How to Source Steam Check Valve Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for steam check valve

In today’s global market, sourcing reliable steam check valves presents a significant challenge for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With the increasing complexity of industrial processes and the need for efficient steam management, selecting the right check valve is crucial for protecting equipment and ensuring operational efficiency. This guide is designed to empower you with comprehensive insights into the various types of steam check valves, their applications, and the factors that influence their performance.

Throughout this guide, we will explore key aspects such as the distinct types of steam check valves—including lift, swing, and disc check valves—and their specific use cases across industries. We will also delve into the essential criteria for vetting suppliers to ensure quality and reliability in your purchases. Cost considerations will be addressed to help you navigate pricing structures and identify the best value options for your operations.

By providing actionable insights and expert knowledge, this guide equips international B2B buyers with the tools necessary to make informed purchasing decisions. Whether you are in Brazil looking for robust solutions for your manufacturing plant or in Saudi Arabia seeking to enhance your steam systems, our comprehensive overview will facilitate your journey towards sourcing the right steam check valves tailored to your unique business needs.

Understanding steam check valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lift Check Valve | Cone-shaped disc, typically used in horizontal pipelines. | Condensate lines, steam traps. | Pros: Simple design, low maintenance. Cons: Limited to small sizes, not suitable for high leakage applications. |

| Swing Check Valve | Flap or disc that swings on hinges; can create turbulence. | Boiler systems, water supply lines. | Pros: Robust design, effective in preventing backflow. Cons: Higher pressure drop, potential for waterhammer. |

| Wafer Check Valve | Compact, designed to fit between flanges; lightweight. | Space-constrained installations. | Pros: Cost-effective, versatile installation options. Cons: Limited size range, may require careful sizing to avoid chatter. |

| Disc Check Valve | Disc moves perpendicular to flow; often spring-loaded. | High-pressure applications, vertical pipes. | Pros: Compact, suitable for various orientations. Cons: Not ideal for pulsating flows, may lead to excessive wear. |

| Piston Check Valve | Utilizes a piston mechanism for damping; suitable for surges. | High-pressure steam systems, dynamic flows. | Pros: Reduces wear, effective in fluctuating conditions. Cons: More complex, potentially higher cost. |

What Are the Key Characteristics of Lift Check Valves?

Lift check valves feature a cone-shaped disc that rises off its seat when fluid flows in the forward direction. This design is best suited for horizontal pipelines and is often used in condensate lines and steam traps. Buyers should consider the valve’s simplicity and low maintenance needs, but be mindful that its size is limited to smaller diameters (typically DN80) and may allow some leakage under reverse flow conditions.

How Do Swing Check Valves Operate and Where Are They Used?

Swing check valves consist of a disc that swings open with forward flow and closes under reverse flow. While they are robust and effective for applications like boiler systems and water supply lines, they can introduce turbulence and a higher pressure drop. B2B buyers should evaluate their application’s flow characteristics and consider the potential for waterhammer when selecting this valve type.

What Makes Wafer Check Valves Ideal for Space-Constrained Installations?

Wafer check valves are compact and designed to fit between flanges, making them a cost-effective solution for installations with limited space. They are versatile but require careful sizing to avoid issues like valve chatter. Buyers should assess their specific application requirements and installation constraints to ensure optimal performance.

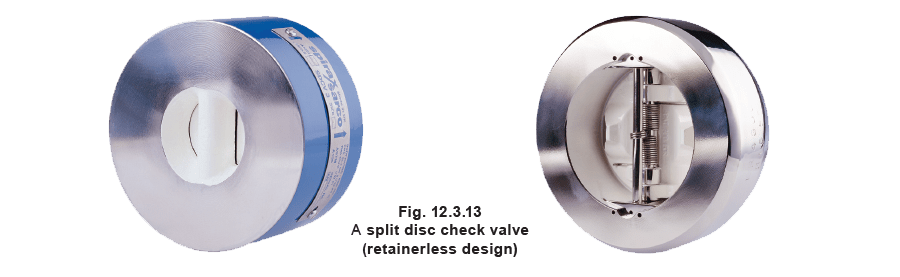

Why Choose Disc Check Valves for High-Pressure Applications?

Disc check valves operate with a spring-loaded disc that moves perpendicularly to the flow direction. They are suitable for high-pressure applications and can be installed in various orientations, including vertical pipelines. However, they are not recommended for pulsating flows, which could lead to excessive wear on components. Buyers should consider the flow conditions and the need for durability when selecting this type.

How Do Piston Check Valves Enhance Performance in Dynamic Flows?

Piston check valves utilize a piston mechanism that provides damping during operation, making them suitable for high-pressure steam systems and applications with dynamic flow changes. This design minimizes wear and enhances longevity but may come with a higher initial cost. B2B buyers should weigh the benefits of reduced wear against the complexity and cost when considering this option for their systems.

Key Industrial Applications of steam check valve

| Industry/Sector | Specific Application of steam check valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Power Generation | Preventing reverse flow in steam lines | Protects turbines and generators from damage and inefficiencies caused by backflow. | Ensure compatibility with high-pressure systems and thermal conditions. |

| Food and Beverage | Steam distribution in processing plants | Maintains consistent steam flow, ensuring efficient cooking and pasteurization processes. | Look for valves that meet food safety standards and can handle varying pressures. |

| Oil and Gas | Steam injection in enhanced oil recovery | Maximizes oil extraction efficiency while protecting equipment from backflow. | Consider materials that withstand corrosive environments and high temperatures. |

| Chemical Manufacturing | Steam heat exchangers | Enhances temperature control in chemical reactions, improving product quality. | Choose valves with precise flow control capabilities to manage chemical processes. |

| Textile Industry | Steam supply in dyeing and finishing | Ensures consistent steam delivery for optimal fabric treatment, reducing waste. | Focus on valves that can handle high flow rates and varying steam pressures. |

How is a steam check valve used in power generation?

In the power generation sector, steam check valves are crucial for preventing reverse flow in steam lines connected to turbines and generators. By ensuring that steam flows in one direction, these valves protect sensitive equipment from damage and inefficiencies caused by backflow. Buyers in this industry should prioritize sourcing valves that can withstand high-pressure environments and extreme thermal conditions, ensuring reliability and longevity in demanding applications.

What role do steam check valves play in the food and beverage industry?

Steam check valves are integral to the food and beverage industry, particularly in processing plants where steam is used for cooking and pasteurization. These valves maintain a consistent steam flow, which is essential for achieving uniform cooking temperatures and ensuring food safety. Buyers should focus on sourcing steam check valves that comply with food safety standards, as well as those capable of handling varying pressure levels to accommodate different processes.

How are steam check valves utilized in oil and gas applications?

In the oil and gas sector, steam check valves are employed in enhanced oil recovery processes where steam is injected into wells to increase oil extraction efficiency. These valves prevent backflow, protecting critical equipment from potential damage and ensuring optimal operational efficiency. Sourcing considerations should include materials that can withstand corrosive environments and high temperatures, as these factors significantly impact the valve’s performance and lifespan.

Why are steam check valves important in chemical manufacturing?

Steam check valves play a vital role in chemical manufacturing, particularly in steam heat exchangers that help control temperatures during chemical reactions. By ensuring proper steam flow, these valves enhance temperature control, which is essential for improving product quality and consistency. Buyers in this sector should seek valves with precise flow control capabilities to effectively manage the dynamics of chemical processes, ensuring safety and efficiency.

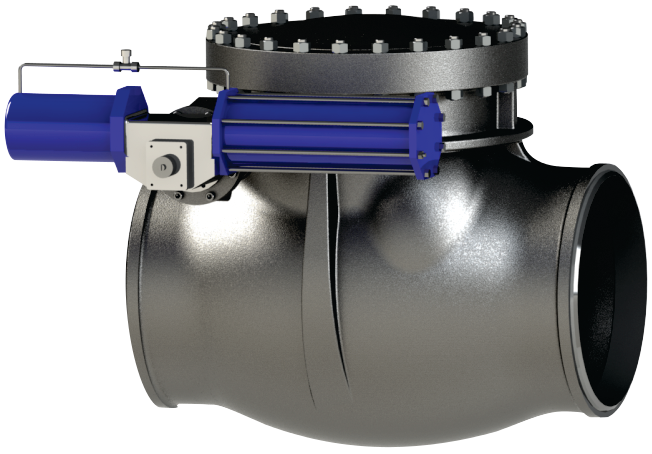

Illustrative image related to steam check valve

How do steam check valves benefit the textile industry?

In the textile industry, steam check valves are used to regulate steam supply in dyeing and finishing processes. These valves ensure a consistent steam delivery, which is critical for optimal fabric treatment and minimizing waste. When sourcing valves for this application, buyers should focus on those that can handle high flow rates and varying steam pressures, as these features are essential for maintaining efficiency and quality in textile production.

3 Common User Pain Points for ‘steam check valve’ & Their Solutions

Scenario 1: High Maintenance Costs Due to Valve Failures

The Problem: Many B2B buyers encounter frequent failures of steam check valves, leading to increased maintenance costs and unplanned downtime. In industries like manufacturing or food processing, where steam is essential for operations, a malfunctioning valve can halt production, resulting in significant financial losses. Buyers often struggle to identify the root cause of these failures, which can stem from improper selection, inadequate sizing, or unsuitable valve design for specific applications.

The Solution: To mitigate these issues, buyers should prioritize thorough valve selection by consulting with manufacturers to ensure they choose the right type of steam check valve for their specific application. Understanding the operational parameters—such as pressure, temperature, and flow characteristics—is crucial. For example, buyers should consider using swing check valves in applications with higher flow rates to minimize turbulence and wear. Additionally, regular maintenance schedules should be established, including inspections and testing, to catch potential issues early. Investing in higher-quality valves with robust materials can also reduce failure rates and enhance longevity, ultimately lowering overall maintenance costs.

Scenario 2: Inefficient Energy Use and Increased Operational Costs

The Problem: Another common pain point for B2B buyers is energy inefficiency caused by poor check valve performance. Steam systems are sensitive, and when check valves do not close properly, steam can escape, leading to wasted energy and higher operational costs. This inefficiency is particularly detrimental in industries where energy costs constitute a significant portion of total expenses, such as in chemical processing or power generation.

The Solution: Buyers can address energy inefficiency by opting for check valves equipped with advanced sealing technology, such as those with spring-assisted mechanisms that ensure a tight closure. Additionally, conducting a system audit to assess the performance of existing check valves can provide insights into energy losses. When replacing valves, it’s essential to choose those with lower pressure drop characteristics to enhance system efficiency. Collaborating with experienced engineers to fine-tune the steam system’s design will also help in selecting the most suitable check valve configurations, ultimately leading to reduced energy consumption and cost savings.

Scenario 3: Issues with Valve Sizing Leading to Flow Problems

The Problem: B2B buyers often face challenges related to the improper sizing of steam check valves, which can lead to flow restrictions or excessive pressure drops. Undersized valves can cause bottlenecks in steam distribution, while oversized valves can result in valve chatter, leading to wear and potential failure. This issue is particularly prevalent in complex systems where multiple valves are installed and the dynamics of steam flow may vary.

The Solution: To solve sizing issues, buyers should utilize flow calculation tools and consult with valve manufacturers to determine the appropriate size based on the specific application requirements. It’s essential to factor in not only the pipe diameter but also the flow rate, pressure, and temperature of the steam. When possible, buyers should conduct a flow analysis to better understand how the check valve will interact within the system. Furthermore, implementing a modular valve design can provide flexibility, allowing for easier adjustments and replacements as system requirements evolve. Regular training for maintenance staff on valve operation and sizing principles can also help prevent these issues from arising in the first place.

Strategic Material Selection Guide for steam check valve

What Are the Key Properties of Common Materials Used in Steam Check Valves?

When selecting materials for steam check valves, several factors must be considered, including temperature and pressure ratings, corrosion resistance, and overall durability. The following analysis covers four common materials used in the manufacturing of steam check valves: stainless steel, carbon steel, bronze, and plastic composites.

How Does Stainless Steel Perform in Steam Check Valve Applications?

Stainless steel is a widely used material for steam check valves due to its excellent corrosion resistance and high-temperature performance. It typically withstands temperatures up to 800°F (427°C) and pressures exceeding 300 psi, making it suitable for high-demand applications. The key advantage of stainless steel is its durability; it resists oxidation and scaling, ensuring a long service life even in harsh environments.

However, stainless steel can be more expensive than other materials, which may impact budget-sensitive projects. Additionally, its manufacturing process can be complex, requiring specialized equipment and techniques. For international buyers, compliance with standards such as ASTM A312 or DIN 17440 is essential, particularly in regions like Europe and the Middle East, where stringent regulations are common.

What Are the Benefits of Using Carbon Steel for Steam Check Valves?

Carbon steel is another popular choice for steam check valves, particularly in applications where cost is a significant concern. It offers good strength and can handle moderate temperatures and pressures (typically up to 400°F or 204°C and 150 psi). Carbon steel valves are generally less expensive than their stainless steel counterparts, making them an attractive option for budget-conscious projects.

However, carbon steel is less resistant to corrosion, which can lead to premature failure in steam applications that involve moisture. Buyers in humid regions, such as parts of Africa and South America, should consider the potential for corrosion and may need to apply protective coatings. Compliance with standards like ASTM A106 or JIS G3452 is also crucial for international buyers.

How Does Bronze Compare as a Material for Steam Check Valves?

Bronze, particularly in the form of brass, is often used in smaller steam check valves due to its excellent corrosion resistance and good thermal conductivity. It can handle temperatures up to 400°F (204°C) and pressures around 150 psi, making it suitable for low to moderate steam applications. The key advantage of bronze is its resistance to galvanic corrosion, which is beneficial in mixed-metal systems.

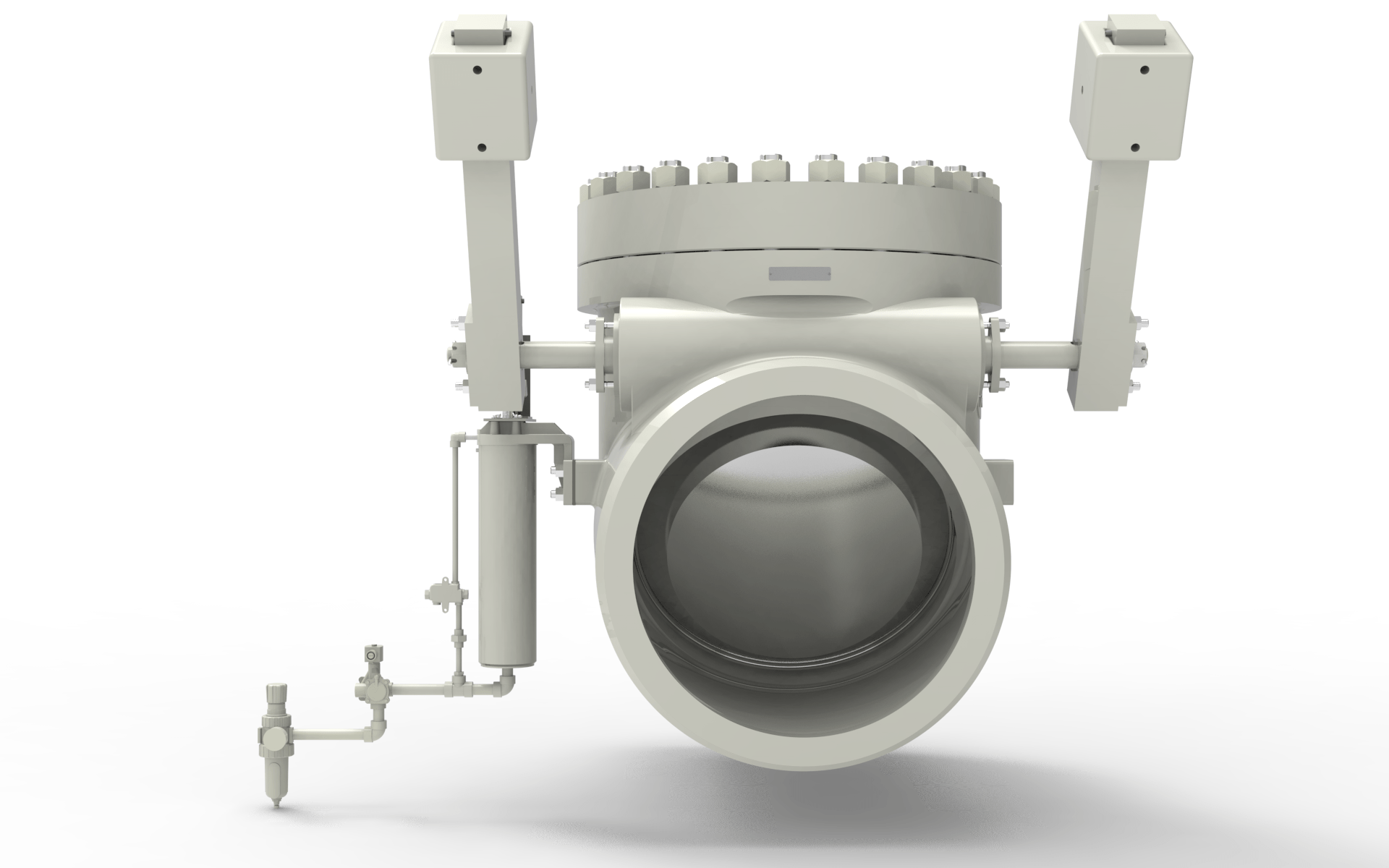

Illustrative image related to steam check valve

On the downside, bronze can be more expensive than carbon steel and may not be suitable for high-pressure applications. Additionally, its mechanical properties can vary significantly based on the alloy used, which may complicate material selection. Buyers in Europe and the Middle East should ensure compliance with standards such as ASTM B62 or DIN 1705, especially when dealing with critical applications.

What Role Do Plastic Composites Play in Steam Check Valve Applications?

Plastic composites, including PVC and CPVC, are increasingly being explored for steam check valves, particularly in specialized applications. These materials can withstand temperatures up to 200°F (93°C) and pressures around 150 psi, making them suitable for low-pressure steam systems. The primary advantage of plastic composites is their resistance to corrosion and chemical attack, which is beneficial in certain environments.

However, plastic composites have limitations regarding temperature and pressure ratings, making them unsuitable for high-demand applications. Additionally, they may not meet the durability requirements for long-term use in steam systems. International buyers should be aware of the relevant standards, such as ASTM D1784 or DIN 8078, to ensure compliance.

Summary Table of Material Selection for Steam Check Valves

| Material | Typical Use Case for steam check valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-pressure steam applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Carbon Steel | Budget-sensitive steam applications | Lower cost | Susceptible to corrosion | Low |

| Bronze | Low to moderate pressure applications | Good thermal conductivity | Variability in mechanical properties | Medium |

| Plastic Composites | Specialized low-pressure applications | Corrosion resistance | Limited temperature and pressure ratings | Low |

By understanding the properties, advantages, and limitations of these materials, B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

Illustrative image related to steam check valve

In-depth Look: Manufacturing Processes and Quality Assurance for steam check valve

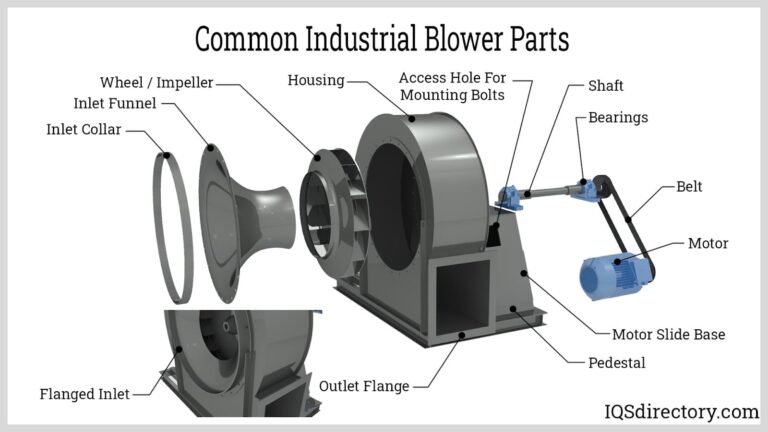

What Are the Key Stages in the Manufacturing Process of Steam Check Valves?

The manufacturing of steam check valves involves several critical stages, each designed to ensure the final product meets stringent performance and safety standards. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Steam Check Valve Production?

The manufacturing process begins with the careful selection and preparation of raw materials. Common materials used for steam check valves include stainless steel, carbon steel, and alloys that can withstand high temperatures and corrosive environments. These materials undergo rigorous testing for quality and composition, ensuring they meet industry specifications.

Once selected, materials are cut and shaped into the required dimensions using techniques such as plasma cutting or laser cutting. This process is crucial for achieving the precise dimensions needed for the valve components, which include the body, disc, and seat.

What Techniques Are Used in Forming Steam Check Valves?

The forming stage involves shaping the cut materials into their final forms. Common techniques include:

-

Forging: This process uses compressive forces to shape the valve body and components, enhancing the material’s strength and durability. Forged components are often more resistant to wear and fatigue.

-

Casting: For certain designs, casting may be employed, where molten metal is poured into molds to create complex shapes. This method allows for intricate designs but may require additional machining to meet specifications.

-

Machining: After forming, components may undergo machining processes such as turning, milling, and drilling to achieve precise tolerances and surface finishes. This step is critical for ensuring proper fit and function.

How Are Steam Check Valves Assembled?

The assembly process is where the individual components are brought together to create the complete steam check valve. This involves:

-

Component Inspection: Each part is inspected for defects before assembly, ensuring that only high-quality components are used.

-

Assembly Procedures: Components are assembled in a clean environment to prevent contamination. This often involves the use of fixtures and jigs to ensure accurate alignment.

-

Sealing and Testing: After assembly, valves are fitted with seals, which may include O-rings or gaskets, to prevent leakage.

-

Initial Function Testing: Valves are tested for basic functionality, ensuring they open and close correctly under simulated conditions.

What Finishing Processes Are Applied to Steam Check Valves?

Finishing processes enhance the valve’s performance and appearance. These may include:

-

Surface Treatments: Techniques such as shot blasting, polishing, or coating are applied to improve corrosion resistance and reduce friction.

-

Heat Treatment: This process alters the material properties to enhance strength and toughness, which is particularly important for valves operating under high temperatures and pressures.

-

Final Inspection: A thorough inspection is performed to check for surface defects, proper assembly, and functionality before packaging.

What Quality Assurance Measures Are Implemented for Steam Check Valves?

Quality assurance (QA) is essential in the manufacturing of steam check valves to ensure compliance with international standards and customer requirements. Key aspects of QA include adherence to various standards, quality checkpoints, and testing methods.

Which International Standards Are Relevant for Steam Check Valve Manufacturing?

Manufacturers must comply with several international standards to ensure quality and safety. Key standards include:

-

ISO 9001: This is a globally recognized standard for quality management systems, focusing on continuous improvement and customer satisfaction.

-

CE Marking: Required for products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

-

API Standards: The American Petroleum Institute (API) sets standards for valves used in the oil and gas industry, ensuring they meet specific performance criteria.

What Are the Key Quality Checkpoints During Production?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure product integrity. These include:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, periodic checks are conducted to monitor processes and ensure compliance with specifications.

-

Final Quality Control (FQC): Before shipping, finished valves undergo comprehensive testing, including pressure testing, to confirm they meet performance standards.

What Common Testing Methods Are Used for Steam Check Valves?

Testing methods are crucial for validating the functionality and safety of steam check valves. Common techniques include:

-

Hydrostatic Testing: Valves are subjected to high-pressure water to check for leaks and ensure structural integrity.

-

Functional Testing: This evaluates the valve’s performance under simulated operational conditions, confirming that it opens and closes correctly.

-

Material Testing: Techniques such as tensile testing and hardness testing assess the mechanical properties of the materials used.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is paramount. Buyers can take several proactive steps:

-

Supplier Audits: Conducting on-site audits allows buyers to assess manufacturing processes, quality control measures, and overall compliance with standards.

-

Requesting Documentation: Buyers should ask for certificates of compliance, quality assurance reports, and test results to verify that products meet required specifications.

-

Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased evaluation of the supplier’s quality control practices and product quality.

-

Understanding Certification Nuances: Buyers should be aware of region-specific requirements and certifications that may affect product acceptance in their markets. For example, valves exported to the EU must meet CE marking requirements, while those intended for the Middle East may need to comply with local standards.

By understanding the manufacturing processes and quality assurance measures associated with steam check valves, B2B buyers can make informed purchasing decisions that align with their operational needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘steam check valve’

To assist international B2B buyers in procuring steam check valves effectively, this guide provides a step-by-step checklist. Following these steps will ensure that you make informed decisions, optimize your procurement process, and secure the right products for your operations.

Step 1: Define Your Technical Specifications

Before engaging suppliers, it is crucial to outline your technical requirements. This includes understanding the specific application of the steam check valve, such as pressure ratings, size, and material compatibility. Clearly defined specifications will help you communicate effectively with suppliers and ensure that you receive suitable products.

- Considerations:

- Operating pressure and temperature ranges.

- Type of fluid the valve will handle (e.g., steam, water, chemicals).

Step 2: Research Different Valve Designs

Familiarize yourself with various steam check valve designs, such as lift, swing, and wafer check valves. Each type has unique advantages and limitations based on application scenarios.

- Key Factors:

- Lift check valves are suitable for horizontal pipelines and low-leakage applications.

- Swing check valves may be better for larger pipelines but can create turbulence.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and quality. Request company profiles, case studies, and references from buyers within your industry or region. This step is essential to avoid pitfalls associated with unverified suppliers.

- What to Look For:

- Supplier certifications (e.g., ISO 9001) that demonstrate adherence to quality standards.

- Customer reviews or testimonials that reflect their experience with the supplier.

Step 4: Request and Compare Quotations

Once you have a shortlist of suppliers, request detailed quotations. Ensure that the quotes include not just pricing but also delivery timelines, warranty information, and terms of service.

- Comparison Criteria:

- Total cost of ownership, including installation and maintenance.

- Lead times and shipping costs, particularly for international procurement.

Step 5: Assess After-Sales Support and Services

Evaluate the after-sales support offered by suppliers. Good after-sales service can significantly impact your operational efficiency in the long run.

- Key Aspects:

- Availability of technical support and training for installation.

- Policies regarding returns, repairs, and warranty claims.

Step 6: Conduct a Risk Assessment

Perform a risk assessment to understand potential supply chain disruptions. This is particularly important when sourcing from international suppliers in regions with varying political and economic stability.

- Considerations:

- Assess the supplier’s location and any geopolitical risks.

- Evaluate the supplier’s financial stability and production capabilities.

Step 7: Finalize Contracts and Order Confirmation

After selecting a supplier, ensure that all terms are clearly outlined in a contract. This should include delivery timelines, payment terms, and quality assurance measures.

- Important Elements:

- Clearly defined responsibilities for both parties.

- Clauses for dispute resolution and penalties for non-compliance.

Following this checklist will help you navigate the complexities of sourcing steam check valves, ensuring that you find reliable suppliers who meet your operational needs while minimizing risk.

Comprehensive Cost and Pricing Analysis for steam check valve Sourcing

What Are the Key Cost Components in Sourcing Steam Check Valves?

When evaluating the cost structure of steam check valves, multiple components come into play. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly impacts pricing. Common materials for steam check valves include brass, stainless steel, and other alloys that can withstand high pressure and temperature. Premium materials may lead to higher costs but also ensure durability and reliability.

-

Labor: Labor costs vary by region and production methods. Automated manufacturing processes can reduce labor costs, while skilled labor is often necessary for quality assurance and assembly in more complex designs.

-

Manufacturing Overhead: This includes costs related to utilities, maintenance, and facility management. Efficient manufacturing processes can lower overhead costs, contributing to a more competitive price.

-

Tooling: The initial investment in tooling can be substantial, especially for custom designs. However, this cost is often amortized over large production runs, leading to lower per-unit costs as volume increases.

-

Quality Control: Quality assurance processes are critical, especially for high-stakes applications like steam systems. Rigorous QC can add to costs but ultimately protects against failures and warranty claims.

-

Logistics: Shipping and handling costs can vary based on location, mode of transport, and Incoterms. International shipping may involve customs fees and tariffs, impacting the overall cost.

-

Margin: Suppliers typically add a margin to cover their costs and generate profit. This margin can vary widely depending on the supplier’s position in the market and the competitive landscape.

How Do Volume and Customization Influence Steam Check Valve Pricing?

Pricing is heavily influenced by volume and customization. Bulk orders often lead to significant discounts, as suppliers can optimize production and reduce per-unit costs. Minimum Order Quantities (MOQs) can vary, with some suppliers offering lower MOQs for standard models but requiring higher quantities for custom designs.

Customization can lead to increased costs due to additional engineering, tooling, and material considerations. Buyers should clearly define specifications and desired features early in negotiations to avoid unexpected costs later in the process.

What Quality and Certification Factors Should Buyers Consider?

Quality certifications, such as ISO and API standards, can affect pricing. Suppliers that meet stringent quality benchmarks may charge higher prices but offer better reliability and performance. Buyers should weigh the cost against the potential risks of using lower-quality products, particularly in critical applications where valve failure could lead to significant downtime or safety hazards.

How Can International Buyers Optimize Their Sourcing Strategy?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiation: Engage in thorough negotiations to leverage volume discounts and favorable payment terms. Understand the supplier’s cost structure to negotiate effectively.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, operational efficiency, and potential downtime when assessing the overall cost of ownership.

-

Understanding Pricing Nuances: Be aware of price fluctuations due to currency exchange rates, local tariffs, and market demand. Establish relationships with multiple suppliers to mitigate risks associated with price volatility.

-

Selecting the Right Incoterms: Choose Incoterms that align with your logistics strategy. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact your total landed cost.

Are Indicative Prices Available for Steam Check Valves?

While indicative prices can provide a ballpark figure, they should be treated cautiously. Pricing varies widely based on the factors outlined above, including material selection, design complexity, and supplier location. Engaging directly with suppliers for quotes based on specific requirements is the best approach for accurate pricing information.

Alternatives Analysis: Comparing steam check valve With Other Solutions

Understanding Alternatives to Steam Check Valves

In industrial applications, selecting the right valve is critical for ensuring efficiency and safety. Steam check valves serve a specific purpose in preventing reverse flow in steam systems, but other solutions can also achieve similar objectives. This section compares steam check valves against two viable alternatives: isolation valves and backflow preventers, providing insights to help B2B buyers make informed decisions.

| Comparison Aspect | Steam Check Valve | Isolation Valve | Backflow Preventer |

|---|---|---|---|

| Performance | High; allows flow in one direction, preventing reverse flow effectively. | Excellent; completely stops flow in both directions, ideal for maintenance. | Good; prevents backflow but may allow some leakage under certain conditions. |

| Cost | Moderate; prices vary by size and material. | Generally higher due to complexity and application versatility. | Lower than steam check valves; cost-effective for basic applications. |

| Ease of Implementation | Easy; straightforward installation in standard piping systems. | Moderate; may require more space and specific orientation for installation. | Easy; often installed in-line with minimal modifications needed. |

| Maintenance | Low; requires minimal upkeep, but performance can degrade over time. | Moderate; may need regular inspection and maintenance to ensure functionality. | Low; typically requires infrequent maintenance unless subjected to extreme conditions. |

| Best Use Case | Ideal for steam systems where reverse flow must be strictly controlled. | Best for applications requiring isolation for maintenance or safety during repairs. | Suitable for water systems where backflow prevention is critical, but steam applications should be avoided. |

Pros and Cons of Alternatives

Isolation Valves

Isolation valves are designed to stop the flow of fluid completely, making them ideal for maintenance and safety. Their robust design allows for complete shut-off in both directions, providing full control over the system. However, they can be more expensive and require more space for installation. Additionally, their operation involves manual intervention, making them less suitable for applications that require automatic flow management.

Backflow Preventers

Backflow preventers are commonly used in water systems to prevent contamination from reverse flow. They are generally more cost-effective than steam check valves and are easy to install. However, they may allow some minor leakage under specific conditions, which could pose a risk in sensitive applications. Backflow preventers are not recommended for steam systems due to their inability to handle high temperatures and pressures effectively.

Illustrative image related to steam check valve

Making the Right Choice for Your Application

When selecting between a steam check valve and its alternatives, B2B buyers must consider specific application requirements. If the primary concern is preventing reverse flow in steam systems, a steam check valve is the best choice due to its high performance and reliability. For applications requiring frequent maintenance, isolation valves offer the necessary control but at a higher cost and complexity. Conversely, backflow preventers are a suitable option for less critical applications, particularly in water systems, where budget constraints are a priority.

Ultimately, understanding the operational environment, maintenance capabilities, and budget constraints will guide buyers in making the most appropriate selection tailored to their needs.

Essential Technical Properties and Trade Terminology for steam check valve

What Are the Key Technical Properties of a Steam Check Valve?

When selecting a steam check valve, understanding its technical specifications is crucial for ensuring optimal performance and reliability in various applications. Here are some essential properties to consider:

1. Material Grade

The material used in the construction of steam check valves, such as stainless steel, carbon steel, or bronze, significantly affects durability and resistance to corrosion. Stainless steel (e.g., ASTM A351 CF8M) is often preferred for high-temperature steam applications due to its strength and resistance to oxidation. Selecting the appropriate material ensures the valve can withstand the harsh conditions typical of steam systems, reducing maintenance costs and extending service life.

2. Pressure Rating

Pressure rating, typically measured in pounds per square inch (psi), indicates the maximum pressure the valve can handle without failure. Common ratings include ANSI Class 150, 300, and 600. Understanding the pressure requirements of your system is essential to prevent valve failure, which can lead to costly downtimes and safety hazards.

Illustrative image related to steam check valve

3. Temperature Range

The temperature range specifies the operational limits of the valve, which is particularly critical in steam applications where temperatures can exceed 200°C (392°F). Valves must be selected based on their ability to perform reliably within the specific temperature range of the system. This ensures that the valve operates effectively without risk of thermal expansion or material degradation.

4. Flow Coefficient (Cv)

The flow coefficient, or Cv, measures the valve’s capacity to allow fluid flow. A higher Cv value indicates a higher flow rate for a given pressure drop. B2B buyers should evaluate the Cv rating to ensure that the valve meets the flow requirements of their application, preventing bottlenecks and ensuring efficient operation.

5. End Connection Type

The end connection type (e.g., flanged, threaded, or welded) determines how the valve will integrate into existing pipeline systems. It is vital to match the valve’s end connection with the system’s design to ensure proper sealing and functionality. This consideration minimizes installation challenges and potential leaks.

Illustrative image related to steam check valve

6. Size and Dimensions

The size of the steam check valve, typically expressed in nominal pipe diameter (DN), must align with the piping system. An oversized or undersized valve can lead to flow issues, pressure drops, and inefficient operation. Proper sizing is essential for maintaining system integrity and performance.

What Are the Common Trade Terms Associated with Steam Check Valves?

Understanding industry terminology is crucial for effective communication and negotiation in B2B transactions. Here are some common terms related to steam check valves:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products used in another company’s end product. In the context of steam check valves, it indicates the supplier whose valves are integrated into larger systems or equipment. Partnering with reputable OEMs ensures quality and compliance with industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for B2B buyers to plan inventory and manage procurement budgets effectively. Suppliers often set MOQs to ensure profitability and minimize production costs.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products or services. When seeking steam check valves, sending an RFQ helps buyers obtain detailed proposals, allowing for informed decision-making based on price, delivery time, and terms.

4. Incoterms (International Commercial Terms)

Incoterms are international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B transactions to clarify who bears the risk and costs associated with transporting steam check valves.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. For steam check valves, understanding lead times helps buyers plan project timelines and manage expectations regarding supply chain delays.

6. Certification

Certification indicates that the valve meets specific industry standards, such as ASME or API. Certifications provide assurance to buyers regarding the quality and safety of the valves, making them critical in regulated industries like oil and gas or power generation.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions, ensuring that the steam check valves selected are suitable for their specific applications and comply with industry standards.

Navigating Market Dynamics and Sourcing Trends in the steam check valve Sector

What Are the Current Market Dynamics and Key Trends in the Steam Check Valve Sector?

The steam check valve market is witnessing significant growth, driven by increased industrialization and the rising demand for efficient steam management systems across various sectors. Key drivers include the expansion of the oil and gas sector, power generation, and manufacturing industries, particularly in regions such as Africa, South America, the Middle East, and Europe. Emerging technologies, including IoT and smart valve systems, are shaping sourcing trends, offering enhanced monitoring capabilities and operational efficiency. International B2B buyers are increasingly seeking valves that integrate with these advanced technologies, leading to a shift toward suppliers that can provide not only products but also innovative solutions.

Illustrative image related to steam check valve

Another notable trend is the growing emphasis on product customization and flexibility. Buyers are looking for steam check valves that can be tailored to specific operational conditions, such as varying temperatures and pressures. This trend is particularly pronounced in industries with unique requirements, such as chemical processing and food production. Additionally, the importance of rapid delivery times and responsive customer service is becoming a key factor in supplier selection. In competitive markets like Brazil and Saudi Arabia, the ability to provide timely support and maintain stock levels can significantly influence purchasing decisions.

How Does Sustainability and Ethical Sourcing Impact the Steam Check Valve Market?

The environmental impact of manufacturing processes is a growing concern for B2B buyers in the steam check valve sector. As industries strive to reduce their carbon footprints, there is an increasing demand for sustainably sourced materials and eco-friendly manufacturing practices. This trend is particularly relevant in regions where regulatory frameworks are tightening, such as Europe, where compliance with stringent environmental standards is mandatory.

Ethical sourcing is also becoming a critical factor for buyers. Companies are increasingly scrutinizing their supply chains to ensure that their suppliers adhere to ethical labor practices and environmentally responsible methods. Certifications such as ISO 14001 for environmental management systems and ISO 45001 for occupational health and safety are gaining importance in supplier evaluations. Buyers are more inclined to partner with manufacturers who can demonstrate commitment to sustainability through transparent reporting and recognized certifications. As a result, suppliers that invest in sustainable practices and materials—such as recycled metals or biodegradable components—are likely to gain a competitive edge in the marketplace.

Illustrative image related to steam check valve

What Is the Historical Context of Steam Check Valves and Its Relevance to Today’s Buyers?

The steam check valve has evolved significantly since its inception, adapting to the changing needs of industrial applications. Initially designed to prevent reverse flow in steam systems, modern steam check valves now incorporate advanced materials and design features that enhance performance and reliability. The introduction of various types—such as lift, swing, and wafer check valves—has allowed for greater application flexibility, catering to diverse operational requirements.

In today’s context, understanding this evolution is essential for B2B buyers. The historical advancements in valve technology not only reflect improvements in efficiency and safety but also underscore the importance of selecting the right valve type for specific applications. Buyers can benefit from this knowledge by aligning their procurement strategies with the latest innovations in valve technology, ensuring they invest in products that meet both current and future operational challenges. As industries continue to evolve, the historical context of steam check valves serves as a foundation for informed decision-making in sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of steam check valve

-

How do I solve issues with reverse flow in my steam system?

To prevent reverse flow in your steam system, installing a steam check valve is essential. These valves are designed to allow flow in one direction while preventing backflow, thereby protecting sensitive equipment such as flowmeters and control valves. When selecting a valve, consider the specific application, such as whether you need a lift, swing, or disc check valve, as each has unique benefits. Additionally, ensure that the valve is correctly sized to avoid issues like water hammer or excessive pressure drop. -

What is the best type of steam check valve for high-pressure systems?

For high-pressure steam systems, lift check valves are often recommended due to their robust design and ability to handle substantial pressure. They automatically open in response to forward flow, minimizing the risk of leakage under reverse conditions. However, if space is a constraint, consider a wafer check valve, which can fit between flanges and is suitable for high-pressure applications. Always consult with a supplier to ensure the valve meets your specific pressure requirements and operational conditions. -

What factors should I consider when selecting a supplier for steam check valves?

When selecting a supplier, assess their experience in the industry, especially in your region, such as Africa, South America, or Europe. Check their certifications and compliance with international standards, as these are critical for quality assurance. Additionally, inquire about their manufacturing capabilities, lead times, and customer support services. A supplier with a robust logistics network can also ensure timely delivery, which is essential for maintaining your operations. -

What are typical minimum order quantities (MOQs) for steam check valves?

Minimum order quantities can vary significantly among suppliers based on their production capacities and the specific type of steam check valve. Generally, MOQs can range from 10 to 100 units. However, some manufacturers may accommodate smaller orders, especially if you are a new customer or require a prototype for testing. It’s advisable to discuss your needs with potential suppliers to negotiate MOQs that align with your project requirements. -

Can steam check valves be customized for specific applications?

Yes, many manufacturers offer customization options for steam check valves to suit specific operational needs. Customizations may include alterations in size, material, pressure ratings, and design features such as spring tension or sealing options. When considering customization, clearly communicate your requirements to the supplier, including the application environment and any relevant industry standards. This ensures that the final product is tailored to your operational needs. -

What payment terms are commonly offered by suppliers of steam check valves?

Payment terms can vary widely based on the supplier’s policies and your relationship with them. Common arrangements include upfront payments, partial payments upon order confirmation, and balance payments prior to shipment. For larger orders, suppliers may offer credit terms or payment plans. Always clarify payment terms before finalizing an order to avoid misunderstandings and ensure smooth transactions. -

How can I ensure quality assurance for my steam check valves?

To ensure quality assurance, request detailed documentation from the supplier, including material certifications, testing results, and compliance with relevant industry standards. Many reputable manufacturers conduct rigorous quality checks throughout the production process. Additionally, consider ordering samples or conducting on-site inspections, if feasible, to verify that the products meet your specifications and quality expectations. -

What logistics considerations should I be aware of when importing steam check valves?

When importing steam check valves, consider shipping methods, customs regulations, and import duties specific to your country. Engage a logistics partner experienced in international trade to navigate the complexities of shipping and customs clearance. Additionally, ensure that the supplier provides proper documentation, such as bills of lading and certificates of origin, to facilitate smooth customs processing and avoid delays in delivery.

Top 2 Steam Check Valve Manufacturers & Suppliers List

1. Keckley – Wafer Silent Check Valves

Domain: keckley.com

Registered: 1998 (27 years)

Introduction: Keckley wafer silent check valves are designed for liquid applications only. They feature a short design with low cracking pressure, and the spring automatically closes the disc at zero flow to prevent flow reversal and water hammer. The disc is fully guided at the top and bottom to prevent binding and cocking, opening with less than 1/2 pound per square inch pressure. The valves have a minimum op…

2. Ferguson – Check Valves

Domain: ferguson.com

Registered: 1999 (26 years)

Introduction: This company, Ferguson – Check Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for steam check valve

What Are the Key Takeaways for Sourcing Steam Check Valves?

In conclusion, the effective sourcing of steam check valves is pivotal for enhancing operational efficiency and safeguarding critical infrastructure across various industries. Understanding the nuances of different check valve types—such as lift, swing, and disc check valves—allows B2B buyers to make informed decisions tailored to their specific applications and environments. Key considerations include valve design, installation requirements, and maintenance needs, all of which can significantly impact both performance and longevity.

Illustrative image related to steam check valve

How Can Strategic Sourcing Benefit International Buyers?

Strategic sourcing not only optimizes costs but also ensures the procurement of high-quality components essential for seamless operations. By establishing strong partnerships with reliable suppliers, businesses can mitigate risks associated with reverse flow and pressure surges, ultimately enhancing process reliability. Moreover, leveraging regional suppliers can provide logistical advantages, reduce lead times, and support local economies.

What’s Next for B2B Buyers in Emerging Markets?

As global industries continue to evolve, the demand for innovative and reliable steam check valve solutions will only grow. International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should actively seek out suppliers who demonstrate a commitment to quality and sustainability. Embrace the future of steam management by prioritizing strategic sourcing today—your operational success depends on it.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.