How to Source Tungsten Price Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for tungsten price

Navigating the complex landscape of tungsten pricing can be a daunting task for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. The fluctuations in tungsten prices are influenced by various factors, including supply chain dynamics, geopolitical tensions, and the growing demand for tungsten in high-tech applications. This guide aims to demystify the intricacies of tungsten pricing, offering a comprehensive overview that encompasses different types of tungsten products, their diverse applications, and effective strategies for supplier vetting.

Within this resource, buyers will find crucial insights into the current market trends, pricing tables, and forecasts that illuminate the future of tungsten procurement. By understanding the unique properties and applications of tungsten, buyers can make informed decisions that align with their operational needs and financial objectives. Furthermore, this guide addresses the importance of sourcing quality materials from reputable suppliers, emphasizing best practices in negotiation and contract management.

For B2B buyers in regions such as Germany and Vietnam, where industrial applications are growing, this guide serves as a strategic tool to navigate the global tungsten market confidently. Whether you are involved in manufacturing, construction, or electronics, our expert insights will empower you to tackle the challenges of tungsten sourcing effectively, ensuring you remain competitive in an ever-evolving market.

Understanding tungsten price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Market Price | Fluctuates based on global supply and demand dynamics | General tungsten procurement | Pros: Reflects current market conditions; Cons: Volatile and can lead to budget unpredictability. |

| Contract Price | Set prices based on long-term agreements with suppliers | Strategic sourcing, bulk purchases | Pros: Stability in pricing; Cons: Potentially higher than market price if demand decreases. |

| Spot Price | Immediate purchase price for tungsten in the market | Quick acquisitions, opportunistic buying | Pros: Flexibility; Cons: Risk of price spikes during high demand periods. |

| Premium Price | Additional costs associated with specific qualities or processing | Specialized applications, high-performance tools | Pros: Access to superior quality; Cons: Increased costs may affect overall project budgets. |

| Regional Price Variations | Price differences based on geographical market conditions | Local manufacturing, regional supply chains | Pros: May offer cost advantages in local markets; Cons: Variations can complicate procurement strategies. |

What Are the Characteristics of Market Price for Tungsten?

Market price refers to the prevailing rate for tungsten based on real-time supply and demand. It is influenced by various factors, including geopolitical events, production levels, and industry consumption trends. B2B buyers should monitor market prices closely as they can fluctuate significantly, impacting procurement budgets. Understanding market dynamics is essential for making informed purchasing decisions, especially for companies that require tungsten for manufacturing processes.

How Does Contract Pricing Work in Tungsten Procurement?

Contract pricing involves establishing a fixed price for tungsten over a specified period, typically through long-term agreements with suppliers. This pricing model is beneficial for businesses that need a consistent supply and wish to mitigate the risks associated with market price volatility. B2B buyers should consider contract pricing when planning large-scale projects or when they have predictable consumption needs, as it provides budget certainty and can foster stronger supplier relationships.

What Is Spot Pricing and When Should Buyers Use It?

Spot pricing is the cost for immediate purchase of tungsten available in the market. This pricing model is ideal for B2B buyers looking for quick acquisitions or those who want to take advantage of favorable market conditions. However, buyers should be cautious, as spot prices can be volatile and may experience sudden increases during periods of high demand. Spot pricing is suitable for opportunistic buying but requires careful timing and market analysis.

What Should Buyers Know About Premium Pricing?

Premium pricing applies to tungsten products that offer superior quality, specialized processing, or specific characteristics that enhance performance. This type of pricing is common in industries where precision and durability are critical, such as aerospace and military applications. B2B buyers should evaluate the long-term benefits of investing in premium products against their project requirements and budgets, as the initial cost may be offset by increased performance and longevity.

Why Are Regional Price Variations Important for Buyers?

Regional price variations occur due to local market conditions, including transportation costs, regional demand, and local supply chain dynamics. B2B buyers operating in different geographical areas may find that tungsten prices vary significantly. Understanding these variations can help businesses optimize their procurement strategies, potentially leading to cost savings or improved supply chain efficiency. Buyers should conduct a thorough analysis of regional markets to make informed purchasing decisions.

Key Industrial Applications of tungsten price

| Industry/Sector | Specific Application of tungsten price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of high-performance turbine blades | Enhanced durability and heat resistance | Ensure compliance with aerospace standards and certifications. |

| Mining | Production of cutting tools and drill bits | Increased efficiency and reduced downtime | Source from reliable suppliers with proven track records. |

| Electronics | Production of electrical contacts and filaments | Improved performance and reliability in devices | Verify purity and quality standards for electronic applications. |

| Defense | Development of armor-piercing ammunition | Superior penetration and effectiveness | Assess regulations and import/export restrictions in target markets. |

| Construction | Creation of wear-resistant machinery components | Longer equipment lifespan and reduced maintenance costs | Evaluate local availability and logistics for timely delivery. |

What Are the Key Industrial Applications of Tungsten Price in Aerospace?

In the aerospace sector, tungsten is crucial for manufacturing high-performance turbine blades. These blades require materials that can withstand extreme temperatures and mechanical stresses. Tungsten’s exceptional heat resistance and durability make it ideal for this application, ensuring efficient engine performance and longevity. International B2B buyers should focus on suppliers that comply with aerospace standards and certifications to ensure product reliability and safety.

How Is Tungsten Price Utilized in Mining Operations?

Tungsten plays a vital role in the mining industry, particularly in the production of cutting tools and drill bits. These tools benefit from tungsten’s hardness and wear resistance, leading to increased efficiency and reduced downtime during operations. Buyers in this sector should prioritize sourcing from suppliers with a proven track record in delivering high-quality tungsten products, as this can significantly impact operational productivity.

In What Ways Does Tungsten Price Enhance Electronics Manufacturing?

In the electronics industry, tungsten is used for electrical contacts and filaments due to its excellent conductivity and thermal stability. The incorporation of tungsten ensures improved performance and reliability in various devices, from mobile phones to industrial machinery. Buyers should verify the purity and quality standards of tungsten used in electronic applications, as these factors directly affect the performance of the final products.

What Are the Applications of Tungsten Price in Defense Technology?

Tungsten is increasingly used in the defense sector for developing armor-piercing ammunition. Its high density and hardness provide superior penetration capabilities, making it an effective choice for military applications. International buyers must assess the regulatory landscape and import/export restrictions related to tungsten products in their target markets to ensure compliance and smooth procurement processes.

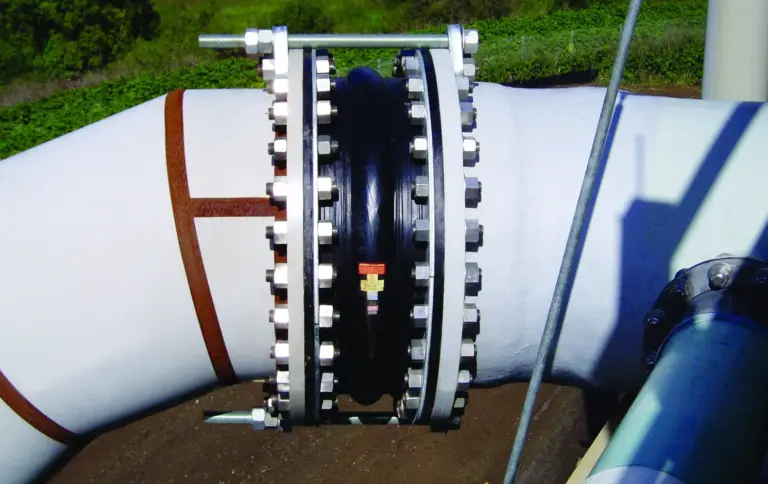

How Does Tungsten Price Benefit the Construction Industry?

In construction, tungsten is utilized to create wear-resistant machinery components, which are essential for heavy-duty applications. The use of tungsten results in longer equipment lifespan and reduced maintenance costs, providing significant cost savings for construction companies. Buyers should evaluate local availability and logistics to ensure timely delivery of tungsten products, facilitating uninterrupted project workflows.

3 Common User Pain Points for ‘tungsten price’ & Their Solutions

Scenario 1: Fluctuating Prices Impacting Budgeting

The Problem: B2B buyers often face the challenge of fluctuating tungsten prices, which can significantly impact project budgets and profitability. For instance, a manufacturing company in South America may have relied on a fixed price for tungsten components in their production cycle. However, sudden price increases can lead to unanticipated costs, jeopardizing contracts and profit margins. This unpredictability can cause stress in procurement planning, as buyers struggle to manage supplier negotiations and customer expectations while staying competitive.

The Solution: To mitigate the effects of price volatility, buyers should establish long-term contracts with suppliers that include price stabilization clauses. This allows for more predictable budgeting and cost management. Additionally, buyers can implement a hedging strategy by purchasing tungsten futures or options to lock in prices ahead of time. Staying informed about market trends and global supply chain factors—such as changes in Chinese export regulations or geopolitical events—will also help buyers anticipate price movements. Regularly reviewing and adjusting procurement strategies based on market insights will empower companies to make more informed purchasing decisions.

Scenario 2: Sourcing Quality Tungsten Amid Supply Chain Disruptions

The Problem: International B2B buyers are often challenged by sourcing high-quality tungsten, especially in regions like Africa and the Middle East, where supply chain disruptions can occur due to political instability or logistical issues. A company in Europe may find it difficult to secure a reliable supplier that meets stringent quality standards, resulting in delays and increased costs. Poor-quality tungsten can lead to production failures and wasted resources, creating a ripple effect that affects the entire supply chain.

The Solution: To address sourcing challenges, buyers should prioritize establishing relationships with multiple suppliers across different regions. This diversification strategy not only secures a steady supply but also mitigates risks associated with single-source dependence. Conducting thorough due diligence on potential suppliers is crucial; this includes assessing their production processes, quality certifications, and track record in timely deliveries. Additionally, utilizing technology, such as supply chain management software, can enhance visibility into supplier performance and help buyers make data-driven decisions. Engaging in regular communication with suppliers can further foster transparency and responsiveness, ensuring a smoother supply chain operation.

Scenario 3: The Complexity of Tungsten Pricing Structures

The Problem: B2B buyers often encounter the complexity of tungsten pricing structures, which can vary widely based on several factors, including market demand, purity levels, and geopolitical influences. A buyer in the aerospace industry may struggle to understand the pricing tiers for tungsten materials, leading to confusion during negotiations and potential overpayments. This lack of clarity can result in budget overruns and strained supplier relationships, as companies are unsure how to effectively communicate their pricing expectations.

The Solution: To navigate the complexities of tungsten pricing, buyers should invest time in understanding the market dynamics that influence pricing structures. This involves studying industry reports, market analysis, and consulting with experts in tungsten procurement. Buyers can also create a comprehensive pricing framework that outlines their specific needs and expectations, which can be shared with suppliers during negotiations. Furthermore, engaging in industry forums or trade associations can provide valuable insights into prevailing pricing trends and best practices. By fostering open communication with suppliers about their pricing methodologies, buyers can enhance their negotiation capabilities and secure more favorable terms.

Illustrative image related to tungsten price

Strategic Material Selection Guide for tungsten price

What Are the Key Materials Affecting Tungsten Pricing?

In the context of tungsten pricing, several materials are commonly utilized in various applications. Understanding their properties, advantages, disadvantages, and specific considerations for international B2B buyers is crucial for making informed purchasing decisions.

1. Tungsten Carbide

Key Properties: Tungsten carbide is renowned for its exceptional hardness and wear resistance, making it suitable for high-stress applications. It can withstand temperatures up to 1,600°C and offers excellent corrosion resistance, particularly in acidic environments.

Pros & Cons: The primary advantage of tungsten carbide is its durability, which significantly extends the lifespan of tools and components. However, it is relatively expensive compared to other materials, and its brittleness can lead to chipping under extreme conditions. Manufacturing processes can also be complex, requiring specialized equipment.

Impact on Application: Tungsten carbide is widely used in mining, drilling, and cutting tools due to its ability to maintain sharp edges and resist wear. Its compatibility with various media, including oil and gas, enhances its applicability in harsh environments.

Illustrative image related to tungsten price

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local sourcing options to mitigate costs. Compliance with international standards such as ASTM and DIN is essential, especially for applications in the aerospace and automotive sectors.

2. Tungsten Alloys

Key Properties: Tungsten alloys combine tungsten with other metals, such as nickel or copper, to enhance specific properties like ductility and machinability. They maintain high strength at elevated temperatures and exhibit good corrosion resistance.

Pros & Cons: These alloys provide a balanced performance, making them suitable for various applications, including aerospace and military. However, the cost can be high due to the alloying elements, and the manufacturing process may require advanced techniques.

Impact on Application: Tungsten alloys are ideal for applications requiring high strength-to-weight ratios, such as counterweights in aircraft and radiation shielding. Their compatibility with various environmental conditions makes them versatile.

Illustrative image related to tungsten price

Considerations for International Buyers: B2B buyers in Europe should be aware of the stringent regulations surrounding aerospace materials, ensuring compliance with standards like JIS and ISO. The demand for tungsten alloys is growing, particularly in emerging markets.

3. Pure Tungsten

Key Properties: Pure tungsten exhibits a high melting point (3,410°C) and excellent thermal conductivity. It is also highly resistant to oxidation and corrosion, making it suitable for high-temperature applications.

Pros & Cons: The main advantage of pure tungsten is its ability to perform under extreme conditions, making it ideal for applications like aerospace and electronics. However, its brittleness can limit its use in some applications, and it is generally more expensive than other metals.

Impact on Application: Pure tungsten is commonly used in the production of electrical contacts, filaments, and high-temperature furnace components. Its compatibility with various media, including gases and liquids, enhances its utility.

Considerations for International Buyers: Buyers from the Middle East and Africa should consider the availability of pure tungsten in their local markets. Understanding the supply chain dynamics and potential tariffs can help optimize procurement strategies.

Illustrative image related to tungsten price

4. Tungsten Disulfide

Key Properties: Tungsten disulfide is a solid lubricant that operates effectively at high temperatures (up to 500°C) and provides excellent wear resistance. It is chemically stable and does not degrade in harsh environments.

Pros & Cons: The key advantage of tungsten disulfide is its ability to reduce friction and wear in mechanical systems, extending the life of components. However, it may not be suitable for all applications, particularly where liquid lubricants are preferred.

Impact on Application: This material is widely used in aerospace, automotive, and industrial applications where lubrication is critical. Its compatibility with various substrates makes it a versatile choice.

Considerations for International Buyers: B2B buyers in Europe and Asia should be aware of the regulatory landscape surrounding lubricants and ensure compliance with environmental standards. The growing demand for high-performance lubricants presents opportunities for suppliers.

Illustrative image related to tungsten price

Summary Table of Key Materials for Tungsten Pricing

| Material | Typical Use Case for tungsten price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Tungsten Carbide | Mining and cutting tools | Exceptional hardness and wear resistance | High cost and brittleness | High |

| Tungsten Alloys | Aerospace and military applications | High strength-to-weight ratio | Expensive and complex manufacturing | High |

| Pure Tungsten | Electrical contacts and filaments | Performs under extreme conditions | Brittleness limits application | High |

| Tungsten Disulfide | Aerospace and industrial lubricants | Reduces friction and wear | Limited to specific applications | Medium |

This analysis provides B2B buyers with critical insights into the properties, advantages, and considerations of various materials related to tungsten pricing, facilitating informed decision-making in procurement strategies.

In-depth Look: Manufacturing Processes and Quality Assurance for tungsten price

What Are the Main Stages of Tungsten Manufacturing?

The manufacturing process for tungsten involves several critical stages, each contributing to the final product’s quality and performance. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The first step in tungsten manufacturing is the extraction and preparation of tungsten ores, primarily wolframite and scheelite. After mining, the ores undergo a series of physical and chemical processes, including crushing, milling, and concentration, to separate tungsten from other minerals. The concentrated tungsten is then converted into tungsten trioxide (WO3) through calcination. This powder is subsequently reduced to produce tungsten metal powder using hydrogen or carbon. -

Forming

In this stage, tungsten powder is shaped into desired forms through various techniques. The most common methods include pressing and sintering. During pressing, tungsten powder is compacted into molds under high pressure. This is followed by sintering, where the compacted powder is heated to a temperature below its melting point, allowing the particles to bond and achieve the required density and strength. Other forming techniques include extrusion and forging, particularly for producing tungsten rods and wires. -

Assembly

For applications requiring complex components, the assembly stage involves combining different tungsten parts or integrating tungsten with other materials. This is particularly relevant in the manufacturing of tungsten carbide products, where tungsten powder is mixed with a binder (usually cobalt or nickel) and then pressed and sintered to form a dense, hard material. -

Finishing

The finishing stage enhances the surface properties and dimensional accuracy of tungsten products. Techniques such as grinding, machining, and polishing are employed to achieve the desired specifications. Surface treatments may also be applied to improve corrosion resistance or enhance performance in specific applications, such as in aerospace or military contexts.

How Is Quality Assurance Implemented in Tungsten Manufacturing?

Quality assurance (QA) is a critical aspect of tungsten manufacturing, ensuring that the final products meet both industry standards and customer expectations. The QA process typically involves adherence to international standards and comprehensive quality checkpoints.

-

International and Industry-Specific Standards

Tungsten manufacturers are often required to comply with international standards such as ISO 9001, which outlines quality management system requirements. Additionally, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for oil and gas applications may be necessary. These certifications help ensure that the products meet safety, health, and environmental protection standards. -

Quality Control Checkpoints

Effective quality control (QC) involves various checkpoints throughout the manufacturing process, including:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified quality standards before processing.

– In-Process Quality Control (IPQC): Continuous monitoring of the manufacturing process to identify and rectify any deviations from quality standards in real-time.

– Final Quality Control (FQC): A thorough inspection of the finished product against predefined specifications, ensuring that it meets all functional and safety requirements. -

Common Testing Methods

Various testing methods are employed to verify tungsten’s physical and chemical properties. These may include:

– X-ray fluorescence (XRF) for elemental composition.

– Tensile testing to determine mechanical properties.

– Hardness testing to assess wear resistance.

– Microstructural analysis using electron microscopy to ensure the integrity of the material.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control is vital to ensure consistent product quality. Here are several strategies:

-

Supplier Audits

Conducting on-site audits of suppliers allows buyers to assess their manufacturing processes, quality control measures, and compliance with international standards. Audits provide insights into the supplier’s capabilities and commitment to quality. -

Requesting Quality Reports

B2B buyers should request detailed quality reports from suppliers, including certifications, test results, and compliance documentation. These reports should demonstrate the supplier’s adherence to relevant standards and the outcomes of various testing methods. -

Third-Party Inspections

Engaging independent third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control practices. These agencies can conduct inspections at various stages of the manufacturing process, ensuring that products meet the required specifications before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate several nuances when dealing with quality control in tungsten manufacturing:

-

Cultural and Regulatory Differences

Understanding the regulatory landscape and cultural practices in different regions is essential. Buyers should familiarize themselves with local regulations concerning product quality, safety, and environmental standards, as these may differ significantly from those in their home markets. -

Language Barriers

Language differences can complicate communication regarding quality expectations. Buyers should ensure that all documentation, including contracts and specifications, are clearly understood by both parties to avoid misinterpretations. -

Logistical Considerations

Quality control also extends to logistics and transportation. Buyers should ensure that suppliers adhere to strict packaging and handling protocols to prevent damage during transit, which can compromise product quality. -

Long-Term Relationships

Building long-term relationships with suppliers can enhance trust and reliability. Regular communication about quality expectations and feedback on products can help suppliers maintain high standards and improve their processes over time.

By understanding the manufacturing processes and quality assurance measures in tungsten production, B2B buyers can make informed decisions, ensuring they procure high-quality tungsten products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tungsten price’

Introduction

Navigating the complexities of tungsten procurement requires a strategic approach, especially given the fluctuating prices and varying quality standards in the market. This guide provides a practical checklist to assist international B2B buyers in sourcing tungsten effectively. By following these steps, you can ensure that you secure the best value while meeting your specific material needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the tungsten you need. This includes purity levels, form (e.g., bars, sheets, or powders), and any specific alloying elements. Knowing your specifications upfront helps narrow down suppliers who can meet your exact needs, ensuring that you receive a product that performs as required in your applications.

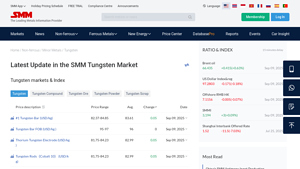

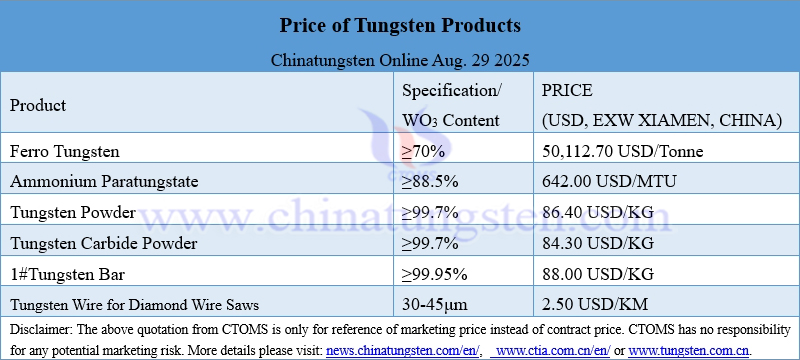

Step 2: Research Current Market Prices

Stay informed about the current market prices for tungsten. Utilize resources like FastMarkets and industry reports to track price trends. Understanding price fluctuations can help you make informed purchasing decisions and negotiate better terms with suppliers.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Look for company profiles, product certifications, and case studies. Request references from other buyers in your region or industry to gauge supplier reliability and product quality. This step is critical to minimize risks associated with supplier performance.

Illustrative image related to tungsten price

- Sub-bullet: Check for ISO certifications or other relevant quality assurances.

- Sub-bullet: Investigate the supplier’s history and their capacity to fulfill orders.

Step 4: Assess Supply Chain Stability

Evaluate the stability and reliability of the supplier’s supply chain. Given that the tungsten market is heavily influenced by geopolitical factors, understanding a supplier’s sourcing and logistics can provide insights into potential delays or price increases. Ensure that your supplier has contingency plans in place to mitigate risks.

Step 5: Negotiate Terms and Pricing

Once you have identified potential suppliers, engage in negotiations to secure favorable terms. Discuss payment options, lead times, and minimum order quantities. Establishing clear terms can help prevent misunderstandings and ensure that both parties are aligned throughout the procurement process.

Step 6: Request Samples for Quality Assurance

Before placing a large order, request samples to assess the quality of the tungsten. This step allows you to verify that the material meets your specifications and quality standards. Testing the samples in your intended applications can prevent costly errors later on.

Step 7: Finalize Contracts with Clear Terms

Once you have selected a supplier and verified the quality, finalize your purchase contracts. Ensure that all terms, including delivery schedules, payment conditions, and quality guarantees, are clearly outlined. A well-drafted contract protects both parties and establishes a framework for future transactions.

Illustrative image related to tungsten price

By following these steps, international B2B buyers can navigate the complexities of tungsten procurement with confidence, ensuring that they secure high-quality materials at competitive prices.

Comprehensive Cost and Pricing Analysis for tungsten price Sourcing

What Are the Key Components of Tungsten Pricing?

Understanding the cost structure of tungsten is crucial for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. The main cost components include:

-

Materials: The primary cost driver in tungsten sourcing is the raw materials, specifically tungsten ore, which is often sourced from regions with high deposits like China, which dominates global supply. Prices can fluctuate based on ore quality and availability.

-

Labor: Labor costs vary significantly based on the geographic location of manufacturing. In regions with lower labor costs, such as parts of South America and Africa, the overall production cost may be lower, but this can impact quality.

-

Manufacturing Overhead: This includes costs associated with the production process, such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help mitigate these overhead costs.

-

Tooling: The production of tungsten products often requires specialized tooling, which adds to the upfront costs. Custom tooling for specific applications can be a significant investment.

-

Quality Control (QC): Ensuring that tungsten meets industry standards and specifications necessitates rigorous quality control processes. These costs are critical to avoid defects that could lead to larger financial losses down the line.

-

Logistics: Transportation costs are influenced by the distance from suppliers to buyers, shipping methods, and compliance with international shipping regulations. Incoterms play a crucial role in defining the responsibilities of buyers and sellers regarding shipping and logistics.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market conditions, competition, and demand.

How Do Various Factors Influence Tungsten Pricing?

Several factors influence the pricing of tungsten, making it imperative for buyers to understand the nuances:

Illustrative image related to tungsten price

-

Volume/MOQ: The minimum order quantity (MOQ) can significantly impact pricing. Bulk orders often lead to discounts, while smaller orders may incur higher per-unit costs.

-

Specifications and Customization: Custom specifications or unique tungsten alloys can lead to increased costs due to additional processing and quality assurance requirements.

-

Materials Quality and Certifications: Higher quality tungsten or those with specific certifications (e.g., ISO) typically command higher prices. Buyers should assess whether the additional cost aligns with their project requirements.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a track record of quality may charge premium prices.

-

Incoterms: Understanding Incoterms is essential for international transactions. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and risks, impacting total pricing.

What Negotiation Strategies Can Optimize Tungsten Sourcing Costs?

B2B buyers can leverage several strategies to enhance their cost-efficiency in tungsten sourcing:

-

Total Cost of Ownership (TCO): Beyond the initial price, consider the TCO, which includes logistics, handling, and potential quality-related costs. A lower upfront cost may not always equate to better overall value.

-

Negotiation: Engage in discussions with suppliers about pricing flexibility, especially for larger orders or long-term contracts. Building a relationship can often yield better terms.

-

Market Research: Stay informed about market trends and fluctuations in tungsten pricing. Understanding supply-demand dynamics can provide leverage during negotiations.

-

Quality Assurance: Emphasize quality requirements to avoid the hidden costs associated with defects or rework. Suppliers may be willing to negotiate on price if they are assured of long-term business.

-

Strategic Sourcing: Evaluate multiple suppliers and consider geographic diversification to mitigate risks associated with supply chain disruptions.

What Should International Buyers Consider When Sourcing Tungsten?

International buyers, particularly from diverse regions, must navigate additional complexities when sourcing tungsten:

-

Regulatory Compliance: Different countries have varying regulations regarding materials sourcing and imports. Understanding these can prevent costly delays.

-

Cultural Sensitivities: Building relationships with suppliers from different cultural backgrounds can enhance negotiation outcomes and foster long-term partnerships.

-

Currency Fluctuations: Be aware of how currency exchange rates can affect pricing, especially in contracts that span extended periods.

Disclaimer on Pricing

Prices for tungsten are subject to frequent fluctuations due to market conditions, geopolitical factors, and changes in supply and demand. Buyers are encouraged to consult multiple sources and conduct thorough market research before finalizing procurement decisions.

Alternatives Analysis: Comparing tungsten price With Other Solutions

Understanding Alternatives to Tungsten Price in Industrial Applications

As industries seek to optimize costs and enhance performance, the search for alternatives to tungsten becomes crucial. Tungsten, known for its high density, exceptional hardness, and thermal stability, is often the material of choice for cutting tools, aerospace components, and various electronic applications. However, rising tungsten prices and supply chain uncertainties prompt businesses to explore other viable materials that can deliver similar benefits. Below is a comparative analysis of tungsten against two prominent alternatives: titanium and carbide.

Comparison Table

| Comparison Aspect | Tungsten Price | Titanium Alloy | Carbide |

|---|---|---|---|

| Performance | High tensile strength and excellent thermal resistance | Good strength-to-weight ratio, corrosion resistant | Superior hardness and wear resistance |

| Cost | Generally high due to limited supply and mining costs | Moderate, but varies based on grade and form | Lower than tungsten, but high for premium grades |

| Ease of Implementation | Requires specialized machining techniques | Relatively easier to machine and weld | Can be challenging to machine due to hardness |

| Maintenance | Low maintenance; durable under high temperatures | Requires occasional maintenance for corrosion | Low maintenance; durable but may require periodic replacement |

| Best Use Case | Aerospace, defense, and high-temperature applications | Aerospace, automotive, and medical devices | Mining, oil drilling, and machining tools |

Detailed Breakdown of Alternatives

Titanium Alloy: A Lightweight Contender

Titanium alloys are known for their impressive strength-to-weight ratio and corrosion resistance. They are often utilized in applications where weight savings are critical, such as in aerospace and automotive sectors. The cost of titanium can be moderate, but it varies significantly depending on the specific grade and form needed. While titanium can be easier to machine than tungsten, it still requires specific techniques to avoid issues like work hardening. The main advantage of titanium is its versatility across various industries, but it may not provide the same high-temperature stability as tungsten.

Carbide: The Hardness Champion

Carbide, particularly tungsten carbide, offers exceptional hardness and wear resistance, making it a preferred choice in mining and machining applications. Its cost is generally lower than tungsten, especially for non-premium grades, making it an attractive alternative for bulk applications. However, the hardness of carbide can make machining challenging and may require specialized tools. Carbide is ideal for applications where extreme durability is required, but it might not perform as well in high-temperature environments compared to tungsten.

Illustrative image related to tungsten price

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting between tungsten and its alternatives, B2B buyers must consider specific application requirements, including performance needs, budget constraints, and ease of implementation. For high-temperature applications where strength is paramount, tungsten remains unmatched. However, for scenarios where weight and cost are more significant concerns, titanium may be the better choice. Meanwhile, carbide stands out for its durability in harsh conditions, making it suitable for mining and machining. Evaluating these factors will enable businesses to make informed decisions that align with their operational needs and strategic goals.

Essential Technical Properties and Trade Terminology for tungsten price

What Are the Key Technical Properties of Tungsten That Affect Pricing?

Understanding the critical technical properties of tungsten is essential for B2B buyers, as these specifications can directly influence both the quality and cost of tungsten products. Here are some key properties to consider:

1. Material Grade

Material grade refers to the classification of tungsten based on purity and performance characteristics. The most common grades are pure tungsten (99.95% purity) and various tungsten alloys. Higher purity grades typically command higher prices due to their enhanced performance in specialized applications, such as aerospace and defense, where material integrity is paramount.

2. Density

Tungsten boasts a density of 19.25 g/cm³, making it the heaviest engineering material. This property is crucial for applications requiring weight, such as counterbalances in machinery or radiation shielding. Understanding density can help buyers select the appropriate tungsten form for their specific needs, impacting cost-effectiveness and performance.

Illustrative image related to tungsten price

3. Melting Point

With a melting point of 3,410°C, tungsten has the highest melting point of all metals. This property is vital for applications in extreme environments, such as aerospace and military uses. Buyers should consider this attribute when assessing potential suppliers, as materials that can withstand high temperatures often incur higher production costs.

4. Hardness

Tungsten is recognized as the hardest pure metal, which contributes to its use in cutting tools, mining equipment, and industrial applications. The hardness of tungsten directly correlates with its wear resistance, making it a preferred choice for manufacturers looking to minimize downtime and maintenance costs.

5. Corrosion Resistance

Tungsten exhibits excellent corrosion resistance, particularly against strong acids and alkalis. This property is essential for applications in chemical processing and electronics, where material degradation could lead to significant operational disruptions. Buyers should prioritize suppliers who can guarantee high-quality tungsten with minimal impurities that could affect corrosion resistance.

Illustrative image related to tungsten price

What Are Common Trade Terms Related to Tungsten Pricing?

Familiarizing yourself with industry jargon can enhance communication and negotiation processes with suppliers. Here are some common trade terms relevant to tungsten pricing:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the tungsten industry, understanding OEM relationships can help buyers identify reputable suppliers that meet specific quality standards and specifications.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cost-efficiency. Understanding MOQ can help buyers negotiate better deals and avoid overstocking.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other terms for specified products. For tungsten, an RFQ can help buyers compare multiple suppliers on price, delivery time, and quality, enabling informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers in the tungsten market, as they clarify who is responsible for shipping, insurance, and tariffs, thus impacting overall costs.

5. Sintering

Sintering is a manufacturing process that involves compacting and forming a solid mass of material by heat or pressure without melting it to the point of liquefaction. This term is particularly relevant for tungsten carbide production, as it affects the quality and price of the final product.

Why Are These Properties and Terms Important for B2B Buyers?

For B2B buyers, grasping the technical properties and industry terminology related to tungsten is essential for making informed purchasing decisions. These insights not only help in evaluating product quality but also in negotiating favorable terms and prices, ultimately leading to cost savings and improved operational efficiency. Understanding these factors will enable buyers to select the right products that align with their specific needs and applications.

Navigating Market Dynamics and Sourcing Trends in the tungsten price Sector

What Are the Current Market Dynamics and Key Trends Affecting Tungsten Prices?

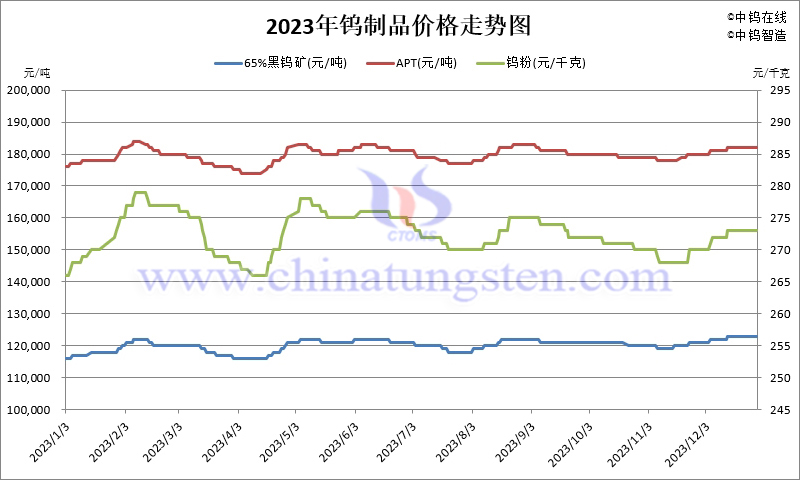

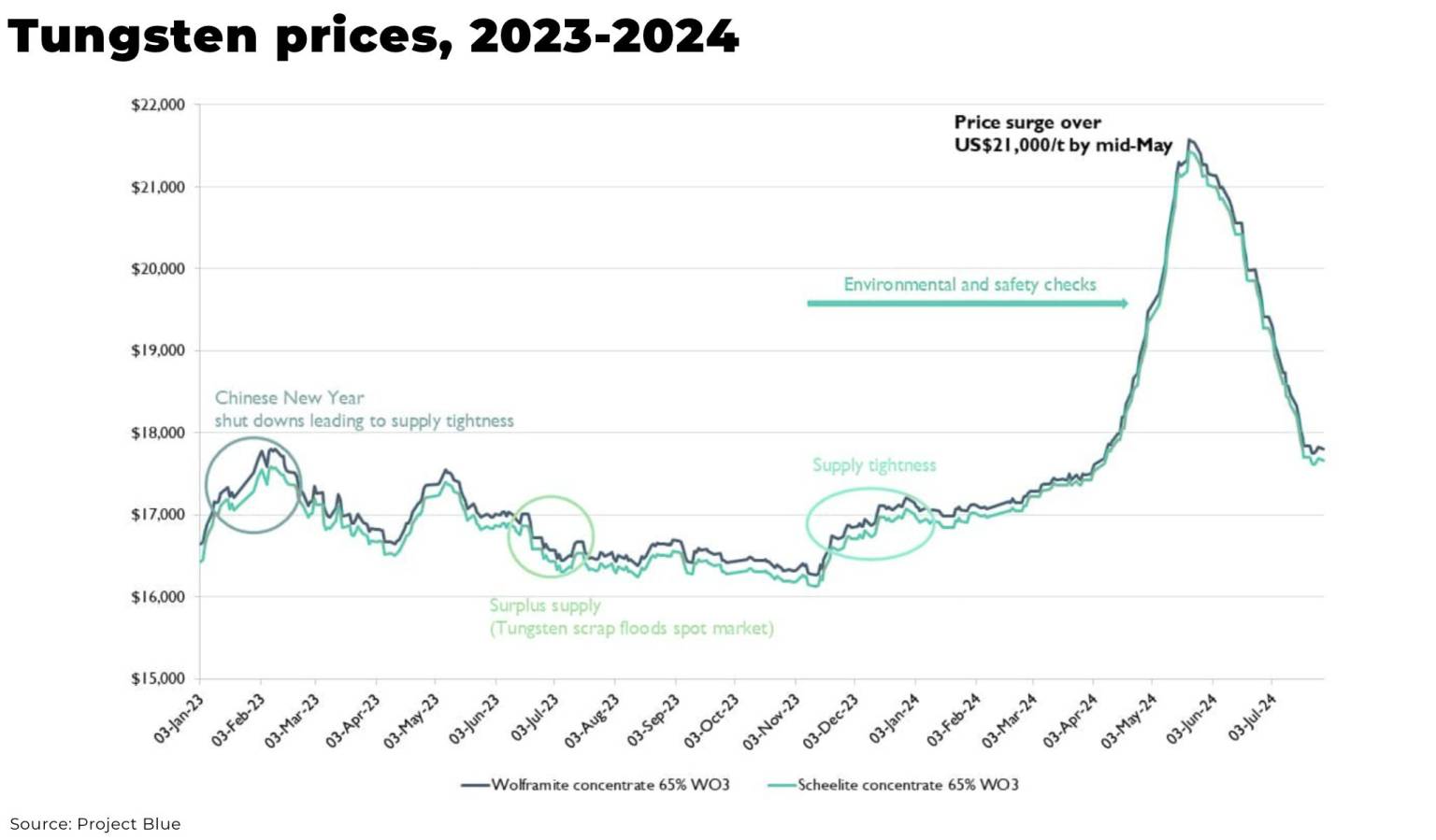

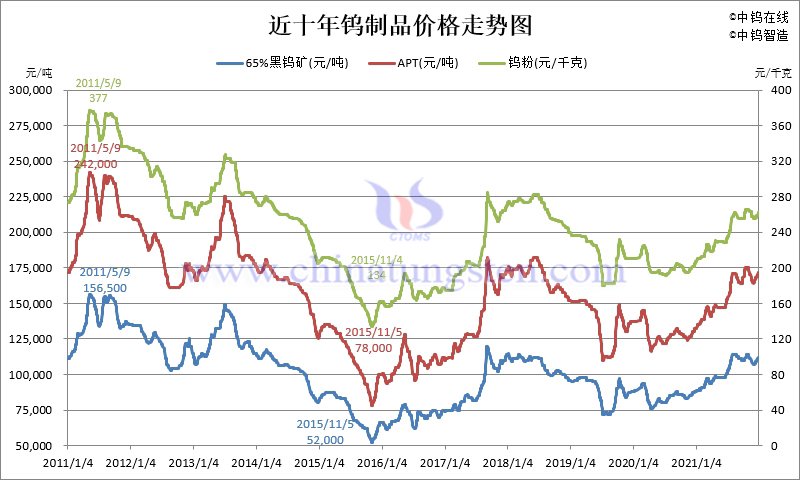

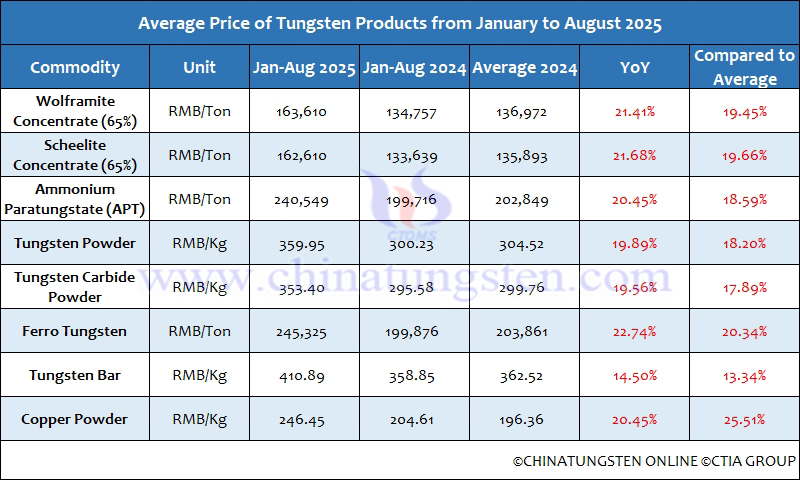

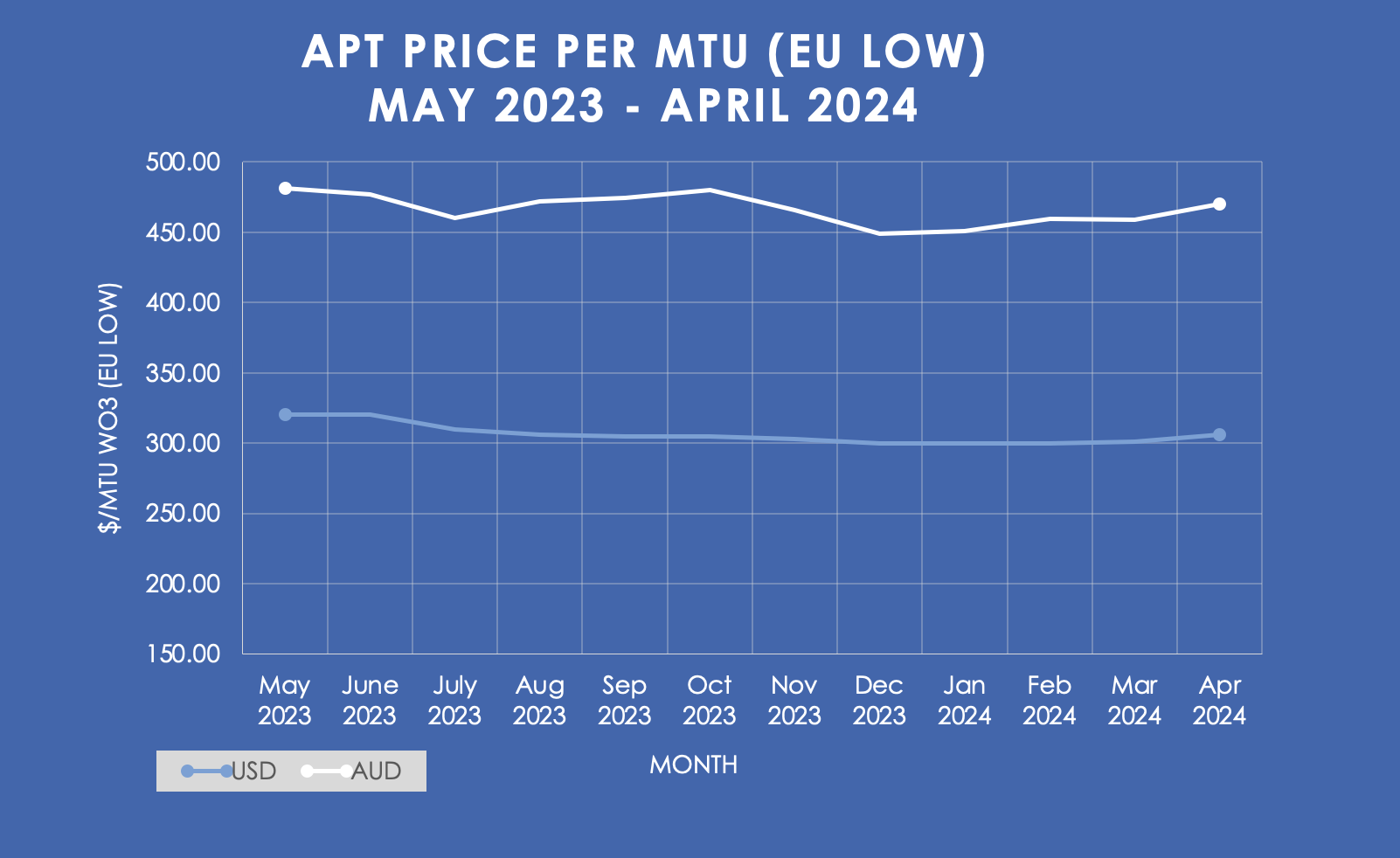

The tungsten market is primarily driven by its unique properties and diverse applications across various industries, particularly aerospace, automotive, and electronics. In recent years, a notable trend has been China’s increasing dominance in tungsten production and consumption. While China has historically been the leading exporter, it has transitioned to becoming a net importer due to rising domestic demand and government regulations restricting ore exports. This shift is expected to place upward pressure on global tungsten prices, with forecasts suggesting an annual increase of 3-7% in demand.

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should also be aware of emerging technologies that enhance the efficiency of tungsten extraction and processing. Innovations such as automated mining and advanced metallurgical techniques are becoming more prevalent, potentially impacting sourcing costs and timelines. Furthermore, as industries increasingly prioritize high-performance materials, the demand for tungsten alloys is expected to experience significant growth, especially in aerospace manufacturing.

Buyers should also monitor geopolitical factors that can influence tungsten supply chains. Trade policies, tariffs, and international relations can create volatility in pricing and availability, making it crucial for companies to establish flexible sourcing strategies.

How Is Sustainability and Ethical Sourcing Influencing Tungsten Pricing?

As global awareness of environmental issues increases, sustainability has become a pivotal concern in the tungsten sector. The extraction and processing of tungsten can have significant environmental impacts, including habitat destruction and pollution. Therefore, businesses are increasingly prioritizing ethical sourcing and sustainability in their supply chains. This shift is not just about compliance; it can also enhance brand reputation and customer loyalty.

For international B2B buyers, investing in suppliers that adhere to sustainable practices and have ‘green’ certifications can lead to better long-term relationships and stability in supply. Certifications such as ISO 14001 for environmental management systems can help buyers identify responsible suppliers. Moreover, the use of recycled tungsten is gaining traction, as it offers a lower environmental footprint while still meeting quality standards.

The growing demand for ethically sourced materials is also reflected in consumer preferences, particularly in Europe and North America, where companies are increasingly held accountable for their supply chain practices. Buyers are encouraged to conduct thorough due diligence on their suppliers’ environmental and ethical practices to mitigate risks and align with global sustainability goals.

What Is the Historical Context Behind Tungsten’s Market Development?

The journey of tungsten from a troublesome byproduct in tin mining to a strategic industrial metal reflects its significant evolution. Discovered in the 18th century, tungsten has transformed into a vital material across various sectors due to its exceptional properties, including high melting point and hardness. Its demand surged during World War II, primarily for military applications, and post-war industrialization further cemented its status as an essential resource.

The development of tungsten carbide in the 1920s marked a critical milestone, positioning tungsten as a key component in cutting tools and machinery. Today, its applications span a wide range of industries, highlighting its adaptability and importance. Understanding this historical context can provide international B2B buyers with valuable insights into current market trends and future projections, enabling more informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of tungsten price

-

How do I determine the current tungsten price?

To determine the current tungsten price, it’s essential to consult reliable market sources such as FastMarkets, which provides weekly updates on tungsten pricing. Additionally, industry reports and market analysis from reputable firms can offer insights into price trends and forecasts. B2B buyers should also consider factors influencing prices, such as supply chain dynamics, geopolitical events, and changes in demand from major industries, particularly in countries like China and the U.S. -

What factors influence tungsten pricing in the global market?

Tungsten pricing is influenced by a variety of factors including supply and demand dynamics, production costs, and geopolitical events. The Chinese market plays a significant role as it dominates both supply and consumption. Other factors include production levels from key mining regions, technological advancements in tungsten applications, and fluctuations in global industries such as aerospace and electronics, which are major consumers of tungsten products. -

What are the minimum order quantities (MOQ) for tungsten products?

Minimum order quantities (MOQ) for tungsten products vary by supplier and product type. Generally, MOQs can range from a few kilograms for raw tungsten to several hundred kilograms for processed tungsten products like tungsten carbide. It’s important to discuss your specific needs with potential suppliers to negotiate suitable MOQs that align with your business requirements and production schedules. -

How can I vet tungsten suppliers for quality and reliability?

To vet tungsten suppliers, conduct thorough due diligence by checking their certifications, production capabilities, and customer reviews. Request samples to evaluate product quality, and inquire about their quality assurance processes. It’s also beneficial to engage in conversations with other businesses in your industry to gather insights on supplier performance. Additionally, consider suppliers with established reputations in regions known for reliable tungsten production, such as Europe or North America. -

What are the common payment terms for purchasing tungsten?

Payment terms for tungsten purchases can vary widely based on supplier policies and the buyer’s creditworthiness. Common arrangements include upfront payments, net 30-60 day terms, or letters of credit for larger transactions. It’s advisable to negotiate terms that suit your cash flow needs while ensuring the supplier is comfortable with the arrangement. Always clarify the payment structure in the contract to avoid misunderstandings later. -

What logistics considerations should I keep in mind when sourcing tungsten?

When sourcing tungsten, consider logistics factors such as shipping times, costs, and import/export regulations. Depending on the supplier’s location, international shipping can impact lead times significantly. Be aware of tariffs and customs duties that may apply to tungsten imports in your country. Working with experienced logistics partners can help streamline the process and ensure compliance with local regulations, thereby minimizing delays. -

Can tungsten products be customized to meet specific requirements?

Yes, many tungsten suppliers offer customization options to meet specific industry needs. This may include tailoring dimensions, alloy compositions, or surface finishes. When discussing customization, be clear about your specifications and intended applications to ensure the final product meets your performance requirements. Collaborating with suppliers early in the design process can lead to more efficient production and better alignment with your business goals. -

What quality assurance measures should I expect from tungsten suppliers?

Reputable tungsten suppliers should implement rigorous quality assurance measures to ensure product consistency and compliance with industry standards. Expect to see certifications such as ISO 9001, which indicates a commitment to quality management systems. Suppliers should also provide detailed documentation regarding material specifications, testing results, and traceability of their tungsten products. Regular audits and inspections can further validate their quality assurance processes, ensuring you receive reliable materials for your applications.

Top 6 Tungsten Price Manufacturers & Suppliers List

1. Almonty – Tungsten Solutions

Domain: almonty.com

Registered: 2005 (20 years)

Introduction: Tungsten is the heaviest engineering material with a density of 19.25 g/cm3. It has the highest melting point of all metals at 3410°C and a boiling point of 5700°C. Tungsten has the lowest vapor pressure of all metals and the highest modulus of elasticity (E = 400GPa). It is the hardest pure metal with excellent high-temperature strength characteristics and the highest tensile strength at temperat…

2. Tungsten – Pure Tungsten Bars and Rods

Domain: shop.tungsten.com

Registered: 1997 (28 years)

Introduction: 99.95% Pure Tungsten; Categories: Pure Tungsten Bars, Discs, Rod, Sheet/Plate, Wire, Powder; Subcategories: Chrome Plated Tungsten Rods, Tungsten Heavy Alloy, Pure Tantalum, Pure Molybdenum, Vacuum Furnace Components, TIG Welding; Diameter Options: 0.0003″ to 0.0014″; Height/Thickness: 0.001″ to 0.02″; Width: 0.335″ to 21″; Length: 1 kg (spool), 1 meter, various lengths; Products: Pure Tungsten Sh…

3. Mining.com – Tungsten Price Surge

Domain: mining.com

Registered: 1994 (31 years)

Introduction: Tungsten prices have surged to their highest level since 2013, with ammonium paratungstate (APT) reaching $400 per metric ton unit (mtu) on the European spot market, an 18% increase since February 2025. China accounts for over 80% of global tungsten production, with a 2024 mining quota set at 58,000 tons, a 6.5% decrease from the previous year. Tungsten is used in various industries, including aer…

4. Argus – Tungsten APT Prices

Domain: argusmedia.com

Registered: 2007 (18 years)

Introduction: Tungsten APT fob China (per mtu WO3) prices, USD/mtu, independent price assessments, Argus Non-Ferrous Markets, historical export data.

5. Metal.com – Tungsten Price Updates

Domain: metal.com

Registered: 1995 (30 years)

Introduction: Daily Tungsten price updates including various forms and their prices as of September 9, 2025:

– #1 Tungsten Bar: Price Range: 82.37-84.85 USD/kg, Average: 83.61 USD/kg, Change: 0.05 USD/kg

– Tungsten Bar FOB: Price Range: 95-97 USD/kg, Average: 96 USD/kg, Change: 0 USD/kg

– Thorium Tungsten Electrode: Price Range: 81.75-84.23 USD/kg, Average: 82.99 USD/kg, Change: 0.05 USD/kg

– Tungsten Rods …

6. Scrap Metal Buyers – Tungsten

Domain: scrapmetalbuyers.com

Registered: 2018 (7 years)

Introduction: {“product_name”: “Tungsten”, “recycling_price”: “$3.25/lb”, “description”: “Tungsten has the highest melting point of all metals and is alloyed with other metals to strengthen them. It is used in high-temperature applications such as arc-welding electrodes and heating elements in high-temperature furnaces.”, “forms_accepted”: [“drill parts”, “cutting inserts”, “rods”], “recycling_process”: “We sor…

Strategic Sourcing Conclusion and Outlook for tungsten price

What Are the Key Takeaways for B2B Buyers in Tungsten Sourcing?

In the dynamic landscape of tungsten pricing, strategic sourcing emerges as a vital tool for B2B buyers. Understanding the intricacies of tungsten’s supply chain, particularly China’s influence, is crucial. With China’s increasing domestic demand and regulatory measures, the market is poised for tighter supply and rising prices. This underscores the importance of establishing reliable supplier relationships and diversifying sourcing strategies to mitigate risks associated with price volatility.

How Can Strategic Sourcing Enhance Your Competitive Edge?

By leveraging strategic sourcing, businesses can secure favorable pricing and ensure continuity of supply, ultimately enhancing their competitive edge in industries reliant on tungsten, such as aerospace and manufacturing. Engaging in long-term contracts and fostering partnerships with suppliers not only stabilizes costs but also opens avenues for innovation and collaboration.

What Should International Buyers Do Next?

As you navigate the complexities of tungsten sourcing, consider exploring new markets and alternative suppliers across Africa, South America, the Middle East, and Europe. By staying informed about market trends and adjusting your sourcing strategies accordingly, you can capitalize on opportunities and drive sustainable growth. Take proactive steps today to secure your tungsten supply chain and position your business for success in an evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.