How to Source Transformer Part Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for transformer part

In the ever-evolving landscape of electrical engineering, sourcing high-quality transformer parts has become a pivotal challenge for B2B buyers globally. As businesses in regions like Africa, South America, the Middle East, and Europe—specifically countries such as Saudi Arabia and Vietnam—expand their infrastructure, the demand for reliable transformer components grows. Understanding the intricacies of these components, from laminated cores to conservator tanks, is essential for ensuring optimal performance and longevity of transformers in various applications.

This comprehensive guide delves into the myriad aspects of transformer parts, covering essential topics such as different types of components, their applications, and the critical factors to consider when vetting suppliers. Buyers will gain insights into cost structures, industry standards, and best practices for sourcing, enabling them to make informed decisions that align with their operational needs.

By providing actionable knowledge and expert insights, this guide empowers international B2B buyers to navigate the complexities of the transformer parts market confidently. Whether you are looking to enhance the efficiency of your electrical systems or seeking to minimize downtime through reliable sourcing, this resource is designed to equip you with the tools necessary for successful procurement in the global market.

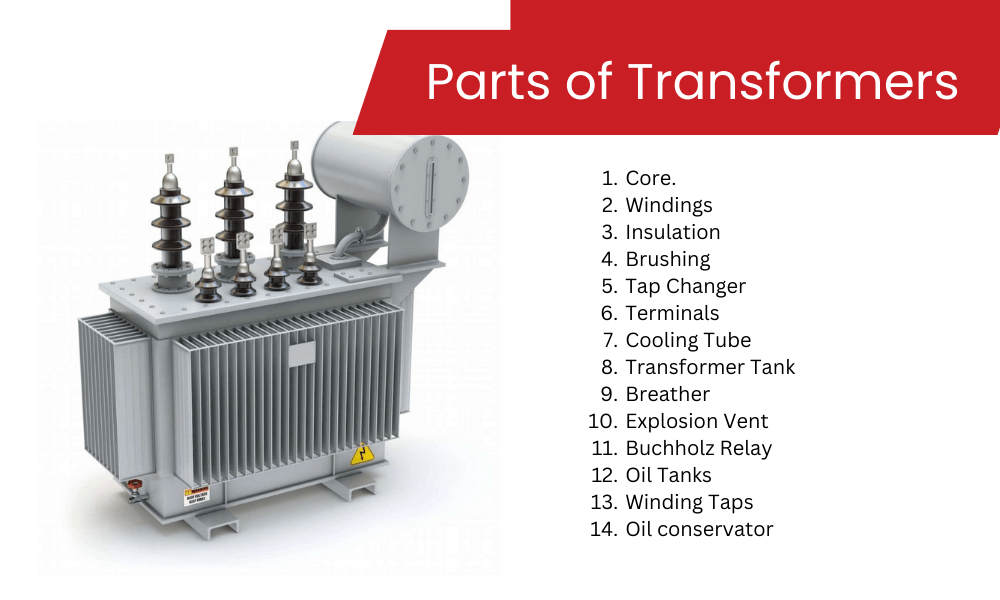

Understanding transformer part Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Laminated Core | Made of stacked sheets of silicon steel or soft iron | Power distribution, industrial systems | Pros: Reduces energy losses; improves efficiency. Cons: Higher initial cost for premium materials. |

| Insulating Materials | High dielectric strength, often paper or oil-based | Electrical transformers, substations | Pros: Critical for reliability; enhances lifespan. Cons: Vulnerable to degradation over time. |

| Conservator Tank | Airtight structure for oil expansion and contraction | Large power transformers | Pros: Maintains oil levels; prevents overheating. Cons: Requires maintenance to ensure integrity. |

| Cooling Systems | Includes radiators and cooling tubes | High-capacity transformers | Pros: Effective heat management; enhances performance. Cons: May require additional space and infrastructure. |

| Dual Voltage Switch | Allows operation at two different voltage levels | Versatile electrical applications | Pros: Flexibility in voltage supply; reduces equipment costs. Cons: Complexity in installation and operation. |

What Are the Key Characteristics of Laminated Cores in Transformers?

Laminated cores are fundamental components in transformers, designed to facilitate efficient electromagnetic flux transfer while minimizing energy losses. Made from stacked sheets of silicon steel or soft iron, they provide low reluctance paths that enhance performance. For B2B buyers, selecting high-quality laminated cores can significantly improve transformer efficiency, making them ideal for power distribution and industrial systems. However, the initial investment may be higher due to the quality of materials used.

Why Are Insulating Materials Critical in Transformer Design?

Insulating materials are essential for maintaining the integrity and safety of transformers. These materials, which can include paper, cardboard, and transformer oil, ensure that electrical components are isolated, preventing faults that could lead to catastrophic failures. For B2B buyers, investing in high-quality insulation is crucial, as approximately 70% to 80% of transformer failures are attributed to insulation issues. While they enhance reliability and lifespan, these materials may degrade over time, necessitating regular inspections and replacements.

How Does a Conservator Tank Enhance Transformer Efficiency?

The conservator tank plays a vital role in transformer operation by managing the oil level within the system. This airtight structure allows for the expansion and contraction of insulating oil as temperatures fluctuate, ensuring that critical components remain submerged and protected from air exposure. For businesses operating large power transformers, the conservator tank is indispensable for preventing overheating and maintaining optimal performance. However, it requires periodic maintenance to ensure its structural integrity and functionality.

What Role Do Cooling Systems Play in Transformer Performance?

Cooling systems, which include radiators and cooling tubes, are designed to manage the heat generated during transformer operation. Effective cooling prevents overheating, which can lead to performance degradation and potential failure. For B2B buyers, investing in robust cooling solutions is essential, especially for high-capacity transformers used in demanding applications. While these systems enhance performance and reliability, they may require additional space and infrastructure, which should be factored into purchasing decisions.

How Does a Dual Voltage Switch Provide Flexibility in Transformer Applications?

A dual voltage switch enables transformers to operate at two different voltage levels, offering versatility for various electrical applications. This feature is particularly beneficial for businesses looking to optimize their equipment and reduce costs by utilizing the same transformer for multiple voltage needs. While the flexibility of a dual voltage switch can lead to significant savings, it also introduces complexity in installation and operation, which buyers must consider when making procurement decisions.

Key Industrial Applications of transformer part

| Industry/Sector | Specific Application of transformer part | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Energy & Utilities | Voltage regulation in power distribution networks | Ensures stable power supply, reducing outages and downtime | Compliance with local standards; reliability of parts; supplier certifications |

| Manufacturing | Power supply for industrial machinery | Increases operational efficiency and equipment longevity | Customization options for specific machinery; maintenance support; lead times |

| Telecommunications | Signal transmission in telecom networks | Enhances communication reliability and reduces signal loss | Compatibility with existing infrastructure; technical support; scalability |

| Mining & Metals | Power management in extraction and processing | Optimizes energy consumption and enhances safety | Robustness under extreme conditions; availability of spare parts; supplier location |

| Transportation & Logistics | Power supply for electric rail systems | Supports efficient transport solutions, reducing carbon footprint | Compliance with international safety standards; modular designs; maintenance services |

How is ‘transformer part’ used in the Energy & Utilities sector?

In the Energy & Utilities sector, transformer parts play a crucial role in voltage regulation within power distribution networks. By ensuring that voltage levels remain stable, these components help prevent outages that can disrupt service to consumers and businesses. For international buyers, sourcing transformer parts requires adherence to local electrical standards and regulations, as well as assurance of the reliability and longevity of the components to minimize maintenance needs.

What applications exist for transformer parts in Manufacturing?

In the Manufacturing sector, transformer parts are essential for providing reliable power supply to industrial machinery. This ensures that operations run smoothly and efficiently, ultimately leading to increased productivity and reduced equipment wear. Buyers should consider customization options to match their specific machinery needs, and they should also prioritize suppliers who offer robust maintenance support to ensure minimal downtime.

How do transformer parts benefit Telecommunications?

In Telecommunications, transformer parts are integral to the transmission of signals across networks. They enhance the reliability of communication systems by regulating voltage levels, which reduces the likelihood of signal loss. When sourcing these components, businesses must ensure compatibility with their existing infrastructure and may need to assess the scalability of the solutions offered by suppliers to accommodate future growth.

What role do transformer parts play in Mining & Metals?

In the Mining & Metals industry, transformer parts are vital for managing power in extraction and processing operations. They help optimize energy consumption, thereby reducing operational costs while enhancing safety measures. Buyers in this sector should look for robust components that can withstand extreme environmental conditions, as well as ensure the availability of spare parts to mitigate any potential operational disruptions.

How are transformer parts utilized in Transportation & Logistics?

In the Transportation & Logistics sector, transformer parts are crucial for powering electric rail systems. They support efficient transport solutions, contributing to reduced carbon footprints and enhanced service reliability. International buyers should focus on suppliers that comply with international safety standards and offer modular designs that can be easily integrated into existing transport infrastructures, along with comprehensive maintenance services to ensure ongoing operational efficiency.

3 Common User Pain Points for ‘transformer part’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Transformer Parts

The Problem: B2B buyers often face significant challenges when sourcing transformer parts, particularly in regions with fluctuating supply chains and diverse quality standards. Buyers may find themselves overwhelmed by the variety of manufacturers, each offering different materials, quality certifications, and pricing structures. This inconsistency can lead to delays in production schedules and increased costs due to the need for replacements or repairs of subpar components. Additionally, buyers may struggle to verify the reliability of suppliers, especially when sourcing from international markets.

The Solution: To effectively navigate this sourcing dilemma, B2B buyers should invest time in establishing relationships with reputable suppliers who have a proven track record in the transformer industry. Conducting thorough due diligence is essential; this includes reviewing supplier certifications, understanding their quality control processes, and requesting references from other customers. Utilizing platforms that aggregate supplier ratings and reviews can also provide valuable insights. Furthermore, buyers should consider engaging in long-term contracts with preferred suppliers to secure better pricing and ensure consistent availability of high-quality parts. Regular communication with suppliers regarding production schedules and quality expectations can mitigate potential disruptions and foster a mutually beneficial partnership.

Scenario 2: Understanding the Technical Specifications of Transformer Parts

The Problem: Many B2B buyers encounter difficulties in understanding the technical specifications of transformer parts, which can lead to incorrect purchases. This is particularly common among buyers who may not have a technical background in electrical engineering. Misunderstanding specifications such as voltage ratings, insulation types, and thermal properties can result in selecting incompatible parts, leading to operational inefficiencies or even equipment failure. This issue is exacerbated in international markets where language barriers and varying standards may further complicate the decision-making process.

The Solution: To overcome this knowledge gap, B2B buyers should prioritize education and training on transformer technology and specifications. Investing in workshops or online courses that cover the fundamentals of transformers and their components can empower buyers to make informed decisions. Additionally, working closely with engineers or technical consultants during the procurement process can help clarify specific requirements and ensure compatibility. When in doubt, buyers should not hesitate to request detailed technical documentation and clarification from suppliers. Furthermore, developing a checklist of essential specifications for each type of transformer part can serve as a practical reference during the purchasing process, reducing the risk of errors.

Scenario 3: Managing Maintenance and Longevity of Transformer Parts

The Problem: After purchasing transformer parts, B2B buyers often grapple with the challenge of ensuring the longevity and optimal performance of these components. Factors such as environmental conditions, load fluctuations, and inadequate maintenance practices can lead to premature wear and failures. This not only disrupts operations but also incurs unexpected costs related to repairs and downtime. Buyers may feel overwhelmed by the lack of clear guidance on how to maintain transformer parts effectively, particularly in regions where local expertise may be limited.

The Solution: To enhance the lifespan of transformer parts, B2B buyers should implement a proactive maintenance strategy that includes regular inspections and monitoring of key performance indicators. Establishing a routine maintenance schedule, guided by best practices and manufacturer recommendations, can help identify potential issues before they escalate. Buyers should also consider investing in condition monitoring technologies that provide real-time data on temperature, insulation integrity, and oil quality, allowing for timely interventions. Additionally, collaboration with local service providers or training staff on maintenance protocols can further bolster operational resilience. Engaging in continuous education about the latest maintenance techniques and technologies will empower buyers to optimize their transformer systems and minimize unplanned outages.

Strategic Material Selection Guide for transformer part

What Are the Key Materials for Transformer Parts and Their Properties?

When selecting materials for transformer parts, it is crucial to consider their properties, advantages, and limitations. This selection directly impacts the performance, durability, and efficiency of transformers, which are vital components in electrical systems. Below, we analyze four common materials used in transformer parts: silicon steel, copper, aluminum, and insulating oil.

How Does Silicon Steel Benefit Transformer Cores?

Silicon steel is the primary material used for transformer cores due to its excellent magnetic properties. Key properties include high permeability and low hysteresis loss, which enhance energy efficiency. Silicon steel typically operates effectively at temperatures up to 150°C and can withstand significant magnetic flux densities.

Pros: Silicon steel is durable and readily available, making it a cost-effective choice. Its magnetic efficiency reduces energy losses, which is critical for transformers operating under high load conditions.

Cons: While it is effective for magnetic applications, silicon steel is susceptible to corrosion if not properly treated. Additionally, the manufacturing process can be complex, requiring precise lamination to minimize eddy current losses.

Impact on Application: Silicon steel’s magnetic properties make it suitable for high-voltage transformers, where efficiency is paramount. However, buyers must ensure compliance with international standards such as ASTM A677 and DIN EN 10106.

What Role Does Copper Play in Transformer Windings?

Copper is the most commonly used material for transformer windings due to its excellent electrical conductivity, which is approximately 60% higher than aluminum. It can operate effectively in temperatures up to 200°C, making it suitable for high-performance applications.

Pros: The high conductivity of copper minimizes resistive losses, enhancing overall transformer efficiency. It is also highly durable and resistant to fatigue, ensuring a long service life.

Cons: Copper is relatively expensive compared to aluminum, which can increase the overall cost of transformer manufacturing. Additionally, it is heavier, which may complicate installation and transportation.

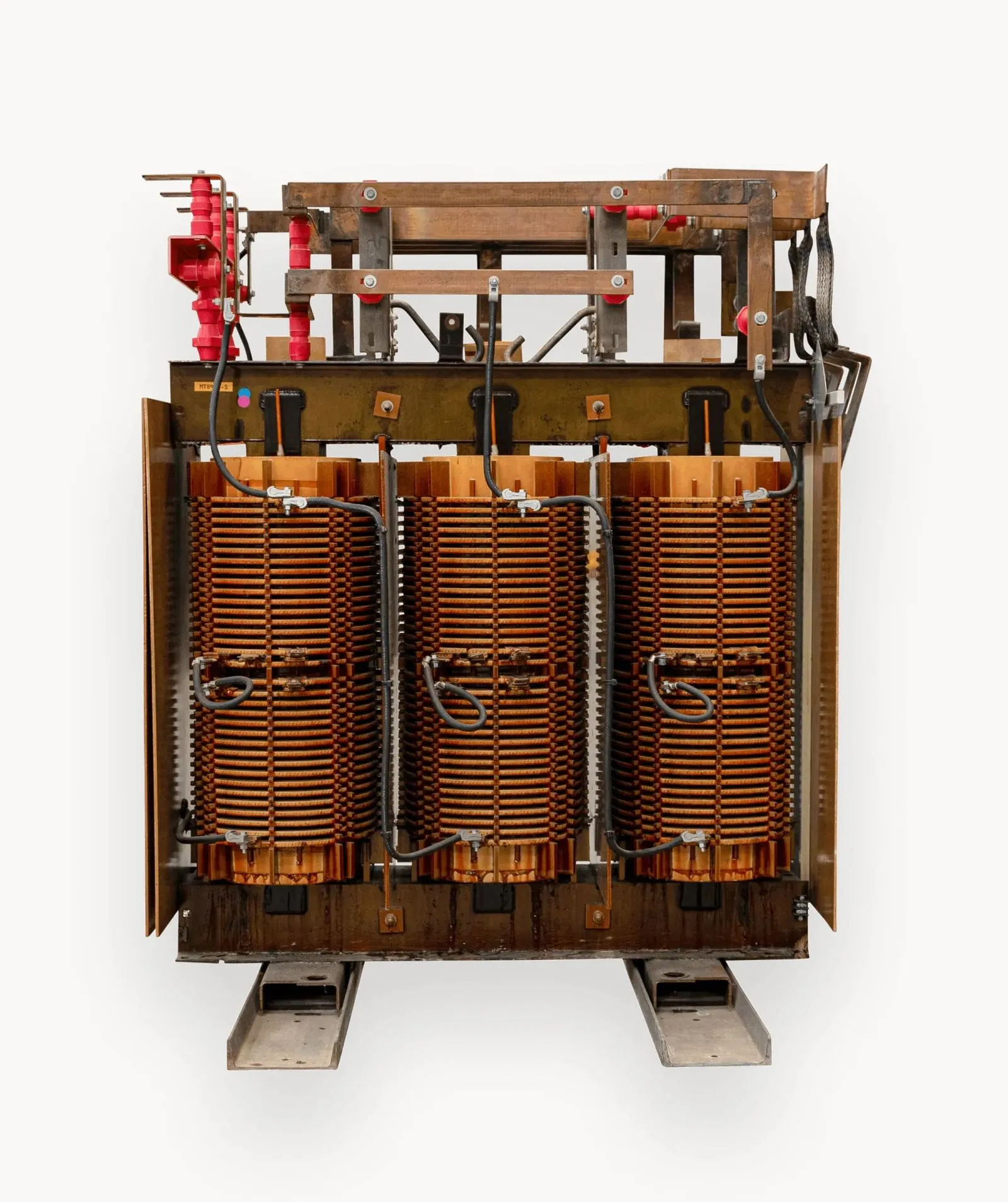

Illustrative image related to transformer part

Impact on Application: Copper windings are ideal for high-voltage transformers where efficiency is crucial. B2B buyers in regions like Europe and the Middle East should consider the availability of copper and the associated costs, as well as compliance with standards such as IEC 60076.

Why Is Aluminum Considered for Transformer Parts?

Aluminum is increasingly used in transformer manufacturing, particularly for windings and casings. It has a lower density than copper, making it lighter and easier to handle. Aluminum can operate effectively in temperatures up to 150°C.

Pros: The lightweight nature of aluminum reduces transportation and installation costs. Additionally, it is more affordable than copper, making it a cost-effective alternative for many applications.

Cons: While aluminum has good conductivity, it is only about 60% as conductive as copper, which can lead to higher energy losses. It is also more prone to oxidation, which can affect performance if not properly treated.

Impact on Application: Aluminum is suitable for low to medium voltage transformers. Buyers in regions with high humidity or corrosive environments, such as parts of Africa and South America, must ensure that aluminum components are adequately protected against corrosion.

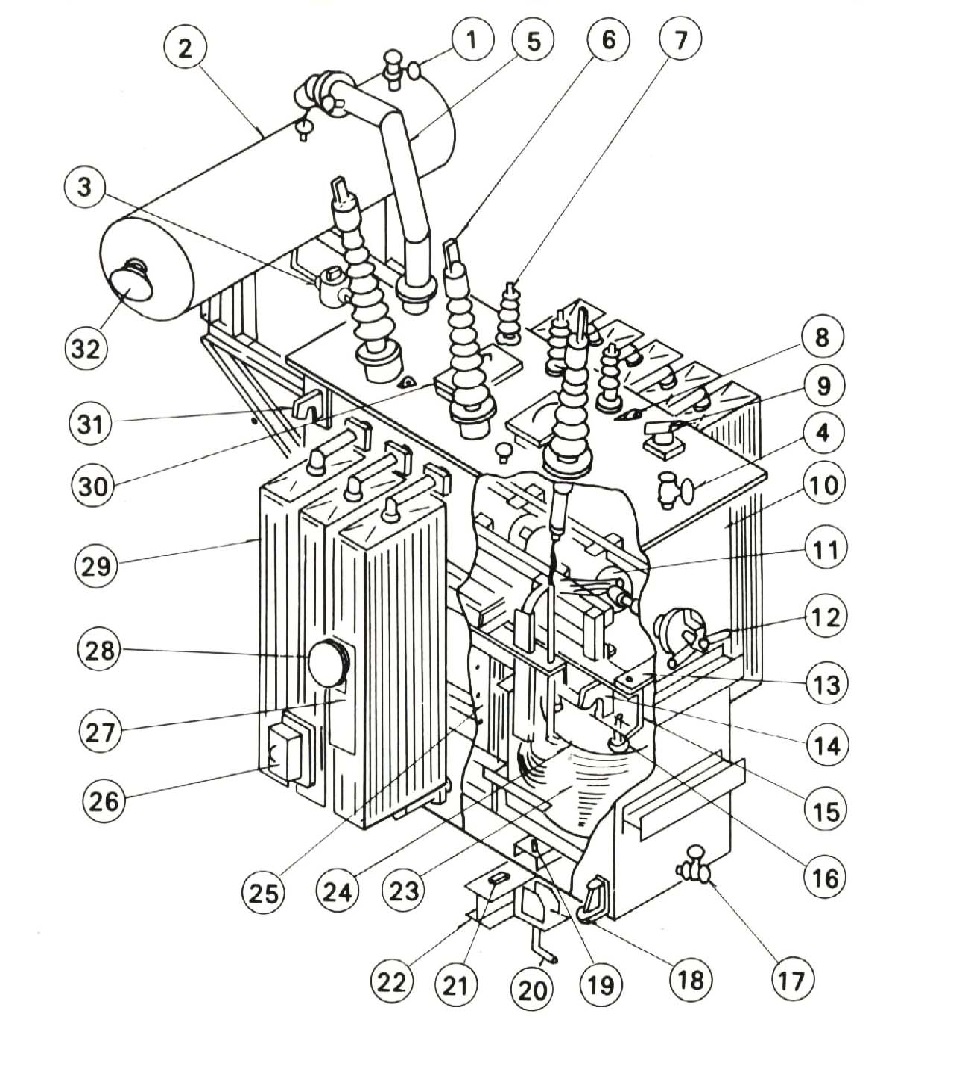

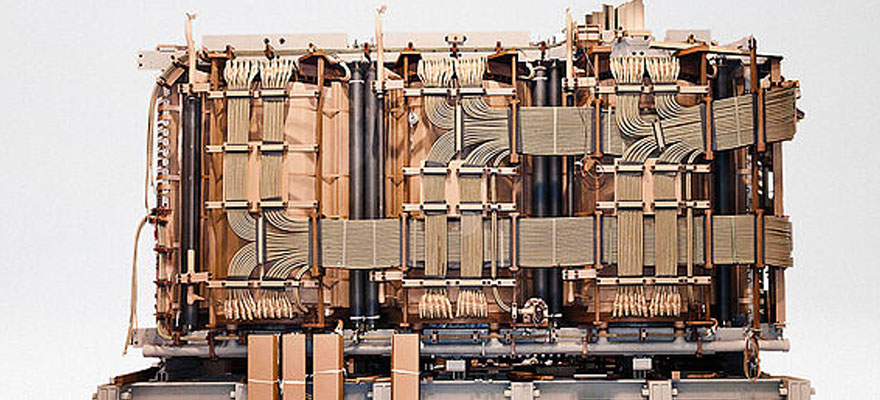

Illustrative image related to transformer part

What Are the Advantages of Using Insulating Oil in Transformers?

Insulating oil is essential for cooling and insulating transformer components. It typically operates effectively at temperatures up to 100°C and provides excellent dielectric strength.

Pros: Insulating oil enhances the thermal management of transformers, preventing overheating. It also serves as an insulator, reducing the risk of electrical faults.

Cons: The environmental impact of mineral oils, particularly in case of leaks, is a significant concern. Additionally, the disposal of used oil must comply with environmental regulations, which can complicate operations.

Impact on Application: Insulating oil is crucial for oil-immersed transformers, particularly in high-temperature environments. B2B buyers must consider local regulations regarding oil use and disposal, especially in regions with stringent environmental laws.

Illustrative image related to transformer part

Summary Table of Material Selection for Transformer Parts

| Material | Typical Use Case for transformer part | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Steel | Transformer cores | High magnetic efficiency | Susceptible to corrosion | Medium |

| Copper | Transformer windings | Excellent electrical conductivity | Higher cost and weight | High |

| Aluminum | Windings and casings | Lightweight and cost-effective | Lower conductivity and oxidation risk | Medium |

| Insulating Oil | Cooling and insulation | Effective thermal management | Environmental concerns and disposal issues | Medium |

This guide provides a comprehensive overview of key materials used in transformer parts, aiding B2B buyers in making informed decisions that align with their operational needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for transformer part

What Are the Main Stages of Manufacturing Transformer Parts?

The manufacturing process of transformer parts involves several critical stages: material preparation, forming, assembly, and finishing. Each stage requires precision and adherence to established protocols to ensure high-quality output.

How Is Material Prepared for Transformer Parts Manufacturing?

The first step in the manufacturing process is material preparation. This phase involves selecting high-grade raw materials, including copper or aluminum for windings, laminated silicon steel for cores, and specialized insulating materials such as paper or transformer oil. The materials undergo rigorous testing to verify their properties, including conductivity, durability, and thermal resistance.

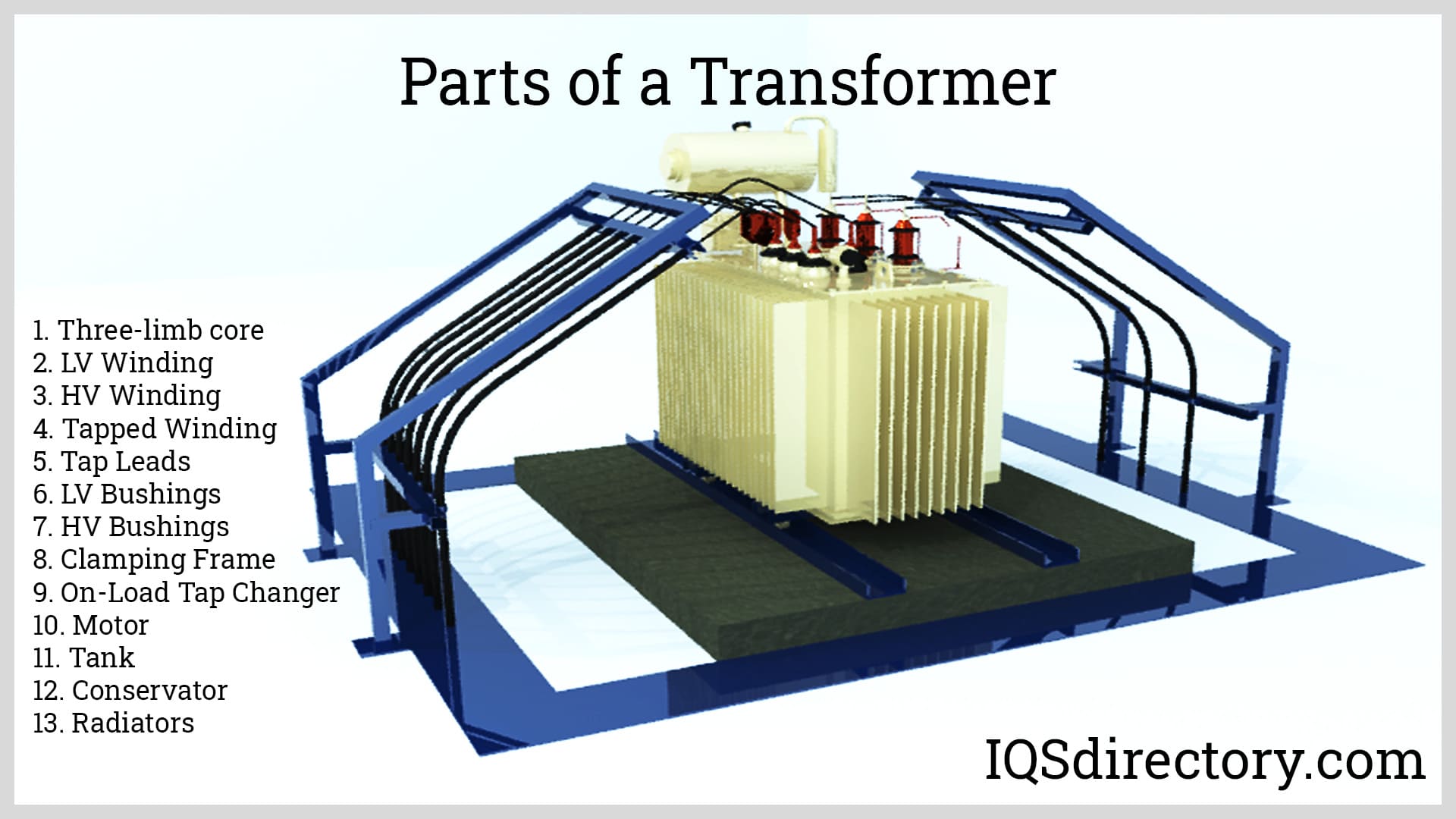

Illustrative image related to transformer part

Once the materials are selected, they are cut and shaped according to specific dimensions. For instance, copper wires are drawn to the required gauge, and steel sheets are cut into laminations. These processes are often supported by CNC machines to ensure precision and reduce waste.

What Techniques Are Used in Forming Transformer Parts?

After material preparation, the forming process takes place. This involves creating the core and windings. The core is assembled from laminated sheets to minimize energy losses due to eddy currents. The windings are created by winding copper or aluminum wire around the core, ensuring the correct number of turns as per the transformer’s design specifications.

Advanced techniques such as vacuum impregnation may be employed during this stage to enhance insulation properties. This process involves saturating the windings with insulating resin under vacuum conditions to eliminate air pockets, which can lead to electrical failures.

How Are Transformer Parts Assembled and Finished?

The assembly stage involves integrating all components, including the core, windings, main tank, and cooling systems. Each part must be aligned precisely to maintain optimal performance. The assembly process is typically conducted in a controlled environment to minimize contamination.

Finishing processes include surface treatments and coatings to protect against corrosion and improve longevity. This may involve galvanization, painting, or applying insulating varnishes. Finally, the assembled transformers undergo various quality checks to ensure they meet stringent industry standards before packaging and shipment.

What Quality Control Measures Are in Place for Transformer Parts?

Quality control (QC) is paramount in the manufacturing of transformer parts. Adherence to international standards, such as ISO 9001, ensures that manufacturers implement systematic quality management processes.

Illustrative image related to transformer part

What Are the Key International Standards for Transformer Parts Quality?

International standards play a vital role in maintaining quality assurance. ISO 9001 focuses on quality management systems, while industry-specific standards like CE (Conformité Européenne) and API (American Petroleum Institute) set benchmarks for safety and performance. Compliance with these standards not only assures product quality but also facilitates market entry across different regions, including Africa, South America, the Middle East, and Europe.

How Are QC Checkpoints Established Throughout the Manufacturing Process?

Quality control checkpoints are established throughout the manufacturing process, typically categorized into three main types: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials upon delivery. Suppliers must provide certificates of compliance and test reports.

-

In-Process Quality Control (IPQC): Continuous checks are conducted during the manufacturing process to ensure that specifications are being met. This includes monitoring temperatures, pressures, and dimensional tolerances.

-

Final Quality Control (FQC): Once the transformer parts are assembled, they undergo final inspections, including electrical testing, thermal imaging, and pressure tests. These assessments ensure that the parts meet operational standards and are free from defects.

What Common Testing Methods Are Used for Transformer Parts?

Testing methods are essential for verifying the performance and reliability of transformer parts. Common methods include:

Illustrative image related to transformer part

-

Electrical Testing: Measures insulation resistance, power factor, and winding resistance to ensure safe operation.

-

Thermal Testing: Evaluates the thermal performance of components under load conditions to prevent overheating.

-

Mechanical Testing: Assesses the structural integrity of transformer housings and components under various stress conditions.

These tests help identify potential failures before the transformer parts are deployed in the field.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is crucial to ensuring reliable product supply. Here are several ways to do this:

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and adherence to quality standards. Buyers should request access to audit reports and corrective action plans.

-

Review Quality Assurance Documentation: Buyers should insist on obtaining certificates of compliance and detailed quality assurance documentation, including test results and inspection reports.

-

Engage Third-Party Inspection Services: Utilizing independent third-party inspection services can offer an unbiased assessment of the supplier’s quality practices. This is particularly important for buyers in regions with varying regulatory environments.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When dealing with international suppliers, it is essential to understand that quality standards may vary by region. For instance, while ISO certifications are recognized globally, certain markets may have specific local certifications that must be adhered to, such as the Saudi Arabian Standards Organization (SASO) in Saudi Arabia or the Bureau of Indian Standards (BIS) in India.

Moreover, cultural differences may influence quality control practices. Buyers should be aware of these nuances and establish clear communication channels to ensure that quality expectations are met consistently.

In conclusion, understanding the manufacturing processes and quality assurance measures for transformer parts is crucial for B2B buyers aiming to procure high-quality components. By focusing on the stages of manufacturing, the importance of quality control standards, and the methods of verification, buyers can make informed decisions that ensure the reliability and efficiency of their electrical systems.

Illustrative image related to transformer part

Practical Sourcing Guide: A Step-by-Step Checklist for ‘transformer part’

Introduction

In the complex landscape of electrical infrastructure, procuring transformer parts is a critical task for international B2B buyers. This guide offers a step-by-step checklist to streamline your sourcing process, ensuring that you select high-quality components that meet your operational requirements while minimizing risks.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential before beginning the procurement process. This includes understanding the voltage ratings, current capacity, and specific type of transformer part required, such as windings, insulating materials, or cooling systems. Detailed specifications help in evaluating potential suppliers and ensure compatibility with existing systems.

Step 2: Research Supplier Credentials

Thoroughly vetting suppliers is crucial to ensure reliability and quality. Look for suppliers with industry certifications such as ISO 9001 or those specific to electrical components. Additionally, investigate their track record by reviewing case studies or testimonials from businesses similar to yours, especially in your target regions like Africa, South America, or the Middle East.

Step 3: Evaluate Potential Suppliers

Before committing, conduct a comprehensive evaluation of potential suppliers. Request detailed company profiles, including their production capabilities, quality assurance processes, and previous project experiences. It’s also beneficial to ask for references from other clients, particularly those in your industry, to gauge the supplier’s reliability and customer service.

Step 4: Compare Pricing and Terms

Cost is always a significant factor in procurement decisions. Collect quotes from multiple suppliers to compare not just prices but also the terms of sale, warranties, and after-sales support. Ensure that the pricing reflects the quality of the components, as opting for the cheapest option may lead to higher long-term costs due to potential failures or inefficiencies.

Step 5: Assess Delivery and Logistics Capabilities

Understanding the supplier’s delivery and logistics capabilities is vital. Confirm their lead times, shipping options, and ability to meet your delivery schedule. In regions with variable infrastructure, such as parts of Africa and South America, reliable logistics can significantly impact project timelines and overall satisfaction with the procurement process.

Step 6: Ensure Compliance with Local Regulations

Compliance with local regulations and standards is non-negotiable. Check that the transformer parts meet local electrical and safety standards, which can vary by country. This step helps avoid legal issues and ensures that your equipment operates safely and efficiently within the specific regulatory framework of your region.

Step 7: Establish Clear Communication Channels

Effective communication with your supplier is essential for a successful partnership. Set expectations for regular updates and establish a point of contact for any inquiries or issues that may arise. This clarity can prevent misunderstandings and ensure that both parties are aligned throughout the procurement and delivery process.

By following this structured checklist, B2B buyers can enhance their procurement strategy for transformer parts, leading to successful sourcing outcomes and long-term operational efficiency.

Comprehensive Cost and Pricing Analysis for transformer part Sourcing

In the competitive landscape of transformer part sourcing, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis delves into the key components affecting the costs and pricing of transformer parts, providing actionable insights tailored for buyers from regions like Africa, South America, the Middle East, and Europe.

Illustrative image related to transformer part

What Are the Key Cost Components in Transformer Part Sourcing?

The cost structure for transformer parts can be segmented into several critical components:

-

Materials: The choice of materials significantly impacts the overall cost. For instance, high-grade copper for windings or specialized insulating materials can drive costs higher. Additionally, the volatility of raw material prices, influenced by global supply chains and market demand, must be considered.

-

Labor: Labor costs vary by region and manufacturing practices. Countries with lower labor costs may offer competitive pricing, but this can be offset by potential quality concerns. Skilled labor for precision manufacturing is essential, particularly for components like windings and laminations.

-

Manufacturing Overhead: This includes costs related to production facilities, utilities, and administrative expenses. Efficient manufacturing processes can reduce overhead, impacting pricing positively.

-

Tooling: Custom tooling for specific transformer components can be a significant upfront cost. However, once amortized over production runs, these costs can lead to savings on per-unit pricing.

-

Quality Control (QC): High-quality components often require rigorous testing and certification processes, adding to the cost. Buyers should prioritize suppliers with robust QC systems to ensure reliability and compliance with international standards.

-

Logistics: Shipping and handling costs vary based on the distance, mode of transport, and Incoterms agreed upon. Buyers should consider the total logistics cost, including potential tariffs and taxes, particularly when sourcing from international suppliers.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. Understanding the standard margins in the industry can aid in negotiations.

What Factors Influence Pricing for Transformer Parts?

Several factors can influence the pricing of transformer parts:

-

Volume/MOQ: Larger orders often lead to discounts due to economies of scale. Buyers should assess their needs carefully to negotiate minimum order quantities (MOQ) that are beneficial.

-

Specifications and Customization: Customized parts can incur additional costs due to unique design and manufacturing processes. Buyers should weigh the necessity of customization against potential cost increases.

-

Quality and Certifications: Higher quality components that meet international certifications may come at a premium. However, investing in quality can lead to lower failure rates and reduced total cost of ownership (TCO).

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers may charge more but offer better service and support.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) will affect the total landed cost of the products. Understanding these terms is vital for accurate pricing assessments.

What Are the Best Negotiation Tips for B2B Buyers in Transformer Parts?

For B2B buyers, particularly in regions like Africa and South America, negotiating effectively can lead to significant cost savings:

-

Research Market Prices: Understanding the market rates for transformer parts helps in setting a baseline for negotiations.

-

Leverage Volume: If planning to make a large purchase, use this as leverage to negotiate better pricing and terms.

-

Evaluate Total Cost of Ownership: Consider not just the purchase price but also long-term costs associated with maintenance, energy efficiency, and potential downtime.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing, priority service, and favorable terms in future transactions.

Conclusion

Navigating the complexities of transformer part sourcing requires a thorough understanding of the cost structure, pricing influencers, and negotiation strategies. By focusing on these elements, international B2B buyers can optimize their sourcing decisions, ensuring they obtain high-quality components at competitive prices while effectively managing their total cost of ownership. Always consider fluctuations in market conditions and supplier reliability when making procurement decisions.

Alternatives Analysis: Comparing transformer part With Other Solutions

Exploring Alternatives to Transformer Parts for Electrical Systems

In the realm of electrical systems, transformers are crucial for voltage regulation and energy transfer. However, there are alternative solutions that can achieve similar goals, particularly for B2B buyers exploring options for their operations. This section evaluates transformer parts against other technologies, providing insights into their performance, cost, implementation, maintenance, and best use cases.

| Comparison Aspect | Transformer Part | Alternative 1: Voltage Regulators | Alternative 2: Static Frequency Converters |

|---|---|---|---|

| Performance | High efficiency, reliable voltage regulation across varying loads | Effective in maintaining stable output voltage but less versatile | Excellent for frequency conversion but limited to specific applications |

| Cost | Moderate initial investment; long-term savings through efficiency | Generally lower upfront costs; potential for higher operational costs | High initial investment but can reduce operational costs in certain setups |

| Ease of Implementation | Requires professional installation and setup; can be complex | Easier to install, especially in existing systems | Complex installation; requires specialized knowledge |

| Maintenance | Regular oil checks and insulation monitoring needed | Minimal maintenance required; regular checks recommended | Requires expert maintenance due to complexity |

| Best Use Case | Ideal for large-scale power distribution and industrial applications | Suitable for smaller scale applications and residential use | Best for applications needing frequency conversion, such as renewable energy integration |

What Are the Benefits and Drawbacks of Voltage Regulators?

Voltage regulators serve as a viable alternative to traditional transformer parts, especially in smaller-scale applications. They are designed to maintain a constant voltage level, providing stability to sensitive electronic equipment. The key advantage of voltage regulators is their lower upfront cost compared to transformers. However, they may not handle large loads as efficiently, which can lead to higher operational costs over time due to energy losses. Their simplicity in installation makes them an attractive option for smaller systems, but for large industrial applications, their limitations in handling varying loads can be a significant drawback.

How Do Static Frequency Converters Compare?

Static frequency converters (SFCs) are another alternative that provides unique benefits, particularly in applications requiring frequency conversion. These devices are highly effective in integrating renewable energy sources into power systems. The primary advantage of SFCs is their ability to convert electrical power from one frequency to another, making them essential for processes that require different operational frequencies. However, they come with a high initial investment and require specialized installation and maintenance. While they can lead to operational savings in specific setups, the complexity and cost may be prohibitive for some businesses.

Conclusion: How Should B2B Buyers Choose the Right Solution?

For B2B buyers evaluating transformer parts against alternatives, the decision hinges on specific operational needs and financial considerations. Factors such as system size, load requirements, and potential for future scalability should guide the choice. In environments where high efficiency and reliability are paramount, transformer parts may be the best fit. Conversely, for smaller systems or specialized applications, voltage regulators or static frequency converters might offer cost-effective and efficient solutions. A thorough analysis of each option’s pros and cons will empower buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for transformer part

What Are the Key Technical Properties of Transformer Parts?

Understanding the essential technical properties of transformer parts is crucial for B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe. Here are some critical specifications to consider:

-

Material Grade

The material grade of components like windings and the core significantly affects a transformer’s efficiency and durability. Common materials include copper for windings due to its high conductivity and laminated silicon steel for the core to minimize losses. Selecting the right material grade ensures optimal performance and longevity, crucial for minimizing maintenance costs and downtime. -

Voltage Rating

Voltage rating indicates the maximum voltage a transformer can handle without risk of failure. For international buyers, understanding the voltage specifications is vital to ensure compatibility with local electrical systems. Using transformers that match the voltage requirements of specific applications prevents equipment damage and ensures safety. -

Thermal Resistance

Thermal resistance refers to a material’s ability to withstand heat without degrading. For transformers, this property is essential as they generate significant heat during operation. High thermal resistance in insulating materials and oil helps maintain efficiency and prevents overheating, which could lead to transformer failure. Buyers should prioritize components that can endure the operational temperature ranges typical in their region. -

Tolerance Levels

Tolerance levels define the acceptable variations in dimensions and electrical properties of transformer parts. This specification is crucial for ensuring that all components fit together correctly and operate efficiently. Inaccurate tolerances can lead to increased wear and tear, reduced performance, and ultimately, costly repairs or replacements. Buyers should ensure that suppliers provide detailed tolerance specifications to avoid compatibility issues. -

Cooling Method

The cooling method of a transformer affects its efficiency and operational lifespan. Options include natural convection and forced oil circulation. Understanding the cooling system’s capabilities helps in selecting transformers that meet specific environmental conditions, particularly in regions with extreme temperatures. This property is essential for maintaining optimal performance and avoiding overheating.

What Trade Terms Should B2B Buyers Know When Sourcing Transformer Parts?

Navigating the complexities of sourcing transformer parts requires familiarity with industry jargon. Here are some essential terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

An OEM refers to companies that manufacture products that may be marketed under another company’s brand name. Understanding whether a supplier is an OEM can help buyers gauge the quality and reliability of transformer parts. OEM parts often come with warranties and are designed to meet specific performance standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for budgeting and inventory planning, as it influences purchasing decisions. Buyers should confirm the MOQ to avoid excess inventory or inadequate supply, particularly in regions where demand can fluctuate significantly. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting a quote for specific products or services. This process helps buyers compare prices, terms, and conditions across different suppliers, facilitating better decision-making. A well-structured RFQ can lead to more favorable pricing and terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms is essential for international transactions, as they dictate who bears the costs and risks at various points during the shipping process. Understanding these terms helps avoid disputes and ensures smoother logistics. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. For B2B buyers, understanding lead times is vital for project planning and inventory management. Longer lead times can affect operations, particularly in industries where transformers are critical for production processes.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and ensure the reliability of their transformer systems.

Navigating Market Dynamics and Sourcing Trends in the transformer part Sector

What Are the Current Market Dynamics and Key Trends in the Transformer Part Sector?

The transformer part sector is witnessing significant transformations driven by global energy demands, technological advancements, and geopolitical factors. The increasing reliance on renewable energy sources, such as solar and wind, necessitates robust transformer systems that can handle variable loads and energy fluctuations. In regions like Africa and South America, the push for electrification and infrastructure development creates a burgeoning market for transformers, enhancing demand for quality parts. Additionally, the Middle East is investing heavily in energy diversification, further amplifying the need for reliable transformer components.

Emerging technologies are reshaping sourcing trends in this sector. For instance, the adoption of smart transformers equipped with IoT capabilities allows for real-time monitoring and predictive maintenance, improving operational efficiency and reducing downtime. International buyers must stay attuned to these technological advancements to ensure they source the most innovative and efficient components. Furthermore, the rise of digital supply chain solutions enables greater transparency and flexibility, allowing buyers to track the sourcing process from manufacturers in Europe and Asia, which is crucial for maintaining quality and compliance.

How Important Is Sustainability and Ethical Sourcing in the Transformer Part Sector?

As global awareness of environmental impacts escalates, the transformer part sector is increasingly focusing on sustainability and ethical sourcing. The production of transformer components often involves materials that can be harmful to the environment if not sourced responsibly. Therefore, buyers must prioritize suppliers that adhere to environmental regulations and best practices. This includes using sustainable materials, such as recycled metals and eco-friendly insulating oils, which not only reduce the carbon footprint but also align with the growing demand for ‘green’ certifications.

Moreover, ethical supply chains are becoming a critical consideration for international buyers. Ensuring that suppliers maintain fair labor practices and minimize environmental harm is essential for building a reputable brand. Certifications like ISO 14001 for environmental management and adherence to the Responsible Business Alliance (RBA) standards can provide assurances of a supplier’s commitment to sustainability. Buyers looking to enhance their market position should consider these factors as they can significantly influence purchasing decisions and foster long-term partnerships.

What Is the Brief Evolution of the Transformer Part Sector?

The transformer part sector has evolved significantly since the inception of electrical power systems in the late 19th century. Initially, transformers were bulky and inefficient, primarily designed for basic voltage adjustments. However, advancements in materials science, such as the development of laminated cores and improved insulating materials, have led to more compact and efficient designs.

In recent decades, the focus has shifted towards enhancing performance and reliability, driven by the increasing complexity of power grids and the integration of renewable energy sources. Digital technology has also transformed the landscape, allowing for smart transformers that enhance monitoring and maintenance practices. As the demand for energy continues to rise globally, the evolution of transformer parts will likely focus on sustainability and efficiency, further shaping the market dynamics for international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of transformer part

-

How do I solve issues related to transformer overheating?

Overheating in transformers can be mitigated by ensuring proper cooling mechanisms are in place, such as adequate transformer oil circulation and functioning radiators. Regular maintenance checks should include inspecting the oil levels, replacing any degraded insulating materials, and ensuring the cooling system operates effectively. If overheating persists, consider analyzing the load conditions and operational environment, as excessive loads or ambient temperatures can contribute to the issue. Collaborating with your supplier for customized solutions tailored to your specific operational needs can also enhance transformer longevity. -

What is the best transformer part for enhancing energy efficiency?

To enhance energy efficiency, investing in high-quality laminated cores is crucial. These cores are designed to minimize energy losses due to eddy currents and hysteresis, allowing for better magnetic path continuity. Additionally, ensure that the windings are made from high-conductivity materials like copper to reduce resistive losses. A well-designed cooling system, including effective radiators and transformer oil, further optimizes performance. Always consult with manufacturers to select transformer parts that align with your operational efficiency goals. -

What factors should I consider when vetting international suppliers for transformer parts?

When vetting suppliers, prioritize their experience in the transformer industry and their understanding of local regulations in your region. Evaluate their manufacturing capabilities and quality assurance processes to ensure they meet international standards. Request references or case studies to gauge their reliability and performance history. Additionally, assess their logistical capabilities to ensure timely delivery and support services. Establishing clear communication channels and understanding their customer support can also enhance your partnership. -

What customization options are available for transformer parts?

Customization options for transformer parts often include tailored dimensions, specific materials, and unique voltage ratings to suit your operational needs. Many manufacturers provide the option to modify components like windings, cores, and insulating materials based on your specifications. It’s advisable to discuss your requirements early in the procurement process, as this can influence lead times and costs. Engaging in a collaborative design process with your supplier can yield solutions that enhance performance and efficiency for your specific applications. -

What are the minimum order quantities (MOQ) for transformer parts?

Minimum order quantities (MOQ) for transformer parts can vary significantly depending on the supplier and the specific components being ordered. Generally, for standard components, MOQs may range from a few units to several hundred. For custom parts, the MOQ may be higher due to the increased complexity in manufacturing. It’s essential to clarify MOQs during initial discussions with potential suppliers to ensure they align with your project requirements and budget constraints. Negotiating terms based on your purchasing frequency can also be beneficial. -

What payment terms are typically offered by suppliers of transformer parts?

Payment terms can differ based on the supplier’s policies and the nature of the transaction. Common terms include upfront payments, net 30, net 60, or even letters of credit for larger orders. It’s advisable to negotiate terms that provide you with adequate cash flow while ensuring the supplier feels secure in their transaction. Building a good relationship with your supplier may also lead to more favorable payment options over time. Always review the terms carefully and consider the implications for your financial planning. -

How can I ensure quality assurance (QA) for transformer parts?

To ensure quality assurance for transformer parts, request detailed documentation of the supplier’s QA processes, including certifications such as ISO 9001. Conducting factory audits, if feasible, can provide insights into their manufacturing practices and adherence to quality standards. Additionally, establish a clear inspection protocol upon receiving goods, including testing for performance, durability, and compliance with specifications. Collaborating with suppliers who offer guarantees or warranties can also provide additional assurance regarding the reliability of their parts. -

What logistics considerations should I keep in mind when sourcing transformer parts internationally?

When sourcing transformer parts internationally, consider shipping times, customs regulations, and potential tariffs that could affect costs. Establish a reliable logistics partner who understands the specific requirements of handling electrical components. Confirm that the supplier can provide necessary documentation for customs clearance and ensure that products are adequately packaged to prevent damage during transit. It’s also beneficial to discuss delivery schedules and inventory management strategies to maintain operational continuity, especially in regions with unpredictable supply chains.

Top 3 Transformer Part Manufacturers & Suppliers List

1. Grant Transformers – Key Components

Domain: grant-transformers.com.au

Introduction: Core: Provides a low reluctance path for magnetic flux, ensuring efficient energy transfer. Windings: Transfers electrical energy between primary and secondary circuits. Insulation: Prevents short circuits and ensures electrical safety. Brushing: Maintains clean surfaces in electrical equipment. Tap changer: Adjusts turns ratio for voltage regulation. Terminals: Connection points for external circ…

2. Corefficient SRL – Transformer Core Essentials

Domain: corefficientsrl.com

Registered: 2014 (11 years)

Introduction: The three essential components of a transformer core include: 1. Core: Made of ferromagnetic material (iron or steel), it provides a low reluctance path for the magnetic field and minimizes eddy current and hysteresis losses. It consists of thin sheets of premium grain-oriented steel separated by insulating materials, with carbon content kept below 0.1%. There are two main types of core constructi…

3. Meta Power Solutions – Power Transformer Components

Domain: metapowersolutions.com

Registered: 2021 (4 years)

Introduction: Power Transformer Components include Single Phase Pad Mount Transformers (25 kVA to 150 kVA), Three Phase Pad Mount Transformers (50 kVA to 5000 kVA), Substation Transformers (76 MVA to 66000 kVA), Substation Container, Pole Mount Transformers (15 kVA to 333 kVA), Grounding Transformers (30 kVA to 300 kVA), and Switchboards (800 A to 4000 A). Key components of a power transformer are windings (mad…

Strategic Sourcing Conclusion and Outlook for transformer part

As the global demand for efficient and reliable electrical systems continues to rise, the strategic sourcing of transformer parts becomes increasingly vital for businesses across various regions. Key components such as laminated cores, windings, and cooling systems not only influence the performance of transformers but also affect the overall operational efficiency of power systems. Understanding the specific roles of these parts can empower buyers to make informed decisions that enhance performance, reduce costs, and mitigate risks associated with equipment failure.

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, prioritizing strategic sourcing is essential. By leveraging supplier partnerships and utilizing advanced procurement strategies, businesses can ensure a steady supply of high-quality transformer components that meet their unique operational needs.

Looking ahead, the importance of sustainability and innovation in transformer technology will shape sourcing strategies. Engaging with suppliers who prioritize eco-friendly practices and cutting-edge technologies will not only future-proof operations but also contribute to global sustainability goals.

Now is the time to evaluate your sourcing strategies and embrace a proactive approach to procurement in the transformer parts market, ensuring your business remains competitive and resilient in an evolving landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

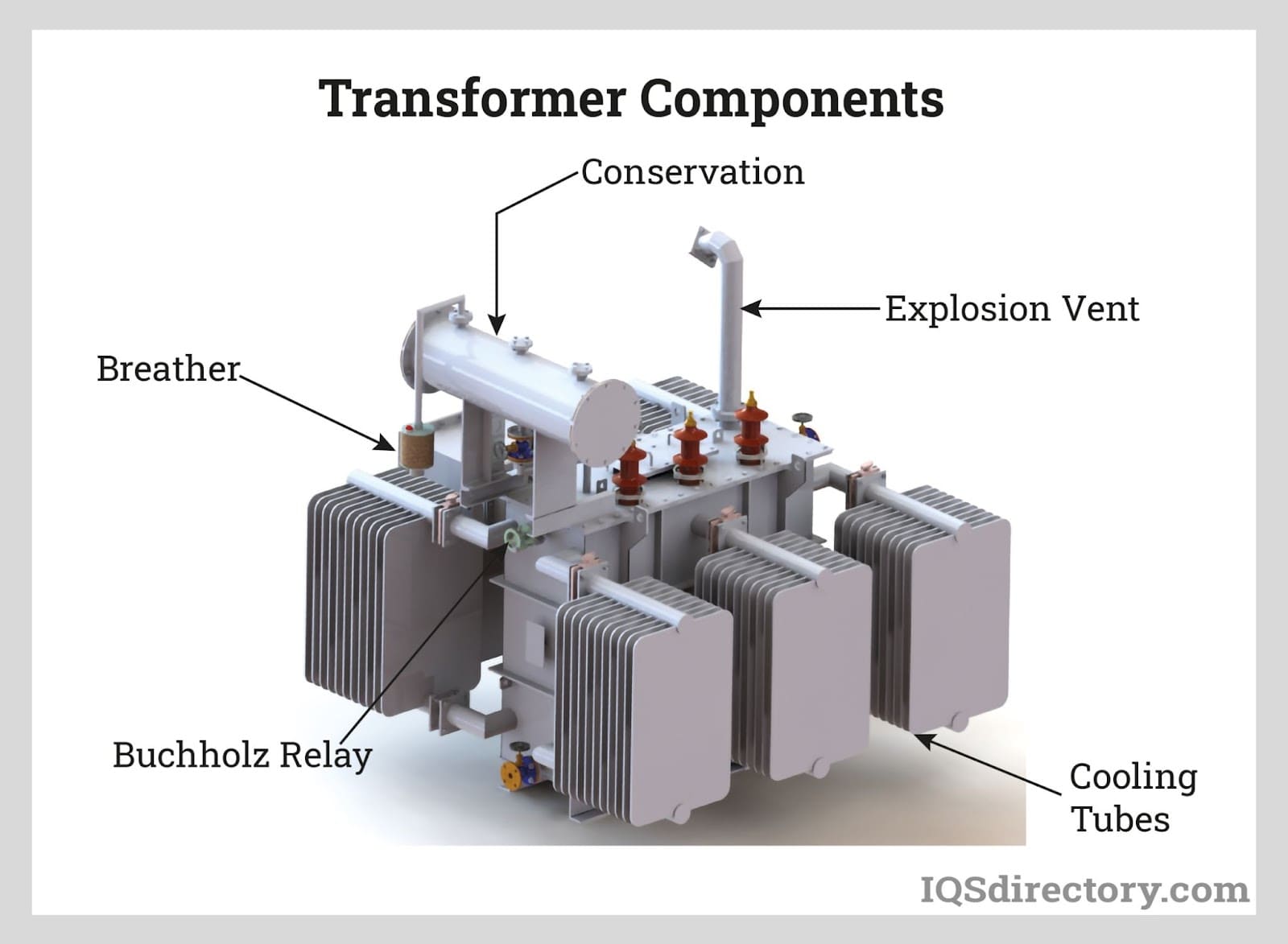

Illustrative image related to transformer part

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.