How to Source Solenoid Valve Actuator Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for solenoid valve actuator

In today’s fast-paced industrial landscape, sourcing the right solenoid valve actuator can be a daunting challenge for B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe, including countries like Nigeria and Saudi Arabia. The need for reliable and efficient control of fluid dynamics drives demand for solenoid valve actuators, which serve as critical components in various applications, from automation systems to automotive solutions. However, navigating the complexities of product specifications, supplier capabilities, and regional regulations can overwhelm even the most seasoned procurement professionals.

This comprehensive guide is designed to empower international B2B buyers with the insights necessary to make informed purchasing decisions regarding solenoid valve actuators. We will explore the various types of solenoid valve actuators available, their specific applications across different industries, and the key factors to consider when vetting suppliers. Additionally, we’ll address cost considerations and provide strategies for optimizing procurement processes to ensure the best value.

By the end of this guide, buyers will have a robust understanding of how to navigate the global market for solenoid valve actuators, equipping them with the knowledge to enhance operational efficiency and drive their businesses forward in an increasingly competitive environment.

Understanding solenoid valve actuator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Direct Acting Solenoid | Operates directly with low pressure; compact design. | Water control, HVAC systems | Pros: Quick response, simple design. Cons: Limited to low-pressure applications. |

| Pilot Operated Solenoid | Uses a small pilot flow to control larger flows. | Industrial automation, gas control | Pros: Suitable for high pressure, efficient. Cons: More complex, requires maintenance. |

| Latching Solenoid | Maintains position without continuous power. | Battery-operated devices, alarms | Pros: Energy-efficient, reliable for intermittent use. Cons: Slower actuation speed. |

| Push-Pull Solenoid | Provides both push and pull actions in one unit. | Robotics, automotive applications | Pros: Versatile motion control. Cons: May require more space for installation. |

| Dual Coil Solenoid | Features two coils for faster actuation and release. | Medical devices, precise flow control | Pros: Quick switching, enhanced control. Cons: Higher cost, more complex wiring. |

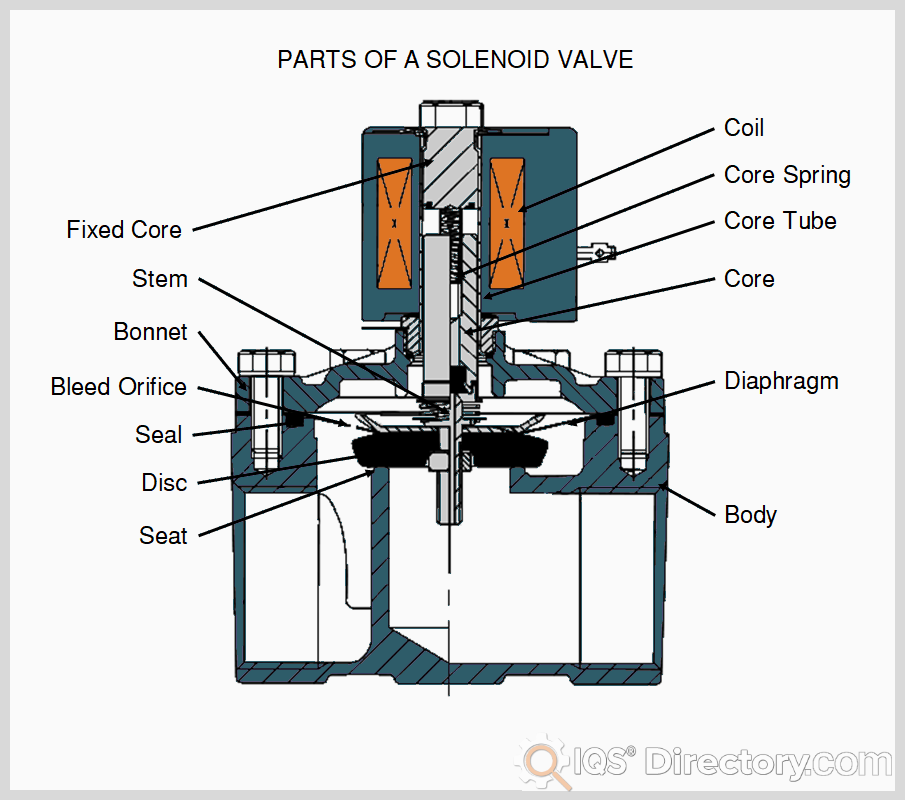

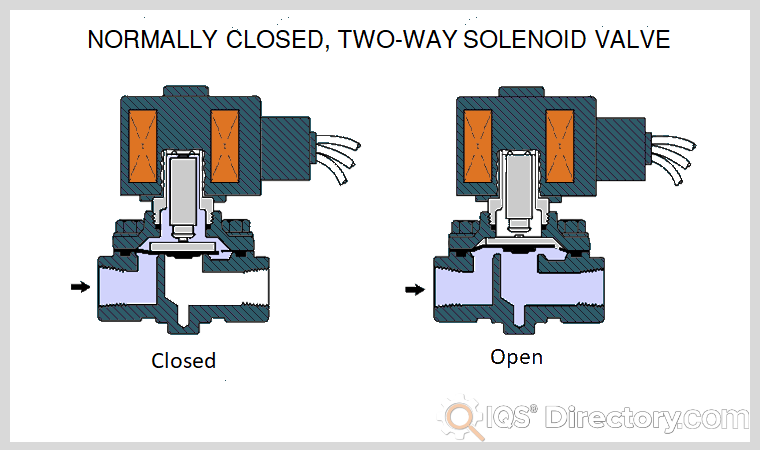

What Are the Characteristics of Direct Acting Solenoids?

Direct acting solenoids are designed for applications that require immediate response with low pressure. Their compact size makes them suitable for installations where space is a constraint, such as in HVAC systems and water control applications. Buyers should consider the operational pressure and the environment in which the solenoid will be used, as these factors can influence performance and longevity.

Illustrative image related to solenoid valve actuator

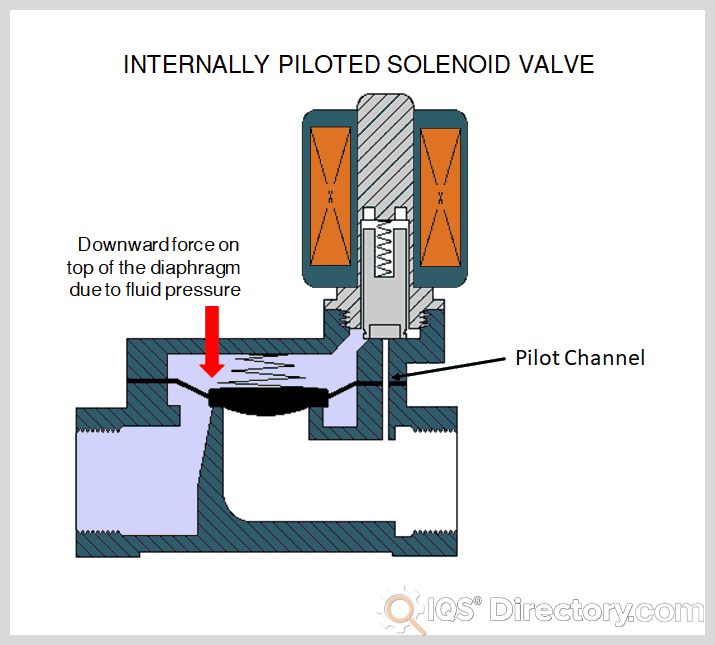

How Do Pilot Operated Solenoids Work?

Pilot operated solenoids leverage a small pilot flow to manage larger fluid flows, making them ideal for high-pressure environments. Commonly used in industrial automation and gas control, these solenoids can efficiently regulate significant volumes of fluid or gas. B2B buyers must evaluate the complexity of installation and maintenance, as these solenoids often require more intricate setups compared to their direct acting counterparts.

What Are the Benefits of Latching Solenoids?

Latching solenoids are unique in that they can maintain their position without continuous power, making them energy-efficient and perfect for applications like alarms and battery-operated devices. Their ability to operate intermittently reduces energy consumption, which can be a critical factor for businesses aiming to minimize operational costs. However, buyers should be aware that the actuation speed may be slower compared to other solenoid types.

Why Choose Push-Pull Solenoids?

Push-pull solenoids offer the versatility of both push and pull actions within a single unit, making them suitable for applications in robotics and automotive systems. Their dual functionality allows for more complex movements, which can enhance the performance of automated systems. When considering this option, B2B buyers should factor in the installation space required and the specific motion needs of their applications.

What Advantages Do Dual Coil Solenoids Provide?

Dual coil solenoids feature two coils that enable faster actuation and release, making them ideal for applications requiring precise flow control, such as in medical devices. Their quick switching capabilities enhance operational efficiency but come at a higher cost and complexity in wiring. Buyers should weigh the benefits of speed and control against the increased investment and potential installation challenges.

Key Industrial Applications of solenoid valve actuator

| Industry/Sector | Specific Application of solenoid valve actuator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Automated Flow Control in Pipelines | Enhances safety and efficiency in fluid transport | Durability under harsh conditions, compliance with industry standards |

| Water Treatment | Control of Chemical Dosing Systems | Improves accuracy in chemical treatment processes | Corrosion resistance, compatibility with various chemicals |

| Automotive | Fuel Injection Systems | Optimizes engine performance and fuel efficiency | Precision control, response time, and reliability |

| HVAC Systems | Temperature Control in HVAC Units | Increases energy efficiency and comfort | Power consumption, size, and installation ease |

| Medical Equipment | Fluid Management in Diagnostic Devices | Ensures precise fluid delivery and patient safety | Compliance with medical standards, reliability, and service life |

How is the Solenoid Valve Actuator Used in the Oil & Gas Sector?

In the oil and gas industry, solenoid valve actuators play a crucial role in automating flow control within pipelines. By enabling precise opening and closing of valves, these actuators enhance operational safety and efficiency during the transport of hazardous fluids. International buyers, particularly from regions like Nigeria and Saudi Arabia, should prioritize sourcing actuators that offer high durability and compliance with stringent industry standards to withstand extreme conditions and ensure reliable performance.

Illustrative image related to solenoid valve actuator

What Role Does the Solenoid Valve Actuator Play in Water Treatment?

In water treatment facilities, solenoid valve actuators are essential for controlling chemical dosing systems. They facilitate accurate measurements of chemicals used for purification, which is vital for maintaining water quality. Buyers from South America and Europe must consider the actuator’s corrosion resistance and compatibility with various chemicals, ensuring longevity and minimal maintenance in demanding environments.

How is the Solenoid Valve Actuator Applied in Automotive Fuel Systems?

Solenoid valve actuators are integral to automotive fuel injection systems, where they regulate the flow of fuel into the engine. This precise control optimizes engine performance and enhances fuel efficiency, which is increasingly important for manufacturers looking to meet environmental standards. B2B buyers should focus on sourcing actuators with a quick response time and reliability to maintain optimal performance in diverse vehicle models.

In What Ways Does the Solenoid Valve Actuator Improve HVAC Systems?

In HVAC systems, solenoid valve actuators are utilized for temperature control, managing the flow of refrigerants and air. This capability is vital for enhancing energy efficiency and maintaining comfort in commercial and residential buildings. Buyers in the Middle East and Europe should evaluate power consumption and the actuator’s size to ensure seamless integration into existing systems, promoting both energy savings and effective climate control.

Why is the Solenoid Valve Actuator Critical in Medical Equipment?

In the medical field, solenoid valve actuators are used for fluid management in diagnostic devices, ensuring precise delivery of fluids necessary for various tests and treatments. This reliability is paramount for patient safety and accurate results. International buyers must ensure that sourced actuators comply with medical standards and have a proven track record of reliability and longevity in critical applications.

3 Common User Pain Points for ‘solenoid valve actuator’ & Their Solutions

Scenario 1: Inconsistent Performance in High-Temperature Environments

The Problem: Many B2B buyers in industries such as oil and gas or food processing face the challenge of solenoid valve actuators failing or performing inconsistently in high-temperature environments. This issue can lead to unexpected downtimes, safety hazards, and increased maintenance costs. For instance, a buyer might find that their actuators are unable to maintain the required flow control due to overheating, which can cause the solenoid coil to fail or the plunger to jam.

The Solution: To mitigate these challenges, buyers should prioritize sourcing solenoid valve actuators specifically designed for high-temperature applications. Look for products with high-temperature ratings and robust materials that can withstand extreme conditions. It’s essential to consult with suppliers about the thermal limits of the actuators and to verify their performance in relevant applications. Additionally, implementing regular maintenance schedules that include thermal inspections can help identify potential failures before they result in costly downtime. Investing in temperature-resistant materials and protective enclosures can also extend the life of the actuators in demanding environments.

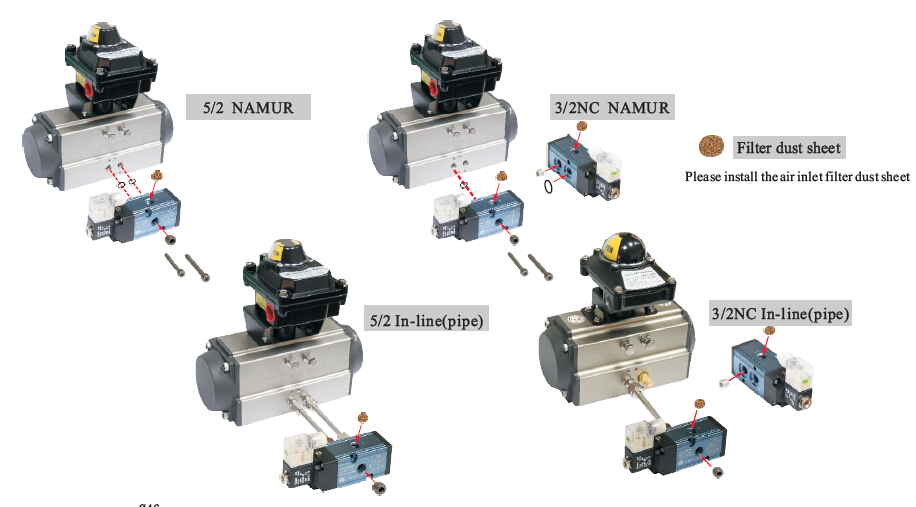

Scenario 2: Complexity in System Integration

The Problem: B2B buyers often encounter difficulties when integrating solenoid valve actuators into existing systems, particularly when dealing with varying voltage requirements or incompatible control systems. This complexity can lead to delays in project timelines and frustration among engineering teams. For example, a manufacturer may find that their new solenoid valve actuators do not communicate properly with their control systems, resulting in erratic valve operation.

The Solution: To overcome integration issues, it is critical to conduct a thorough compatibility analysis before purchasing solenoid valve actuators. Buyers should gather detailed specifications of their existing systems, including voltage, current requirements, and communication protocols. Engaging with suppliers early in the process can provide insights into the best actuator options that will seamlessly integrate with current setups. Additionally, consider using programmable logic controllers (PLCs) or relays that can bridge any compatibility gaps, ensuring smooth operation. Training staff on the specific integration processes can also reduce integration time and enhance overall system reliability.

Illustrative image related to solenoid valve actuator

Scenario 3: High Maintenance Costs Due to Component Wear

The Problem: Frequent wear and tear of solenoid valve actuators can lead to high maintenance costs, especially in applications requiring continuous operation. Buyers may find themselves replacing actuators more often than anticipated, resulting in both financial strain and operational inefficiencies. For example, in a manufacturing facility, a solenoid actuator may fail after only a few months of operation, disrupting production and requiring costly replacements.

The Solution: To address maintenance concerns, B2B buyers should invest in high-quality solenoid valve actuators that feature durable construction and robust materials capable of withstanding operational stresses. Conducting a lifecycle cost analysis can help identify the total cost of ownership associated with different actuator models, guiding buyers to make informed decisions based on reliability rather than initial price alone. Furthermore, implementing predictive maintenance strategies—such as monitoring actuator performance and utilizing sensors to detect early signs of wear—can significantly reduce unexpected failures. Establishing a partnership with manufacturers for ongoing support and guidance can also ensure that buyers stay updated on the best practices for actuator maintenance and longevity.

Strategic Material Selection Guide for solenoid valve actuator

What Are the Common Materials Used in Solenoid Valve Actuators?

When selecting materials for solenoid valve actuators, it is essential to consider the specific requirements of the application, including performance, environmental conditions, and regulatory compliance. Below, we analyze four common materials used in solenoid valve actuators, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Stainless Steel Perform in Solenoid Valve Actuators?

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 400°F (204°C) and can handle pressures exceeding 2000 psi, depending on the grade.

Pros & Cons: The durability of stainless steel makes it suitable for harsh environments, including those found in the oil and gas industries. However, its higher cost compared to other materials can be a deterrent for budget-conscious buyers. Manufacturing complexity can also increase due to the need for specialized machining and welding techniques.

Impact on Application: Stainless steel is compatible with a wide range of fluids, including corrosive media like acids and alkalis, making it ideal for applications in chemical processing and food industries.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM A240 for stainless steel. In Africa and South America, local sourcing may affect availability and pricing.

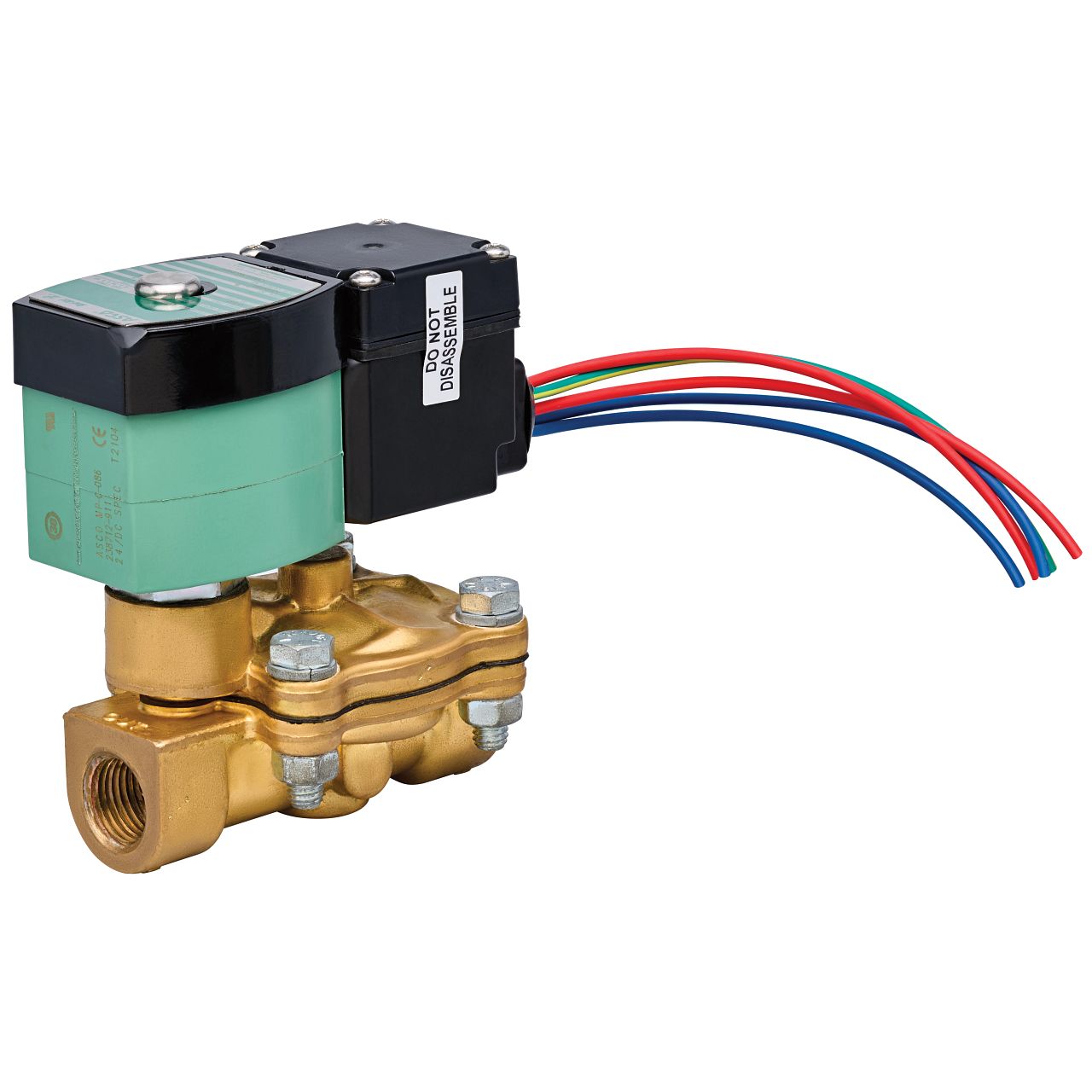

What Role Does Brass Play in Solenoid Valve Actuators?

Key Properties: Brass is an alloy of copper and zinc, known for its good corrosion resistance and thermal conductivity. It typically operates effectively at temperatures up to 200°F (93°C) and pressures around 150 psi.

Pros & Cons: Brass is relatively inexpensive and easy to machine, making it a popular choice for many applications. However, it may not be suitable for high-pressure or high-temperature environments, and its susceptibility to dezincification can limit its use in certain corrosive applications.

Impact on Application: Brass is often used in water and gas applications due to its compatibility with these media. However, it is not recommended for use with strong acids or chlorinated solutions.

Considerations for International Buyers: Compliance with standards such as ASTM B453 is crucial for buyers in Europe and North America. In regions like Africa and South America, understanding local regulations regarding material specifications can impact project timelines.

How Does Plastic Material Affect Solenoid Valve Actuators?

Key Properties: Plastics, such as polyamide (nylon) or polyvinyl chloride (PVC), are lightweight and resistant to corrosion. They typically operate at lower temperatures, around 140°F (60°C), and pressures up to 100 psi.

Pros & Cons: The low cost and ease of manufacturing make plastics an attractive option for many applications. However, their lower strength and thermal resistance compared to metals can limit their use in demanding environments.

Impact on Application: Plastic solenoid valve actuators are ideal for low-pressure applications, particularly in water treatment and irrigation systems. However, they may not be suitable for applications involving high temperatures or aggressive chemicals.

Considerations for International Buyers: Buyers should be aware of compliance with standards such as ASTM D1784 for PVC. In regions with high humidity or temperature fluctuations, the choice of plastic material should be carefully evaluated.

What Advantages Does Aluminum Offer in Solenoid Valve Actuators?

Key Properties: Aluminum is lightweight, has good corrosion resistance, and can handle temperatures up to 250°F (121°C) and pressures around 150 psi.

Pros & Cons: Aluminum’s lightweight nature makes it easy to handle and install. However, it may not be as durable as stainless steel in harsh environments, and its cost can vary significantly based on local market conditions.

Impact on Application: Aluminum is suitable for applications where weight is a critical factor, such as in aerospace or automotive industries. However, it may not be ideal for applications involving corrosive fluids.

Illustrative image related to solenoid valve actuator

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B221 for aluminum. In regions with varying economic conditions, the availability and cost of aluminum can influence purchasing decisions.

Summary Table of Material Selection for Solenoid Valve Actuators

| Material | Typical Use Case for solenoid valve actuator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Chemical processing, food industry | Excellent corrosion resistance | Higher cost, manufacturing complexity | High |

| Brass | Water and gas applications | Cost-effective, easy to machine | Limited high-pressure/temperature use | Medium |

| Plastic | Water treatment, irrigation systems | Lightweight, low-cost | Lower strength, temperature limitations | Low |

| Aluminum | Aerospace, automotive applications | Lightweight, good corrosion resistance | Less durable in harsh environments | Medium |

This strategic material selection guide aims to empower B2B buyers by providing insights into the properties and implications of various materials used in solenoid valve actuators, aiding in informed decision-making for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for solenoid valve actuator

What Are the Main Stages of Manufacturing Solenoid Valve Actuators?

Manufacturing solenoid valve actuators involves several critical stages that ensure the final product meets the required specifications and quality standards. Each stage plays a significant role in determining the actuator’s performance, reliability, and overall quality.

How is Material Prepared for Solenoid Valve Actuators?

The first step in the manufacturing process is material preparation, which involves selecting and sourcing high-quality materials. Common materials used in solenoid valve actuators include stainless steel, brass, and various plastics, chosen for their durability and resistance to corrosion.

Once sourced, materials undergo rigorous inspection to ensure they meet industry standards. This includes checking for impurities and ensuring dimensional accuracy. After approval, materials are cut, machined, or molded into the necessary shapes, ready for the next manufacturing stage.

What Techniques Are Used in the Forming Process?

The forming stage is where the individual components of the solenoid valve actuator are created. Techniques employed can vary based on the material and design requirements. Common forming processes include:

- Machining: Precision machining is often used for metal parts, ensuring tight tolerances and smooth finishes. This may involve turning, milling, or grinding operations.

- Injection Molding: For plastic components, injection molding is a prevalent technique. It allows for mass production of complex shapes with high accuracy.

- Stamping: This method is used for producing flat metal parts and is ideal for high-volume production.

Each technique must adhere to strict specifications to ensure that components fit together seamlessly in the assembly phase.

How Are Solenoid Valve Actuators Assembled?

Once components are formed, they move to the assembly stage. This phase is crucial as it combines various parts into a functional actuator.

Illustrative image related to solenoid valve actuator

Assembly typically involves:

- Component Integration: Each component, such as the solenoid coil, plunger, and valve body, is carefully assembled. Automated assembly lines may be employed for efficiency.

- Wiring: Electrical connections must be established for the solenoid to function properly. Careful attention is paid to ensure proper insulation and connections to prevent electrical failures.

- Sealing: Seals and gaskets are added to prevent leaks, particularly in solenoid valves used in fluid control applications.

Quality checks are often integrated into the assembly line to catch defects early in the process.

What Finishing Techniques Are Commonly Applied?

Finishing processes enhance the actuator’s durability and aesthetic appeal. Typical finishing techniques include:

- Surface Treatment: Processes such as anodizing, plating, or painting are used to enhance corrosion resistance and improve appearance.

- Testing and Calibration: Before leaving the factory, solenoid valve actuators undergo functional testing to ensure they operate according to specifications. This may involve checking response times, stroke lengths, and load capacities.

What International Standards Govern Quality Assurance for Solenoid Valve Actuators?

Quality assurance is paramount in the manufacturing of solenoid valve actuators, particularly when catering to international markets. Various standards help ensure that products are safe, reliable, and meet customer expectations.

Which International Standards Should B2B Buyers Be Aware Of?

- ISO 9001: This standard outlines the criteria for a quality management system. Companies certified under ISO 9001 demonstrate a commitment to continuous improvement and customer satisfaction.

- CE Marking: For products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: The American Petroleum Institute (API) sets standards for oil and gas industry products, including solenoid valves. Compliance with API standards is critical for manufacturers targeting this sector.

Understanding these standards helps B2B buyers assess suppliers’ capabilities and ensure that products meet necessary regulations.

Illustrative image related to solenoid valve actuator

What Are the Key Quality Control Checkpoints in Manufacturing?

Implementing robust quality control (QC) measures throughout the manufacturing process is essential for ensuring product reliability and performance. Typical QC checkpoints include:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival. Materials that do not meet specifications are rejected, preventing defects from entering the production line.

- In-Process Quality Control (IPQC): During manufacturing, IPQC checks are performed at various stages to monitor the production process. This helps identify issues early, allowing for corrective action before the product is completed.

- Final Quality Control (FQC): Once the actuator is assembled, FQC involves comprehensive testing of the final product. This includes functional tests, dimensional checks, and performance evaluations.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is vital for ensuring product integrity. Here are actionable steps buyers can take:

What Steps Can Buyers Take to Audit Supplier Quality?

-

Request Documentation: Buyers should ask suppliers for quality management certifications, inspection reports, and testing data. This documentation provides insights into the supplier’s commitment to quality.

-

Conduct Audits: Performing site audits can provide a firsthand view of the manufacturing processes and QC measures in place. This is especially important when establishing long-term partnerships.

-

Engage Third-Party Inspectors: Utilizing independent inspection services can offer an unbiased assessment of the supplier’s quality control processes. These inspections can be tailored to specific needs and provide detailed reports.

-

Check References: Speaking to other customers who have worked with the supplier can provide valuable insights into their reliability and quality performance.

What Are the Specific Quality Control Nuances for International Buyers?

International buyers should be aware of potential nuances in quality control when dealing with suppliers across different regions:

- Regulatory Variations: Different countries may have specific regulations that affect product standards. Buyers should familiarize themselves with local requirements, especially when importing goods.

- Cultural Differences: Understanding cultural attitudes towards quality can help buyers manage expectations and communication effectively. This is particularly relevant in regions where manufacturing practices may vary significantly.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing solenoid valve actuators, ensuring they receive products that meet their operational needs and quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘solenoid valve actuator’

To assist B2B buyers in procuring solenoid valve actuators effectively, this guide provides a structured checklist. It focuses on critical steps to ensure that you make informed decisions aligned with your operational needs.

Illustrative image related to solenoid valve actuator

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clarify your technical requirements. This includes understanding the specific application of the solenoid valve actuator, such as the type of fluid or gas it will control, the required pressure ratings, and the expected load capacities.

– Considerations:

– Required stroke length and force

– Operating environment (temperature, humidity, etc.)

Step 2: Research Industry Standards and Compliance

Ensure that the solenoid valve actuators comply with relevant industry standards. This may include certifications such as ISO, CE, or UL, which indicate that the products meet specific safety and performance criteria.

– Why it matters:

– Compliance ensures reliability and safety in operation.

– It can also facilitate smoother import/export processes across regions.

Step 3: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers to gauge their reliability and reputation. Request company profiles, case studies, and references from other businesses within your industry.

– Key actions:

– Verify their experience with solenoid valve actuators.

– Look for customer reviews and testimonials to assess satisfaction levels.

Step 4: Request Detailed Quotations

Once you have identified potential suppliers, request detailed quotations that outline pricing, lead times, and payment terms. This step is crucial for budget planning and ensuring that you understand the total cost of ownership.

– What to include in your request:

– Specific technical specifications

– Expected delivery timelines

Step 5: Assess After-Sales Support and Warranty Policies

Before finalizing your purchase, inquire about the after-sales support and warranty policies. Reliable support can significantly impact your operational efficiency, especially in case of technical issues or product failures.

– Consider these aspects:

– Availability of technical support

– Duration and coverage of warranty terms

Step 6: Conduct a Risk Assessment

Evaluate potential risks associated with sourcing solenoid valve actuators from different suppliers. This includes examining geopolitical factors, supply chain stability, and currency fluctuations that could affect pricing or availability.

– Focus areas:

– Supplier location and political stability

– Currency exchange rates and their potential impact on costs

Illustrative image related to solenoid valve actuator

Step 7: Finalize the Contract with Clear Terms

Once you’ve selected a supplier, ensure that the contract outlines all agreed-upon terms, including delivery schedules, payment terms, and specifications. Clarity in the contract can prevent disputes and ensure accountability.

– Key elements to include:

– Penalties for delays

– Conditions for returns or exchanges

Following this checklist can streamline your sourcing process for solenoid valve actuators, ensuring that you choose the right products and suppliers while minimizing risks and maximizing efficiency.

Comprehensive Cost and Pricing Analysis for solenoid valve actuator Sourcing

What Are the Key Cost Components in Sourcing Solenoid Valve Actuators?

When sourcing solenoid valve actuators, it’s essential to understand the various cost components that contribute to the overall price. These components include:

-

Materials: The primary materials used in solenoid valve actuators include copper for coils, steel or aluminum for the casing, and various polymers for seals and insulation. The quality and source of these materials can significantly affect the cost.

-

Labor: Labor costs encompass the wages paid to workers involved in the manufacturing process, from assembly to quality control. Regions with higher labor costs, such as Europe, may see increased prices compared to areas in Africa or South America where labor is generally less expensive.

-

Manufacturing Overhead: This includes costs associated with facility maintenance, utilities, and administrative expenses related to production. Efficient manufacturing processes can help reduce overhead costs, thereby influencing pricing.

-

Tooling: Custom tooling for specific actuator designs can be a substantial upfront investment. The amortization of these costs over production volume can lead to varying unit prices.

-

Quality Control (QC): QC processes ensure that the actuators meet required specifications and certifications. Rigorous testing and compliance with international standards can add to the overall costs.

-

Logistics: Transporting the finished products to international markets involves shipping, customs, and handling fees. The choice of shipping method (air vs. sea) can also impact costs significantly.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and ensure profitability. This margin can vary widely based on the supplier’s positioning in the market.

How Do Price Influencers Affect Solenoid Valve Actuator Costs?

Several factors can influence the pricing of solenoid valve actuators, which buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities often leads to lower per-unit costs. Suppliers may offer discounts for bulk orders, making it advantageous for buyers to forecast their needs accurately.

-

Specifications and Customization: Customized actuators designed for specific applications may incur additional costs due to unique tooling and material requirements. Standardized products are generally more cost-effective.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ISO, CE) can increase costs but may provide long-term savings through enhanced durability and reliability.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can affect pricing. Suppliers with a proven track record of reliability may command higher prices, but they may also reduce risk for buyers.

-

Incoterms: The chosen Incoterms (International Commercial Terms) dictate the responsibilities of buyers and sellers in shipping and delivery. Understanding these terms can help buyers manage costs effectively.

What Are Effective Tips for Negotiating Solenoid Valve Actuator Prices?

International B2B buyers, especially from regions like Africa, South America, and the Middle East, can benefit from strategic negotiation and procurement practices:

-

Conduct a Total Cost of Ownership (TCO) Analysis: Consider not only the initial purchase price but also maintenance, operational efficiency, and potential downtime costs. A lower upfront price may not always result in lower overall costs.

-

Leverage Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Regular communication and trust can facilitate negotiations.

-

Explore Local Suppliers: For buyers in Africa and South America, sourcing from local manufacturers can reduce logistics costs and lead times, providing a competitive edge.

-

Stay Informed on Market Trends: Understanding market conditions, such as material availability and geopolitical factors, can give buyers leverage during negotiations.

-

Negotiate Payment Terms: Flexible payment terms can ease cash flow concerns, allowing buyers to invest in larger orders while managing financial risks.

What Should Buyers Keep in Mind Regarding Pricing Nuances?

When sourcing solenoid valve actuators internationally, buyers must be aware of pricing nuances. Currency fluctuations can affect costs, and tariffs may impact the final price. Additionally, differing regulatory environments may influence the compliance costs associated with imports.

As prices for solenoid valve actuators can vary widely based on the factors outlined above, it’s crucial to obtain multiple quotes and conduct thorough market research. Always seek to understand the rationale behind pricing structures to ensure you are making informed purchasing decisions.

Disclaimer: The prices mentioned in this analysis are indicative and may vary based on market conditions and specific supplier agreements.

Alternatives Analysis: Comparing solenoid valve actuator With Other Solutions

When evaluating the best solutions for controlling fluid flow or providing linear motion in various applications, it is essential to consider alternatives to solenoid valve actuators. While solenoid valve actuators are widely used for their reliability and speed, other technologies may offer distinct advantages depending on the specific requirements of the application. This section provides a comparative analysis of solenoid valve actuators against two viable alternatives: pneumatic actuators and linear electric actuators.

Illustrative image related to solenoid valve actuator

| Comparison Aspect | Solenoid Valve Actuator | Pneumatic Actuator | Linear Electric Actuator |

|---|---|---|---|

| Performance | Fast response time, suitable for on/off control | High speed and force, but less precise | Excellent precision and control over position and speed |

| Cost | Generally low cost | Moderate cost, higher operational costs | Higher initial investment but lower long-term costs |

| Ease of Implementation | Simple wiring and installation | Requires compressed air infrastructure | Straightforward installation with electrical connections |

| Maintenance | Low maintenance needs but may wear out faster | Regular maintenance needed for air supply and seals | Low maintenance, durable in harsh conditions |

| Best Use Case | Rapid on/off applications | Heavy-duty operations requiring significant force | Applications needing precise control and variable speed |

What are the Advantages and Disadvantages of Pneumatic Actuators?

Pneumatic actuators utilize compressed air to create motion. They are well-suited for applications that require high speed and considerable force, such as in manufacturing and automation processes. One of the main advantages of pneumatic actuators is their ability to handle heavy loads and provide rapid movement, making them ideal for assembly lines. However, their reliance on compressed air systems can lead to higher operational costs, and they may require regular maintenance to ensure optimal performance.

How Do Linear Electric Actuators Compare?

Linear electric actuators convert electrical energy into linear motion and are renowned for their precision and control capabilities. These actuators are often used in applications where accurate positioning is crucial, such as in robotics and automated machinery. While they generally involve a higher initial investment than solenoid valve actuators, their long-term operational costs can be lower due to reduced maintenance needs and energy efficiency. However, they may not be the best option for environments requiring rapid on/off switching due to their slower response times compared to solenoids.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right actuator solution hinges on understanding the specific requirements of your application. For tasks that demand rapid on/off control with low initial costs, solenoid valve actuators are a strong choice. However, for applications requiring significant force and speed, pneumatic actuators may be more appropriate, albeit with higher operational costs. If precision and control are paramount, linear electric actuators offer excellent performance but come with a higher upfront investment. B2B buyers should carefully assess their operational needs, budget constraints, and maintenance capabilities to determine which actuator technology aligns best with their objectives.

Essential Technical Properties and Trade Terminology for solenoid valve actuator

What Are the Critical Technical Properties of Solenoid Valve Actuators?

When evaluating solenoid valve actuators, certain technical properties are essential for ensuring reliability and performance in various applications. Understanding these specifications can aid B2B buyers in making informed purchasing decisions.

1. Material Grade

The material grade of the solenoid valve actuator significantly affects its durability and suitability for specific environments. Common materials include brass, stainless steel, and plastic. Brass offers excellent corrosion resistance and is ideal for water applications, while stainless steel is preferred in harsh chemical environments due to its superior strength and resistance to corrosion. Selecting the appropriate material is crucial to ensure longevity and minimize maintenance costs.

2. Operating Voltage

Solenoid valve actuators typically operate at specific voltage levels, such as 12V, 24V, or 110V AC/DC. Understanding the required operating voltage is vital to ensure compatibility with existing systems and to avoid electrical failures. Choosing the correct voltage helps in optimizing energy consumption and prolonging the actuator’s lifespan.

3. Actuation Time

The actuation time refers to how quickly the solenoid valve actuator can open or close a valve. This property is particularly important in applications requiring rapid response times, such as in automated processes. A shorter actuation time can improve system efficiency and responsiveness, making it a key specification for buyers focused on performance.

4. Pressure Rating

The pressure rating indicates the maximum pressure that the solenoid valve actuator can withstand while maintaining safe operation. This specification is critical in applications involving fluids or gases under high pressure. Buyers must ensure that the pressure rating aligns with their system requirements to prevent failures and ensure safety.

5. Temperature Range

The operational temperature range defines the environmental conditions under which the actuator can function effectively. Solenoid valve actuators designed for extreme temperatures—both high and low—are crucial in industries such as oil and gas or aerospace. Understanding this range helps in selecting actuators that can withstand specific environmental challenges.

6. Flow Rate

Flow rate determines the volume of fluid that can pass through the valve in a given time frame, usually measured in liters per minute (L/min) or gallons per minute (GPM). This property is essential for applications requiring precise fluid control. Selecting a solenoid valve actuator with the appropriate flow rate ensures optimal performance in the intended application.

What Are Common Trade Terms Related to Solenoid Valve Actuators?

Familiarity with industry-specific terminology can facilitate smoother transactions and better communication between buyers and suppliers. Here are some critical terms to know:

Illustrative image related to solenoid valve actuator

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is essential for buyers looking for custom solutions or replacements, as it affects warranty and compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is crucial for budget-conscious buyers, as understanding MOQ can help in managing inventory costs and ensuring that purchasing aligns with production needs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products or services. It is a fundamental part of the procurement process and is essential for buyers to obtain competitive pricing and evaluate multiple suppliers effectively.

Illustrative image related to solenoid valve actuator

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers engaged in global trade, as they dictate shipping responsibilities, risk, and costs.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. Knowing the lead time is essential for planning and inventory management, as it affects project timelines and operational efficiency.

By grasping these technical properties and industry terms, B2B buyers can navigate the procurement process for solenoid valve actuators more effectively, ensuring they select the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the solenoid valve actuator Sector

What Are the Current Market Dynamics Affecting Solenoid Valve Actuators?

The solenoid valve actuator market is witnessing significant growth driven by a surge in automation across various sectors, including manufacturing, automotive, and healthcare. Global trends indicate an increasing demand for reliable and efficient valve control systems that enhance operational efficiency and reduce energy consumption. In regions such as Africa, South America, and the Middle East, the push towards industrialization and infrastructure development is particularly strong. Countries like Nigeria and Saudi Arabia are investing heavily in energy and water management systems, propelling the need for advanced solenoid valve actuators.

Emerging technologies, such as IoT and AI, are reshaping the sourcing landscape, enabling manufacturers to develop smart solenoid actuators that offer real-time monitoring and control. This technological advancement not only enhances performance but also provides significant cost savings through predictive maintenance capabilities. Furthermore, the integration of Industry 4.0 principles is fostering collaborations between manufacturers and technology providers, facilitating the development of innovative solutions tailored to specific industry needs.

International B2B buyers must remain attuned to these market dynamics, as the competition intensifies and the demand for customization increases. Suppliers that can offer tailored solutions, fast turnaround times, and competitive pricing will hold a distinct advantage. Additionally, buyers should consider regional sourcing strategies to mitigate risks associated with global supply chain disruptions, ensuring a consistent supply of solenoid valve actuators.

Illustrative image related to solenoid valve actuator

How Is Sustainability Influencing the Sourcing of Solenoid Valve Actuators?

Sustainability has become a focal point for B2B buyers in the solenoid valve actuator sector. The environmental impact of manufacturing processes and product life cycles is increasingly scrutinized, prompting companies to adopt greener practices. This shift is not only a response to regulatory pressures but also a reflection of changing consumer preferences that favor eco-friendly products.

Ethical sourcing and supply chain transparency are paramount, especially for buyers in regions like Europe, where sustainability regulations are stringent. Manufacturers are now required to demonstrate compliance with environmental standards and certifications, such as ISO 14001, which focuses on effective environmental management systems. Buyers should prioritize suppliers that use sustainable materials and energy-efficient production methods, contributing to a reduced carbon footprint.

The adoption of ‘green’ certifications is becoming a key differentiator in the market. Buyers are encouraged to seek solenoid valve actuators made from recyclable materials or those that incorporate energy-saving technologies. By aligning with sustainable sourcing practices, companies can not only enhance their corporate social responsibility profile but also gain a competitive edge in a market increasingly driven by environmental considerations.

What Is the Historical Context of Solenoid Valve Actuators in the B2B Market?

The evolution of solenoid valve actuators can be traced back to the early 19th century when the principles of electromagnetism were first harnessed. Initially, these devices were primarily used in simple applications such as door locks and telegraphs. However, as industrial automation gained traction in the 20th century, solenoid actuators began to find their way into more complex systems, particularly in manufacturing and automotive applications.

Illustrative image related to solenoid valve actuator

Over the decades, advancements in materials and technology have significantly improved the performance and reliability of solenoid valve actuators. The introduction of digital control systems in the late 20th century allowed for greater precision and efficiency, setting the stage for the modern era of automation. Today, solenoid valve actuators are integral components in a myriad of applications, from household appliances to sophisticated aerospace systems, highlighting their versatility and importance in the B2B marketplace.

As the demand for automation continues to grow, understanding the historical context of solenoid valve actuators provides valuable insights for international B2B buyers, enabling them to make informed sourcing decisions that align with current market trends and technological advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of solenoid valve actuator

-

How do I select the right solenoid valve actuator for my application?

To select the right solenoid valve actuator, first assess your specific application needs, including the type of fluid (liquid or gas), pressure requirements, and temperature ranges. Evaluate the actuator’s power consumption, stroke length, and load capacity. Consider the actuator’s response time and control capabilities, as some applications may require precise positioning. Lastly, review compatibility with your existing systems and ensure the actuator meets industry standards for safety and performance. -

What is the best solenoid valve actuator for high-pressure applications?

For high-pressure applications, look for solenoid valve actuators specifically designed to withstand elevated pressures. Options such as high-pressure solenoid valves made from durable materials like stainless steel or brass are ideal. Additionally, consider actuators with robust sealing mechanisms to prevent leaks. Always consult with suppliers for technical specifications and application suitability to ensure optimal performance under pressure. -

What factors should I consider when vetting suppliers for solenoid valve actuators?

When vetting suppliers, prioritize their industry experience, reputation, and certifications. Assess their manufacturing capabilities, quality control processes, and compliance with international standards. It’s beneficial to request references or case studies from previous clients. Additionally, inquire about their customer support services, delivery timelines, and willingness to accommodate custom specifications or modifications to meet your needs. -

What are the typical minimum order quantities (MOQs) for solenoid valve actuators?

Minimum order quantities (MOQs) for solenoid valve actuators can vary significantly depending on the supplier and the specific actuator model. Generally, MOQs can range from as low as 10 units to several hundred. Always check with the supplier for their specific terms, as many are willing to negotiate MOQs, especially for first-time orders or long-term partnerships. -

What are the common payment terms for international purchases of solenoid valve actuators?

Common payment terms for international purchases often include options like advance payment, letter of credit, or net payment terms (e.g., net 30, net 60). Some suppliers may require a deposit upfront, with the balance due upon shipment or delivery. It’s crucial to clarify payment terms and any associated fees, such as currency conversion or transaction fees, to avoid surprises. -

How can I ensure quality assurance for my solenoid valve actuators?

To ensure quality assurance, request detailed product specifications, material certifications, and compliance with international standards. Many reputable suppliers offer quality control documentation and testing reports. Additionally, consider visiting the manufacturing facility, if possible, to observe their quality control processes. Establishing a clear communication channel with the supplier for ongoing quality monitoring is also essential. -

What logistics considerations should I keep in mind when sourcing solenoid valve actuators internationally?

When sourcing internationally, consider factors such as shipping methods, lead times, and customs regulations. Assess the total landed cost, including shipping, tariffs, and taxes. Ensure that the supplier can provide reliable logistics support and tracking information. Additionally, familiarize yourself with import regulations in your country to avoid delays or additional charges at customs. -

Can solenoid valve actuators be customized for specific applications?

Yes, many manufacturers offer customization options for solenoid valve actuators to meet specific application requirements. Customizations may include adjustments to size, stroke length, materials, and electrical specifications. When discussing customization with suppliers, provide detailed specifications and application details to ensure the actuator meets your unique needs. Always request prototypes or samples before finalizing your order to verify performance.

Top 9 Solenoid Valve Actuator Manufacturers & Suppliers List

1. Actuonix – Linear Actuators

Domain: actuonix.com

Registered: 2016 (9 years)

Introduction: Linear Actuators: Devices that convert rotational motion into linear motion, consisting of a motor, gearbox, and screw drive. Types include Ball Screw Actuators (high efficiency, low friction), Roller Screw Actuators (higher load capacities), and Lead Screw Actuators (economical). Advantages include precise positioning, variable speed, and high load capacity. Solenoids: Electromagnetic devices tha…

2. McMaster – Pneumatic Solenoid Valves

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Pneumatic Solenoid Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Jameco – Electric Solenoid Actuators

Domain: jameco.com

Registered: 1998 (27 years)

Introduction: Solenoid actuators use electromagnetism to create linear or rotary motion, commonly used in electronic projects to control levers and switches. Jameco Electronics offers a wide selection of electric solenoid actuators, including solenoid valves, open-frame dual-shaft push solenoids, and continuous tubular pull solenoids. These actuators are reliable, high-quality, and built to last, with various p…

4. CrossCo – Electro-Pneumatic Solenoid Valve

Domain: crossco.com

Registered: 1997 (28 years)

Introduction: Electro-pneumatic solenoid valve: Takes electrical signal (AC or DC Voltage) to control air supply to pneumatic actuator. Components include electromagnetic coil, plunger or piston, piston return spring, and valve body. Functions by attracting piston to open/close ports for air supply. Types of actuators: double acting (fail in place).

5. Reacton – Electric 24VDC Valve Actuator Solenoid

Domain: portal.reactonfire.com

Registered: 2016 (9 years)

Introduction: {“product_name”: “Reacton Electric 24VDC Valve Actuator Solenoid”, “part_number”: “RE7390-24”, “voltage”: “24VDC”, “operation”: “direct-acting solenoid for reliable operation of the Indirect valve”, “variants”: [“12VDC”, “24VDC”], “features”: [“lightning-fast operation”, “removable solenoid coil for testing purposes”, “permanent adaptor feature”], “market_availability”: [“CE”, “DOT”]}

6. MSC Direct – Pneumatic Solenoid Valves

Domain: mscdirect.com

Registered: 1996 (29 years)

Introduction: This company, MSC Direct – Pneumatic Solenoid Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Telematic – Electric Solenoid Valves & Actuators

Domain: telematic.com

Registered: 1996 (29 years)

Introduction: Electric Solenoid Valves & Actuators

8. Kimray – Solenoid Valves

Domain: kimray.com

Registered: 1996 (29 years)

Introduction: A solenoid valve is controlled by a solenoid, which operates on an on/off or snap acting mechanism. It requires an electric current to function, which magnetizes a coil and moves a plunger, sending a pneumatic signal to the valve’s actuator. When the current stops, the actuator returns to its original position. Solenoids are used in various applications including oil and gas, automotive, marine, a…

9. Peaktronics – Solenoid Valve Controllers

Domain: peaktronics.com

Registered: 2001 (24 years)

Introduction: Solenoid Valve Controllers (SVC series) for pneumatic actuators provide proportional positioning. Ideal for replacing bulky I/P controls when AC power is available. Controls two external AC solenoid valves for actuator open/close ports. Available voltages: 117VAC (SVC-100, SVC-100A, SVC-102), 234VAC (SVC-100B, SVC-100C, SVC-102A), and 24VAC (SVC-100D, SVC-100E, SVC-102B). Pricing available upon re…

Strategic Sourcing Conclusion and Outlook for solenoid valve actuator

How Can Strategic Sourcing Enhance Your Supply Chain for Solenoid Valve Actuators?

In today’s competitive landscape, strategic sourcing of solenoid valve actuators is crucial for optimizing operational efficiency and reducing costs. By understanding the unique features of solenoids and linear actuators, buyers can make informed decisions that align with their specific application needs, whether it be for precise control in automation or rapid on/off functionality in simpler tasks.

Investing in quality solenoid valve actuators not only ensures reliability but also enhances the durability of your systems, minimizing downtime and maintenance expenses. Moreover, sourcing from reputable manufacturers who emphasize innovation and sustainability can provide long-term benefits, especially for markets across Africa, South America, the Middle East, and Europe.

Illustrative image related to solenoid valve actuator

As you navigate the complexities of the global supply chain, consider forming partnerships with suppliers who demonstrate a commitment to quality and customer support. The future of solenoid valve actuators is promising, with advancements in technology paving the way for more efficient solutions. Take the next step in your procurement strategy today—evaluate your sourcing options and position your business for success in an evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.