How to Source Thin Tile Plastic Resin Flooring Plastic Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for thin tile plastic resin flooring plastic

In today’s global marketplace, sourcing thin tile plastic resin flooring presents a unique set of challenges for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. These challenges include navigating varying quality standards, understanding local regulations, and selecting the right suppliers to meet specific project needs. This comprehensive guide is designed to address these complexities by providing an in-depth exploration of thin tile plastic resin flooring, including types, applications, and the critical aspects of supplier vetting.

Buyers will find valuable insights into the cost implications of different flooring options, helping them make informed purchasing decisions that align with budgetary constraints without compromising quality. Furthermore, the guide outlines the versatility of thin tile plastic resin flooring across various environments—from commercial spaces to residential applications—highlighting its durability, ease of installation, and maintenance benefits.

By empowering international buyers with the knowledge to assess product specifications, supplier reliability, and cost-effectiveness, this guide serves as an essential resource. Whether you are a buyer in Nigeria seeking sustainable flooring solutions or a distributor in Brazil looking to expand your product offerings, understanding the nuances of thin tile plastic resin flooring will enhance your competitive edge in the market.

Understanding thin tile plastic resin flooring plastic Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PVC Flooring | Flexible, waterproof, and anti-slip properties | Indoor gyms, commercial kitchens | Pros: Cost-effective, easy to maintain. Cons: Less durable under heavy loads. |

| Polypropylene Flooring | Rigid, highly durable, UV resistant | Outdoor sports courts, garages | Pros: Excellent durability, moisture resistant. Cons: Limited flexibility. |

| Interlocking Tiles | Easy DIY installation with interlocking edges | Trade shows, exhibitions, temporary setups | Pros: Quick installation, versatile designs. Cons: May require a subfloor for stability. |

| Raised Floor Tiles | Elevated design for moisture control and drainage | Basements, wet areas | Pros: Prevents water damage, enhances ventilation. Cons: Higher installation costs. |

| Carpet Tiles | Made from recycled materials, cushioned feel | Offices, trade shows | Pros: Eco-friendly, comfortable underfoot. Cons: Can stain easily, requires regular cleaning. |

What Are the Characteristics of PVC Flooring and Its Suitability for B2B Buyers?

PVC flooring is known for its flexibility and waterproof nature, making it ideal for environments such as indoor gyms and commercial kitchens. Its anti-slip properties enhance safety in high-traffic areas, which is crucial for businesses that prioritize employee and customer safety. When purchasing PVC flooring, B2B buyers should consider the specific environment and foot traffic levels, as while it is cost-effective and easy to maintain, it may not withstand heavy loads as well as other materials.

How Does Polypropylene Flooring Compare in Terms of Durability and Application?

Polypropylene flooring is characterized by its rigidity and high durability, making it suitable for outdoor applications such as sports courts and garages. This material is UV resistant, ensuring longevity even in direct sunlight. For B2B buyers, its moisture resistance is a significant advantage, especially in regions prone to weather variations. However, buyers should be aware that its lack of flexibility may limit its application in environments requiring softer surfaces.

Why Choose Interlocking Tiles for Quick Installations?

Interlocking tiles are designed for easy DIY installation, making them ideal for trade shows, exhibitions, and temporary setups. Their interlocking edges allow for quick assembly without the need for adhesives, which can save time and labor costs. B2B buyers should evaluate the design options available, as these tiles come in various colors and patterns. However, it’s essential to ensure a stable subfloor to maximize their performance and longevity.

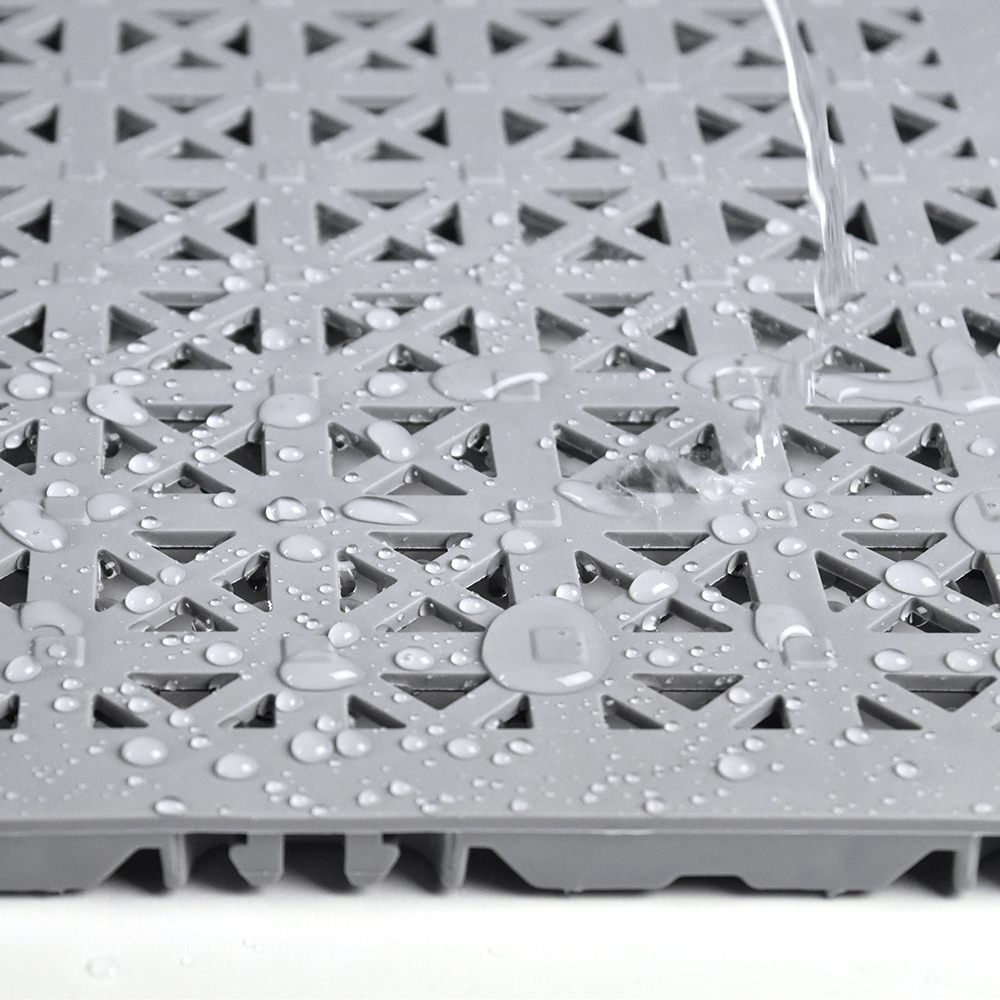

What Advantages Do Raised Floor Tiles Offer in Moisture-Prone Areas?

Raised floor tiles provide an elevated design that facilitates moisture control and drainage, making them an excellent choice for basements and wet areas. Their ability to prevent water damage and enhance ventilation can protect investments in flooring and underlying structures. B2B buyers should consider the higher installation costs associated with raised tiles, but the long-term benefits of moisture management often outweigh these initial expenses.

How Can Carpet Tiles Be a Sustainable Option for Businesses?

Carpet tiles, often made from recycled materials, offer a cushioned feel that enhances comfort in office spaces and trade shows. Their eco-friendly nature appeals to businesses looking to improve sustainability practices. However, B2B buyers should keep in mind that carpet tiles can stain easily and require regular cleaning to maintain appearance. Evaluating the specific needs of the workspace can help buyers decide if the benefits of comfort and sustainability align with their operational requirements.

Key Industrial Applications of thin tile plastic resin flooring plastic

| Industry/Sector | Specific Application of thin tile plastic resin flooring plastic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Factory floors for heavy machinery | Enhanced durability and resistance to heavy loads | Ensure tiles can withstand specific weights and provide anti-slip features. |

| Retail | Showroom and retail space flooring | Aesthetic appeal and ease of maintenance | Look for customizable designs and quick installation options. |

| Sports & Recreation | Indoor and outdoor sports courts | High-performance surface for athletic activities | Verify compliance with sports regulations and ensure water resistance. |

| Automotive | Garage and workshop flooring | Protection against chemicals and easy cleaning | Sourcing should focus on chemical resistance and durability under heavy usage. |

| Healthcare | Hospital and clinic flooring | Hygiene and easy sanitization | Consider antimicrobial properties and slip-resistance for safety. |

How is Thin Tile Plastic Resin Flooring Used in Manufacturing?

In the manufacturing sector, thin tile plastic resin flooring is often used in factory environments where heavy machinery operates. Its robust construction allows it to endure significant weight and impact, reducing the risk of damage and ensuring safety. The flooring is also designed to be resistant to spills and stains, making it easier to maintain cleanliness. Buyers in this sector should prioritize sourcing tiles that meet specific load-bearing requirements and have anti-slip surfaces to enhance worker safety.

What Are the Benefits of Thin Tile Plastic Flooring in Retail Spaces?

Retail environments benefit from thin tile plastic resin flooring due to its aesthetic versatility and ease of maintenance. This flooring can be customized in various colors and designs to align with branding, creating an inviting atmosphere for customers. Additionally, the durability of the tiles ensures they can withstand high foot traffic without significant wear. International buyers should consider sourcing options that allow for quick installation to minimize disruption to business operations.

Illustrative image related to thin tile plastic resin flooring plastic

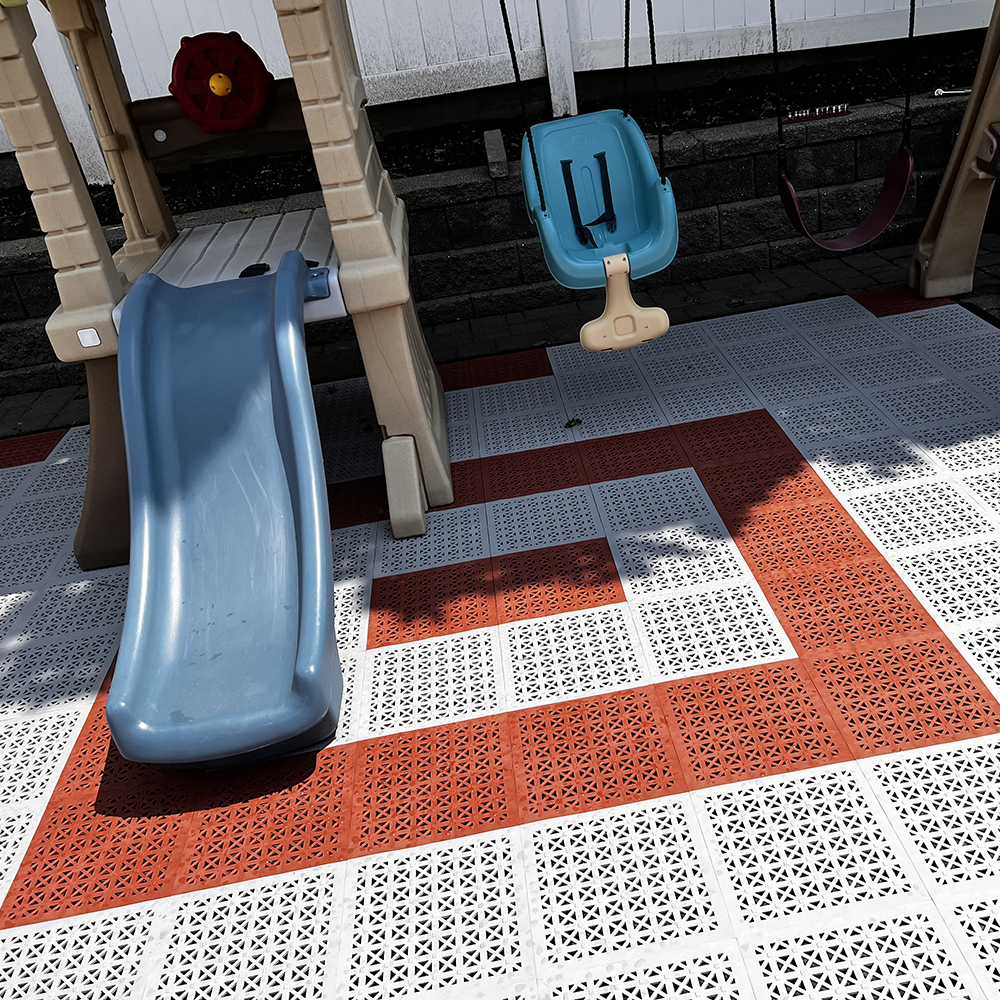

How Does Thin Tile Plastic Flooring Enhance Sports & Recreation Facilities?

In sports and recreation facilities, thin tile plastic resin flooring is essential for creating safe, high-performance surfaces for various athletic activities. The flooring can be used for both indoor and outdoor courts, providing excellent traction and shock absorption. Compliance with sports regulations is crucial, so buyers should ensure that the flooring meets necessary standards for performance and safety. Water resistance is another critical factor, especially for outdoor applications in regions with high rainfall.

Why Choose Thin Tile Plastic Flooring for Automotive Applications?

Automotive workshops and garages often utilize thin tile plastic resin flooring for its durability and chemical resistance. This type of flooring can withstand spills from oils and fluids, making cleanup straightforward and maintaining a safe working environment. When sourcing flooring for automotive applications, businesses should focus on the material’s ability to resist staining and damage from heavy equipment. Additionally, ease of installation is vital to minimize downtime during renovations.

What Role Does Thin Tile Plastic Flooring Play in Healthcare Settings?

In healthcare facilities, thin tile plastic resin flooring is favored for its hygiene and easy sanitization features. The smooth surface allows for efficient cleaning, which is essential in preventing infections in clinical environments. Buyers in this sector should prioritize sourcing flooring with antimicrobial properties and slip-resistance to ensure patient safety. Additionally, the tiles should be durable enough to withstand the constant movement of medical equipment and foot traffic.

3 Common User Pain Points for ‘thin tile plastic resin flooring plastic’ & Their Solutions

Scenario 1: Difficulty in Ensuring Durability for High-Traffic Areas

The Problem: Many B2B buyers are concerned about the longevity and durability of thin tile plastic resin flooring, especially in high-traffic commercial environments such as gyms, warehouses, or retail spaces. These buyers often face the challenge of flooring that wears out quickly, leading to frequent replacements, increased maintenance costs, and potential disruptions to business operations. The need for a flooring solution that can withstand heavy foot traffic while maintaining aesthetic appeal becomes paramount.

The Solution: To address durability concerns, it is essential to select high-quality thin tile plastic resin flooring specifically designed for heavy-duty applications. Look for products that feature reinforced structures, such as polypropylene or high-density polyethylene, which are known for their superior strength and resistance to wear and tear. Additionally, consider tiles with anti-slip surfaces to enhance safety in busy environments. Collaborate with reputable suppliers who can provide samples and data on the flooring’s performance in similar use cases. Investing in a high-grade product will not only reduce the frequency of replacements but also ensure that the flooring maintains its appearance and safety standards over time.

Scenario 2: Challenges with Installation and Maintenance

The Problem: A significant pain point for B2B buyers is the complexity of installation and ongoing maintenance of thin tile plastic resin flooring. Many businesses lack the expertise or manpower to execute a proper installation, which can lead to uneven surfaces, premature wear, and higher maintenance needs. Furthermore, buyers may be overwhelmed by the cleaning and upkeep requirements of different flooring types, leading to inconsistent results and dissatisfaction.

The Solution: To simplify installation, choose thin tile plastic resin flooring that offers interlocking features or peel-and-stick options, enabling quick and easy DIY installation. Providing training resources, such as instructional videos or detailed manuals, can empower your team to install the flooring efficiently. For maintenance, select flooring that is easy to clean—ideally, with a smooth surface that can be quickly mopped or swept. Establish a regular cleaning schedule and use recommended cleaning agents to maintain the flooring’s integrity and appearance. Providing your team with a clear maintenance plan will enhance the longevity of the flooring and improve overall satisfaction.

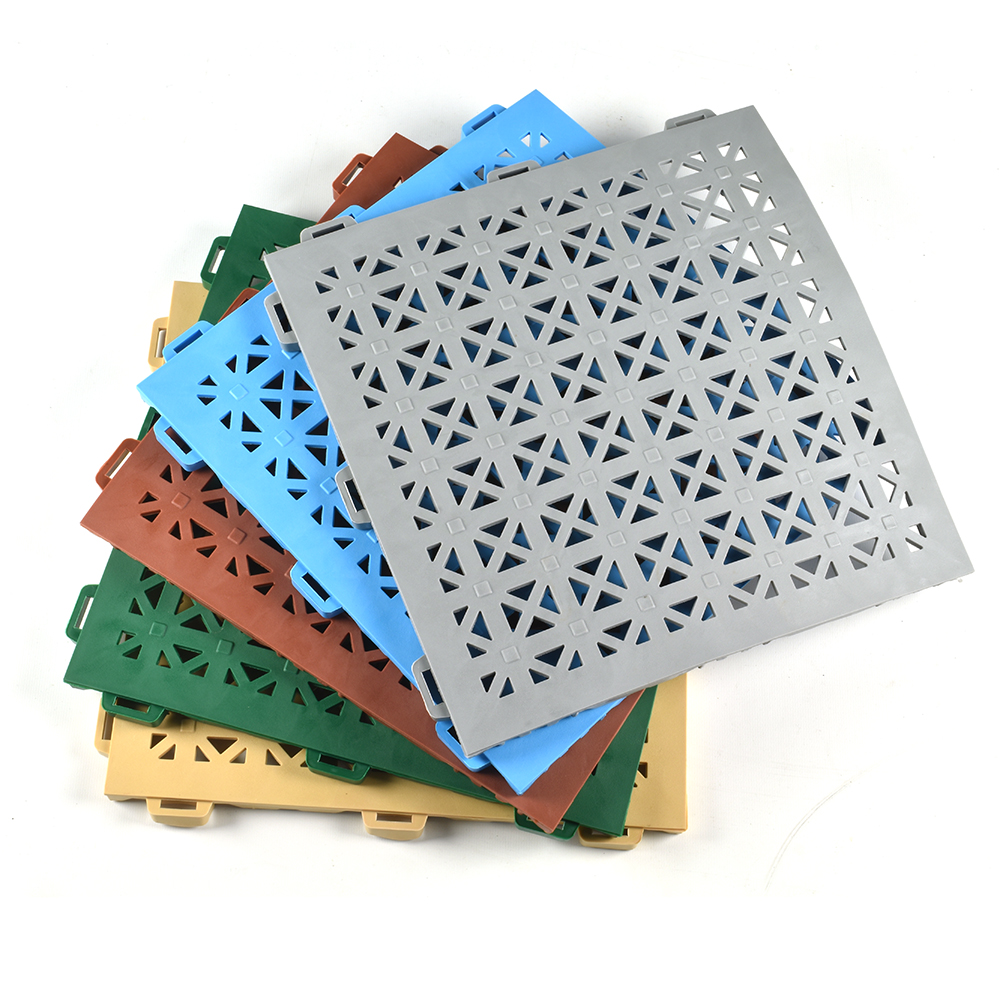

Scenario 3: Limited Design Options Affecting Brand Image

The Problem: B2B buyers often struggle with finding thin tile plastic resin flooring that aligns with their brand image and design aesthetics. In industries where first impressions matter—such as retail, hospitality, or corporate environments—having visually appealing flooring is crucial. Buyers may find that many flooring options are limited in color and design, which can undermine the professional look they wish to achieve.

The Solution: When sourcing thin tile plastic resin flooring, prioritize suppliers that offer a diverse range of styles, colors, and textures. Consider options that mimic natural materials like wood or stone to enhance the visual appeal without sacrificing durability. Look for customization options where colors can be tailored to match corporate branding or specific design themes. Engaging with manufacturers who are willing to collaborate on custom designs can also provide a competitive edge. By selecting flooring that complements your brand identity, you can create a welcoming atmosphere that resonates with customers and clients, reinforcing your company’s professionalism and attention to detail.

Strategic Material Selection Guide for thin tile plastic resin flooring plastic

What Are the Key Materials for Thin Tile Plastic Resin Flooring?

When selecting thin tile plastic resin flooring, understanding the various materials available is crucial for ensuring optimal performance, durability, and cost-effectiveness. Below, we analyze four common materials used in thin tile plastic resin flooring, emphasizing their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Polyvinyl Chloride (PVC)

Key Properties: PVC is known for its flexibility and resistance to moisture, chemicals, and abrasion. It can withstand temperatures ranging from -10°C to 60°C, making it suitable for various environments.

Pros & Cons: PVC flooring is relatively inexpensive and easy to install, often featuring interlocking designs that simplify DIY projects. However, it may not be as durable as other materials under heavy loads, and it can emit volatile organic compounds (VOCs), which may raise health concerns.

Impact on Application: PVC is ideal for areas prone to moisture, such as basements and bathrooms. Its chemical resistance makes it suitable for industrial applications where spills may occur.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers in regions like Africa and South America should verify local regulations regarding VOC emissions.

Illustrative image related to thin tile plastic resin flooring plastic

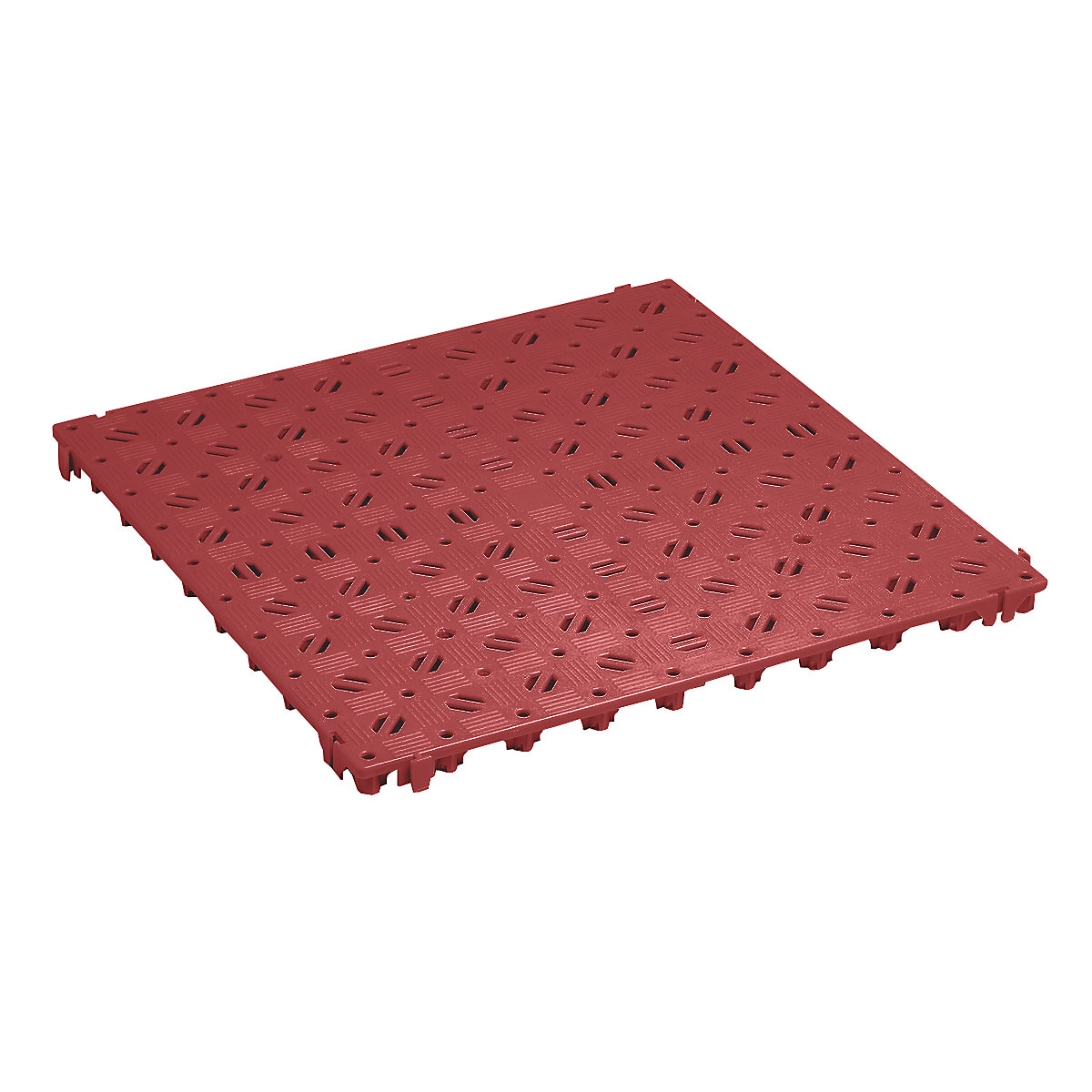

2. Polypropylene

Key Properties: Polypropylene is a rigid material that offers excellent durability and resistance to chemicals, UV light, and moisture. It can handle higher temperatures than PVC, typically up to 80°C.

Pros & Cons: The durability of polypropylene makes it suitable for high-traffic areas, including commercial and industrial settings. However, it can be more expensive than PVC, and its rigidity may not provide the same level of comfort underfoot.

Impact on Application: This material is commonly used in athletic facilities and warehouses due to its ability to withstand heavy loads and impact.

Considerations for International Buyers: Buyers in Europe and the Middle East should ensure that polypropylene products meet relevant safety and performance standards. Additionally, the higher cost may be a consideration for budget-conscious buyers.

3. Ethylene Vinyl Acetate (EVA)

Key Properties: EVA is a flexible, lightweight material known for its cushioning properties and resistance to UV light and moisture. It typically performs well in temperatures ranging from -30°C to 70°C.

Illustrative image related to thin tile plastic resin flooring plastic

Pros & Cons: EVA flooring is comfortable underfoot, making it suitable for residential applications and areas requiring anti-fatigue properties. However, it may not be as durable as PVC or polypropylene in high-traffic commercial settings.

Impact on Application: EVA is often used in home gyms and recreational areas due to its shock-absorbing qualities.

Considerations for International Buyers: Compliance with local regulations regarding material safety and environmental impact is essential. Buyers in regions like Nigeria and Brazil should consider the availability of EVA products and their suitability for local climates.

Illustrative image related to thin tile plastic resin flooring plastic

4. Rubber

Key Properties: Rubber flooring is known for its exceptional durability, slip resistance, and ability to absorb sound. It can withstand a wide temperature range, typically from -30°C to 80°C.

Pros & Cons: Rubber is highly durable and ideal for heavy-duty applications, such as gyms and industrial settings. However, it can be more expensive than plastic alternatives and may require more complex installation methods.

Impact on Application: The slip-resistant properties of rubber make it ideal for wet areas and high-traffic environments.

Considerations for International Buyers: Buyers should be aware of the different grades of rubber flooring available and ensure that they meet local standards for safety and performance. The higher cost may also be a factor for budget-sensitive projects.

Summary Table of Material Selection for Thin Tile Plastic Resin Flooring

| Material | Typical Use Case for thin tile plastic resin flooring plastic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride | Moisture-prone areas (bathrooms, basements) | Cost-effective and easy to install | May emit VOCs and less durable | Low |

| Polypropylene | High-traffic commercial and industrial settings | Excellent durability and chemical resistance | Higher cost and rigidity | Medium |

| Ethylene Vinyl Acetate | Home gyms and recreational areas | Comfortable and shock-absorbing | Less durable for high-traffic applications | Medium |

| Rubber | Gyms and industrial settings | Highly durable and slip-resistant | More expensive and complex installation | High |

This guide provides a comprehensive overview of the materials available for thin tile plastic resin flooring, helping international B2B buyers make informed decisions that align with their specific needs and compliance requirements.

Illustrative image related to thin tile plastic resin flooring plastic

In-depth Look: Manufacturing Processes and Quality Assurance for thin tile plastic resin flooring plastic

What Are the Main Stages of Manufacturing Thin Tile Plastic Resin Flooring?

Manufacturing thin tile plastic resin flooring involves several critical stages, each designed to ensure the final product meets high standards of durability and performance. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Thin Tile Plastic Resin Flooring?

The first stage involves sourcing and preparing the raw materials, which primarily consist of plastic resins such as PVC or polypropylene. These materials are often blended with additives to enhance properties like flexibility, color, and UV resistance.

Once the materials are sourced, they undergo quality checks to ensure they meet the required specifications. This step is crucial as it prevents defects that can compromise the flooring’s performance. The materials are then granulated or pelletized for easier handling in subsequent stages.

What Techniques Are Used in the Forming Process of Plastic Flooring?

The forming stage typically employs advanced techniques such as extrusion and injection molding.

- Extrusion is used to create long sheets of flooring, which are then cut into tiles. This method allows for consistent thickness and surface texture, ensuring uniformity across the product line.

- Injection molding is often used for creating intricate tile designs, enabling manufacturers to produce detailed patterns and textures that enhance aesthetics.

Both techniques require precise temperature and pressure control to ensure the resin flows correctly and achieves the desired properties.

How Are Tiles Assembled and Finished?

After forming, tiles move to the assembly stage, where they are organized into batches for further processing. This stage may involve the addition of interlocking mechanisms or surface treatments to enhance grip and performance.

Illustrative image related to thin tile plastic resin flooring plastic

Finishing processes include applying protective coatings, coloring, and adding textures. These treatments not only improve the aesthetic appeal but also enhance the durability and slip resistance of the tiles. Quality assurance checkpoints during this stage are vital to confirm that the tiles meet design specifications and performance standards.

What Quality Assurance Standards Are Relevant for Thin Tile Flooring?

For B2B buyers, understanding the quality assurance (QA) standards that govern thin tile plastic resin flooring is essential. International standards such as ISO 9001 focus on quality management systems, ensuring that manufacturers maintain consistent quality in their processes.

In addition to ISO certifications, industry-specific standards may include CE marking in Europe, which indicates compliance with health, safety, and environmental protection standards. Buyers should also be aware of relevant certifications, such as the American National Standards Institute (ANSI) standards for safety and performance.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated throughout the manufacturing process, with several checkpoints to ensure product integrity:

Illustrative image related to thin tile plastic resin flooring plastic

- Incoming Quality Control (IQC): This initial checkpoint assesses raw materials upon arrival to confirm they meet specified standards.

- In-Process Quality Control (IPQC): This stage monitors the manufacturing process in real-time, checking for defects during forming and assembly.

- Final Quality Control (FQC): Before shipment, finished tiles undergo rigorous testing to confirm they meet performance criteria, such as durability, slip resistance, and aesthetic standards.

Common testing methods include tensile strength tests, slip resistance tests, and water absorption tests. These assessments help ensure that the flooring can withstand the demands of various environments.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance processes is crucial. Buyers can employ several strategies to ensure their suppliers adhere to high standards:

-

Conduct Supplier Audits: Regular audits allow buyers to assess the manufacturing processes and quality control measures firsthand. This can include reviewing documentation related to certifications and compliance with international standards.

-

Request Quality Reports: Suppliers should provide detailed reports on their quality control processes, including results from IQC, IPQC, and FQC testing. These documents should outline any corrective actions taken in case of non-conformance.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s operations. These services can verify compliance with international standards and provide insights into the overall quality of the products.

What Are the Nuances of Quality Certification for International Buyers?

Understanding the nuances of quality certification is vital for international B2B buyers. Different regions may have varying standards and certifications, which can affect product acceptance. For instance, compliance with European CE marking may not be necessary in other markets, but it enhances credibility in Europe.

Additionally, buyers should consider the implications of local regulations in their respective markets. For example, certain countries may have specific requirements for environmental sustainability or safety that must be met for products to be imported.

Illustrative image related to thin tile plastic resin flooring plastic

Conclusion: Ensuring Quality in Thin Tile Plastic Resin Flooring

For B2B buyers, ensuring quality in thin tile plastic resin flooring is a multi-faceted process that involves understanding manufacturing techniques, quality assurance standards, and effective verification methods. By leveraging international standards and implementing rigorous quality checks, buyers can confidently select suppliers that deliver durable and reliable flooring solutions suitable for diverse applications. Whether sourcing from Africa, South America, the Middle East, or Europe, a thorough understanding of these processes is key to making informed purchasing decisions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘thin tile plastic resin flooring plastic’

To effectively procure thin tile plastic resin flooring plastic, it’s essential to follow a systematic approach that ensures quality, cost-effectiveness, and suitability for your specific needs. This guide outlines the key steps to help international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, navigate the sourcing process efficiently.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly define the technical specifications for the flooring. Consider factors such as thickness, durability, color, and intended use (e.g., residential, commercial, or industrial). This step is crucial as it sets the foundation for all subsequent decisions and helps in aligning supplier capabilities with your project requirements.

Step 2: Research Market Trends and Standards

Understanding current market trends and industry standards is vital. Research the latest innovations in thin tile plastic resin flooring, including sustainability practices and regulatory compliance specific to your region. This knowledge will enable you to identify suppliers who offer cutting-edge solutions and adhere to necessary regulations, ensuring that your purchase meets both performance and legal requirements.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Look for company profiles, product catalogs, and case studies that demonstrate their experience in your industry. Request references from other businesses that have sourced similar products. This diligence helps in assessing the reliability and reputation of the supplier, which is critical for long-term partnerships.

Step 4: Request Samples for Quality Assessment

Always request samples of the flooring tiles before finalizing your order. This allows you to assess the quality, texture, and color accuracy firsthand. Evaluate the samples in real-world conditions, considering factors such as slip resistance and ease of installation. Ensuring that the product meets your quality standards can prevent costly issues after installation.

Step 5: Verify Certifications and Compliance

Confirm that the flooring products meet relevant certifications and standards, such as ISO, CE, or ASTM. These certifications often indicate that the product has undergone rigorous testing for safety, durability, and environmental impact. Compliance with local regulations is particularly important, especially in regions with strict building codes or sustainability mandates.

Step 6: Compare Pricing and Payment Terms

Once you have shortlisted suppliers, compare their pricing structures and payment terms. Look beyond the initial cost and consider factors like shipping, tariffs, and potential bulk discounts. Establish clear payment terms that align with your budget and cash flow requirements. Negotiating favorable terms can significantly impact your overall project costs.

Illustrative image related to thin tile plastic resin flooring plastic

Step 7: Plan for Logistics and Installation

Finally, develop a logistics plan that includes delivery timelines, installation procedures, and post-installation support. Discuss with suppliers about their delivery capabilities and support services to ensure a smooth installation process. Proper planning at this stage can help avoid delays and ensure that your project stays on schedule.

By following these steps, B2B buyers can confidently source thin tile plastic resin flooring that meets their specifications and supports their operational needs.

Comprehensive Cost and Pricing Analysis for thin tile plastic resin flooring plastic Sourcing

What Are the Key Cost Components in Sourcing Thin Tile Plastic Resin Flooring?

When considering the sourcing of thin tile plastic resin flooring, understanding the cost structure is essential for B2B buyers. The primary components include:

-

Materials: The choice of resin significantly impacts costs. Polypropylene and PVC are common materials, with polypropylene typically being more durable but also more expensive. Buyers should consider the long-term benefits of higher-quality materials against initial costs.

-

Labor: The installation process for plastic flooring can vary in complexity. While many products feature interlocking designs that facilitate DIY installation, labor costs may still arise if professional installation is required. This is particularly relevant for large-scale projects.

-

Manufacturing Overhead: This includes expenses related to production facilities, utilities, and administrative costs. Manufacturers with advanced technology may have higher overhead but can offer better quality assurance and production efficiency.

-

Tooling: If customization is required, tooling costs can escalate. This includes molds for specific designs or thicknesses, which can affect the pricing structure significantly.

-

Quality Control (QC): Ensuring that products meet international standards and certifications involves additional costs. Quality assurance processes are critical, especially for buyers in regions with stringent regulations.

-

Logistics: Shipping costs can vary widely based on the origin of the materials, the destination, and the chosen Incoterms. Buyers should factor in potential tariffs and customs duties, especially when sourcing internationally.

-

Margin: Suppliers typically mark up their prices to ensure profitability. Understanding the margin expectations of suppliers can help buyers negotiate more effectively.

What Influences Pricing for Thin Tile Plastic Resin Flooring?

Several factors can influence the pricing of thin tile plastic resin flooring:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs. Negotiating MOQs can lead to significant savings for businesses planning extensive installations.

-

Specifications and Customization: Customized solutions may incur additional costs. Buyers should assess whether standard products meet their needs to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher-quality materials or those with specific certifications (like eco-friendly or fire-resistant) typically command higher prices. However, these investments can lead to lower maintenance costs and longer lifespans.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may offer more consistent quality and service, which could justify higher costs.

-

Incoterms: The choice of Incoterms can significantly impact the total cost of ownership. Understanding whether costs include freight, insurance, and customs can help buyers make informed decisions.

How Can Buyers Negotiate Cost-Effectively for Thin Tile Plastic Resin Flooring?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies are crucial:

-

Research and Compare: Before entering negotiations, research various suppliers and their pricing models. Comparison can provide leverage during discussions.

-

Focus on Total Cost of Ownership (TCO): Highlighting the long-term savings associated with higher-quality materials can shift the conversation from upfront costs to overall value.

-

Leverage Volume Discounts: If planning multiple projects, consolidate orders to negotiate better rates.

-

Understand Local Market Dynamics: Familiarize yourself with the specific market conditions in your region, such as tariffs or shipping costs, which can affect overall pricing.

-

Build Relationships: Establishing a rapport with suppliers can facilitate better negotiation outcomes and potential discounts.

Conclusion: What Should Buyers Keep in Mind?

While indicative prices for thin tile plastic resin flooring can vary widely, understanding the intricate cost components and pricing influences is critical for making informed purchasing decisions. Buyers should approach negotiations with a clear strategy, focusing on both immediate costs and long-term value. By leveraging these insights, international buyers can optimize their sourcing process and ensure they receive the best possible return on investment.

Alternatives Analysis: Comparing thin tile plastic resin flooring plastic With Other Solutions

Introduction to Flooring Alternatives for B2B Buyers

When considering flooring solutions for commercial or industrial spaces, buyers often encounter a variety of options that promise durability, aesthetic appeal, and cost-effectiveness. Among these, thin tile plastic resin flooring stands out for its versatility and performance. However, it’s essential to evaluate other viable alternatives to ensure the best fit for specific business needs. This comparison will highlight the key aspects of thin tile plastic resin flooring against two prominent alternatives: PVC interlocking tiles and rubber flooring.

Comparison Table

| Comparison Aspect | Thin Tile Plastic Resin Flooring Plastic | PVC Interlocking Tiles | Rubber Flooring |

|---|---|---|---|

| Performance | Highly durable, resistant to moisture | Durable, but less rigid than resin | Excellent shock absorption, slip-resistant |

| Cost | Moderate to high per square foot | Lower initial cost | Higher initial investment |

| Ease of Implementation | DIY-friendly, interlocking design | Easy to install, requires minimal tools | Requires professional installation for best results |

| Maintenance | Easy to clean, resistant to stains | Low maintenance, can be swept or mopped | Requires regular cleaning, prone to wear over time |

| Best Use Case | Retail spaces, gyms, and residential areas | Garages, basements, and event spaces | Fitness centers, playgrounds, and industrial environments |

Detailed Breakdown of Alternatives

PVC Interlocking Tiles

PVC interlocking tiles are a popular choice for many commercial applications due to their cost-effectiveness and ease of installation. They are designed to snap together, making them a practical option for DIY projects. While they provide decent durability and moisture resistance, they may not be as rigid or long-lasting as thin tile plastic resin flooring. PVC tiles are best suited for low-traffic areas or where flooring may need frequent changes, such as event spaces or temporary installations. However, their lower initial cost comes at the expense of long-term durability, making them a less optimal choice for high-traffic environments.

Illustrative image related to thin tile plastic resin flooring plastic

Rubber Flooring

Rubber flooring is widely recognized for its exceptional shock absorption and slip resistance, making it ideal for fitness centers and playgrounds. It provides a comfortable underfoot experience and reduces the risk of injuries due to falls. However, the installation of rubber flooring can be complex, often requiring professional help to ensure a proper fit and finish. While rubber is durable, it can show wear over time, particularly in high-traffic areas, and requires regular cleaning to maintain its appearance. Additionally, the initial investment can be higher than both thin tile plastic resin flooring and PVC tiles, which may deter some B2B buyers.

Conclusion: Choosing the Right Flooring Solution

When selecting the right flooring solution, B2B buyers must consider their specific use cases, budget, and long-term maintenance expectations. Thin tile plastic resin flooring offers a balance of durability and aesthetic flexibility, making it a strong contender for various applications. However, if cost is a primary concern or if the flooring needs to be frequently modified, PVC interlocking tiles may be more suitable. On the other hand, for environments requiring maximum shock absorption and safety, rubber flooring could be the best option despite its higher initial costs. Ultimately, aligning the flooring choice with the unique demands of the business will lead to a more satisfactory investment.

Essential Technical Properties and Trade Terminology for thin tile plastic resin flooring plastic

What Are the Essential Technical Properties of Thin Tile Plastic Resin Flooring?

Understanding the technical properties of thin tile plastic resin flooring is crucial for B2B buyers, especially when considering durability, application, and cost-effectiveness. Here are some key specifications that are critical to making informed purchasing decisions:

Illustrative image related to thin tile plastic resin flooring plastic

1. Material Grade

The material grade indicates the quality and durability of the plastic resin used in flooring. Common materials include Polyvinyl Chloride (PVC) and Polypropylene (PP). Higher-grade materials offer better resistance to wear, chemicals, and UV exposure, which is essential for outdoor applications or high-traffic areas. Selecting the right material grade can significantly affect the flooring’s lifespan and maintenance needs.

2. Thickness

Thickness is a critical factor that influences both the performance and aesthetic of the flooring. Thin tile plastic resin flooring typically ranges from 1/4 inch to 1/2 inch. Thicker tiles often provide better insulation and sound absorption, while thinner options may be more suitable for quick installations and lower costs. Evaluating the thickness required based on usage—be it residential or commercial—can help buyers choose the right product.

3. Tolerance

Tolerance refers to the allowable variation in dimensions of the flooring tiles. High tolerance levels ensure that the tiles fit together seamlessly, which is crucial for maintaining a professional appearance and ensuring safety. Poor tolerance can lead to gaps or misalignments, increasing the risk of damage over time. Buyers should ensure that suppliers provide detailed specifications regarding tolerance levels.

4. Slip Resistance

Slip resistance is a vital property for ensuring safety, especially in commercial environments where spills may occur. Flooring with a higher coefficient of friction minimizes the risk of slips and falls. This property is particularly important in regions with wet climates or in applications like gyms and kitchens. Look for flooring products that meet international slip resistance standards to ensure compliance and safety.

5. UV Stability

For outdoor applications, UV stability is crucial to prevent fading and degradation caused by sunlight exposure. Flooring with UV stabilization retains its color and structural integrity over time, making it suitable for patios, balconies, and other outdoor environments. This property not only enhances aesthetic appeal but also prolongs the lifespan of the flooring.

Illustrative image related to thin tile plastic resin flooring plastic

6. Water Resistance

The water resistance of thin tile plastic resin flooring is particularly important for areas prone to moisture, such as basements or bathrooms. Tiles that offer high water resistance can prevent mold growth and structural damage, ensuring a healthier environment. Buyers should inquire about the water absorption rate and overall water resistance features when selecting products for moisture-prone areas.

What Are Common Trade Terms in the Thin Tile Plastic Resin Flooring Industry?

Navigating the B2B landscape requires familiarity with industry-specific jargon. Here are some common terms that buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. In the flooring industry, OEMs produce tiles that may be branded and marketed by distributors. Understanding OEM relationships can help buyers negotiate pricing and quality assurance.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is critical for buyers to understand as it affects inventory management and initial investment costs. Knowing the MOQ can help businesses plan their purchases more effectively and avoid overstocking or understocking.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price offers from suppliers. It typically includes detailed specifications of the desired product, including material, dimensions, and quantities. Submitting an RFQ can help buyers receive competitive pricing and better understand the market.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), can help buyers mitigate risks and clarify responsibilities in international transactions.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. Understanding lead times is essential for effective project planning and inventory management, especially for businesses with tight deadlines.

By grasping these essential properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and strategic goals.

Illustrative image related to thin tile plastic resin flooring plastic

Navigating Market Dynamics and Sourcing Trends in the thin tile plastic resin flooring plastic Sector

What Are the Key Market Drivers for Thin Tile Plastic Resin Flooring?

The global market for thin tile plastic resin flooring is experiencing significant growth driven by various factors. One of the primary drivers is the increasing demand for versatile and durable flooring solutions across multiple sectors, including residential, commercial, and industrial applications. Regions like Africa, South America, the Middle East, and Europe are witnessing rapid urbanization and infrastructure development, leading to heightened investment in flooring materials. The rise in construction activities, particularly in emerging markets such as Nigeria and Brazil, is propelling demand for lightweight, easy-to-install flooring options that can withstand high foot traffic.

Additionally, technological advancements are influencing the sourcing landscape. Digital platforms are streamlining the procurement process, allowing international buyers to compare products and suppliers more efficiently. This trend is particularly relevant for B2B buyers, as it enhances transparency and facilitates informed decision-making. The integration of smart technologies in flooring solutions, such as anti-slip features and moisture resistance, is also gaining traction, enhancing product appeal.

How Is Sustainability Impacting the Sourcing of Thin Tile Plastic Resin Flooring?

Sustainability is becoming a critical consideration for B2B buyers in the thin tile plastic resin flooring sector. The environmental impact of flooring materials is under scrutiny, prompting businesses to seek products that are not only durable but also eco-friendly. Ethical sourcing is gaining importance as companies increasingly prioritize supply chains that minimize environmental harm and support fair labor practices.

The use of recycled materials in manufacturing thin tile plastic resin flooring is a prominent trend. For instance, some manufacturers are incorporating recycled plastics into their products, which not only reduces waste but also offers a compelling selling point for environmentally-conscious buyers. Certifications such as LEED (Leadership in Energy and Environmental Design) and FloorScore can further validate the sustainability claims of flooring products, providing assurance to B2B buyers about their choices.

Moreover, the push for green building initiatives is influencing procurement decisions. Buyers are increasingly looking for flooring solutions that contribute to energy efficiency and indoor air quality, aligning with broader corporate social responsibility goals. This shift not only enhances brand reputation but also appeals to a growing segment of environmentally-aware consumers.

What Is the Historical Context of Thin Tile Plastic Resin Flooring?

The evolution of thin tile plastic resin flooring can be traced back to the mid-20th century when vinyl flooring began to gain popularity as a cost-effective and versatile alternative to traditional materials. Initially developed for residential use, advancements in technology and manufacturing processes led to the introduction of interlocking tiles and a broader range of aesthetic options, including textures that mimic natural materials like wood and stone.

By the late 20th century, the introduction of polypropylene and PVC-based tiles marked a significant shift in the market. These materials offered enhanced durability and moisture resistance, making them suitable for a variety of applications, from garages to sports facilities. Today, thin tile plastic resin flooring is recognized for its multifunctionality, ease of installation, and adaptability to diverse environments, making it a preferred choice for international B2B buyers looking for efficient flooring solutions.

In summary, the thin tile plastic resin flooring market is shaped by evolving customer preferences, technological advancements, and a growing emphasis on sustainability. For B2B buyers, understanding these dynamics is crucial for making informed sourcing decisions that align with both business objectives and environmental considerations.

Frequently Asked Questions (FAQs) for B2B Buyers of thin tile plastic resin flooring plastic

-

How do I choose the right thin tile plastic resin flooring for my specific application?

Selecting the appropriate thin tile plastic resin flooring involves assessing the intended use. Consider factors such as foot traffic levels, exposure to moisture, and the environment (indoor vs. outdoor). For high-traffic areas, durable options like polypropylene may be ideal, while PVC offers flexibility for spaces requiring cushioning. Additionally, ensure the flooring has the necessary anti-slip features and is easy to clean, as this can enhance safety and maintenance efficiency. -

What is the best way to install thin tile plastic resin flooring?

Installation of thin tile plastic resin flooring is generally straightforward due to its interlocking design. Start by ensuring the subfloor is clean and dry. Lay the tiles from one corner, using a rubber mallet to secure them without damaging the edges. For specific patterns or designs, pre-plan your layout. In environments like garages or sports courts, consider adding an underlayment for added durability and cushioning. Always follow the manufacturer’s guidelines for optimal results. -

What are the minimum order quantities (MOQ) for thin tile plastic resin flooring?

Minimum order quantities can vary significantly between suppliers, often depending on the type of flooring and customization options. Typically, for international B2B transactions, MOQs may range from 100 to 1,000 square feet or more. It’s advisable to inquire directly with suppliers for their specific policies. Bulk orders often come with discounts, so negotiating terms may also yield favorable pricing. -

How can I ensure the quality of thin tile plastic resin flooring before making a purchase?

To ensure quality, request samples from potential suppliers before committing to a bulk order. Evaluate the material’s durability, flexibility, and finish. Additionally, inquire about certifications that indicate compliance with international quality standards. Establishing a relationship with reputable suppliers who have a history of positive customer feedback can also help mitigate risks associated with product quality. -

What payment terms should I expect when sourcing thin tile plastic resin flooring internationally?

Payment terms can vary by supplier and region but typically include options like a deposit upfront (30-50%) with the balance due upon shipment. Some suppliers may offer letter of credit or open account terms for established clients. Always clarify payment methods accepted (e.g., bank transfer, PayPal) and any potential fees associated with currency conversion or international transactions. -

What shipping and logistics considerations should I be aware of when importing flooring products?

When importing thin tile plastic resin flooring, consider shipping costs, delivery timelines, and customs regulations. It’s essential to work with a logistics partner experienced in international shipping to navigate potential challenges, such as tariffs or import duties. Ensure that the supplier provides proper documentation, including bills of lading and customs declarations, to facilitate smooth clearance at ports. -

Can I customize the design or color of thin tile plastic resin flooring?

Many suppliers offer customization options for thin tile plastic resin flooring, including colors, patterns, and sizes. Custom orders may require higher MOQs and longer lead times. Discuss your design specifications with the supplier to understand available options and any additional costs involved. Be prepared to provide detailed mockups or samples to ensure the final product meets your expectations. -

What should I know about the environmental impact of thin tile plastic resin flooring?

When sourcing flooring materials, consider their environmental sustainability. Many manufacturers now produce flooring from recycled materials or offer eco-friendly options. Inquire about the lifecycle of the product, including its recyclability and any certifications related to environmental compliance. This is particularly important for companies committed to sustainability, as it can enhance brand reputation and meet regulatory standards in various markets.

Top 3 Thin Tile Plastic Resin Flooring Plastic Manufacturers & Suppliers List

1. GreatMats – Plastic Flooring Solutions

Domain: greatmats.com

Registered: 1999 (26 years)

Introduction: Plastic Flooring & Tiles, 25 Years of Quality Customer Service, Expert Help Available, Quick Material Calculator, Floor Plan Designer, Buyers Guide, Free Samples, Deals, Today’s Sales, Clearance Deals, Rewards, Reviews, Tools, Price Match, Contact Information, Glossary, Customer Support, Live Chat, Sales Contact, Hours: M-F – 7 AM to 4:30 PM CST, Call 877-822-6622.

2. WallPops – Peel and Stick Floor Tiles

Domain: wallpops.com

Registered: 2006 (19 years)

Introduction: Peel and stick floor tiles, easy installation, no grout or glue needed, available in various designs and colors, durable and water-resistant, suitable for residential and commercial use, ideal for DIY projects, easy to clean and maintain.

3. CTASC – Adhesive Removal Strips

Domain: ctasc.com

Registered: 2001 (24 years)

Introduction: 1. Special strips available to remove adhesive from old plastic tiles. 2. Thin-set mortars can bond to plastic tile adhesive residuals, but this bonds to the adhesive, not the concrete slab. 3. Some thin-set mortars can bond directly to well-bonded plastic or vinyl tiles after proper cleaning or scarifying. 4. Recommended adhesives for bonding tile to plastic include epoxy adhesive, pure silicone,…

Strategic Sourcing Conclusion and Outlook for thin tile plastic resin flooring plastic

As the demand for versatile and durable flooring solutions continues to grow, thin tile plastic resin flooring emerges as a critical component for various industries. This material offers exceptional durability, moisture resistance, and ease of installation, making it an ideal choice for commercial and residential applications alike. Strategic sourcing of thin tile plastic resin flooring not only ensures access to high-quality products but also enhances supply chain efficiency, allowing businesses to meet consumer demands promptly.

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, understanding the unique benefits of thin tile plastic resin flooring can provide a competitive edge. The diverse range of styles and colors available allows for customization to meet specific design needs while maintaining functionality.

Looking forward, the focus on sustainable sourcing and innovative materials will drive the evolution of flooring solutions. As you consider your next flooring project, engage with suppliers who prioritize quality and sustainability. By doing so, you can enhance your offerings and cater to the growing market for eco-friendly products. Take the next step in your sourcing strategy today and explore the potential of thin tile plastic resin flooring to elevate your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.