How to Source Spring-Loaded Hinges Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for spring-loaded hinges

In an increasingly interconnected global market, sourcing spring-loaded hinges presents unique challenges for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. These essential components, which provide automatic closing or opening functions for doors and cabinets, are crucial for various applications ranging from industrial environments to consumer products. However, navigating the myriad of options—ranging from material types to specific designs—can be daunting.

This comprehensive guide delves into the diverse world of spring-loaded hinges, offering insights into the different types available, their specific applications, and key factors to consider when selecting the right hinge for your needs. It also provides actionable strategies for vetting suppliers, understanding cost implications, and ensuring compliance with regional standards. By equipping B2B buyers with this knowledge, the guide empowers them to make informed purchasing decisions, ultimately leading to improved operational efficiency and product reliability.

Whether you are in Vietnam, Nigeria, or any other market, the insights contained within this guide will serve as a valuable resource. With a focus on practical advice and industry best practices, it aims to simplify the sourcing process, allowing businesses to confidently integrate the right spring-loaded hinges into their operations.

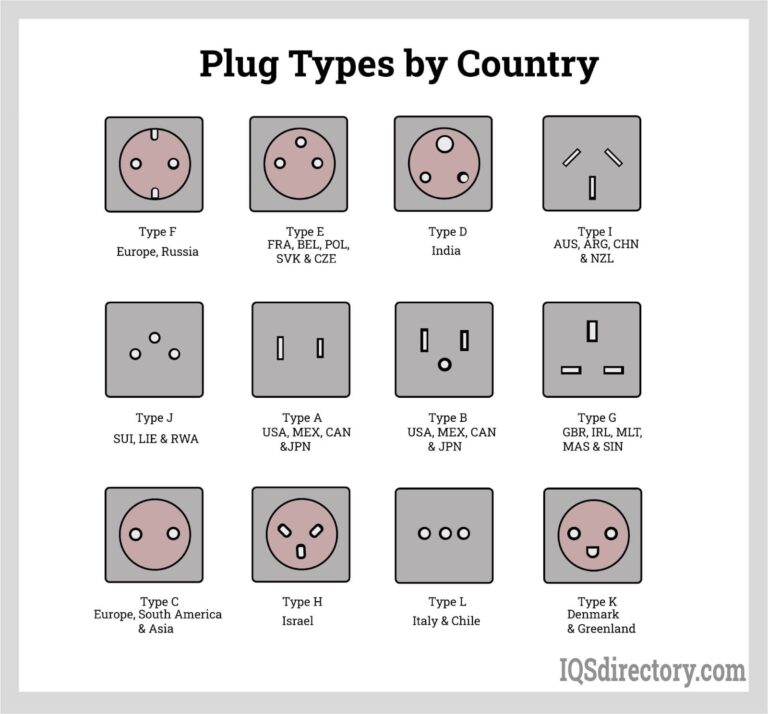

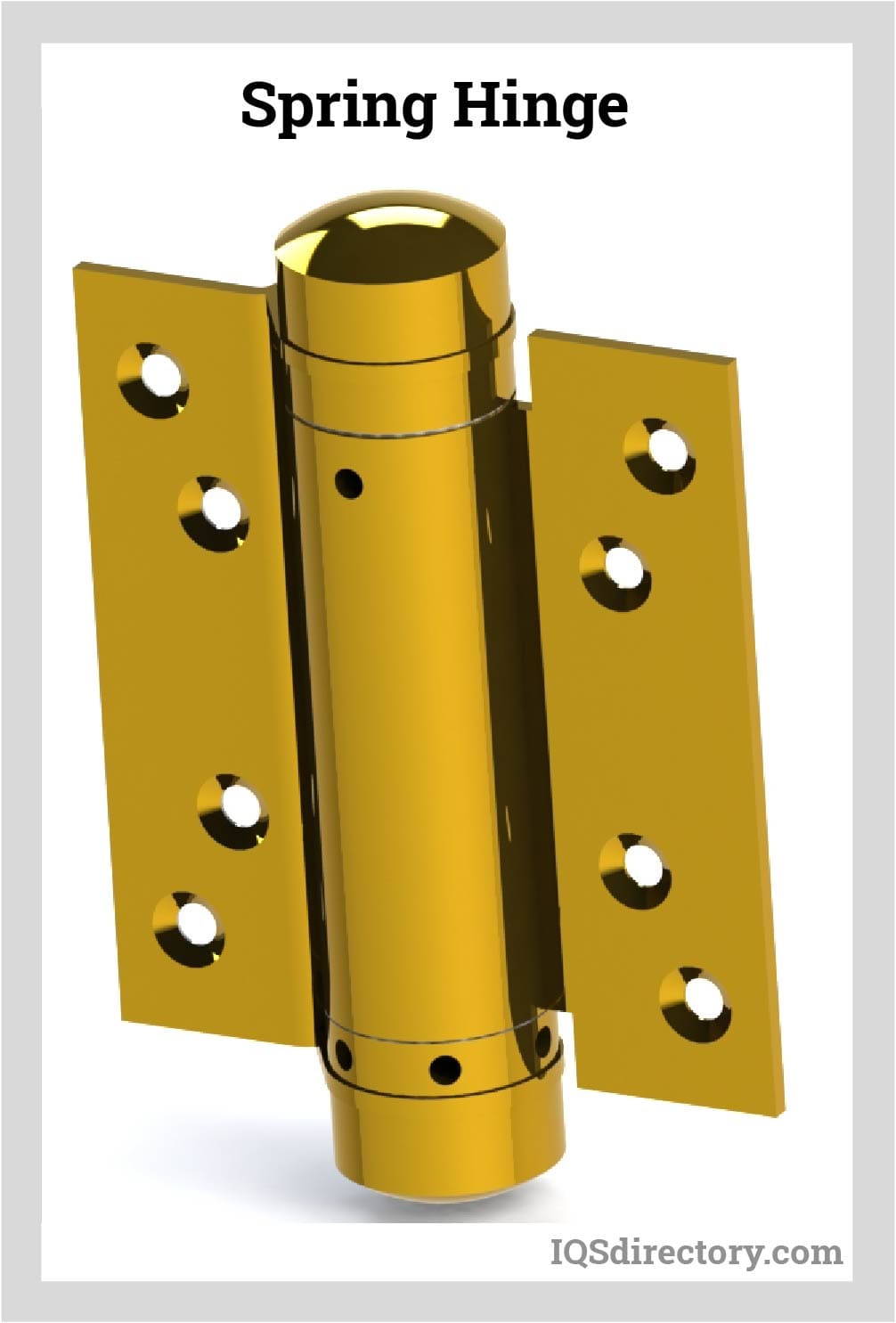

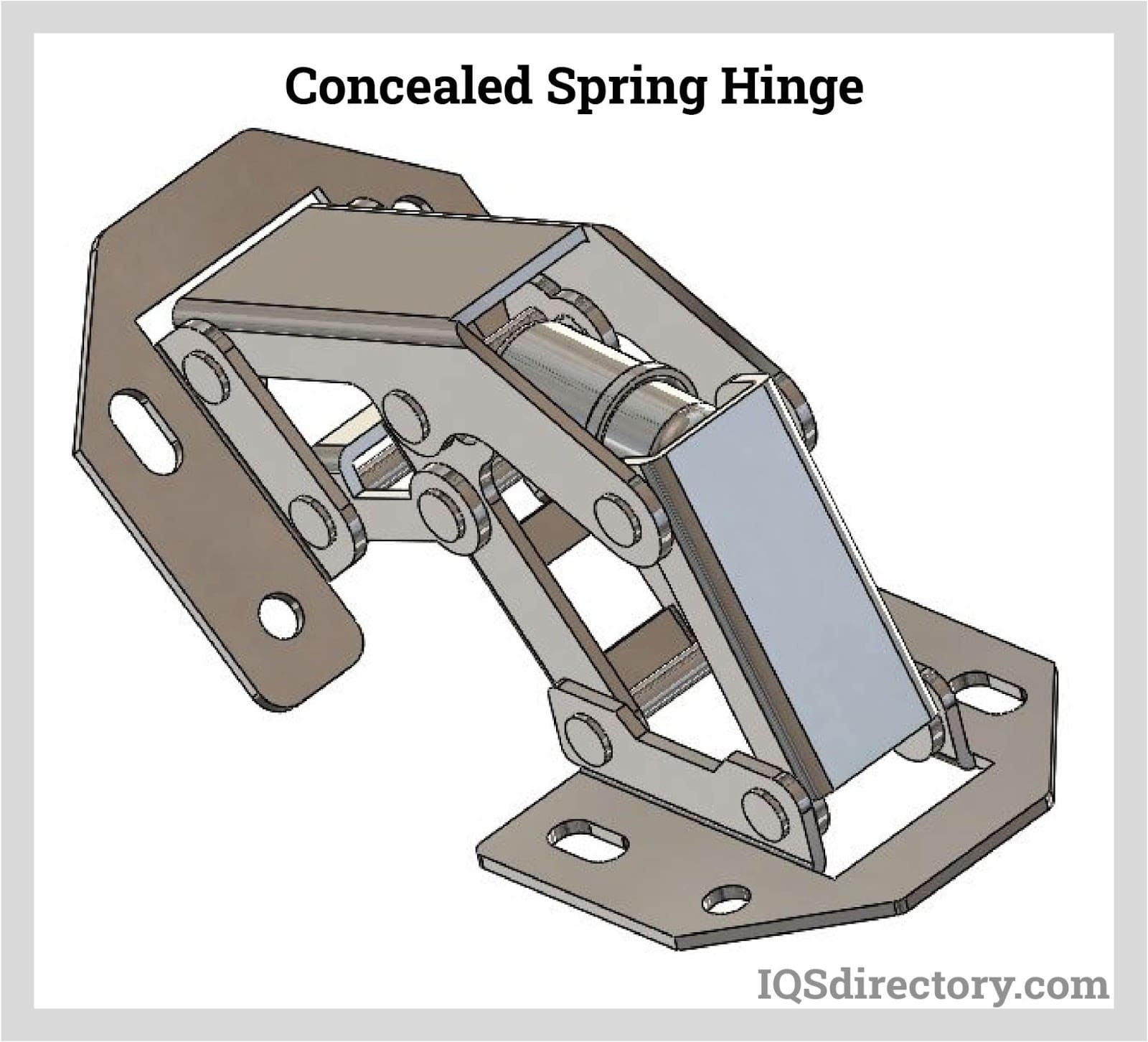

Understanding spring-loaded hinges Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Spring-Loaded to Close | Springs push hinge leaves together to close | Industrial doors, cabinets, access panels | Pros: Secure closure, reduces wear on door; Cons: Requires careful alignment to function properly. |

| Spring-Loaded to Open | Springs push hinge leaves apart to open | Automatic doors, machinery access | Pros: Facilitates easy access, ideal for high-traffic areas; Cons: May require more force to operate. |

| Continuous Spring Hinge | Long, uninterrupted hinge with integrated spring | Heavy doors, outdoor gates, security doors | Pros: Durability and stability; Cons: Can be bulkier and more expensive. |

| Cover Hinge | Designed for small openings, provides quick access | Electrical cabinets, maintenance panels | Pros: Cost-effective, compact design; Cons: Limited weight capacity. |

| Custom Spring Hinge | Tailored specifications for unique applications | Specialized machinery, custom installations | Pros: Perfect fit for specific needs; Cons: Longer lead time and potentially higher costs. |

What are the Characteristics of Spring-Loaded to Close Hinges?

Spring-loaded to close hinges are designed to automatically close doors or panels after they have been opened. The spring mechanism pushes the hinge leaves together, ensuring a secure closure. These hinges are commonly used in industrial settings, such as on heavy doors and cabinets, where secure closure is critical. Buyers should consider the alignment and installation requirements to ensure optimal performance, as improper setup can lead to malfunction.

How Do Spring-Loaded to Open Hinges Function?

Spring-loaded to open hinges operate by pushing the hinge leaves apart, facilitating easy access to doors or panels. This type is particularly useful in high-traffic areas such as automatic doors or machinery access points. Buyers should evaluate the required force for operation, as heavier doors may necessitate stronger springs. Additionally, the installation environment should be considered to ensure that the hinge can withstand frequent use.

What Makes Continuous Spring Hinges Unique?

Continuous spring hinges feature a long, uninterrupted design that integrates a spring mechanism throughout the length of the hinge. This design provides enhanced stability and durability, making them suitable for heavy doors and outdoor gates. B2B buyers should assess the weight and frequency of use in their applications, as continuous hinges can be more costly but offer superior performance and longevity.

In What Scenarios are Cover Hinges Beneficial?

Cover hinges are specifically designed for small openings that require quick access, such as in electrical cabinets or maintenance panels. Their compact design allows for a cost-effective solution for securing access points without compromising functionality. Buyers should consider the weight capacity and application environment, as cover hinges may not be suitable for heavy-duty use.

How Can Custom Spring Hinges Meet Unique Needs?

Custom spring hinges are tailored to meet specific application requirements, making them ideal for specialized machinery or unique installations. These hinges can be designed with varying lengths, widths, and spring tensions to perfectly fit the intended use. While they offer a perfect fit, buyers should be aware of potentially longer lead times and higher costs associated with custom manufacturing.

Key Industrial Applications of spring-loaded hinges

| Industry/Sector | Specific Application of spring-loaded hinges | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Assembly line equipment access doors | Enhances safety and efficiency by ensuring doors close automatically, minimizing downtime. | Durability, corrosion resistance, and compatibility with existing systems. |

| Automotive | Engine compartments and service panels | Provides secure access while ensuring quick closure, improving maintenance workflows. | Material specifications, load capacity, and spring tension for reliability. |

| Aerospace | Access panels for aircraft maintenance | Ensures safety and quick access for inspections, reducing maintenance time. | Compliance with aviation standards, lightweight materials, and custom torque settings. |

| Construction | Temporary site storage units | Facilitates easy access while maintaining security, protecting tools and materials. | Weather resistance, size specifications, and customization options for various applications. |

| Marine | Hatches and access doors on vessels | Enhances safety and operational efficiency in marine environments, ensuring secure closure. | Resistance to saltwater corrosion, strength under dynamic loads, and ease of installation. |

How Are Spring-Loaded Hinges Used in Manufacturing?

In the manufacturing sector, spring-loaded hinges are commonly employed in assembly line equipment access doors. These hinges automatically close doors, which enhances safety by preventing accidental openings and minimizing downtime during operations. For international buyers, particularly in regions like Africa and South America, sourcing hinges that offer durability and corrosion resistance is crucial, especially in environments with high humidity or exposure to harsh conditions. Compatibility with existing equipment is also a key consideration to ensure seamless integration.

What Role Do Spring-Loaded Hinges Play in the Automotive Industry?

In the automotive industry, spring-loaded hinges are essential for engine compartments and service panels. They provide secure access while ensuring that these components close quickly, which is vital for efficient maintenance workflows. Buyers need to focus on material specifications, such as stainless steel for corrosion resistance, and the load capacity of the hinges to ensure they can withstand the rigors of automotive environments. Custom spring tension may also be required for specific applications to ensure reliable operation.

Why Are Spring-Loaded Hinges Critical in Aerospace Applications?

In aerospace, spring-loaded hinges are used in access panels for aircraft maintenance. These hinges ensure that panels close securely, providing quick access for inspections and repairs, which is vital for safety and operational efficiency. Buyers in this sector must consider compliance with strict aviation standards, lightweight materials to reduce overall aircraft weight, and custom torque settings to match specific operational needs. The ability to provide samples for testing can also be an advantage when sourcing.

How Are Spring-Loaded Hinges Utilized in Construction?

In construction, spring-loaded hinges are often found in temporary site storage units, allowing for easy access while maintaining security for tools and materials. These hinges help to facilitate quick movement in and out of storage units, which is essential for productivity on job sites. Buyers should prioritize sourcing hinges that are weather-resistant and capable of withstanding various environmental conditions. Customization options may be necessary to fit the specific dimensions and weight requirements of different storage solutions.

What Benefits Do Spring-Loaded Hinges Offer in Marine Applications?

Spring-loaded hinges are crucial for hatches and access doors on vessels, enhancing safety and operational efficiency. They ensure that hatches close securely, which is vital in preventing water ingress and maintaining vessel integrity. For international buyers in the marine sector, sourcing hinges that resist saltwater corrosion and can endure dynamic loads is essential. Ease of installation and the ability to customize sizes and spring tensions are also important factors to consider when making a purchase.

3 Common User Pain Points for ‘spring-loaded hinges’ & Their Solutions

Scenario 1: Inconsistent Spring Tension Leading to Equipment Malfunction

The Problem: B2B buyers often encounter the challenge of inconsistent spring tension in spring-loaded hinges, which can lead to equipment malfunction. This issue is particularly problematic in industrial settings where heavy doors or equipment must open and close reliably. An inadequate tension can cause doors to slam shut unexpectedly or fail to remain open when needed, compromising safety and efficiency. This inconsistency can lead to costly downtime and increased maintenance expenses, making it a significant pain point for operations managers.

Illustrative image related to spring-loaded hinges

The Solution: To mitigate the risk of inconsistent spring tension, it’s essential to carefully evaluate the specifications of the spring-loaded hinges being sourced. Buyers should prioritize hinges that allow for adjustable tension settings or choose those that clearly specify their torque ratings. Conducting thorough testing with engineering samples before full implementation can help ensure the correct spring tension is achieved. In addition, collaborating with manufacturers who offer customization options can ensure that the hinges meet the precise requirements of the application, such as the weight and frequency of use of the door or equipment. Regular maintenance and inspections should also be scheduled to ensure that the hinges continue to operate smoothly over time.

Scenario 2: Difficulty in Selecting the Right Type of Spring-Loaded Hinge

The Problem: Another common issue faced by B2B buyers is the confusion surrounding the selection of the appropriate type of spring-loaded hinge. With various options available, such as spring-loaded-to-open and spring-loaded-to-close hinges, it can be challenging to determine which type best fits a specific application. This can result in purchasing the wrong type of hinge, leading to installation issues and operational inefficiencies.

The Solution: To simplify the selection process, buyers should first conduct a detailed analysis of their specific application requirements. Understanding the operational dynamics—such as whether the hinge needs to hold a door open or close it automatically—will guide the selection process. Furthermore, consulting with hinge manufacturers or suppliers can provide valuable insights into the best products for specific applications. Utilizing online resources, such as product comparison charts and detailed specification sheets, can also aid in making informed decisions. Lastly, taking advantage of sample orders to test different hinge types in real-world conditions can help ensure the right fit and functionality.

Scenario 3: Corrosion and Durability Issues in Harsh Environments

The Problem: In regions with extreme weather conditions, such as high humidity or salt exposure, B2B buyers frequently face durability challenges with spring-loaded hinges. Corrosion can significantly reduce the lifespan of standard hinges, leading to premature failures and the need for costly replacements. This is especially critical in industries like marine, food processing, or outdoor installations, where the hinges are exposed to harsh elements.

The Solution: To combat corrosion and enhance durability, buyers should opt for spring-loaded hinges made from high-quality materials, such as stainless steel or specialized coatings that offer enhanced resistance to environmental factors. When sourcing hinges, it’s crucial to inquire about the specific material properties and finishes that can withstand corrosive conditions. Additionally, implementing a routine maintenance schedule that includes inspections and protective treatments can further prolong the life of the hinges. Engaging with manufacturers who specialize in industrial-grade products and can provide tailored solutions based on local environmental challenges can also ensure optimal performance and longevity of the hinges in demanding applications.

Strategic Material Selection Guide for spring-loaded hinges

What Are the Key Properties of Common Materials Used in Spring-Loaded Hinges?

When selecting materials for spring-loaded hinges, it is crucial to understand the properties that influence their performance in various applications. Here, we analyze four common materials: stainless steel, plain steel, aluminum, and brass.

How Does Stainless Steel Perform in Spring-Loaded Hinges?

Stainless steel is renowned for its excellent corrosion resistance, making it suitable for environments exposed to moisture, chemicals, or salt. It can withstand high temperatures and pressures, which is beneficial in industrial applications. The durability of stainless steel hinges ensures a long lifespan, reducing maintenance costs.

Pros: High corrosion resistance, strength, and durability.

Cons: Higher manufacturing costs and weight compared to other materials.

Impact on Application: Ideal for food processing, marine environments, and any application requiring hygiene and durability.

Considerations for International Buyers: Compliance with ASTM and DIN standards is crucial. Buyers from regions with high humidity, such as parts of Africa and South America, may prefer stainless steel for its longevity.

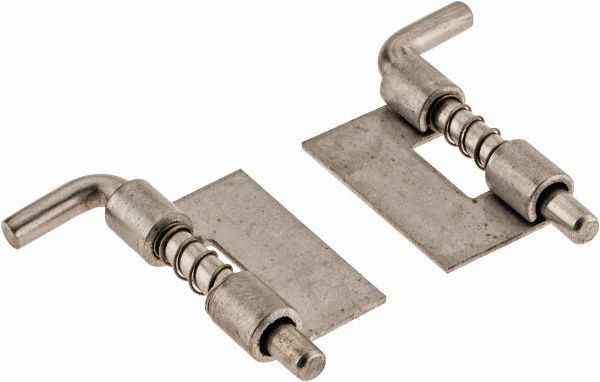

What Are the Benefits of Using Plain Steel for Spring-Loaded Hinges?

Plain steel is a cost-effective option for spring-loaded hinges, offering good strength and rigidity. However, it lacks the corrosion resistance of stainless steel, making it less suitable for outdoor or humid environments unless coated.

Pros: Low cost and high strength.

Cons: Susceptible to rust and corrosion without protective coatings.

Impact on Application: Suitable for indoor applications where exposure to moisture is minimal.

Considerations for International Buyers: Buyers should ensure that plain steel hinges are coated or treated to meet local environmental conditions, especially in humid regions like Nigeria.

Illustrative image related to spring-loaded hinges

Why Choose Aluminum for Spring-Loaded Hinges?

Aluminum is lightweight and resistant to corrosion, making it an excellent choice for applications where weight is a concern, such as in aerospace or portable equipment. It also has good thermal conductivity, which can be beneficial in specific applications.

Pros: Lightweight, corrosion-resistant, and easy to manufacture.

Cons: Lower strength compared to steel options and may not withstand heavy loads.

Impact on Application: Ideal for lightweight applications and environments where corrosion is a concern.

Considerations for International Buyers: Aluminum hinges may need to comply with specific international standards, particularly in industries like aerospace and automotive.

When Is Brass the Right Choice for Spring-Loaded Hinges?

Brass offers a unique combination of aesthetic appeal and corrosion resistance. It is often used in decorative applications or where a low-friction surface is desired. However, brass is generally more expensive than steel and aluminum.

Pros: Attractive appearance, good corrosion resistance, and low friction.

Cons: Higher cost and lower strength compared to steel.

Impact on Application: Suitable for decorative applications, such as furniture or cabinetry.

Considerations for International Buyers: Buyers should consider the aesthetic requirements and ensure compliance with local standards for decorative hardware.

Summary Table of Material Selection for Spring-Loaded Hinges

| Material | Typical Use Case for spring-loaded hinges | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, marine environments | High corrosion resistance | Higher manufacturing costs | High |

| Plain Steel | Indoor applications | Low cost and high strength | Susceptible to rust without coating | Low |

| Aluminum | Aerospace, portable equipment | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Brass | Decorative applications | Attractive appearance and low friction | Higher cost and lower strength | High |

By understanding these materials and their properties, B2B buyers can make informed decisions that align with their specific application needs and regional considerations.

Illustrative image related to spring-loaded hinges

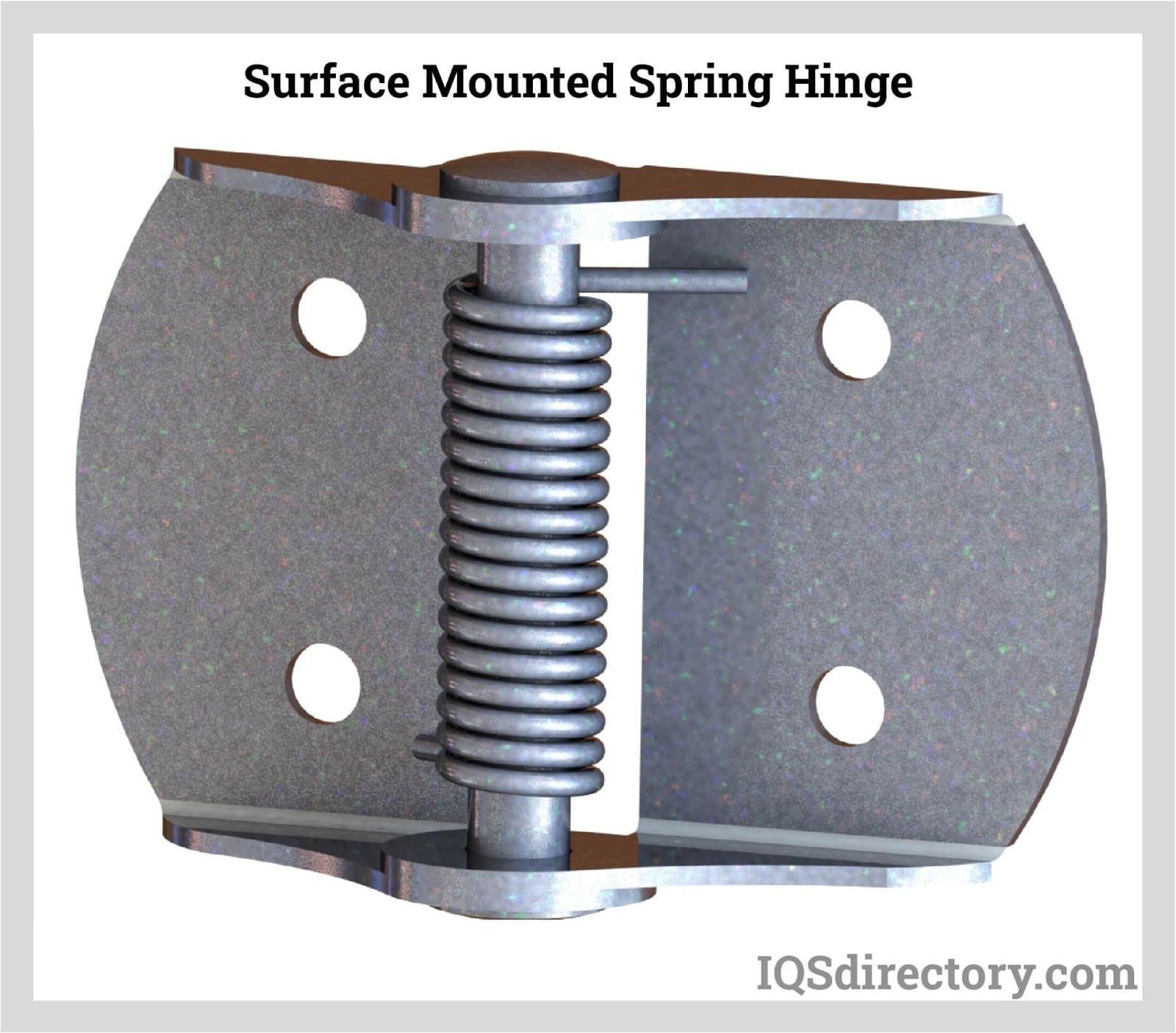

In-depth Look: Manufacturing Processes and Quality Assurance for spring-loaded hinges

What Are the Key Stages in the Manufacturing Process of Spring-Loaded Hinges?

The manufacturing process of spring-loaded hinges involves several critical stages, each designed to ensure the final product meets the stringent demands of various industries. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Spring-Loaded Hinges?

Material preparation begins with the selection of high-quality raw materials, typically stainless steel, aluminum, or brass. The choice of material is crucial, as it affects the hinge’s durability, corrosion resistance, and overall performance. Once selected, the materials undergo treatments such as annealing or tempering to enhance their mechanical properties. This step is essential for ensuring the hinge can withstand repeated use without deformation or failure.

What Forming Techniques Are Used in Spring-Loaded Hinge Production?

The forming stage involves shaping the raw materials into hinge components through processes such as stamping, forging, or machining. Stamping is widely used for producing hinge leaves, where flat sheets of metal are cut and shaped under high pressure. For more complex designs, forging may be employed, where heated metal is shaped using compressive forces. Machining ensures precision in dimensions, often necessary for components that require tight tolerances. Advanced CNC (Computer Numerical Control) machines are frequently utilized to enhance accuracy and efficiency during this stage.

Illustrative image related to spring-loaded hinges

How Are Spring-Loaded Hinges Assembled?

Assembly is where the individual components come together to form a complete spring-loaded hinge. This process includes attaching the torsion spring to the hinge leaves. The correct orientation and tension of the spring are critical, as they determine the hinge’s operational characteristics—whether it opens or closes automatically. Automated assembly lines are often used to improve production speed and reduce labor costs, while still maintaining high standards of quality.

What Finishing Processes Are Applied to Spring-Loaded Hinges?

The finishing stage enhances the aesthetic and functional properties of the hinges. Common finishing techniques include plating, painting, or anodizing, which provide corrosion resistance and improve surface hardness. For instance, zinc plating is often applied to steel hinges to prevent rust, while anodizing is a preferred method for aluminum hinges to enhance their appearance and durability. Quality control measures during this stage ensure that the finish meets specified standards, preventing defects that could affect performance.

What Quality Assurance Practices Are Essential for Spring-Loaded Hinges?

Quality assurance (QA) is a fundamental aspect of the manufacturing process, ensuring that spring-loaded hinges meet international standards and customer specifications. Various quality assurance practices are employed throughout the manufacturing process, from initial material inspections to final product testing.

Illustrative image related to spring-loaded hinges

Which International Standards Should Spring-Loaded Hinge Manufacturers Comply With?

Compliance with international standards, such as ISO 9001, is crucial for manufacturers aiming to serve B2B markets effectively. ISO 9001 outlines the requirements for a quality management system that helps organizations ensure they consistently meet customer and regulatory requirements. Additionally, industry-specific certifications, such as CE marking for European markets, ensure that products meet safety and environmental standards. For applications in oil and gas, compliance with API (American Petroleum Institute) standards may also be necessary.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are integrated at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials to ensure they meet specified quality standards before they are used in production.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring occurs to identify and rectify any deviations from quality standards in real-time. This includes checking dimensions, tolerances, and assembly accuracy.

-

Final Quality Control (FQC): At this stage, finished spring-loaded hinges undergo comprehensive testing to verify functionality, strength, and durability. Common testing methods include torque testing, fatigue testing, and corrosion resistance tests.

How Can B2B Buyers Verify Supplier Quality Assurance Processes?

B2B buyers must take proactive steps to verify the quality assurance processes of potential suppliers. Here are some effective strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes, quality control systems, and adherence to industry standards. This firsthand evaluation can reveal the supplier’s commitment to quality.

-

Requesting Quality Reports: Buyers should ask for documentation that outlines the supplier’s quality assurance procedures, including records of inspections and tests performed on products. This transparency is key to building trust.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control practices. These organizations often have the expertise to conduct thorough evaluations.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Factors such as local regulations, import standards, and cultural differences can impact the quality assurance landscape.

Illustrative image related to spring-loaded hinges

Buyers should be aware of varying compliance requirements in different regions. For example, while CE marking is essential for products sold in Europe, other regions may have different certification needs. This diversity necessitates thorough research and communication with suppliers to ensure compliance with all relevant regulations.

Additionally, language barriers and differing business practices can complicate the quality assurance process. Establishing clear communication channels and expectations upfront can help mitigate misunderstandings and ensure that quality standards are met.

In summary, the manufacturing processes and quality assurance practices for spring-loaded hinges involve meticulous attention to detail and adherence to international standards. By understanding these processes, B2B buyers can make informed decisions, ensuring they source high-quality products that meet their specific requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘spring-loaded hinges’

To assist international B2B buyers in sourcing spring-loaded hinges effectively, this guide offers a practical checklist designed to streamline the procurement process. Following these steps will ensure that you choose the right products for your applications while minimizing risks.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical requirements for your spring-loaded hinges. This includes dimensions, material types (such as stainless steel or aluminum), and spring action preferences (spring-loaded-to-open or spring-loaded-to-close). Knowing these specifications upfront helps in filtering suppliers and ensuring compatibility with your application needs.

Step 2: Research Potential Suppliers

Take the time to research various suppliers who specialize in spring-loaded hinges. Look for companies with a strong reputation in the industry and positive customer reviews. Consider suppliers that offer a diverse range of products to ensure you can find the exact specifications you require.

- Tip: Use industry-specific platforms and directories to find credible suppliers.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant industry certifications, which can indicate their adherence to quality standards. Certifications such as ISO 9001 signify a commitment to quality management systems, while safety certifications ensure compliance with international regulations. This step is essential to mitigate risks associated with product failures.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the spring-loaded hinges you are considering. Testing samples in your application allows you to evaluate their performance, torque, and overall fit. This hands-on approach ensures that the hinges meet your operational requirements and can save costs related to returns or replacements later on.

Step 5: Assess Customization Options

Determine if you need customized hinges to better fit your specific applications. Many suppliers offer customization in terms of size, strength, and finishes. Engaging in discussions about custom solutions can help you achieve the desired functionality without compromising on quality.

Step 6: Review Pricing and Delivery Terms

Compare pricing among different suppliers while considering the total cost of ownership, which includes shipping and handling fees. Additionally, review delivery timelines to ensure that they align with your project schedules. Establishing clear expectations regarding lead times can prevent delays in your operations.

Step 7: Check After-Sales Support and Warranty

Finally, inquire about after-sales support and warranty policies offered by suppliers. Reliable customer service can be invaluable for addressing any issues that arise post-purchase. A good warranty can also provide peace of mind, ensuring that you are protected against manufacturing defects.

By following this checklist, B2B buyers can effectively navigate the procurement process for spring-loaded hinges, ensuring they make informed decisions that align with their operational needs and quality standards.

Comprehensive Cost and Pricing Analysis for spring-loaded hinges Sourcing

What Are the Key Cost Components in Sourcing Spring-Loaded Hinges?

When sourcing spring-loaded hinges, understanding the cost structure is vital for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials for spring-loaded hinges include stainless steel, aluminum, and zinc-plated steel. Stainless steel generally commands a higher price due to its durability and corrosion resistance, while aluminum is lighter and often less expensive.

-

Labor: Labor costs encompass the workforce involved in manufacturing the hinges. This includes both skilled labor for assembly and unskilled labor for basic tasks. Labor costs can vary considerably based on the region, with markets in Africa and South America typically having lower labor costs compared to Europe.

-

Manufacturing Overhead: This includes indirect costs related to production, such as utilities, rent, and administrative expenses. Efficient operations and automation can help lower these costs, which is crucial for maintaining competitive pricing.

-

Tooling: Tooling costs relate to the equipment and machinery needed to manufacture the hinges. Custom designs may require specialized tools, increasing the initial investment but potentially lowering costs per unit for high-volume orders.

-

Quality Control (QC): Implementing robust QC processes ensures that the hinges meet specified standards. While this adds to the cost, it is essential for maintaining product quality and reducing returns or defects.

-

Logistics: Transportation and warehousing costs are critical, especially for international shipments. Factors like distance, mode of transport, and shipping regulations can influence these expenses.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can vary based on market demand, supplier reputation, and the complexity of the product.

How Do Pricing Influencers Impact Spring-Loaded Hinges Costs?

Several factors influence the pricing of spring-loaded hinges:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide better pricing for larger orders. Understanding the MOQ can help buyers optimize their purchasing strategy to reduce per-unit costs.

-

Specifications and Customization: Custom hinges tailored to specific applications may incur higher costs due to additional design and manufacturing processes. Buyers should weigh the benefits of customization against the potential increase in price.

-

Material Quality and Certifications: High-quality materials and specific certifications (like ISO or ASTM) may raise costs but can also enhance durability and performance, ultimately leading to lower maintenance costs.

-

Supplier Factors: The reputation and reliability of a supplier can impact pricing. Established suppliers may charge a premium for their reputation, while emerging suppliers might offer more competitive rates to gain market share.

-

Incoterms: The agreed-upon Incoterms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Choosing the right Incoterms can help manage logistics costs effectively.

What Are the Best Tips for Buyers Negotiating Prices for Spring-Loaded Hinges?

For B2B buyers, especially those in international markets like Africa, South America, and the Middle East, negotiating effectively can lead to significant cost savings:

-

Conduct Market Research: Understand the pricing landscape and competitor offerings. This knowledge can empower negotiations and help identify reasonable price points.

-

Leverage Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, durability, and replacement. Highlighting TCO can justify a higher upfront investment for better quality products.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better terms, including discounts or flexible payment options. Long-term partnerships often yield benefits like priority service and reduced pricing.

-

Explore Local Suppliers: Sourcing from local manufacturers can minimize logistics costs and lead times, which is particularly beneficial for buyers in regions with less developed shipping infrastructure.

-

Be Prepared to Walk Away: Having alternative suppliers can strengthen your negotiation position. Don’t hesitate to explore other options if a supplier is unwilling to meet your budgetary requirements.

Conclusion

Understanding the cost structure and pricing influencers for spring-loaded hinges is crucial for B2B buyers. By leveraging insights into cost components and employing effective negotiation strategies, buyers can achieve better pricing while ensuring the right product quality for their applications. Always remember that prices can fluctuate based on market conditions, so maintaining flexibility and awareness is essential in international sourcing.

Alternatives Analysis: Comparing spring-loaded hinges With Other Solutions

Exploring Alternatives to Spring-Loaded Hinges for Industrial Applications

In the realm of industrial hardware, spring-loaded hinges are a popular choice due to their unique functionality, allowing doors and lids to close automatically. However, several alternative solutions can achieve similar objectives, each with distinct advantages and disadvantages. This section compares spring-loaded hinges with gas springs and hydraulic dampers, two widely used alternatives in various applications.

| Comparison Aspect | Spring-Loaded Hinges | Gas Springs | Hydraulic Dampers |

|---|---|---|---|

| Performance | Reliable for frequent use, providing consistent tension and closure | Excellent for controlled motion and adjustable force | Smooth motion control with variable resistance |

| Cost | Generally affordable, especially in bulk | Moderate to high, depending on specifications | Typically higher due to complex mechanisms |

| Ease of Implementation | Straightforward installation; requires minimal tools | Requires precise mounting and alignment | More complex installation; may need specialized tools |

| Maintenance | Low maintenance; durable under various conditions | Moderate; seals may need periodic checks | Low; long-lasting but may require occasional servicing |

| Best Use Case | Ideal for doors and lids that need automatic closure | Best for adjustable force applications, like hatches | Suitable for dampening motion in heavy doors or machinery |

What Are the Advantages and Disadvantages of Gas Springs?

Gas springs offer a compelling alternative to spring-loaded hinges, particularly in applications where adjustable force is necessary. They use compressed gas to provide a smooth and controlled motion, making them ideal for lifting and supporting heavy lids or panels. The primary advantage of gas springs is their ability to vary the amount of force exerted, allowing users to customize performance based on specific needs. However, they can be more expensive than spring-loaded hinges and require careful installation to ensure correct alignment and function.

How Do Hydraulic Dampers Compare to Spring-Loaded Hinges?

Hydraulic dampers excel in providing smooth motion control, making them suitable for applications requiring gradual resistance, such as heavy machinery doors or automotive components. Their design allows for variable resistance, adapting to the speed of motion, which is advantageous in preventing abrupt stops that could cause damage. The downside is that hydraulic dampers tend to be more complex and costly than spring-loaded hinges. Additionally, their installation may require specialized tools and expertise, making them less accessible for simple applications.

Conclusion: How to Choose the Right Solution for Your Needs

When evaluating solutions for automatic closure and motion control, B2B buyers should consider specific application requirements, including performance needs, budget constraints, and installation capabilities. Spring-loaded hinges offer simplicity and cost-effectiveness, making them ideal for many industrial applications. However, for scenarios demanding adjustable force or smooth motion control, gas springs or hydraulic dampers may be more suitable. By assessing the unique demands of their projects, buyers can select the most effective solution to enhance functionality and efficiency in their operations.

Essential Technical Properties and Trade Terminology for spring-loaded hinges

When sourcing spring-loaded hinges, understanding their technical properties and relevant trade terminology is crucial for making informed purchasing decisions. This section provides key specifications and industry terms that will aid B2B buyers in evaluating their options effectively.

What Are the Key Technical Properties of Spring-Loaded Hinges?

1. Material Grade

Spring-loaded hinges are typically manufactured from materials such as stainless steel, plain steel, or aluminum. The choice of material affects durability, corrosion resistance, and weight. For instance, stainless steel is often preferred for outdoor applications due to its resistance to rust, while aluminum may be favored for lightweight designs. Understanding material grades helps buyers select hinges that meet specific environmental and load-bearing requirements.

2. Spring Action Type

Spring-loaded hinges come in two primary types: spring-loaded-to-open and spring-loaded-to-close. The action type determines how the hinge operates after installation. Buyers must analyze their application to ensure the correct action type is selected, as it directly impacts functionality. Choosing the right spring action is essential for applications requiring reliable door closure or opening.

Illustrative image related to spring-loaded hinges

3. Torque Rating

The torque rating, measured in inch-pounds, indicates the amount of force required to open or close the hinge. This specification is vital for ensuring that the hinge can handle the weight and frequency of use of the door or panel it supports. A higher torque rating means that the hinge can manage heavier loads or more frequent operations, making this a critical factor in selecting the appropriate hinge for a specific application.

4. Open Width and Length

These dimensions define the size of the hinge when fully extended and are crucial for compatibility with the installation surface. Buyers should ensure that the open width and length fit the design specifications of their doors or cabinets. Accurate measurements prevent misalignment and ensure optimal performance.

5. Finish Type

The finish of a spring-loaded hinge can influence its aesthetic appeal and durability. Common finishes include zinc plating for corrosion resistance, nickel plating for enhanced appearance, and no finish for specific industrial applications. Selecting the right finish can enhance the hinge’s lifespan and performance in various environments, making it an important consideration for buyers.

What Are Common Trade Terms Used in the Spring-Loaded Hinge Industry?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking to source high-quality components that meet specific manufacturing standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Being aware of the MOQ helps buyers plan their purchasing strategy, ensuring they meet supplier requirements while optimizing inventory levels.

Illustrative image related to spring-loaded hinges

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products or services. This process is essential for B2B buyers to compare costs and make informed purchasing decisions, especially when sourcing customized or bulk items like spring-loaded hinges.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for international buyers to avoid misunderstandings and ensure smooth transactions.

5. Customization

Customization refers to the ability to modify standard products to meet specific requirements, such as size, strength, or material. Understanding the options for customization allows buyers to tailor products to their unique needs, enhancing functionality and performance.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring that the spring-loaded hinges they procure will meet their operational needs and contribute to the success of their applications.

Navigating Market Dynamics and Sourcing Trends in the spring-loaded hinges Sector

What Are the Current Market Dynamics and Key Trends Affecting Spring-Loaded Hinges?

The global market for spring-loaded hinges is experiencing significant growth, driven by the increasing demand for efficient and durable fastening solutions across various industries, including construction, automotive, and consumer electronics. Key trends influencing this sector include the rise of automation and smart technologies, which necessitate high-performance hinges that can withstand repeated use. Additionally, the shift towards lightweight materials, such as aluminum and advanced composites, is reshaping sourcing strategies as manufacturers seek to optimize product performance while reducing costs.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly focused on sourcing hinges that meet specific application requirements. Customization is becoming a significant trend, allowing buyers to specify dimensions, spring tensions, and materials to suit unique operational needs. The incorporation of digital platforms for sourcing is also on the rise, enabling buyers to access a broader range of suppliers and products, thus enhancing their procurement efficiency.

Moreover, the post-pandemic market landscape has highlighted the importance of supply chain resilience. B2B buyers are now prioritizing suppliers with robust logistics capabilities and shorter lead times, particularly in emerging markets where infrastructure may present challenges. Sustainability is another critical factor, as buyers are increasingly aligning their purchasing decisions with environmental considerations, prompting suppliers to adapt accordingly.

How Does Sustainability and Ethical Sourcing Impact Spring-Loaded Hinges?

In today’s market, sustainability and ethical sourcing are paramount for B2B buyers of spring-loaded hinges. The environmental impact of manufacturing processes and materials used in hinges is under scrutiny, leading to a growing preference for eco-friendly options. Manufacturers are responding by adopting sustainable practices, such as using recycled materials and minimizing waste during production. This shift not only reduces the carbon footprint but also appeals to environmentally conscious buyers.

Ethical supply chains are becoming increasingly important, with buyers seeking transparency regarding labor practices and sourcing methods. Certifications such as ISO 14001 for environmental management and FSC certification for sustainable materials are gaining traction among buyers who prioritize responsible sourcing. By choosing suppliers with these certifications, buyers can ensure that their procurement processes align with broader sustainability goals.

Additionally, the use of green materials in spring-loaded hinges, such as bio-based plastics and non-toxic coatings, is becoming more prevalent. This aligns with the growing demand for products that contribute to a circular economy, where materials are reused and recycled, further reducing environmental impact. As buyers prioritize sustainability, they are likely to favor suppliers who can demonstrate a commitment to ethical practices and environmental responsibility.

What Is the Brief Evolution of Spring-Loaded Hinges?

The evolution of spring-loaded hinges can be traced back to their early use in various applications, primarily in doors and cabinets, where they provided the dual function of fastening and facilitating movement. Initially constructed from heavy metals, advancements in materials science have led to the development of lighter and more durable alternatives, such as aluminum and high-grade stainless steel.

As industries evolved, so did the designs and functionalities of spring-loaded hinges. The introduction of automation and smart technology has prompted manufacturers to innovate further, resulting in hinges that offer enhanced torque, customizable features, and improved performance under varying conditions. This evolution reflects the broader trend in B2B manufacturing towards efficiency, customization, and sustainability, setting the stage for future advancements in the sector.

Illustrative image related to spring-loaded hinges

In conclusion, understanding these market dynamics, sustainability imperatives, and the historical context of spring-loaded hinges is essential for international B2B buyers looking to make informed sourcing decisions that align with their operational and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of spring-loaded hinges

-

How do I determine the right spring-loaded hinge for my application?

To select the appropriate spring-loaded hinge, assess the specific requirements of your application, including the direction of the spring action (open or close), the weight and size of the door or panel, and the environmental conditions (e.g., humidity, temperature). It’s advisable to experiment with different torque levels and materials to ensure the hinge meets your operational demands. Ordering samples can be a practical approach to test the fit and functionality before committing to a larger order. -

What materials are commonly used for spring-loaded hinges, and how do they affect performance?

Spring-loaded hinges are typically made from materials like stainless steel, aluminum, and brass. Stainless steel is favored for its corrosion resistance and strength, making it suitable for outdoor or humid environments. Aluminum is lightweight and offers good resistance, while brass provides an aesthetic appeal. Selecting the right material is crucial as it influences durability, weight capacity, and overall performance in your specific application. -

Can I customize the specifications of my spring-loaded hinges?

Yes, most manufacturers offer customization options for spring-loaded hinges. You can specify dimensions, torque strength, and materials to suit your application needs. Customization can help in achieving the desired functionality, especially for unique projects. However, it is often recommended to explore standard options first, as they can be more cost-effective and quicker to deliver. -

What are the minimum order quantities (MOQs) for spring-loaded hinges?

Minimum order quantities vary by supplier, but many manufacturers have flexible MOQs for standard products. For custom orders, MOQs may be higher due to the additional production processes involved. It’s best to inquire directly with your chosen supplier about their specific policies and consider negotiating terms that align with your purchasing needs and volume. -

How can I ensure quality assurance when sourcing spring-loaded hinges internationally?

To ensure quality assurance, partner with reputable suppliers who have established quality control processes. Request certifications, such as ISO 9001, and ask for samples to evaluate before placing a larger order. Additionally, consider utilizing third-party inspection services to verify product quality and compliance with your specifications, especially when dealing with international shipments. -

What payment terms should I expect when ordering spring-loaded hinges from international suppliers?

Payment terms can vary significantly between suppliers. Common options include upfront payment, partial payment upon order confirmation, and balance payment prior to shipment. It is essential to clarify these terms during negotiations and consider using secure payment methods, such as letters of credit or escrow services, to mitigate risks associated with international transactions. -

What logistics considerations should I keep in mind when sourcing spring-loaded hinges?

When sourcing internationally, consider shipping methods, lead times, and customs clearance processes. Ensure that your supplier can provide timely shipping options that meet your project deadlines. Understanding the import regulations and potential tariffs in your country is also critical to avoid unexpected costs. Collaborating with a reliable freight forwarder can help streamline logistics and ensure smooth delivery. -

How do I evaluate potential suppliers of spring-loaded hinges?

Evaluating suppliers involves assessing their industry experience, product quality, and customer service. Review their portfolio and seek references from previous clients to gauge satisfaction levels. Additionally, consider suppliers’ certifications, manufacturing capabilities, and responsiveness to inquiries. Establishing a strong communication channel is vital for a successful long-term partnership, especially in international trade.

Top 6 Spring-Loaded Hinges Manufacturers & Suppliers List

1. Guden – Spring Hinges for Industrial Doors and Cabinets

Domain: guden.com

Registered: 1995 (30 years)

Introduction: Guden offers a variety of Spring Hinges for industrial doors and cabinets, available in lengths from 1.10 inches to 8.75 inches. They are spring-loaded to open and close, with options for same-day shipment. The hinges come in both spring-loaded-to-open and spring-loaded-to-close versions, with and without holes, and are made from materials including steel, zinc plated steel, stainless steel, and a…

2. HingeOutlet – Spring Hinges for Commercial Doors

Domain: hingeoutlet.com

Registered: 2004 (21 years)

Introduction: Spring Hinges for Commercial Doors – HingeOutlet offers a variety of spring hinges specifically designed for commercial applications. The product category includes options suitable for heavy-duty use, ensuring durability and reliability in high-traffic environments. Customers can benefit from free shipping on orders over $160. The website provides expert support and various resources, including gu…

3. Therma-Tru – Spring Loaded Hinge

Domain: store.thermatru.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “Spring Loaded Hinge”, “price”: “$37.49”, “SKU”: “HG58SL-1C”, “shipping_info”: “Expected to ship within 3 business days”, “available_colors”: [“Brushed Nickel”, “Black Nickel”, “Oil Rubbed Bronze”, “Polished Chrome”, “Stainless Steel”, “Zinc Dichromate”], “description”: “Genuine Therma-Tru® hinges position the door to properly compress the weatherstrip to help form a tight, even s…

4. House of Antique Hardware – Swinging Door Spring Hinges

Domain: houseofantiquehardware.com

Registered: 1999 (26 years)

Introduction: This company, House of Antique Hardware – Swinging Door Spring Hinges, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Therma-Tru – Spring-Loaded Hinge

Domain: projectcenter.thermatru.com

Registered: 1995 (30 years)

Introduction: Product: Spring-Loaded Hinge

Purchase Link: buy now from Therma-Tru

Time Required: Not specified

Difficulty: Not specified

Tools Required: Safety Glasses, Hex Wrench, Pliers

Materials Required: Spring-Loaded Hinge, Cross Pin

Adjustment Steps: 1) Determine the Number of Spring Loaded Hinges 2) Locate the Hex Adjustment Hole 3) Insert Allen Wrench 4) Adjust Tension 5) Insert the Cross Pin 6) Remove …

6. McMaster – Spring-Loaded Hinges

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Spring-Loaded Hinges, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for spring-loaded hinges

In summary, strategic sourcing of spring-loaded hinges offers international B2B buyers a pathway to enhance operational efficiency while ensuring product reliability. By understanding the diverse options available—ranging from different sizes and materials to customizable designs—buyers can select hinges that best fit their specific applications. The importance of evaluating hinge tension, strength, and the type of spring action cannot be overstated, as these factors directly influence the performance and longevity of the hinges in various environments.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, leveraging strategic sourcing practices will be crucial for companies looking to maintain a competitive edge. Engaging with suppliers who offer a broad range of stock and custom solutions can significantly streamline procurement processes and reduce lead times.

Looking ahead, it is imperative for businesses to stay informed about advancements in hinge technology and materials. By prioritizing strategic sourcing and building strong supplier relationships, companies can ensure they are well-equipped to meet future demands and challenges in their respective industries. Take action now by exploring reliable suppliers and considering your specific needs for spring-loaded hinges, setting the stage for success in your upcoming projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.