How to Source Snow Flake Ice Making Machine Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for snow flake ice making machine

In today’s competitive landscape, sourcing a reliable snow flake ice making machine can pose significant challenges for international B2B buyers. As businesses in sectors such as hospitality, food service, and healthcare increasingly demand high-quality ice solutions, understanding the nuances of this market becomes essential. This comprehensive guide aims to equip buyers from Africa, South America, the Middle East, and Europe—regions known for their diverse culinary and industrial needs—with the insights necessary to make informed purchasing decisions.

Throughout this guide, we will explore various types of snow flake ice machines, their applications across different industries, and the critical factors to consider when vetting suppliers. Additionally, we will address cost considerations and maintenance requirements, ensuring you have a holistic view of what to expect when investing in these machines. By leveraging the information provided, buyers can navigate the complexities of the global market with confidence, ultimately enhancing their operational efficiency and service offerings.

As you delve into this guide, you’ll discover actionable strategies that not only simplify the sourcing process but also empower your business to thrive in a competitive environment. Whether you are looking to enhance your ice production capabilities or seeking innovative solutions to meet evolving customer demands, this resource is designed to support your journey towards successful procurement.

Understanding snow flake ice making machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Commercial Flake Ice Machine | High production capacity (up to 176 lbs/24h), stainless steel | Restaurants, cafes, catering services | Pros: High efficiency, durable; Cons: Higher upfront cost. |

| Automatic Snowflake Ice Maker | Fully automated, compact, energy-efficient | Laboratories, hospitals, schools | Pros: Low maintenance, energy-saving; Cons: Limited ice production capacity. |

| Ice Cream Snowflake Maker | Adjustable ice texture and shapes, fast production (3 seconds) | Dessert shops, ice cream parlors | Pros: Versatile ice shapes, quick operation; Cons: May require frequent cleaning. |

| Air-Cooled Snowflake Ice Machine | Rapid cooling capabilities, no drainage needed | Food service, events, mobile vendors | Pros: Easy setup, reliable performance; Cons: Can be noisy. |

| Industrial Snowflake Ice Machine | Large capacity (over 200 lbs/24h), designed for heavy use | Industrial kitchens, ice suppliers | Pros: High output, robust design; Cons: Requires substantial space and investment. |

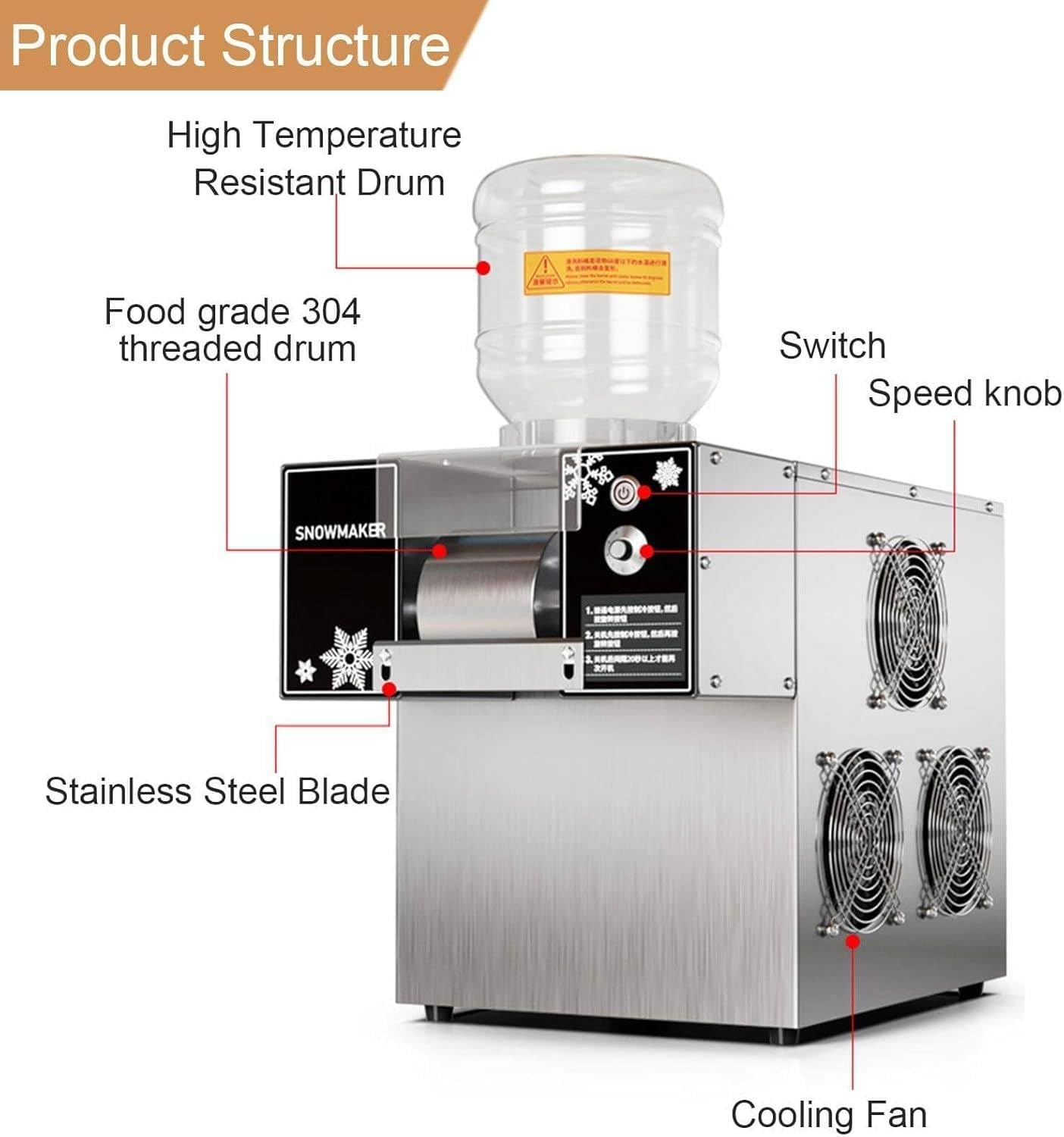

What Are the Characteristics of a Commercial Flake Ice Machine?

Commercial flake ice machines are designed for high output, typically producing up to 176 lbs of ice per 24 hours. Made primarily from stainless steel, these machines are built for durability and efficiency, making them ideal for restaurants, cafes, and catering services. When considering this type, buyers should evaluate their daily ice needs, installation space, and energy consumption, as these factors will influence their operational costs and efficiency.

Illustrative image related to snow flake ice making machine

How Does an Automatic Snowflake Ice Maker Differ from Others?

Automatic snowflake ice makers are characterized by their fully automated operation, compact design, and energy efficiency. They are particularly suitable for environments such as laboratories, hospitals, and schools where ice production is needed without manual intervention. Buyers should consider the machine’s capacity, energy-saving features, and the quality of materials used, as these will impact long-term reliability and maintenance costs.

Why Choose an Ice Cream Snowflake Maker?

Ice cream snowflake makers are unique in their ability to produce various textures and shapes of ice, which is crucial for dessert shops and ice cream parlors. With a rapid production time of just three seconds, these machines are perfect for high-demand settings. Buyers should evaluate the versatility of ice shapes, ease of cleaning, and overall maintenance requirements, as these factors will affect operational efficiency and customer satisfaction.

What Are the Advantages of an Air-Cooled Snowflake Ice Machine?

Air-cooled snowflake ice machines are favored for their rapid cooling capabilities and the convenience of not requiring drainage. This makes them suitable for food service operations, events, and mobile vendors. When purchasing, buyers should assess the machine’s noise levels, cooling efficiency, and ease of installation, as these aspects can influence the overall user experience and operational workflow.

Illustrative image related to snow flake ice making machine

What Makes Industrial Snowflake Ice Machines a Good Investment?

Industrial snowflake ice machines are designed for heavy-duty use, with capacities often exceeding 200 lbs of ice per day. These machines are ideal for industrial kitchens and ice suppliers. Buyers should consider the machine’s footprint, energy consumption, and upfront investment, as these elements will determine their return on investment and suitability for large-scale operations.

Key Industrial Applications of snow flake ice making machine

| Industry/Sector | Specific Application of snow flake ice making machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Ice production for restaurants and bars | Enhances drink presentation and keeps beverages cold | Energy efficiency, production capacity, and maintenance |

| Healthcare | Ice for medical applications, including storage of perishable samples | Preserves the integrity of temperature-sensitive items | Compliance with health regulations, ease of cleaning |

| Seafood Processing | Ice for preserving fish and seafood during transport | Extends shelf life and maintains product quality | Durability, ice production rate, and water filtration |

| Hospitality | Ice for catering services and events | Improves guest experience and operational efficiency | Size, portability, and storage capacity |

| Laboratories | Ice for cooling and preserving biological samples | Ensures accurate results and sample integrity | Temperature control, automation, and reliability |

How is snow flake ice making machine used in the Food and Beverage industry?

In the food and beverage sector, snow flake ice making machines are crucial for producing ice that enhances the presentation of drinks and keeps them cold. Bars and restaurants utilize this ice to elevate customer experience, particularly during peak seasons. Buyers should focus on energy efficiency and production capacity to ensure they can meet high demand without incurring excessive operational costs. Additionally, considering maintenance requirements is vital for minimizing downtime.

What role does snow flake ice play in Healthcare applications?

In healthcare settings, snow flake ice is used for preserving temperature-sensitive medical supplies and biological samples. The ability to maintain a consistent low temperature is critical for the integrity of these items. Buyers from this sector must prioritize compliance with health regulations and the ease of cleaning when sourcing machines. Ensuring reliable ice production is also essential to avoid any disruptions in laboratory operations.

Why is snow flake ice essential for Seafood Processing?

Seafood processors rely on snow flake ice to keep fish and seafood fresh during transportation and storage. This ice helps extend the shelf life of products, maintaining quality and preventing spoilage. When sourcing ice machines, businesses should consider durability and the production rate to handle the volume of ice needed. Water filtration systems are also important to ensure the ice is free from contaminants, which is critical for food safety.

How does snow flake ice enhance Hospitality services?

In the hospitality industry, snow flake ice making machines are essential for catering services and events, where large quantities of ice are required. This ice not only keeps drinks cold but also enhances the overall guest experience. Buyers should evaluate the size and portability of the machines to ensure they can be easily integrated into various event settings. Storage capacity is another key consideration, especially for large gatherings.

What is the significance of snow flake ice in Laboratories?

Laboratories use snow flake ice for cooling and preserving biological samples during experiments. The ability to maintain precise temperature control is crucial for achieving accurate results. Buyers in this field should look for machines that offer automation features and reliability to ensure consistent performance. Additionally, sourcing machines that comply with safety standards is essential to mitigate risks associated with laboratory operations.

3 Common User Pain Points for ‘snow flake ice making machine’ & Their Solutions

Scenario 1: Ensuring Consistent Ice Quality for Food Service Businesses

The Problem: In the food service industry, maintaining the quality and consistency of ice is crucial for beverages and food presentation. B2B buyers often face challenges with machines that produce ice that is too hard or too soft, affecting the quality of cocktails, smoothies, or seafood displays. Variations in ice quality can lead to customer dissatisfaction and wastage, ultimately impacting the bottom line. Additionally, inconsistent production can disrupt service during peak hours when demand is high.

The Solution: To overcome this issue, buyers should prioritize machines that offer adjustable ice texture settings. When sourcing a snowflake ice making machine, look for models that allow operators to modify the roller speed to produce different textures of ice. This flexibility ensures that the ice can be tailored to specific beverage or food requirements. Additionally, consider investing in a machine with a high-capacity production rate, allowing for ample supply during busy periods. Regular maintenance is also essential; ensure that the machine is routinely cleaned and serviced to maintain optimal performance and ice quality. Finally, train staff to understand the machine’s functionalities so they can adjust settings on-the-fly based on customer needs.

Scenario 2: Managing Energy Costs in Ice Production

The Problem: Energy consumption is a significant concern for many businesses, especially in regions where electricity costs are high. B2B buyers often find themselves dealing with snowflake ice making machines that consume excessive amounts of power, leading to inflated operational costs. This is particularly critical for businesses operating in hot climates or in high-volume settings, where ice production needs to be constant.

The Solution: Buyers should focus on energy-efficient models that are designed to minimize power consumption without compromising ice production capabilities. Look for machines equipped with high-efficiency compressors and energy-saving modes. When evaluating options, check for energy certifications or ratings that indicate the machine’s efficiency. Additionally, consider the operational environment; placing machines in well-ventilated areas can enhance their cooling efficiency and reduce energy use. Implementing a routine maintenance schedule can also help in identifying and rectifying any inefficiencies in the machine’s operation. Finally, explore suppliers that provide detailed operational cost analyses to better understand the long-term savings associated with energy-efficient ice making machines.

Scenario 3: Addressing Space Constraints in Commercial Settings

The Problem: Many businesses, particularly in urban areas, face significant space constraints. B2B buyers often struggle to find snowflake ice making machines that fit within limited floor space while still meeting their ice production needs. This can be especially challenging in restaurants, cafes, or mobile food vendors where every square meter counts, and bulky equipment can impede workflow and efficiency.

The Solution: When dealing with space limitations, buyers should opt for compact and multifunctional ice making machines. Look for models that are designed with a smaller footprint but still offer high production capacity. Some manufacturers provide stackable or modular designs that can be tailored to fit specific spaces. Additionally, consider machines that combine ice making with storage capabilities, reducing the need for separate storage units. Before making a purchase, it’s advisable to conduct a thorough space analysis to determine the optimal layout for the machine’s placement. Engaging with suppliers who offer customization options can also provide solutions tailored to unique space requirements. Finally, ensure that the chosen machine’s output aligns with peak demand times to avoid bottlenecks, thus maintaining operational efficiency even in limited spaces.

Illustrative image related to snow flake ice making machine

Strategic Material Selection Guide for snow flake ice making machine

What Are the Key Materials Used in Snow Flake Ice Making Machines?

When selecting materials for snow flake ice making machines, it’s essential to consider their properties, performance, and suitability for various applications. Here, we analyze four common materials used in these machines, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

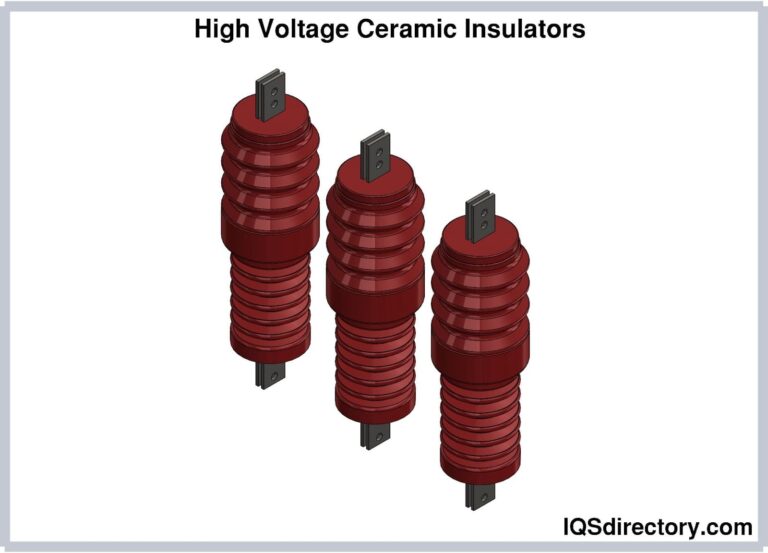

How Does Stainless Steel Benefit Snow Flake Ice Making Machines?

Key Properties: Stainless steel, particularly grades like SUS304 and SUS201, is known for its excellent corrosion resistance and durability. It can withstand high pressures and temperatures, making it suitable for the demanding environments of ice production.

Pros & Cons: The primary advantage of stainless steel is its longevity and resistance to rust and staining, which is crucial in wet environments. However, it can be more expensive than other materials and may require specialized manufacturing processes, which can increase production costs.

Impact on Application: Stainless steel is compatible with food-grade standards, making it ideal for machines producing ice for consumption. Its robust nature ensures that it can handle the mechanical stresses involved in ice production without degrading.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the stainless steel used meets international standards such as ASTM or DIN. Compliance with food safety regulations is also critical, particularly in the Middle East and Europe.

Illustrative image related to snow flake ice making machine

What Role Does Plastic Play in Ice Making Machines?

Key Properties: Plastics used in ice machines, such as food-grade polyethylene, are lightweight, resistant to moisture, and can be molded into complex shapes.

Pros & Cons: The primary advantage of plastic is its lower cost and ease of manufacturing. However, plastics may not offer the same level of durability or temperature resistance as metals, leading to potential wear and tear over time.

Impact on Application: Plastic components are often used for water tanks and internal linings, where corrosion resistance is essential, but they must be chosen carefully to ensure they can withstand the low temperatures of ice production.

Considerations for International Buyers: Buyers should verify that the plastics used are compliant with food safety standards and are suitable for the specific environmental conditions of their region, such as high humidity or temperature fluctuations.

Why Is Copper a Consideration in Snow Flake Ice Making Machines?

Key Properties: Copper is an excellent conductor of heat, making it ideal for components that require efficient heat exchange, such as evaporators and condensers.

Illustrative image related to snow flake ice making machine

Pros & Cons: The advantage of copper is its thermal conductivity, which enhances the efficiency of ice production. However, copper is prone to corrosion and can be expensive, which may not justify its use in all applications.

Impact on Application: Copper’s properties make it suitable for parts that require rapid cooling and heating. However, its susceptibility to corrosion means it may not be the best choice for all environments, particularly those with high levels of moisture.

Considerations for International Buyers: Buyers should ensure that copper components are treated or coated to prevent corrosion, especially in humid climates. They should also consider the cost implications of using copper versus more durable alternatives.

How Do Alloys Enhance Performance in Ice Making Machines?

Key Properties: Alloys, such as aluminum or various stainless steel blends, offer a balance between strength, weight, and cost-effectiveness.

Illustrative image related to snow flake ice making machine

Pros & Cons: Alloys can provide enhanced performance characteristics, such as improved corrosion resistance and reduced weight. However, they may require more complex manufacturing processes, potentially increasing costs.

Impact on Application: Alloys are often used in structural components of ice machines, where a combination of strength and weight savings is beneficial. Their versatility allows for customization based on specific operational needs.

Considerations for International Buyers: Buyers should be aware of the specific alloy compositions and their compliance with local regulations. Understanding the mechanical properties of the alloys used can also help in assessing their suitability for different operational environments.

Summary Table

| Material | Typical Use Case for snow flake ice making machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, ice production surfaces | Excellent corrosion resistance | Higher cost, specialized mfg. | High |

| Plastic | Water tanks, internal linings | Lightweight, cost-effective | Less durable, potential wear | Low |

| Copper | Heat exchangers, evaporators | Superior thermal conductivity | Corrosion-prone, higher cost | Med |

| Alloys | Structural and performance-critical components | Balanced properties, customizable | Complex manufacturing | Med |

By understanding the properties and implications of these materials, international B2B buyers can make informed decisions that align with their operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for snow flake ice making machine

What Are the Key Stages in the Manufacturing Process of Snow Flake Ice Making Machines?

The manufacturing process of snow flake ice making machines is intricate and comprises several critical stages, each essential for ensuring quality and efficiency. Understanding these stages is crucial for B2B buyers looking to procure reliable equipment.

Material Preparation: What Materials Are Used?

The first stage involves selecting high-quality materials, primarily food-grade stainless steel (often SUS304 or SUS201) for the machine body and components. These materials are chosen for their durability, corrosion resistance, and ease of cleaning, which are vital in food service applications. Additionally, components like compressors and electrical parts must meet international safety and performance standards.

Before production, materials undergo a thorough inspection to verify their quality. This includes checking for any surface defects and ensuring compliance with specifications that meet international standards.

How Are Snow Flake Ice Machines Formed?

Forming processes include cutting, bending, and welding of the stainless steel sheets into the desired shapes. Advanced CNC (Computer Numerical Control) machines are often employed for precision cutting, ensuring that every component fits perfectly. After forming, components are welded using techniques that provide strong, durable joints.

Illustrative image related to snow flake ice making machine

Some manufacturers may also utilize laser cutting technology for enhanced accuracy and efficiency. This technology allows for intricate designs that contribute to better airflow and cooling efficiency in the final product.

What Does the Assembly Process Involve?

Once components are formed, the assembly stage begins. This typically involves the following steps:

- Component Assembly: Individual components such as the compressor, evaporator, and control panels are assembled into the main unit.

- Electrical Wiring: Proper wiring is critical for functionality. Technicians ensure that all electrical connections are secure and meet safety standards.

- Cooling System Installation: The refrigeration system, which is crucial for ice production, is installed at this stage. It must be tested for leaks to ensure efficient operation.

Quality control checkpoints are established throughout the assembly process to monitor the integrity of the construction and functionality of the components.

What Finishing Techniques Are Applied?

Finishing processes enhance both the aesthetic appeal and functionality of the machines. This may include:

- Surface Treatment: Machines are often treated to resist corrosion and wear. Techniques like electro-polishing are used to create a smooth surface that is easier to clean and maintain.

- Painting and Coating: Non-toxic, food-safe coatings may be applied for additional protection against rust and corrosion.

- Final Inspection: Each unit undergoes a final inspection to ensure all components are correctly installed and functioning as intended.

How Is Quality Assurance Implemented in Snow Flake Ice Machine Manufacturing?

Quality assurance is integral to the manufacturing of snow flake ice machines. It encompasses various international and industry-specific standards, ensuring that the final product meets customer expectations and regulatory requirements.

What International Standards Apply to Snow Flake Ice Machines?

Manufacturers often adhere to international standards like ISO 9001, which specifies requirements for a quality management system. Compliance with this standard demonstrates a commitment to quality and continuous improvement.

Additionally, industry-specific certifications, such as CE (Conformité Européenne) and API (American Petroleum Institute), may be required, especially for machines intended for use in specific regions or industries.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is implemented at various stages of the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before they are used in production.

- In-Process Quality Control (IPQC): Continuous monitoring during the assembly process ensures that any defects are identified and corrected in real-time.

- Final Quality Control (FQC): The final inspection involves testing the operational performance of the machine, ensuring that it meets the specified production capacity and operational standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control processes of potential suppliers:

- Request Documentation: Buyers should ask for quality assurance documentation, including ISO certifications, test reports, and records of previous inspections.

- Conduct Audits: On-site audits of the manufacturing facility can provide insights into the supplier’s operational practices and adherence to quality standards.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the product quality before shipment.

What Are the Specific QC Considerations for International Buyers?

For international buyers, especially those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital. Factors such as import regulations, certification requirements, and local standards may vary significantly across countries.

How Do Regulatory Differences Impact Quality Assurance?

Different countries may have varying standards for food safety, electrical safety, and machinery operation. Buyers should ensure that their suppliers comply with both local and international regulations to avoid legal issues and ensure product safety.

What Should Buyers Know About Certification Nuances?

Understanding the certification nuances is crucial. For example, while CE marking is mandatory for products sold in the European Economic Area, it might not be necessary in other regions. Buyers should clarify these requirements with suppliers to ensure compliance and market readiness.

Conclusion

The manufacturing processes and quality assurance practices for snow flake ice making machines are comprehensive and designed to ensure high-quality output. By understanding these processes, international B2B buyers can make informed decisions when sourcing equipment. Verifying supplier quality through documentation, audits, and third-party inspections will further enhance confidence in procurement, ensuring that the machines meet both operational needs and regulatory standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘snow flake ice making machine’

In the competitive landscape of commercial ice production, selecting the right snowflake ice making machine is pivotal for businesses aiming to meet their operational needs efficiently. This practical sourcing guide provides a step-by-step checklist to assist B2B buyers in procuring the best equipment for their specific requirements.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly define your operational needs, including ice production capacity, size, and specific features required. Consider the volume of ice needed daily—machines vary widely, with some producing as little as 60 kg to over 200 kg per day. Additionally, assess the space available in your facility to ensure compatibility with machine dimensions.

Step 2: Research Market Options

Conduct thorough market research to identify available brands and models that meet your specifications. Look for machines with varying features such as energy efficiency, noise levels, and production speed. Utilize online resources, trade shows, and industry publications to gather insights on leading manufacturers and emerging technologies.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Pay attention to their experience with international shipping and support, especially if you’re sourcing from different continents, as this can significantly affect delivery timelines and service quality.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers have the necessary certifications and compliance with international quality standards. Look for certifications such as ISO 9001, CE, or other industry-specific credentials that indicate reliability and safety. This step is essential to mitigate risks associated with equipment failure or subpar performance.

Step 5: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations that include pricing, shipping costs, warranty terms, and after-sales support. Compare the total cost of ownership rather than just the upfront price. Be wary of hidden fees and ensure that the quotation aligns with your budget and operational needs.

Step 6: Assess After-Sales Support and Warranty

Evaluate the after-sales support provided by the supplier, including warranty terms, maintenance services, and customer support. A robust support system is vital for minimizing downtime and ensuring the machine operates efficiently throughout its lifespan. Inquire about the availability of spare parts and the supplier’s response time for service requests.

Step 7: Finalize the Purchase Agreement

Once you are satisfied with a supplier and their offerings, negotiate the purchase agreement. Ensure all terms discussed, including delivery timelines, installation services, and payment conditions, are documented. This agreement should also address any potential contingencies to protect your investment and facilitate a smooth transaction process.

By following this checklist, B2B buyers can confidently navigate the procurement process for snowflake ice making machines, ensuring they select the right equipment to enhance their operational efficiency and meet customer demands.

Comprehensive Cost and Pricing Analysis for snow flake ice making machine Sourcing

What Are the Key Cost Components in Sourcing Snow Flake Ice Making Machines?

When evaluating the costs associated with sourcing snow flake ice making machines, it’s crucial to consider several key components that contribute to the overall pricing structure. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The primary materials used in manufacturing snow flake ice machines are high-grade stainless steel and food-grade plastics. The quality of these materials significantly influences the durability and efficiency of the machines. For instance, machines made from SUS304 stainless steel tend to have a higher price point due to their corrosion resistance and longevity.

-

Labor: Labor costs can vary greatly depending on the country of manufacture. Countries with lower labor costs may offer more competitive pricing, but this can sometimes come at the expense of quality. Skilled labor is essential for high-quality assembly and quality control processes, which should not be overlooked.

-

Manufacturing Overhead: This includes costs related to the production environment, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce these overheads, ultimately leading to more favorable pricing for buyers.

-

Tooling: Investment in tooling is necessary for producing specific components of ice machines. Custom tooling can lead to increased initial costs but may result in lower per-unit costs at higher production volumes.

-

Quality Control (QC): Rigorous quality control processes are essential to ensure that machines meet international safety and performance standards. Suppliers that implement comprehensive QC measures may charge higher prices, reflecting the added value of reliability and compliance.

-

Logistics: Transportation and shipping costs can significantly affect the total cost of ownership, especially for international buyers. Factors such as distance, freight mode, and packaging will influence these costs.

-

Margin: Supplier margins can vary widely based on their market positioning and the value-added services they provide, such as after-sales support or warranties.

How Do Price Influencers Affect Snow Flake Ice Machine Sourcing?

Several factors can influence the pricing of snow flake ice machines. Understanding these can help buyers negotiate better deals and make informed purchasing decisions.

-

Volume/MOQ: Minimum order quantities (MOQs) can impact unit pricing. Suppliers often offer better pricing for bulk orders, allowing buyers to achieve economies of scale.

-

Specifications and Customization: Customized machines tailored to specific needs can lead to higher costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Material Quality and Certifications: Machines with higher-grade materials or specific certifications (e.g., NSF, CE) typically carry a premium price. Buyers should assess the value of these certifications based on their operational needs.

-

Supplier Factors: The reputation, reliability, and service level of the supplier can also influence pricing. Established suppliers may charge more, but they often provide better support and warranty options.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) can affect total costs and responsibilities during shipping. Buyers should understand these terms to avoid unexpected charges.

What Buyer Tips Can Help in Negotiating Snow Flake Ice Machine Prices?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, effective negotiation and cost-management strategies are vital.

-

Negotiate Wisely: Leverage your purchasing volume and long-term relationship potential to negotiate better pricing and terms. Be clear about your expectations and the value you bring to the supplier.

-

Focus on Total Cost of Ownership (TCO): Consider the TCO, including maintenance, energy efficiency, and potential downtime costs. A higher upfront cost may be justified if the machine offers lower operating costs and longer lifespan.

-

Understand Pricing Nuances: Be aware that currency fluctuations and import duties can affect overall costs. Work with suppliers who can provide clarity on these factors to avoid surprises.

-

Seek Multiple Quotations: Obtaining quotes from various suppliers allows for better comparison and may reveal significant price differences based on service levels or product features.

-

Assess After-Sales Support: Evaluate the supplier’s commitment to after-sales service and warranty. A machine that is slightly more expensive but comes with robust support may save costs in the long run.

Disclaimer on Indicative Prices

The pricing for snow flake ice making machines can vary significantly based on the factors outlined above. The prices mentioned in various sources may serve as a general guideline, but potential buyers should conduct thorough market research and supplier assessments to obtain accurate quotes tailored to their specific needs.

Alternatives Analysis: Comparing snow flake ice making machine With Other Solutions

Introduction: Exploring Alternatives to Snow Flake Ice Making Machines

When it comes to producing ice, particularly for commercial applications, businesses often seek the most efficient and cost-effective solutions. While snow flake ice making machines are popular for their unique ice texture and high production rates, several alternatives can fulfill similar needs. This analysis compares snow flake ice making machines against two viable alternatives: traditional ice cube machines and ice flake production via refrigeration systems.

Comparison Table

| Comparison Aspect | Snow Flake Ice Making Machine | Traditional Ice Cube Machine | Ice Flake Production via Refrigeration Systems |

|---|---|---|---|

| Performance | 132-176 lbs/24 hours | 100-200 lbs/24 hours | Variable, dependent on system design |

| Cost | $2,118 – $3,000 | $1,000 – $2,500 | $1,500 – $5,000 depending on capacity |

| Ease of Implementation | Moderate; requires plumbing | Easy; plug-and-play | Complex; requires setup and space |

| Maintenance | Regular cleaning; low parts wear | Low; minimal maintenance | High; requires regular servicing |

| Best Use Case | Restaurants, cafes, seafood | Bars, restaurants, hotels | Industrial applications, large-scale food production |

Detailed Breakdown of Alternatives

Traditional Ice Cube Machine

Traditional ice cube machines are widely used for their ease of operation and lower upfront costs. They typically produce between 100 to 200 lbs of ice per day, making them suitable for bars, restaurants, and hotels that require regular ice supply. The initial investment can range from $1,000 to $2,500, depending on the capacity and features. Maintenance is generally low, with occasional cleaning needed to prevent scale buildup. However, they produce standard ice cubes, which may not meet specific needs for certain beverages or food applications that require specialty ice.

Illustrative image related to snow flake ice making machine

Ice Flake Production via Refrigeration Systems

Ice flake production using refrigeration systems is another alternative that can be highly effective for industrial applications. These systems can vary significantly in price, from $1,500 to $5,000, depending on the scale and efficiency. They are capable of producing ice flakes at a larger volume, making them ideal for food processing and large-scale distribution. However, the setup can be complex, requiring dedicated space and plumbing, and they demand higher maintenance levels due to their intricate components. This option excels in environments where large quantities of ice are required continuously, but it may not be practical for smaller operations.

Conclusion: Choosing the Right Ice Solution for Your Business Needs

In selecting the appropriate ice production solution, B2B buyers should consider their specific operational needs, budget constraints, and maintenance capabilities. Snow flake ice making machines offer high production rates and specialized ice types, making them ideal for food-related businesses. However, if ease of use and lower initial investment are priorities, traditional ice cube machines may suffice. For larger enterprises focused on high-volume ice requirements, refrigeration systems provide a compelling option despite their complexity. Ultimately, the decision should align with the business’s long-term goals and operational demands.

Essential Technical Properties and Trade Terminology for snow flake ice making machine

What Are the Key Technical Properties of Snow Flake Ice Making Machines?

1. Ice Production Capacity

The ice production capacity is measured in pounds or kilograms per 24 hours (e.g., 132 lbs/24h or 176 kg/24h). This specification indicates the efficiency of the machine and is critical for businesses with high ice demand, such as restaurants, supermarkets, or food processing plants. Selecting the right capacity ensures that the operation can meet peak demands without interruptions.

2. Material Grade

Snow flake ice machines are typically constructed from stainless steel, with grades such as SUS201 or SUS304 being common. These materials are essential for durability and resistance to corrosion, which is vital in humid environments. Choosing high-grade materials not only prolongs the lifespan of the machine but also ensures compliance with health and safety regulations, particularly in food service applications.

3. Cooling Method

The cooling method, whether air-cooled or water-cooled, impacts the machine’s operational efficiency and energy consumption. Air-cooled systems are generally more environmentally friendly and easier to install, while water-cooled systems may offer better performance in high-temperature environments. Understanding the cooling method helps businesses choose machines that are appropriate for their specific operational conditions.

4. Power Consumption

Power consumption is typically expressed in watts (e.g., 360W). This metric is crucial for calculating operational costs and energy efficiency. Machines with lower power consumption can significantly reduce electricity bills, making them more economical for long-term use. B2B buyers should assess power requirements against local energy costs to evaluate the total cost of ownership.

Illustrative image related to snow flake ice making machine

5. Noise Level

Noise level is often measured in decibels (dB) and is an essential consideration for businesses operating in noise-sensitive environments. Machines that operate quietly enhance the customer experience in places like cafes or restaurants. Low-noise machines are often designed with advanced technologies that minimize operational sound, making them a more appealing choice for many businesses.

6. Ice Shape and Texture

The ability to produce different ice shapes and textures (e.g., snow ice, noodle ice) enhances versatility in product offerings. This feature is particularly valuable for businesses in the food and beverage industry, allowing them to create unique presentations and flavors. Machines that offer adjustable settings for ice production can cater to diverse customer preferences.

What Common Trade Terms Should B2B Buyers Know for Snow Flake Ice Machines?

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of snow flake ice machines, understanding OEM relationships can help buyers identify reputable suppliers and gauge product quality based on the manufacturer’s reputation.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects purchasing strategies and inventory management. Understanding MOQ helps businesses plan their orders and avoid excess inventory costs.

Illustrative image related to snow flake ice making machine

3. RFQ (Request for Quotation)

An RFQ is a standard business process wherein a buyer requests pricing and terms from suppliers for specific products. For snow flake ice machines, submitting an RFQ allows buyers to compare costs, delivery times, and other important terms across multiple suppliers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, defining the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risk transfer, and delivery responsibilities, ensuring smoother international procurement processes.

5. Warranty and Service Terms

These terms specify the conditions under which a manufacturer guarantees their product, including repair or replacement policies. Understanding warranty terms is essential for B2B buyers, as it impacts long-term operational costs and support available for troubleshooting or maintenance.

6. Lead Time

Lead time refers to the period between placing an order and receiving the product. This metric is vital for B2B buyers as it affects inventory management and operational planning. Knowing the lead time allows businesses to schedule their operations effectively and avoid disruptions due to insufficient ice supply.

By understanding these critical properties and trade terms, B2B buyers can make informed decisions when selecting snow flake ice making machines that best suit their operational needs.

Illustrative image related to snow flake ice making machine

Navigating Market Dynamics and Sourcing Trends in the snow flake ice making machine Sector

What Are the Current Market Dynamics and Key Trends in the Snow Flake Ice Making Machine Sector?

The global market for snow flake ice making machines is witnessing significant growth, driven by increasing demand across various sectors, including food and beverage, healthcare, and hospitality. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, seek reliable and efficient ice production solutions, several key trends are emerging. Firstly, the emphasis on energy efficiency is reshaping purchasing decisions. Machines that boast high production rates with lower energy consumption are becoming increasingly popular, aligning with the global push for sustainability.

Technological advancements are also influencing the market. Automated and smart ice machines equipped with IoT capabilities are gaining traction, allowing for remote monitoring and management. This trend is particularly relevant for businesses in countries like Brazil and Vietnam, where operational efficiency can significantly impact profitability. Additionally, the rise of e-commerce platforms has simplified the sourcing process, enabling buyers to compare products and suppliers more effectively.

The competitive landscape is evolving, with manufacturers focusing on producing high-quality, durable machines that meet international safety and performance standards. As a result, B2B buyers are encouraged to consider suppliers with a robust reputation for quality and service, ensuring long-term reliability and support.

How Is Sustainability and Ethical Sourcing Reshaping the Snow Flake Ice Making Machine Industry?

Sustainability has become a critical consideration in the sourcing of snow flake ice making machines. The environmental impact of production processes and the materials used is under scrutiny, prompting businesses to seek suppliers that prioritize eco-friendly practices. Buyers are increasingly looking for machines made from recyclable materials and those that utilize energy-efficient technology.

Moreover, the importance of ethical supply chains cannot be overstated. B2B buyers are urged to engage with manufacturers who adhere to responsible sourcing practices, including fair labor standards and environmentally sound manufacturing processes. Certifications such as ISO 14001 for environmental management systems and CE marking for compliance with EU safety standards are becoming essential criteria for procurement.

In addition, buyers should be aware of the impact of water usage in ice production. Machines designed with water-saving technologies not only reduce operational costs but also contribute to broader sustainability goals. By prioritizing suppliers that integrate these practices, businesses can enhance their brand reputation and align with consumer preferences for environmentally responsible products.

What Is the Evolution of Snow Flake Ice Making Machines and Its Relevance to B2B Buyers?

The evolution of snow flake ice making machines dates back several decades, with significant advancements in technology and design. Initially, these machines were primarily mechanical, requiring extensive manual operation and maintenance. However, as demand grew, manufacturers began to innovate, introducing automated features that enhance efficiency and reduce labor costs.

The introduction of stainless steel construction has improved durability and hygiene, making these machines suitable for a variety of commercial applications, from restaurants to hospitals. Today, modern snow flake ice makers are equipped with advanced cooling systems and smart controls, enabling rapid ice production while minimizing energy consumption.

For B2B buyers, understanding this evolution is crucial for making informed purchasing decisions. Recognizing the value of advanced features and materials can lead to better investment choices that yield long-term benefits in terms of performance, reliability, and sustainability. As the market continues to evolve, staying informed about these trends will help buyers align their sourcing strategies with industry best practices and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of snow flake ice making machine

-

How do I choose the right snow flake ice making machine for my business?

When selecting a snow flake ice making machine, consider factors such as daily ice production capacity, energy efficiency, and the machine’s size and footprint. Evaluate your specific needs based on your business type—restaurants, cafes, or ice cream shops may require different capacities and features. Additionally, look for machines made from durable materials, like stainless steel, which ensure longevity and ease of maintenance. Reading customer reviews and requesting demos can also help you make an informed decision. -

What is the typical ice production capacity for commercial snow flake ice machines?

Commercial snow flake ice machines generally produce between 60 kg to 250 kg of ice per day. The capacity you need will depend on your business operations and customer demand. For instance, a busy restaurant might require a machine with a higher output, while a small café could suffice with a lower capacity model. Always assess your peak usage times to ensure the machine can meet your demands without interruption. -

What should I consider regarding energy efficiency in ice machines?

Energy efficiency is crucial for minimizing operational costs. Look for machines that have energy-saving features, such as high-efficiency compressors and insulation that reduces energy consumption. Also, check for certifications like Energy Star, which indicates compliance with energy efficiency standards. Understanding the power requirements and operational costs associated with different models can significantly impact your overall budget. -

Are there customization options available for snow flake ice making machines?

Many manufacturers offer customization options to meet specific business needs. This can include adjustments in production capacity, dimensions, and even features like automated controls or different ice textures. Discuss your requirements with potential suppliers to explore available options. Customization may incur additional costs, so ensure that these align with your budget and operational needs. -

What are the minimum order quantities (MOQ) for snow flake ice making machines?

Minimum order quantities can vary significantly based on the manufacturer and your location. Some suppliers may offer machines on a per-unit basis, while others might require bulk orders to access better pricing. Always inquire about MOQs and any associated discounts for larger orders. Understanding these details is essential for budgeting and planning your procurement strategy. -

How do I vet suppliers of snow flake ice making machines?

To ensure you partner with a reliable supplier, conduct thorough research. Check for certifications, customer reviews, and case studies to assess their reputation. Request references from past clients and evaluate their response time and customer service quality. Visiting the supplier’s manufacturing facility, if possible, can provide insight into their production capabilities and quality control processes. -

What payment terms should I expect when purchasing ice machines internationally?

Payment terms can vary by supplier but typically include options such as upfront payments, letters of credit, or payment upon delivery. It’s essential to clarify these terms before finalizing the purchase. Additionally, consider using secure payment methods and, if applicable, discuss warranties and return policies to safeguard your investment. -

How is logistics and shipping handled for international purchases of snow flake ice machines?

Logistics and shipping arrangements will depend on the supplier and the destination. Discuss shipping options, including freight forwarders and delivery timelines, to ensure your machine arrives on time. Understand the customs regulations in your country to avoid unexpected delays. It’s advisable to request tracking information and insurance for high-value shipments to mitigate risks during transit.

Top 4 Snow Flake Ice Making Machine Manufacturers & Suppliers List

1. Vevor – Commercial Snowflake Ice Machine

Domain: vevor.com

Registered: 2009 (16 years)

Introduction: {“Product Name”: “Commercial Snowflake Ice Machine”, “Ice Production”: “176.4 lbs / 80 kg per 24 hours”, “Cooling Method”: “Air Cooling”, “Power”: “360W”, “Main Materials”: “SUS201 / SUS304 / 5CR15 Stainless Steel / PC”, “Bucket Capacity”: “3 L / 0.8 gal”, “Refrigeration Speed”: “40 seconds”, “Product Weight”: “51.4 lbs / 23.3 kg”, “Product Size”: “18.1 x 12.6 x 15.7 in / 460 x 320 x 400 mm”, “Fea…

2. Reddit – Flake Ice Solutions

Domain: reddit.com

Introduction: Flake ice is the most cost-effective type of ice used for cooling fresh caught fish, broiler and poultry chilling, cooling concrete for mass concrete pour projects, cooling and transporting produce such as corn and broccoli, and food processing applications including meat processing and commercial bakery.

3. Infitek – Automatic Snowflake Ice Maker

Domain: infitek.com

Registered: 2020 (5 years)

Introduction: {“Product Name”: “Automatic Snowflake Ice Maker”, “Models”: [“IM-FK60”, “IM-FK70”, “IM-FK85”], “Ice Making Capacity (kg/24h)”: {“IM-FK60”: 60, “IM-FK70”: 70, “IM-FK85”: 85}, “Ice Storage (kg)”: 25, “Ice Type”: “Irregular fine-grained”, “Cooling Mode”: “Forced-Air Cooling”, “Refrigerant”: “R290 (CFC Free)”, “Electricity”: “AC110 / 220V±10%, 50 / 60Hz”, “Power Consumption (W)”: {“IM-FK60”: 420, “IM-…

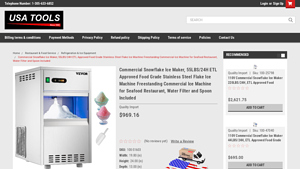

4. USA Tools – Commercial Snowflake Ice Maker

Domain: usatoolsinc.com

Registered: 2006 (19 years)

Introduction: {“Product Name”: “Commercial Snowflake Ice Maker”, “Production Capacity”: “55 lbs/24h”, “Approval”: “ETL Approved”, “Material”: “Food Grade Stainless Steel”, “Type”: “Flake Ice Machine”, “Installation Type”: “Freestanding”, “Target Use”: “Commercial (Seafood Restaurant)”, “Included Accessories”: [“Water Filter”, “Spoon”], “Contact Number”: “1-305-633-6852”}

Strategic Sourcing Conclusion and Outlook for snow flake ice making machine

In the competitive landscape of the snow flake ice making machine market, strategic sourcing plays a pivotal role in ensuring that international buyers can access high-quality, efficient equipment tailored to their specific needs. By leveraging insights from diverse suppliers, businesses can optimize their procurement processes, reduce costs, and enhance operational efficiency. Key considerations include evaluating the production capacity, energy efficiency, and durability of machines, as well as understanding the local market dynamics across regions such as Africa, South America, the Middle East, and Europe.

As demand for snow flake ice machines continues to rise, particularly in sectors like food service and healthcare, the importance of establishing reliable supply chains cannot be overstated. Buyers should seek partnerships with reputable manufacturers that prioritize quality and sustainability, ensuring they can meet their operational requirements while adhering to environmental standards.

Looking ahead, the market is poised for growth, driven by innovations in technology and increasing consumer preferences for frozen treats. We encourage international B2B buyers to act proactively in sourcing the right machines that align with their business goals, positioning themselves at the forefront of this expanding industry. Engage with trusted suppliers today to secure the best solutions for your needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to snow flake ice making machine

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.