How to Source What Is A Lab Bench Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for what is a lab bench

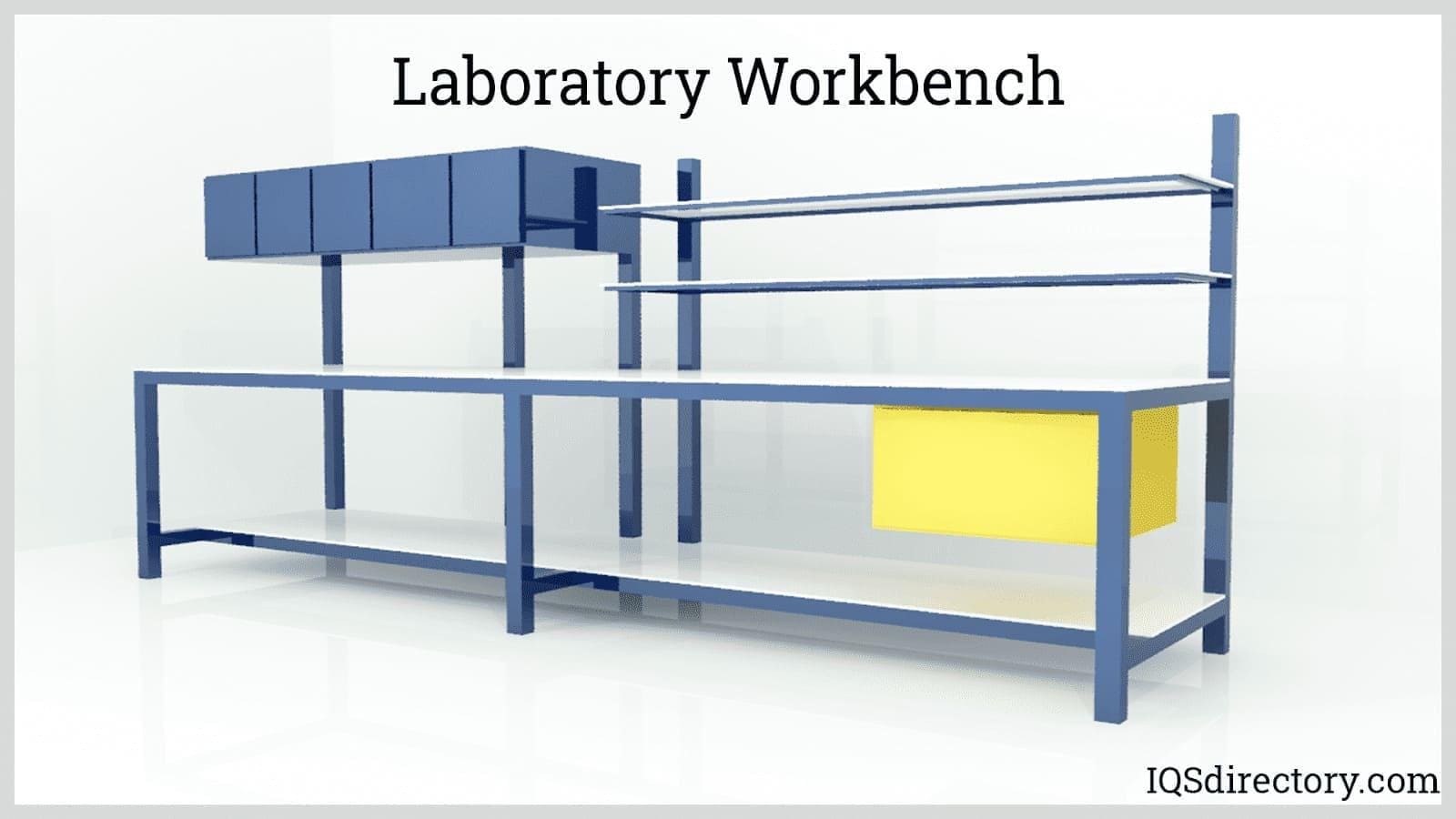

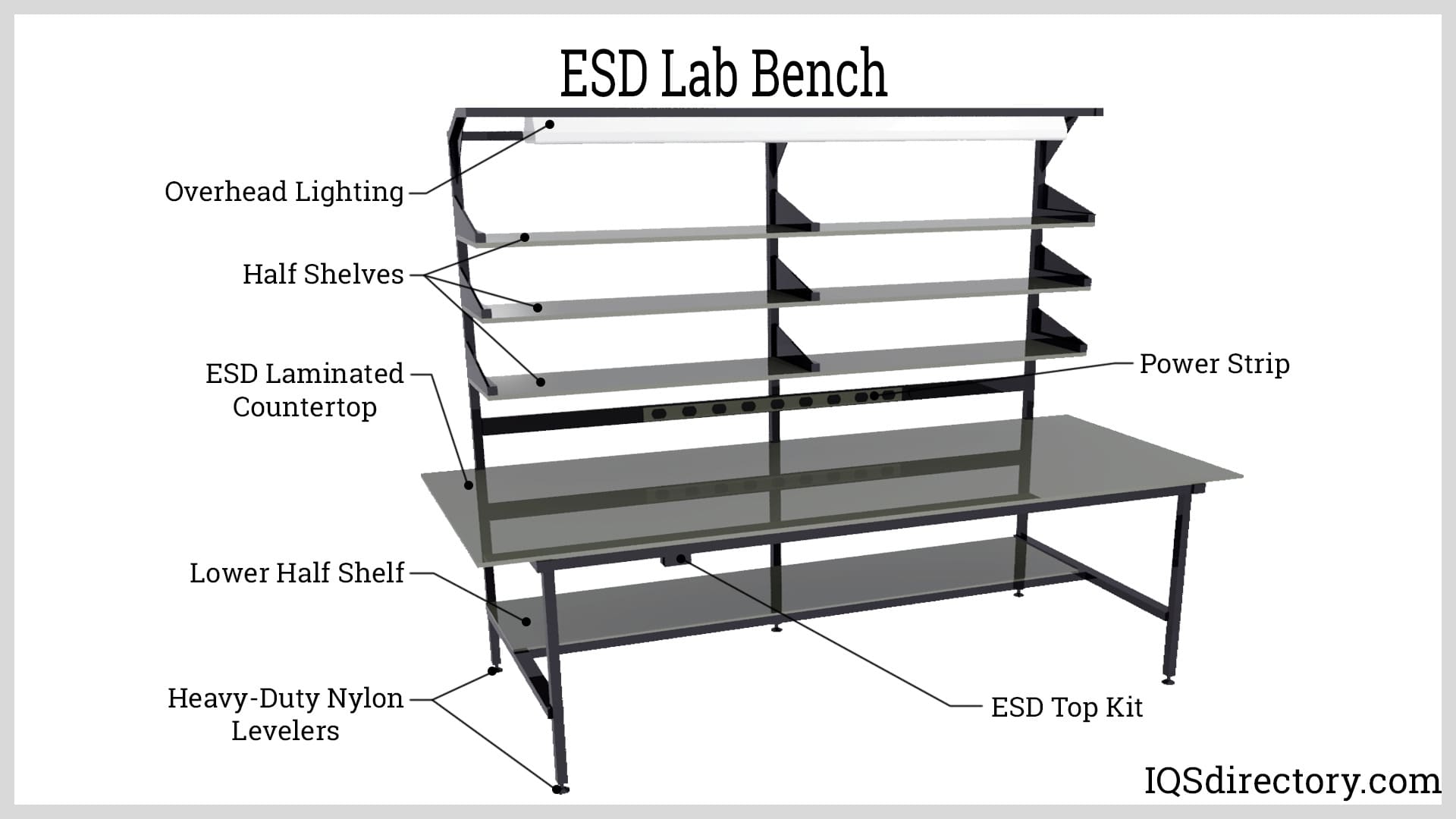

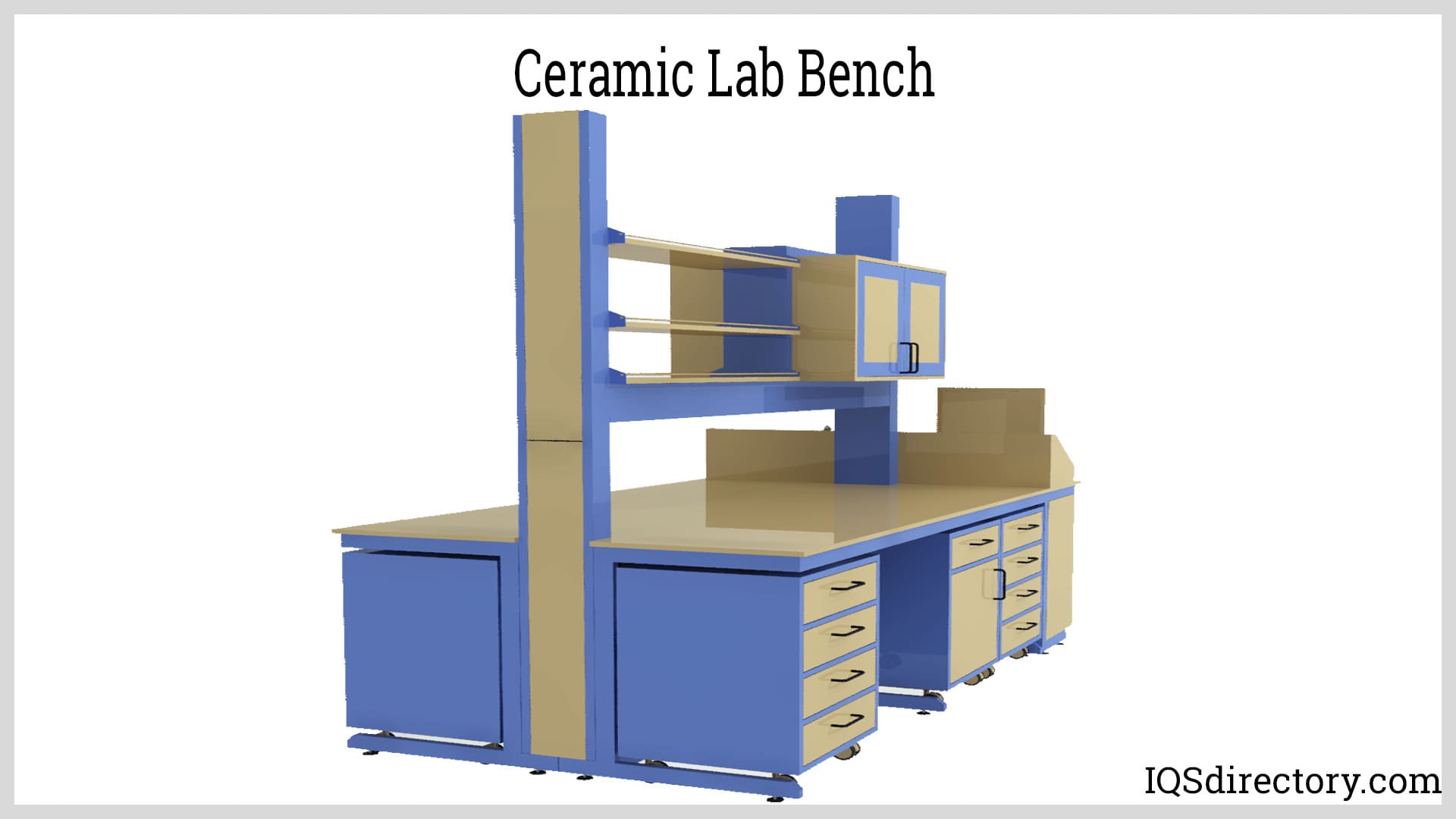

In today’s competitive global market, sourcing the right laboratory bench can pose a significant challenge for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. A laboratory bench is not merely a piece of furniture; it is the cornerstone of laboratory operations, designed to support a diverse range of scientific activities. Whether you’re establishing a new research facility or upgrading existing equipment, understanding the various types of lab benches and their specific applications is crucial for ensuring efficiency and safety in your workspace.

This comprehensive guide delves into the multifaceted world of lab benches, exploring essential topics such as the different types available—ranging from wet and dry lab benches to adjustable and portable options. Additionally, we will address the critical factors for supplier vetting, helping you identify reliable manufacturers that meet international standards. Cost considerations will also be outlined, enabling you to budget effectively while still securing high-quality products.

By equipping international B2B buyers with actionable insights, this guide empowers you to make informed purchasing decisions that enhance laboratory functionality and productivity. Understanding the intricacies of lab benches not only optimizes your workspace but also drives innovation and success in your scientific endeavors.

Understanding what is a lab bench Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wet Lab Workbench | Features sinks, reagent racks, and utility connections for liquids. | Chemistry and biology laboratories. | Pros: Versatile for liquid experiments. Cons: Requires regular maintenance to prevent water damage. |

| Dry Lab Workbench | Flat surface with minimal attachments, ideal for dry experiments. | Physics labs and electronics testing. | Pros: Provides ample surface area. Cons: Limited utility for wet applications. |

| Adjustable Workbench | Height adjustable for ergonomic use, catering to various user needs. | Research labs, industrial applications. | Pros: Customizable comfort. Cons: May have a higher initial cost. |

| Stainless Steel Bench | Durable, easy to sterilize, and resistant to chemicals and heat. | Medical labs, food processing. | Pros: Long-lasting and low maintenance. Cons: Conductive nature may limit use in specific labs. |

| Portable Workbench | Lightweight and mobile, designed for flexibility across environments. | Fieldwork, temporary setups. | Pros: Easy to transport and set up. Cons: May lack stability for heavy equipment. |

What Are the Characteristics of Wet Lab Workbenches?

Wet lab workbenches are specifically designed to accommodate experiments involving liquids. These benches often include built-in sinks for easy cleaning and disposal, as well as reagent racks for storing chemicals. They are crucial in chemistry and biology laboratories where liquid handling is frequent. When purchasing, consider the materials used to ensure durability against chemical spills and the ease of maintenance required to keep the workspace safe and functional.

How Do Dry Lab Workbenches Differ in Functionality?

Dry lab workbenches are characterized by their flat surfaces and minimal attachments, making them ideal for experiments that do not involve liquids, such as physics or electronics testing. Their design allows for a spacious work area, which is essential for intricate tasks. B2B buyers should focus on the surface material and stability when selecting a dry lab workbench, ensuring it meets the specific needs of their laboratory environment.

Why Choose an Adjustable Workbench?

Adjustable workbenches allow users to modify the height of the work surface, promoting ergonomic practices and accommodating different user preferences. This flexibility makes them suitable for a variety of applications, from research labs to industrial settings. Buyers should consider the ease of adjustment and the weight capacity to ensure they can support the intended equipment and workloads.

What Are the Benefits of Stainless Steel Benches?

Stainless steel benches are renowned for their durability and resistance to heat, chemicals, and moisture, making them a staple in medical labs and food processing facilities. Their smooth surfaces facilitate easy cleaning and sterilization. Buyers should evaluate the quality of the stainless steel used, as well as the design features that enhance usability, such as rounded edges or integrated storage options.

Illustrative image related to what is a lab bench

How Do Portable Workbenches Enhance Flexibility?

Portable workbenches provide a lightweight and mobile solution for various applications, including fieldwork or temporary setups. Their design allows for easy transportation and assembly, making them ideal for organizations that require flexibility. However, buyers should assess the stability and weight capacity of portable options to ensure they can safely support the necessary equipment in diverse environments.

Key Industrial Applications of what is a lab bench

| Industry/Sector | Specific Application of what is a lab bench | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceutical | Drug formulation and testing | Ensures precise measurements and safe handling of chemicals | Quality materials resistant to chemicals and easy to clean |

| Educational Institutions | Science labs for practical experiments | Supports hands-on learning and experimentation | Customizable designs to fit different lab layouts and needs |

| Biotechnology | Genetic research and molecular biology experiments | Facilitates complex procedures with necessary utility connections | Ergonomic designs to enhance researcher productivity |

| Food and Beverage | Quality control and product testing | Guarantees compliance with safety standards and quality assurance | Durable surfaces that withstand spills and are easy to sanitize |

| Environmental Testing | Sample preparation and analysis of pollutants | Enables accurate data collection for regulatory compliance | Versatile setups for different types of testing and analysis |

How is a Lab Bench Used in the Pharmaceutical Industry?

In the pharmaceutical sector, lab benches are essential for drug formulation and testing. They provide a stable and safe surface for conducting experiments involving potentially hazardous chemicals. The benches often include built-in sinks and utility connections for seamless workflow. Buyers in this sector must prioritize benches made from high-quality, chemical-resistant materials that facilitate easy cleaning to maintain a sterile environment.

What Role Do Lab Benches Play in Educational Institutions?

Educational institutions utilize lab benches to create science labs where students can conduct practical experiments. These benches support a variety of activities, from biology dissections to chemistry experiments. Customizable designs allow institutions to optimize space and meet specific curriculum needs. When sourcing, it’s crucial to consider durability and safety features to withstand frequent use by students.

How Do Biotechnology Labs Benefit from Lab Benches?

In biotechnology, lab benches are used for genetic research and molecular biology experiments. These benches often come equipped with necessary utility connections, such as gas and electricity, to accommodate advanced equipment. Ergonomic designs are particularly important in this sector to enhance researcher productivity and comfort during long hours of experimentation. Buyers should seek customizable options that can adapt to evolving research needs.

Illustrative image related to what is a lab bench

Why Are Lab Benches Critical in the Food and Beverage Industry?

In the food and beverage industry, lab benches are vital for quality control and product testing. They provide a clean, durable surface for testing food samples and ensuring compliance with safety standards. The ability to withstand spills and facilitate easy sanitation is key for maintaining hygiene. When sourcing, businesses should look for benches that offer high resistance to stains and are easy to maintain.

What is the Importance of Lab Benches in Environmental Testing?

Lab benches in environmental testing labs support the preparation and analysis of samples, such as air or water pollutants. They enable accurate data collection that is crucial for regulatory compliance. Buyers in this field need versatile setups that can accommodate various testing methods and ensure the safety of the operator. Choosing benches that offer ample storage and organization options is also critical for efficiency in the lab.

3 Common User Pain Points for ‘what is a lab bench’ & Their Solutions

Scenario 1: Selecting the Right Lab Bench Material for Specific Experiments

The Problem: Many B2B buyers struggle with choosing the right material for their lab benches, particularly when their laboratories perform various experiments that require different properties. For instance, a chemistry lab may need benches that can withstand corrosive chemicals, while a physics lab might prioritize durability and ease of cleaning. Without a clear understanding of the materials available—such as epoxy resin, stainless steel, or phenolic resin—buyers may end up selecting benches that do not meet their specific needs, leading to potential safety hazards and increased costs due to premature replacements.

The Solution: To effectively source the right lab bench, buyers should first conduct a thorough needs assessment that considers the types of experiments performed, the materials handled, and the anticipated wear and tear. This assessment will inform the selection of materials. For example, epoxy resin benches offer chemical resistance and durability, making them suitable for wet labs, while stainless steel benches are ideal for heavy-duty applications due to their impact resistance and easy maintenance. Buyers should consult with manufacturers or suppliers who can provide technical specifications and insights into the best materials for their specific applications. Additionally, visiting showrooms or labs that utilize these materials can provide practical insight into how each type performs in real-world conditions.

Illustrative image related to what is a lab bench

Scenario 2: Space Constraints and Customization Needs

The Problem: Space limitations are a common issue in laboratories, especially in facilities where every square foot must be utilized efficiently. B2B buyers may find that standard lab benches do not fit their available space or meet their specific operational requirements. This can lead to cluttered work areas, inefficiencies in workflow, and even safety concerns.

The Solution: To address space constraints, buyers should consider customized lab benches that can be tailored to their specific dimensions and functional needs. Engaging with suppliers who specialize in modular or adjustable lab benches can provide solutions that optimize space while enhancing usability. For example, L-shaped or U-shaped benches can make better use of corner spaces, while height-adjustable benches can accommodate various tasks and promote ergonomic working conditions. When working with suppliers, buyers should present a detailed layout of their lab, including utility connections and workflow patterns, to ensure that the customized benches align perfectly with their operational needs.

Scenario 3: Ensuring Compliance with Safety and Ergonomic Standards

The Problem: Compliance with safety and ergonomic standards can be a daunting task for B2B buyers when selecting lab benches. Many laboratories are subject to stringent regulations regarding equipment safety and workplace ergonomics. Failure to comply can result in penalties and may compromise employee safety and productivity. Buyers may be overwhelmed by the various standards and certifications required, leading to poor purchasing decisions.

The Solution: To ensure compliance, buyers should familiarize themselves with the relevant local and international standards that apply to laboratory furniture. Engaging with suppliers who offer lab benches certified for safety and ergonomics, such as those meeting ISO or ANSI standards, is crucial. Buyers should request documentation and certifications from manufacturers to validate compliance. Additionally, integrating ergonomic design principles—such as adjustable height features and appropriate surface areas—will not only meet regulatory requirements but also enhance user comfort and productivity. Conducting periodic reviews and audits of the lab environment can further ensure that all equipment, including lab benches, continues to meet necessary standards over time.

Strategic Material Selection Guide for what is a lab bench

What Are the Key Properties of Common Lab Bench Materials?

When selecting materials for laboratory benches, understanding the properties, advantages, and limitations of each option is crucial for B2B buyers. Below, we analyze four common materials used in lab bench construction: epoxy resin, stainless steel, phenolic resin, and maple wood. Each material has unique characteristics that can significantly impact laboratory operations.

How Does Epoxy Resin Perform in Laboratory Settings?

Epoxy resin is a popular choice for lab benches due to its excellent durability and chemical resistance. It can withstand a wide range of temperatures and is impervious to most chemicals, making it suitable for various laboratory applications. Epoxy surfaces are also antimicrobial, which is beneficial in maintaining hygiene standards.

Pros: Epoxy resin benches are highly durable, aesthetically versatile, and resistant to UV light and moisture. They can last for many years with proper care.

Cons: The primary drawback is the potential for surface imperfections, such as air bubbles, if not sourced from quality suppliers. Maintenance is required to prevent scratches and stains.

Impact on Application: Ideal for wet labs where chemical exposure is frequent, epoxy resin benches can handle various media without degradation.

Illustrative image related to what is a lab bench

Considerations for International Buyers: Compliance with standards like ASTM and DIN is essential. Buyers from regions like Africa and South America should ensure the supplier meets local regulations regarding chemical resistance and safety.

What Are the Benefits of Stainless Steel for Lab Benches?

Stainless steel is renowned for its unmatched strength and longevity. It is highly resistant to heat, moisture, and chemicals, making it an excellent choice for high-impact laboratory environments.

Pros: Stainless steel benches are easy to clean and sterilize, which is vital for laboratories dealing with biological materials. They require minimal maintenance and can withstand heavy wear.

Cons: While durable, stainless steel can be more expensive than other materials and may not be suitable for labs requiring non-conductive surfaces.

Impact on Application: Suitable for both wet and dry labs, stainless steel benches can accommodate a variety of laboratory tasks, including those involving heat or corrosive substances.

Considerations for International Buyers: Buyers should verify that the stainless steel used meets international standards for corrosion resistance, especially in humid environments typical of some African and South American regions.

How Does Phenolic Resin Compare to Other Lab Bench Materials?

Phenolic resin offers a cost-effective alternative to epoxy resin, providing similar chemical resistance and a seamless finish. However, it is less durable and more suitable for lighter laboratory activities.

Pros: Phenolic resin is non-conductive and resistant to chemicals, bacteria, and fungi, making it a good option for specific laboratory tasks.

Cons: Its lower durability means it may not be suitable for heavy-duty applications, and it may require more frequent replacement.

Illustrative image related to what is a lab bench

Impact on Application: Best for labs with lighter workloads, phenolic resin benches can handle various media but may not withstand harsh conditions.

Considerations for International Buyers: Ensure that the phenolic resin complies with local safety and quality standards, particularly in regions with stringent laboratory regulations.

Why Choose Maple Wood for Lab Benches?

Maple wood is often chosen for its aesthetic appeal and natural properties. While it is not as common as synthetic materials, it offers a warm and inviting workspace.

Pros: Maple wood is durable and provides a comfortable working surface. It is also relatively easy to work with during installation.

Cons: Wood is susceptible to moisture damage and may not be suitable for wet labs. It requires more maintenance to prevent wear and tear.

Impact on Application: Best for dry labs or educational settings, maple wood benches can support various tasks but are limited in chemical compatibility.

Considerations for International Buyers: Buyers should ensure that the wood is treated to meet local environmental regulations and standards, especially in humid climates.

Summary Table of Lab Bench Materials

| Material | Typical Use Case for what is a lab bench | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Epoxy Resin | Wet labs with chemical exposure | Highly durable and antimicrobial | Potential surface imperfections | Medium |

| Stainless Steel | High-impact and sterile environments | Easy to clean and long-lasting | Higher cost and conductive | High |

| Phenolic Resin | Light-duty labs | Cost-effective and chemical resistant | Lower durability | Low |

| Maple Wood | Dry labs and educational settings | Aesthetic appeal and comfort | Susceptible to moisture damage | Medium |

This analysis provides a comprehensive overview for B2B buyers to make informed decisions when selecting lab bench materials tailored to their specific needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for what is a lab bench

What Are the Key Stages in the Manufacturing Process of Laboratory Benches?

The manufacturing process of laboratory benches encompasses several essential stages, each crucial to ensuring that the final product meets the rigorous demands of laboratory environments. The main stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for Laboratory Benches?

Material preparation begins with the selection of high-quality raw materials, which can range from wood, metal, and various composites like epoxy and phenolic resin. For wooden benches, materials are typically sourced from sustainably managed forests to comply with environmental regulations. Metal components, such as stainless steel, are often chosen for their durability and resistance to corrosion.

Once sourced, the materials undergo processing, which may include cutting, sanding, and treating to enhance their properties. For composite materials, mixing and curing processes are vital to ensure that the final product achieves the desired strength and durability.

What Forming Techniques Are Used in Lab Bench Manufacturing?

The forming stage involves shaping the prepared materials into the desired bench configurations. This may include techniques such as:

Illustrative image related to what is a lab bench

- Molding: For composite materials like epoxy resin, molding is a common method. Liquid resin is poured into molds, where it is cured to form solid benchtops.

- Fabrication: Metal benches are often fabricated using processes like laser cutting, welding, and bending to create precise shapes and joints.

- Machining: Wooden benches may undergo machining to ensure accurate dimensions and fit. This includes drilling, routing, and planing to achieve a smooth finish.

These techniques are critical for ensuring that the benches can withstand the rigors of laboratory use, including exposure to chemicals and physical stress.

How Are Laboratory Benches Assembled?

Assembly is the stage where individual components are brought together to form the complete lab bench. This can involve:

- Joining Techniques: Depending on the materials, various joining techniques such as screws, bolts, or adhesive bonding are used to ensure structural integrity.

- Customization: Many lab benches are customized to meet specific client requirements, which may involve integrating features like sinks, utility connections, or storage compartments.

Quality craftsmanship during assembly is essential, as it affects the bench’s overall durability and functionality.

What Finishing Processes Are Applied to Lab Benches?

The finishing stage enhances both the aesthetic appeal and functionality of the laboratory benches. This may include:

Illustrative image related to what is a lab bench

- Surface Treatments: Applying finishes such as varnishes, paints, or sealants to wooden benches to protect against moisture and chemical spills.

- Polishing: Metal surfaces, particularly stainless steel, are often polished to a high shine, enhancing their resistance to corrosion and making them easier to clean.

- Quality Checks: Before the benches leave the manufacturing facility, they undergo final inspections to ensure that they meet design specifications and quality standards.

What Quality Assurance Measures Are Essential for Laboratory Benches?

Quality assurance (QA) is a critical aspect of laboratory bench manufacturing, ensuring that the products meet international and industry-specific standards.

What International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 are vital for ensuring that manufacturing processes are efficient and produce high-quality products. This standard focuses on a quality management system that can enhance customer satisfaction and operational efficiency.

Additionally, compliance with industry-specific standards, such as CE marking for products sold in Europe, ensures that the benches meet health, safety, and environmental protection requirements. In the medical and pharmaceutical sectors, adherence to standards set by organizations like the API (American Petroleum Institute) may also be necessary.

What Quality Control Checkpoints Are Common in Lab Bench Manufacturing?

Quality control (QC) is typically segmented into several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the manufacturing process, random samples may be taken to check for defects and adherence to specifications.

- Final Quality Control (FQC): Completed benches undergo thorough inspections to verify that they meet all design and performance requirements.

These checkpoints help mitigate risks and ensure that any issues are identified and rectified early in the production process.

What Testing Methods Are Commonly Used in Quality Assurance?

Common testing methods for laboratory benches include:

- Load Testing: Assessing the bench’s ability to withstand specified weight loads.

- Chemical Resistance Testing: Evaluating how well the materials hold up against various chemicals used in laboratory settings.

- Durability Testing: Conducting stress tests to ensure the bench can endure everyday laboratory use without degradation.

These tests help B2B buyers ascertain that the laboratory benches will perform effectively in their intended environments.

Illustrative image related to what is a lab bench

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from diverse markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial.

What Audits and Reports Should Buyers Request?

Buyers should request copies of quality audits, certifications, and test reports to verify compliance with international standards. Regular audits conducted by third parties can provide an additional layer of assurance regarding the supplier’s adherence to quality standards.

What Role Do Third-Party Inspections Play in Quality Assurance?

Third-party inspections can serve as an effective means for buyers to ensure that the products meet the required quality standards. Engaging an independent inspection agency can help verify that the manufacturing processes and final products align with specified requirements.

What Are the Quality Control Nuances for International Buyers?

International buyers should be aware of potential discrepancies in quality standards across regions. For instance, while European standards may emphasize environmental sustainability, other regions may focus more on cost-effectiveness. Understanding these nuances can help buyers make more informed decisions when selecting suppliers.

By considering these manufacturing processes and quality assurance measures, B2B buyers can ensure they procure laboratory benches that are not only fit for purpose but also meet the highest standards of quality and durability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is a lab bench’

Introduction

This practical sourcing guide aims to assist B2B buyers in understanding and procuring laboratory benches, which are essential for any lab environment. By following this step-by-step checklist, buyers will ensure they select the right type of lab bench that meets their specific operational needs while also considering quality, supplier reliability, and cost-effectiveness.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your laboratory’s requirements. Consider the type of work being performed—whether it’s a wet lab requiring chemical resistance or a dry lab needing a more straightforward surface. Identifying these specifications helps narrow down the options and ensures that the selected lab bench will support your experiments effectively.

- Material Considerations: Determine if you need materials like epoxy resin for chemical resistance or stainless steel for durability.

- Size and Configuration: Assess the space available and the number of users to establish the appropriate size and layout of the bench.

Step 2: Assess Your Budget Constraints

Establishing a budget is crucial in guiding your procurement decisions. Laboratory benches can vary significantly in price based on material, features, and customization options.

Illustrative image related to what is a lab bench

- Total Cost of Ownership: Consider not only the initial purchase price but also maintenance and replacement costs over time.

- Potential for Customization: Be prepared to allocate more budget for benches that may require specialized configurations or additional features.

Step 3: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers to ensure they can meet your needs. Request detailed company profiles, product catalogs, and case studies to understand their capabilities.

- Industry Experience: Look for suppliers with a proven track record in providing lab furniture, particularly in your region or industry.

- References and Reviews: Seek testimonials or references from other clients to gauge supplier reliability and product quality.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers hold relevant certifications that guarantee product quality and compliance with safety standards. Certifications can vary by region, so it’s essential to confirm they meet local regulations.

- Quality Assurance Standards: Check for ISO certifications or other industry-specific quality assurances.

- Safety Compliance: Ensure that the lab benches meet safety standards relevant to your laboratory’s operations.

Step 5: Request Samples or Demonstrations

Whenever possible, request samples or arrange demonstrations of the lab benches you are considering. This hands-on experience can provide insights into the bench’s usability, stability, and overall quality.

- Evaluate Ergonomics: Test the height and surface area to ensure they meet the ergonomic needs of your lab personnel.

- Assess Durability: Look for signs of wear and tear on sample products to evaluate how they may hold up under heavy use.

Step 6: Review Warranty and Support Options

Before finalizing your purchase, carefully review the warranty and support options provided by the supplier. A solid warranty can protect your investment and provide peace of mind.

- Warranty Coverage: Understand what is covered under the warranty and for how long.

- Post-Purchase Support: Confirm if the supplier offers installation, maintenance, or repair services.

Step 7: Finalize Your Purchase and Logistics

Once you have selected the appropriate lab benches, finalize your purchase by confirming the order details, delivery timelines, and payment terms.

Illustrative image related to what is a lab bench

- Delivery and Setup: Ensure that the logistics of delivery and installation are clearly outlined and agreed upon.

- Documentation: Keep all purchase agreements, warranties, and supplier contacts readily available for future reference.

By following this checklist, B2B buyers can navigate the complexities of procuring laboratory benches effectively, ensuring a suitable and cost-efficient choice for their laboratory needs.

Comprehensive Cost and Pricing Analysis for what is a lab bench Sourcing

What Are the Key Cost Components for Sourcing a Lab Bench?

When sourcing a lab bench, it’s essential to understand the various cost components involved. The primary cost elements include:

-

Materials: The type of material significantly influences the price. Options range from economical phenolic resin to high-end epoxy resin and stainless steel. Each material comes with its own cost implications based on durability, maintenance, and resistance to chemicals.

-

Labor: Labor costs can vary based on the complexity of the bench’s design and the manufacturing process. Customization generally requires more skilled labor, increasing the overall cost.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and factory space. Efficient manufacturing processes can help reduce overhead costs, which can be reflected in the final price.

-

Tooling: Specialized tooling for manufacturing custom lab benches can add to the initial cost. Investments in high-quality tooling may lead to better product consistency and longevity.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the lab benches meet safety and performance standards. Although this adds to the cost, it is crucial for maintaining product integrity, especially in laboratory settings.

-

Logistics: Shipping costs can vary significantly based on the origin and destination. Considerations such as freight charges, customs duties, and insurance play a critical role in the total cost of ownership.

-

Margin: Suppliers typically build a profit margin into their pricing structure. Understanding the average markup for lab furniture can aid in evaluating supplier quotes.

How Do Price Influencers Affect Lab Bench Costs?

Several factors can influence the pricing of lab benches:

-

Volume/MOQ: Purchasing in larger quantities often leads to lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk orders, making it beneficial for organizations with ongoing needs.

-

Specifications/Customization: Custom specifications can substantially increase costs. Standard models are generally less expensive, while tailored designs that accommodate specific laboratory requirements will require additional investment.

-

Materials: The choice of materials directly affects both price and functionality. High-quality materials may incur higher upfront costs but can result in lower maintenance expenses over time.

-

Quality/Certifications: Lab benches that meet international safety and quality standards (such as ISO certifications) may come at a premium. However, investing in certified products ensures compliance and safety, reducing long-term risks.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding the terms of trade (Incoterms) is vital for international buyers. These terms determine who bears the costs and risks during shipping, affecting the overall price.

What Are Effective Buyer Tips for Negotiating Lab Bench Prices?

When negotiating lab bench prices, consider the following strategies:

-

Leverage Volume Discounts: If your organization plans to purchase multiple units, negotiate for a better price based on volume. Suppliers are often willing to offer significant discounts for large orders.

-

Evaluate Total Cost of Ownership: Look beyond the initial purchase price. Consider long-term costs, including maintenance, replacement, and operational efficiencies. A more expensive bench may offer better durability and lower maintenance costs.

-

Research Supplier Options: Don’t settle for the first quote. Research multiple suppliers to compare prices, quality, and service levels. This can provide leverage in negotiations.

-

Be Aware of International Pricing Nuances: For buyers in Africa, South America, the Middle East, and Europe, be mindful of currency fluctuations, import duties, and shipping costs. These factors can dramatically alter the final price.

-

Request Detailed Quotes: Ensure that any quotes received are comprehensive, breaking down costs into materials, labor, and logistics. This transparency aids in making informed decisions and comparing offers.

Disclaimer on Indicative Prices

Pricing for lab benches can vary widely based on the aforementioned factors. It is advisable for buyers to obtain detailed quotations from suppliers to determine exact costs tailored to their specific needs.

Illustrative image related to what is a lab bench

Alternatives Analysis: Comparing what is a lab bench With Other Solutions

Understanding Alternatives to Lab Benches

In the world of laboratory equipment, lab benches stand out as essential fixtures. However, various alternative solutions exist that can meet specific needs or offer different functionalities. This comparison will help B2B buyers understand how lab benches stack up against other options, ensuring informed decision-making.

Comparison Table

| Comparison Aspect | What Is A Lab Bench | Adjustable Workbench | Portable Workbench |

|---|---|---|---|

| Performance | High durability; versatile for various lab activities | Ergonomic height adjustment; excellent for repetitive tasks | Flexible usage in multiple settings; lightweight |

| Cost | Moderate to high, depending on materials and customizations | Typically moderate; varies based on features | Generally lower; offers cost-effective portability |

| Ease of Implementation | Requires planning and space allocation; may need customization | Simple setup; requires minimal adjustments | Quick to set up and relocate; no permanent installation needed |

| Maintenance | Requires regular cleaning and occasional repairs | Low maintenance; primarily cleaning | Minimal maintenance; easy to store |

| Best Use Case | Ideal for fixed lab environments, supporting extensive experiments | Best for labs with diverse user needs and ergonomic considerations | Suitable for temporary labs or fieldwork, where mobility is essential |

Pros and Cons of Alternatives

Adjustable Workbench

An adjustable workbench offers significant advantages for laboratories that prioritize ergonomic design. Users can modify the height to suit individual preferences, making it ideal for tasks requiring prolonged standing or sitting. This flexibility enhances productivity and reduces the risk of musculoskeletal injuries. However, these benches may lack the extensive durability and specialized features found in traditional lab benches, making them less suitable for heavy-duty applications.

Portable Workbench

Portable workbenches provide an excellent solution for laboratories requiring mobility. Their lightweight design allows for easy transportation and setup in various environments, making them perfect for fieldwork or temporary labs. This flexibility, combined with a lower cost, makes them attractive to budget-conscious buyers. However, the trade-off is often in stability and durability; portable workbenches may not withstand heavy usage or accommodate specialized lab equipment as effectively as traditional lab benches.

Conclusion: How to Choose the Right Solution for Your Lab Needs

When evaluating alternatives to lab benches, B2B buyers should carefully consider their specific requirements. Assess the nature of the work being conducted, the need for mobility versus stability, and budget constraints. A traditional lab bench may be the best choice for fixed laboratory environments, while adjustable or portable workbenches can offer valuable flexibility for dynamic or temporary setups. Ultimately, understanding the pros and cons of each option will empower buyers to select the solution that best aligns with their operational needs and enhances their laboratory’s efficiency.

Essential Technical Properties and Trade Terminology for what is a lab bench

What Are the Key Technical Properties of a Lab Bench?

When investing in laboratory benches, understanding their technical properties is crucial for ensuring the right fit for your laboratory’s specific needs. Here are some essential specifications to consider:

1. Material Grade

The material grade of a lab bench significantly influences its durability and suitability for various applications. Common materials include epoxy resin, phenolic resin, stainless steel, and maple wood. Each material offers distinct properties, such as chemical resistance, heat tolerance, and ease of cleaning. Selecting the appropriate material is vital for maintaining laboratory safety and ensuring longevity, especially in environments subject to spills or heavy wear.

2. Load Capacity

Load capacity refers to the maximum weight a lab bench can safely support. This specification is critical, especially for benches intended for heavy equipment or extensive laboratory work. Understanding the load capacity helps prevent structural failure, ensuring that experiments can be conducted safely and efficiently. B2B buyers should always verify load capacity against their anticipated use cases.

3. Dimensions and Ergonomics

The dimensions of a lab bench, including height, width, and depth, are essential for ergonomic design. An ergonomic bench allows for comfortable use and can reduce fatigue during long working hours. Customization options for height adjustment are particularly valuable in multi-user environments, ensuring that each user can work comfortably. Investing in ergonomically designed benches can enhance productivity and worker satisfaction.

Illustrative image related to what is a lab bench

4. Chemical Resistance

Chemical resistance is a critical property for lab benches, particularly in wet labs. Materials like epoxy resin and stainless steel are favored for their resistance to various chemicals, including acids and solvents. Evaluating chemical resistance is essential for preventing damage to the bench and maintaining a safe working environment, as spills can lead to hazardous situations.

5. Surface Finish

The surface finish of a lab bench impacts both functionality and maintenance. Smooth finishes are easier to clean and sterilize, making them suitable for sterile environments. Additionally, a good surface finish minimizes the risk of contamination. For B2B buyers, understanding the implications of surface finish can guide decisions related to hygiene standards and maintenance costs.

What Are Common Trade Terms Related to Lab Benches?

Familiarity with industry terminology can facilitate smoother transactions and better communication with suppliers. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products that can be marketed by another company under its brand name. In the context of lab benches, buyers may encounter OEM products that offer customized features at competitive prices. Understanding OEM relationships can help buyers assess quality and sourcing options.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects budget planning and inventory management. Knowing the MOQ helps businesses determine whether they can meet supplier requirements without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. For laboratory benches, issuing an RFQ enables buyers to gather competitive bids and assess different suppliers’ offerings. This process is essential for informed decision-making and ensuring value for money.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade transactions, including shipping costs and risk management. Familiarity with Incoterms can help buyers negotiate better terms and understand their obligations during shipping and delivery. This is particularly relevant for international buyers seeking lab benches from suppliers in different regions.

5. Customization Options

Customization options refer to the ability to tailor lab benches to specific requirements, such as additional storage, specialized surfaces, or integrated utilities. This term is significant for buyers looking for solutions that meet unique laboratory needs and enhance operational efficiency.

Illustrative image related to what is a lab bench

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when procuring laboratory benches, ensuring they choose the right products for their specific applications and operational needs.

Navigating Market Dynamics and Sourcing Trends in the what is a lab bench Sector

What Are the Key Market Trends Influencing Lab Bench Sourcing?

The global laboratory bench market is experiencing significant growth driven by increasing investment in research and development across various sectors, including pharmaceuticals, biotechnology, and education. In regions like Africa and South America, there is a burgeoning interest in enhancing laboratory capabilities, spurred by government initiatives and international partnerships aimed at improving healthcare and scientific research. In Europe, particularly in Germany, strict regulations on laboratory safety and efficiency are pushing organizations to upgrade their facilities, which includes sourcing high-quality lab benches tailored to specific needs.

Emerging technologies such as modular and customizable laboratory furniture are gaining traction. These innovations offer flexibility in design and functionality, allowing laboratories to adapt their workspaces to changing research requirements. Furthermore, the integration of smart technologies into lab benches—such as built-in utilities for gas and water, or even digital monitoring systems—enhances operational efficiency and safety, making them attractive to international buyers.

B2B buyers are also increasingly focusing on suppliers that can demonstrate a robust understanding of regional market dynamics and compliance with local regulations. This trend is particularly pertinent in regions with developing laboratory infrastructures, where buyers require suppliers to provide not only products but also consultation on best practices and layout optimization.

How Important is Sustainability and Ethical Sourcing in the Lab Bench Market?

Sustainability has become a critical consideration in laboratory furniture procurement. International buyers are increasingly aware of the environmental impact of their sourcing decisions, leading to a demand for lab benches made from sustainable materials. This includes the use of recycled or responsibly sourced wood, as well as synthetic materials that minimize environmental harm during production and disposal.

Illustrative image related to what is a lab bench

Ethical sourcing is equally important. Buyers are looking for suppliers who maintain transparent supply chains and adhere to fair labor practices. Certifications such as Forest Stewardship Council (FSC) for wood products and ISO certifications for manufacturing processes can serve as indicators of a supplier’s commitment to sustainability and ethical practices. Moreover, as laboratories strive to meet their own sustainability goals, they prefer products that contribute to a greener footprint, such as lab benches made from low-VOC (volatile organic compounds) materials that improve indoor air quality.

Investing in sustainable and ethically sourced lab benches not only enhances a company’s reputation but can also lead to long-term cost savings through reduced waste and improved energy efficiency in laboratory operations.

How Have Lab Benches Evolved Over Time to Meet B2B Needs?

The evolution of laboratory benches reflects the changing demands of scientific research and educational needs. Initially, lab benches were primarily utilitarian, designed to provide a flat surface for experiments. However, advancements in material science and ergonomic design have transformed lab benches into multifunctional workstations that cater to diverse laboratory environments.

Modern lab benches are available in a variety of materials, including epoxy resin, stainless steel, and phenolic resin, each offering unique advantages in terms of durability and resistance to chemicals. Additionally, the rise of modular designs allows laboratories to customize their workspaces efficiently, accommodating the specific needs of wet labs, dry labs, and specialized research areas.

As the focus on safety and ergonomics has increased, lab benches now often come equipped with integrated utilities and features that enhance user comfort and operational efficiency. This evolution not only supports more complex experimental setups but also aligns with the broader trends of sustainability and smart technology integration in laboratory environments.

Overall, the lab bench market continues to adapt, driven by technological advancements and the evolving needs of international B2B buyers looking for high-quality, versatile, and sustainable laboratory solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of what is a lab bench

-

How do I choose the right lab bench for my specific needs?

Choosing the right lab bench involves assessing the specific requirements of your laboratory environment. Consider factors such as the type of work being conducted (wet vs. dry), available space, and necessary utilities (water, gas, electricity). Additionally, evaluate the materials used in the bench construction, as they should be durable and resistant to the chemicals or substances you’ll be handling. Customization options should also be explored to ensure the bench fits seamlessly into your workflow. -

What types of lab benches are available for different laboratory environments?

Lab benches come in various types tailored to specific functions. Wet lab benches typically include sinks and reagent racks for handling liquids, while dry lab benches focus on providing a flat surface with electrical connections for experiments like physics or engineering. Other options include adjustable benches for ergonomic needs and portable benches for flexibility. Understanding the unique demands of your lab will guide you in selecting the appropriate type. -

What customization options should I consider when sourcing lab benches?

Customization is key to ensuring your lab bench meets specific operational requirements. Options may include modifying dimensions, adding utility connections, and selecting materials resistant to chemicals or heat. Storage solutions like drawers or shelves can also be customized based on your equipment needs. Discussing your unique laboratory requirements with suppliers will help you identify suitable custom features that enhance functionality. -

What are the typical minimum order quantities (MOQs) for lab benches from suppliers?

Minimum order quantities for lab benches can vary significantly depending on the supplier and the type of bench being ordered. Some manufacturers may allow single-unit purchases, especially for custom or specialized benches, while others may set MOQs ranging from 5 to 100 units for standard models. When sourcing, inquire about MOQs to determine if they align with your project needs and budget constraints. -

What payment terms are commonly offered by lab bench suppliers?

Payment terms can vary widely among suppliers, often depending on the order size and relationship with the buyer. Common terms include net 30 or net 60, meaning payment is due within 30 or 60 days of invoice receipt. Some suppliers may offer discounts for upfront payments or larger orders. It’s essential to clarify payment expectations early in the negotiation process to avoid any misunderstandings. -

How can I ensure the quality of lab benches when sourcing internationally?

To ensure quality when sourcing lab benches internationally, consider working with reputable suppliers who have established quality assurance processes. Request certifications and product specifications, and ask for references or case studies from previous clients. If possible, conduct factory visits or request samples before placing large orders. Utilizing third-party inspection services can also help verify product quality prior to shipment. -

What logistics considerations should I keep in mind when ordering lab benches?

Logistics is a critical aspect of sourcing lab benches, especially for international shipments. Consider factors such as shipping costs, delivery timelines, and customs regulations specific to your region. Ensure that the supplier has experience with international shipping and can handle documentation for customs clearance. Discuss packaging solutions to protect the benches during transit, as well as the availability of tracking services for better shipment visibility. -

What after-sales support should I expect from a lab bench supplier?

After-sales support is vital for addressing any issues that may arise post-purchase. Reputable suppliers typically offer warranties on their products, as well as technical support for installation or maintenance. Inquire about their return policy and procedures for handling defective items. Additionally, some suppliers may provide training for your staff on proper usage and care of the lab benches to ensure longevity and optimal performance.

Top 7 What Is A Lab Bench Manufacturers & Suppliers List

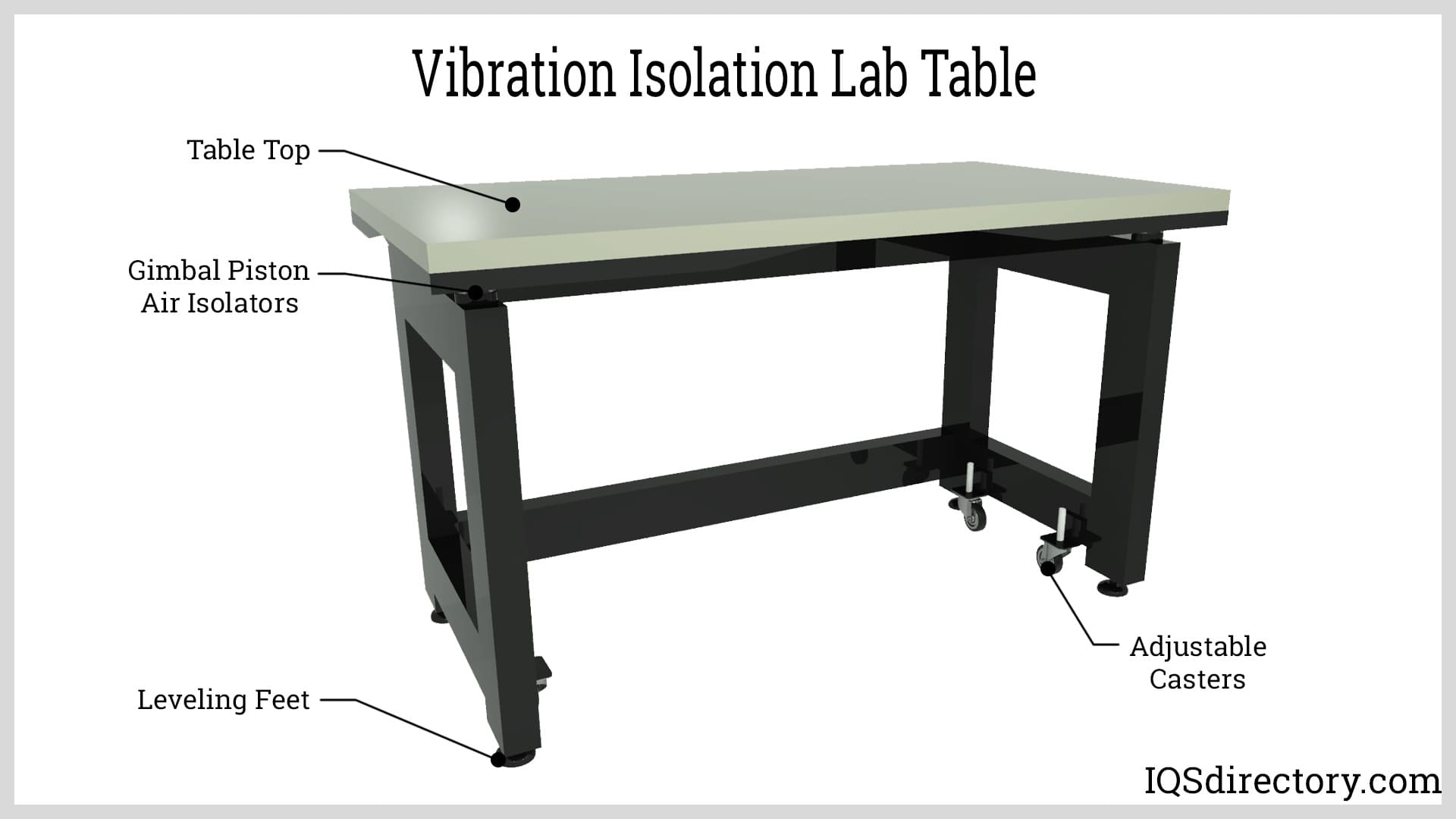

1. IQS Directory – Lab Benches

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Lab benches are customized tables designed for laboratory tasks and experiments, featuring finishes that withstand corrosion and reduce vibrations. They are classified into wet and dry lab benches based on the type of work. Wet lab benches are equipped for liquid processing with features like sinks and racks, while dry lab benches offer extensive work surfaces and storage. Lab benches can be class…

2. Lab Tech Supply Co – Epoxy & Phenolic Resins

Domain: labtechsupplyco.com

Registered: 2014 (11 years)

Introduction: 1. Epoxy Resin: Durable, aesthetic, antimicrobial, resistant to chemicals, UV light, and shock; requires maintenance to avoid scratches and stains. 2. Phenolic Resin: Lower price, less durable than epoxy, seamless finish, resistant to chemicals, bacteria, and fungus; suitable for lighter lab activities. 3. Stainless Steel: Highly durable, resistant to moisture, heat, and chemicals; easy to maintai…

3. Genie Scientific – Lab Benches

Domain: geniescientific.com

Registered: 2001 (24 years)

Introduction: Lab benches are crucial for research facilities, impacting efficiency, safety, and functionality. They are classified by purpose, function, and structure. Purpose includes specialized designs like cleanroom benches, sink lab benches, and island lab benches. Function covers dry lab benches for non-reactive activities and wet lab benches for handling chemicals and biological samples. Structure inclu…

4. Vocabulary.com – Laboratory Workbench

Domain: vocabulary.com

Registered: 1996 (29 years)

Introduction: This company, Vocabulary.com – Laboratory Workbench, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Fisher Scientific – Laboratory Benches and Tables

Domain: fishersci.com

Registered: 1995 (30 years)

Introduction: Laboratory benches and tables designed for safe laboratory tasks and handling of reagents and samples. Features may include corrosion-resistant and vibration-resistant finishes, as well as mobile units. Available colors include Almond, Amber Stain, Auburn Stain, Black, Gray, Green, Harvest Stain, Honey Stain, Light Gray, Maple, Mocha Stain, Natural Maple, Natural Stain, Oak, Silver, Teal, and Whit…

6. Workbench Manufacturers – Laboratory Workbenches

Domain: workbenchmanufacturers.com

Registered: 2012 (13 years)

Introduction: Laboratory workbenches, also known as lab benches, provide space and surface for tests, equipment storage, and workstations in scientific laboratories. Key features include: stability, durability, adaptability, heavy-duty locking casters for mobility and secure positioning, and various materials such as High-Density Polyethylene (HDPE), wood, metal (stainless steel or powder-coated), and specialty…

7. Engineering by Lee – Lab Bench Materials

Domain: engineeringbylee.com

Registered: 2015 (10 years)

Introduction: Lab Bench Materials: Frame material (wood, metal, composite), Fastening hardware (screws, nuts, bolts, braces), Finishing material (sheet material or adhesive varnish), Caulk or adhesive, Heavy-duty casters (for mobile benches), Sink, plumbing, faucets (optional), Eyewash station (optional). Bench Depth Guidelines: Casework Benchtops – 30 or 33 inches; Mobile Benchtops – 30 inches; Mobile Benchtop…

Strategic Sourcing Conclusion and Outlook for what is a lab bench

As you navigate the complexities of laboratory setups, understanding the critical role of lab benches is paramount. These foundational elements not only support a wide range of scientific activities but also enhance the overall efficiency and safety of laboratory environments. With options ranging from wet lab benches equipped with essential utilities to adjustable workbenches that cater to ergonomic needs, the right lab bench can significantly impact productivity and user comfort.

Strategic sourcing is essential for B2B buyers looking to procure high-quality lab benches tailored to specific operational needs. By investing in durable materials, such as epoxy resin or stainless steel, businesses can ensure longevity and resistance to the rigors of laboratory work. Moreover, customizing benches to suit particular scientific applications fosters a more effective workspace.

Looking ahead, international buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers who understand local regulations and can provide tailored solutions. This proactive approach will not only streamline procurement processes but also enhance the overall laboratory experience. For businesses ready to elevate their laboratory infrastructure, now is the time to explore and invest in high-quality lab benches that meet your unique requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.