How to Source Temperature Gauge For 331 Bobcat Sale Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for temperature gauge for 331 bobcat sale

Navigating the global market for temperature gauges for Bobcat 331 models presents a unique set of challenges for B2B buyers, particularly when sourcing reliable components that ensure optimal machine performance. One of the key difficulties faced by international buyers, especially from regions like Africa, South America, the Middle East, and Europe, is identifying trustworthy suppliers who provide high-quality temperature gauges that meet industry standards. This guide is designed to illuminate various aspects of the purchasing process, covering essential topics such as types of temperature gauges, their applications, supplier vetting criteria, and pricing structures.

By delving into the specific requirements for the Bobcat 331, this comprehensive resource empowers B2B buyers to make informed decisions that align with their operational needs. Whether you are looking for direct replacements or aftermarket options, understanding the nuances of temperature gauge specifications can significantly impact machinery efficiency and longevity. Additionally, the guide will highlight crucial factors to consider when assessing potential suppliers, ensuring that your procurement process is streamlined and effective.

In a market characterized by diverse offerings and varying quality, this guide serves as a strategic tool, equipping you with the knowledge necessary to navigate the complexities of sourcing temperature gauges for the Bobcat 331. Enhance your purchasing strategy and secure the best solutions for your heavy machinery needs with our expert insights and actionable recommendations.

Understanding temperature gauge for 331 bobcat sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM Temperature Sensor | Direct replacement, high reliability | Heavy machinery maintenance, construction equipment | Pros: Guaranteed fit, high quality; Cons: Higher cost compared to aftermarket. |

| Aftermarket Temperature Sensor | Cost-effective, various brands available | Budget-sensitive projects, fleet maintenance | Pros: Lower price, wider availability; Cons: Variable quality, may require additional research. |

| Digital Temperature Gauge | Enhanced accuracy, real-time readings | Precision monitoring in excavators and loaders | Pros: High precision, easy to read; Cons: May need complex installation, higher price. |

| Analog Temperature Gauge | Simple design, mechanical operation | Basic equipment monitoring, older machines | Pros: Easy to use, less prone to electrical issues; Cons: Less accurate than digital, limited features. |

| Multi-functional Gauge | Combines multiple readings (temperature, pressure) | Comprehensive monitoring systems for machinery | Pros: Versatile, space-saving; Cons: More complex, potentially higher installation costs. |

What Are the Characteristics of OEM Temperature Sensors for Bobcat 331?

OEM (Original Equipment Manufacturer) temperature sensors are specifically designed for the Bobcat 331, ensuring a perfect fit and reliable performance. These sensors are known for their durability and precision, making them ideal for heavy machinery maintenance and construction equipment applications. B2B buyers should consider OEM sensors when looking for a guaranteed quality product, although they may come at a higher price point compared to aftermarket options.

How Do Aftermarket Temperature Sensors Differ in Suitability?

Aftermarket temperature sensors offer a cost-effective alternative for B2B buyers, providing a variety of brands and models to choose from. These sensors can be suitable for budget-sensitive projects or fleet maintenance where multiple units are required. However, buyers must conduct thorough research to ensure the quality and compatibility of these sensors, as they can vary significantly in performance.

What Advantages Do Digital Temperature Gauges Provide?

Digital temperature gauges are characterized by their enhanced accuracy and real-time readings, making them particularly beneficial for precision monitoring in excavators and loaders. These gauges often feature easy-to-read displays that allow operators to quickly assess machinery conditions. However, B2B buyers should be aware that installation may be more complex and the initial investment can be higher compared to traditional gauges.

Why Choose Analog Temperature Gauges for Basic Monitoring?

Analog temperature gauges are straightforward mechanical devices that offer a simple design for basic equipment monitoring, especially in older machines. Their ease of use and lower susceptibility to electrical issues make them appealing to some buyers. However, B2B purchasers should note that analog gauges may lack the accuracy and advanced features found in digital models, making them less suitable for applications requiring precise monitoring.

What Are the Benefits of Multi-functional Gauges?

Multi-functional gauges combine several readings, such as temperature and pressure, into one unit, offering a comprehensive monitoring solution for machinery. This versatility can be especially advantageous in environments where space is limited. However, potential buyers should consider the complexity of installation and the possibility of higher costs, which may not be justified for simpler applications.

Key Industrial Applications of temperature gauge for 331 bobcat sale

| Industry/Sector | Specific Application of temperature gauge for 331 bobcat sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Monitoring engine temperature in heavy machinery | Prevents overheating, enhancing equipment lifespan | Ensure compatibility with Bobcat models; focus on durability and accuracy of readings. |

| Agriculture | Temperature regulation in agricultural loaders | Increases operational efficiency and reduces downtime | Look for sensors that withstand harsh environments and offer reliable performance. |

| Mining | Engine temperature management in excavators | Minimizes risk of equipment failure and costly repairs | Consider sensors with robust construction for high-impact settings. |

| Waste Management | Temperature monitoring in waste handling equipment | Enhances safety and operational reliability | Source high-quality sensors that can handle extreme conditions. |

| Logistics and Transportation | Temperature control in material handling equipment | Improves efficiency and reduces maintenance costs | Prioritize sensors that ensure accurate readings under varying loads. |

How is the temperature gauge for Bobcat 331 used in the construction industry?

In the construction sector, the temperature gauge for the Bobcat 331 is crucial for monitoring engine temperatures in heavy machinery. This application helps prevent overheating, which can lead to equipment failure and costly downtime. For international buyers, especially in regions like Africa and South America, sourcing temperature gauges that are compatible with Bobcat models is vital. Durability and accuracy are key considerations, ensuring that the equipment operates effectively in various environmental conditions.

What role does the temperature gauge play in agricultural applications?

In agriculture, the temperature gauge is employed in loaders and excavators to regulate engine temperatures during operation. This ensures that machinery operates efficiently, reducing the risk of overheating and subsequent breakdowns. Buyers from the Middle East and Europe should focus on sourcing gauges that can withstand harsh agricultural environments, including dust and moisture. Reliable performance and ease of installation are also critical factors for these buyers.

How does the temperature gauge enhance mining operations?

In mining operations, the temperature gauge is essential for managing engine temperatures in excavators like the Bobcat 331. By providing real-time temperature readings, it minimizes the risk of equipment failure, which can be costly in terms of repairs and operational delays. For B2B buyers in the mining industry, especially in regions with extreme conditions, sourcing robust temperature sensors that can endure high-impact settings is crucial. Ensuring compatibility with existing machinery is also a significant consideration.

Why is the temperature gauge important in waste management?

The temperature gauge plays a vital role in waste management by monitoring the performance of waste handling equipment. This application enhances safety and operational reliability by preventing overheating, which can lead to equipment malfunctions. Buyers in this sector should prioritize sourcing high-quality temperature gauges that can withstand extreme conditions often found in waste management environments. Durability and accuracy of the sensors are essential for maintaining operational efficiency.

How does the temperature gauge improve logistics and transportation efficiency?

In logistics and transportation, the temperature gauge is utilized to control engine temperatures in material handling equipment. This application improves overall efficiency and reduces maintenance costs by ensuring that machinery operates within optimal temperature ranges. International B2B buyers should focus on sourcing temperature gauges that provide accurate readings under varying loads and conditions. Reliability and ease of integration with existing systems are also key factors for buyers in this sector.

3 Common User Pain Points for ‘temperature gauge for 331 bobcat sale’ & Their Solutions

Scenario 1: Inaccurate Temperature Readings Leading to Equipment Failure

The Problem: A frequent challenge faced by B2B buyers is the inconsistency in temperature readings from the gauge installed on Bobcat 331 models. When the gauge inaccurately indicates overheating, it can lead to premature shutdowns, causing significant downtime and potential damage to the equipment. This not only hampers productivity but also incurs additional costs for repairs and maintenance. Buyers often find themselves frustrated, as they have already invested in what they believed to be reliable components.

The Solution: To mitigate this issue, it is crucial to source high-quality temperature sensors that are specifically designed for the Bobcat 331. Buyers should look for sensors with robust materials that guarantee durability and reliable performance. Before making a purchase, verify that the sensor has undergone thorough testing and comes with a warranty. Once the correct sensor is acquired, it should be installed by a professional to ensure accurate placement and functionality. Regular calibration and maintenance checks can also be instituted to monitor the gauge’s performance, preventing future inaccuracies.

Scenario 2: Difficulty in Finding Compatible Replacement Parts

The Problem: Many international B2B buyers encounter difficulties in sourcing compatible replacement parts for the temperature gauge of the Bobcat 331. This can be especially challenging for those operating in regions with limited access to specialized suppliers. Inaccurate parts can lead to further complications, resulting in wasted time and financial resources. Such challenges can significantly impact operational efficiency, particularly for businesses in sectors like construction and agriculture that rely heavily on their machinery.

The Solution: To streamline the replacement process, buyers should invest time in identifying reputable suppliers that specialize in Bobcat parts. It’s advisable to request detailed specifications, including part numbers like 6718414 or 6718415, to ensure compatibility. Leveraging online platforms that cater specifically to heavy machinery can also yield better results. Furthermore, establishing relationships with local distributors who can facilitate quicker shipping options can significantly reduce lead times for essential parts, ensuring that operations remain uninterrupted.

Scenario 3: Complicated Installation Process Causing Delays

The Problem: Another common pain point is the complicated installation process associated with temperature gauges, which can lead to delays in getting equipment operational. Many buyers may not have the technical expertise to install these components properly, leading to improper setups that could further exacerbate temperature issues. This is particularly detrimental for businesses needing to deploy their machinery quickly to meet project deadlines.

The Solution: To overcome installation challenges, buyers should prioritize sourcing temperature gauges that come with clear installation instructions or consider suppliers that offer installation services. If possible, partnering with local technicians familiar with Bobcat equipment can ease the installation process. Additionally, investing in training for in-house maintenance teams can empower them to handle installations and repairs more efficiently. Regular training sessions can keep staff updated on best practices, significantly reducing the likelihood of installation errors and enhancing overall operational readiness.

Strategic Material Selection Guide for temperature gauge for 331 bobcat sale

When selecting materials for temperature gauges used in Bobcat 331 excavators, it’s crucial to consider properties that affect performance, durability, and compatibility with various operating conditions. Below, we analyze four common materials used in the construction of these gauges, highlighting their key properties, advantages, disadvantages, and implications for international buyers.

What Are the Key Properties of Stainless Steel for Temperature Gauges?

Stainless steel is a popular choice for temperature gauges due to its excellent corrosion resistance and high-temperature tolerance. It typically withstands temperatures up to 800°F (427°C) and pressures of up to 10,000 psi, making it suitable for harsh environments.

Pros: Stainless steel is durable, offers good mechanical properties, and is relatively easy to fabricate. It is also compliant with international standards such as ASTM A240, which is crucial for buyers in Europe and North America.

Cons: The primary drawback is its cost, which is higher than other materials like plastic or aluminum. Its manufacturing complexity can also increase production time and costs.

Impact on Application: Stainless steel is compatible with various media, including water, oils, and gases, making it versatile for different industrial applications.

How Does Aluminum Compare as a Material for Temperature Gauges?

Aluminum is another common material used in temperature gauges, known for its lightweight nature and good thermal conductivity. It typically operates effectively at temperatures up to 400°F (204°C) and can handle moderate pressure.

Pros: The lightweight design of aluminum makes it easier to install and handle. It is also less expensive than stainless steel, which can be advantageous for cost-sensitive projects.

Cons: Aluminum has lower corrosion resistance compared to stainless steel, especially in saline or acidic environments. This can lead to reduced lifespan in certain applications.

Impact on Application: Aluminum is suitable for applications involving non-corrosive media but may not be ideal for environments with aggressive chemicals.

What Are the Benefits of Using Plastic in Temperature Gauges?

Plastic, particularly high-performance polymers like polyamide (Nylon) or polycarbonate, is increasingly used in temperature gauges due to its excellent insulation properties and resistance to chemical corrosion. These materials can typically handle temperatures up to 200°F (93°C).

Pros: The primary advantages of plastic include its low cost and lightweight nature. It is also resistant to many chemicals, making it suitable for specific applications.

Cons: However, plastic has a lower temperature and pressure rating compared to metals, which may limit its use in high-performance applications. Its mechanical strength is also generally lower than that of metals.

Impact on Application: Plastic gauges are ideal for applications where weight savings are critical, but they may not be suitable for high-temperature or high-pressure environments.

Why is Copper Still a Viable Option for Temperature Gauges?

Copper is often used in temperature sensors due to its excellent thermal conductivity and reliability. It can typically handle temperatures up to 400°F (204°C) and moderate pressures.

Pros: Copper’s high thermal conductivity allows for quick response times in temperature measurement, making it effective for dynamic applications. It is also relatively inexpensive.

Cons: Copper is prone to corrosion, particularly in moist environments, which can lead to degradation over time. This may necessitate additional protective coatings or treatments.

Impact on Application: While copper is suitable for many applications, it is essential to consider the operating environment to avoid premature failure.

Summary of Material Selection for Temperature Gauges

| Material | Typical Use Case for temperature gauge for 331 bobcat sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty applications in harsh environments | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Lightweight applications, cost-sensitive projects | Lightweight and cost-effective | Lower corrosion resistance | Medium |

| Plastic | Non-corrosive, low-temperature applications | Low cost and lightweight | Limited temperature and pressure ratings | Low |

| Copper | General-purpose applications with good thermal response | High thermal conductivity | Prone to corrosion | Medium |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, ensuring informed decisions that align with operational requirements and compliance standards across various regions.

In-depth Look: Manufacturing Processes and Quality Assurance for temperature gauge for 331 bobcat sale

What Are the Main Stages in the Manufacturing Process of Temperature Gauges for Bobcat 331?

The manufacturing process of temperature gauges for the Bobcat 331 involves several critical stages that ensure the final product meets the required specifications and quality standards. Understanding these stages can help B2B buyers make informed decisions when sourcing parts.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in manufacturing temperature gauges involves sourcing high-quality materials, typically metals and plastics that can withstand extreme temperatures and environmental conditions. Suppliers often select materials based on specific properties, such as thermal conductivity and resistance to corrosion.

Once selected, materials undergo initial processing, which may include cutting, machining, or molding, depending on the design specifications. This preparation phase is crucial as it sets the foundation for the gauge’s performance and longevity.

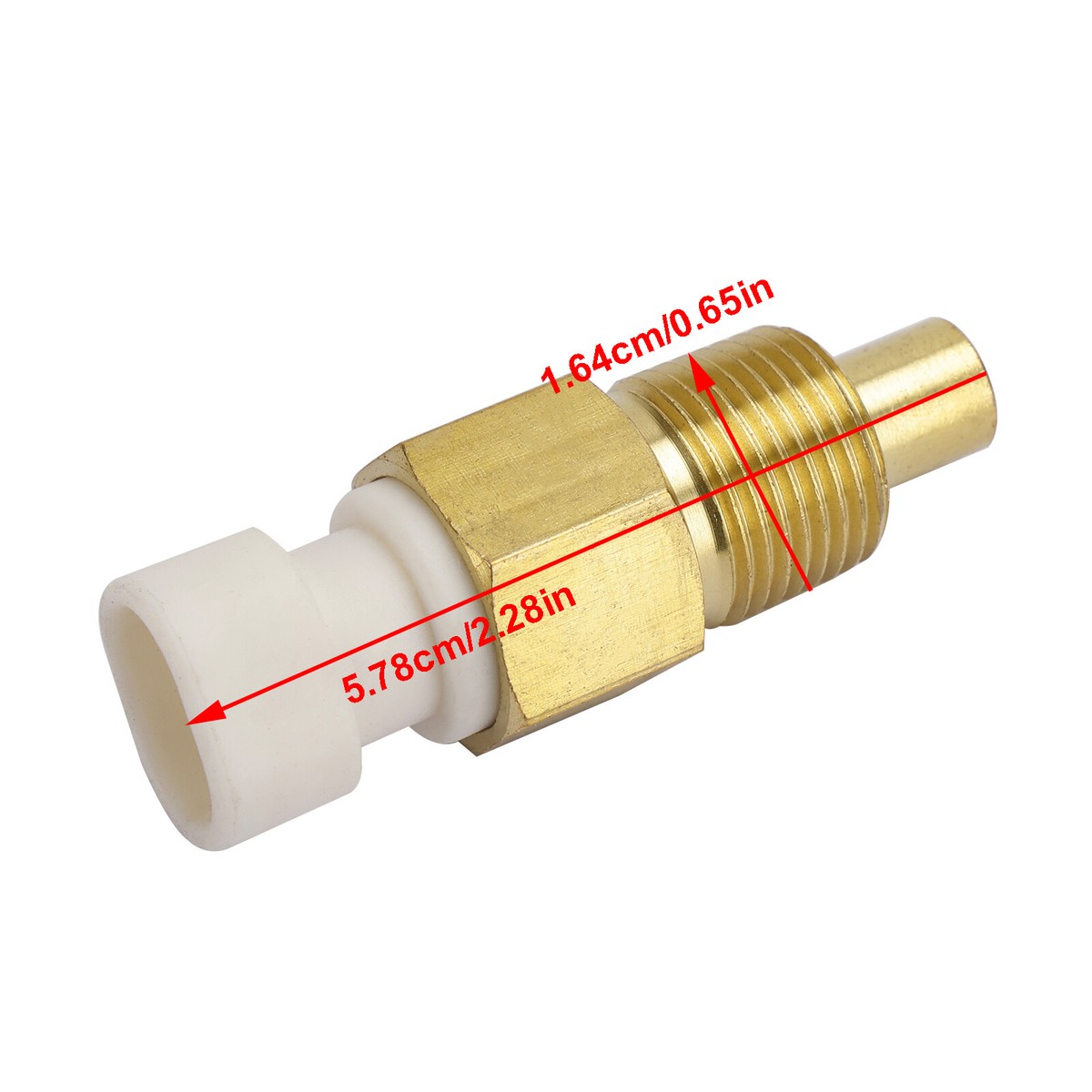

Illustrative image related to temperature gauge for 331 bobcat sale

Forming: What Techniques Are Used to Shape the Components?

The forming stage encompasses several techniques to create the various components of the temperature gauge. Common methods include:

- Machining: Precision machining is employed to ensure that parts fit together seamlessly. CNC (Computer Numerical Control) machines are often used for high accuracy.

- Injection Molding: For plastic components, injection molding is the preferred technique, allowing for mass production with consistent quality.

- Stamping: Metal parts may be stamped into shape, which is both cost-effective and efficient for high-volume production.

These techniques are chosen based on the material properties and the desired specifications of the final product.

Assembly: How Are the Components Brought Together?

After the individual components are formed, the assembly process begins. This typically involves:

- Component Integration: Each part, such as the sensor, housing, and connectors, is carefully assembled to form the complete gauge.

- Soldering and Wiring: Electrical connections are established through soldering and wiring, ensuring that the gauge can accurately transmit temperature readings.

- Calibration: Once assembled, gauges are calibrated to ensure accuracy. This step is critical, as temperature gauges must provide precise readings to avoid operational issues in machinery.

Finishing: What Are the Final Touches That Ensure Quality?

The finishing stage involves several treatments to enhance the durability and functionality of the temperature gauge. Common finishing processes include:

- Surface Treatment: Protective coatings may be applied to resist corrosion and wear. This is particularly important for gauges exposed to harsh environments.

- Quality Checks: Final inspections are conducted to ensure that each gauge meets design specifications and performance standards.

What Quality Assurance Standards Are Relevant to Temperature Gauges?

Quality assurance is a vital aspect of manufacturing temperature gauges, ensuring that products meet both international and industry-specific standards.

Which International Standards Should Buyers Be Aware Of?

For temperature gauges, compliance with international quality standards is essential. Key standards include:

- ISO 9001: This standard focuses on quality management systems and is crucial for manufacturers aiming to enhance customer satisfaction and operational efficiency.

- CE Marking: This indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: For gauges used in oil and gas applications, adherence to American Petroleum Institute (API) standards may also be relevant.

What Quality Control Checkpoints Are Implemented in the Manufacturing Process?

Quality control (QC) is integrated into various stages of the manufacturing process through several checkpoints:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): During production, ongoing inspections are performed to monitor processes and identify any deviations from quality standards.

- Final Quality Control (FQC): Before shipping, finished products undergo rigorous testing to verify their performance and reliability.

What Common Testing Methods Are Used to Ensure Accuracy and Reliability?

Testing methods for temperature gauges include:

- Functional Testing: Gauges are tested under simulated operating conditions to ensure they accurately measure temperature.

- Environmental Testing: This includes subjecting gauges to extreme temperatures and humidity to assess their durability and performance under stress.

- Electrical Testing: Ensures that all electrical connections are sound and that the gauge operates correctly within its specified voltage range.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. Here are some effective strategies:

Illustrative image related to temperature gauge for 331 bobcat sale

- Supplier Audits: Conducting audits allows buyers to assess the supplier’s manufacturing practices, quality management systems, and compliance with relevant standards.

- Requesting Quality Reports: Suppliers should provide documentation of their quality control processes, including test results and certifications.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures and product reliability.

What Are the QC and Certification Nuances for International Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must navigate various nuances in quality control and certification:

- Customs Regulations: Understanding the import regulations and necessary certifications for their specific region is crucial. Buyers should ensure that all products comply with local laws.

- Cultural Considerations: Different regions may have varying expectations regarding quality and service. Buyers should engage with suppliers who understand these cultural nuances.

- Documentation Requirements: Proper documentation is essential for smooth customs clearance and may include certificates of conformity, quality assurance reports, and shipping documents.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures associated with temperature gauges for the Bobcat 331 can significantly enhance the purchasing decisions of B2B buyers. By focusing on material selection, manufacturing techniques, quality standards, and verification methods, buyers can ensure they source reliable, high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘temperature gauge for 331 bobcat sale’

In the competitive landscape of sourcing parts for heavy machinery, particularly the temperature gauge for the Bobcat 331, it’s vital to have a structured approach. This guide serves as a checklist to streamline your procurement process, ensuring you make informed decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the cornerstone of any successful sourcing strategy. Identify the specific model of the temperature gauge required for the Bobcat 331, including part numbers like 6718414 or 6718415. This ensures compatibility and helps avoid costly returns or delays.

Illustrative image related to temperature gauge for 331 bobcat sale

Step 2: Research Reliable Suppliers

Conduct thorough research to identify suppliers with a proven track record. Look for suppliers who specialize in heavy machinery parts and have positive reviews from other B2B buyers. Online platforms, industry forums, and trade shows can provide insights into reputable suppliers.

- Check Supplier Ratings: Use platforms like Alibaba or industry-specific directories to assess ratings and reviews.

- Examine Product Range: Ensure the supplier offers a variety of compatible parts, as this indicates expertise and reliability.

Step 3: Verify Supplier Certifications

Before finalizing any agreements, verify that your potential suppliers hold necessary certifications. Certifications such as ISO 9001 for quality management or specific industry certifications can be indicators of reliability and product quality.

- Request Documentation: Ask for copies of certifications and ensure they are current and relevant to your needs.

- Assess Compliance: Ensure the supplier complies with local and international standards, particularly if you are importing parts.

Step 4: Evaluate Product Quality and Warranty

Quality assurance is critical when sourcing machinery parts. Inquire about the materials used in the temperature gauge and any performance testing conducted prior to shipment. A warranty of at least one year is a good indicator of the supplier’s confidence in their product.

- Ask for Samples: If possible, request a sample gauge to assess quality firsthand.

- Review Warranty Terms: Understand what the warranty covers and the process for claims to protect your investment.

Step 5: Understand Shipping and Delivery Terms

Shipping logistics can significantly impact your procurement timeline. Clarify shipping options, costs, and estimated delivery times to avoid unexpected delays. Ensure the supplier provides tracking information to monitor your order.

- Inquire About Import Duties: Understand any additional costs associated with importing parts into your region, as this can affect your budget.

- Check Shipping Policies: Confirm the supplier’s policy on damaged goods during transit and their process for handling such issues.

Step 6: Negotiate Pricing and Payment Terms

Once you have selected a supplier, negotiate pricing that reflects the market value and your budget constraints. Discuss payment terms that are favorable for your cash flow, such as partial upfront payments or net payment terms.

- Explore Discounts for Bulk Orders: If you plan to purchase multiple gauges or other parts, inquire about volume discounts.

- Consider Secure Payment Methods: Opt for secure payment options like PayPal or letters of credit to mitigate financial risks.

Step 7: Establish a Relationship for Future Needs

Building a long-term relationship with your supplier can lead to better terms and priority service in the future. Regular communication can help you stay informed about new products and promotions that could benefit your operations.

- Schedule Regular Check-Ins: Maintain contact to discuss any upcoming needs or changes in your operations.

- Provide Feedback: Share your experiences with the supplier to foster mutual growth and improvement.

By following this checklist, you can effectively navigate the complexities of sourcing a temperature gauge for the Bobcat 331, ensuring that your procurement process is efficient and aligned with your business goals.

Comprehensive Cost and Pricing Analysis for temperature gauge for 331 bobcat sale Sourcing

What Are the Key Cost Components of Temperature Gauges for Bobcat 331?

When sourcing temperature gauges for Bobcat 331, understanding the cost structure is critical for making informed purchasing decisions. The cost components can be broadly categorized into materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to temperature gauge for 331 bobcat sale

-

Materials: The primary material for temperature sensors typically includes high-quality metals and electronic components that ensure durability and accuracy. The price of these materials can fluctuate based on market conditions and the supplier’s sourcing capabilities.

-

Labor: Labor costs encompass the wages of workers involved in manufacturing, assembly, and quality assurance. Regions with higher labor costs may influence the overall price of the temperature gauge.

-

Manufacturing Overhead: This includes the indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Initial investment in tooling for production can be significant, particularly for customized or high-spec gauges. This cost can be amortized over larger production runs, making it essential to consider volume when evaluating pricing.

-

Quality Control: Ensuring that the temperature gauge meets industry standards requires rigorous testing and QC processes. This adds to the overall cost but is crucial for maintaining reliability and safety.

-

Logistics: The costs associated with transporting the product from the manufacturer to the buyer can vary significantly based on distance, shipping methods, and packaging requirements. International shipments may incur additional tariffs and customs fees.

-

Margin: Suppliers typically include a profit margin that can vary based on the competitive landscape and perceived value of the product. Understanding this margin can provide insights into the pricing strategy of different suppliers.

How Do Price Influencers Affect the Sourcing of Temperature Gauges?

Several factors can influence the price of temperature gauges for Bobcat 331, making it essential for buyers to consider these when sourcing.

-

Volume/MOQ: The minimum order quantity (MOQ) can significantly impact pricing. Bulk orders often lead to lower per-unit costs, incentivizing buyers to purchase larger quantities.

-

Specifications and Customization: Custom specifications, such as specific temperature ranges or unique connectors, can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like ISO or CE) can elevate the price but may offer long-term reliability. Buyers should assess whether the additional cost aligns with their operational needs.

-

Supplier Factors: Supplier reputation, experience, and geographical location can affect pricing. Established suppliers with a history of reliability may charge a premium, but they can also offer better support and warranty services.

-

Incoterms: Understanding the terms of delivery (Incoterms) is crucial for budgeting. Buyers should clarify whether the quoted price includes shipping, insurance, and customs duties to prevent unexpected costs.

What Buyer Tips Can Enhance Cost-Efficiency?

To maximize cost efficiency when sourcing temperature gauges for Bobcat 331, international B2B buyers should consider the following strategies:

-

Negotiation: Engaging in negotiations with suppliers can yield better pricing, especially for large orders. Establishing a strong relationship can also lead to favorable terms in the future.

-

Total Cost of Ownership (TCO): Assessing the total cost of ownership, including maintenance and replacement costs, can provide a clearer picture of value over time. Cheaper initial prices may not always equate to lower overall costs.

-

Pricing Nuances for International Buyers: Different regions may have varying pricing structures due to local economic conditions, import duties, and currency fluctuations. Buyers should conduct thorough market research to identify competitive pricing.

-

Supplier Diversity: Exploring multiple suppliers can lead to better pricing and terms. A diverse supplier base mitigates risks associated with dependency on a single source.

In conclusion, understanding the cost structure, price influencers, and strategic buyer tips can empower B2B buyers in Africa, South America, the Middle East, and Europe to make informed decisions when sourcing temperature gauges for Bobcat 331. Always keep in mind that prices can vary, and it’s advisable to request quotes from multiple suppliers to ensure the best deal.

Alternatives Analysis: Comparing temperature gauge for 331 bobcat sale With Other Solutions

Introduction: Understanding Alternative Solutions for Temperature Monitoring

When it comes to ensuring optimal performance and safety in heavy machinery like the Bobcat 331, accurate temperature monitoring is essential. While the temperature gauge specifically designed for the Bobcat 331 is a reliable solution, B2B buyers may also consider alternative technologies or methods that can offer similar functionality. This analysis compares the ‘temperature gauge for 331 Bobcat sale’ against two viable alternatives: aftermarket temperature sensors and infrared temperature monitoring systems. Understanding these options allows businesses to make informed decisions tailored to their operational needs.

Illustrative image related to temperature gauge for 331 bobcat sale

Comparison Table

| Comparison Aspect | Temperature Gauge For 331 Bobcat Sale | Aftermarket Temperature Sensors | Infrared Temperature Monitoring Systems |

|---|---|---|---|

| Performance | Accurate readings for Bobcat 331; reliable under heavy use | Varies by brand; may not be OEM quality | Non-contact measurement; quick results |

| Cost | Typically priced around $25-50 | Generally cheaper; $10-30 per sensor | Higher upfront costs; $200+ for equipment |

| Ease of Implementation | Direct replacement; straightforward installation | Requires compatibility check; easy to install | Installation can be complex; training may be needed |

| Maintenance | Minimal; occasional checks needed | Varies; generally low-maintenance | Requires regular calibration and upkeep |

| Best Use Case | Ideal for direct replacement in Bobcat 331 | Suitable for budget-conscious buyers seeking OEM alternatives | Best for environments needing rapid temperature checks without contact |

Detailed Breakdown of Alternatives

Aftermarket Temperature Sensors

Aftermarket temperature sensors are designed to fit various models of Bobcat machinery, including the 331. These sensors can provide a cost-effective solution for businesses looking to replace malfunctioning gauges without the expense of original equipment manufacturer (OEM) parts. While they are generally cheaper, the quality can vary significantly between brands. Buyers must ensure compatibility and consider the potential trade-off in reliability and accuracy compared to OEM products.

Infrared Temperature Monitoring Systems

Infrared temperature monitoring systems offer a high-tech alternative by allowing operators to measure temperature without direct contact. This technology is particularly advantageous in environments where safety is a concern, as it can provide rapid readings from a distance. However, the initial investment is considerably higher, and the systems require proper training and calibration to ensure accuracy. For businesses that need quick and frequent temperature assessments across multiple machines or in hazardous environments, infrared systems can be worth the investment despite the complexities involved.

Conclusion: Choosing the Right Temperature Monitoring Solution

Selecting the appropriate temperature monitoring solution for the Bobcat 331 or similar machinery involves evaluating specific operational needs, budget constraints, and desired performance levels. The original temperature gauge offers reliability and ease of installation, making it an excellent choice for businesses prioritizing straightforward replacements. In contrast, aftermarket sensors provide a budget-friendly option but may lack the same quality assurance. For advanced operations that require quick, non-invasive temperature measurements, infrared systems present a modern solution, albeit at a higher cost. By carefully assessing these alternatives, B2B buyers can make informed decisions that enhance their operational efficiency and machinery longevity.

Essential Technical Properties and Trade Terminology for temperature gauge for 331 bobcat sale

What Are the Key Technical Properties of Temperature Gauges for Bobcat 331?

When considering the purchase of a temperature gauge for the Bobcat 331, understanding its technical specifications is vital for ensuring optimal performance and compatibility with your equipment. Here are several critical specs to keep in mind:

-

Material Grade

Temperature gauges are typically made from high-quality materials such as stainless steel or aluminum. The choice of material impacts durability and resistance to corrosion, which is crucial for equipment exposed to harsh environments. For B2B buyers, selecting a gauge with superior material can lead to reduced maintenance costs and longer service life. -

Temperature Range

Each temperature gauge is designed to measure specific temperature ranges. For Bobcat 331, the sensor should effectively operate within the engine’s expected temperature limits, typically from -40°C to +120°C. Understanding the temperature range is essential for preventing equipment failure due to overheating or underperformance. -

Accuracy and Tolerance

Accuracy indicates how closely the gauge readings reflect the actual temperature, while tolerance defines the allowable deviation from this accuracy. A gauge with a tolerance of ±1°C is generally preferred in industrial settings. High accuracy ensures that operators receive reliable data, leading to timely interventions and optimal machine operation. -

Fitment Type

This refers to whether the gauge is a direct replacement or requires modifications for installation. For the Bobcat 331, a direct replacement gauge (like the 6718414 or 6718415) simplifies the installation process, reducing downtime. B2B buyers should prioritize gauges that promise easy fitment to ensure swift operational resumption. -

Electrical Compatibility

It’s important to ensure that the gauge’s electrical specifications match the Bobcat 331’s system requirements, such as voltage and current ratings. Incompatibility can lead to incorrect readings and potential damage to both the gauge and the equipment. -

Warranty and Testing Procedures

A good warranty (typically one year or more) indicates manufacturer confidence in product reliability. Additionally, gauges should undergo rigorous testing before shipment to ensure they meet performance standards. For B2B buyers, these factors mitigate risks associated with faulty products.

What Are Common Trade Terms Relevant to Temperature Gauges for Bobcat 331?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common terms:

Illustrative image related to temperature gauge for 331 bobcat sale

-

OEM (Original Equipment Manufacturer)

This term refers to parts made by the original manufacturer of the equipment. OEM parts are often preferred for their guaranteed compatibility and reliability, which can be essential for maintaining equipment performance. -

MOQ (Minimum Order Quantity)

This represents the smallest number of units a supplier is willing to sell. Understanding MOQ is critical for buyers, as it affects inventory management and purchasing decisions, especially for companies looking to minimize overhead costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting price quotes for specific products or services. This process helps buyers compare options and negotiate better terms, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are pre-defined commercial terms that clarify the responsibilities of buyers and sellers regarding shipping, delivery, and risk management. Familiarity with Incoterms is crucial for international transactions, particularly for buyers in regions such as Africa or South America. -

Lead Time

This term refers to the time taken from placing an order to the receipt of goods. Understanding lead times is essential for planning and ensuring equipment availability, particularly in industries where downtime can result in significant losses. -

Aftermarket Parts

These are replacement parts not made by the OEM but designed to fit and function as the original. While often more cost-effective, buyers should assess the quality and warranty offered to ensure reliability.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the temperature gauge for 331 bobcat sale Sector

What Are the Current Market Dynamics and Key Trends for Temperature Gauges in the Bobcat Sector?

The global market for temperature gauges, specifically for machinery like the Bobcat 331, is driven by several factors, including the increasing demand for construction and agricultural equipment across various regions. In Africa, South America, the Middle East, and Europe, infrastructure development is a significant driver, with countries investing heavily in construction projects. This trend leads to a heightened need for reliable machinery, thus increasing the demand for temperature gauges that ensure operational safety and efficiency.

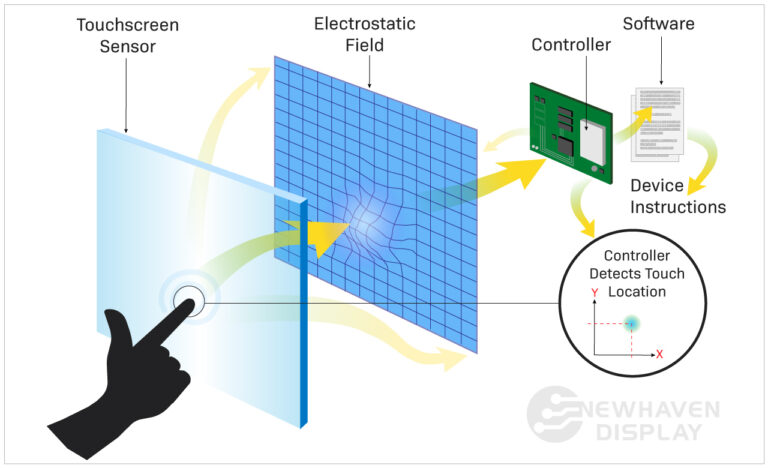

Current B2B technology trends emphasize digitalization and smart equipment. Innovations such as IoT (Internet of Things) are transforming how temperature sensors operate, allowing for real-time data monitoring and predictive maintenance. Buyers are increasingly looking for temperature gauges that can integrate with advanced diagnostic tools to enhance machinery performance and reduce downtime. Furthermore, the rise of e-commerce platforms facilitates easier access for international buyers to source high-quality temperature gauges from reputable manufacturers, streamlining the procurement process.

Emerging sourcing trends also highlight the importance of aftermarket parts. As equipment ages, the need for cost-effective and durable replacement parts, such as temperature sensors, grows. This shift presents opportunities for suppliers who can provide high-quality, compatible components at competitive prices, appealing to budget-conscious buyers in emerging markets.

How Can Sustainability and Ethical Sourcing Impact the Temperature Gauge Market?

Sustainability is becoming a central tenet for B2B buyers in the temperature gauge sector. The environmental impact of manufacturing processes, including resource extraction and waste generation, is under scrutiny. Buyers are increasingly favoring suppliers who demonstrate a commitment to sustainable practices, which may include using recycled materials in their products or implementing energy-efficient manufacturing processes.

Ethical supply chains are also gaining prominence. Buyers are now more concerned about the labor practices and working conditions within the manufacturing facilities of their suppliers. This awareness is prompting companies to seek partners who can provide transparency regarding their sourcing practices and labor policies. Certifications such as ISO 14001 (Environmental Management) and ISO 26000 (Social Responsibility) can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Illustrative image related to temperature gauge for 331 bobcat sale

For temperature gauges specifically, suppliers who can demonstrate the use of ‘green’ materials, such as non-toxic metals or biodegradable components, are likely to attract environmentally-conscious buyers. This trend not only enhances brand reputation but also aligns with the growing global emphasis on corporate responsibility.

What Is the Evolution of Temperature Gauges in Heavy Machinery?

The evolution of temperature gauges in heavy machinery, including the Bobcat series, reflects broader technological advancements in the industrial sector. Initially, temperature measurement relied on basic mechanical gauges, which provided limited accuracy and responsiveness. As machinery became more sophisticated, the demand for more reliable and precise temperature monitoring systems grew.

With the advent of electronic sensors in the late 20th century, temperature gauges began to incorporate advanced features such as digital readouts and automated alerts for overheating. This shift significantly improved operational efficiency and safety, leading to reduced equipment failure rates.

In recent years, the integration of IoT technology has further revolutionized temperature monitoring. Modern gauges can now transmit real-time data to centralized systems, enabling predictive maintenance and reducing the risk of catastrophic failures. This evolution not only enhances the reliability of equipment but also offers significant cost savings for businesses that rely on heavy machinery, making it a critical aspect of sourcing decisions in the B2B landscape.

Illustrative image related to temperature gauge for 331 bobcat sale

Frequently Asked Questions (FAQs) for B2B Buyers of temperature gauge for 331 bobcat sale

-

How do I troubleshoot temperature gauge issues on a Bobcat 331?

To troubleshoot temperature gauge issues, start by verifying that the temperature sensor is functioning correctly. Use an infrared thermometer to check the actual engine temperature and compare it with the gauge reading. If there’s a discrepancy, consider replacing the sensor. Additionally, inspect the wiring for any damage or corrosion that could affect readings. If problems persist, it may be necessary to check the electrical system, as faults in the alternator or battery can influence gauge performance. -

What is the best temperature gauge for a Bobcat 331?

The best temperature gauge for a Bobcat 331 is one that meets OEM specifications for accuracy and durability. Look for gauges that feature a direct replacement part number, such as 6718414 or 6718415, ensuring compatibility with your equipment. It’s also advisable to choose gauges made from high-quality materials, which can withstand the rigors of heavy-duty use. Consider suppliers that offer warranties or guarantees on their products for added peace of mind. -

What should I consider when sourcing temperature gauges for international trade?

When sourcing temperature gauges for international trade, consider factors such as supplier reliability, compliance with international standards, and import regulations specific to your region. Verify the supplier’s certifications and previous customer feedback to assess quality. Additionally, clarify shipping terms, estimated delivery times, and whether the supplier can accommodate customs documentation. Understanding local import duties and taxes is crucial to avoid unexpected costs. -

How can I vet suppliers for temperature gauges for Bobcat equipment?

Vetting suppliers involves several steps: check their business credentials, review customer testimonials, and request references. Look for suppliers who specialize in heavy machinery parts, particularly those with experience in the Bobcat brand. It’s beneficial to assess their response time and customer service quality, as these factors indicate their reliability. Additionally, consider visiting their facility or arranging a video call to discuss your needs and inspect their inventory. -

What is the minimum order quantity (MOQ) for temperature gauges?

The minimum order quantity (MOQ) for temperature gauges can vary significantly between suppliers. Some may offer flexibility with low MOQs for new customers, while others might require bulk orders to lower production costs. It’s essential to discuss your purchasing needs upfront and inquire about potential discounts for larger orders. If you’re a smaller buyer, look for suppliers who can accommodate smaller shipments or offer mixed orders of different parts. -

What payment terms should I expect when purchasing temperature gauges internationally?

Payment terms can vary widely based on the supplier’s policies and your negotiation. Common terms include payment in advance, a deposit with the balance upon shipment, or payment upon delivery. For international transactions, PayPal and letters of credit are often used for added security. Clarify any additional fees associated with currency conversion and ensure that you understand the total costs involved in the transaction, including shipping and customs duties. -

How do I ensure quality assurance for temperature gauges purchased?

To ensure quality assurance, request detailed product specifications and certifications from the supplier. Consider suppliers that perform rigorous quality checks before shipping, including testing temperature gauges under real-world conditions. Ask about warranty options and the return policy in case of defects. If possible, obtain samples for testing prior to placing a bulk order. Regular communication with the supplier throughout the process can also help maintain quality control. -

What logistics considerations should I keep in mind when ordering temperature gauges?

When ordering temperature gauges, consider logistics factors such as shipping methods, lead times, and delivery locations. Verify that the supplier can provide timely shipping to your region, and inquire about tracking options for your shipment. It’s also essential to understand the customs clearance process and ensure that all necessary documentation is provided. If ordering in bulk, discuss the best freight options, whether by air or sea, to minimize costs and delivery times.

Top 7 Temperature Gauge For 331 Bobcat Sale Manufacturers & Suppliers List

1. Bobcat – Coolant Temperature Gauge

Domain: shop.bobcat.com

Registered: 1997 (28 years)

Introduction: Coolant Temperature Gauge, Part Number: 6669663

2. Bobcat – Temperature Gauge Coolant 6669663

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Fits Bobcat Temperature Gauge Coolant 6669663 for models 641, 642, 643, 645, 653, 741, 742, 743. Condition: New. Quantity available: 7. Approximate price: $46.07 AU, $18.00 shipping. 34 sold, 23 watching. Item number: 284021270629. MPN: 6669663, 6658817, 6679027, 6599696, 895771.

3. Bobcat – Temperature Sensor 6718414

Domain: genpartstec.com

Registered: 2022 (3 years)

Introduction: {“Product Name”: “Temperature Sensor 6718414”, “Compatible Models”: [“Bobcat Excavator 325”, “Bobcat Excavator 328”, “Bobcat Excavator 329”, “Bobcat Excavator 331”, “Bobcat Excavator 334”, “Bobcat Excavator 335”, “Bobcat Excavator 337”, “Bobcat Excavator 341”, “Bobcat Loader A300”, “Bobcat Loader A770”, “Bobcat Loader S100”, “Bobcat Loader S130”, “Bobcat Loader S150”, “Bobcat Loader S160”, “Bobcat…

4. Industrial® – Coolant Temperature Gauge for Bobcat®

Domain: stores.allskidsteers.com

Registered: 2012 (13 years)

Introduction: {“part_number”:”6669663″,”product_name”:”Coolant Temperature Gauge for Bobcat®”,”price”:”$26.95″,”shipping_info”:”Ships Today, In Stock, Free Returns, Free Shipping over $99″,”brand”:”Industrial®”,”allskidsteers_number”:”6978″,”fits_bobcat”:”Yes”,”description”:”Gauge Only, Fits Brands: Bobcat®”}

5. YemParts – Temp Sensor for Bobcat Diesel Engines

Domain: yemparts.com

Registered: 2022 (3 years)

Introduction: 6718415 331 773 S160 S175 Temp Sensor for Bobcat 331 773 S160 S175 diesel engines.

6. Mad Hornets – 6718414 Temperature Sensor

Domain: madhornets.com

Registered: 2011 (14 years)

Introduction: 6718414 Temperature Sensor for Bobcat Excavator models 325, 328, 329, 331, 334, 335, 337, 341.

7. Loader Parts Source – Engine Temperature Sensor

Domain: loaderpartssource.com

Registered: 2008 (17 years)

Introduction: {“product_name”:”Engine Temperature Sensor”,”replacement_for”:”Bobcat OEM 6718414″,”compatible_with”:”Mini Excavators”}

Strategic Sourcing Conclusion and Outlook for temperature gauge for 331 bobcat sale

In summary, strategic sourcing for temperature gauges specifically designed for the Bobcat 331 offers international B2B buyers significant opportunities to enhance their equipment performance while reducing downtime and maintenance costs. The reliability of these temperature sensors is critical, particularly in regions like Africa, South America, the Middle East, and Europe, where operational efficiency can be a key competitive advantage. By focusing on high-quality aftermarket parts, buyers can ensure compatibility and performance, as evidenced by the successful use of models like the 6718414 and 6718415.

As the demand for Bobcat machinery continues to grow, sourcing from reputable suppliers who emphasize product testing and warranty offerings will be crucial. Buyers should also be mindful of logistics, customs duties, and shipping timelines to optimize their procurement processes.

Looking ahead, the market for temperature sensors in heavy machinery is poised for expansion, driven by technological advancements and increasing global demand. We encourage B2B buyers to engage with trusted suppliers, leverage bulk purchasing options, and stay informed about emerging technologies to ensure they are well-positioned to meet future challenges and capitalize on new opportunities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to temperature gauge for 331 bobcat sale

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.