How to Source Slide Latches For Doors Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for slide latches for doors

In the ever-evolving global market, sourcing slide latches for doors presents a unique set of challenges for B2B buyers, particularly those operating across diverse regions such as Africa, South America, the Middle East, and Europe. As businesses strive to enhance security and functionality in their operations, understanding the intricacies of slide latch options becomes imperative. This guide delves into the various types of slide latches, their applications, and the critical factors to consider when vetting suppliers.

From rustic designs that complement traditional aesthetics to modern, heavy-duty options tailored for commercial use, the landscape of slide latches is vast and varied. Additionally, we provide insights into pricing structures and emerging trends that influence the cost of these essential components. By equipping international buyers with the necessary knowledge to make informed purchasing decisions, this guide aims to streamline the procurement process, ensuring that you choose the right slide latch solutions that meet your specific needs.

Whether you are a buyer in Nigeria looking for cost-effective yet durable options or a procurement officer in Germany seeking high-quality latches for commercial projects, this comprehensive resource will serve as your roadmap to navigating the complexities of the global market for slide latches for doors. With actionable insights at your fingertips, you can confidently select the right products and suppliers to enhance your operations.

Understanding slide latches for doors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Surface Slide Bolt | Mounted on the surface of the door; easy installation | Gates, barn doors, cabinets | Pros: Simple to install, versatile; Cons: Less secure than other types. |

| Heavy-Duty Slide Bolt | Constructed from robust materials for high security | Industrial doors, warehouses | Pros: Excellent durability and security; Cons: Higher cost and may require professional installation. |

| Cane Bolt | Long, vertical bolt for securing gates and doors | Agricultural buildings, outdoor gates | Pros: Effective for heavy doors; Cons: Limited aesthetic options. |

| Thumb Latch | Operated by a thumb lever; often decorative | Residential gates, decorative doors | Pros: Easy to operate, adds aesthetic value; Cons: May not provide high security. |

| Lockable Slide Bolt | Features a locking mechanism for enhanced security | Commercial properties, secure areas | Pros: Offers high security; Cons: More complex installation and higher price. |

What are the Characteristics of Surface Slide Bolts for B2B Buyers?

Surface slide bolts are characterized by their straightforward installation and surface mounting. Typically used in applications such as gates, barn doors, and cabinets, they offer a practical solution for securing lightweight to medium-weight doors. B2B buyers appreciate their ease of use and versatility, as they can be installed without extensive modifications to existing doors. However, it’s essential to consider that while surface slide bolts are user-friendly, they may lack the level of security required for high-risk environments.

How Do Heavy-Duty Slide Bolts Enhance Security for Businesses?

Heavy-duty slide bolts are designed for high-security applications and are made from robust materials that withstand wear and tear. Commonly found in industrial settings and warehouses, these bolts are ideal for securing large doors against unauthorized access. B2B buyers should weigh the benefits of enhanced security against the higher cost and potential need for professional installation. Their durability makes them a worthwhile investment for businesses prioritizing safety.

Why Choose Cane Bolts for Agricultural Applications?

Cane bolts are long, vertical bolts that effectively secure doors and gates, making them particularly suitable for agricultural buildings and outdoor gates. Their design allows for easy operation, ensuring that heavy doors remain securely closed even in windy conditions. Buyers in the agricultural sector should consider cane bolts for their reliability and ease of use, although they may find limited aesthetic choices compared to other latch types.

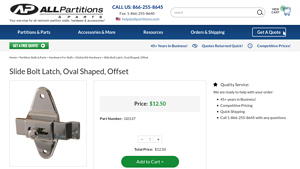

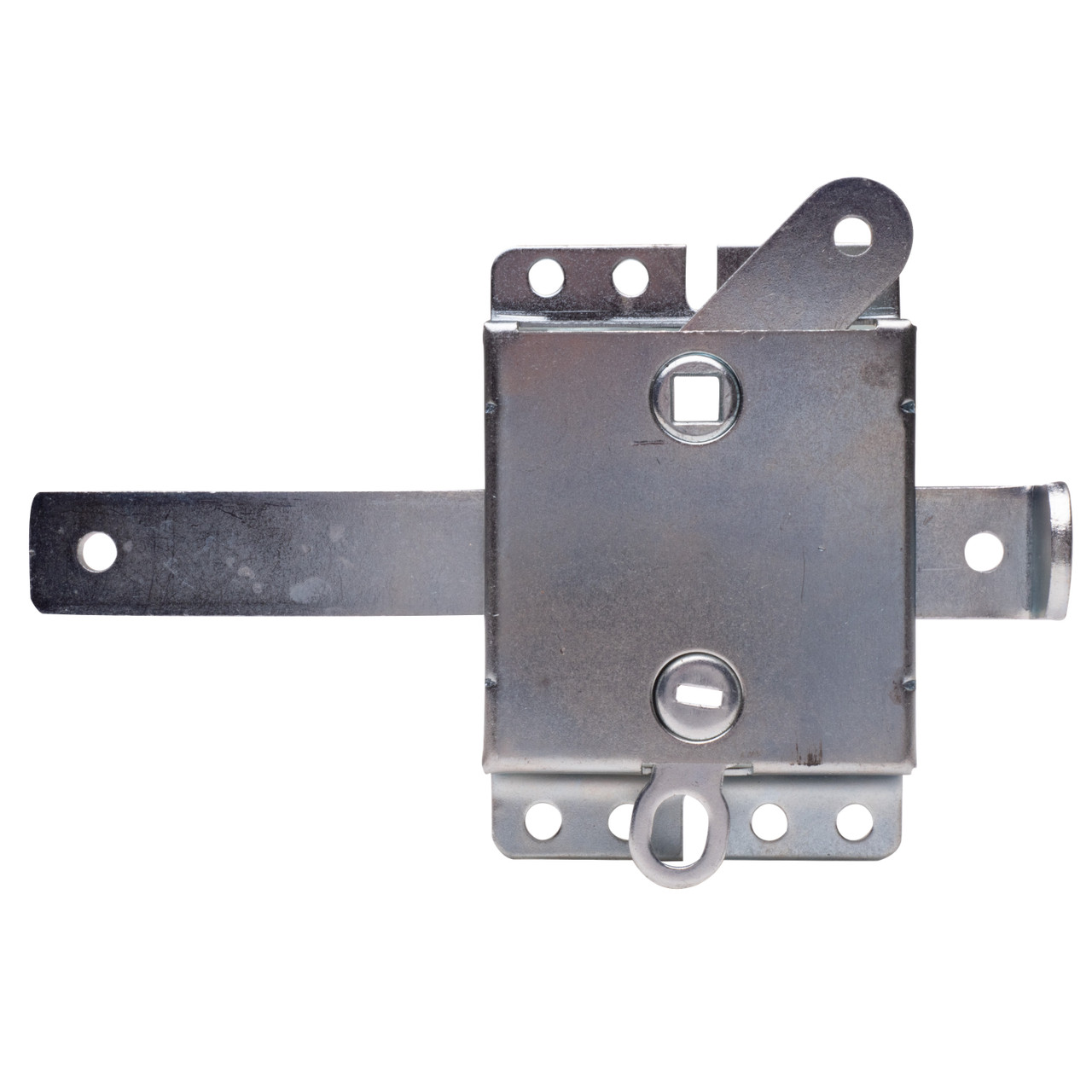

Illustrative image related to slide latches for doors

What Are the Benefits of Thumb Latches in Residential Applications?

Thumb latches are operated with a simple thumb lever, often featuring decorative designs that enhance the visual appeal of gates and doors. They are widely used in residential settings, providing convenience and style. B2B buyers looking for attractive yet functional solutions for residential projects will find thumb latches appealing. However, they may not be suitable for high-security areas due to their relatively lower security features.

How Do Lockable Slide Bolts Provide Enhanced Security for Commercial Properties?

Lockable slide bolts incorporate a locking mechanism, making them an excellent choice for commercial properties and secure areas. They provide a significant security advantage over standard slide bolts, deterring unauthorized access effectively. B2B buyers should consider their specific security needs when opting for lockable slide bolts, as they may involve a more complex installation process and a higher price point. The added security justifies the investment for many businesses.

Key Industrial Applications of slide latches for doors

| Industry/Sector | Specific Application of slide latches for doors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Securing interior and exterior sliding doors | Enhances security and access control | Durability, weather resistance, and compliance with local building codes |

| Agriculture | Locking agricultural gates and storage sheds | Protects valuable equipment and livestock | Heavy-duty materials, corrosion resistance, and ease of installation |

| Hospitality | Access control for guest room sliding doors | Improves guest experience and safety | Aesthetic design, ease of use, and compatibility with existing systems |

| Manufacturing | Securing sliding access panels in factories | Increases operational efficiency and safety | Load capacity, material strength, and automation compatibility |

| Retail | Locking display cases and stock room doors | Prevents theft and unauthorized access | Customization options, ease of installation, and security features |

How are slide latches for doors utilized in the construction industry?

In the construction sector, slide latches are commonly used to secure both interior and exterior sliding doors. They provide an essential layer of security and access control, ensuring that spaces such as warehouses, offices, and residential properties remain safe. For international buyers, especially in regions like Africa and South America, sourcing durable and weather-resistant latches that comply with local building codes is crucial. Buyers must consider the latch’s longevity and ability to withstand various environmental conditions.

What role do slide latches play in agricultural applications?

In agriculture, slide latches are vital for locking gates and storage sheds, safeguarding equipment and livestock from theft or wandering. The use of heavy-duty materials ensures that these latches can withstand harsh outdoor conditions, including moisture and corrosion, which is particularly important for buyers in the Middle East and regions with high humidity. When sourcing, businesses should prioritize latches that offer ease of installation and robust locking mechanisms to enhance security.

How do slide latches enhance safety in the hospitality sector?

In the hospitality industry, slide latches are integral to managing access to guest room sliding doors. They not only enhance security but also improve the overall guest experience by providing easy access while ensuring safety. Buyers from Europe and the Middle East should focus on aesthetic designs that complement the hotel’s decor, as well as latches that are user-friendly for guests. Compatibility with existing locking systems is also a significant consideration during the sourcing process.

Illustrative image related to slide latches for doors

Why are slide latches important in manufacturing environments?

Manufacturers often use slide latches to secure sliding access panels in factories, which helps increase operational efficiency and safety. By ensuring that access points are securely locked, businesses can prevent unauthorized entry, thereby protecting sensitive equipment and inventory. International buyers, particularly in developing markets, should consider the load capacity and material strength of the latches, along with their compatibility with automation systems to streamline operations.

How do retail businesses benefit from using slide latches?

In retail environments, slide latches are crucial for locking display cases and stock room doors, effectively preventing theft and unauthorized access to valuable merchandise. Retailers must prioritize sourcing latches that offer customization options to fit various display cases while ensuring ease of installation. Additionally, security features such as key locks or combination mechanisms can further enhance the safety of products, appealing to international buyers looking for comprehensive security solutions.

3 Common User Pain Points for ‘slide latches for doors’ & Their Solutions

Scenario 1: Difficulty in Ensuring Security with Sliding Doors

The Problem: B2B buyers often face challenges in securing sliding doors, particularly in commercial settings where high foot traffic and valuable inventory are present. Standard slide latches may not provide adequate security, leading to concerns about unauthorized access and potential theft. This issue is particularly pronounced in regions with higher crime rates or in industries where sensitive materials are handled, such as pharmaceuticals or electronics.

The Solution: To address security concerns, buyers should invest in heavy-duty slide latches that are specifically designed for commercial use. When sourcing these products, look for latches made from robust materials such as stainless steel or reinforced aluminum, which offer greater resistance to tampering. Additionally, consider latches that incorporate locking mechanisms, such as padlocks or key-operated systems, to enhance security further. It is also advisable to collaborate with manufacturers who can provide custom solutions tailored to specific door dimensions and security needs. Regular maintenance and inspections of the latch mechanisms will ensure long-term reliability and security.

Illustrative image related to slide latches for doors

Scenario 2: Incompatibility with Existing Door Structures

The Problem: Another common pain point is the incompatibility of slide latches with existing door structures. Many businesses, especially those in older buildings, may find that standard slide latches do not align properly with their doors, leading to operational inefficiencies and increased wear on both the latch and the door. This can result in costly repairs and a frustrating user experience for employees.

The Solution: To mitigate compatibility issues, buyers should conduct a thorough assessment of their existing door structures before selecting slide latches. This involves measuring the door thickness, width, and the distance between the latch and door frame. Engaging with suppliers who offer a wide range of latch sizes and styles can provide options that fit specific door configurations. Additionally, consider adjustable slide latches that can be modified to fit various door sizes. Some manufacturers also offer consultation services to recommend the best solutions based on unique door specifications.

Scenario 3: Challenges in Installation and Maintenance

The Problem: Many B2B buyers encounter difficulties with the installation and maintenance of slide latches, which can be labor-intensive and require specialized tools. This can lead to delays in project timelines and increased labor costs, particularly for companies without dedicated maintenance staff or those operating in remote areas.

The Solution: To streamline the installation process, it is essential to choose slide latches that come with comprehensive installation guides and all necessary hardware. Suppliers who provide video tutorials or on-site support can significantly reduce installation time and complexity. For maintenance, buyers should opt for latches that are designed for easy access to internal mechanisms, allowing for straightforward cleaning and lubrication. Regular training sessions for staff on proper maintenance procedures can also enhance the longevity of the latches, ensuring that they function correctly and securely over time. By proactively addressing installation and maintenance challenges, businesses can improve operational efficiency and reduce overall costs.

Strategic Material Selection Guide for slide latches for doors

When selecting materials for slide latches for doors, it’s essential to consider the specific requirements of the application, including environmental factors, durability, and compliance with international standards. Below, we analyze four common materials used in the manufacturing of slide latches, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to slide latches for doors

What Are the Key Properties of Stainless Steel for Slide Latches?

Stainless steel is a popular choice for slide latches due to its excellent mechanical properties and corrosion resistance. It typically has a temperature rating up to 870°C and can withstand high pressure, making it suitable for various applications. The most common grades, such as 304 and 316, offer different levels of resistance to corrosive environments, with 316 being particularly suited for marine or coastal applications.

Pros: Stainless steel is highly durable, resistant to rust and corrosion, and requires minimal maintenance. Its aesthetic appeal also makes it suitable for high-end applications.

Cons: The primary drawback is the cost, as stainless steel is generally more expensive than other materials. Additionally, its manufacturing can be complex, requiring specialized equipment.

Impact on Application: Stainless steel slide latches are ideal for environments exposed to moisture, chemicals, or high temperatures, ensuring long-term performance.

Considerations for International Buyers: Compliance with standards such as ASTM A240 for stainless steel is crucial. Buyers from regions like Europe and the Middle East may also prefer specific grades that meet local regulations.

How Does Aluminum Compare as a Material for Slide Latches?

Aluminum is another widely used material for slide latches, known for its lightweight and corrosion-resistant properties. It typically has a temperature rating of around 600°C, making it suitable for moderate temperature applications.

Pros: The lightweight nature of aluminum makes it easy to handle and install. It is also cost-effective and offers good resistance to corrosion, especially when anodized.

Cons: While aluminum is durable, it is generally less strong than stainless steel and can be prone to deformation under heavy loads.

Impact on Application: Aluminum slide latches are suitable for residential applications and light commercial use, particularly where weight savings are essential.

Considerations for International Buyers: Buyers should ensure that the aluminum used complies with standards like ASTM B221. In regions like Africa and South America, where cost is a significant factor, aluminum may be preferred for budget-sensitive projects.

What Are the Advantages of Plastic Materials for Slide Latches?

Plastic materials, such as polycarbonate or nylon, are increasingly used in slide latches due to their versatility and resistance to corrosion. These materials can typically withstand temperatures up to 120°C.

Pros: Plastic is lightweight, non-corrosive, and can be manufactured in various colors and designs. It is also less expensive than metal options.

Cons: The main limitation is its lower strength compared to metals, which may restrict its use in heavy-duty applications.

Impact on Application: Plastic slide latches are ideal for indoor applications or environments where exposure to moisture is minimal.

Illustrative image related to slide latches for doors

Considerations for International Buyers: Compliance with safety standards, such as UL 94 for flammability, is essential. Buyers in Europe may also look for REACH compliance to ensure the absence of harmful substances.

Why Is Brass Considered for Slide Latches?

Brass is a traditional material for slide latches, known for its aesthetic appeal and good corrosion resistance. It typically has a temperature rating of around 300°C.

Pros: Brass offers excellent durability and a classic look, making it suitable for decorative applications. Its antimicrobial properties are also beneficial in certain environments.

Cons: Brass can be more expensive than other materials and may require regular maintenance to prevent tarnishing.

Impact on Application: Brass slide latches are often used in residential and decorative applications, where appearance is as important as functionality.

Illustrative image related to slide latches for doors

Considerations for International Buyers: Compliance with standards such as ASTM B36 is important. Buyers in regions like Germany may prefer brass for its traditional appeal in architectural applications.

Summary Table of Material Selection for Slide Latches

| Material | Typical Use Case for slide latches for doors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty and outdoor applications | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Residential and light commercial use | Lightweight and cost-effective | Less strength under heavy loads | Medium |

| Plastic | Indoor applications | Lightweight and non-corrosive | Lower strength compared to metals | Low |

| Brass | Decorative and residential applications | Aesthetic appeal and durability | Higher cost and maintenance required | Medium |

This strategic material selection guide provides B2B buyers with essential insights to make informed decisions when sourcing slide latches for doors, considering both performance and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for slide latches for doors

What Are the Key Stages in the Manufacturing Process of Slide Latches for Doors?

The manufacturing of slide latches involves several critical stages that ensure the production of high-quality, reliable products. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used and How Are They Prepared?

The primary materials used in the manufacture of slide latches are metals such as steel, stainless steel, and aluminum. These materials are chosen for their strength, durability, and resistance to corrosion. The preparation process typically involves:

- Material Selection: Choosing the right alloy based on the latch’s intended use and environmental conditions.

- Cutting and Sizing: The raw materials are cut into appropriate sizes using techniques such as laser cutting or water jet cutting. This step ensures that the material dimensions meet the design specifications.

- Surface Treatment: Initial surface treatments may include cleaning, de-greasing, and sometimes applying a protective coating to prevent oxidation.

How Are Slide Latches Formed and Assembled?

The forming process involves shaping the prepared materials into the specific components of the slide latches.

What Techniques Are Commonly Used for Forming?

- Stamping: This technique is widely used to create flat components from sheet metal. It involves pressing the metal into molds to achieve the desired shape.

- Forging: For heavier-duty latches, forging is employed to enhance the material’s strength through deformation at high temperatures.

- Machining: Precision machining processes, such as turning and milling, are used to refine the dimensions and features of the latch components.

Once the components are formed, the assembly process begins. This stage is crucial for ensuring the latch functions correctly and meets safety standards.

How Is the Assembly Process Conducted?

- Component Fitting: Each component, such as the bolt, housing, and locking mechanism, is fitted together. This may involve manual or automated assembly lines, depending on production scale.

- Welding and Fastening: Various techniques, including welding and the use of screws or rivets, are employed to secure the components together.

- Final Adjustments: Each latch is tested for movement and fit, ensuring it operates smoothly before moving to the finishing stage.

What Finishing Techniques Are Used to Enhance Slide Latch Quality?

The finishing process not only improves the aesthetic appeal of slide latches but also enhances their durability and resistance to environmental factors.

What Are the Common Finishing Methods?

- Coating: Powder coating, electroplating, or anodizing are applied to provide a protective layer that prevents rust and wear. These coatings can also add color and texture to the latch.

- Polishing: For aesthetic purposes, surfaces may be polished to achieve a smooth and shiny finish, which also helps in reducing friction during operation.

- Quality Control: After finishing, each latch undergoes a final inspection to ensure it meets all specifications and quality standards.

How Is Quality Assurance Implemented in Slide Latch Manufacturing?

Quality assurance is a critical aspect of the manufacturing process, ensuring that products meet international standards and customer expectations.

What International Standards Should B2B Buyers Be Aware Of?

Manufacturers often adhere to several international quality standards, including:

- ISO 9001: This standard outlines criteria for a quality management system, focusing on meeting customer expectations and regulatory requirements.

- CE Marking: For products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For specialized applications, such as industrial settings, the American Petroleum Institute (API) standards may apply.

What Are the Key Quality Control Checkpoints?

Quality control in the manufacturing process typically involves multiple checkpoints:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor processes and detect any deviations from quality standards.

- Final Quality Control (FQC): Before the products are shipped, a final inspection verifies that all items meet the required specifications and performance criteria.

Which Testing Methods Are Commonly Used for Slide Latches?

Several testing methods are employed to validate the performance and durability of slide latches:

- Functionality Testing: This includes testing the latch’s locking mechanism under various conditions to ensure reliability.

- Environmental Testing: Latches are subjected to conditions such as humidity, temperature variations, and salt spray to evaluate corrosion resistance.

- Load Testing: The latches are tested under maximum load conditions to ensure they can withstand stress without failure.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers should consider the following methods:

Illustrative image related to slide latches for doors

- Supplier Audits: Conducting on-site audits can provide insights into a supplier’s manufacturing processes, quality control measures, and adherence to standards.

- Requesting Quality Reports: Buyers should ask for documentation detailing quality control processes, including inspection results and testing data.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality management systems and product quality.

What Are the Quality Certification Nuances for International B2B Buyers?

International buyers should be aware of the specific quality certification nuances when sourcing slide latches:

- Regional Compliance: Different regions may have specific regulations and standards that manufacturers must comply with. Buyers should verify that products are compliant with local regulations in their target markets.

- Documentation Requirements: Ensure that all necessary documentation, including certificates of compliance and test reports, are available and valid for the intended market.

Understanding these manufacturing processes and quality assurance measures can empower B2B buyers to make informed decisions when sourcing slide latches for doors. By prioritizing quality and compliance, buyers can enhance their supply chain reliability and ensure customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘slide latches for doors’

Introduction

This practical sourcing guide provides B2B buyers with a structured checklist for procuring slide latches for doors. Given the variety of applications and specifications required across different regions, this guide aims to streamline the sourcing process, ensuring you select the right products that meet your operational needs and compliance requirements.

Step 1: Define Your Technical Specifications

Start by clearly identifying the technical requirements for your slide latches. Consider factors such as size, material, weight capacity, and intended use (e.g., residential or commercial).

- Material Selection: Determine if you need stainless steel, brass, or other materials based on durability and environmental factors.

- Size and Design: Ensure the dimensions and design fit the specific door types you are working with, whether they are sliding glass doors or heavy barn doors.

Step 2: Research Market Trends and Standards

Understanding current market trends and industry standards is crucial. Research which types of slide latches are gaining popularity and what features are deemed essential by customers in your region.

- Compliance and Certification: Look for products that meet international standards such as ISO or specific regional regulations to avoid compliance issues.

- Innovations: Keep an eye on new locking mechanisms or features that enhance security, as these can be selling points in your market.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

- Supplier Reputation: Investigate supplier reviews and ratings on independent platforms to gauge their reliability and product quality.

- Experience and Expertise: Consider suppliers who specialize in slide latches and have a proven track record in your specific market.

Step 4: Request Samples for Quality Assessment

Once you’ve narrowed down potential suppliers, request samples to evaluate the quality and functionality of their slide latches.

Illustrative image related to slide latches for doors

- Functional Testing: Check how smoothly the latch operates and whether it meets your specified requirements.

- Material Inspection: Examine the sample for any manufacturing defects and ensure the material quality aligns with your expectations.

Step 5: Negotiate Terms and Conditions

Engage in discussions with your chosen supplier regarding pricing, delivery timelines, and payment terms.

- Volume Discounts: Inquire about bulk purchasing options to leverage cost savings.

- Lead Times: Ensure that the supplier can meet your delivery timelines, especially if you have specific project deadlines.

Step 6: Review Shipping and Logistics Options

Effective logistics can significantly impact your procurement process. Assess the shipping methods and costs associated with your orders.

- Shipping Times: Understand the estimated delivery schedule and factor this into your project timelines.

- Customs and Duties: For international procurement, ensure you are aware of any customs regulations and duties that may apply to your shipment.

Step 7: Establish a Feedback Loop

Once you’ve procured and installed the slide latches, create a system for gathering feedback from your team or customers regarding their performance.

- Performance Evaluation: Regularly assess how well the latches are functioning in real-world conditions.

- Supplier Relationship Management: Use feedback to maintain open communication with your supplier for future orders and improvements.

By following these steps, you can enhance your procurement process, ensuring that you select the right slide latches for your needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for slide latches for doors Sourcing

What Are the Key Cost Components for Slide Latches for Doors?

The cost structure for slide latches for doors can be broken down into several key components. Materials account for a significant portion of the cost, with options ranging from basic steel to high-grade stainless steel or even decorative finishes that may include powder coating. The choice of materials not only influences the durability and aesthetic appeal but also impacts the overall cost.

Labor is another critical factor, with costs varying based on the region of production. Manufacturing locations with lower labor costs may reduce the overall price, but it’s essential to consider the trade-off between cost and quality. Manufacturing overhead includes expenses related to utilities, facility maintenance, and equipment depreciation, which can vary widely depending on the production scale and location.

Tooling costs are incurred for the machinery and molds required to produce slide latches. If custom designs are necessary, these costs can increase significantly. Quality control (QC) processes also add to the expenses, as ensuring compliance with safety and performance standards is crucial, especially for international buyers.

Finally, logistics encompass shipping and handling costs, which can fluctuate based on the shipping terms and the distance to the destination. These logistics costs are particularly relevant for international transactions, where tariffs and import duties may also come into play.

How Do Price Influencers Affect the Cost of Slide Latches?

Several price influencers can significantly affect the cost of slide latches for doors. Volume and minimum order quantities (MOQs) play a pivotal role; larger orders typically result in lower per-unit costs due to economies of scale. Customization requests for specific specifications or unique designs can also drive up prices, as they may require specialized tooling or materials.

The quality of materials directly correlates with cost. High-quality materials may yield higher upfront costs but can reduce maintenance expenses and prolong the product’s lifespan, thereby enhancing overall value. Additionally, certifications for safety and environmental standards can add to the cost but are often essential for compliance in certain markets.

Supplier factors, such as reputation and reliability, can also influence pricing. Established suppliers may charge a premium for their products due to perceived quality, while emerging suppliers might offer lower prices to gain market share. Finally, Incoterms play a crucial role in determining who bears the shipping costs and risks, affecting the final price for buyers.

What Are the Best Negotiation Strategies for B2B Buyers?

For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of negotiation is vital. Start by conducting thorough market research to understand typical pricing trends and competitor offerings. Use this information to inform your negotiations, aiming for transparency in pricing structures.

Consider discussing total cost of ownership (TCO) rather than just upfront costs. Highlighting the long-term benefits of higher-quality latches can justify a higher initial price. Additionally, leverage your purchasing power by negotiating for discounts on larger orders or establishing long-term contracts that might lead to better pricing.

When negotiating, be aware of pricing nuances specific to international markets. Currency fluctuations can impact costs, and understanding local economic conditions can provide leverage in negotiations. Always clarify Incoterms to avoid unexpected costs during shipping, and ensure that all terms are documented to prevent misunderstandings.

What Should International Buyers Keep in Mind About Pricing?

International buyers should exercise caution regarding indicative prices. Prices can fluctuate based on numerous factors, including changes in material costs, labor rates, and shipping expenses. Always request formal quotes that include all potential fees to get a clear picture of the total cost.

Buyers should also be aware of the regulatory environment surrounding imports in their respective countries. Tariffs and customs duties can significantly impact the final cost of slide latches, and understanding these regulations is essential for accurate budgeting.

In conclusion, while the cost and pricing analysis for slide latches for doors encompasses various components and influencers, a strategic approach can help international buyers optimize their sourcing process and achieve cost-effective solutions.

Alternatives Analysis: Comparing slide latches for doors With Other Solutions

Exploring Alternatives to Slide Latches for Doors

In the realm of securing doors, slide latches are a popular choice due to their simplicity and effectiveness. However, it’s essential to explore alternative solutions that may offer different advantages, depending on specific business needs. This analysis will compare slide latches to two viable alternatives: deadbolts and electronic locks.

Comparison Table

| Comparison Aspect | Slide Latches for Doors | Deadbolts | Electronic Locks |

|---|---|---|---|

| Performance | Good for light security | Excellent; resistant to forced entry | Very good; features may vary |

| Cost | Generally low-cost | Moderate initial investment | Higher upfront costs; variable ongoing costs |

| Ease of Implementation | Easy to install | Requires precise installation | Moderate; may need electrical work |

| Maintenance | Low maintenance | Low maintenance | Moderate; battery replacements needed |

| Best Use Case | Interior doors, gates | Exterior doors, high-security areas | Businesses with access control needs |

What Are the Advantages and Disadvantages of Deadbolts?

Deadbolts provide a significant security upgrade over slide latches. They are designed to prevent unauthorized entry, making them ideal for exterior doors. The locking mechanism is robust, often requiring a key or thumb turn for access. However, their installation can be more complex, requiring precise fitting into the door frame. While they generally require minimal maintenance, deadbolts do not allow for quick access compared to slide latches, which may be a drawback in environments needing frequent entry and exit.

How Do Electronic Locks Compare with Slide Latches?

Electronic locks represent a modern solution for securing doors, integrating technology to enhance security. They can be accessed via keypads, RFID cards, or smartphone apps, allowing for a high level of customization in terms of user access. This makes them suitable for businesses that require tracking of entry and exit. However, they come with higher upfront costs and may necessitate professional installation, particularly if electrical work is involved. Maintenance can also be more demanding, as battery changes and software updates are necessary to ensure continued functionality.

Conclusion: How to Choose the Right Door Security Solution?

When deciding between slide latches, deadbolts, and electronic locks, B2B buyers should consider their specific security needs, budget constraints, and the environment in which the locking mechanism will be used. Slide latches may suffice for internal applications or gates, while deadbolts are better suited for external doors needing enhanced security. For businesses requiring detailed access control, electronic locks offer advanced features despite the higher investment. Ultimately, understanding the unique requirements of your business will guide you in selecting the most appropriate door security solution.

Essential Technical Properties and Trade Terminology for slide latches for doors

When selecting slide latches for doors, understanding the essential technical properties and trade terminology is crucial for making informed purchasing decisions. Here, we delve into key specifications and jargon that can impact procurement and usage in various markets, particularly for international B2B buyers.

What are the Key Technical Properties of Slide Latches for Doors?

-

Material Grade

Slide latches are commonly manufactured from materials like stainless steel, brass, and zinc-plated steel. The material grade affects durability, corrosion resistance, and suitability for different environments. For instance, stainless steel latches are ideal for coastal regions due to their resistance to rust, while zinc-plated options may suffice for indoor applications. Selecting the right material is vital for ensuring longevity and minimizing maintenance costs. -

Load Capacity

The load capacity refers to the maximum weight a latch can support without failure. This is particularly important for industrial applications where heavy doors or gates are involved. Buyers should assess the load requirements based on the door type and usage frequency to ensure the latch will perform adequately under stress, thereby preventing operational disruptions. -

Tolerance

Tolerance indicates the acceptable limits of variation in dimensions during manufacturing. A tighter tolerance often results in better fit and function, which is essential for security and ease of use. In B2B environments, where precision is critical, understanding tolerance specifications can help buyers select latches that integrate seamlessly with other hardware components. -

Finish

The finish of a latch not only contributes to aesthetic appeal but also affects its resistance to environmental factors. Common finishes include powder-coated, galvanized, and polished. The choice of finish can influence the latch’s ability to withstand elements like moisture, UV light, and chemical exposure. Buyers should consider the specific conditions where the latch will be used to ensure optimal performance. -

Size and Dimensions

The size of the latch, including length, width, and height, is crucial for compatibility with door designs. Buyers must measure existing hardware and ensure that the new latches fit appropriately. Poor sizing can lead to operational inefficiencies and increased installation costs. -

Locking Mechanism

The type of locking mechanism (e.g., thumb latch, padlockable) determines the security level provided by the latch. Understanding the security needs of the application will guide buyers in selecting the appropriate mechanism to safeguard their premises.

What are Common Trade Terms Used in the Slide Latch Industry?

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of slide latches, buyers often seek OEM components to ensure compatibility and quality assurance with existing door systems. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory costs effectively. Suppliers may impose MOQs to ensure profitability, so buyers should negotiate terms that align with their purchasing needs. -

RFQ (Request for Quotation)

An RFQ is a document sent by a buyer to suppliers requesting pricing and terms for specific products. This is a common practice in B2B transactions, allowing buyers to compare quotes and make informed purchasing decisions based on price, delivery, and terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in the shipping process. Understanding Incoterms is critical for international transactions as they dictate who pays for shipping, insurance, and tariffs, thus impacting overall cost and risk management. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. Buyers should consider lead times when planning projects, as delays can affect overall timelines. Establishing clear lead time expectations can help manage supply chain efficiency. -

Certification Standards

Certification standards (like ISO or ANSI) indicate that a product meets specific safety and quality benchmarks. Understanding these standards can provide assurance of product reliability and may be a requirement for certain projects, particularly in regulated industries.

By comprehensively understanding these technical properties and trade terminology, B2B buyers can make more informed decisions regarding the procurement of slide latches for doors, ensuring they select products that meet their specific operational needs while optimizing cost and performance.

Navigating Market Dynamics and Sourcing Trends in the slide latches for doors Sector

What Are the Current Market Dynamics and Key Trends in the Slide Latches for Doors Sector?

The global market for slide latches for doors is witnessing significant growth, driven by several factors including urbanization, increased construction activities, and a rising demand for security solutions. B2B buyers from regions like Africa, South America, the Middle East, and Europe are particularly influenced by these dynamics as they seek reliable and innovative locking mechanisms for various applications, including residential, commercial, and industrial settings.

Emerging technologies are shaping the sourcing landscape. Digital platforms are facilitating easier access to suppliers and product information, enabling buyers to make informed decisions quickly. The rise of e-commerce in hardware sourcing is empowering international buyers to compare prices, quality, and certifications seamlessly. Additionally, smart technology integration is becoming prevalent, with automated and electronically controlled slide latches gaining traction in modern architecture.

Regional trends show a growing preference for customizable solutions that cater to local aesthetic and functional needs. For example, European buyers may lean towards sleek, modern designs, while African buyers might prioritize durability and resilience against environmental challenges. Moreover, sustainability is becoming a key concern, with buyers increasingly looking for eco-friendly materials and practices in their sourcing strategies.

How Is Sustainability and Ethical Sourcing Impacting the Slide Latches for Doors Sector?

The environmental impact of manufacturing slide latches is prompting a shift towards sustainability and ethical sourcing practices. B2B buyers are increasingly aware of the importance of sourcing products from manufacturers that prioritize reduced carbon footprints and responsible resource management. This shift is not merely a trend but a necessity as businesses face growing scrutiny from consumers and regulatory bodies regarding their environmental impact.

Ethical supply chains are crucial in ensuring that the materials used in slide latches are sourced responsibly. Buyers are encouraged to look for certifications like FSC (Forest Stewardship Council) for wood materials or ISO 14001 for environmental management systems. Furthermore, the use of recycled or sustainably sourced materials is becoming a significant differentiator in product offerings.

Implementing sustainable practices not only helps in minimizing environmental harm but also enhances brand reputation and customer loyalty. As a result, buyers are urged to engage with suppliers who can provide transparency about their sourcing methods and environmental certifications, ensuring that their procurement aligns with their corporate social responsibility goals.

What Is the Historical Context of Slide Latches for Doors in B2B Markets?

The evolution of slide latches for doors dates back to ancient civilizations, where simple mechanical devices were employed for securing entrances. Historically, these latches were made from materials like wood and iron, often featuring intricate designs that reflected the craftsmanship of the time.

As industrialization progressed in the 19th century, the manufacturing of slide latches transitioned to more standardized processes, allowing for mass production and wider accessibility. The introduction of materials such as stainless steel and advancements in engineering further enhanced the durability and functionality of slide latches.

Illustrative image related to slide latches for doors

Today, slide latches are not only functional but also serve aesthetic purposes, with manufacturers offering a variety of styles and finishes to cater to diverse consumer preferences. This historical context highlights the ongoing innovation in the sector, with a clear trajectory towards enhanced security features and design customization, catering to the evolving needs of B2B buyers across global markets.

Frequently Asked Questions (FAQs) for B2B Buyers of slide latches for doors

-

How do I select the right slide latch for my door?

Choosing the right slide latch involves assessing your specific needs, including door type, usage frequency, and security requirements. For commercial settings, opt for heavy-duty materials such as stainless steel or brass to withstand wear and tear. Additionally, consider the latch’s design; for instance, a surface-mounted latch might be ideal for a barn door, while a mortise latch is better for traditional doors. Always check the compatibility with your door’s thickness and the environment in which it will be used, such as indoor versus outdoor settings. -

What is the best slide latch for commercial use?

For commercial applications, heavy-duty slide latches made from durable materials like stainless steel or galvanized steel are recommended. Look for features such as weather resistance for outdoor use and tamper-proof designs for enhanced security. Brands that provide certifications or ratings for their products can also be beneficial. A dual-sided operating latch may be ideal for high-traffic areas, allowing ease of access from both sides, while maintaining robust security. -

What factors should I consider when sourcing slide latches internationally?

When sourcing slide latches internationally, consider the manufacturer’s reputation, product quality, and compliance with international standards. Verify their certifications and quality assurance processes. Additionally, research shipping logistics, including customs regulations and import duties for your specific region. Establishing clear communication regarding lead times and availability is crucial to avoid unexpected delays in your supply chain. -

How can I verify the credibility of a slide latch supplier?

To verify a supplier’s credibility, conduct thorough background checks, including reading customer reviews and requesting references from previous clients. Utilize platforms like LinkedIn or industry-specific forums to gauge their reputation. Additionally, consider visiting their manufacturing facility if feasible, or request a virtual tour to inspect their operations. Ensure they have relevant certifications and quality control measures in place to maintain product integrity. -

What customization options are available for slide latches?

Many suppliers offer customization options for slide latches, including various finishes, sizes, and locking mechanisms. You may also request specific branding or labeling on the latches for marketing purposes. When inquiring, provide detailed specifications and usage scenarios to the supplier to facilitate accurate custom solutions. Be mindful of any minimum order quantities (MOQs) associated with customized products. -

What are the typical minimum order quantities (MOQs) for slide latches?

MOQs for slide latches can vary significantly based on the supplier and product type. Generally, they range from 50 to several hundred units. It’s essential to clarify these requirements upfront to align with your purchasing capacity. If you are a smaller buyer, consider negotiating with suppliers for lower MOQs or seeking suppliers that specialize in smaller orders. -

What payment terms should I expect when ordering slide latches?

Payment terms can vary widely depending on the supplier’s policies and your relationship with them. Common terms include a deposit upfront (often 30% to 50%) with the balance due upon shipment or delivery. Some suppliers may offer credit terms for established clients. Always ensure that payment methods are secure, and consider using escrow services for larger orders to protect your investment. -

How can I ensure quality assurance for slide latches sourced internationally?

To ensure quality assurance, request samples before placing large orders. Establish clear quality criteria and inspection protocols with your supplier, and consider third-party inspection services to evaluate product quality before shipment. Additionally, familiarize yourself with the quality standards applicable in your region and ensure the supplier complies with these regulations. Regular communication throughout the production process can help address any issues proactively.

Top 6 Slide Latches For Doors Manufacturers & Suppliers List

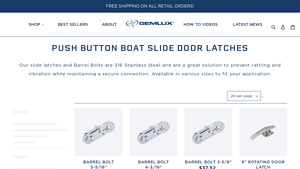

1. Gemlux – Push Button Boat Slide Door Latches

Domain: gemlux.com

Registered: 1995 (30 years)

Introduction: Push Button Boat Slide Door Latches made of 316 Stainless Steel to prevent rattling and vibration while ensuring a secure connection. Available sizes include:

– Barrel Bolt 5-5/16″ – $54.84

– Barrel Bolt 4-3/16″ – $41.86

– Barrel Bolt 3-5/8″ – $37.52

– 8″ Rotating Door Latch – $188.09

– Door Latch Spacer for 1470 Rotating Latch – $73.42

– Push Button Slide Latch – $102.54

– Keeper for 1460 …

2. Sugatsune – Zwei L Knob Latch Indicator

Domain: sugatsune.com

Registered: 1996 (29 years)

Introduction: Zwei L Knob Latch Indicator for Glass Door, ZL-2402-INR-GB

3. Wild West Hardware – Rustic Slide Bolts and Latches

Domain: wildwesthardware.com

Registered: 2002 (23 years)

Introduction: This company, Wild West Hardware – Rustic Slide Bolts and Latches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. McMaster – Slide Latches

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Slide Latches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

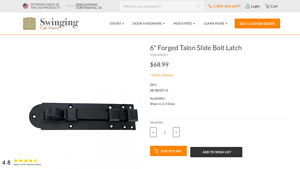

5. John Wright – 6 Forged Talon Slide Bolt Latch

Domain: swingingcafedoors.com

Registered: 2008 (17 years)

Introduction: {“name”: “6\” Forged Talon Slide Bolt Latch”, “brand”: “John Wright”, “msrp”: “$68.99”, “dimensions”: “6.625\” x 2.00\””, “throw”: “1.5\””, “material”: “Cast Iron”, “finish”: “Powder Coated Black Primer Coat”, “hardware_included”: true, “description”: “The purpose of a door latch is to hold doors, windows, cabinets or shutters in a closed position. The design allows the door, cabinet or shutter to…

6. AllPartitions – Slide Bolt Latch, Oval Shaped, Offset

Domain: allpartitions.com

Registered: 2001 (24 years)

Introduction: {“Product Name”: “Slide Bolt Latch, Oval Shaped, Offset”, “Price”: “$12.50”, “Part Number”: “G0137”, “Material”: “Chrome plated zamak”, “Dimensions”: {“Screw Spacing”: “3-1/2 inch”, “Offset”: “3/8 inch”}, “Compatibility”: “Used when door and pilaster are the same thickness”, “Related Items”: [{“Name”: “Slide Bolt Latch”, “Part Number”: “G0136”, “Price”: “$8”}, {“Name”: “Stop/Inswing and Outswing”,…

Strategic Sourcing Conclusion and Outlook for slide latches for doors

How Can Strategic Sourcing Enhance Your Procurement of Slide Latches?

In summary, effective strategic sourcing of slide latches for doors is crucial for optimizing supply chain efficiency and ensuring product quality. By leveraging insights into market trends, regional specifications, and supplier capabilities, international B2B buyers can make informed decisions that align with their operational needs. Prioritizing suppliers who demonstrate reliability, innovation, and compliance with international standards will enhance the overall value proposition of your procurement strategy.

Furthermore, as the global market evolves, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should remain agile and responsive to shifts in demand and supply dynamics. Engaging in collaborative partnerships with manufacturers can lead to customized solutions, reducing costs while enhancing product offerings.

Looking ahead, the future of slide latch procurement is promising, with advancements in material technology and design. We encourage buyers to actively seek out suppliers who are committed to sustainable practices and technological innovation. By doing so, you not only elevate your product offerings but also position your business for long-term success in a competitive marketplace. Take the next step in your strategic sourcing journey—explore new suppliers and embrace innovation in your door hardware solutions today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.