM parts and provide technical support. It is beneficial to establish relationships with international distributors that specialize in HVAC components, ensuring a reliable supply chain. Additionally, leverage online platforms that offer detailed product descriptions and customer reviews to make informed purchasing decisions. By creating a well-defined procurement strategy, you can avoid the pitfalls of sourcing and ensure your HVAC systems remain operational with the right components.

Scenario 3: Unclear Maintenance Procedures for High-Pressure Switches

The Problem: Many B2B buyers struggle with unclear or inconsistent maintenance procedures for high-pressure switches within their HVAC systems. Without a structured approach, maintenance teams may overlook critical checks, leading to premature switch failures or inefficient operation. This issue is particularly prevalent in companies that lack comprehensive training programs for their HVAC technicians, resulting in increased operational costs and potential system failures.

The Solution: To address this pain point, invest in creating a detailed maintenance checklist specifically for high-pressure switches. This checklist should include steps for routine inspections, testing switch functionality, and verifying electrical connections. Additionally, consider implementing a training program for your maintenance personnel that covers the importance of the high-pressure switch in system efficiency and safety. Utilize visual aids, such as diagrams and instructional videos, to enhance understanding and retention. By formalizing maintenance procedures and educating your team, you can significantly improve the reliability of your HVAC systems, ultimately leading to cost savings and enhanced operational efficiency.

Strategic Material Selection Guide for hvac high pressure switch

What Are the Common Materials Used in HVAC High-Pressure Switches?

Selecting the right material for HVAC high-pressure switches is critical for ensuring optimal performance and longevity. Below is an analysis of four common materials used in the manufacturing of these switches, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Brass Perform in HVAC High-Pressure Switches?

Key Properties: Brass is known for its excellent corrosion resistance, particularly against moisture and certain chemicals. It can withstand moderate temperature and pressure levels, making it suitable for various HVAC applications.

Pros & Cons: The durability of brass is a significant advantage, as it can endure harsh environments without deteriorating. However, its cost can be higher compared to other materials like plastic, and it may require more complex manufacturing processes. Additionally, brass is not suitable for applications involving highly corrosive media.

Impact on Application: Brass is compatible with refrigerants commonly used in HVAC systems, making it a preferred choice for many manufacturers. However, buyers should ensure that the specific refrigerant used does not react adversely with brass.

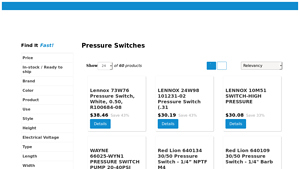

Illustrative image related to hvac high pressure switch

Considerations for International Buyers: Compliance with standards such as ASTM B453 for brass fittings is crucial. Buyers from regions like Europe and the Middle East should also consider local regulations regarding material safety and environmental impact.

What Role Does Plastic Play in HVAC High-Pressure Switches?

Key Properties: Plastics, particularly reinforced thermoplastics, offer good chemical resistance and can handle a range of temperatures and pressures, although they generally have lower ratings compared to metals.

Pros & Cons: The primary advantage of plastic is its lightweight nature and lower cost, making it an attractive option for budget-conscious projects. However, plastics may not be as durable as metals and can degrade over time when exposed to UV light or extreme temperatures.

Impact on Application: While plastics can be suitable for low-pressure applications, they may not be ideal for high-pressure systems where metal components are preferred for added safety and reliability.

Considerations for International Buyers: Buyers should check for compliance with international standards like ISO 9001 for quality management systems. In regions like South America, where temperature variations can be significant, the choice of plastic must consider thermal stability.

How Does Stainless Steel Enhance HVAC High-Pressure Switches?

Key Properties: Stainless steel is renowned for its exceptional strength and corrosion resistance, particularly in environments exposed to moisture and various chemicals. It can handle high temperatures and pressures, making it ideal for demanding applications.

Pros & Cons: The durability of stainless steel is a major benefit, as it can withstand harsh operating conditions without significant wear. However, it is generally more expensive than brass or plastic, which may impact budget considerations.

Impact on Application: Stainless steel is highly compatible with various refrigerants and is often used in high-pressure applications, ensuring safety and reliability. Its robust nature helps prevent leaks and failures.

Illustrative image related to hvac high pressure switch

Considerations for International Buyers: Compliance with standards like ASTM A276 for stainless steel grades is essential. Buyers from Africa and the Middle East should also consider the availability of stainless steel in local markets, as it may influence lead times and costs.

What Advantages Does Copper Offer in HVAC High-Pressure Switches?

Key Properties: Copper is highly conductive and offers excellent thermal properties. It has good corrosion resistance, particularly when properly treated, and can withstand high pressures and temperatures.

Pros & Cons: The primary advantage of copper is its thermal efficiency, which enhances the performance of HVAC systems. However, copper can be more expensive than other materials and may require specialized handling due to its malleability.

Impact on Application: Copper is widely used in HVAC systems, particularly in refrigerant lines, due to its compatibility with various refrigerants and its ability to handle high pressures.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B280 for copper tubing. In regions like Europe, where environmental regulations are stringent, the sourcing of copper should consider sustainability practices.

Illustrative image related to hvac high pressure switch

Summary Table of Material Selection for HVAC High-Pressure Switches

| Material | Typical Use Case for hvac high pressure switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | General HVAC applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | Medium |

| Plastic | Low-pressure HVAC systems | Lightweight and cost-effective | Less durable under extreme conditions | Low |

| Stainless Steel | High-pressure and corrosive environments | Exceptional strength and durability | Higher cost compared to other materials | High |

| Copper | Refrigerant lines in HVAC systems | Superior thermal conductivity | More expensive and requires careful handling | Medium |

This analysis provides a comprehensive overview of material options for HVAC high-pressure switches, offering valuable insights for B2B buyers navigating the complexities of international sourcing and compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for hvac high pressure switch

What Are the Key Manufacturing Processes for HVAC High Pressure Switches?

The manufacturing of HVAC high-pressure switches involves several critical stages, each designed to ensure the final product meets stringent operational and safety standards. Understanding these processes can empower B2B buyers to make informed decisions when sourcing these essential components.

What Materials Are Typically Used in High Pressure Switch Production?

The first stage in manufacturing high-pressure switches is material preparation. Common materials include high-grade metals such as brass and stainless steel for the housing and components, ensuring durability and resistance to corrosion. Additionally, specialized plastics are often used for insulation and sealing purposes. These materials are selected based on their ability to withstand high pressures and temperature variations inherent in HVAC systems.

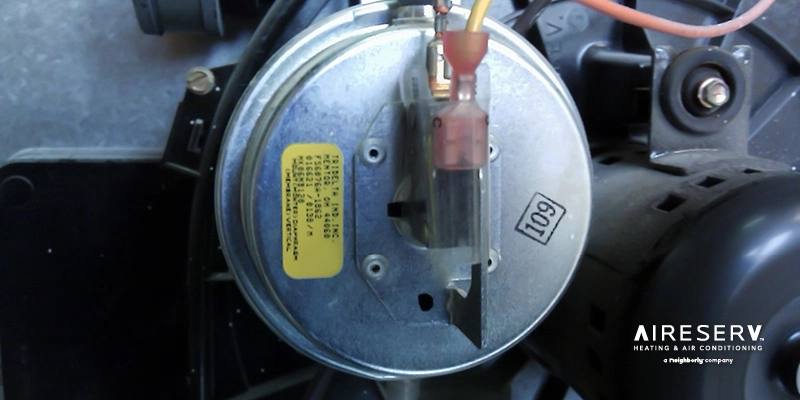

Illustrative image related to hvac high pressure switch

How Are High Pressure Switches Formed?

Once the materials are prepared, the next stage involves forming. This includes processes such as machining, stamping, and molding. Machining is frequently used to create precise components such as the switch housing and internal mechanisms. Stamping is often employed for producing metal parts quickly and efficiently, while molding techniques may be utilized for any plastic components. These methods ensure that each part is crafted to exact specifications, which is crucial for the switch’s reliability.

What Is the Assembly Process for High Pressure Switches?

After forming, the assembly process takes place. This stage involves integrating the various components, including the pressure sensor, electrical contacts, and housing. Skilled technicians or automated systems typically perform this assembly, ensuring that each part fits together correctly to maintain the integrity of the switch. Quality control measures are incorporated throughout the assembly process to detect any defects early.

How Is the Finishing Stage Conducted?

The final stage of manufacturing is finishing, which may include surface treatments, painting, or coating to enhance corrosion resistance and aesthetic appeal. Finishing processes not only improve the product’s durability but also ensure compliance with international standards for safety and performance. This stage is critical, especially for products intended for diverse climates and conditions encountered across regions like Africa, South America, and the Middle East.

What Quality Assurance Practices Are Essential for High Pressure Switches?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that each high-pressure switch functions reliably and safely. Various international and industry-specific standards guide these practices.

Which International Standards Should Buyers Be Aware Of?

One of the most widely recognized standards is ISO 9001, which outlines the criteria for a quality management system. Adherence to this standard indicates that a manufacturer has established processes to ensure consistent quality in their products. Additionally, certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) are essential for compliance with European and industry-specific regulations, respectively. B2B buyers should prioritize suppliers who hold these certifications, as they reflect a commitment to quality and safety.

What Are the Key Quality Control Checkpoints?

Quality control in manufacturing high-pressure switches typically involves several checkpoints throughout the production process:

- Incoming Quality Control (IQC): This initial checkpoint assesses raw materials for compliance with specifications before they enter the production line.

- In-Process Quality Control (IPQC): During manufacturing, random samples are tested to ensure that components meet predefined quality criteria, allowing for immediate corrective actions if needed.

- Final Quality Control (FQC): This final inspection stage verifies that the assembled high-pressure switches meet all operational standards and specifications before they are packaged and shipped.

What Testing Methods Are Commonly Used?

Common testing methods for high-pressure switches include pressure testing, electrical testing, and environmental testing. Pressure testing ensures that the switch can withstand specified pressure levels without failure, while electrical testing assesses the integrity of the electrical components. Environmental testing simulates various conditions, such as extreme temperatures and humidity, to ensure reliable operation in real-world scenarios.

How Can B2B Buyers Verify Supplier Quality Control?

When sourcing HVAC high-pressure switches, B2B buyers should take proactive steps to verify the quality control measures of potential suppliers.

What Steps Should Buyers Take to Ensure Supplier Compliance?

-

Conduct Audits: Regular audits of suppliers can reveal their adherence to quality standards and manufacturing processes. Buyers should request audit reports and performance metrics.

-

Request Documentation: Suppliers should provide documentation for certifications, including ISO and CE. This documentation serves as proof of compliance with international standards.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of a supplier’s manufacturing and quality assurance processes. These inspections can be particularly valuable for buyers unfamiliar with the supplier’s local standards and practices.

What Nuances Should International Buyers Consider?

International B2B buyers, particularly those from diverse regions like Africa, South America, and the Middle East, must be aware of specific nuances when sourcing high-pressure switches.

How Do Regional Regulations Impact Sourcing?

Different regions may have varying regulations regarding HVAC components. Buyers should familiarize themselves with local compliance requirements, including specific certifications that may be necessary for importing HVAC products. For instance, the Middle East may have unique standards compared to Europe, necessitating additional documentation or testing.

What Should Buyers Know About Supply Chain Logistics?

Understanding the logistics of international shipping is crucial. Buyers should account for potential delays in shipping, customs clearance, and the need for additional inspections upon arrival. Establishing a relationship with suppliers who have experience in international trade can mitigate these challenges.

Conclusion

An in-depth understanding of the manufacturing processes and quality assurance practices for HVAC high-pressure switches is essential for B2B buyers. By focusing on material selection, forming techniques, assembly processes, and rigorous quality control measures, buyers can ensure they procure reliable and compliant components. Additionally, verifying supplier quality through audits and documentation, while considering regional regulations and logistics, will further enhance their sourcing strategy. This comprehensive approach not only safeguards investments but also contributes to the long-term efficiency and safety of HVAC systems.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hvac high pressure switch’

To assist B2B buyers in procuring HVAC high-pressure switches effectively, this guide offers a comprehensive checklist to ensure informed purchasing decisions. The high-pressure switch is a critical safety component in HVAC systems, and selecting the right one is essential for optimal performance and system reliability.

Illustrative image related to hvac high pressure switch

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications required for the high-pressure switch. This includes the pressure range, type (manual or automatic reset), and compatibility with existing HVAC systems. Knowing these details helps streamline your search and ensures you select a product that meets your operational needs.

Step 2: Research Reliable Suppliers

Identifying reputable suppliers is crucial for securing quality products. Start by exploring industry directories, online marketplaces, and local distributors specializing in HVAC components. Look for suppliers with a proven track record, positive customer reviews, and established relationships with manufacturers. This foundational research will set the stage for successful procurement.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers possess relevant certifications and comply with international standards, such as ISO 9001. These certifications indicate that the supplier follows quality management practices, which can significantly reduce the risk of product failure. Additionally, inquire about their warranty policies, as a strong warranty can provide peace of mind regarding the product’s reliability.

Step 4: Request Product Samples

Whenever possible, request samples of the high-pressure switches you are considering. Testing samples allows you to assess the product’s quality, functionality, and compatibility with your systems before committing to a larger order. This step is particularly important for international buyers who may have unique environmental conditions affecting the product’s performance.

Step 5: Assess Pricing and Payment Terms

Conduct a thorough comparison of pricing across different suppliers, keeping in mind the total cost of ownership, including shipping and potential import duties. Inquire about payment terms and financing options, as favorable terms can improve cash flow for your business. Ensure that the pricing aligns with your budget while also considering the long-term value of the components.

Step 6: Understand After-Sales Support and Service

Evaluate the level of after-sales support offered by the supplier. This includes technical assistance, warranty claims, and availability of replacement parts. Reliable after-sales service can significantly enhance your operational efficiency and minimize downtime in case of product issues.

Step 7: Establish a Long-Term Relationship

Once you’ve successfully sourced and installed the high-pressure switches, consider establishing a long-term relationship with the supplier. Regular collaboration can lead to better pricing, priority service during emergencies, and access to new products as they become available. A strong partnership can provide strategic advantages in maintaining your HVAC systems.

By following this checklist, B2B buyers can make informed decisions when sourcing HVAC high-pressure switches, ultimately ensuring the reliability and efficiency of their HVAC systems.

Comprehensive Cost and Pricing Analysis for hvac high pressure switch Sourcing

Understanding the cost structure and pricing of HVAC high-pressure switches is essential for international B2B buyers looking to optimize their procurement strategies. This analysis delves into the various components that influence costs, pricing dynamics, and strategic tips for buyers in regions such as Africa, South America, the Middle East, and Europe.

Illustrative image related to hvac high pressure switch

What Are the Key Cost Components for HVAC High-Pressure Switches?

When sourcing HVAC high-pressure switches, several cost components must be considered:

-

Materials: The primary materials used in high-pressure switches include plastics, metals, and electronic components. The choice of materials directly impacts the durability and reliability of the switch. Higher-quality materials generally lead to increased costs but can result in lower failure rates and longer lifespans.

-

Labor: Labor costs encompass the wages of workers involved in manufacturing and assembly. In regions with higher labor costs, such as parts of Europe, the overall price of the switch may increase. Conversely, sourcing from countries with lower labor costs can provide cost savings.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize overhead and, in turn, the pricing of the switches.

-

Tooling: Initial tooling costs for custom or specialized switches can be significant. This one-time expense needs to be factored into the overall cost structure, particularly for orders that require unique specifications.

-

Quality Control (QC): Ensuring that each high-pressure switch meets quality standards involves testing and inspection processes, which can add to the overall cost. Buyers should consider the implications of QC on the reliability of the product.

-

Logistics: Shipping and handling costs vary significantly based on the origin and destination of the products. Freight charges, insurance, and import duties can substantially affect the final price, especially for international buyers.

-

Margin: Suppliers typically add a profit margin to cover their risks and operational costs. Understanding the standard margins in the HVAC industry can assist buyers in evaluating offers from different suppliers.

What Influences Pricing for HVAC High-Pressure Switches?

Several factors can influence the pricing of HVAC high-pressure switches:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in volume discounts. Buyers should assess their needs and negotiate pricing based on potential order size.

-

Specifications and Customization: Custom specifications or high-performance switches may incur additional costs. Buyers should clearly define their requirements to avoid unexpected price increases.

-

Materials and Certifications: Higher-quality materials and certifications (such as ISO or UL ratings) may drive up costs. However, they can also enhance product reliability and safety, providing long-term value.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their quality assurance processes but can offer greater peace of mind.

-

Incoterms: Understanding Incoterms is crucial for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of products.

How Can Buyers Optimize Their Purchasing Strategy?

To maximize cost efficiency when sourcing HVAC high-pressure switches, consider the following tips:

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Building a strong relationship can lead to better deals.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the long-term costs associated with installation, maintenance, and potential failures. Investing in higher-quality switches may reduce TCO over time.

-

Be Aware of Pricing Nuances: International buyers should be cognizant of regional market conditions, currency fluctuations, and local regulations that can impact pricing.

-

Conduct Supplier Research: Vet potential suppliers for quality, reliability, and support. Request samples or case studies to evaluate their products before committing to large orders.

Conclusion

In conclusion, understanding the comprehensive cost structure and pricing dynamics for HVAC high-pressure switches is vital for international B2B buyers. By considering all cost components, recognizing price influencers, and implementing strategic procurement practices, buyers can make informed decisions that enhance their operational efficiency and reduce overall expenses.

Alternatives Analysis: Comparing hvac high pressure switch With Other Solutions

Introduction: Understanding Alternatives to HVAC High-Pressure Switches

In the HVAC industry, ensuring optimal system performance and safety is paramount. While the HVAC high-pressure switch serves as a critical safety device that monitors refrigerant pressure, there are alternative solutions and technologies that can also enhance system performance and reliability. This section explores viable alternatives, providing B2B buyers with insights to make informed decisions based on their specific operational needs.

Comparison Table

| Comparison Aspect | HVAC High-Pressure Switch | Electronic Pressure Sensors | Safety Relief Valves |

|---|---|---|---|

| Performance | Effective in monitoring high pressure and preventing compressor damage. | Highly accurate with real-time data and diagnostics. | Provides immediate pressure relief to prevent system failures. |

| Cost | Typically ranges from $20 to $60. Professional installation may cost $150 to $300. | Costs vary, generally starting from $100, plus installation fees. | Generally costs between $50 and $200, depending on size and type. |

| Ease of Implementation | Straightforward installation; requires basic tools and knowledge. | Installation may require advanced knowledge and calibration. | Simple installation, often requiring minimal adjustments. |

| Maintenance | Requires regular checks for functionality; can fail due to wear. | Minimal maintenance, though calibration may be necessary. | Low maintenance; regular inspection is recommended for functionality. |

| Best Use Case | Ideal for standard HVAC systems needing reliable pressure monitoring. | Best for advanced systems requiring precise pressure control and diagnostics. | Suitable for high-pressure systems where immediate pressure relief is critical. |

Detailed Breakdown of Alternatives

Electronic Pressure Sensors

Electronic pressure sensors offer a modern approach to pressure monitoring within HVAC systems. These devices provide real-time data and diagnostics, allowing for more precise control over system performance. Their high accuracy can lead to improved energy efficiency and enhanced operational reliability. However, they typically come with a higher initial cost and may require more technical knowledge for installation and calibration, making them less accessible for basic HVAC setups.

Safety Relief Valves

Safety relief valves act as a safeguard against excessive pressure in HVAC systems. When pressure exceeds a predetermined limit, these valves open to release the excess, preventing potential system damage or failure. They are generally straightforward to install and require minimal ongoing maintenance. While they offer a quick solution for pressure control, they do not provide the continuous monitoring that high-pressure switches or electronic sensors offer. Therefore, they are best suited for high-pressure systems where immediate pressure relief is necessary.

Conclusion: Choosing the Right Solution for Your HVAC Needs

When selecting a pressure control solution for HVAC systems, B2B buyers should consider their specific operational requirements, budget constraints, and technical capabilities. The HVAC high-pressure switch remains a reliable and cost-effective option for many standard systems, while electronic pressure sensors may be more appropriate for advanced setups requiring precise control. Safety relief valves provide essential protection in high-pressure scenarios but lack the continuous monitoring capabilities of other solutions. By carefully evaluating these alternatives, businesses can enhance their HVAC system’s efficiency, safety, and longevity, ensuring optimal performance tailored to their unique needs.

Essential Technical Properties and Trade Terminology for hvac high pressure switch

What Are the Key Technical Properties of HVAC High-Pressure Switches?

When sourcing HVAC high-pressure switches, it is essential to understand their critical specifications that ensure reliability and performance. Here are some key technical properties to consider:

Illustrative image related to hvac high pressure switch

-

Pressure Rating

The pressure rating indicates the maximum allowable pressure the switch can handle before it activates. Typically measured in psi (pounds per square inch), this specification is crucial for ensuring that the switch can withstand the operational pressures of the HVAC system. Understanding this rating helps buyers select switches that align with their system requirements, preventing failures and costly repairs. -

Electrical Ratings

These ratings define the voltage and current that the high-pressure switch can safely handle. For instance, a switch might be rated for 24V AC, which is common in HVAC applications. Proper electrical ratings are essential to prevent overheating and ensure the longevity of the switch, particularly in high-demand environments. -

Switch Type

High-pressure switches can be manual reset or automatic reset types. The choice between these types affects operational efficiency and safety protocols. Automatic reset switches allow for continuous operation, while manual resets require user intervention, which can be beneficial for thorough inspections. Understanding the type helps businesses optimize maintenance protocols and operational safety. -

Material Composition

The materials used in high-pressure switches, such as brass or plastic, can significantly impact durability and corrosion resistance. Components made of high-quality materials are less prone to wear and tear, especially in harsh environments. This property is vital for buyers seeking long-term investments in HVAC systems, particularly in regions with extreme weather conditions. -

Tolerance Levels

Tolerance levels refer to the acceptable range of deviation from the specified pressure setting. High tolerance levels ensure the switch operates effectively without triggering false alarms. For international buyers, especially in diverse climate conditions, understanding tolerance is crucial for maintaining system efficiency and reliability. -

Environmental Ratings

This specification indicates the switch’s ability to withstand environmental factors such as temperature and humidity. For instance, a switch with a high environmental rating can operate in extreme temperatures or high humidity, making it ideal for various geographic locations. Buyers should consider these ratings to ensure the switch performs optimally in their specific conditions.

What Are Common Trade Terms Related to HVAC High-Pressure Switches?

Familiarizing oneself with industry terminology is essential for effective communication and decision-making in B2B transactions. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are sold under another company’s brand. In the context of HVAC high-pressure switches, sourcing OEM parts ensures compatibility and reliability, as these components are specifically designed for particular systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is critical for buyers, especially in international markets, as it affects inventory management and cost-efficiency. Buyers should negotiate MOQs to align with their purchasing needs. -

RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price quotes from suppliers. It typically includes detailed specifications and quantities. For HVAC buyers, submitting RFQs can lead to competitive pricing and better sourcing decisions. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for buyers to navigate shipping logistics, costs, and risks involved in procuring HVAC components from different regions. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For HVAC systems, understanding lead times is crucial for project planning and ensuring timely installations, especially in regions where climate control is essential. -

Warranty Period

This term describes the duration during which the manufacturer is responsible for repairing or replacing defective products. Knowing the warranty period helps buyers assess the reliability and expected lifespan of high-pressure switches, which is particularly important for long-term investments.

By understanding these technical properties and trade terms, international buyers can make informed decisions that enhance their HVAC systems’ efficiency and reliability.

Navigating Market Dynamics and Sourcing Trends in the hvac high pressure switch Sector

What Are the Current Market Dynamics and Key Trends in the HVAC High-Pressure Switch Sector?

The HVAC high-pressure switch market is experiencing significant growth, driven by increasing demand for energy-efficient HVAC systems across various regions, particularly in Africa, South America, the Middle East, and Europe. As urbanization accelerates and climate control becomes a priority, the need for reliable HVAC components, such as high-pressure switches, has surged. B2B buyers are keenly focused on sourcing high-quality, durable components that can enhance system efficiency and longevity.

Illustrative image related to hvac high pressure switch

Emerging technologies, including IoT-enabled sensors, are reshaping the HVAC landscape by providing real-time monitoring and predictive maintenance capabilities. This trend is particularly pertinent for international buyers seeking to optimize their operations and reduce downtime. Additionally, as regulatory frameworks tighten around energy consumption and environmental impact, there is a noticeable shift towards sourcing components that meet stringent energy efficiency standards.

Another crucial trend is the rise of digital marketplaces and online sourcing platforms, which enable B2B buyers to access a broader range of suppliers and competitive pricing. This digital transformation facilitates easier comparisons and faster procurement processes, essential for businesses looking to maintain a competitive edge in a dynamic market. Furthermore, buyers are increasingly valuing suppliers who provide comprehensive technical support and documentation, ensuring that installations and replacements are executed with precision.

How Does Sustainability and Ethical Sourcing Impact the HVAC High-Pressure Switch Market?

Sustainability is becoming a cornerstone of the HVAC industry, influencing how high-pressure switches are sourced and manufactured. The environmental impact of HVAC systems, particularly in terms of energy consumption and refrigerant management, has prompted buyers to prioritize products that are designed with sustainability in mind. This includes sourcing high-pressure switches made from recyclable materials or those that comply with green certifications, such as Energy Star or ISO 14001.

Ethical sourcing is equally important for B2B buyers, particularly in regions where supply chain transparency is gaining traction. Companies are increasingly expected to demonstrate responsible sourcing practices, which not only support environmental goals but also promote social responsibility within the supply chain. This includes ensuring that the materials used in high-pressure switches are sourced from suppliers who adhere to fair labor practices and environmentally friendly operations.

Moreover, as global awareness of climate change intensifies, buyers are looking for high-pressure switches that minimize refrigerant leaks and enhance system efficiency. This focus on reducing the carbon footprint aligns with broader corporate sustainability goals, making it essential for suppliers to showcase their commitment to ethical practices and sustainable products.

What Has Been the Evolution of HVAC High-Pressure Switches?

The evolution of HVAC high-pressure switches has been marked by advancements in technology and increased understanding of HVAC systems’ operational dynamics. Initially, mechanical switches dominated the market, relying on simple mechanical components to monitor pressure. However, as HVAC systems became more complex and the need for precision grew, electronic high-pressure switches emerged, offering enhanced reliability and accuracy.

Over the years, the integration of smart technology has further transformed high-pressure switches, allowing for real-time monitoring and remote diagnostics. This shift has not only improved system efficiency but also facilitated proactive maintenance strategies that can prevent costly failures. As the HVAC industry continues to innovate, the future of high-pressure switches will likely see even more advanced features, including connectivity to broader building management systems and increased adaptability to various refrigerants and operational conditions.

In summary, the HVAC high-pressure switch sector is evolving rapidly, with sustainability and technology at the forefront of its development. For B2B buyers, understanding these dynamics is crucial for making informed sourcing decisions that align with both operational needs and corporate responsibility goals.

Frequently Asked Questions (FAQs) for B2B Buyers of hvac high pressure switch

-

How do I solve high-pressure switch failures in HVAC systems?

High-pressure switch failures can often be attributed to issues like refrigerant overcharging, dirty condenser coils, or blocked airflow. To address these problems, start by inspecting the refrigerant levels and ensuring they are within manufacturer specifications. Clean or replace any dirty filters and check for airflow obstructions. It’s also essential to have a qualified technician evaluate the compressor’s functionality, as it can impact pressure regulation. Regular maintenance, including routine inspections, will help prevent such failures and ensure system reliability. -

What is the best high-pressure switch for HVAC systems in different climates?

The best high-pressure switch varies depending on the specific HVAC system and the climate it operates in. For regions with extreme temperatures, such as the Middle East or parts of South America, selecting a switch designed for high tolerance to heat is crucial. Look for switches with robust construction and precise pressure settings tailored to your system’s specifications. Additionally, consider the type (manual vs. automatic reset) based on operational needs. Consulting with suppliers who understand local climate challenges can help ensure optimal performance. -

What factors should I consider when vetting suppliers of HVAC high-pressure switches?

When vetting suppliers, consider their reputation, product quality, and customer service. Check for certifications or compliance with international standards, as this indicates reliability. Reviews and testimonials from other B2B buyers can provide insight into their experiences. Additionally, inquire about the supplier’s manufacturing processes, warranty policies, and return/exchange terms. Establishing a strong relationship with a supplier who understands your market can enhance the procurement process. -

Are there customization options available for HVAC high-pressure switches?

Many manufacturers offer customization options for high-pressure switches to meet specific operational requirements. This can include adjustments to pressure settings, housing materials, or connection types. When seeking customization, communicate your needs clearly to the supplier and ask for minimum order quantities (MOQ) that may apply. Custom switches can enhance compatibility with unique HVAC systems, so it’s worthwhile to explore these options if standard products do not meet your specifications. -

What are the typical payment terms when sourcing HVAC high-pressure switches internationally?

Payment terms can vary significantly depending on the supplier and the nature of the transaction. Common terms include upfront payment, partial payment upon order confirmation, and the balance upon delivery. Some suppliers may offer credit terms for established relationships. It’s essential to discuss and agree on payment methods (e.g., wire transfer, letters of credit) upfront. Additionally, be aware of any currency exchange considerations when dealing with international suppliers, particularly in regions like Africa and South America. -

How do I ensure quality assurance (QA) when purchasing HVAC high-pressure switches?

To ensure quality assurance, request documentation that verifies compliance with international standards, such as ISO certifications. Establish a quality control process with the supplier, including pre-shipment inspections or third-party audits. Additionally, ask for sample products before placing a bulk order to assess quality firsthand. Setting clear expectations regarding performance specifications and warranty terms can also help safeguard against defects and ensure reliable operation in your HVAC systems. -

What logistics considerations should I keep in mind when importing HVAC high-pressure switches?

When importing HVAC high-pressure switches, consider shipping methods, lead times, and customs regulations. Choose a reliable logistics partner familiar with international shipping to navigate potential challenges. Ensure that all necessary documentation, including invoices and certificates of origin, is prepared to avoid delays at customs. Be mindful of tariffs and import duties that may affect overall costs. Additionally, tracking shipments can provide visibility into delivery timelines, helping you manage inventory effectively. -

How can I find reliable suppliers for HVAC high-pressure switches in Africa, South America, and Europe?

To find reliable suppliers, start by researching online platforms that specialize in HVAC components, such as trade directories or industry-specific marketplaces. Attend trade shows and exhibitions relevant to the HVAC industry, as they provide opportunities to connect with manufacturers and distributors. Networking with industry peers and seeking recommendations can also lead to trustworthy suppliers. Finally, leverage social media and professional networks like LinkedIn to identify and engage with potential suppliers in your target regions.

Top 3 Hvac High Pressure Switch Manufacturers & Suppliers List

1. Lennox – Pressure Switches

Domain: hvacpartsshop.com

Registered: 2006 (19 years)

Introduction: HVAC Repair Parts & Accessories including Pressure Switches for Furnace and Air Conditioning systems. The shop offers a wide range of HVAC parts such as blower motors, gas valves, air conditioner parts, and control boards. They provide quality OEM parts from brands like Lennox, Goodman, Armstrong, Trane, and York. The website emphasizes fast shipping with same-day delivery and offers expert suppor…

2. DIY Heat Pump Troubleshooting Guide

Domain: doityourself.com

Registered: 1995 (30 years)

Introduction: Heat Pump, 18 years old, condenser motor replaced four times, new motor and motor run capacitor recently installed, high pressure switch keeps tripping, operates 24/7, issues noted during cooling operation, outdoor temperatures around 90-95°F, system has never been serviced or cleaned.

3. PlumbersStock – Pressure Switches

Domain: plumbersstock.com

Registered: 2007 (18 years)

Introduction: HVAC Pressure Switches, High Pressure Switches, Low Pressure Switches, over 100 different pressure switches available, brands include Frigidaire, Honeywell, Meridian, Ducane, competitive pricing, free shipping on qualifying purchases, troubleshooting guide for stuck pressure switches.

Strategic Sourcing Conclusion and Outlook for hvac high pressure switch

In conclusion, strategic sourcing for HVAC high-pressure switches is vital for maintaining system efficiency and preventing costly repairs. By understanding the functionality and types of high-pressure switches, buyers can make informed decisions that enhance operational reliability. Prioritizing quality OEM parts ensures that HVAC systems function optimally, while regular maintenance can mitigate potential failures and extend equipment lifespan.

For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, establishing relationships with reputable suppliers can lead to improved procurement processes and better pricing strategies. As global demand for energy-efficient HVAC solutions continues to rise, sourcing high-quality components like pressure switches will be crucial for staying competitive in the market.

As we look to the future, consider the evolving landscape of HVAC technology and the growing emphasis on sustainability. Now is the time to evaluate your sourcing strategies and align them with industry advancements. Explore partnerships with trusted suppliers to ensure your HVAC systems are equipped with the best components, paving the way for enhanced performance and profitability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.