How to Source Used Tillers For Sale Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for used tillers for sale

In the ever-evolving agricultural landscape, sourcing reliable used tillers for sale can pose significant challenges for international B2B buyers. As farming practices become more sophisticated, the demand for high-quality tilling equipment that can enhance soil health and crop yields is paramount. This comprehensive guide serves as a critical resource, addressing the complexities of navigating the global market for used tillers. From understanding the various types of tillers—such as rotary tillers, strip tillers, and power tillers—to exploring their specific applications in diverse agricultural settings, we cover essential insights that empower informed purchasing decisions.

International buyers from regions like Africa, South America, the Middle East, and Europe, including Germany and Vietnam, will benefit from our detailed analysis of supplier vetting processes, pricing structures, and the latest market trends. With a focus on both cost-effectiveness and equipment performance, this guide equips you with the knowledge needed to select the right tillers that align with your operational needs. Additionally, we delve into best practices for maintenance and after-sales support, ensuring that your investment yields optimal returns. By the end of this guide, you will be well-prepared to navigate the complexities of the used tiller market, making strategic choices that drive agricultural success.

Understanding used tillers for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conventional Tillers | Standard design with tines for soil mixing | Small to medium farms | Pros: Cost-effective, versatile. Cons: Limited depth control. |

| Strip Tillers | Minimal soil disturbance, designed for row crops | Precision agriculture, large farms | Pros: Enhances soil health, water conservation. Cons: Higher initial investment. |

| Rotary Tillers | Equipped with rotating blades for fine tillage | Landscaping, garden preparation | Pros: Excellent soil aeration, fine texture. Cons: May compact soil if used improperly. |

| Heavy-Duty Tillers | Built for tough soil conditions, robust construction | Large scale farming, commercial use | Pros: Durable, efficient in tough terrains. Cons: Heavier, requires more power. |

| Electric Tillers | Powered by electricity, often lightweight | Small gardens, urban farming | Pros: Eco-friendly, quieter operation. Cons: Limited power, may not suit large areas. |

What Are the Key Characteristics of Conventional Tillers?

Conventional tillers are the most commonly used type in agriculture, featuring tines that mix the soil effectively. They are ideal for small to medium-sized farms where versatility is essential. When considering a purchase, B2B buyers should evaluate the tiller’s capacity to handle various soil types and conditions. They tend to be more cost-effective than specialized models, making them an attractive option for budget-conscious buyers. However, their limited depth control can be a drawback for specific applications.

Why Choose Strip Tillers for Precision Agriculture?

Strip tillers are designed to minimize soil disturbance, making them perfect for precision agriculture practices. They prepare narrow strips of soil for planting while leaving the rest of the field undisturbed, which helps conserve moisture and enhance soil health. This type of tiller is particularly suitable for large farms focusing on sustainability and efficiency. B2B buyers should consider the higher initial investment against long-term benefits such as improved yield and reduced erosion.

How Do Rotary Tillers Enhance Soil Quality?

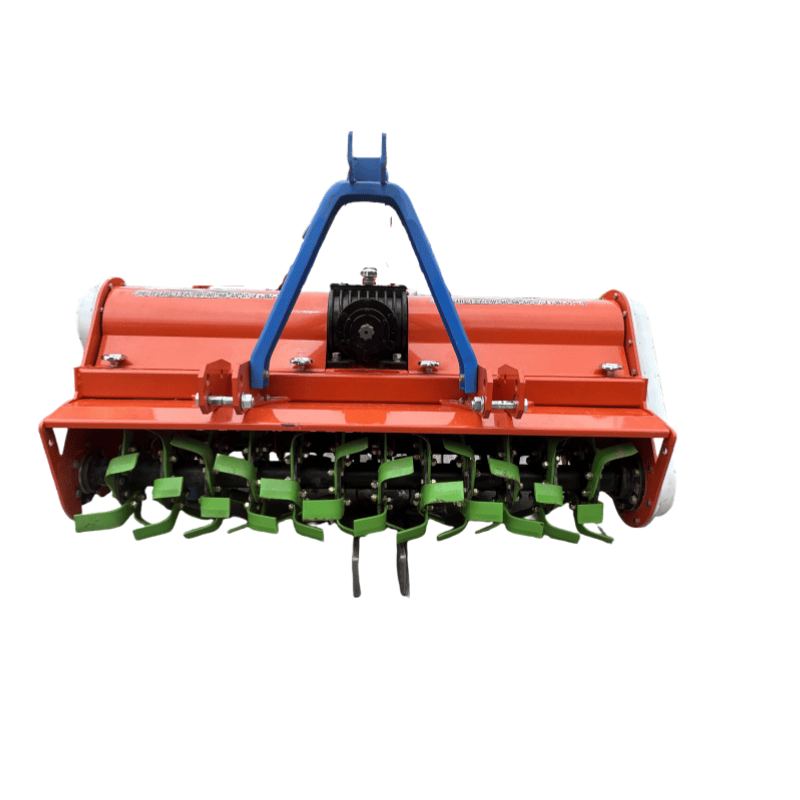

Rotary tillers utilize rotating blades to break up the soil, providing excellent aeration and a fine texture, making them ideal for landscaping and garden preparation. They are well-suited for small-scale operations or where soil conditioning is a priority. Buyers should assess the tiller’s capacity and the potential for soil compaction, which can be an issue if not managed properly. The versatility and effectiveness in creating seedbeds make rotary tillers a valuable addition to any landscaping toolkit.

What Makes Heavy-Duty Tillers Suitable for Large Scale Farming?

Heavy-duty tillers are built for rugged conditions and designed to work efficiently in tough terrains, making them perfect for large-scale farming operations. Their robust construction allows them to handle dense and rocky soils, which can be a significant advantage in specific agricultural regions. B2B buyers should weigh their durability and efficiency against the need for more power and potential operational costs. These tillers can significantly enhance productivity when matched with appropriate tractors.

Are Electric Tillers a Viable Option for Urban Farming?

Electric tillers are lightweight and eco-friendly, making them suitable for small gardens and urban farming initiatives. They operate quietly and reduce carbon emissions, appealing to environmentally conscious buyers. However, their limited power may not be adequate for larger areas, which is a critical consideration for B2B buyers looking at scalability. When purchasing, it’s essential to evaluate the intended use and whether the benefits of reduced noise and emissions align with operational needs.

Key Industrial Applications of used tillers for sale

| Industry/Sector | Specific Application of used tillers for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Soil Preparation for Crop Cultivation | Enhances soil aeration and nutrient mixing for better yields | Assess tiller compatibility with local soil types and crop requirements |

| Landscaping and Gardening | Land Rehabilitation and Garden Bed Creation | Improves soil quality and prepares land for planting | Evaluate the tiller’s working width and depth settings for specific projects |

| Erosion Control and Land Management | Soil Stabilization and Erosion Prevention | Reduces soil erosion and enhances water retention | Consider the tiller’s durability and maintenance history for long-term use |

| Organic Farming | Prepping Fields for Organic Crops | Maintains soil health and supports organic farming practices | Ensure compliance with organic standards and inspect for wear on blades |

| Horticulture | Bed Preparation for Specialty Crops | Facilitates optimal planting conditions for high-value crops | Focus on the tiller’s ability to handle diverse planting depths and row spacing |

How Are Used Tillers Beneficial in Agriculture?

In the agricultural sector, used tillers are invaluable for soil preparation prior to planting crops. They break up compacted soil, aerate it, and mix in nutrients, which leads to improved crop yields. For international buyers, especially in regions like Africa and South America, it is essential to consider the specific soil types and crop requirements in their area to ensure the tiller’s compatibility. Additionally, understanding the tiller’s maintenance history can prevent unexpected breakdowns during critical planting periods.

What Role Do Used Tillers Play in Landscaping and Gardening?

In landscaping and gardening, used tillers are commonly employed for land rehabilitation and creating garden beds. They effectively improve soil quality, making it easier to plant and maintain gardens. Buyers in the landscaping sector must evaluate the tiller’s working width and depth settings to match the scale of their projects. This is particularly crucial for international buyers who may face diverse soil conditions and project requirements.

Illustrative image related to used tillers for sale

How Do Used Tillers Support Erosion Control and Land Management?

Used tillers are instrumental in erosion control and land management applications. They help stabilize soil and prevent erosion by creating a conducive environment for vegetation growth. Businesses focused on land management should consider the durability of the tiller and its maintenance history, as these factors influence long-term effectiveness. In regions prone to severe weather patterns, a robust tiller can be a critical asset.

Why Are Used Tillers Important for Organic Farming?

In organic farming, used tillers play a crucial role in preparing fields while maintaining soil health. They allow for effective mixing of organic matter without the use of synthetic fertilizers, aligning with organic farming practices. Buyers in this sector should ensure that the tillers comply with organic standards and carefully inspect them for any wear on blades that could affect performance. This is especially relevant for buyers in Europe, where organic regulations are stringent.

How Do Used Tillers Enhance Horticulture Practices?

In horticulture, used tillers are essential for bed preparation, particularly for specialty crops that require specific planting conditions. They ensure optimal soil structure and moisture retention, which are vital for high-value crops. Buyers should focus on the tiller’s ability to handle diverse planting depths and row spacing to cater to the unique needs of horticultural crops. This attention to detail can significantly enhance the success of horticultural endeavors, especially in competitive markets.

3 Common User Pain Points for ‘used tillers for sale’ & Their Solutions

Scenario 1: Difficulty in Assessing the Condition of Used Tillers

The Problem: One of the most significant challenges faced by B2B buyers in the used tiller market is accurately assessing the condition of equipment. Buyers are often unable to physically inspect machinery due to geographical constraints or logistical issues. This leads to uncertainty regarding the tiller’s operational efficiency, potential repairs needed, and overall value. Many buyers worry about purchasing equipment that may require extensive maintenance or replacement parts shortly after the sale, which can significantly impact their operational budgets.

The Solution: To mitigate this issue, buyers should prioritize sourcing tillers from reputable dealers who offer detailed inspections and transparent reporting on equipment condition. Buyers can request comprehensive documentation that includes maintenance history, operational hours, and photographs showcasing various angles of the tiller. Leveraging digital platforms that specialize in used agricultural equipment can also facilitate virtual inspections. Additionally, engaging a local expert or technician to assess the tiller before purchase can provide an extra layer of assurance. Buyers should ensure that they establish a clear return policy or warranty terms, which can protect them from unforeseen issues post-purchase.

Scenario 2: Navigating Varied Pricing and Quality Standards

The Problem: The used tiller market is characterized by a wide range of pricing and quality standards, making it challenging for buyers to determine fair market value. This disparity can arise from differences in brand reputation, model specifications, and geographical location. Buyers may find themselves paying a premium for equipment that does not meet their quality expectations or, conversely, underestimating the value of high-quality machinery due to insufficient market knowledge.

The Solution: To navigate pricing effectively, buyers should conduct thorough market research to understand the average prices for specific models and conditions. Utilizing online marketplaces and agricultural equipment trade platforms can help buyers compare prices across various listings. Additionally, engaging in industry forums or networks can provide insights into the best practices for pricing and equipment quality. Buyers should also consider creating a checklist of essential features and specifications that meet their operational needs, which can assist in evaluating whether a tiller is worth the asking price. Establishing relationships with reliable suppliers can lead to negotiated deals and better pricing strategies over time.

Scenario 3: Limited Availability of Specialized Models

The Problem: Many B2B buyers require specific tiller models tailored to unique agricultural practices or soil types, yet the availability of these specialized models in the used market can be limited. This scarcity often forces buyers to compromise on their operational efficiency or delay purchasing decisions, resulting in lost productivity and increased costs.

The Solution: To overcome this availability challenge, buyers should broaden their search strategies by utilizing international platforms and networks that specialize in used agricultural equipment. Joining agricultural trade shows or exhibitions can also provide exposure to suppliers who may have the specific models needed. Buyers should actively communicate their requirements to dealers and consider placing ‘wanted’ ads in industry publications or online forums, which can attract sellers with the exact models sought. Exploring rental options for specialized tillers can serve as a temporary solution while searching for a purchase. Establishing a proactive approach to sourcing equipment will enhance the likelihood of finding the right tiller for specific agricultural needs.

Strategic Material Selection Guide for used tillers for sale

What Are the Key Materials Used in Manufacturing Tillers for Sale?

When considering used tillers for sale, understanding the materials used in their construction is crucial for B2B buyers. The choice of materials impacts performance, durability, and overall cost-effectiveness. Here, we analyze four common materials used in tiller manufacturing: steel, aluminum, plastic, and rubber.

How Does Steel Influence the Performance of Used Tillers?

Steel is the most prevalent material used in tiller construction, particularly for the frame and tilling components. Its key properties include high tensile strength and excellent durability, which allow it to withstand significant stress and pressure during operation. Steel components can typically handle high temperatures and resist deformation, making them suitable for heavy-duty applications.

Illustrative image related to used tillers for sale

Pros: Steel’s strength translates to longevity and reliability, essential for agricultural equipment that faces harsh conditions. Additionally, it is relatively cost-effective due to its widespread availability and ease of manufacturing.

Cons: However, steel is prone to corrosion if not properly treated or coated, which can be a significant drawback in humid or wet environments. This necessitates regular maintenance and protective coatings, increasing long-term costs.

Impact on Application: Steel’s compatibility with various soil types and its ability to perform well under heavy loads make it ideal for tilling. However, buyers must consider the local climate and soil conditions to ensure optimal performance.

International Considerations: In regions like Africa and South America, where humidity and soil conditions vary, buyers should look for steel components with corrosion-resistant treatments. Compliance with international standards such as ASTM or DIN can also ensure quality and reliability.

What Role Does Aluminum Play in Tiller Design?

Aluminum is increasingly used in tiller components due to its lightweight nature and resistance to corrosion. This material is particularly beneficial for parts that require reduced weight without compromising strength.

Pros: The primary advantage of aluminum is its resistance to rust and corrosion, making it ideal for use in moist environments. Additionally, its lightweight characteristic allows for easier maneuverability and reduced fuel consumption.

Cons: On the downside, aluminum is generally more expensive than steel and may not offer the same level of strength under heavy loads. This can limit its use in critical structural components of tillers.

Illustrative image related to used tillers for sale

Impact on Application: Aluminum is suitable for tillers used in less demanding applications or in regions with less abrasive soil. Its lightweight nature can enhance performance in specific scenarios, but buyers must assess whether the trade-off in strength is acceptable.

International Considerations: Buyers from Europe, particularly Germany, may prefer aluminum for its lightweight benefits and environmental considerations. Compliance with relevant European standards is essential to ensure quality and performance.

How Does Plastic Contribute to Tiller Functionality?

Plastic components are often used in tillers for non-structural parts, such as guards and covers. The key properties of plastic include lightweight, corrosion resistance, and flexibility.

Pros: Plastic is cost-effective and can reduce the overall weight of the tiller, improving fuel efficiency. Its resistance to corrosion makes it suitable for various environmental conditions.

Cons: However, plastic is generally less durable than metal options and can become brittle over time, especially under UV exposure. This limits its use in high-stress applications.

Impact on Application: Plastic components are ideal for protecting sensitive parts from soil and debris but should not be relied upon for structural integrity.

International Considerations: Buyers should ensure that any plastic components meet relevant safety and environmental standards, such as REACH in Europe, to avoid compliance issues.

What Is the Importance of Rubber in Tiller Applications?

Rubber is primarily used in tiller tires and certain vibration-dampening components. Its key properties include flexibility, shock absorption, and resistance to wear.

Pros: Rubber provides excellent traction and shock absorption, enhancing the tiller’s performance on uneven terrains. Its durability makes it suitable for various agricultural applications.

Cons: However, rubber can degrade over time due to exposure to UV light and extreme temperatures, necessitating regular replacement.

Impact on Application: The use of rubber is critical for ensuring optimal traction and stability during tilling operations, especially in diverse soil conditions.

International Considerations: Buyers should look for tires that comply with local agricultural standards and consider the availability of replacement parts in their region.

Summary Table of Material Selection for Used Tillers

| Material | Typical Use Case for used tillers for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frame and tilling components | High strength and durability | Prone to corrosion | Medium |

| Aluminum | Lightweight components | Corrosion resistance | Higher cost and lower strength | High |

| Plastic | Non-structural parts | Cost-effective and lightweight | Less durable under stress | Low |

| Rubber | Tires and vibration dampeners | Excellent traction and shock absorption | Degrades over time | Medium |

This analysis provides a comprehensive overview of the materials commonly used in tillers, helping international B2B buyers make informed decisions based on their specific needs and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for used tillers for sale

What Are the Main Stages in the Manufacturing Process of Used Tillers?

The manufacturing process for used tillers involves several key stages that ensure the final product is reliable, efficient, and ready for agricultural use. Understanding these stages can help B2B buyers assess the quality and value of the tillers they are considering for purchase.

-

Material Preparation: The process begins with sourcing high-quality raw materials, including steel and other alloys, which are essential for the structural integrity of the tillers. Suppliers often prioritize durability and resistance to corrosion, considering the harsh conditions tillers face in the field. Rigorous inspection of materials is crucial, as it ensures that only top-grade components are utilized in the manufacturing process.

-

Forming: This stage involves shaping the materials into specific components. Techniques such as stamping, bending, and welding are commonly used. Advanced machinery, like CNC (Computer Numerical Control) machines, can enhance precision during this phase, ensuring that parts fit together seamlessly during assembly. The forming process directly impacts the performance and longevity of the tiller, making it a critical step.

-

Assembly: The assembly phase brings together all the formed components into a complete tiller. Skilled technicians typically oversee this process, ensuring that each part is installed correctly and securely. Attention to detail is vital here, as improper assembly can lead to mechanical failures or reduced efficiency in the field.

-

Finishing: The finishing stage includes surface treatments such as painting, coating, or galvanizing to protect against environmental wear and tear. This not only enhances the aesthetic appeal but also adds an additional layer of protection against rust and corrosion. Quality assurance during this stage is essential to ensure that the finish is uniform and meets industry standards.

How Is Quality Assurance Implemented in Manufacturing Used Tillers?

Quality assurance (QA) is a crucial aspect of the manufacturing process for used tillers, ensuring that each unit meets both international standards and specific industry requirements. A thorough QA process can significantly influence a B2B buyer’s decision, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

-

International Standards Compliance: Many manufacturers adhere to ISO 9001 standards, which focus on quality management systems. This certification indicates that the manufacturer has met rigorous criteria for quality assurance throughout its production processes. Other relevant certifications may include CE marking for compliance with European safety standards or API standards for equipment used in oil and gas applications.

-

Quality Control Checkpoints: Effective QA involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial phase checks the quality of raw materials before they enter production. Any subpar materials are rejected to prevent quality issues downstream.

– In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to ensure that processes are being followed correctly and that components meet specified standards.

– Final Quality Control (FQC): Before a tiller is shipped, a comprehensive inspection is performed to verify that the finished product meets all quality and safety standards. This includes functional tests to ensure the tiller operates as intended. -

Common Testing Methods: Various testing methods are employed to validate the performance and durability of used tillers. These include stress testing, load testing, and performance assessments under simulated field conditions. Such rigorous testing helps identify any weaknesses before the product reaches the market.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial to ensuring that the equipment meets their specific needs and standards. Here are several actionable steps buyers can take:

Illustrative image related to used tillers for sale

-

Conduct Supplier Audits: Regular audits of the manufacturing facility can provide insight into the supplier’s quality control processes. During an audit, buyers can assess compliance with international standards, review documentation, and observe production practices firsthand.

-

Request Quality Control Reports: Suppliers should be able to provide detailed reports on their quality control processes, including results from IQC, IPQC, and FQC phases. These documents can demonstrate the supplier’s commitment to maintaining high-quality standards.

-

Engage Third-Party Inspectors: Employing independent third-party inspection services can offer an unbiased evaluation of a supplier’s manufacturing and quality control processes. These inspectors can provide certifications and detailed reports that affirm the quality of the tillers.

-

Understand Certification Nuances: Different regions may have varying certification requirements. For instance, while CE marking is essential for the European market, products sold in Africa or South America may require different certifications. Buyers should familiarize themselves with these requirements to ensure compliance.

What Unique Quality Considerations Exist for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges in ensuring the quality of used tillers. Here are some considerations:

-

Adaptation to Local Conditions: Buyers should consider whether the tillers are designed to withstand the specific agricultural conditions in their region. For example, tillers used in arid climates may require different materials or designs compared to those intended for more temperate regions.

-

Warranty and After-Sales Support: Understanding the warranty terms and the availability of after-sales support is critical. Buyers should ensure that suppliers can provide adequate service and parts support, especially in remote areas where equipment downtime can significantly impact productivity.

-

Cultural and Regulatory Differences: Buyers must be aware of cultural differences and local regulations that may affect the importation and use of agricultural equipment. This includes understanding tariffs, import restrictions, and compliance with local safety standards.

-

Building Relationships with Suppliers: Establishing strong relationships with suppliers can enhance trust and facilitate better communication regarding quality expectations and concerns. Long-term partnerships may also lead to improved pricing and preferential treatment in terms of product availability and support.

By understanding the manufacturing processes and quality assurance practices associated with used tillers, B2B buyers can make informed decisions that align with their operational needs and regional requirements. This knowledge not only enhances procurement strategies but also fosters long-term relationships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘used tillers for sale’

This sourcing guide provides a structured approach for B2B buyers seeking to procure used tillers. By following these steps, you will ensure a more efficient and successful purchasing process, minimizing risks and maximizing value.

Step 1: Define Your Technical Specifications

Before starting your search for used tillers, it’s essential to clearly outline your technical requirements. Consider factors such as tiller type (e.g., rotary or chisel), width, horsepower, and any specific features that meet your agricultural needs.

– Why it matters: Defining specifications helps streamline your search, ensuring you focus on equipment that will meet your operational demands.

Step 2: Research Market Prices

Conduct thorough research on the current market prices for used tillers. Utilize platforms like Fastline or United Rentals to compare listings and gain insights into price ranges for different brands and models.

– Why it matters: Understanding market pricing allows you to identify fair deals and avoid overpaying for equipment.

Illustrative image related to used tillers for sale

Step 3: Evaluate Potential Suppliers

Assess potential suppliers by reviewing their reputation and track record. Request company profiles, customer testimonials, and references from past clients to gauge reliability.

– Why it matters: A reputable supplier can provide better post-sale support and warranty options, which are critical for used equipment.

Step 4: Inspect Equipment Thoroughly

Always arrange for a physical inspection of the tillers you are considering. Look for signs of wear, rust, or damage, and verify that all parts are functioning as expected.

– Why it matters: A thorough inspection can prevent costly repairs later and ensure the equipment meets your operational standards.

Step 5: Request Documentation and Service History

Obtain all relevant documentation for the tillers, including service history, maintenance records, and any warranties still in effect.

– Why it matters: This information can provide insights into the equipment’s reliability and help you make an informed decision about its longevity.

Illustrative image related to used tillers for sale

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable tiller, engage in negotiations regarding the price, payment terms, and any additional services such as delivery or installation.

– Why it matters: Effective negotiation can lead to better terms that enhance your overall purchasing experience, potentially saving you money.

Step 7: Finalize the Purchase and Arrange Logistics

After agreeing on the terms, finalize the purchase and arrange for logistics, including transportation and delivery. Ensure that you understand the delivery timeline and any associated costs.

– Why it matters: Proper logistics management is crucial to ensure timely availability of the tillers for your operations, minimizing downtime.

By following this step-by-step checklist, you can navigate the complexities of sourcing used tillers with confidence, ensuring that your investment aligns with your agricultural goals.

Comprehensive Cost and Pricing Analysis for used tillers for sale Sourcing

What Are the Key Cost Components for Sourcing Used Tillers?

When analyzing the cost structure of used tillers, several critical components must be considered. Materials encompass the raw materials used in tiller construction, including steel, plastics, and hydraulic components. The labor cost involves the workforce required for assembly, repair, and maintenance of these machines. Manufacturing overhead accounts for indirect costs such as utilities, rent, and administrative expenses associated with production facilities.

Tooling costs relate to the equipment and machinery necessary for the manufacturing and refurbishment of tillers. Quality Control (QC) is essential, ensuring that each unit meets safety and operational standards, which may involve testing and certification processes. Lastly, logistics covers transportation and handling expenses, which can vary significantly based on geographic location and shipping methods. Each of these components contributes to the overall pricing of used tillers in the market.

How Do Price Influencers Impact the Cost of Used Tillers?

Several factors can influence the pricing of used tillers. Volume and Minimum Order Quantity (MOQ) play crucial roles; purchasing in bulk often leads to lower per-unit costs. The specifications and customization of the tillers—such as size, attachments, and technology—also affect pricing. Higher-quality materials and certifications can lead to increased costs but may result in better longevity and performance.

Supplier factors, including the reputation and reliability of the manufacturer, can dictate price variations. The Incoterms selected for the transaction can also influence costs, as they define the responsibilities of buyers and sellers in shipping and delivery. Understanding these nuances is vital for B2B buyers to navigate the pricing landscape effectively.

What Buyer Tips Should Be Considered for Cost-Efficiency?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, certain strategies can enhance cost-efficiency. Negotiation is a critical skill; buyers should be prepared to discuss prices, payment terms, and other conditions to secure favorable deals. It’s also beneficial to conduct a Total Cost of Ownership analysis, which includes not just the purchase price but also maintenance, repair, and operational costs over the equipment’s lifespan.

Buyers should remain vigilant about pricing nuances that can arise from currency fluctuations, import duties, and local taxation. Understanding the supply chain dynamics and logistical challenges associated with sourcing used tillers can lead to more informed purchasing decisions. Additionally, leveraging local contacts or agents can help in navigating regulations and ensuring smooth transactions.

Why Are Indicative Prices Important for B2B Buyers?

When considering used tillers, it is essential to note that prices can vary widely based on condition, specifications, and market demand. Indicative prices serve as a guide but should not be viewed as fixed. Buyers should conduct thorough research and possibly request multiple quotes to establish a realistic price range. This approach not only aids in budgeting but also empowers buyers to negotiate effectively.

In conclusion, understanding the intricate cost structure and price influencers is crucial for B2B buyers looking to source used tillers. By employing strategic negotiation techniques and conducting comprehensive cost analyses, buyers can enhance their purchasing decisions and ensure they acquire equipment that meets their operational needs while remaining within budget.

Illustrative image related to used tillers for sale

Alternatives Analysis: Comparing used tillers for sale With Other Solutions

Exploring Alternatives to Used Tillers for Sale

In the realm of agricultural equipment, used tillers serve a significant role in soil preparation and crop management. However, there are alternative solutions that can also meet the needs of B2B buyers looking to enhance their farming operations. This section explores viable alternatives to used tillers, offering a comprehensive comparison to help buyers make informed decisions.

| Comparison Aspect | Used Tillers For Sale | Alternative 1: Rotary Tillers | Alternative 2: Cultivators |

|---|---|---|---|

| Performance | Effective for deep soil aeration and mixing | Excellent for seedbed preparation and weed control | Good for shallow tillage and weed management |

| Cost | Varies widely, typically affordable | Generally lower initial cost | Typically lower than tillers but varies by model |

| Ease of Implementation | Requires tractor compatibility and setup | Easy to attach and use with most tractors | Simple to operate and requires minimal setup |

| Maintenance | Moderate; requires regular checks | Low; mostly wear parts need replacement | Low; requires basic maintenance only |

| Best Use Case | Ideal for large-scale operations needing deep tillage | Best for gardens and small farms needing seedbed prep | Suitable for weeding and shallow cultivation in smaller plots |

What Are the Advantages and Disadvantages of Rotary Tillers?

Rotary tillers are a popular alternative to used tillers for their ability to prepare seedbeds effectively. They work by rotating blades through the soil, which can be beneficial for mixing in organic matter and breaking up compacted earth. The lower initial cost is a significant advantage, making them accessible for small farmers. However, rotary tillers may not penetrate as deeply as traditional tillers, limiting their effectiveness in hardpan soils or for certain crops that require deeper tillage.

How Do Cultivators Compare to Used Tillers?

Cultivators offer a different approach to soil management, primarily focusing on weed control and shallow soil aeration. They are easy to operate and can be quickly attached to tractors, making them an appealing option for smaller farms or gardens. The cost is typically lower, which can be a deciding factor for budget-conscious buyers. However, cultivators are not designed for deep tillage, so they may not be suitable for all farming needs, especially in areas requiring significant soil disruption.

Making the Right Choice for Your Agricultural Needs

When choosing between used tillers and their alternatives, B2B buyers should consider their specific agricultural requirements. Factors such as the scale of operations, soil conditions, and budget constraints play crucial roles in this decision-making process. For large-scale farming operations requiring deep soil preparation, used tillers may still be the best option. Conversely, for smaller farms or specific tasks like weed control, rotary tillers or cultivators could provide a more cost-effective and efficient solution. By evaluating these aspects, buyers can select the equipment that aligns with their operational goals and enhances their productivity.

Essential Technical Properties and Trade Terminology for used tillers for sale

What Are the Key Technical Properties of Used Tillers for Sale?

When evaluating used tillers for sale, several critical technical properties should be considered to ensure that the equipment meets operational needs. Understanding these specifications can help B2B buyers make informed purchasing decisions.

-

Tine Configuration and Material

The tines are crucial for soil preparation, and their configuration (e.g., straight, curved) affects the tilling depth and soil aeration. Common materials used include hardened steel for durability and resistance to wear. A well-designed tine configuration can enhance soil mixing and seedbed preparation, which is vital for crop yield. -

Working Width

The working width of a tiller indicates how wide an area it can till in a single pass, typically measured in inches or centimeters. A wider working width can increase efficiency and reduce the number of passes required, saving time and labor costs. For B2B buyers, selecting the right working width is essential to match the tiller’s capability with the size of the agricultural field. -

Power Requirements

This specification details the horsepower (HP) needed to operate the tiller effectively. Understanding the power requirements helps buyers ensure compatibility with existing tractors or equipment. Insufficient power can lead to inefficiencies and increased wear on the tiller, while excessive power can lead to unnecessary fuel consumption. -

Weight and Build Quality

The overall weight of the tiller impacts its stability and performance in various soil conditions. Heavier tillers may provide better penetration in tough soils, while lighter models may be more maneuverable. Buyers should assess the build quality, including frame construction and components, to ensure longevity and reliability in demanding agricultural applications. -

Adjustability Features

Many tillers come with adjustable features such as depth control and tine spacing. These adjustments allow for customization based on specific soil types and tilling requirements. For B2B buyers, the ability to modify settings can enhance operational flexibility and optimize performance across different fields. -

Maintenance History and Condition

Understanding the maintenance history of a used tiller is crucial. A well-maintained machine is likely to have a longer lifespan and fewer operational issues. Buyers should inquire about any repairs or replacements made and check for signs of wear or damage.

Which Trade Terms Are Essential for B2B Transactions in Used Tillers?

Familiarity with industry terminology is vital for B2B transactions involving used tillers. Here are some common trade terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to the company that originally manufactured the tiller. Understanding whether a tiller is an OEM product or an aftermarket part can influence quality and compatibility with existing equipment. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. In B2B transactions, understanding MOQ is essential for budgeting and inventory management, especially when purchasing multiple tillers or parts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products. This process helps buyers compare prices and terms from different vendors, ensuring they get the best deal for their purchase. -

Incoterms (International Commercial Terms)

These are standardized trade terms used in international shipping to define responsibilities between buyers and sellers. Understanding Incoterms is crucial for determining who is responsible for shipping costs, insurance, and risk during transportation. -

Warranty and After-Sales Support

Warranty terms and after-sales support policies are critical considerations when purchasing used tillers. Buyers should clarify the duration and coverage of warranties, as well as the availability of technical support, to ensure they are protected against potential issues. -

Condition Grade

This term classifies the physical state of the used tiller, often ranging from “like new” to “fair.” Knowing the condition grade can help buyers gauge the expected lifespan and reliability of the equipment.

In summary, understanding these technical properties and trade terms can significantly enhance the decision-making process for B2B buyers looking to purchase used tillers. By focusing on these aspects, buyers can better align their purchases with operational needs and ensure successful transactions.

Navigating Market Dynamics and Sourcing Trends in the used tillers for sale Sector

What Are the Key Trends and Dynamics Shaping the Used Tillers Market?

The used tillers market is experiencing significant transformation, driven by several global factors. The rising demand for sustainable agricultural practices is pushing farmers to seek cost-effective equipment solutions. In regions like Africa and South America, where agriculture remains a primary economic driver, the adoption of used tillers is accelerating due to their affordability and efficiency. Additionally, technological advancements are reshaping sourcing strategies. Platforms that facilitate B2B transactions are increasingly utilizing AI and machine learning to enhance buyer-seller connections, making it easier for international buyers to locate equipment that meets their specific needs.

Emerging markets are witnessing a growing trend of online purchasing, with platforms offering detailed listings, including specifications, condition reports, and user reviews. This trend is particularly relevant for buyers from Europe and the Middle East, who are looking for reliable, quality-assured used tillers. Furthermore, the integration of blockchain technology is gaining traction, ensuring transparency in the supply chain and building trust among buyers regarding the equipment’s history and maintenance records.

How Can Sustainability and Ethical Sourcing Impact the Used Tillers Market?

Sustainability is becoming a crucial consideration for B2B buyers in the used tillers market. The environmental impact of agricultural machinery, particularly in terms of emissions and resource consumption, has prompted many organizations to adopt greener practices. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainability through ethical sourcing and responsible disposal of machinery.

The importance of ethical supply chains cannot be overstated. Buyers are now looking for suppliers who provide ‘green’ certifications, indicating that the equipment meets specific environmental standards. This trend is particularly pronounced in Europe, where regulations around sustainability are stringent. Certifications such as ISO 14001 for environmental management can enhance a supplier’s reputation and appeal to environmentally conscious buyers.

Illustrative image related to used tillers for sale

Moreover, the demand for eco-friendly materials and practices in the production and refurbishment of used tillers is rising. Buyers are increasingly interested in equipment that minimizes environmental impact while maintaining efficiency. This shift not only supports global sustainability goals but also aligns with the growing consumer preference for ethically sourced products.

What Is the Historical Context Behind the Used Tillers Market?

The used tillers market has evolved significantly over the decades, shaped by technological advancements and changing agricultural practices. Initially, tillers were simple, mechanical devices designed for small-scale farming. However, as agriculture became more industrialized in the mid-20th century, the need for more sophisticated and efficient tilling solutions grew. This evolution led to the development of a variety of tiller models, catering to different soil types and farming techniques.

In recent years, the market has seen a pronounced shift toward the sale of used equipment, driven by economic factors and technological advancements. Farmers are increasingly recognizing the value of investing in used tillers as a means of reducing operational costs while still benefiting from advanced technologies. This historical context underlines the current dynamics in the market, where the demand for used tillers continues to rise as agricultural practices evolve and sustainability becomes a priority.

Frequently Asked Questions (FAQs) for B2B Buyers of used tillers for sale

-

How can I ensure the quality of used tillers before purchase?

To ensure the quality of used tillers, conduct a thorough inspection or arrange for a professional appraisal. Check for signs of wear, rust, and mechanical issues. Request maintenance records to understand how well the equipment has been cared for. Additionally, consider purchasing from reputable dealers or platforms with established buyer protection policies. If possible, test the tiller in action to evaluate its performance. -

What are the key features to look for in a used tiller?

When sourcing used tillers, focus on features such as the tilling width, depth adjustment capabilities, and engine power. Consider the type of tiller (e.g., rear-tine, front-tine) that best suits your agricultural needs. Evaluate the tiller’s compatibility with various soil types and conditions, as well as its ease of use and maintenance requirements. Additionally, check for available attachments that can enhance functionality. -

What should I consider when negotiating the price of used tillers?

Negotiating the price of used tillers requires understanding the market value based on model, age, and condition. Research comparable listings to establish a baseline price. Highlight any defects or needed repairs during negotiations to justify a lower offer. Be prepared to discuss your budget and explore financing options. Building a good rapport with the seller can also enhance your bargaining position. -

What are the typical payment terms for used tiller purchases?

Payment terms for used tillers can vary widely among sellers. Common options include full upfront payment, installment plans, or letters of credit, especially for international transactions. Always clarify payment methods accepted (e.g., wire transfer, credit card, escrow services) and any associated fees. Ensure that all terms are documented in a sales agreement to protect both parties. -

How can I verify the legitimacy of a supplier when purchasing used tillers?

To verify a supplier’s legitimacy, conduct due diligence by checking their business credentials, reviews, and customer testimonials. Utilize platforms like LinkedIn to assess their professional background and connections. Request references from previous clients and reach out to them for feedback. Additionally, consider using third-party verification services to ensure that the supplier adheres to industry standards. -

What logistics considerations should I be aware of when importing used tillers?

When importing used tillers, consider shipping methods, costs, and delivery timelines. Research customs regulations and import duties specific to your country to avoid unexpected fees. Ensure that the seller provides necessary documentation, such as a bill of lading and proof of ownership. Partnering with a logistics provider experienced in agricultural machinery can streamline the process and mitigate risks. -

What is the minimum order quantity (MOQ) for used tillers?

The minimum order quantity (MOQ) for used tillers varies by supplier and can depend on the specific models and condition. Some suppliers may allow individual purchases, while others may have MOQs based on shipping or bulk pricing incentives. Always inquire about MOQs upfront and consider negotiating terms if you are interested in multiple units. -

Can I customize used tillers to meet my specific agricultural needs?

Yes, many used tillers can be customized or retrofitted with additional attachments or modifications to better suit your agricultural requirements. Discuss your needs with the supplier to explore available options for upgrades, such as different tines or additional features. Keep in mind that extensive customization may require a higher investment and could affect the overall lead time for delivery.

Top 3 Used Tillers For Sale Manufacturers & Suppliers List

1. Facebook – Tillers for Sale

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Tillers for Sale, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Mantis – 7940 4-Cycle Plus Tiller

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Garden Tillers for Sale on eBay, including various types such as Gasoline, Corded Electric, Battery, Rear Tine Tillers, Cultivators, Mini Tillers, Front Tine Tillers, and Tow Behind Tillers. Popular brands include Mantis, Honda, Ryobi, and more. Featured products include Mantis 7940 4-Cycle Plus Tiller, Garden Weasel Long Handle Cultivator, Dewalt Quickload Replacement Spool Head, and Honda FG110 …

3. Honda Power Equipment – FC600 Tiller

Domain: equipmenttrader.com

Registered: 1998 (27 years)

Introduction: {“tillers”:[{“make”:”Honda Power Equipment”,”model”:”FC600″,”year”:”2023″,”price”:”$1,399″,”tilling_width”:”26 inches”,”tine_diameter”:”13 inches”,”dealer”:”Flagstaff Equipment Co. Inc.”,”location”:”Flagstaff, AZ”},{“make”:”VIRNIG”,”model”:”TLR72″,”year”:”New”,”price”:”$8,100″,”type”:”Forestry Tiller”,”dealer”:”Buck & Knobby Equipment Co.”,”location”:”Ottawa Lake, MI”},{“make”:”HANDY”,”model”:”HSC…

Strategic Sourcing Conclusion and Outlook for used tillers for sale

In navigating the global market for used tillers, B2B buyers must prioritize strategic sourcing to maximize value and efficiency. The competitive landscape highlights the importance of thorough market research, allowing buyers to identify reputable dealers and quality machinery that meets their operational needs. Engaging in direct negotiations and establishing long-term partnerships with suppliers can further enhance procurement strategies, ensuring access to well-maintained equipment at competitive prices.

Buyers from regions such as Africa, South America, the Middle East, and Europe, including Germany and Vietnam, should leverage technology and data analytics to assess market trends and pricing fluctuations. This proactive approach not only aids in making informed purchasing decisions but also aligns with evolving agricultural practices and sustainability goals.

Looking ahead, the demand for reliable and efficient tillers is expected to grow, driven by advancements in agricultural technology and increased emphasis on food security. By adopting a strategic sourcing mindset, international buyers can position themselves to capitalize on emerging opportunities in the used tiller market. We encourage you to take action today—explore listings, connect with trusted dealers, and invest in equipment that will enhance your agricultural productivity for years to come.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.