How to Source Solar Powered Welding Helmet Batteries Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for solar powered welding helmet batteries

Navigating the global market for solar powered welding helmet batteries presents unique challenges for B2B buyers, particularly when sourcing reliable and efficient options that meet diverse operational needs. As industries worldwide increasingly adopt sustainable practices, the demand for solar powered solutions, including welding helmets, has surged. This comprehensive guide will delve into various types of solar powered welding helmet batteries, their applications across different sectors, and essential criteria for supplier vetting. Additionally, we will analyze cost factors and provide insights on maximizing value while ensuring quality.

For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Nigeria and Germany—this guide serves as a valuable resource in making informed purchasing decisions. By understanding the nuances of solar technology and battery integration in welding helmets, buyers can effectively navigate the complexities of the market. This guide not only outlines the advantages of solar powered solutions but also addresses common concerns related to performance, longevity, and operational efficiency. Ultimately, it aims to empower buyers with the knowledge necessary to select the right products that align with their business goals and sustainability initiatives.

Understanding solar powered welding helmet batteries Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Solar-Only Helmets | Operate solely on solar energy; no battery backup | Outdoor welding, construction | Pros: No battery maintenance, lightweight. Cons: Limited use in low-light conditions. |

| Solar-Battery Hybrid Helmets | Combine solar charging with a rechargeable battery | Versatile welding environments | Pros: Works indoors and outdoors, reliable. Cons: Battery replacement may be needed. |

| Lithium-Ion Powered Helmets | Use advanced lithium-ion batteries for extended performance | Heavy-duty industrial welding | Pros: Long battery life, quick charge time. Cons: Higher upfront cost, requires careful handling. |

| Standard Battery-Powered Helmets | Use traditional batteries, often with a solar assist | Budget-conscious buyers | Pros: Affordable, easy to find. Cons: Frequent battery changes required, less efficient. |

| Auto-Darkening Solar Helmets | Feature auto-darkening lenses activated by arc light | Precision welding applications | Pros: Immediate protection, enhances visibility. Cons: May require calibration for optimal performance. |

What Are the Characteristics of Solar-Only Helmets in B2B Applications?

Solar-only helmets are designed to harness sunlight for their operation, making them ideal for outdoor welding tasks. They are lightweight and require no battery maintenance, appealing to businesses focused on cost-effective solutions. However, their performance is limited in low-light conditions, which can be a significant drawback for operations that require flexibility in various environments.

How Do Solar-Battery Hybrid Helmets Enhance Versatility?

Solar-battery hybrid helmets offer the best of both worlds, utilizing solar power while also featuring a rechargeable battery for use in low-light conditions. This design is particularly beneficial for B2B buyers who operate in diverse settings, ensuring reliable performance regardless of the environment. While these helmets may require occasional battery replacements, their versatility makes them a solid investment for companies engaged in both indoor and outdoor welding tasks.

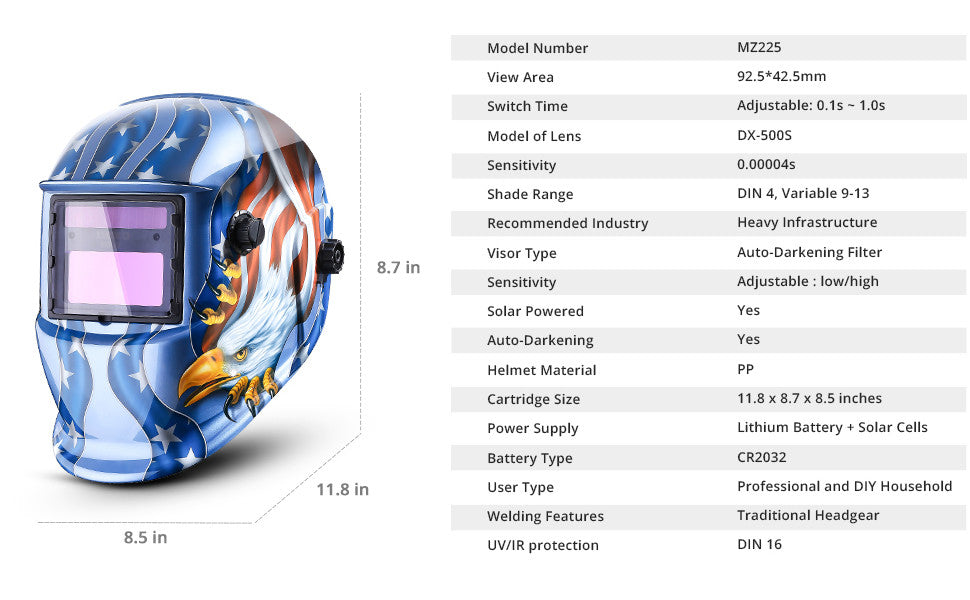

Illustrative image related to solar powered welding helmet batteries

Why Choose Lithium-Ion Powered Helmets for Heavy-Duty Applications?

Lithium-ion powered helmets are equipped with advanced battery technology, providing longer operational life and faster charging capabilities. These helmets are suitable for heavy-duty industrial applications, where extended use and reliability are paramount. Although they come with a higher initial cost, the reduced frequency of battery changes and superior performance make them a worthwhile investment for businesses focused on efficiency and productivity.

What Are the Benefits of Standard Battery-Powered Helmets for Budget-Conscious Buyers?

Standard battery-powered helmets are often the most affordable option, making them attractive for budget-conscious buyers or smaller operations. While they are easy to find and maintain, users must frequently replace batteries, which can lead to increased long-term costs. These helmets are best suited for businesses that prioritize initial investment over long-term performance reliability.

How Do Auto-Darkening Solar Helmets Improve Safety and Visibility?

Auto-darkening solar helmets automatically adjust the lens tint based on the intensity of the welding arc, providing immediate protection and enhanced visibility. This feature is particularly valuable for precision welding applications where visibility is critical. While these helmets may require calibration for optimal performance, their ability to improve safety and work quality makes them an essential tool for B2B buyers in the welding industry.

Key Industrial Applications of solar powered welding helmet batteries

| Industry/Sector | Specific Application of solar powered welding helmet batteries | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Use in onsite welding tasks for structural steel and metal fabrication | Reduces downtime due to battery replacements; enhances worker safety | Durability, solar efficiency, and comfort features for long hours |

| Automotive Manufacturing | Welding components in vehicle assembly lines | Continuous operation without battery failure; cost efficiency | Compatibility with various welding techniques and quick charging time |

| Oil & Gas | Pipeline construction and repair welding | Reliability in remote locations; minimizes operational interruptions | Weather resistance, battery longevity, and ease of use |

| Renewable Energy | Installation and maintenance of solar panels and wind turbines | Sustainability alignment; reduces reliance on conventional power | Lightweight design, solar charging capabilities, and adaptability |

| Heavy Machinery | Repair and maintenance of heavy equipment in harsh environments | Increased productivity and reduced operational costs | Robustness, high sensitivity auto-darkening features, and comfort |

How Are Solar Powered Welding Helmet Batteries Used in the Construction Industry?

In the construction sector, solar powered welding helmet batteries are invaluable for onsite welding tasks, particularly in structural steel and metal fabrication. These helmets provide the convenience of not needing frequent battery replacements, which can disrupt workflow and lead to project delays. For international buyers, especially in regions like Africa and South America, sourcing helmets that offer durability and comfort features is crucial, as workers often spend extended hours in challenging environments.

What Role Do Solar Powered Welding Helmet Batteries Play in Automotive Manufacturing?

In automotive manufacturing, solar powered welding helmet batteries are essential for welding components on assembly lines. The reliability of these helmets ensures continuous operation without the risk of battery failure, ultimately contributing to cost efficiency. Buyers in Europe, such as Germany, should focus on helmets that are compatible with various welding techniques and offer quick charging times to maintain high production standards and efficiency.

Illustrative image related to solar powered welding helmet batteries

How Are Solar Powered Welding Helmet Batteries Beneficial in the Oil & Gas Sector?

The oil and gas industry utilizes solar powered welding helmet batteries during pipeline construction and repair welding. The ability to operate reliably in remote locations is a significant advantage, as it minimizes operational interruptions often caused by conventional power limitations. Buyers from the Middle East and other regions should prioritize helmets that are weather-resistant and provide long battery life to withstand harsh working conditions.

Why Are Solar Powered Welding Helmet Batteries Important for Renewable Energy Projects?

In renewable energy sectors, such as solar panel and wind turbine installations, solar powered welding helmet batteries align with sustainability goals. These helmets reduce reliance on conventional power sources, enhancing the eco-friendliness of the projects. For international B2B buyers, sourcing lightweight designs with excellent solar charging capabilities is essential to ensure worker mobility and efficiency during installations.

How Do Solar Powered Welding Helmet Batteries Enhance Heavy Machinery Maintenance?

In the heavy machinery sector, solar powered welding helmet batteries facilitate repair and maintenance tasks in harsh environments. The increased productivity and reduced operational costs associated with these helmets make them a preferred choice for businesses. Buyers should consider sourcing helmets with high sensitivity auto-darkening features to protect workers’ eyes effectively while ensuring comfort during prolonged use.

3 Common User Pain Points for ‘solar powered welding helmet batteries’ & Their Solutions

Scenario 1: Inconsistent Performance in Low Light Conditions

The Problem: B2B buyers often encounter issues with solar-powered welding helmets failing to perform effectively in low light environments, such as indoors or at night. This inconsistency can lead to unexpected interruptions during welding tasks, which may compromise worker safety and productivity. When a helmet’s solar feature relies on direct sunlight, users can find themselves in a bind when they need to weld indoors or in shaded areas, resulting in frustration and potential delays in project timelines.

The Solution: To address this issue, buyers should prioritize sourcing solar-powered welding helmets that come equipped with a battery backup. This feature ensures that the helmet maintains optimal functionality regardless of ambient light conditions. When evaluating options, look for models that specify a dual power source—solar and battery—to enhance reliability. Additionally, it’s advisable to educate users on how to adjust the sensitivity settings of the helmet for varying light conditions. For instance, during indoor use, users should set the sensitivity to a higher level to ensure the helmet darkens promptly upon arc activation, thus preventing eye strain and enhancing overall safety.

Scenario 2: Battery Life Concerns and Replacement Challenges

The Problem: Another common pain point for B2B buyers is the concern over the longevity and replacement of the batteries in solar-powered welding helmets. Many buyers worry about the unpredictability of battery life, especially in regions where usage frequency varies. When batteries die unexpectedly, it can lead to downtime and increased costs, particularly in projects with tight deadlines. Furthermore, some helmets may have non-replaceable batteries, which raises concerns about the long-term value of the investment.

The Solution: To mitigate these concerns, buyers should conduct thorough research before making a purchase. Opt for helmets that explicitly state battery life expectancy and provide indicators for low battery status. Additionally, consider models with replaceable batteries, as this allows for easy maintenance and prolongs the helmet’s lifespan. Buyers can also implement a regular maintenance schedule to check battery performance and ensure helmets are always ready for use. Investing in a helmet with a warranty that covers battery-related issues can further safeguard against unexpected costs and downtime.

Scenario 3: Sensitivity Adjustment Difficulties

The Problem: B2B buyers frequently report issues with sensitivity adjustments on solar-powered welding helmets. If the sensitivity settings are not optimal, users may experience discomfort or inadequate protection, especially when working under fluctuating light conditions. For instance, in bright sunlight, a helmet that is too sensitive can darken unnecessarily, causing interruptions, while one that is not sensitive enough may fail to darken when needed, risking eye damage.

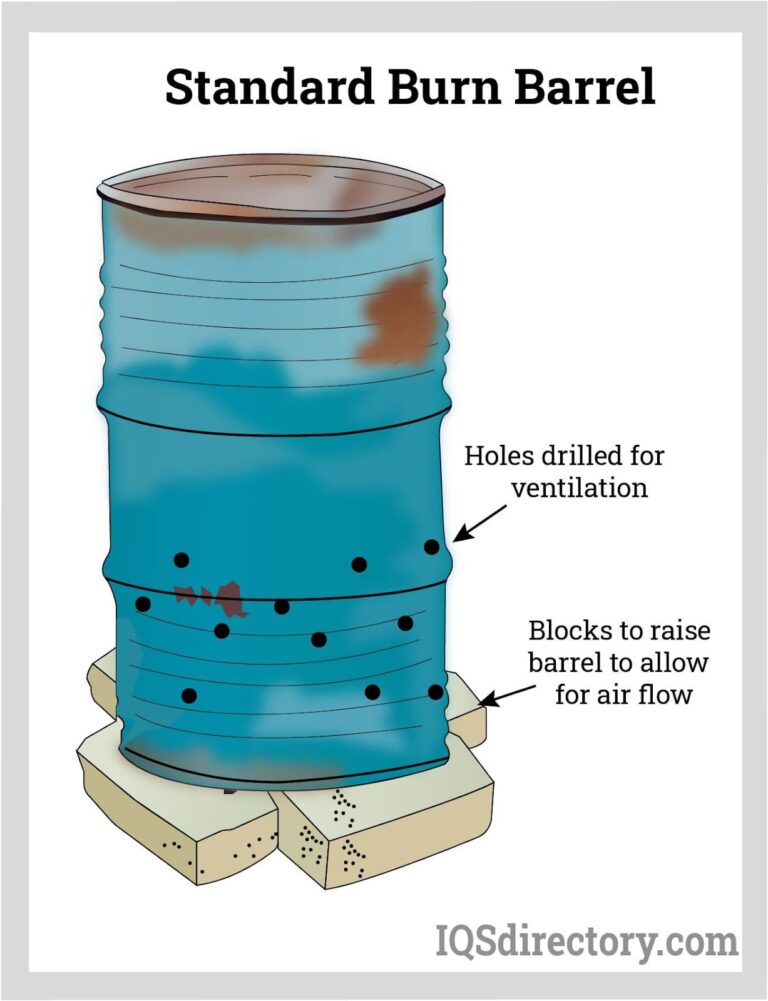

Illustrative image related to solar powered welding helmet batteries

The Solution: To overcome sensitivity adjustment difficulties, buyers should select helmets that offer customizable settings. Look for models that allow users to fine-tune sensitivity levels based on the specific welding environment, whether indoors or outdoors. Providing training for users on how to adjust these settings can significantly enhance their welding experience. Additionally, consider investing in helmets with automatic adjustment features that can intelligently respond to varying light conditions, thus reducing the need for manual adjustments. Encouraging feedback from users on their experiences with sensitivity settings can also help in selecting the right helmets for different operational environments.

Strategic Material Selection Guide for solar powered welding helmet batteries

What Are the Key Materials Used in Solar Powered Welding Helmet Batteries?

When selecting materials for solar powered welding helmet batteries, it is essential to consider various factors such as performance, durability, and cost. The following analysis focuses on four common materials: Lithium-Ion, Nickel-Metal Hydride (NiMH), Lead-Acid, and Supercapacitors. Each material has unique properties that impact its suitability for use in solar powered welding helmets.

How Does Lithium-Ion Battery Technology Benefit Solar Powered Welding Helmets?

Lithium-Ion batteries are widely used in solar powered welding helmets due to their high energy density and lightweight design. They typically operate efficiently at a temperature range of -20°C to 60°C, making them suitable for various environmental conditions. Their corrosion resistance is also notable, allowing them to withstand exposure to moisture and other elements.

Pros: Lithium-Ion batteries offer a longer lifespan and faster charging times compared to other battery types. They are compact, which is crucial for maintaining a lightweight helmet design.

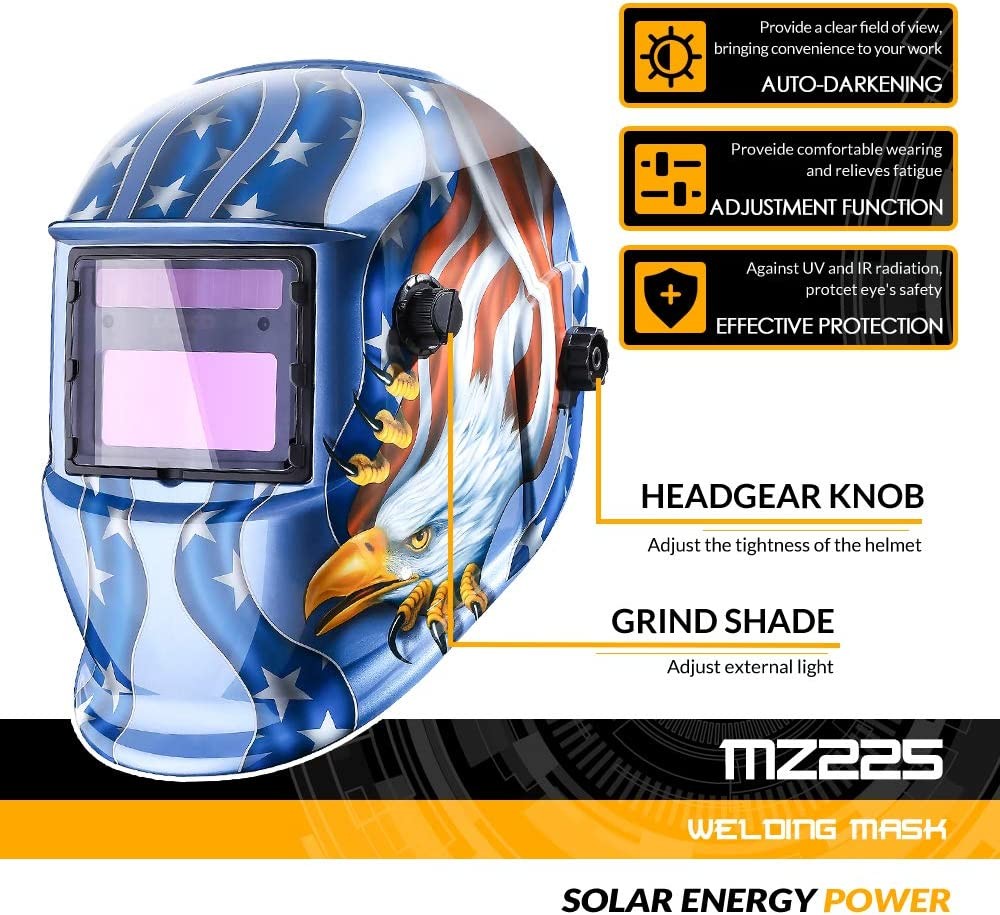

Illustrative image related to solar powered welding helmet batteries

Cons: However, they can be more expensive to manufacture, and their performance can degrade if exposed to extreme temperatures. Additionally, they require specific charging protocols to ensure safety and longevity.

For international B2B buyers, compliance with safety standards such as IEC 62133 is essential, particularly in regions like Europe and the Middle East, where regulations are stringent.

What Advantages Do Nickel-Metal Hydride Batteries Offer?

Nickel-Metal Hydride (NiMH) batteries are another viable option for solar powered welding helmets. They typically have a temperature rating of -20°C to 50°C and are less prone to thermal runaway compared to Lithium-Ion batteries. NiMH batteries also exhibit good resistance to corrosion.

Pros: One of the key advantages of NiMH batteries is their relatively lower cost compared to Lithium-Ion. They also have a decent energy density and can be recycled more easily.

Cons: However, they have a shorter lifespan and lower energy density than Lithium-Ion batteries, which may limit their effectiveness in high-demand applications. Their self-discharge rate is also higher, requiring more frequent recharging.

For buyers in regions like Africa and South America, the availability of NiMH batteries may be more favorable due to lower costs and easier sourcing.

Why Are Lead-Acid Batteries Still Relevant?

Lead-Acid batteries, while older technology, are still relevant in the solar powered welding helmet market. They have a temperature range of -20°C to 50°C and are highly durable, with good resistance to physical shocks.

Pros: The primary advantage of Lead-Acid batteries is their low cost and widespread availability. They can provide reliable performance in various conditions, making them a popular choice for budget-conscious buyers.

Cons: On the downside, Lead-Acid batteries are heavier and bulkier than their lithium counterparts. They also have a shorter cycle life and can be less efficient in energy use.

Illustrative image related to solar powered welding helmet batteries

For international buyers, especially in developing regions, Lead-Acid batteries may meet budget constraints but may not comply with more stringent environmental regulations found in Europe.

How Do Supercapacitors Enhance Performance?

Supercapacitors are an emerging technology in solar powered welding helmets, known for their rapid charge and discharge capabilities. They can operate effectively within a temperature range of -40°C to 65°C and are highly resistant to corrosion.

Pros: The primary advantage of supercapacitors is their ability to deliver high power output quickly, which is beneficial for applications requiring immediate energy bursts. They also have an exceptionally long cycle life.

Illustrative image related to solar powered welding helmet batteries

Cons: However, supercapacitors have a lower energy density compared to traditional batteries, which limits their use as a standalone power source. They are also generally more expensive to manufacture.

For B2B buyers in Europe and the Middle East, the adoption of supercapacitors may align with trends toward sustainable and efficient energy solutions.

Summary Table of Material Selection for Solar Powered Welding Helmet Batteries

| Material | Typical Use Case for solar powered welding helmet batteries | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Lithium-Ion | High-performance helmets requiring lightweight design | High energy density and lightweight | Higher manufacturing cost | High |

| Nickel-Metal Hydride | Budget-friendly helmets with moderate performance | Lower cost and easier recycling | Shorter lifespan and higher self-discharge | Medium |

| Lead-Acid | Economical options for basic welding applications | Low cost and wide availability | Heavier and shorter cycle life | Low |

| Supercapacitors | Advanced helmets needing rapid energy bursts | Long cycle life and quick discharge | Lower energy density | High |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in solar powered welding helmet batteries, helping them make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for solar powered welding helmet batteries

What Are the Key Stages in the Manufacturing Process of Solar-Powered Welding Helmet Batteries?

The manufacturing process of solar-powered welding helmet batteries is a complex sequence that ensures high performance, reliability, and safety. This process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Battery Production?

Material preparation involves sourcing high-quality raw materials, such as lithium-ion or nickel-cadmium cells, which are commonly used in batteries. Manufacturers typically engage in rigorous supplier assessments to ensure that the materials meet international standards for safety and performance. This includes checking for purity, chemical composition, and consistency.

Illustrative image related to solar powered welding helmet batteries

Once materials are approved, they undergo a series of pre-manufacturing tests, including electrical conductivity and thermal stability assessments, to confirm they are suitable for battery production. This stage is crucial as it lays the groundwork for the performance of the final product.

What Techniques Are Used in the Forming Stage of Battery Manufacturing?

During the forming stage, the prepared materials are shaped into the necessary components. This typically involves processes such as electrode fabrication, where active materials are coated onto conductive substrates. Techniques like roll-to-roll coating or screen printing are employed to ensure uniformity and efficiency.

Following electrode fabrication, cells are assembled into battery modules. This can include stacking or winding techniques, depending on the design specifications. Advanced automation is often utilized to ensure precision and reduce human error, which is particularly important in achieving the desired energy density and cycle life.

How Are Solar-Powered Welding Helmet Batteries Assembled?

The assembly stage integrates the formed components into complete battery units. This includes the installation of protective casings, solar cells, and electronic control systems that manage charging and discharging. Manufacturers may utilize robotic arms and automated assembly lines to enhance efficiency and consistency.

During assembly, it is essential to maintain a clean environment to prevent contamination, which can lead to battery failure. This is typically achieved through controlled environments that limit dust and humidity, ensuring that the batteries are built to withstand the rigors of welding applications.

Illustrative image related to solar powered welding helmet batteries

What Finishing Techniques Are Applied to Ensure Battery Quality?

Finishing processes include sealing, labeling, and packaging the batteries. Sealing is critical for protecting the internal components from moisture and dust, which can significantly affect performance. After sealing, each battery is labeled with important safety information and performance specifications, complying with international standards.

Packaging is also a vital aspect, as it protects the batteries during transit and storage. Manufacturers often employ sustainable packaging solutions to appeal to environmentally conscious buyers.

What Quality Assurance Measures Are Critical in Battery Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of solar-powered welding helmet batteries. Various international standards, such as ISO 9001, provide frameworks for establishing and maintaining quality management systems. Compliance with these standards ensures that manufacturers consistently produce high-quality products.

How Do International Standards Impact Battery Quality Assurance?

International standards like CE and API are crucial for exporting batteries to markets in Europe, Africa, and South America. CE marking indicates that products meet European health, safety, and environmental protection standards, while API certification ensures that products meet the specific needs of the petroleum and natural gas industry.

B2B buyers should verify that their suppliers are compliant with these standards, as it not only assures product quality but also facilitates smoother entry into different markets.

What Are the Key QC Checkpoints in Battery Manufacturing?

Quality control (QC) checkpoints are implemented at various stages of the manufacturing process, including:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon receipt to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing helps identify and rectify issues as they arise, reducing defects in the final product.

- Final Quality Control (FQC): Before shipping, finished batteries undergo rigorous testing, including performance assessments, safety checks, and environmental testing.

These checkpoints help in maintaining product integrity and ensuring that the final batteries are safe and efficient for use in welding applications.

What Testing Methods Are Used to Ensure Battery Performance and Safety?

Common testing methods for solar-powered welding helmet batteries include:

- Cycle Life Testing: Evaluates how many charge and discharge cycles a battery can undergo before its capacity significantly diminishes.

- Temperature Testing: Assesses performance under various temperature conditions to ensure reliability in different environments.

- Safety Testing: Involves short-circuit tests, overcharge tests, and thermal stability assessments to prevent hazards.

B2B buyers should request detailed reports from suppliers regarding these tests, as they provide critical insights into battery performance and safety.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of their suppliers:

- Audits: Conducting regular audits of suppliers can help assess compliance with international standards and internal quality benchmarks. This can include both announced and unannounced visits.

- Quality Reports: Requesting detailed quality reports, including metrics on defect rates and testing outcomes, can provide insights into a supplier’s performance.

- Third-Party Inspections: Engaging independent third-party inspectors can offer an unbiased evaluation of a supplier’s manufacturing processes and quality assurance measures.

What Nuances Should International Buyers Be Aware of Regarding QC Certification?

International buyers, particularly from regions like Africa and South America, should be aware of the nuances in QC certification and standards. Different regions may have varying requirements for safety and performance certifications. Understanding these differences is essential for ensuring compliance and avoiding potential trade barriers.

For instance, while CE marking is crucial for European markets, UL certification may be more relevant in North American contexts. Buyers should familiarize themselves with these standards to ensure their products meet the necessary regulations for their target markets.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for solar-powered welding helmet batteries is vital for B2B buyers. By focusing on the key stages of manufacturing and the importance of rigorous quality control, buyers can make informed decisions and select reliable suppliers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘solar powered welding helmet batteries’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure solar-powered welding helmet batteries. As the demand for sustainable and efficient welding solutions grows globally, understanding the critical factors in sourcing quality batteries is essential. This checklist will help streamline your procurement process, ensuring you make informed decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful sourcing process. Identify the battery type, capacity, and voltage requirements that match your welding helmet model. Consider the specific needs of your operations, such as environmental conditions and frequency of use, to ensure compatibility and optimal performance.

- Battery Type: Decide between rechargeable lithium-ion or NiMH batteries based on longevity and performance.

- Capacity and Voltage: Ensure the specifications align with the welding helmet’s requirements to avoid malfunctions.

Step 2: Research Market Trends and Innovations

Stay informed about the latest advancements in solar-powered battery technology. Understanding current market trends will help you identify innovative solutions that enhance efficiency and sustainability. Look for products that incorporate advanced features, such as rapid charging or extended battery life.

Illustrative image related to solar powered welding helmet batteries

- Industry Reports: Utilize market research reports to gain insights into leading manufacturers and emerging technologies.

- Competitor Analysis: Assess what similar companies are using to ensure your procurement strategy remains competitive.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conducting a thorough evaluation is crucial. Request detailed company profiles, case studies, and references from previous clients within your industry. This will provide insight into their reliability, quality standards, and after-sales support.

- Certifications: Ensure suppliers hold relevant certifications, such as ISO or CE, which indicate compliance with international safety and quality standards.

- Customer Feedback: Review testimonials and ratings from existing customers to gauge their satisfaction and the supplier’s responsiveness.

Step 4: Request Samples for Testing

Once you’ve shortlisted potential suppliers, request battery samples for testing. Evaluating samples allows you to assess performance, compatibility, and overall quality before making a bulk purchase. This step is vital to avoid future operational disruptions due to defective products.

- Performance Testing: Check for discharge rates, charging efficiency, and lifespan under typical operating conditions.

- Compatibility Checks: Ensure the batteries work seamlessly with the welding helmets to prevent operational issues.

Step 5: Negotiate Terms and Conditions

Engaging in negotiations with suppliers is essential to secure favorable terms. Discuss pricing, payment terms, warranty conditions, and delivery timelines. A well-structured agreement will help prevent misunderstandings and protect your investment.

- Volume Discounts: Inquire about pricing tiers based on order volume to optimize your procurement budget.

- Warranty and Support: Clarify warranty terms and the availability of technical support to address potential issues post-purchase.

Step 6: Plan for Logistics and Supply Chain Management

Effective logistics planning is critical to ensure timely delivery and minimize downtime. Coordinate with your supplier regarding shipping methods, timelines, and any potential customs issues if sourcing internationally.

Illustrative image related to solar powered welding helmet batteries

- Shipping Options: Evaluate air versus sea freight based on urgency and cost-effectiveness.

- Customs Regulations: Be aware of import regulations and duties in your region to avoid unexpected delays.

Step 7: Establish a Quality Control Process

Implementing a robust quality control process is vital for maintaining high standards. Ensure that incoming battery shipments are inspected for quality and conformity to specifications. This proactive approach will mitigate risks associated with defective products impacting your operations.

- Inspection Protocols: Develop a checklist for assessing battery quality, including visual inspections and performance tests.

- Feedback Loop: Create a system for providing feedback to suppliers based on quality assessments to foster continuous improvement.

By following this checklist, B2B buyers can confidently navigate the procurement process for solar-powered welding helmet batteries, ensuring that they select the best options for their operational needs.

Comprehensive Cost and Pricing Analysis for solar powered welding helmet batteries Sourcing

What Are the Key Cost Components for Solar Powered Welding Helmet Batteries?

When analyzing the cost structure of solar powered welding helmet batteries, several key components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The battery components, including lithium-ion cells, solar panels, and electronic circuitry, represent a significant portion of the total cost. Quality materials not only enhance performance but also influence pricing. As solar technology advances, sourcing high-efficiency panels can lead to higher initial costs but lower long-term expenses.

-

Labor: Skilled labor is essential for the assembly and quality assurance of these complex products. Labor costs vary significantly based on geographic location, with regions like Europe generally commanding higher wages compared to countries in Africa or South America.

-

Manufacturing Overhead: This includes expenses related to factory operations, equipment maintenance, and utilities. Efficient manufacturing processes can help keep these costs in check, impacting the overall pricing structure.

-

Tooling: Investment in specialized tools for battery production can be substantial but is crucial for maintaining product consistency and quality. This cost can be amortized over larger production runs, making it vital for suppliers to balance order volume with tooling expenses.

-

Quality Control: Ensuring compliance with international standards and certifications can add to costs. Batteries must undergo rigorous testing to ensure safety and reliability, which is particularly critical for B2B buyers seeking to minimize risks.

-

Logistics: Shipping and handling costs vary based on the destination and the chosen Incoterms. Buyers need to consider these expenses, especially when sourcing from international suppliers, to avoid unexpected costs.

-

Margin: Suppliers typically incorporate a margin that reflects market conditions, competition, and perceived value. Understanding the market landscape can aid buyers in negotiating better deals.

How Do Price Influencers Affect Solar Powered Welding Helmet Battery Costs?

Several factors influence the pricing of solar powered welding helmet batteries, particularly for B2B transactions.

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Larger orders often secure lower per-unit costs due to economies of scale, making it essential for buyers to assess their purchasing strategy and forecasted needs.

-

Specifications and Customization: Custom specifications, such as unique sizes or additional features, can increase costs. Buyers should weigh the benefits of customization against potential price hikes.

-

Materials and Quality: The choice of materials directly impacts both performance and cost. Buyers should consider the total cost of ownership, which includes durability and longevity, rather than just the upfront price.

-

Supplier Factors: Supplier reputation, reliability, and experience play a crucial role in pricing. Established suppliers may command higher prices due to perceived quality, while newer entrants may offer competitive rates to gain market share.

-

Incoterms: Understanding Incoterms is crucial for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and responsibilities, influencing the total landed cost.

What Negotiation Tips Should B2B Buyers Consider?

When sourcing solar powered welding helmet batteries, buyers can employ several strategies to enhance cost-efficiency:

-

Leverage Volume Discounts: Consolidating orders to meet higher MOQs can lead to significant savings. Engage suppliers in discussions about tiered pricing based on order size.

-

Negotiate Payment Terms: Flexible payment terms can improve cash flow. Discuss options like extended payment schedules or discounts for upfront payments.

-

Evaluate Total Cost of Ownership: Focus on the long-term value of the batteries rather than just initial costs. Consider factors like energy efficiency, lifespan, and maintenance when making purchasing decisions.

-

Conduct Supplier Research: Investigate potential suppliers’ histories, reviews, and certifications. A reliable supplier may justify a higher price point if it ensures quality and minimizes risk.

-

Be Aware of Currency Fluctuations: For international transactions, currency exchange rates can impact final costs. Locking in rates or negotiating in stable currencies can mitigate risks.

Conclusion

Understanding the cost structure and pricing dynamics of solar powered welding helmet batteries is essential for B2B buyers, particularly in diverse markets across Africa, South America, the Middle East, and Europe. By considering the outlined cost components, price influencers, and negotiation tips, buyers can make informed purchasing decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing solar powered welding helmet batteries With Other Solutions

When evaluating options for welding helmets, particularly in the context of international markets such as Africa, South America, the Middle East, and Europe, it is essential to consider various solutions that can meet specific operational needs. Solar powered welding helmet batteries are one popular choice, but alternative technologies also present viable options. This analysis compares solar powered welding helmet batteries against two alternatives: traditional battery-powered welding helmets and manual welding helmets.

| Comparison Aspect | Solar Powered Welding Helmet Batteries | Traditional Battery-Powered Helmets | Manual Welding Helmets |

|---|---|---|---|

| Performance | Fast auto-darkening; reliant on solar for optimal function | Consistent performance regardless of light conditions | Simple, non-automatic operation |

| Cost | Moderate initial investment, low operating cost | Varies widely; replacement batteries can add long-term costs | Low upfront cost, no ongoing costs |

| Ease of Implementation | Easy to use, minimal setup; requires sunlight for optimal performance | Simple operation; battery management needed | Straightforward; no technology involved |

| Maintenance | Low maintenance; occasional solar panel cleaning | Regular battery replacement needed | Minimal; no moving parts |

| Best Use Case | Ideal for outdoor and sunny environments | Suitable for indoor and varied light conditions | Best for occasional use or in budget-constrained situations |

What Are the Pros and Cons of Traditional Battery-Powered Helmets?

Traditional battery-powered welding helmets provide consistent performance irrespective of the external lighting conditions, making them versatile for both indoor and outdoor use. These helmets often come with advanced features such as adjustable shade levels and quick response times to changing light conditions, which are crucial for eye protection. However, they require regular battery replacements, which can incur additional costs over time. This aspect may deter budget-conscious buyers or those operating in remote areas where battery access is limited.

How Do Manual Welding Helmets Compare?

Manual welding helmets, while the most basic option, are straightforward and cost-effective. They do not rely on any technology, making them durable and easy to maintain. However, the lack of automatic darkening means that welders must manually flip the lens down before starting to work, which can be inconvenient and less safe. This option is best suited for infrequent users or those working in environments where high-tech solutions are not necessary or feasible.

Illustrative image related to solar powered welding helmet batteries

Which Welding Helmet Solution Should B2B Buyers Choose?

Choosing the right welding helmet solution hinges on various factors, including operating environment, budget constraints, and specific user needs. For organizations in sunny regions or outdoor applications, solar powered helmets can be an excellent long-term investment due to their low operating costs and sustainability. Conversely, for those who operate in varied conditions or require a reliable solution without the hassle of battery management, traditional battery-powered helmets may be more appropriate. Lastly, for occasional welders or those seeking a simple, cost-effective option, manual helmets remain a viable choice. By weighing these aspects, B2B buyers can make informed decisions tailored to their operational requirements.

Essential Technical Properties and Trade Terminology for solar powered welding helmet batteries

What Are the Key Technical Properties of Solar Powered Welding Helmet Batteries?

When evaluating solar powered welding helmet batteries, several essential technical specifications are critical for B2B buyers to understand. These specifications influence performance, reliability, and overall user satisfaction.

1. Battery Type

The most common battery types used in solar powered welding helmets are lithium-ion and nickel-metal hydride (NiMH). Lithium-ion batteries are preferred due to their lightweight nature, higher energy density, and longer life cycle. Understanding battery type is vital for assessing maintenance needs and ensuring compatibility with solar charging systems.

2. Capacity (Ah)

Battery capacity, measured in ampere-hours (Ah), indicates how much charge a battery can hold. A higher capacity typically translates to longer usage times between charges. For B2B buyers, this specification is essential for determining how often helmets will need recharging, which can impact operational efficiency in industrial settings.

3. Charge Time

Charge time refers to the duration required to fully charge the battery. This specification is crucial for users who need to minimize downtime. A faster charge time can enhance productivity, especially in environments where multiple helmets are in use. Buyers should evaluate charge times in conjunction with operational schedules to ensure seamless workflow.

Illustrative image related to solar powered welding helmet batteries

4. Operating Temperature Range

The operating temperature range denotes the environmental conditions in which the battery can function effectively. This specification is particularly relevant for international buyers in diverse climates, as extreme temperatures can affect battery performance and longevity. Understanding this range helps ensure that the helmets will operate reliably in specific geographic regions.

5. Cycle Life

Cycle life is the number of complete charge and discharge cycles a battery can undergo before its capacity significantly diminishes. A longer cycle life results in lower replacement costs and reduced waste. B2B buyers should prioritize helmets with batteries that offer extended cycle life, as this can lead to more sustainable operations and cost savings over time.

6. Self-Discharge Rate

The self-discharge rate indicates how quickly a battery loses its charge when not in use. For solar powered helmets, a low self-discharge rate is advantageous, as it ensures that the battery remains usable for longer periods between charges. This is particularly important for businesses that may not use the helmets daily.

What Are Common Trade Terms Related to Solar Powered Welding Helmet Batteries?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common trade terms relevant to solar powered welding helmet batteries.

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces components or products that are used in another company’s end product. In the context of welding helmets, knowing whether a supplier is an OEM can affect warranty terms, product quality, and support services.

Illustrative image related to solar powered welding helmet batteries

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers to understand, as it can impact inventory management and cash flow. Buyers should negotiate MOQs based on their operational needs to avoid excess stock.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers asking for pricing and availability of products. For B2B buyers, issuing an RFQ can help gather competitive pricing and terms from multiple suppliers, aiding in informed decision-making.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping costs, risks, and delivery timelines, ensuring smooth logistics.

5. Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and performance of a product. For solar powered welding helmets, warranty terms can vary significantly, so it’s essential for buyers to assess coverage to protect their investment.

6. Lead Time

Lead time refers to the period between placing an order and receiving the product. This term is crucial for project planning, especially in industries with tight deadlines. Buyers should inquire about lead times to ensure timely delivery and avoid operational disruptions.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions regarding solar powered welding helmet batteries, leading to improved operational efficiency and cost-effectiveness.

Illustrative image related to solar powered welding helmet batteries

Navigating Market Dynamics and Sourcing Trends in the solar powered welding helmet batteries Sector

What Are the Current Market Dynamics and Key Trends in Solar Powered Welding Helmet Batteries?

The global market for solar powered welding helmet batteries is experiencing significant growth, driven by increasing demand for sustainable and efficient welding solutions. Key factors influencing this trend include a rise in manufacturing activities across sectors such as automotive, construction, and metal fabrication, particularly in emerging markets like Nigeria and Brazil. As these regions develop, the need for advanced protective gear that offers both safety and convenience becomes paramount. Moreover, technological advancements are leading to better battery efficiency and longer life spans, which are critical for B2B buyers who prioritize cost-effectiveness.

Emerging trends include the integration of smart technologies into welding helmets, such as sensors that adjust shading levels based on ambient light conditions, enhancing user experience. Additionally, there is a growing preference for hybrid models that combine solar power with battery backup, ensuring reliability in various working environments. International buyers are increasingly seeking products that not only meet safety standards but also offer enhanced performance features, such as rapid darkening times and improved optical clarity.

Another dynamic at play is the competitive landscape, where manufacturers are focusing on innovation and product differentiation. For instance, companies are investing in research and development to create lighter, more comfortable helmets with advanced features. As such, B2B buyers must stay informed about the latest products and technologies to make informed purchasing decisions.

How Can Sustainability and Ethical Sourcing Impact the Solar Powered Welding Helmet Batteries Market?

Sustainability is becoming a central theme in the procurement strategies of international B2B buyers, particularly in the solar powered welding helmet batteries sector. The environmental impact of manufacturing processes and the materials used is under scrutiny, prompting companies to seek out products that align with their sustainability goals. This includes the adoption of renewable energy sources in manufacturing and the use of recyclable materials in product design.

Ethical sourcing practices are also gaining traction. Buyers are increasingly interested in suppliers that demonstrate a commitment to social responsibility, whether through fair labor practices or environmentally friendly production techniques. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) serve as benchmarks for quality and responsibility, making them attractive to buyers aiming to enhance their corporate social responsibility profiles.

Illustrative image related to solar powered welding helmet batteries

Moreover, the demand for “green” certifications is on the rise, as end-users are more likely to choose products that have been vetted for their environmental impact. B2B buyers are encouraged to inquire about the sustainability practices of their suppliers, ensuring that their supply chains contribute positively to the environment while meeting regulatory standards. This focus on ethical sourcing not only benefits the planet but also enhances brand reputation and customer loyalty.

What Is the Brief Evolution and History of Solar Powered Welding Helmet Batteries?

The evolution of solar powered welding helmet batteries can be traced back to the broader advancements in welding technology and safety equipment. Initially, traditional welding helmets relied solely on passive filters that provided limited protection against harmful light and UV radiation. As the welding industry evolved, so did the need for more sophisticated protective gear, leading to the introduction of auto-darkening helmets in the late 20th century.

The integration of solar power into these helmets marked a significant milestone, allowing for self-sustaining operation without the constant need for battery replacements. This innovation not only improved the user experience but also aligned with growing environmental concerns, as solar energy is a clean and renewable resource. Today, the market has advanced to include hybrid models that utilize both solar power and rechargeable batteries, catering to the diverse needs of welders across various environments.

As the technology continues to advance, B2B buyers can expect even more enhancements in performance, comfort, and sustainability, making solar powered welding helmet batteries an essential consideration for industries focused on safety and efficiency.

Frequently Asked Questions (FAQs) for B2B Buyers of solar powered welding helmet batteries

-

1. How do I solve the problem of battery failure in solar powered welding helmets?

Battery failure can be a common issue with solar powered welding helmets, especially if the battery is not regularly charged. To mitigate this, choose helmets that feature both solar and battery power options. This dual system ensures that even if the solar charging fails, the battery will still function. Additionally, it’s crucial to follow the manufacturer’s guidelines for maintenance and charging intervals to prolong battery life. Regularly check for signs of wear or damage to the battery and replace it as needed to ensure optimal performance. -

2. What is the best solar powered welding helmet battery for high-intensity welding?

For high-intensity welding, opt for solar powered helmets with batteries that have a rapid response time and high durability. Helmets equipped with lithium-ion batteries are often recommended due to their longevity and efficiency. Look for helmets that also feature auto-darkening filters with adjustable sensitivity to cater to various welding environments. Brands with a proven track record in heavy-duty applications, such as Miller or Lincoln Electric, are ideal choices. Ensure that the battery specifications align with the demands of your welding operations. -

3. How can I vet suppliers for solar powered welding helmet batteries?

When vetting suppliers, start by researching their reputation and customer reviews in the industry. Verify their certifications and compliance with international quality standards, such as ISO 9001. Request samples to assess product quality and performance firsthand. Engaging in direct communication to discuss their manufacturing processes and supply chain logistics can provide insight into their reliability. Additionally, consider suppliers that offer transparent warranty and return policies, as this indicates confidence in their products. -

4. What are the minimum order quantities (MOQ) for solar powered welding helmet batteries?

MOQs can vary significantly depending on the supplier and the specific battery model. Typically, manufacturers may set an MOQ ranging from 50 to 500 units for custom orders. For bulk purchases, you may negotiate lower MOQs. Always clarify the MOQ before placing an order, as some suppliers may offer flexibility for first-time buyers or long-term partnerships. Additionally, inquire about lead times and the implications of ordering below the MOQ. -

5. What payment terms should I expect when purchasing solar powered welding helmet batteries internationally?

Payment terms can differ based on the supplier and your negotiation. Common options include full payment upfront, a deposit with the balance due upon shipping, or payment upon delivery. For large orders, consider requesting payment through letters of credit or escrow services to ensure transaction security. It’s advisable to establish clear terms regarding currency, payment methods (e.g., wire transfer, PayPal), and any potential taxes or tariffs that may apply to international shipments. -

6. How do I ensure quality assurance for solar powered welding helmet batteries?

To ensure quality assurance, request detailed documentation of the battery’s specifications, testing processes, and compliance with safety standards. Many reputable manufacturers will provide certificates of quality control and third-party testing results. Consider setting up a quality assurance agreement that outlines inspection protocols upon receipt. Engaging in a pre-shipment inspection can also help confirm that the products meet your standards before they are shipped. -

7. What logistics considerations are there when importing solar powered welding helmet batteries?

Logistics considerations include shipping methods, customs clearance, and delivery timelines. Evaluate whether air freight or sea freight is more cost-effective based on your urgency and budget. Understand the import regulations in your country, including any tariffs or duties applicable to electronic components. Collaborating with a freight forwarder experienced in handling such imports can streamline the process and ensure compliance with all legal requirements. -

8. Are there customization options available for solar powered welding helmet batteries?

Many manufacturers offer customization options to meet specific operational needs. This could include variations in battery capacity, integrated features like LED indicators, or branding options for business identity. When discussing customization, clearly outline your requirements and confirm any additional costs or lead times associated with the changes. Collaborating closely with the supplier during the design phase can ensure that the final product aligns with your expectations and operational needs.

Top 5 Solar Powered Welding Helmet Batteries Manufacturers & Suppliers List

1. Euromarc – Solar-Powered Auto-Darkening Helmets

Domain: euromarc.co.nz

Introduction: This company, Euromarc – Solar-Powered Auto-Darkening Helmets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Miller Welds – Solar and Battery Powered Hoods

Domain: forum.millerwelds.com

Registered: 1996 (29 years)

Introduction: 1. Solar Powered Hoods: These helmets rely on solar power to charge an internal battery, which is essential for operation. They can work without direct sunlight but may become ineffective if the battery is dead. Some models may have button battery backups. 2. Battery Powered Hoods: These helmets can switch faster than solar-only models, providing better protection for the eyes. They often come wit…

3. Auto-Tinting Welding Helmets – Solar-Powered Efficiency

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Auto-tinting welding helmets with solar panel for battery charging; approximately a dozen helmets; used 1-15 hours per week; stored face up on a table; exposed to 8-10 hours of light from high-ceiling fluorescent bulbs; batteries replaced twice in one year.

4. TOOLIOM – Solar Power Auto Darkening Welding Helmet

Domain: tooliom.com

Registered: 2019 (6 years)

Introduction: TOOLIOM Welding Helmet Solar Power Auto Darkening Welding Helmet Adjustable Shade Range for MIG TIG Stick Welder Mask Blue Eagle. Regular price: $31.99 (originally $49.99). Features include: 1/1/1/2 optical clarity lens with advanced true color technology, 3.64*1.67 viewing screen, auto-darkening filter with 2 arc sensors (dark to bright transition time: 0.1s to 1.0s), compatibility with magnifyin…

5. Harbor Freight – Auto-Darkening Welding Helmet

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: – Product: Auto-Darkening Welding Helmet

– Brand: Harbor Freight

– Required Items for Repair:

– Dremel tool with arbor and abrasive cutting disks (or diamond wheel types)

– Hot glue gun and glue sticks

– Soldering iron and solder

– 4 AAA or 4 AA batteries

– 2 x 2-Cell holders (3VDC) for the batteries

– Battery Types: Coin cell (CR3023) and external AA/AAA batteries

– Repair Steps:

1….

Strategic Sourcing Conclusion and Outlook for solar powered welding helmet batteries

In summary, the strategic sourcing of solar-powered welding helmet batteries offers significant advantages for B2B buyers across diverse markets, particularly in Africa, South America, the Middle East, and Europe. Prioritizing quality and reliability in sourcing decisions can lead to enhanced operational efficiency and reduced downtime. The integration of solar technology not only ensures sustainability but also mitigates the challenges associated with traditional battery-powered helmets, such as maintenance and frequent replacements.

Illustrative image related to solar powered welding helmet batteries

Moreover, understanding the nuances between solar-only and hybrid battery systems can empower buyers to make informed choices tailored to their specific operational contexts. As the demand for eco-friendly and cost-effective solutions continues to rise, investing in advanced solar-powered helmets will likely yield long-term benefits in safety and productivity.

Looking ahead, international buyers are encouraged to engage with reputable suppliers who can provide comprehensive product support and innovation. By fostering strong partnerships within the solar welding equipment sector, businesses can position themselves at the forefront of this growing market, ensuring they remain competitive and responsive to evolving industry standards. Embrace the future of welding safety—consider solar-powered solutions today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.