How to Source Tri Plug Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for tri plug

In the ever-evolving landscape of global commerce, sourcing tri plugs can present unique challenges for B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe. Ensuring compliance with local electrical standards while addressing safety concerns and energy efficiency is critical for successful procurement. This comprehensive guide serves as a vital resource for international buyers looking to navigate the complexities of tri plug sourcing, offering insights into various types, applications, and standards that influence purchasing decisions.

Throughout this guide, we will delve into the multifaceted aspects of tri plugs, from understanding their technical specifications to exploring their applications in different industries. We will also highlight best practices for vetting suppliers, ensuring that your sourcing aligns with both quality standards and market demands. Moreover, we will provide an analysis of cost factors, allowing you to make informed decisions that balance budget constraints with quality requirements.

By equipping B2B buyers with the knowledge needed to confidently select tri plugs that meet their operational needs, this guide empowers businesses to enhance their electrical safety protocols and operational efficiency. As you embark on your sourcing journey, let this resource be your trusted companion in making strategic purchasing decisions that will drive success in your market.

Understanding tri plug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Tri-Plug | Three-prong design for grounding; used globally | Electrical appliances, machinery | Pros: Enhanced safety; universal compatibility. Cons: May require adapter in older systems. |

| Triple Outlet Plug | Allows multiple devices to connect; compact design | Offices, retail spaces, events | Pros: Space-efficient; cost-effective. Cons: Limited power capacity; can overheat. |

| Tri-Plug for Horticulture | Designed for seedling propagation; specific dimensions | Greenhouses, nurseries | Pros: Optimized for plant growth; easy handling. |

| Industrial Tri-Plug | Heavy-duty construction; high voltage capacity | Manufacturing, construction sites | Pros: Durable; withstands harsh environments. |

| Outdoor Tri-Plug | Weather-resistant; designed for outdoor use | Landscaping, outdoor events | Pros: Resistant to elements; safe for outdoor use. |

What are the Characteristics of a Standard Tri-Plug?

The standard tri-plug features a three-prong configuration that ensures a secure connection and grounding, making it a staple in electrical safety across various regions. Its universal design allows compatibility with numerous appliances and machinery, making it suitable for a wide range of B2B applications. Buyers should consider the electrical standards in their region, as some older systems may require adapters for integration. The enhanced safety offered by the grounding feature is a significant advantage for businesses looking to protect their equipment and personnel.

Illustrative image related to tri plug

How Does a Triple Outlet Plug Enhance Workspace Efficiency?

The triple outlet plug is designed to accommodate multiple devices simultaneously, making it ideal for offices and retail spaces where space is a premium. Its compact design allows for easy integration into existing setups, promoting efficiency without the need for extensive rewiring. Buyers should evaluate the power capacity to prevent overheating and ensure that it meets the demands of their devices. This type of plug is particularly beneficial for businesses seeking cost-effective solutions to power multiple devices without compromising safety.

What Makes Tri-Plugs for Horticulture Unique?

Tri-plugs designed for horticulture are specifically engineered for seedling propagation, featuring dimensions that optimize plant growth. These plugs facilitate easy handling and planting, making them indispensable in greenhouses and nurseries. B2B buyers in agriculture should consider the specific needs of their plants, such as soil type and moisture retention, when selecting these plugs. Although they are limited to agricultural applications, their effectiveness in promoting healthy plant growth is a compelling reason for nurseries to invest in them.

Why Choose an Industrial Tri-Plug for Heavy-Duty Applications?

Industrial tri-plugs are built to withstand demanding environments, characterized by heavy-duty construction and high voltage capacity. They are essential in manufacturing and construction sites, where reliability and durability are paramount. Buyers should assess the specific voltage and amperage requirements of their equipment to ensure compatibility. While these plugs tend to be more expensive, their longevity and performance under pressure justify the investment for businesses that require robust electrical solutions.

What Are the Benefits of Using Outdoor Tri-Plugs?

Outdoor tri-plugs are designed to resist weather elements, making them suitable for landscaping and outdoor events. Their robust construction ensures safety in outdoor settings, where exposure to moisture and temperature fluctuations can pose risks. B2B buyers should consider the plug’s weight and storage requirements, as outdoor plugs can be bulkier. However, the assurance of safety and functionality in outdoor applications makes them a valuable asset for businesses operating in outdoor environments.

Key Industrial Applications of tri plug

| Industry/Sector | Specific Application of tri plug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electrical Equipment | Power distribution in manufacturing facilities | Enhances safety and reliability of electrical systems | Compliance with international safety standards and certifications |

| Agricultural Technology | Automated irrigation systems | Facilitates efficient power management for agricultural tools | Durability against environmental conditions and voltage requirements |

| Construction & Infrastructure | Temporary power setups on construction sites | Provides safe and flexible power solutions for various tools | Adaptability to different voltage systems and local regulations |

| Hospitality & Events | Event lighting and audio equipment | Ensures reliable power for large gatherings and events | Portability and ease of installation in diverse venues |

| Renewable Energy | Integration with solar power systems | Supports sustainable energy solutions with efficient power distribution | Compatibility with various energy systems and local regulations |

How is ‘tri plug’ utilized in electrical equipment for manufacturing?

In manufacturing facilities, tri plugs are critical for power distribution systems. They provide a reliable connection for heavy machinery and electrical equipment, ensuring that operations run smoothly without interruptions. The use of tri plugs enhances safety by grounding electrical systems, preventing potential shocks. For B2B buyers in this sector, sourcing tri plugs requires attention to compliance with international safety standards, as well as ensuring the plugs can handle the specific voltage and current requirements of the equipment used.

What role does ‘tri plug’ play in agricultural technology?

In agricultural settings, tri plugs are commonly used in automated irrigation systems and other electrically powered agricultural tools. They allow farmers to manage power distribution effectively, ensuring that irrigation systems operate efficiently, which is crucial for crop yield. Buyers from regions like Africa and South America should consider the durability of tri plugs against environmental factors such as moisture and temperature variations, as well as the voltage requirements specific to their equipment.

How do construction and infrastructure sectors benefit from ‘tri plug’?

The construction industry frequently employs tri plugs for temporary power setups at job sites. These plugs provide a flexible and safe way to connect various power tools and equipment, enhancing productivity. For international buyers, it is essential to ensure that the tri plugs are adaptable to different voltage systems and comply with local regulations, which can vary significantly between regions, particularly in the Middle East and Europe.

In what ways does ‘tri plug’ support hospitality and events?

In the hospitality sector, tri plugs are vital for powering lighting and audio equipment during events. They offer a reliable connection that can be quickly set up and taken down, making them ideal for temporary installations. B2B buyers in this industry should prioritize the portability and ease of installation of tri plugs, as well as their ability to handle varying power loads, ensuring seamless operation during events.

How is ‘tri plug’ integrated into renewable energy systems?

Tri plugs play a significant role in renewable energy applications, particularly in connecting solar power systems to appliances and other electrical devices. They facilitate efficient power distribution, enabling users to harness solar energy effectively. Buyers should focus on sourcing tri plugs that are compatible with various energy systems and ensure they meet local regulations, which can differ widely, especially in emerging markets across Africa and South America.

3 Common User Pain Points for ‘tri plug’ & Their Solutions

Scenario 1: Navigating Electrical Safety Compliance for Equipment

The Problem: In the international B2B landscape, buyers often face stringent electrical safety compliance regulations, especially when sourcing equipment that uses three-prong plugs. This is particularly critical in regions like Europe and the Middle East, where adherence to safety standards is non-negotiable. Buyers can find themselves in a bind when the equipment they plan to import does not meet local standards, leading to potential penalties, increased costs for modifications, and delays in project timelines.

The Solution: To navigate these compliance challenges, buyers should thoroughly research local electrical regulations before purchasing tri plugs and associated equipment. This involves consulting local codes and standards, such as the International Electrotechnical Commission (IEC) standards for Europe or the Saudi Arabian Standards Organization (SASO) regulations in the Middle East. Additionally, engaging with suppliers who can provide certification documents proving compliance with local safety standards is crucial. Buyers should also consider investing in a pre-import inspection to ensure that equipment meets all necessary requirements. By prioritizing compliance, buyers can avoid costly delays and ensure a smooth operational process.

Scenario 2: Managing Supply Chain Disruptions for Tri Plugs

The Problem: Global supply chain disruptions, exacerbated by geopolitical tensions and natural disasters, can significantly impact the availability of tri plugs for businesses. For B2B buyers, this unpredictability can lead to project delays, increased costs, and frustration, particularly in sectors that rely heavily on timely delivery of electrical components for production or installation.

The Solution: To mitigate supply chain risks, B2B buyers should diversify their supplier base. Rather than relying on a single source, consider establishing relationships with multiple manufacturers across different regions. This strategy not only enhances supply chain resilience but also provides leverage in negotiations. Implementing just-in-time inventory practices can also help manage stock levels more effectively, ensuring that essential components like tri plugs are always available. Additionally, using supply chain management software can provide real-time insights into inventory levels and supplier performance, allowing for proactive decision-making in the face of disruptions.

Scenario 3: Ensuring Compatibility with Diverse Electrical Systems

The Problem: One of the most common pain points for B2B buyers is ensuring that tri plugs are compatible with the electrical systems in various countries. With different voltage levels and plug configurations across regions—such as 220V in Europe and 110V in parts of Africa and South America—buyers may inadvertently purchase equipment that cannot be used in their target markets, resulting in costly modifications or returns.

The Solution: To avoid compatibility issues, buyers should conduct a thorough analysis of the electrical specifications required for their target markets. This includes understanding the voltage requirements, frequency, and plug types used in each region. When sourcing tri plugs, it’s advisable to work with suppliers who offer customizable solutions or a wide range of options that cater to different international standards. Additionally, creating a compatibility checklist for each region can streamline the procurement process, ensuring that all purchased equipment meets local electrical specifications. Investing in universal adapters may also provide a temporary solution for mismatched equipment, giving buyers the flexibility needed to operate across different markets without immediate modification.

Illustrative image related to tri plug

Strategic Material Selection Guide for tri plug

What Are the Common Materials Used for Tri Plugs?

When selecting materials for tri plugs, it’s essential to consider the unique properties and applications of each material. Here, we analyze four common materials used in the manufacturing of tri plugs, focusing on their performance characteristics, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Polyvinyl Chloride (PVC) Perform in Tri Plugs?

Key Properties: PVC is known for its excellent electrical insulation properties, making it a popular choice for tri plugs. It has a temperature rating of up to 70°C and is resistant to moisture, chemicals, and UV light.

Pros & Cons: PVC is relatively low-cost and easy to manufacture, allowing for mass production. However, it can become brittle over time, especially when exposed to extreme temperatures, which may affect its durability. Additionally, while it offers good insulation, it is not as robust against mechanical stress compared to other materials.

Impact on Application: PVC is suitable for indoor applications where exposure to harsh conditions is minimal. It is compatible with standard electrical systems, making it a common choice for residential and light commercial use.

Considerations for International Buyers: Compliance with international standards such as IEC and ASTM is crucial when sourcing PVC tri plugs. Buyers should also be aware of regional preferences, as some markets may favor more durable materials.

What Advantages Does Thermoplastic Elastomer (TPE) Offer?

Key Properties: TPE combines the properties of rubber and plastic, providing excellent flexibility and resilience. It can withstand temperatures ranging from -40°C to 100°C and is resistant to oils and greases.

Pros & Cons: The flexibility of TPE allows for easy handling and installation, making it user-friendly. However, TPE can be more expensive than PVC, which may impact cost-sensitive projects. Its manufacturing complexity is also higher, potentially leading to longer lead times.

Impact on Application: TPE is ideal for applications requiring frequent movement or bending, such as in portable power tools or outdoor equipment. Its chemical resistance makes it suitable for environments where exposure to oils and solvents is common.

Considerations for International Buyers: TPE materials should comply with specific regulations in different regions, such as REACH in Europe. Buyers in regions like Saudi Arabia and Brazil should ensure that their suppliers meet local safety and environmental standards.

How Does Nylon Compare as a Material for Tri Plugs?

Key Properties: Nylon is a high-strength thermoplastic known for its exceptional durability and resistance to abrasion and impact. It can operate effectively in temperatures up to 120°C.

Pros & Cons: The robustness of nylon makes it an excellent choice for heavy-duty applications. However, it is typically more expensive than PVC and TPE, which may deter some buyers. Additionally, nylon can absorb moisture, which may affect its electrical properties over time.

Impact on Application: Nylon is suitable for industrial applications where durability and strength are paramount. It is often used in environments with high mechanical stress, such as manufacturing plants.

Considerations for International Buyers: Buyers should ensure that nylon tri plugs meet relevant international standards, such as UL and IEC. Given its higher cost, buyers should weigh the benefits of durability against budget constraints.

What Role Does Metal Play in Tri Plug Manufacturing?

Key Properties: Metals such as brass or copper are often used for the prongs in tri plugs due to their excellent conductivity and strength. They can handle high temperatures and are resistant to corrosion when properly treated.

Pros & Cons: Metal components provide superior electrical conductivity and mechanical strength, ensuring reliable performance. However, they can be more expensive and require additional manufacturing processes, such as plating, to prevent corrosion.

Impact on Application: Metal is essential for applications requiring high electrical loads, such as industrial machinery. Its durability makes it suitable for both indoor and outdoor applications.

Considerations for International Buyers: Compliance with electrical safety standards is critical when sourcing metal components. Buyers should also consider the environmental impact of metal sourcing and processing in their regions.

Summary Table of Material Selection for Tri Plugs

| Material | Typical Use Case for tri plug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride (PVC) | Indoor residential and light commercial | Excellent electrical insulation | Brittle over time | Low |

| Thermoplastic Elastomer (TPE) | Portable tools and outdoor equipment | Flexibility and resilience | Higher cost and complexity | Medium |

| Nylon | Heavy-duty industrial applications | Exceptional durability | Absorbs moisture | High |

| Metal (Brass/Copper) | High electrical load applications | Superior conductivity | Higher cost and corrosion risk | Medium to High |

This strategic material selection guide provides a comprehensive overview of the materials commonly used in tri plugs, equipping international B2B buyers with the insights necessary to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for tri plug

What Are the Main Stages in the Manufacturing Process of Tri Plugs?

The manufacturing of tri plugs involves several critical stages that ensure functionality and safety. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Tri Plug Manufacturing?

Material preparation is crucial as it lays the groundwork for the entire manufacturing process. Typically, high-quality thermoplastics or thermosetting plastics are selected for their electrical insulation properties. Copper or brass is often used for the prongs due to its excellent conductivity. Suppliers should ensure that these materials meet international standards for electrical components.

Before production, raw materials undergo rigorous quality assessments to eliminate any defects. This might involve chemical testing to ensure that the plastics can withstand heat and electrical stress. B2B buyers should request material certifications to verify compliance with local and international standards, such as RoHS (Restriction of Hazardous Substances).

What Techniques Are Used in Forming Tri Plugs?

The forming stage involves transforming raw materials into usable components through various techniques. Injection molding is the predominant method for creating the plastic housing of the tri plug. This process allows for high precision and repeatability, ensuring that each component meets the required specifications.

For the prongs, stamping or extrusion techniques may be employed. These methods ensure that the prongs are produced with the right dimensions and strength to handle electrical loads. A well-structured forming process minimizes waste and maximizes efficiency, crucial for B2B suppliers aiming to keep costs competitive.

How Are Tri Plugs Assembled?

The assembly stage integrates the components into the final product. Automated assembly lines are commonly used to enhance efficiency and reduce human error. The assembly process generally follows these steps:

- Component Insertion: Prongs are inserted into the molded plastic housing.

- Electrical Connections: Ensuring that the connections between the prongs and internal wiring are secure is critical. This step might include crimping or soldering.

- Final Assembly: The housing is closed, and any additional features, such as safety shutters, are added.

B2B buyers should inquire about the assembly methods used by suppliers, as automated processes often yield higher quality and consistency compared to manual labor.

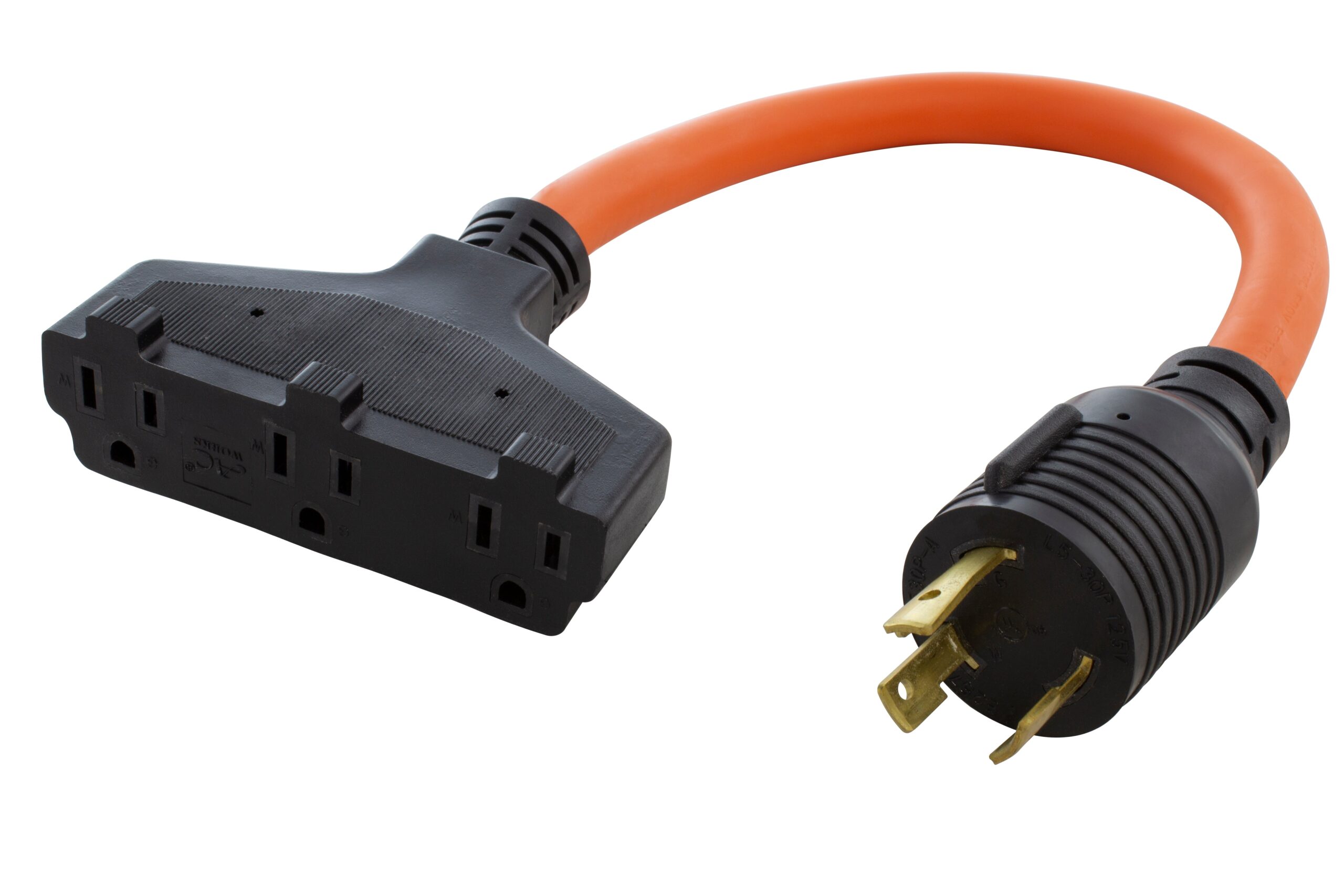

Illustrative image related to tri plug

What Finishing Processes Are Commonly Used for Tri Plugs?

Finishing processes enhance the product’s durability and aesthetic appeal. Common techniques include:

- Surface Treatment: This may involve coating the prongs with nickel or tin to improve conductivity and resistance to corrosion.

- Quality Marking: Markings for voltage, current ratings, and safety certifications are typically printed or embossed on the plug.

- Packaging: Proper packaging is essential for ensuring the plugs remain undamaged during transport. B2B buyers should check that packaging materials also adhere to environmental standards.

How Is Quality Assurance Implemented in Tri Plug Manufacturing?

Quality assurance (QA) is paramount in manufacturing tri plugs, particularly when catering to international markets. Adherence to ISO 9001 ensures that the manufacturing process is standardized and consistently produces high-quality products.

What International Standards Should Buyers Be Aware Of?

For tri plugs, several international standards play a significant role in ensuring safety and compliance:

- ISO 9001: This standard focuses on quality management systems and is applicable across various industries, including electrical components.

- CE Marking: Required for products sold in the European Economic Area, the CE mark indicates compliance with health, safety, and environmental protection standards.

- UL Certification: In North America, UL certification is vital for ensuring that electrical products meet safety standards.

B2B buyers should request documentation that demonstrates compliance with these standards, as it reflects the supplier’s commitment to quality and safety.

What Are the Key Quality Control Checkpoints in Tri Plug Production?

Quality control (QC) checkpoints are integral to maintaining product integrity throughout the manufacturing process. Typical checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival ensures they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing help identify defects early. This may include dimensional checks and electrical tests.

- Final Quality Control (FQC): After assembly, tri plugs undergo comprehensive testing, including electrical safety tests and visual inspections, to ensure they meet all regulatory requirements.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify a supplier’s quality control processes:

- Supplier Audits: Conducting audits provides insight into the supplier’s manufacturing practices and quality assurance measures.

- Quality Reports: Requesting regular quality reports can help buyers monitor consistency in production quality.

- Third-party Inspections: Engaging third-party inspection agencies can add an additional layer of assurance, particularly for buyers unfamiliar with local manufacturing practices.

What Are the Quality Control Nuances for International Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality control. Different markets may have varying compliance requirements, which can affect product acceptance.

For instance, a tri plug that meets European CE standards may not automatically comply with safety regulations in the Middle East or South America. Therefore, understanding regional compliance requirements is crucial for B2B buyers to avoid costly delays or product recalls.

In conclusion, the manufacturing processes and quality assurance protocols for tri plugs are comprehensive and multi-faceted. B2B buyers should prioritize suppliers that demonstrate a commitment to quality through adherence to international standards and robust QC practices. By doing so, they can ensure that the tri plugs they procure are safe, reliable, and compliant with the necessary regulations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tri plug’

To assist B2B buyers in procuring tri plugs, this practical sourcing guide outlines essential steps to ensure a successful purchase. By following this checklist, buyers can make informed decisions that meet their specific requirements and ensure safety and compliance in their operations.

Illustrative image related to tri plug

Step 1: Define Your Technical Specifications

Before beginning your search for tri plugs, clearly outline your technical requirements. Consider factors such as voltage, current rating, and compatibility with existing systems. This step is crucial as it helps narrow down options and ensures that the selected tri plugs will meet your operational needs.

- Voltage and current ratings should align with the equipment they will be used with.

- Determine the required type (e.g., indoor vs. outdoor use) based on environmental conditions.

Step 2: Research Supplier Market Reputation

Investigate potential suppliers to assess their market standing. Look for companies with a proven track record in providing electrical components, particularly tri plugs. Supplier reputation can significantly influence product quality and reliability.

- Check online reviews, industry forums, and customer testimonials.

- Consider suppliers who have been in the market for several years, as longevity often indicates stability and reliability.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. This evaluation ensures that the supplier has the capability and experience to meet your needs.

- Ask for certifications that demonstrate compliance with international safety standards.

- Investigate their customer service responsiveness and support capabilities.

Step 4: Request Product Samples

Whenever possible, request samples of the tri plugs you are considering. Testing samples in your operational environment allows you to verify their compatibility and performance before making a bulk purchase. This step can prevent costly mistakes down the line.

Illustrative image related to tri plug

- Assess the quality of materials used and overall build.

- Ensure the sample meets your defined technical specifications.

Step 5: Verify Supplier Certifications

Ensure that your chosen supplier holds relevant certifications and complies with international safety and quality standards. Certifications such as ISO 9001 or IEC standards indicate a commitment to quality assurance and product safety.

- Check for compliance with local regulations in your target markets, especially if you are sourcing internationally.

- Understanding the certifications can also help in mitigating risks associated with product safety and reliability.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, enter into negotiations regarding pricing, delivery timelines, and payment terms. Clear communication about expectations will help in establishing a mutually beneficial relationship.

- Discuss bulk order discounts and payment options that fit your budget.

- Ensure that delivery timelines align with your project schedules to avoid delays.

Step 7: Establish a Quality Control Process

Implement a quality control process to monitor the tri plugs once they arrive. This step is vital for ensuring that the products meet your specifications and quality standards, thereby protecting your operations.

- Inspect the products upon arrival for any damage or defects.

- Set up periodic reviews of supplier performance based on product quality and service delivery.

By adhering to this checklist, B2B buyers can effectively navigate the procurement process for tri plugs, ensuring that they select the right products and suppliers for their needs.

Comprehensive Cost and Pricing Analysis for tri plug Sourcing

What Are the Key Cost Components for Sourcing Tri Plugs?

When sourcing tri plugs for B2B transactions, understanding the cost structure is crucial for effective budgeting and pricing strategy. The primary cost components include:

-

Materials: The cost of raw materials, such as plastic for the casing and copper for the prongs, significantly impacts overall pricing. High-quality materials may incur higher initial costs but can lead to better performance and durability.

-

Labor: Labor costs encompass wages for workers involved in manufacturing, assembling, and quality control. Regions with higher labor costs may affect the final pricing, so consider sourcing from areas with competitive labor rates.

-

Manufacturing Overhead: This includes costs associated with utilities, factory maintenance, and equipment depreciation. A well-managed facility can reduce these overhead costs, contributing to more competitive pricing.

-

Tooling: Initial investments in tooling can be substantial, particularly for custom designs. However, effective tooling can lead to economies of scale, reducing per-unit costs in larger production runs.

-

Quality Control (QC): Implementing rigorous QC measures ensures product reliability and safety, which can add to costs. Nonetheless, investing in quality can minimize returns and enhance customer satisfaction, ultimately providing long-term savings.

-

Logistics: Transportation, warehousing, and handling costs vary significantly based on the distance to the buyer and the mode of transport. Efficient logistics can mitigate these costs, particularly for international shipments.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market dynamics can help buyers negotiate better terms.

How Do Price Influencers Impact Tri Plug Sourcing?

Several factors can influence the pricing of tri plugs, and recognizing these can aid buyers in making informed decisions:

-

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing. Larger orders usually qualify for discounts, making it essential to assess your needs realistically to optimize costs.

-

Specifications and Customization: Custom designs or specific features can lead to increased costs. Buyers should balance the need for customization with budget constraints.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as ISO) typically command higher prices. However, they may also provide better safety and performance, justifying the investment.

-

Supplier Factors: Supplier reputation, reliability, and historical performance can influence pricing. Established suppliers may offer better quality but at a premium, while newer suppliers might present lower initial costs with potential risks.

-

Incoterms: The chosen Incoterm affects shipping costs and responsibilities. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for accurate cost estimation.

What Are Some Buyer Tips for Cost-Efficient Tri Plug Sourcing?

For B2B buyers, especially those in regions such as Africa, South America, the Middle East, and Europe, here are practical tips for effective sourcing:

-

Negotiation: Approach suppliers with a clear understanding of your requirements and market prices. Effective negotiation can lead to better pricing and terms.

-

Cost-Efficiency: Evaluate total cost of ownership (TCO), which includes purchase price, operational costs, and potential resale value. This comprehensive approach helps identify the best long-term investment.

-

Pricing Nuances for International Buyers: Be mindful of currency fluctuations, import duties, and tariffs that can affect overall costs. Establishing relationships with local partners can provide insights into navigating these challenges.

-

Quality vs. Cost: While it may be tempting to choose lower-priced options, consider the long-term implications of quality. Investing in reliable products can reduce future costs associated with failures or recalls.

-

Research and Due Diligence: Conduct thorough research on suppliers, including reviews and feedback from previous clients. This helps in identifying trustworthy partners who offer both quality and value.

Disclaimer on Indicative Prices

Prices for tri plugs can vary significantly based on the aforementioned factors. The figures discussed here are indicative and should be verified with suppliers for the most accurate and current pricing. Always consider the specific context of your sourcing needs to make the best purchasing decisions.

Alternatives Analysis: Comparing tri plug With Other Solutions

Exploring Alternatives to Tri Plug: An In-Depth Comparison

In the competitive landscape of electrical connectivity solutions, understanding the alternatives to the tri plug can help B2B buyers make informed decisions. This analysis compares the tri plug with two viable alternatives: the dual outlet plug and the power strip. Each solution offers unique features tailored to different business needs, from performance to cost-effectiveness.

| Comparison Aspect | Tri Plug | Dual Outlet Plug | Power Strip |

|---|---|---|---|

| Performance | High, stable connection with grounding for safety | Moderate, lacks grounding | Variable, depends on quality |

| Cost | Moderate initial investment | Low cost | Variable, often low to moderate |

| Ease of Implementation | Simple, requires standard outlet | Easy, plugs into existing outlet | Straightforward, plug-and-play |

| Maintenance | Minimal, durable design | Minimal, straightforward | Moderate, depends on surge protection |

| Best Use Case | High-power appliances needing grounding | Basic devices without grounding | Multiple devices, temporary setups |

Understanding the Pros and Cons of Each Alternative

Dual Outlet Plug

The dual outlet plug is a straightforward alternative to the tri plug, designed to accommodate devices that do not require grounding. It is cost-effective and easy to implement, making it ideal for low-power applications or temporary setups. However, its performance may be limited when it comes to high-power devices, as it lacks the safety features provided by the grounding pin. Businesses using sensitive or high-voltage equipment should consider the potential risks associated with this solution.

Power Strip

Power strips are versatile tools that allow multiple devices to be plugged in simultaneously, making them a popular choice for offices and workshops. They come in various configurations, often including surge protection and USB ports. While they offer flexibility, the performance can vary significantly based on the quality of the strip and its safety features. Additionally, power strips may require more maintenance to ensure they remain in good condition, especially if they are frequently used with high-power devices. For businesses needing to manage multiple devices efficiently, power strips can be an excellent solution, but caution should be exercised regarding their electrical load capacity.

Making the Right Choice: Factors for B2B Buyers to Consider

When selecting the right electrical connectivity solution, B2B buyers should assess their specific needs. The tri plug is ideal for high-power appliances requiring grounding, ensuring safety and stable performance. Conversely, dual outlet plugs and power strips may suffice for lower-power applications or environments where multiple devices need to be connected.

Ultimately, the decision should be guided by factors such as the nature of the devices being used, safety requirements, and budget constraints. By understanding the comparative advantages and limitations of each option, buyers can choose the most suitable solution for their operational needs.

Illustrative image related to tri plug

Essential Technical Properties and Trade Terminology for tri plug

What Are the Key Technical Properties of Tri Plugs That B2B Buyers Should Consider?

Understanding the critical specifications of tri plugs is essential for B2B buyers, especially when sourcing for international markets. Here are some fundamental properties to consider:

1. Material Grade

Tri plugs are typically made from various materials, including thermoplastics like polycarbonate or nylon, which offer durability and insulation. The material grade impacts the plug’s heat resistance, electrical insulation properties, and overall longevity. For international buyers, selecting the right material ensures compliance with safety standards and enhances product reliability.

2. Voltage and Current Rating

Voltage and current ratings are crucial for ensuring that a tri plug can handle the electrical load of the devices it powers. Most tri plugs are rated for 110-250 volts, accommodating a wide range of appliances. Understanding these ratings helps buyers match plugs with the appropriate applications, preventing overloading and potential hazards.

3. Tolerance and Dimensions

Tolerance refers to the permissible variation in the dimensions of the plug, which affects compatibility with sockets and devices. Accurate dimensions ensure a secure fit, reducing the risk of electrical faults. Buyers must ensure that the plugs meet local regulations regarding size and fit, particularly when dealing with varying socket standards across regions.

4. Safety Certifications

Safety certifications, such as CE, UL, or IEC, indicate that a tri plug has undergone rigorous testing for safety and performance. These certifications are critical for international trade, as they assure buyers of compliance with local safety regulations, minimizing liability risks associated with electrical products.

5. Grounding Mechanism

Tri plugs typically feature a grounding prong, which is essential for preventing electric shock by directing excess electricity safely into the ground. Understanding the grounding mechanism is vital for buyers in regions where electrical safety standards are strictly enforced. A well-designed grounding system enhances user safety and product reliability.

What Are Common Trade Terms Related to Tri Plugs That B2B Buyers Should Know?

In addition to technical specifications, familiarity with industry terminology is essential for effective communication and negotiation. Here are some common trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces components or products that are used in another company’s end products. For B2B buyers, working with an OEM can provide access to high-quality tri plugs tailored to specific applications, ensuring compatibility and performance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell in a single order. Understanding MOQ is crucial for buyers, especially when managing inventory and cash flow. Negotiating MOQs can lead to better pricing and terms, particularly for bulk purchases.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products, such as tri plugs. This process allows buyers to compare offers and make informed purchasing decisions. A well-structured RFQ can streamline the procurement process and foster competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B buyers engaged in international trade, as they clarify the logistics and cost implications of purchasing tri plugs from different countries.

5. CE Marking

CE marking indicates that a product meets EU safety, health, and environmental protection standards. For buyers in Europe, ensuring that tri plugs have the CE mark is essential for compliance and marketability, impacting the product’s acceptance in various European markets.

Understanding these technical properties and trade terminologies equips B2B buyers with the necessary insights to make informed purchasing decisions when sourcing tri plugs for their operations.

Navigating Market Dynamics and Sourcing Trends in the tri plug Sector

What Are the Global Drivers and Key Trends in the Tri Plug Market?

The tri plug market is currently experiencing dynamic growth driven by several global factors. The increasing reliance on electronic devices and appliances across various sectors, including residential, commercial, and industrial, has elevated the demand for efficient power supply solutions. Additionally, the rise of smart homes and IoT (Internet of Things) technology is propelling the need for versatile power solutions that tri plugs can provide, especially in emerging markets like Africa and South America.

International B2B buyers must be aware of the sourcing trends that are reshaping the tri plug landscape. The shift towards digital procurement platforms is significant, allowing buyers from regions such as the Middle East and Europe to streamline their sourcing processes. Moreover, customization is becoming a key trend, as businesses seek tri plugs that meet specific regional electrical standards and aesthetic preferences. This trend is particularly relevant for markets like Saudi Arabia and Brazil, where local regulations may dictate specific plug configurations.

Additionally, sustainability is becoming increasingly important, with buyers prioritizing suppliers who adopt eco-friendly manufacturing practices and materials. As the market evolves, understanding these dynamics will be crucial for B2B buyers to make informed sourcing decisions that align with their business objectives.

How Is Sustainability and Ethical Sourcing Impacting the Tri Plug Market?

The environmental impact of manufacturing processes in the tri plug sector cannot be overlooked. Increasing regulatory pressures and consumer demand for sustainable practices are pushing manufacturers to adopt greener methods. B2B buyers are now focusing on suppliers who demonstrate a commitment to sustainability, such as utilizing recyclable materials and minimizing waste during production.

Ethical supply chains are also gaining traction. Buyers are increasingly scrutinizing the sourcing of raw materials, ensuring that they come from responsible suppliers who adhere to labor and environmental standards. Certifications such as ISO 14001 for environmental management and Fair Trade practices are becoming essential indicators of a supplier’s commitment to ethical sourcing.

Moreover, there is a growing trend towards the use of ‘green’ materials in the production of tri plugs. Innovations in biodegradable plastics and other sustainable materials can enhance product appeal and align with buyers’ sustainability goals. By prioritizing suppliers who emphasize environmental stewardship, B2B buyers can not only contribute to a healthier planet but also enhance their brand reputation in a competitive marketplace.

What Is the Brief Evolution and History of Tri Plugs Relevant to B2B Buyers?

The tri plug has evolved significantly since its inception in the early 20th century, primarily to address safety concerns associated with electrical appliances. Originally, two-pronged plugs were standard, but as the use of metal-encased appliances increased, the need for a grounding mechanism became apparent. The introduction of the third prong provided a crucial safety feature, preventing electric shocks and enhancing the overall safety of electrical systems.

Over the decades, tri plugs have adapted to meet varying international standards, leading to a plethora of designs tailored for specific regions. For B2B buyers, understanding this evolution is vital, as it influences current compliance requirements and market expectations. As global trade expands, the ability to navigate these historical developments will empower buyers to make informed decisions, ensuring that their sourcing strategies align with both safety standards and regional preferences.

Frequently Asked Questions (FAQs) for B2B Buyers of tri plug

-

How do I choose the right tri plug for my electrical needs?

When selecting a tri plug, consider the voltage and amperage requirements of your devices, as well as the plug’s compatibility with your local electrical standards. Ensure the tri plug is designed for the specific application—whether residential, commercial, or industrial. Additionally, look for plugs with safety certifications relevant to your region, such as CE in Europe or UL in the United States. It’s also beneficial to choose plugs that offer surge protection or additional safety features to protect your equipment. -

What are the key safety features to look for in a tri plug?

Key safety features include a grounding prong to prevent electric shock, surge protection to guard against power spikes, and a robust design that can withstand wear and tear. Additionally, check for compliance with international safety standards, such as IEC standards. A tri plug with built-in fuses can also provide extra protection by cutting off power in case of overload. Always prioritize products from reputable manufacturers known for quality and safety. -

How can I verify the reliability of a supplier for tri plugs?

To vet a supplier, start by checking their business credentials, such as registration and certifications. Request references or case studies from previous clients to assess their reliability and product quality. You can also look for online reviews or ratings. Conducting a factory audit, if feasible, can provide insights into their production processes and quality control measures. Lastly, consider suppliers who are members of recognized industry associations, as this often indicates adherence to best practices. -

What are typical minimum order quantities (MOQ) for tri plugs?

Minimum order quantities for tri plugs can vary widely based on the supplier and the specific product. Generally, MOQs may range from 100 to 1,000 units for standard products, while customized designs might require higher quantities. It’s advisable to discuss your needs directly with the supplier to negotiate favorable terms, especially if you are a smaller business. Additionally, inquire if they offer samples or trial orders to assess product quality before committing to larger orders. -

What payment terms should I expect when sourcing tri plugs internationally?

Payment terms can vary significantly between suppliers and regions. Common options include wire transfers, letters of credit, or payment through platforms like PayPal. Many suppliers may require a deposit (typically 30-50%) upfront, with the balance due upon shipment or delivery. It’s essential to clarify these terms before finalizing your order and to understand any additional costs, such as shipping fees or customs duties. Always ensure that payment terms are documented in your contract to avoid misunderstandings. -

How do I ensure quality assurance for tri plugs?

To ensure quality, request samples before placing a large order and conduct thorough testing for compliance with relevant standards. Many suppliers offer quality assurance programs, including inspections at various production stages. Consider specifying quality control measures in your contract, such as third-party inspections or certifications. It’s also beneficial to establish a clear return policy in case the products do not meet your specifications or quality standards. -

What logistics considerations should I keep in mind when importing tri plugs?

Logistics considerations include shipping methods, lead times, and customs regulations in your country. Choose a reliable freight forwarder familiar with electrical products to help navigate import regulations and ensure timely delivery. It’s also wise to consider Incoterms, which define the responsibilities of buyers and sellers in the shipping process. Understanding potential tariffs or duties on electrical goods will help you budget accurately for your imports. -

Are there customization options available for tri plugs?

Many suppliers offer customization options for tri plugs, including branding, specific colors, or tailored features like different voltage ratings. Discuss your requirements with potential suppliers early in the negotiation process to determine feasibility and cost implications. Customization may involve higher MOQs and longer lead times, so plan accordingly. Ensure that any custom designs meet the necessary safety and performance standards for your target market.

Top 3 Tri Plug Manufacturers & Suppliers List

1. HowStuffWorks – Three-Prong Plugs Explained

Domain: electronics.howstuffworks.com

Registered: 1998 (27 years)

Introduction: Three-prong plugs help guard against electric shock. A typical 120-volt outlet in the U.S. has two vertical slots (neutral and hot) and a round hole (ground). The left slot is neutral, the right is hot, and the ground is for safety. Appliances with metal cases typically use three-prong plugs to ensure grounding. If a wire inside a metal case touches the case, the ground prong directs electricity a…

2. Target – Surge Protection Plug Adapter

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Surge Protection Plug Adapter, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Wadsworth City – Three-Prong Plug Safety

Domain: wadsworthcity.com

Registered: 1997 (28 years)

Introduction: The three-prong plug features a third prong that provides a path to ground for stray or leaking electricity, enhancing equipment protection and reducing the risk of electric shock. It is advised not to remove or bend the third prong to fit a two-slot outlet; instead, use an adapter only if the grounding wire is connected to an electrical ground or install an appropriate three-slot outlet.

Strategic Sourcing Conclusion and Outlook for tri plug

In today’s competitive landscape, understanding the strategic sourcing of tri plugs is vital for international B2B buyers. The tri plug, characterized by its three-prong design, not only enhances safety by providing a grounding mechanism but also ensures compatibility with a wide range of electrical appliances. As global markets in regions such as Africa, South America, the Middle East, and Europe continue to expand, the demand for reliable and safe electrical components is on the rise.

By focusing on strategic sourcing, businesses can secure high-quality tri plugs that meet international safety standards, ultimately enhancing operational efficiency and reducing potential risks associated with electrical failures. Suppliers that prioritize innovation and sustainability will be well-positioned to meet these growing demands, offering products that cater to diverse markets and regulatory requirements.

Looking forward, it is essential for international buyers to engage with suppliers who not only understand the local market dynamics but also possess a commitment to quality and safety. Collaborating with strategic partners will not only streamline procurement processes but also foster long-term growth. Now is the time to act—explore your sourcing options and invest in tri plugs that align with your business needs, ensuring a secure and efficient electrical future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.