How to Source What Is A Polarized Plug Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for what is a polarized plug

In today’s rapidly evolving global marketplace, understanding the intricacies of electrical components such as polarized plugs is crucial for B2B buyers. Polarized plugs are essential for ensuring electrical safety and proper functioning in various applications, particularly in regions with specific voltage and safety standards. As international buyers from Africa, South America, the Middle East, and Europe (including Germany and Vietnam) seek reliable electrical solutions, knowing how to source quality polarized plugs can significantly mitigate risks associated with electrical failures.

This comprehensive guide delves into the diverse types of polarized plugs, their applications across different industries, and the critical factors to consider when vetting suppliers. Key insights into cost structures, compliance with international safety standards, and best practices for procurement will empower you to make informed purchasing decisions. By understanding the specifications and functionality of polarized plugs, you can enhance product safety, ensure compatibility with existing electrical systems, and ultimately contribute to the operational efficiency of your business.

Navigating the complexities of electrical components can be daunting, but this guide aims to simplify the process. With actionable insights and expert recommendations, you will be equipped to effectively meet your sourcing needs while adhering to regional regulations and standards. Whether you are expanding your product offerings or upgrading existing equipment, a thorough understanding of polarized plugs is a foundational step toward success in the global market.

Understanding what is a polarized plug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| NEMA 1-15P | Two-prong design with one prong smaller than the other | Household appliances, small electronics | Pros: Simple design, low cost. Cons: Limited to low power applications. |

| NEMA 5-15P | Three-prong design including ground pin | Office equipment, consumer electronics | Pros: Enhanced safety with grounding. Cons: May be bulkier than two-prong types. |

| NEMA 6-15P | Heavy-duty design for higher voltage and current | Industrial machinery, commercial appliances | Pros: Suitable for high-power devices. Cons: Requires compatible outlets. |

| CEE 7/7 | European standard with a unique shape for safety | European electrical appliances, power tools | Pros: Commonly used in Europe, versatile. Cons: Not compatible with non-European outlets. |

| BS 1363 | UK standard with integrated fuse for additional protection | Home appliances, office equipment in the UK | Pros: Built-in safety features, widely accepted. Cons: Requires adapters for non-UK devices. |

What Are the Key Characteristics of NEMA 1-15P Polarized Plugs?

NEMA 1-15P polarized plugs are characterized by their two-prong design, with one prong smaller than the other to ensure correct polarity when connecting to outlets. This design is primarily used in North America for low-power applications such as household appliances and small electronics. B2B buyers should consider the limited power capacity of this type, making it unsuitable for high-demand devices. However, the simplicity and cost-effectiveness of NEMA 1-15P plugs make them a popular choice for basic electrical needs.

How Does NEMA 5-15P Improve Electrical Safety?

The NEMA 5-15P plug features three prongs, including a grounding pin, which enhances safety by preventing electrical shocks and ensuring proper grounding. This design is commonly used for office equipment and consumer electronics, making it essential for any B2B buyer looking to enhance workplace safety. While the added grounding pin provides significant advantages, it may also increase the size and complexity of the plug, necessitating compatible outlets.

What Makes NEMA 6-15P Suitable for Industrial Use?

NEMA 6-15P polarized plugs are designed for heavy-duty applications, capable of handling higher voltages and currents. These plugs are ideal for industrial machinery and commercial appliances, making them a critical component for businesses that rely on high-power electrical devices. Buyers should evaluate the specific power requirements of their equipment to ensure compatibility with NEMA 6-15P plugs. Despite their advantages, these plugs require compatible outlets, which may limit their use in certain settings.

Why Choose CEE 7/7 Plugs for European Applications?

The CEE 7/7 plug is a widely used European standard that features a unique shape designed for safety. Its versatility makes it compatible with various European electrical appliances and power tools. B2B buyers operating in or exporting to Europe should consider CEE 7/7 plugs for their projects, as they are commonly accepted across the continent. However, compatibility with non-European outlets can be a challenge, necessitating the use of adapters.

What Are the Benefits of BS 1363 Plugs in the UK?

BS 1363 plugs are the standard in the UK and come equipped with an integrated fuse for added protection against electrical faults. This design is prevalent in home appliances and office equipment, making it a reliable choice for B2B buyers in the UK market. While the built-in safety features provide peace of mind, buyers should be aware that these plugs may require adapters for use with devices from other regions, potentially complicating international trade.

Key Industrial Applications of what is a polarized plug

| Industry/Sector | Specific Application of what is a polarized plug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Powering small appliances like blenders and mixers | Enhanced safety reduces risk of electrical accidents | Compliance with local electrical standards and certifications |

| Healthcare | Medical devices requiring reliable power supply | Ensures proper operation of critical devices, enhancing patient safety | Need for high-quality, durable plugs that meet health regulations |

| Hospitality | Kitchen equipment in restaurants and hotels | Prevents equipment malfunction, ensuring smooth operations | Sourcing plugs that withstand heavy usage and comply with safety codes |

| Manufacturing | Machinery and tools in production lines | Improves operational efficiency by ensuring correct power connections | Consideration of voltage requirements and plug compatibility |

| Automotive | Charging stations for electric vehicles | Supports the shift to sustainable energy solutions | Need for robust plugs that meet international charging standards |

How Is a Polarized Plug Used in Consumer Electronics?

In the consumer electronics sector, polarized plugs are commonly used in small appliances such as blenders, toasters, and coffee makers. These plugs ensure that the hot and neutral wires are connected correctly, minimizing the risk of electrical shock. For international B2B buyers, sourcing polarized plugs that comply with local safety standards is crucial to avoid liability issues and ensure consumer safety. Additionally, ensuring compatibility with existing electrical systems can prevent operational disruptions.

What Role Do Polarized Plugs Play in Healthcare?

In healthcare, polarized plugs are essential for powering medical devices that require a stable and safe electrical supply. Devices such as infusion pumps and diagnostic machines rely on the correct electrical configuration to function properly. This application is critical for patient safety, as any malfunction can lead to severe consequences. Buyers in this sector must prioritize sourcing high-quality polarized plugs that meet stringent health regulations and standards to ensure reliability in medical environments.

Illustrative image related to what is a polarized plug

How Are Polarized Plugs Beneficial in the Hospitality Industry?

In the hospitality industry, especially in restaurants and hotels, polarized plugs are used in various kitchen appliances. Their design prevents incorrect connections, which can lead to equipment failure and safety hazards. This reliability is vital for maintaining smooth operations, as downtime can significantly affect customer service and revenue. B2B buyers should seek plugs that are not only safe but also durable enough to withstand the rigorous demands of commercial kitchens.

Why Are Polarized Plugs Important in Manufacturing?

Manufacturers utilize polarized plugs in machinery and tools to ensure that power is supplied safely and efficiently. The correct configuration of electrical connections is crucial for operational efficiency and safety in production environments. International buyers must consider the voltage requirements and compatibility of polarized plugs with their machinery to avoid operational delays and ensure compliance with safety regulations.

How Do Polarized Plugs Support the Automotive Industry?

In the automotive sector, polarized plugs are increasingly found in electric vehicle charging stations. They are designed to provide a secure and reliable connection, which is essential for the safe charging of vehicles. As the industry shifts towards sustainable energy solutions, sourcing robust polarized plugs that meet international charging standards is critical for businesses looking to invest in EV infrastructure. Ensuring these plugs are durable and weather-resistant can enhance their reliability in outdoor environments.

3 Common User Pain Points for ‘what is a polarized plug’ & Their Solutions

Scenario 1: Navigating Electrical Compliance Standards

The Problem: B2B buyers in industries like manufacturing or construction often face challenges when ensuring that their electrical equipment complies with local safety standards. In many regions, especially in Africa and South America, the lack of clear guidelines on polarized versus non-polarized plugs can create confusion. This may lead to sourcing equipment that does not meet safety regulations, resulting in potential fines, liability issues, and operational downtime.

The Solution: To avoid compliance pitfalls, businesses should prioritize sourcing equipment that adheres to international electrical safety standards, such as IEC (International Electrotechnical Commission) and local codes. When purchasing appliances or electrical components, buyers should specifically inquire about the type of plug and whether it is polarized. Additionally, collaborating with suppliers who provide detailed product specifications and compliance documentation can ensure that all equipment meets necessary safety requirements. Regular training for procurement and maintenance teams on electrical safety standards can also enhance awareness and compliance.

Scenario 2: Ensuring Proper Equipment Functionality

The Problem: In industries that rely heavily on electrical appliances, such as hospitality or healthcare, improper equipment functionality due to incorrect plug types can lead to operational disruptions. For example, a coffee machine that requires a polarized plug may fail to operate correctly if plugged into a non-polarized outlet. This not only impacts service delivery but can also result in financial losses.

The Solution: To mitigate this risk, businesses should conduct a thorough assessment of their electrical infrastructure before purchasing new equipment. It is essential to ensure that all outlets are compatible with the polarized plugs of the appliances being used. When sourcing new equipment, buyers should confirm that suppliers provide products with the appropriate plug types and voltage specifications for their region. In instances where existing outlets are non-polarized, businesses should consider upgrading to polarized outlets, which may require consultation with an electrician to ensure a safe and compliant installation.

Scenario 3: Managing Diverse Global Plug Standards

The Problem: For international B2B buyers, particularly those operating in multiple regions such as Europe and the Middle East, the diverse electrical plug standards can create significant logistical challenges. A company may find that its devices with polarized plugs are incompatible with local outlets in certain countries, leading to increased costs for adapters or even new equipment.

The Solution: To address this challenge, buyers should engage in thorough research regarding the electrical standards of each market they operate in. Partnering with local distributors can provide valuable insights into the types of plugs and voltages that are commonly used in that region. Additionally, businesses can adopt a standardized approach to equipment purchasing by selecting devices that offer interchangeable plug options or universal compatibility. Investing in high-quality, versatile equipment that meets various international standards can streamline operations and reduce the need for costly modifications or replacements.

Strategic Material Selection Guide for what is a polarized plug

What Materials Are Commonly Used in Polarized Plugs?

When selecting materials for polarized plugs, various factors such as electrical properties, durability, and compliance with international standards must be considered. Here, we analyze four common materials used in the construction of polarized plugs: thermoplastics, thermosetting plastics, copper alloys, and stainless steel.

Illustrative image related to what is a polarized plug

What Are the Key Properties of Thermoplastics in Polarized Plugs?

Thermoplastics, such as polycarbonate and nylon, are frequently used in the outer casing of polarized plugs due to their excellent electrical insulation properties and impact resistance. They typically have a high-temperature rating, often exceeding 100°C, making them suitable for various applications. Additionally, thermoplastics are lightweight and can be easily molded into complex shapes, which simplifies manufacturing.

Pros: Thermoplastics are generally cost-effective and can be produced in large volumes with minimal waste. They also offer good chemical resistance, which is beneficial in environments where exposure to oils or solvents may occur.

Cons: However, thermoplastics can be less durable than some alternatives, particularly under extreme temperature fluctuations or prolonged exposure to UV light. They may also have lower mechanical strength compared to thermosetting plastics.

Impact on Application: The choice of thermoplastic can significantly influence the plug’s performance in different environments. For instance, plugs made from UV-stabilized polycarbonate are ideal for outdoor applications.

Considerations for International Buyers: Compliance with international standards such as IEC 60884-1 is crucial. Buyers in Europe and Africa should ensure that the thermoplastics used meet the relevant safety and environmental regulations.

How Do Thermosetting Plastics Perform in Polarized Plugs?

Thermosetting plastics, like phenolic resins, are known for their superior mechanical strength and thermal stability. They can withstand higher temperatures (up to 150°C) without deforming, making them suitable for heavy-duty applications.

Pros: These materials are highly resistant to electrical arcing and have excellent insulating properties, which enhance safety in electrical applications.

Cons: The manufacturing process for thermosetting plastics is more complex and costly than for thermoplastics, as they require curing. This can lead to longer lead times for production.

Impact on Application: Thermosetting plastics are particularly beneficial in applications where high durability and heat resistance are required, such as in industrial machinery.

Considerations for International Buyers: Buyers should verify that thermosetting plastics comply with ASTM and DIN standards, particularly in regions with stringent safety regulations like Germany.

What Role Do Copper Alloys Play in Polarized Plugs?

Copper alloys are commonly used for the conductive pins in polarized plugs due to their excellent electrical conductivity and resistance to corrosion. They typically have a high melting point, making them suitable for high-temperature applications.

Pros: Copper alloys provide reliable electrical connections and are relatively easy to manufacture. They also offer good resistance to oxidation, which is important for maintaining conductivity over time.

Cons: The main drawback is that copper can be susceptible to corrosion in certain environments, especially in humid or saline conditions. This can lead to reduced performance and lifespan.

Impact on Application: The choice of copper alloy can affect the plug’s performance in various media, particularly in environments with high humidity or exposure to corrosive substances.

Considerations for International Buyers: Compliance with international electrical standards, such as IEC 60900, is essential. Buyers from South America and the Middle East should also consider local environmental factors that may affect copper’s longevity.

Why Is Stainless Steel Used in Polarized Plugs?

Stainless steel is often used for grounding pins and other components in polarized plugs due to its corrosion resistance and mechanical strength. It can withstand high temperatures and is less prone to wear and tear.

Pros: The durability of stainless steel makes it ideal for applications where the plug may be subject to physical stress or exposure to moisture.

Cons: However, stainless steel can be more expensive than other materials, and its electrical conductivity is lower than that of copper, which may affect performance in some applications.

Impact on Application: Stainless steel is particularly suitable for outdoor or industrial applications where durability and resistance to environmental factors are critical.

Considerations for International Buyers: Buyers should ensure that stainless steel components meet relevant standards for corrosion resistance, particularly in coastal regions where salt exposure is common.

Summary Table of Material Selection for Polarized Plugs

| Material | Typical Use Case for what is a polarized plug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastics | Outer casing of polarized plugs | Cost-effective and lightweight | Less durable under extreme conditions | Low |

| Thermosetting Plastics | Heavy-duty applications | High mechanical strength and heat resistance | More complex and costly to manufacture | High |

| Copper Alloys | Conductive pins | Excellent electrical conductivity | Susceptible to corrosion in humid environments | Medium |

| Stainless Steel | Grounding pins and durable components | Corrosion resistant and durable | Higher cost and lower conductivity | High |

This guide provides a comprehensive overview of material considerations for polarized plugs, aiding B2B buyers in making informed decisions that align with their specific application needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for what is a polarized plug

What are the Main Stages in the Manufacturing Process of Polarized Plugs?

The manufacturing process of polarized plugs encompasses several key stages, each crucial to ensuring product safety, reliability, and compliance with international standards. Understanding these stages helps B2B buyers make informed decisions when sourcing from suppliers.

How is Material Prepared for Polarized Plug Production?

The first stage of manufacturing polarized plugs involves meticulous material preparation. High-quality materials such as thermoplastics for the plug body and copper or brass for the pins are selected based on their electrical conductivity and durability.

- Material Selection: The materials must meet specific electrical and thermal resistance properties to ensure safety and longevity.

- Material Testing: Before production, materials undergo rigorous testing for compliance with relevant safety standards (e.g., UL, CE). This testing ensures that they can withstand the conditions they will face in actual use.

What Forming Techniques are Used in the Production of Polarized Plugs?

Once materials are prepared, the next stage involves forming the components of the polarized plug. This can include several techniques:

- Injection Molding: This is the most common method for creating the plastic body of the plug. The thermoplastic is heated until molten and injected into a mold to form the desired shape.

- Metal Stamping: For the pins, metal stamping is employed. Sheets of metal are cut and shaped into the required dimensions, ensuring that the hot and neutral pins are of different sizes for proper polarization.

- Surface Treatment: Post-forming, metal components may undergo surface treatments such as plating to enhance conductivity and corrosion resistance.

How are Polarized Plugs Assembled?

The assembly of polarized plugs is a critical phase that combines all individual components into the final product:

- Component Integration: The plastic body is combined with the metal pins, ensuring that the polarization is correctly oriented. The assembly process must be performed with precision to avoid any misalignment.

- Soldering and Connection: In some designs, pins are soldered to internal wiring to secure electrical connections. This step requires skilled labor to ensure that connections are solid and compliant with safety standards.

- Final Assembly: The plug is then assembled, and any additional components, such as strain reliefs or internal insulation, are added to enhance safety and performance.

What Finishing Processes are Involved in Polarized Plug Manufacturing?

Finishing processes enhance the aesthetics and functionality of polarized plugs:

- Quality Inspection: After assembly, each plug undergoes quality checks to ensure compliance with specifications. This includes visual inspections for defects and dimensional checks.

- Labeling and Packaging: Plugs are labeled with necessary safety information and packaged according to international shipping standards. Packaging must also protect the plugs during transportation.

How is Quality Assurance Conducted in Polarized Plug Manufacturing?

Quality assurance is paramount in the manufacturing of polarized plugs to ensure that they meet international safety standards and perform reliably.

What International Standards Should B2B Buyers Consider?

B2B buyers should be aware of various international standards that govern the quality and safety of electrical products:

- ISO 9001: This standard focuses on quality management systems and is essential for manufacturers to demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: In Europe, plugs must comply with the Low Voltage Directive (LVD) and the Electromagnetic Compatibility Directive (EMC) to earn CE marking, indicating conformity with health and safety standards.

- UL Certification: In North America, Underwriters Laboratories (UL) certification is crucial for ensuring that plugs meet safety requirements for electrical devices.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure that every polarized plug meets required standards:

- Incoming Quality Control (IQC): At this stage, raw materials are inspected for quality and compliance with specifications before they enter the production line.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to monitor production and ensure adherence to quality standards. This includes checking dimensions, electrical properties, and assembly integrity.

- Final Quality Control (FQC): Before shipping, every finished polarized plug undergoes a comprehensive inspection to confirm that it meets all functional and safety standards. Testing may include electrical testing, mechanical stress tests, and environmental durability tests.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying the quality control practices of suppliers is vital for B2B buyers to ensure they receive reliable and safe products.

What Are Effective Methods for Supplier Audits?

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturer’s quality control processes, equipment, and adherence to international standards. This can be a significant factor in supplier selection.

- Reviewing Quality Reports: Requesting detailed quality reports, including inspection and testing results, can provide insights into the supplier’s commitment to quality.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the manufacturer’s quality control measures. This is especially important for buyers in regions with stringent safety requirements.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, understanding the nuances of quality control is essential, particularly when sourcing from diverse markets such as Africa, South America, the Middle East, and Europe:

- Regional Compliance: Different regions may have unique compliance requirements. For instance, buyers in Europe must ensure products meet CE standards, while those in North America focus on UL certification.

- Communication Barriers: Language and cultural differences may affect the clarity of quality expectations. Establishing clear communication channels and documentation can mitigate misunderstandings.

- Logistical Considerations: The transportation of polarized plugs may involve various regulations, including packaging and labeling requirements. Familiarity with these regulations can prevent costly delays or rejections at customs.

By comprehensively understanding the manufacturing processes and quality assurance measures for polarized plugs, B2B buyers can make informed decisions that ensure product safety and reliability while fostering strong supplier relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is a polarized plug’

Introduction

In the context of electrical safety and compliance, understanding polarized plugs is essential for international B2B buyers. This guide provides a practical checklist for sourcing polarized plugs, ensuring that your procurement aligns with safety standards and operational requirements. By following these steps, you can make informed decisions that enhance safety and functionality in your electrical applications.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications required for your polarized plugs. Consider the voltage, amperage, and environmental conditions under which the plugs will be used. This clarity will streamline your search for suppliers and ensure compatibility with existing equipment.

Step 2: Research Regulatory Compliance

Ensure that the polarized plugs you intend to procure meet local and international safety standards. Look for certifications such as UL, CE, or IEC, which signify compliance with safety regulations. Understanding these requirements is crucial, especially when dealing with electrical components in various regions, including Africa, South America, and Europe.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your quality and compliance needs. Request company profiles, case studies, and references from buyers in similar industries or regions. Evaluate their manufacturing processes and quality control measures to ascertain their reliability.

Step 4: Assess Product Quality and Durability

Investigate the materials and design of the polarized plugs to ensure they are robust and suitable for your applications. Look for features such as high-temperature resistance and durable construction, which can extend the lifespan of the plugs. This assessment is vital to avoid future costs related to replacements or repairs.

Step 5: Request Samples for Testing

Before finalizing any orders, request samples of the polarized plugs to conduct thorough testing. This allows you to evaluate performance in real-world applications and verify that they meet your operational standards. Testing samples can help identify any potential issues before large-scale procurement.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in discussions about pricing, payment terms, and delivery schedules. Ensure that the terms align with your budget and operational timelines. Establishing clear agreements can prevent misunderstandings and foster a positive long-term relationship with the supplier.

Step 7: Plan for Ongoing Support and Maintenance

Consider the availability of after-sales support and warranty options from your supplier. A reliable supplier should offer technical assistance and replacement parts as needed. Ensuring ongoing support can enhance the longevity of your investment and maintain operational efficiency.

By following this checklist, B2B buyers can confidently navigate the sourcing process for polarized plugs, ensuring that their selections contribute to safety and compliance in their electrical applications.

Illustrative image related to what is a polarized plug

Comprehensive Cost and Pricing Analysis for what is a polarized plug Sourcing

What Are the Key Cost Components for Sourcing Polarized Plugs?

When sourcing polarized plugs, understanding the cost structure is crucial for B2B buyers aiming for cost-efficiency. The primary cost components include:

-

Materials: The raw materials for polarized plugs typically involve high-quality plastics for insulation and copper for the prongs. The choice of materials significantly affects both performance and safety standards.

-

Labor: Labor costs vary depending on the manufacturing location. In regions with lower wage standards, labor costs can be minimized, but this may impact quality. Skilled labor is often required for assembly, especially for plugs that need to meet specific safety certifications.

-

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, equipment maintenance, and administrative expenses. Manufacturers in different countries may have varying overhead costs, influenced by local regulations and economic conditions.

-

Tooling: The initial investment in tooling for polarized plugs can be substantial, especially for custom designs. Tooling costs can be amortized over larger production runs, making high-volume orders more cost-effective.

-

Quality Control (QC): Ensuring that polarized plugs meet safety standards incurs additional costs. Robust QC measures are essential, especially for exports, to comply with international safety certifications like UL, CE, or IEC.

-

Logistics: Transportation costs can fluctuate based on distance, shipping methods, and customs duties. For international buyers, understanding Incoterms is vital to estimate logistics expenses accurately.

-

Margin: Manufacturers will typically add a profit margin to cover their costs and ensure sustainability. This margin can vary widely depending on the market, competition, and demand.

How Do Price Influencers Affect Polarized Plug Sourcing?

Several factors can influence the pricing of polarized plugs:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounted pricing. Manufacturers may offer better rates for bulk purchases, which is advantageous for businesses looking to reduce unit costs.

-

Specifications and Customization: Custom designs or specific technical specifications can increase costs. Buyers should clearly define requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials and compliance with international certifications can raise the price. However, investing in quality reduces the risk of product failures and recalls.

-

Supplier Factors: The reputation and reliability of the supplier can also impact pricing. Established suppliers may command higher prices but often provide better quality assurance and customer support.

-

Incoterms: The choice of Incoterms (like FOB, CIF, etc.) affects the total landed cost of goods. Buyers must understand these terms to negotiate favorable shipping and handling costs.

What Buyer Tips Can Help Optimize Costs for Polarized Plug Sourcing?

B2B buyers can adopt various strategies to optimize sourcing costs for polarized plugs:

-

Negotiation: Leverage your purchasing power by negotiating pricing, especially if you are a repeat customer or can guarantee large order volumes.

-

Focus on Total Cost of Ownership (TCO): Consider not only the initial purchase price but also long-term costs associated with maintenance, warranty, and potential replacements. Quality plugs may have a higher upfront cost but can save money over time.

-

Pricing Nuances for International Buyers: When sourcing from regions such as Africa, South America, the Middle East, and Europe, be aware of local market conditions, tariffs, and exchange rates. This knowledge can inform better purchasing decisions and negotiation strategies.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, priority in production schedules, and improved service.

Disclaimer on Indicative Prices

Prices for polarized plugs can fluctuate based on numerous factors, including market demand, raw material costs, and geopolitical conditions. It is advisable for buyers to request updated quotes from suppliers regularly to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing what is a polarized plug With Other Solutions

Introduction: Exploring Alternatives to Polarized Plugs

When considering electrical safety and functionality, polarized plugs are often viewed as the standard solution in many regions, particularly in North America. However, there are alternative technologies and methods that can achieve similar goals of safety and efficiency in electrical applications. This section will compare polarized plugs with two viable alternatives, enabling B2B buyers to make informed decisions tailored to their specific operational needs.

Comparison Table

| Comparison Aspect | What Is A Polarized Plug | Alternative 1 Name: Non-Polarized Plug | Alternative 2 Name: Smart Plugs |

|---|---|---|---|

| Performance | Ensures correct electrical flow; reduces shock risk | Less safe; can lead to incorrect wiring | Provides remote control and monitoring |

| Cost | Generally low cost | Typically lower cost than polarized plugs | Higher initial investment |

| Ease of Implementation | Simple to install | Easy installation; compatible with older outlets | Requires Wi-Fi setup and app integration |

| Maintenance | Low maintenance | Low maintenance; durable | May require software updates and troubleshooting |

| Best Use Case | Household appliances, safety-critical devices | Older appliances without polarized options | Modern appliances, energy management |

Detailed Breakdown of Alternatives

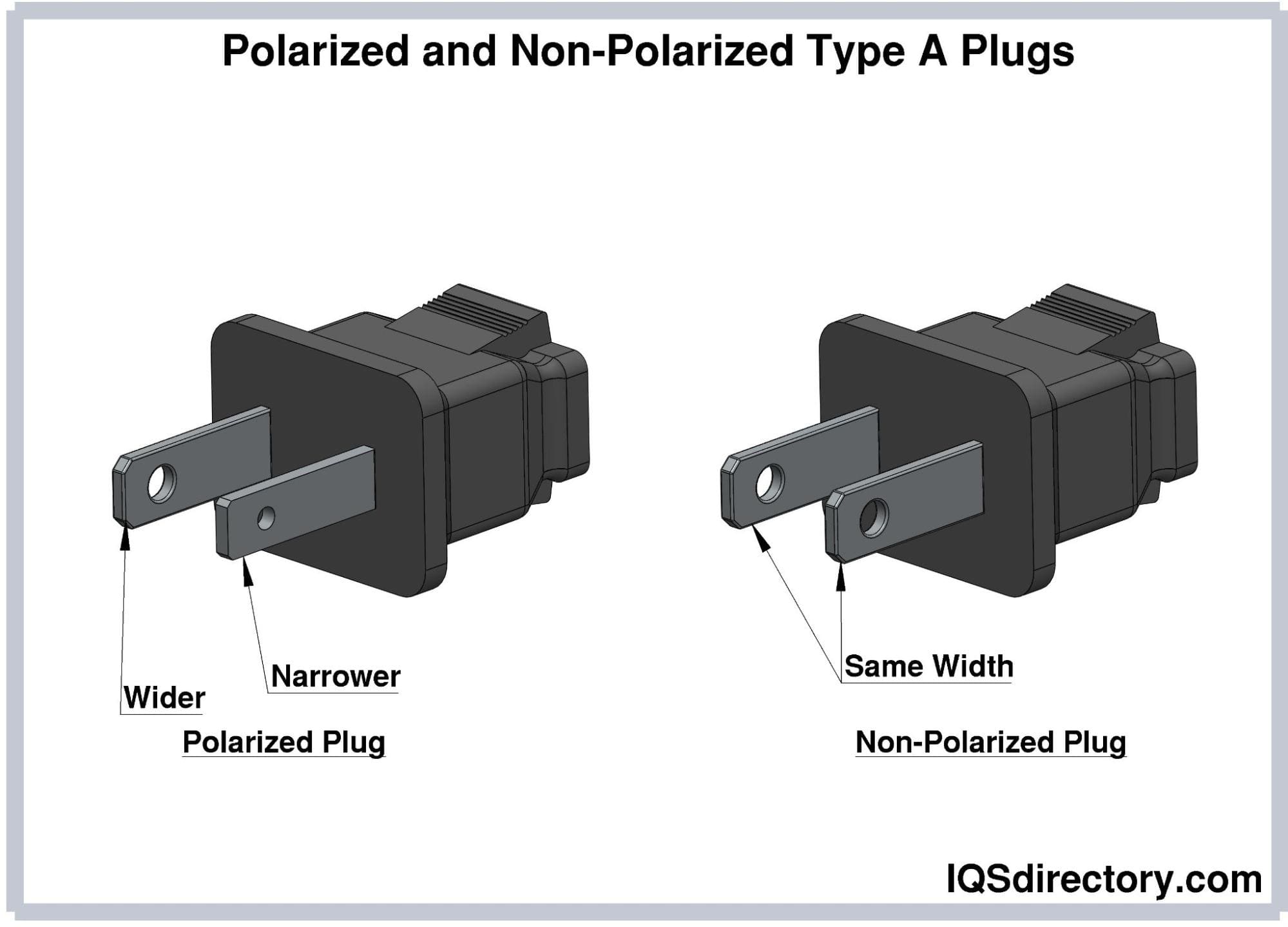

Non-Polarized Plugs

Non-polarized plugs feature two pins of equal size, allowing them to connect to outlets regardless of orientation. While they are generally less expensive and compatible with older systems, they pose safety risks. The lack of polarity can result in incorrect wiring, increasing the chances of electrical shock or equipment damage. Non-polarized plugs are best suited for low-risk applications or older devices that do not require stringent safety measures.

Smart Plugs

Smart plugs offer a modern solution by enabling remote control and energy monitoring through a smartphone application. While they typically require a higher initial investment and a stable Wi-Fi connection, their capabilities extend beyond traditional plug functions. Users can schedule devices, monitor energy usage, and even integrate them into home automation systems. However, smart plugs may not provide the same level of safety as polarized plugs, especially in environments where electrical safety is critical, such as in commercial kitchens or industrial settings.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate plug technology hinges on your specific operational context and safety requirements. Polarized plugs are ideal for applications where safety and proper electrical flow are paramount. In contrast, non-polarized plugs can be a cost-effective choice for older devices, while smart plugs are better suited for tech-savvy environments focused on energy management and remote control. B2B buyers should evaluate the performance, cost, and operational needs of their applications to determine the most suitable solution. Balancing safety, functionality, and budget will ultimately guide the decision-making process.

Essential Technical Properties and Trade Terminology for what is a polarized plug

What Are the Key Technical Properties of a Polarized Plug?

Understanding the technical specifications of polarized plugs is essential for B2B buyers involved in electrical equipment procurement. Here are critical properties to consider:

-

Material Grade

The materials used in polarized plugs typically include high-grade thermoplastics and copper alloys. Thermoplastics provide durability and insulation, while copper alloys ensure efficient electrical conductivity. Selecting plugs made from these materials can minimize the risk of overheating and electrical failures, which is crucial for maintaining operational safety in industrial settings. -

Voltage Rating

Polarized plugs are designed for specific voltage levels, commonly rated for 120V or 240V, depending on regional electrical standards. Buyers should ensure that the plugs match the voltage requirements of their equipment to prevent malfunctions or hazards. Understanding the voltage rating helps in selecting the appropriate plug for various applications, particularly in regions with distinct electrical systems. -

Current Rating (Amperage)

The current rating, usually expressed in amperes (A), indicates the maximum load a plug can safely handle. Common ratings for polarized plugs range from 10A to 20A. It’s essential for B2B buyers to select plugs that match or exceed the current requirements of their devices to ensure reliable performance and prevent potential overcurrent situations. -

Pin Configuration

Polarized plugs feature two pins of different sizes, with the smaller pin designated for the hot wire and the larger pin for the neutral wire. This design prevents incorrect insertion into sockets, enhancing user safety. Buyers should be aware of the pin configuration to ensure compatibility with existing outlets and to adhere to safety standards in various markets. -

Certification and Compliance Standards

Many polarized plugs are certified by international standards organizations such as UL (Underwriters Laboratories) or IEC (International Electrotechnical Commission). Compliance with these standards ensures that the plugs have undergone rigorous testing for safety and performance. Buyers should prioritize products with recognized certifications to mitigate risks associated with substandard electrical components. -

Temperature Rating

The temperature rating indicates the maximum operating temperature a polarized plug can withstand without degrading. This is particularly important in high-heat environments, such as manufacturing facilities. Understanding the temperature rating helps buyers select plugs that can maintain performance and safety under varying operational conditions.

What Are Common Trade Terms Related to Polarized Plugs?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for buyers looking to source high-quality polarized plugs that meet specific equipment standards. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their procurement strategies and manage inventory effectively, particularly in regions where storage space may be limited. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and availability of specific products. B2B buyers should utilize RFQs to gather competitive pricing and terms for polarized plugs, ensuring they receive the best value for their investment. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping and delivery terms. Understanding these terms is crucial for B2B buyers to clarify logistics and avoid misunderstandings during the procurement process. -

Lead Time

This term refers to the time it takes from placing an order to receiving the product. Knowing the lead time for polarized plugs can help buyers plan their project timelines and avoid delays in operations. -

Warranty Period

The warranty period specifies the duration a product is guaranteed to perform without defects. Buyers should pay attention to warranty terms for polarized plugs to ensure long-term reliability and support in case of product failures.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing polarized plugs, ensuring they meet safety standards and operational needs across various markets.

Navigating Market Dynamics and Sourcing Trends in the what is a polarized plug Sector

What Are the Key Drivers Influencing the Polarized Plug Market?

The polarized plug market is increasingly driven by global safety standards and regulatory compliance across various regions. In North America, the adoption of polarized plugs is mandated for electrical safety, which ensures that devices operate correctly by maintaining a consistent electrical flow. Emerging markets in Africa and South America are also beginning to prioritize electrical safety, leading to a gradual shift towards polarized systems in both residential and commercial applications. As industries evolve, the demand for polarized plugs is expected to rise, especially in sectors such as consumer electronics, appliances, and industrial machinery.

Another significant trend is the integration of smart technology within electrical components. B2B buyers are now seeking plugs that not only meet safety standards but also offer enhanced functionalities, such as smart monitoring and energy efficiency. The growing emphasis on energy conservation aligns with global sustainability goals, propelling manufacturers to innovate. Furthermore, as businesses become more interconnected, the demand for standardized plugs compatible with international voltage systems is also increasing, particularly in Europe and the Middle East.

How Can Sustainability and Ethical Sourcing Impact the Polarized Plug Supply Chain?

Sustainability in the polarized plug sector is becoming crucial for international B2B buyers, particularly given the growing awareness of environmental impacts. The production of electrical components, including polarized plugs, often involves materials that can be harmful to the environment if not sourced responsibly. As a result, buyers are increasingly favoring manufacturers that utilize eco-friendly materials and processes. This includes the use of recyclable plastics and metals, which not only reduce waste but also lower the carbon footprint associated with production.

Moreover, ethical sourcing practices are essential for building trust with consumers and partners alike. B2B buyers are encouraged to partner with suppliers who adhere to environmental regulations and maintain transparency in their supply chains. Certifications such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) are becoming benchmarks for assessing the sustainability of suppliers. These certifications ensure that manufacturers are committed to reducing their environmental impact and promoting ethical labor practices.

What Is the Historical Context of Polarized Plugs in the Market?

The polarized plug was first introduced in the early 20th century as a response to the increasing need for electrical safety in households and businesses. Initially, electrical systems were predominantly non-polarized, which posed risks when connecting appliances, as users could inadvertently connect devices in a manner that led to electrical shocks or equipment damage. The introduction of polarized plugs, characterized by their differently sized prongs, ensured that devices could only be plugged in one way, aligning hot and neutral connections correctly.

Illustrative image related to what is a polarized plug

Over the decades, as electrical safety standards evolved, polarized plugs became a requirement in many regions, particularly in North America. Their adoption has been further propelled by the rise of consumer electronics and the need for safer appliances in homes and workplaces. This historical context is essential for B2B buyers to understand, as it highlights the ongoing commitment to electrical safety and the need for reliable, standardized products in the global market.

In summary, navigating the polarized plug sector involves understanding key market dynamics, embracing sustainable practices, and acknowledging the historical evolution that has shaped current sourcing trends.

Frequently Asked Questions (FAQs) for B2B Buyers of what is a polarized plug

-

How do I identify a polarized plug?

To identify a polarized plug, examine the size and shape of its prongs. A polarized plug typically has one prong that is wider than the other; the wider prong connects to the neutral wire while the narrower prong connects to the hot wire. This design prevents incorrect connections that could lead to electrical hazards. In contrast, non-polarized plugs have prongs of equal size, making it difficult to determine which is which. Understanding this distinction is crucial for ensuring safety in electrical devices, especially when sourcing components for international markets. -

What are the benefits of using polarized plugs in electrical devices?

Polarized plugs enhance safety by ensuring that electrical devices are connected correctly, reducing the risk of electric shock and equipment damage. They help maintain the integrity of the electrical circuit, ensuring that the hot wire connects to the appropriate terminal. This is particularly important in regions with varying electrical standards, as improper connections can lead to malfunctions or hazards. For B2B buyers, sourcing polarized plugs can also meet compliance with local electrical safety regulations, making them a preferred choice for manufacturers and distributors. -

What international standards should I consider when sourcing polarized plugs?

When sourcing polarized plugs, it’s essential to consider international standards such as IEC (International Electrotechnical Commission) and regional standards like NEMA (National Electrical Manufacturers Association) for North America, or BS (British Standards) for the UK. Compliance with these standards ensures that the plugs meet safety and performance requirements in various markets. Additionally, understanding the specific electrical regulations in your target region—such as voltage and frequency—can help you select the right products for your needs, facilitating smoother international trade. -

What customization options are available for polarized plugs?

Many manufacturers offer customization options for polarized plugs, including variations in prong shape, length, and material. Customization can also extend to features such as added grounding pins or different voltage ratings to meet specific regional needs. When discussing customization with suppliers, ensure you communicate your requirements clearly, including any certifications or standards that must be met. This level of customization can enhance product appeal and functionality, helping you cater to diverse markets across Africa, South America, the Middle East, and Europe. -

What are the minimum order quantities (MOQs) for polarized plugs?

Minimum order quantities (MOQs) for polarized plugs can vary significantly among suppliers, typically ranging from a few hundred to several thousand units. Factors influencing MOQs include manufacturing capabilities, customization requests, and the supplier’s inventory policies. When negotiating MOQs, consider your demand forecasts and the potential for scaling up orders in the future. Understanding the supplier’s production capacity can also help you gauge whether they can meet your needs in a timely manner, ensuring a reliable supply chain. -

What payment terms should I expect when sourcing polarized plugs internationally?

Payment terms for international orders of polarized plugs can vary widely depending on the supplier, order size, and relationship with the buyer. Common terms include upfront payments, partial payments before shipment, or net payment terms (e.g., 30, 60, or 90 days after delivery). It’s essential to clarify payment methods accepted, such as wire transfers, letters of credit, or payment platforms. Establishing favorable payment terms can help manage cash flow and mitigate risks associated with international trade. -

How can I ensure quality assurance (QA) when sourcing polarized plugs?

To ensure quality assurance when sourcing polarized plugs, request product samples and conduct thorough testing to verify compliance with relevant safety standards. Additionally, inquire about the supplier’s quality control processes, including certifications such as ISO 9001. Implementing a quality inspection protocol during production and before shipment can further safeguard against defects. Collaborating with trusted suppliers known for their commitment to quality can help mitigate risks and enhance product reliability in your offerings. -

What logistics considerations should I keep in mind when importing polarized plugs?

Logistics considerations when importing polarized plugs include understanding shipping methods, customs regulations, and potential tariffs or duties. Evaluate the most cost-effective and timely shipping options based on your location and urgency. It’s also vital to work with a logistics partner familiar with international shipping processes to ensure compliance with local regulations. Proper documentation, including invoices and certificates of conformity, will facilitate smoother customs clearance, reducing delays and unforeseen costs.

Top 5 What Is A Polarized Plug Manufacturers & Suppliers List

1. Wadsworth City – Polarized Plug

Domain: wadsworthcity.com

Registered: 1997 (28 years)

Introduction: A polarized plug is designed with one large or wide prong and one narrow prong to ensure correct insertion into a socket, promoting proper electric current flow and reducing the risk of electrical shock. Consumers should avoid forcing a polarized plug into a non-polarized outlet or altering the prongs. Instead, they should use an adapter or locate an appropriate polarized outlet. Additionally, som…

2. Reddit – Polarized Plugs

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Polarized plugs are designed to ensure that electrical devices are connected in a specific orientation, enhancing safety by ensuring that the ‘hot’ wire is switched off when the device is turned off. This prevents electrical shock by ensuring that the internal components are not energized when the device is off. Additionally, polarized plugs help prevent incorrect connections that could lead to da…

3. Interpower – NEMA 1-15 Plugs

Domain: interpower.com

Registered: 1996 (29 years)

Introduction: The NEMA 1-15 plug can be polarized or non-polarized. A polarized plug has a wider neutral blade than the line (hot) blade, ensuring correct wiring to circuit wires. The non-polarized plug does not maintain a known condition for neutral and line connections. Polarized plugs will fit into polarized sockets, but not vice versa. Polarized plugs are often used in products where a defined electrical pa…

4. 1000Bulbs – Polarized vs Non-Polarized Plugs

Domain: blog.1000bulbs.com

Registered: 2001 (24 years)

Introduction: Polarized plugs have two prongs of unequal size or three prongs, ensuring safe insertion into outlets. Non-polarized plugs have two identical prongs, which can lead to reversed polarity and potential electrical hazards. Polarized plugs are designed to complete electrical circuits safely, while non-polarized plugs are often double-insulated for safety. Most modern US receptacles are polarized.

5. Polarized Plugs – Safety Features

Domain: electronics.stackexchange.com

Introduction: Polarized plugs are designed to ensure that the ‘hot’ wire is connected to the hot terminal and the ‘neutral’ wire is connected to the neutral terminal, providing an extra measure of safety. This is particularly important for appliances with single-pole switches, as interrupting the hot wire reduces the risk of electric shock. In 120V countries, the wider blade on the 2-prong plug indicates the ne…

Strategic Sourcing Conclusion and Outlook for what is a polarized plug

In conclusion, understanding polarized plugs is essential for international B2B buyers looking to enhance electrical safety and ensure compliance with regional standards. Polarized plugs, characterized by their unequal prong sizes, provide a critical safety function by ensuring proper electrical flow and reducing the risk of electrical shocks. This is particularly relevant in regions undergoing modernization, where outdated non-polarized systems may pose safety hazards.

For businesses in Africa, South America, the Middle East, and Europe, sourcing polarized plugs not only aligns with current safety codes but also enhances the reliability of electrical devices used in various industries. Strategic sourcing of these components can lead to improved operational efficiency, reduced liability, and increased customer trust.

As the global market continues to evolve, staying ahead of safety standards is paramount. We encourage you to engage with trusted suppliers who can provide high-quality polarized plugs tailored to your specific needs. By prioritizing safety and compliance in your sourcing strategies, you position your business for long-term success in an increasingly competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to what is a polarized plug

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.