How to Source Square Pvc Pipe Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for square pvc pipe

Navigating the complexities of the global market for square PVC pipe presents a unique challenge for B2B buyers, particularly those sourcing materials for construction and industrial applications. The increasing demand for durable, lightweight, and cost-effective solutions has made square PVC pipe a popular choice across diverse industries. However, with a multitude of suppliers and varying quality standards, making informed purchasing decisions can be daunting.

This comprehensive guide serves as a vital resource for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including key markets like Germany and Vietnam. Within these pages, we explore the various types of square PVC pipes available, their diverse applications—from fencing and framing to plumbing and electrical conduits—and critical insights on supplier vetting processes. Furthermore, we provide an in-depth analysis of cost factors, ensuring you can effectively budget for your projects.

By equipping you with actionable insights and expert guidance, this guide empowers you to navigate the global market with confidence. Whether you are a seasoned procurement officer or a business owner looking to expand your material sourcing strategies, understanding the intricacies of square PVC pipe will enhance your purchasing decisions and optimize your supply chain.

Understanding square pvc pipe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rigid PVC Square Pipe | Solid structure, high durability | Fencing, structural support | Pros: Weather-resistant, low maintenance. Cons: Limited flexibility, heavier than alternatives. |

| Schedule 40 PVC Pipe | Standard wall thickness, versatile sizing | Plumbing, electrical conduits | Pros: Widely available, cost-effective. Cons: Can be less durable under extreme conditions. |

| Foam Core PVC Pipe | Lightweight, insulating properties | Signage, indoor applications | Pros: Easy to cut and shape, good for printing. Cons: Less structural integrity, not suitable for heavy loads. |

| Clear PVC Square Tube | Transparent, aesthetic appeal | Display cases, lighting fixtures | Pros: Visual access to contents, UV resistant. Cons: More expensive, scratches easily. |

| Cellular PVC Pipe | Hollow core, lightweight | Decking, outdoor furniture | Pros: Resistant to moisture and insects, easy installation. Cons: May not bear heavy loads. |

What Are the Characteristics of Rigid PVC Square Pipe?

Rigid PVC square pipes are known for their solid structure and high durability, making them an ideal choice for applications requiring strength and stability, such as fencing and structural support. Their weather-resistant properties reduce maintenance needs, making them suitable for outdoor environments. However, buyers should consider that while they offer excellent durability, they are heavier than other types, which may affect transportation and installation.

How Does Schedule 40 PVC Pipe Stand Out in the Market?

Schedule 40 PVC pipes are characterized by their standard wall thickness and versatility in sizing, making them a popular choice in plumbing and electrical applications. This type is widely available and generally cost-effective, appealing to a broad range of industries. However, businesses should be cautious, as these pipes may not withstand extreme environmental conditions as well as thicker alternatives, potentially leading to increased costs over time.

What Are the Advantages of Using Foam Core PVC Pipe?

Foam core PVC pipes are lightweight and possess insulating properties, making them ideal for indoor applications such as signage and displays. Their ease of cutting and shaping allows for versatile design options, particularly for printed materials. However, businesses should be aware that foam core pipes lack the structural integrity of solid options, making them unsuitable for heavy load-bearing applications.

Why Choose Clear PVC Square Tubes for Your Projects?

Clear PVC square tubes offer a unique aesthetic appeal due to their transparency, making them suitable for display cases and lighting fixtures. They provide visual access to contents and are UV resistant, which is beneficial for outdoor or sun-exposed applications. On the downside, clear PVC is generally more expensive than opaque options and can be prone to scratches, which may affect visual quality over time.

What Makes Cellular PVC Pipe a Practical Choice for Outdoor Use?

Cellular PVC pipes feature a hollow core design that makes them lightweight and easy to install, particularly in outdoor applications like decking and furniture. Their resistance to moisture and insects enhances their longevity in outdoor settings. However, businesses should consider their load-bearing limitations, as they may not be suitable for applications requiring significant structural support.

Key Industrial Applications of square pvc pipe

| Industry/Sector | Specific Application of Square PVC Pipe | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural Support in Framing | Lightweight yet durable, reducing transportation costs and labor. | Ensure compliance with local building codes and standards. |

| Agriculture | Irrigation Systems | Resistant to corrosion and chemicals, enhancing longevity in harsh environments. | Consider UV resistance and flexibility for varying climates. |

| Manufacturing | Conveyor Systems | Provides smooth transport of goods, minimizing wear and tear. | Look for custom sizes and fittings to match existing systems. |

| Telecommunications | Cable Management Systems | Protects and organizes cables, ensuring safety and ease of access. | Evaluate the pipe’s electrical insulation properties. |

| Retail and Commercial | Display Fixtures | Offers a professional appearance while being cost-effective. | Focus on aesthetics and customization options for branding. |

How is Square PVC Pipe Used in Construction Projects?

In the construction industry, square PVC pipes serve as structural support in framing applications. Their lightweight yet durable nature allows for easier handling and installation, reducing labor costs and transportation expenses. Additionally, these pipes are resistant to moisture and pests, making them ideal for both indoor and outdoor projects. International buyers, particularly in regions like Africa and the Middle East, should ensure that the materials comply with local building codes and standards to avoid costly reworks.

What Role Does Square PVC Pipe Play in Agricultural Irrigation Systems?

Square PVC pipes are increasingly used in agricultural irrigation systems due to their resistance to corrosion and chemicals. These properties enhance the longevity of irrigation setups, which is critical in regions with harsh climates, such as parts of South America and Africa. Additionally, their lightweight design simplifies installation and maintenance. Buyers should consider UV resistance and flexibility to ensure the pipes can withstand varying environmental conditions, thus maximizing their investment.

How Does Square PVC Pipe Enhance Manufacturing Processes?

In manufacturing, square PVC pipes are frequently utilized in conveyor systems to facilitate the smooth transport of goods. Their robust construction minimizes wear and tear, leading to lower maintenance costs and increased operational efficiency. For international buyers, particularly in Europe and Asia, sourcing options should include custom sizes and fittings to ensure compatibility with existing systems, thereby enhancing productivity.

Why is Square PVC Pipe Essential for Telecommunications Cable Management?

Square PVC pipes are vital in telecommunications for organizing and protecting cables. They provide a safe conduit that ensures the integrity of sensitive wiring while allowing for easy access during maintenance. This is particularly beneficial in regions experiencing rapid technological growth, such as parts of the Middle East and Asia. Buyers should evaluate the pipe’s electrical insulation properties to ensure compliance with safety standards, thus safeguarding their investments.

How Can Retail and Commercial Sectors Benefit from Square PVC Pipe?

In the retail and commercial sectors, square PVC pipes are often used to create display fixtures that are both functional and visually appealing. Their cost-effectiveness allows businesses to invest in high-quality displays without exceeding budgets. For international buyers, focusing on aesthetics and customization options can enhance branding efforts, making it essential to partner with suppliers who offer tailored solutions that meet specific design requirements.

3 Common User Pain Points for ‘square pvc pipe’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Square PVC Pipe

The Problem: B2B buyers often face challenges when sourcing square PVC pipe that meets specific quality standards and regulations. This is particularly true for international buyers who must navigate varying manufacturing standards, certifications, and material specifications across different regions. Inadequate sourcing can lead to project delays, increased costs, and even safety issues if the materials do not meet the required strength or durability for their intended applications.

The Solution: To effectively source quality square PVC pipe, buyers should establish relationships with reputable suppliers who have a proven track record of compliance with international standards, such as ISO or ASTM certifications. Conducting thorough due diligence on suppliers can involve requesting product samples, reviewing test reports, and verifying certifications. Additionally, utilizing online marketplaces that specialize in industrial materials can provide access to a broader range of suppliers, allowing buyers to compare quality and pricing. Engaging in direct communication with suppliers about specific project requirements can also help ensure that the materials sourced will meet the necessary criteria for performance and safety.

Scenario 2: Incompatibility with Existing Infrastructure

The Problem: A common issue arises when B2B buyers discover that the square PVC pipe they have purchased is incompatible with existing infrastructure or fittings. This can occur due to variations in dimensions, wall thickness, or connection types, leading to costly modifications or even complete project rework. Such incompatibilities not only disrupt timelines but can also strain budgets and resources.

The Solution: To mitigate the risk of incompatibility, buyers should conduct a comprehensive review of their current infrastructure before making a purchase. This involves measuring existing pipes and fittings to ensure compatibility with the new square PVC pipe. Utilizing industry-standard specifications, such as those outlined by the ASTM or ANSI, can provide a reliable framework for ensuring that all components will fit together seamlessly. Furthermore, buyers should consider investing in customized solutions or consult with suppliers who offer tailored products that can meet specific project needs, reducing the likelihood of future compatibility issues.

Scenario 3: Limited Knowledge on Installation Techniques

The Problem: Installation challenges can arise when B2B buyers lack knowledge about the proper techniques for working with square PVC pipe. This can result in improper fittings, leaks, or structural failures that compromise the integrity of the entire system. Newer teams may particularly struggle with understanding the nuances of PVC pipe installation, leading to errors that can be time-consuming and costly to rectify.

The Solution: To overcome installation challenges, buyers should prioritize training and resources for their teams. This could involve partnering with suppliers who provide comprehensive installation guides, video tutorials, or even on-site training sessions. Additionally, leveraging online resources such as industry forums or instructional videos can enhance team knowledge on best practices for installation. Establishing a checklist that includes necessary tools, safety precautions, and step-by-step procedures can also serve as a valuable reference during the installation process. Encouraging an environment of continuous learning will not only improve the quality of installations but will also foster team confidence in handling square PVC pipe projects.

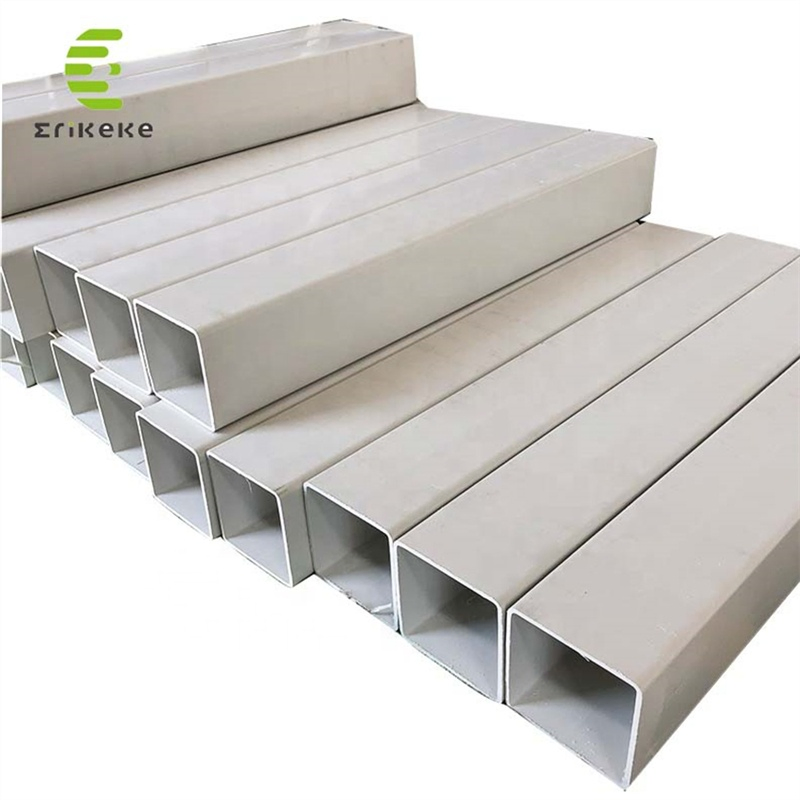

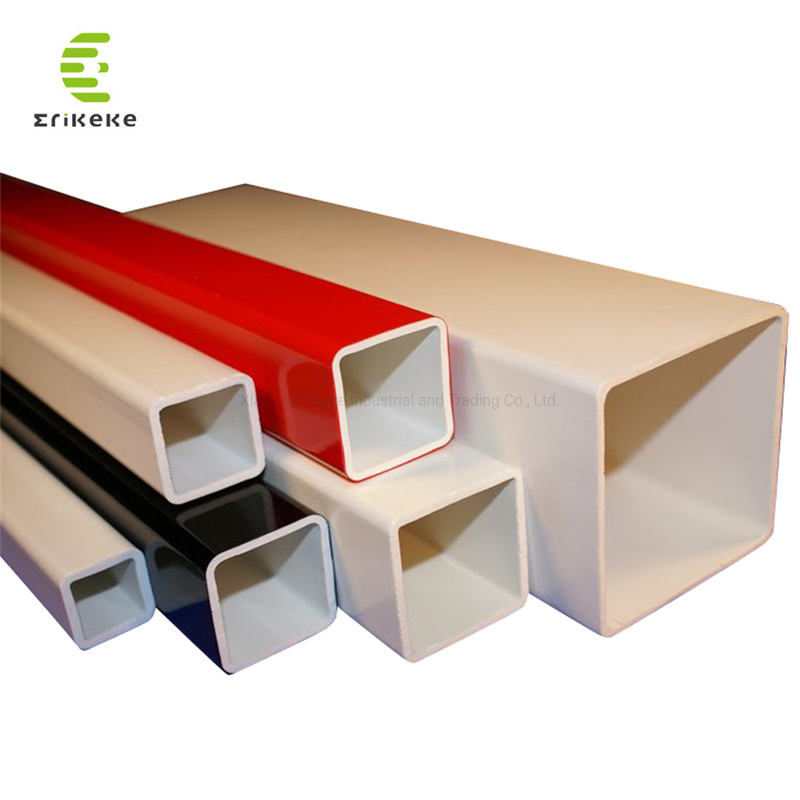

Illustrative image related to square pvc pipe

Strategic Material Selection Guide for square pvc pipe

When selecting materials for square PVC pipe, B2B buyers must consider various factors that affect product performance, manufacturing complexity, and cost. Below is an analysis of four common materials used in the production of square PVC pipe, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

What Are the Key Properties of Rigid PVC for Square Pipe Applications?

Rigid PVC (Polyvinyl Chloride) is the most commonly used material for square PVC pipes. It boasts excellent mechanical strength, high impact resistance, and good chemical stability. Rigid PVC can withstand temperatures ranging from -15°C to 60°C and has a pressure rating suitable for various applications, making it ideal for structural applications such as fencing and framing.

Pros: The durability of rigid PVC ensures a long lifespan, reducing the need for frequent replacements. It is also cost-effective, with lower manufacturing complexity compared to other materials.

Cons: One limitation is its susceptibility to UV degradation, which can weaken the material over time when exposed to sunlight. Additionally, while it is resistant to many chemicals, it may not be suitable for certain solvents.

Impact on Application: Rigid PVC is compatible with water and various chemicals, making it suitable for plumbing and drainage systems. However, buyers should ensure compatibility with specific media to avoid premature failure.

Considerations for International Buyers: Compliance with standards such as ASTM D1784 and DIN 8061 is crucial. Buyers from regions like Europe and the Middle East may have specific regulations regarding material certifications.

How Does CPVC Compare for High-Temperature Applications?

Chlorinated Polyvinyl Chloride (CPVC) is another material option that offers enhanced temperature resistance, making it suitable for hot water applications. CPVC can handle temperatures up to 93°C, which is significantly higher than standard PVC.

Pros: The ability to withstand higher temperatures makes CPVC ideal for industrial applications involving hot liquids. It also exhibits good corrosion resistance, particularly against aggressive chemicals.

Cons: However, CPVC is generally more expensive than rigid PVC, which may impact project budgets. Additionally, the manufacturing process is slightly more complex, potentially leading to longer lead times.

Impact on Application: CPVC is particularly effective in environments where hot water or corrosive chemicals are present, such as in chemical processing or hot water distribution systems.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards such as ASTM D2846 and JIS K 6743, particularly in regions like South America and Africa, where local regulations may differ.

What Are the Benefits of Using PVC Foam for Lightweight Applications?

PVC foam is a lightweight alternative that can be used for applications where weight is a critical factor. It offers good insulation properties and is easier to handle during installation.

Pros: The low weight of PVC foam makes it easier to transport and install, reducing labor costs. It also has good resistance to moisture and is less prone to corrosion.

Cons: However, PVC foam is less durable than rigid PVC or CPVC and may not be suitable for high-stress applications. Its lower impact resistance can lead to damage in harsh environments.

Impact on Application: PVC foam is ideal for applications such as signage, decorative structures, and non-load-bearing installations.

Illustrative image related to square pvc pipe

Considerations for International Buyers: Buyers should verify the foam’s compliance with fire safety standards, especially in regions like Europe where regulations are stringent.

How Does ABS Compare as an Alternative Material for Square Pipe?

Acrylonitrile Butadiene Styrene (ABS) is another material option for square pipes, known for its high impact resistance and toughness. ABS can handle temperatures up to 80°C and has good chemical resistance.

Pros: The strength and durability of ABS make it suitable for a variety of applications, including drainage and waste management systems. It is also easier to fabricate than PVC, allowing for more intricate designs.

Cons: However, ABS is generally more expensive than PVC and may not be as UV resistant, which can limit its outdoor applications.

Impact on Application: ABS is compatible with a wide range of chemicals, making it suitable for industrial applications. However, its UV sensitivity may restrict its use in outdoor settings without additional protection.

Considerations for International Buyers: Compliance with standards such as ASTM D3965 is essential, particularly for buyers in the Middle East and Africa, where material certifications may vary.

Summary Table of Material Selection for Square PVC Pipe

| Material | Typical Use Case for square pvc pipe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rigid PVC | Fencing, plumbing, drainage | Cost-effective and durable | Susceptible to UV degradation | Low |

| CPVC | Hot water systems, chemical processing | High-temperature resistance | More expensive, complex manufacturing | Med |

| PVC Foam | Signage, decorative structures | Lightweight, easy to handle | Less durable, lower impact resistance | Low |

| ABS | Drainage, waste management | High impact resistance | More expensive, UV sensitivity | Med |

This analysis provides a clear understanding of the various materials available for square PVC pipe applications, allowing international B2B buyers to make informed decisions based on their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for square pvc pipe

What Are the Key Stages in the Manufacturing Process of Square PVC Pipe?

The manufacturing of square PVC pipes involves a series of well-defined stages that ensure the final product meets industry standards for quality and durability. Understanding these stages is crucial for B2B buyers who are looking to source high-quality products.

Material Preparation: How Are Raw Materials Processed?

The process begins with the selection and preparation of raw materials, primarily polyvinyl chloride (PVC) resin. This resin is often combined with various additives to enhance the properties of the final product, including impact resistance, UV stability, and color. The materials are then fed into a compounding machine where they are mixed and melted to form a homogeneous material. This stage is critical as the quality of the raw materials directly impacts the performance of the PVC pipes.

Forming: What Techniques Are Used to Shape Square PVC Pipes?

After the materials are prepared, the next step is forming. This is typically achieved through an extrusion process, where the melted PVC is forced through a die that shapes it into a square profile. The extrusion process is closely monitored to ensure that the dimensions and wall thickness are consistent with specifications. Techniques such as calibration and cooling are also employed during this stage to maintain the shape and integrity of the pipe as it cools down.

Assembly: Are There Additional Components in Square PVC Pipes?

In some applications, square PVC pipes may require additional components, such as fittings or connectors. In these cases, the assembly process involves joining the extruded pipe with these components, often using techniques like solvent welding or mechanical fastening. Quality checks are essential at this stage to ensure that the assembly is secure and meets the required specifications.

Finishing: What Final Touches Are Applied to Enhance Quality?

The finishing stage includes processes such as cutting the pipes to specified lengths, surface treatment, and packaging. Surface treatments may involve cleaning, polishing, or applying coatings to improve resistance against environmental factors. Proper packaging is also crucial to prevent damage during transportation and storage.

How Is Quality Assurance Implemented in the Production of Square PVC Pipe?

Quality assurance (QA) is an integral part of the manufacturing process for square PVC pipes. It ensures that the products meet both international standards and the specific requirements of buyers.

What International Standards Govern Square PVC Pipe Quality?

B2B buyers should be aware of various international quality standards that govern the manufacturing of PVC pipes. ISO 9001 is a widely recognized standard that outlines the requirements for a quality management system. Compliance with this standard indicates that the manufacturer has a systematic approach to managing quality. Additionally, industry-specific standards, such as CE marking in Europe and API standards for certain applications, may also apply. These certifications provide buyers with confidence in the quality and safety of the products they are sourcing.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves a series of checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This stage assesses the quality of raw materials before production begins. Suppliers must provide certificates of analysis and material safety data sheets to ensure compliance with specifications.

-

In-Process Quality Control (IPQC): During production, continuous monitoring is essential. Techniques such as dimensional checks, visual inspections, and random sampling tests are performed to ensure that the manufacturing process remains within specified tolerances.

-

Final Quality Control (FQC): Once the pipes are produced, they undergo rigorous testing. Common tests include pressure testing, impact resistance tests, and dimensional accuracy checks to ensure that they meet the required standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying the QC processes of potential suppliers is critical. Here are some effective strategies:

What Role Do Audits and Reports Play in Quality Verification?

Conducting supplier audits can provide valuable insights into a manufacturer’s quality management practices. Buyers should look for suppliers who are open to audits and can provide documentation of their QC processes. Reports from previous audits, including findings and corrective actions taken, can serve as indicators of a supplier’s commitment to quality.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct random inspections and testing of the products before they are shipped. This is particularly important for international buyers who may not have the ability to perform on-site inspections.

What Are the Nuances of Quality Certification for International Buyers?

Quality certification can vary by region and may include specific nuances that B2B buyers should be aware of. For instance, European buyers might prioritize CE marking, while buyers in the Middle East may look for compliance with local standards. Understanding these regional differences can help buyers make informed decisions when selecting suppliers.

Additionally, international buyers should consider the supplier’s ability to adapt to specific market needs, including customizations or compliance with local regulations. This adaptability can significantly enhance the overall value of the procurement process.

Conclusion: Why Is a Robust Manufacturing and Quality Assurance Process Essential for Square PVC Pipe Suppliers?

In the highly competitive landscape of square PVC pipe manufacturing, a robust manufacturing process and stringent quality assurance measures are essential. For B2B buyers, understanding these processes not only aids in making informed purchasing decisions but also ensures that they are sourcing products that meet their specific application requirements. By focusing on suppliers with proven QA systems, buyers can mitigate risks and enhance their supply chain reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘square pvc pipe’

In the competitive landscape of B2B procurement, sourcing square PVC pipe requires a strategic approach to ensure quality, compliance, and value. This guide provides a step-by-step checklist to assist international buyers, particularly those from Africa, South America, the Middle East, and Europe, in making informed decisions.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the square PVC pipe you need. Consider dimensions, wall thickness, and intended application, as these factors will influence performance and compatibility with existing systems.

– Key Considerations:

– Ensure that the specifications meet industry standards relevant to your region.

– Think about environmental factors, such as UV resistance or chemical exposure, based on the application.

Step 2: Research Compliance and Standards

Verify that the square PVC pipe complies with local and international standards. This includes certifications such as ISO, ASTM, or specific regional regulations.

– Why This Matters:

– Non-compliance can lead to legal issues and project delays.

– Meeting standards ensures product safety and reliability, crucial for maintaining operational integrity.

Step 3: Evaluate Potential Suppliers

Conduct thorough due diligence on potential suppliers. This involves assessing their market reputation, financial stability, and production capabilities.

– What to Look For:

– Request company profiles, product samples, and references from other clients.

– Investigate their supply chain practices to ensure reliability and ethical sourcing.

Step 4: Request Quotes and Compare Pricing

Solicit quotes from multiple suppliers to gauge market pricing and terms. Ensure that you are comparing similar products and services.

– Considerations:

– Look beyond the base price; factor in shipping costs, lead times, and payment terms.

– Analyze volume discounts or long-term contract options that might benefit your procurement strategy.

Step 5: Assess Quality Control Processes

Inquire about the quality control measures implemented by potential suppliers. Understanding their testing protocols and quality assurance practices is vital.

– Important Questions:

– What types of inspections and tests are conducted during production?

– Can they provide documentation of quality certifications?

Step 6: Verify Supplier Certifications

Confirm that suppliers hold necessary certifications to ensure product quality and compliance. This step is essential for maintaining the integrity of your supply chain.

– Documentation to Request:

– Certificates of compliance with relevant standards.

– Quality management system certifications, such as ISO 9001.

Illustrative image related to square pvc pipe

Step 7: Establish Communication Protocols

Before finalizing any agreements, establish clear communication protocols with your supplier. This ensures that expectations are aligned and issues can be addressed promptly.

– Best Practices:

– Set regular check-ins to discuss order progress and potential challenges.

– Define points of contact for both sides to streamline communication.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing square PVC pipe, ensuring they partner with reliable suppliers who meet their specific needs.

Comprehensive Cost and Pricing Analysis for square pvc pipe Sourcing

What Are the Key Cost Components in Sourcing Square PVC Pipe?

When considering the sourcing of square PVC pipe, understanding the cost structure is critical for effective budgeting and financial planning. The primary cost components include:

-

Materials: The type of PVC used significantly affects pricing. Higher-grade materials, which may include additives for UV resistance or impact strength, will elevate costs. In regions with limited access to quality raw materials, prices may spike.

-

Labor: Labor costs vary by location. In regions such as Africa and South America, labor may be less expensive, potentially lowering manufacturing costs. However, in areas like Europe, labor can be a substantial part of the overall cost.

-

Manufacturing Overhead: This includes costs associated with machinery maintenance, factory utilities, and administrative expenses. Efficient factories with modern machinery can produce square PVC pipe at lower overhead rates.

-

Tooling: The initial investment in molds and production tools is significant, especially for custom sizes or specifications. Tooling costs are often amortized over large production runs, making high-volume orders more cost-effective.

-

Quality Control (QC): Ensuring product quality can add to costs, particularly if third-party inspections or certifications are required. For international buyers, compliance with local standards can incur additional expenses.

-

Logistics: Shipping costs can vary dramatically based on destination, mode of transport, and volume. Incoterms can influence how these costs are allocated between buyers and suppliers.

-

Margin: Suppliers typically add a profit margin, which can vary based on competition, market demand, and the supplier’s position within the supply chain.

How Do Price Influencers Affect Square PVC Pipe Sourcing?

Several factors can influence pricing dynamics in the square PVC pipe market:

-

Volume/MOQ: Higher order volumes often lead to lower per-unit prices due to economies of scale. Establishing a minimum order quantity (MOQ) can help negotiate better rates.

-

Specifications and Customization: Custom sizes, colors, or specific certifications can increase costs. Buyers should clearly communicate their needs to avoid unexpected charges.

-

Materials and Quality Certifications: The quality of materials and any certifications (e.g., ASTM standards) can impact price. Buyers should weigh the benefits of higher-quality products against their budget constraints.

-

Supplier Factors: The supplier’s reputation, reliability, and geographical location can affect pricing. Engaging with multiple suppliers for quotes can provide a clearer market perspective.

-

Incoterms: Understanding Incoterms is essential for international transactions. They dictate the responsibilities and costs associated with shipping, insurance, and tariffs, significantly impacting the total cost of ownership.

What Buyer Tips Can Enhance Cost-Efficiency in Square PVC Pipe Sourcing?

To maximize cost-efficiency when sourcing square PVC pipe, consider the following strategies:

-

Negotiation: Establish strong relationships with suppliers and be prepared to negotiate prices, especially for larger orders. Leverage multiple quotes to strengthen your position.

-

Total Cost of Ownership (TCO): Assess not just the purchase price but also logistics, potential tariffs, and the expected lifespan of the product. A lower initial price may lead to higher long-term costs if the quality is compromised.

-

Understand Pricing Nuances for International Buyers: Different regions may have varying pricing structures influenced by local economies, tariffs, and availability of materials. Engage local experts or consultants who understand the market dynamics in your target region.

-

Be Aware of Market Trends: Keep an eye on fluctuations in raw material prices and global supply chain disruptions, which can impact pricing. Staying informed can help you make timely purchasing decisions.

Disclaimer on Pricing

Please note that the prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult multiple sources and conduct thorough market research before making purchasing decisions.

Alternatives Analysis: Comparing square pvc pipe With Other Solutions

Understanding the Importance of Alternative Solutions in Square PVC Pipe Applications

In the realm of construction and manufacturing, square PVC pipes have established themselves as a popular choice due to their versatility and durability. However, it’s crucial for international B2B buyers to explore alternative solutions that may better suit specific project requirements or budget constraints. Evaluating these alternatives can help businesses make informed decisions that enhance efficiency and reduce costs.

Comparison Table of Square PVC Pipe and Alternatives

| Comparison Aspect | Square PVC Pipe | Aluminum Square Tubing | Galvanized Steel Square Pipe |

|---|---|---|---|

| Performance | High resistance to chemicals and moisture, lightweight | High strength-to-weight ratio, excellent corrosion resistance | Strong and durable, good for structural applications |

| Cost | Generally low-cost | Moderate cost, higher than PVC | Higher initial investment but durable over time |

| Ease of Implementation | Easy to cut and join with adhesives | Requires special tools for cutting and joining | Requires welding or heavy-duty connectors |

| Maintenance | Low maintenance, resistant to corrosion | Low maintenance, may require periodic inspection | Moderate maintenance, may rust if not properly coated |

| Best Use Case | Ideal for residential and light commercial applications | Best for structural applications where weight is a concern | Suitable for heavy-duty industrial applications |

Detailed Breakdown of Alternatives

Aluminum Square Tubing: Is It a Suitable Alternative?

Aluminum square tubing is renowned for its strength and lightweight properties, making it a viable alternative to square PVC pipes. It offers excellent corrosion resistance, which is particularly beneficial in coastal or humid environments. However, the cost of aluminum is generally higher than that of PVC, which may be a consideration for budget-sensitive projects. Additionally, while aluminum is easy to handle, it requires specialized tools for cutting and joining, which can complicate the implementation process.

Galvanized Steel Square Pipe: What Are Its Advantages and Disadvantages?

Galvanized steel square pipes are another strong contender in this comparison. They are extremely durable and capable of withstanding heavy loads, making them suitable for industrial applications. The galvanized coating provides some corrosion resistance, but they may require regular maintenance to prevent rust in harsher environments. The initial investment for galvanized steel is typically higher than that for PVC, but their longevity and strength can justify the cost for many businesses.

Conclusion: How to Choose the Right Solution for Your Needs

When determining the most suitable piping solution, B2B buyers should evaluate their specific project requirements, including budget, environmental conditions, and the intended application. Square PVC pipes are excellent for cost-effective, low-maintenance installations, particularly in residential and light commercial sectors. In contrast, aluminum square tubing and galvanized steel square pipes offer superior strength and durability, making them ideal for more demanding industrial applications. By carefully considering these factors, buyers can select the right solution that aligns with their operational goals and financial parameters.

Essential Technical Properties and Trade Terminology for square pvc pipe

What Are the Key Technical Properties of Square PVC Pipe?

When sourcing square PVC pipe for industrial or commercial applications, understanding its technical properties is crucial for making informed purchasing decisions. Here are several essential specifications to consider:

-

Material Grade

Square PVC pipes are typically manufactured from polyvinyl chloride (PVC), which is known for its durability, resistance to corrosion, and low maintenance requirements. The material grade indicates the specific formulation used, affecting the pipe’s strength and suitability for various applications. Higher-grade PVC (like Schedule 80) offers increased pressure ratings and is ideal for demanding environments, making it essential for industries such as construction and plumbing. -

Dimensions and Tolerances

The dimensions of square PVC pipes, including wall thickness and external/internal diameters, are critical for ensuring compatibility with fittings and other components in a system. Tolerances refer to the allowable variations in these dimensions, which can impact the ease of installation and the overall integrity of the system. Accurate dimensions and tight tolerances are vital for applications that require precise fit and alignment. -

Temperature Resistance

Square PVC pipes can typically withstand a range of temperatures, but their performance can degrade in extreme heat. Understanding the temperature resistance of the specific pipe being considered is vital for applications that may involve exposure to high temperatures, such as in agricultural irrigation systems or industrial processes. This property can influence the longevity and reliability of the installed piping system. -

Pressure Rating

The pressure rating, often denoted in pounds per square inch (PSI), indicates the maximum pressure the pipe can handle without failure. This specification is crucial for ensuring that the selected pipe can withstand the operational pressures of the intended application, such as in water distribution or fluid transfer systems. Selecting a pipe with an appropriate pressure rating helps prevent leaks or bursts, safeguarding both infrastructure and investments. -

Chemical Resistance

Different grades of PVC exhibit varying degrees of resistance to chemicals. For B2B buyers, understanding the chemical compatibility of square PVC pipes with the intended fluids or gases is critical, especially in industries such as chemical processing or wastewater management. Utilizing the right grade of PVC can prevent corrosion and degradation, ensuring the longevity of the piping system.

What Are Common Trade Terms Related to Square PVC Pipe?

Navigating the procurement process involves familiarizing oneself with industry jargon. Here are several common terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of square PVC pipes, understanding OEM relationships can help buyers identify reliable suppliers and ensure the quality and compatibility of components used in their projects. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers as it can affect purchasing decisions, inventory management, and budgeting. Suppliers may set MOQs to ensure profitability and justify production costs. -

RFQ (Request for Quotation)

An RFQ is a formal document used by buyers to solicit price quotes from suppliers for specific products or services. This process is crucial for B2B buyers to compare prices, quality, and delivery timelines from various suppliers before making a purchasing decision. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for B2B buyers engaged in cross-border procurement, as they determine who bears the costs and risks associated with shipping and delivery. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until it is delivered. Understanding lead times is crucial for effective project planning and inventory management, allowing buyers to align their schedules and avoid delays in construction or manufacturing processes. -

Certification Standards

These standards, such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization), ensure that products meet specific quality and safety requirements. Buyers should seek out square PVC pipes that comply with relevant certification standards to guarantee product reliability and performance.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement strategies and make informed decisions when sourcing square PVC pipes for their projects.

Navigating Market Dynamics and Sourcing Trends in the square pvc pipe Sector

What are the Current Market Dynamics and Key Trends Affecting the Square PVC Pipe Sector?

The square PVC pipe market is experiencing significant growth driven by urbanization, infrastructure development, and the rising demand for durable and lightweight materials across various industries. International buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly recognizing the advantages of square PVC pipes, including their corrosion resistance, low maintenance requirements, and cost-effectiveness. Emerging technologies such as advanced manufacturing processes and digital supply chain management are reshaping sourcing strategies, enabling businesses to optimize inventory and reduce lead times.

Moreover, the rise of e-commerce platforms is facilitating easier access to suppliers globally, allowing buyers to source square PVC pipes from diverse markets. Notable trends include an increasing preference for customized products that meet specific application needs, such as fencing, structural applications, and drainage systems. Additionally, the implementation of smart technologies in logistics and inventory management is providing businesses with real-time data, enhancing decision-making processes and operational efficiency.

How is Sustainability Shaping the Square PVC Pipe Market and What are the Ethical Sourcing Considerations?

Sustainability is becoming a pivotal focus within the square PVC pipe sector, driven by both regulatory pressures and consumer demand for environmentally friendly products. The environmental impact of PVC production and disposal has led to increased scrutiny, making it essential for suppliers to adopt sustainable practices. Buyers are encouraged to prioritize suppliers who demonstrate a commitment to ethical sourcing, such as using recycled materials or adhering to recognized sustainability certifications.

Certifications like the Global Recycled Standard (GRS) and the Forest Stewardship Council (FSC) can serve as indicators of a supplier’s dedication to sustainability. Additionally, eco-friendly alternatives, such as biobased PVC, are gaining traction as they offer reduced carbon footprints. This shift towards sustainable practices not only helps mitigate environmental impacts but also enhances brand reputation and customer loyalty among environmentally conscious consumers.

What is the Historical Context of Square PVC Pipes and Their Evolution in the B2B Sector?

The use of PVC in construction dates back to the 1930s, but the evolution of square PVC pipes as a specialized product has gained momentum over the last few decades. Initially utilized for plumbing applications, advancements in manufacturing technologies have broadened their usage into diverse sectors, including agriculture, construction, and electrical conduit applications.

The introduction of innovative designs and variations, such as varying wall thicknesses and sizes, has enabled square PVC pipes to meet specific industry standards and application requirements. This evolution has not only diversified the product offerings available to B2B buyers but has also contributed to the overall growth of the PVC market as businesses seek versatile solutions for their operational needs.

In conclusion, understanding the market dynamics, sustainability considerations, and historical context of square PVC pipes provides international B2B buyers with valuable insights to make informed sourcing decisions and align with emerging trends in the industry.

Frequently Asked Questions (FAQs) for B2B Buyers of square pvc pipe

-

How do I choose the right square PVC pipe for my project?

Choosing the right square PVC pipe involves considering several factors such as the application, load-bearing requirements, and environmental conditions. For structural applications, opt for high-strength options with the appropriate wall thickness. Additionally, consider the pipe’s resistance to chemicals and UV exposure if it will be used outdoors. Always consult with your supplier about specific product specifications and any relevant industry standards to ensure compliance. -

What are the common applications of square PVC pipe?

Square PVC pipes are versatile and used in various applications, including construction, fencing, plumbing, and electrical conduits. They are particularly favored for their lightweight properties, resistance to corrosion, and ease of installation. In industrial settings, square PVC pipes serve as frames for structures, supports for signage, and protective covers for electrical wiring, making them a popular choice across multiple sectors. -

What customization options are available for square PVC pipe?

Many suppliers offer customization options for square PVC pipes, including varying lengths, colors, and diameters. Additionally, you can request specific wall thicknesses or the addition of pre-drilled holes for easier installation. When placing an order, be clear about your specifications and inquire about lead times, as custom orders may require additional processing time. -

What is the minimum order quantity (MOQ) for square PVC pipe?

The minimum order quantity for square PVC pipe varies by supplier and region. Typically, manufacturers may have an MOQ ranging from a few dozen to several hundred units, depending on the size and type of pipe. For large-scale projects, it’s often beneficial to negotiate MOQs with suppliers to ensure you receive the best pricing and availability for your needs. -

How do I vet suppliers of square PVC pipe for international trade?

To vet suppliers for international trade, start by checking their credentials, including certifications and compliance with international standards. Request references from past clients and review their track record for timely delivery and product quality. Utilizing platforms like Alibaba or Global Sources can also help you access reviews and ratings. Finally, consider requesting product samples to assess quality before committing to a larger order. -

What are the typical payment terms for purchasing square PVC pipe internationally?

Payment terms can vary significantly among suppliers. Common arrangements include upfront payments, deposits with balance upon delivery, or net payment terms (e.g., net 30 or net 60 days). Always negotiate terms that align with your cash flow needs, and consider using secure payment methods like letters of credit or escrow services to mitigate risk in international transactions. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers should have quality assurance processes in place, including material testing, dimensional checks, and compliance with relevant standards (e.g., ISO certifications). Ask for documentation such as test reports and certificates of compliance to ensure the pipes meet your specifications. Additionally, inquire about their return policy and warranty options in case of defects or discrepancies. -

How should I manage logistics for importing square PVC pipe?

Managing logistics involves careful planning of shipping methods, customs clearance, and delivery timelines. Collaborate with your supplier to determine the most efficient shipping options, whether by air or sea, and factor in any potential delays at customs. It’s also wise to work with a reliable freight forwarder who can assist with documentation and compliance to ensure a smooth import process.

Top 5 Square Pvc Pipe Manufacturers & Suppliers List

1. Home Depot – 4 Square PVC Pipe

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 4″ square PVC pipe, commonly used in hydroponics projects. Available at Home Depot for $12-$14 for 40 inches. Concerns about vinyl for potable water; alternatives suggested include polyethylene (PE) and high-density polyethylene (HDPE) for safety.

2. Professional Plastics – Gray PVC Square Tube

Domain: professionalplastics.com

Registered: 1997 (28 years)

Introduction: {“Product Code”: “TPVCSQGY3.384X3.540-10”, “Material”: “Gray PVC”, “Type”: “Square Tube”, “Inner Diameter (ID)”: “3.384 inches”, “Outer Diameter (OD)”: “3.540 inches”, “Length”: “10 feet”}

3. McMaster – PVC Square Tubing

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – PVC Square Tubing, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. GEHR® Plastics – Gray PVC Square Rod/Bar

Domain: usplastic.com

Registered: 1996 (29 years)

Introduction: {“Item Number”: “45206”, “Catalog Page Number”: “P-436”, “Manufacturer”: “GEHR® Plastics”, “Manufacturer Part Number”: “USP 45206”, “Country of Origin”: “Germany”, “Material”: “PVC”, “Color”: “Gray”, “Form”: “Square Rod/Bar”, “Outside Dimension”: “1 inch”, “Length”: “10 feet”, “Thickness”: “0.078 inch”, “Weight”: “0.181 lbs”, “Maximum Temperature”: “140°F”, “Sold In”: “10′ sections only”, “Price”:…

5. API Plastics – Custom Furniture Grade PVC Pipe

Domain: custom-plastics.apiplastics.com

Registered: 1997 (28 years)

Introduction: Furniture Grade Square PVC Pipe and Tube, custom sizes available, fast turnaround time, tooling can be made for non-listed sizes, produced to order.

Strategic Sourcing Conclusion and Outlook for square pvc pipe

In navigating the complexities of sourcing square PVC pipe, international buyers must prioritize strategic partnerships and supplier reliability. The versatility and durability of square PVC pipe make it a preferred choice across various industries, from construction to automotive applications. By leveraging strategic sourcing, businesses can not only reduce costs but also ensure consistent quality and supply chain efficiency.

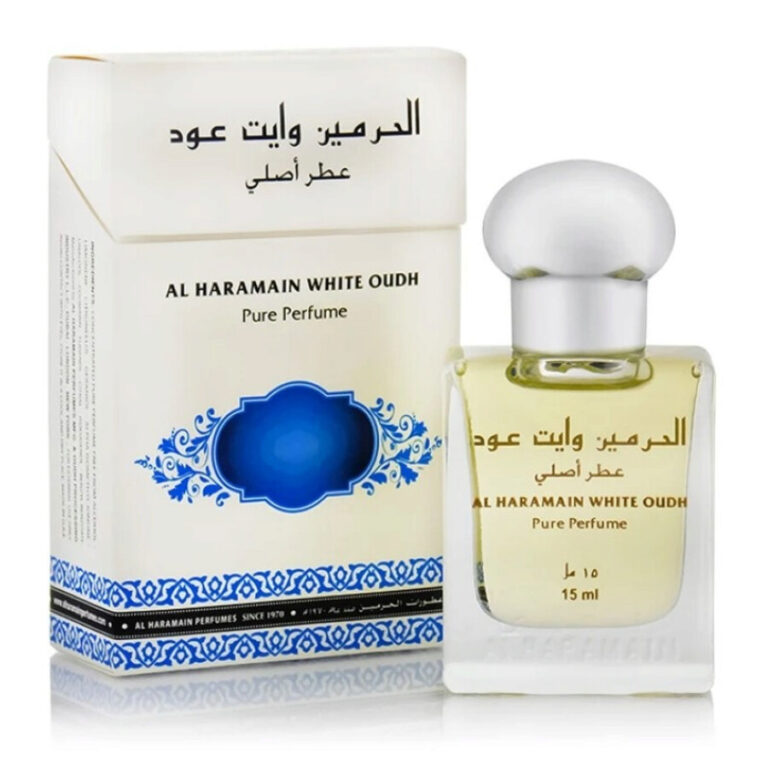

Illustrative image related to square pvc pipe

Understanding regional market dynamics, especially in Africa, South America, the Middle East, and Europe, will empower buyers to make informed decisions. The demand for sustainable and eco-friendly materials is rising, making it crucial to partner with suppliers who align with these values.

As you consider your next procurement decision, focus on building long-term relationships with manufacturers who offer innovative solutions and competitive pricing. By doing so, you position your business for growth and resilience in an ever-evolving marketplace. Embrace the future of sourcing square PVC pipe with confidence, and take proactive steps to secure your supply chain for the challenges ahead.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.