How to Source Shopping Conveyor Belt Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for shopping conveyor belt

In the fast-paced world of retail, sourcing high-quality shopping conveyor belts is essential for streamlining operations and enhancing customer experiences. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe—including notable markets such as Nigeria and Germany—you face unique challenges in identifying reliable suppliers that meet your specific operational needs. This comprehensive guide is designed to empower your purchasing decisions by providing a thorough overview of shopping conveyor belts, including various types, applications, and supplier vetting strategies.

Within these pages, you will discover the latest innovations in conveyor technology, the critical role of conveyor systems in optimizing checkout efficiency, and how to navigate the complexities of international procurement. We will also delve into cost considerations, ensuring you are equipped to make informed financial decisions. By understanding the diverse range of options available—from flexible gravity conveyors to automated sorting systems—you will be better positioned to select solutions that enhance productivity and reduce operational risks.

This guide is more than just a resource; it is a strategic tool that will help you identify and connect with reputable suppliers, ensuring you can implement the best shopping conveyor belt systems that align with your business objectives. As you explore these insights, you will gain the confidence needed to elevate your operations and stay competitive in the global market.

Understanding shopping conveyor belt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Checkout Counter Conveyor | Designed for customer checkout; typically straight and flat. | Supermarkets, retail stores | Pros: Efficient customer flow; easy to clean. Cons: Limited to checkout areas. |

| Flexible Gravity Conveyor | Non-powered, adjustable length; rolls on wheels or casters. | Smaller grocery stores, warehouses | Pros: Versatile layout; low maintenance. Cons: Requires manual effort to reposition. |

| Automated Sorting Conveyor | Powered systems that sort products automatically. | Large retail chains, distribution centers | Pros: Increases efficiency; reduces labor costs. Cons: Higher initial investment. |

| Teflon Food Conveyor | Food-grade, high-temperature resistant material. | Food processing, packaging facilities | Pros: Complies with health regulations; durable. Cons: Can be more expensive than standard belts. |

| Modular Conveyor Systems | Customizable sections that can be configured as needed. | Various retail and industrial settings | Pros: Adaptable to changing needs; easy to expand. Cons: Complexity in assembly and design. |

What Are the Characteristics of Checkout Counter Conveyors?

Checkout counter conveyors are primarily used in supermarkets and retail environments to facilitate the quick and efficient processing of customer purchases. These belts are designed to be straight and flat, allowing for easy loading of items directly from shopping carts. When considering a purchase, B2B buyers should evaluate the durability of the materials and the ease of cleaning, as hygiene is critical in food retail. Additionally, the speed at which customers can check out directly affects customer satisfaction and store throughput.

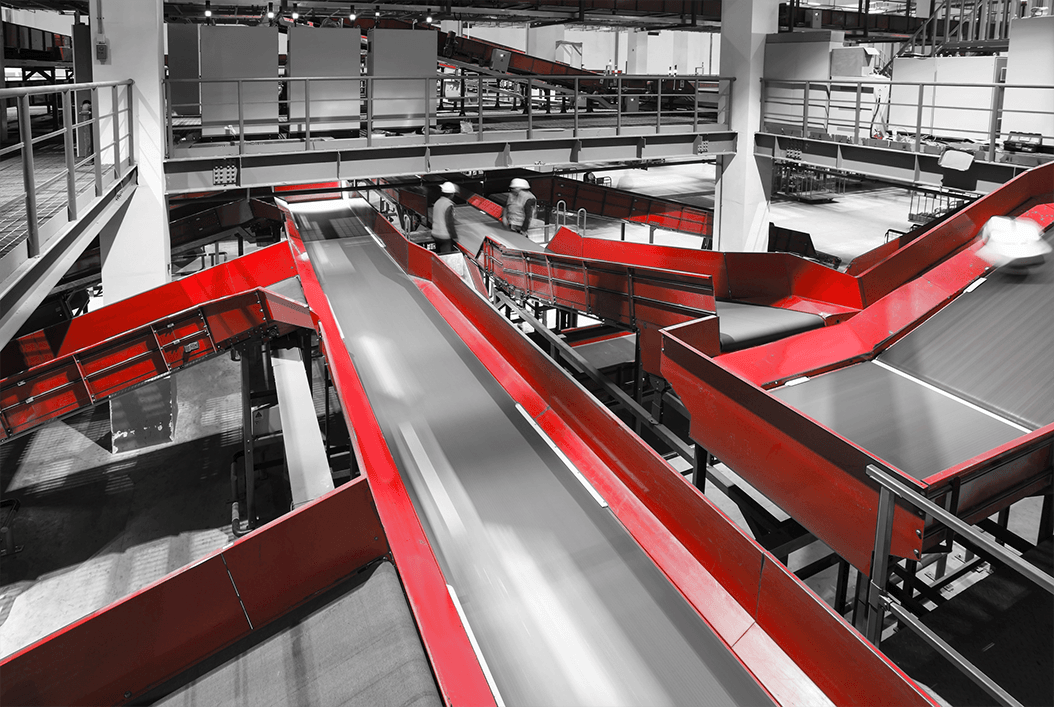

Illustrative image related to shopping conveyor belt

How Do Flexible Gravity Conveyors Operate?

Flexible gravity conveyors are characterized by their non-powered design, allowing them to be easily reconfigured based on the layout of a store or warehouse. These systems are ideal for smaller grocery stores or environments without dedicated loading docks. Buyers should consider factors such as the weight capacity and material composition, as these will influence the conveyor’s longevity and performance. The low maintenance requirement is a significant advantage, but buyers must also account for the manual effort needed to reposition these systems as necessary.

What Makes Automated Sorting Conveyors Beneficial for Large Retailers?

Automated sorting conveyors utilize powered systems to efficiently sort and move products within large retail chains and distribution centers. These systems significantly enhance operational efficiency by reducing the need for manual sorting, which can be time-consuming and prone to errors. B2B buyers should weigh the initial investment costs against long-term labor savings and operational efficiencies. While these systems can be more expensive upfront, the return on investment can be substantial when considering reduced labor costs and increased throughput.

Why Choose Teflon Food Conveyors for Food Processing?

Teflon food conveyors are constructed from high-temperature resistant materials, making them suitable for food processing and packaging applications. These belts meet USDA regulations, ensuring they are safe for food handling. Buyers should prioritize compliance with health and safety standards when selecting these conveyors. While the initial costs may be higher than standard conveyor belts, their durability and ability to withstand harsh conditions can lead to lower replacement costs over time.

How Do Modular Conveyor Systems Adapt to Changing Needs?

Modular conveyor systems offer a customizable solution that can be tailored to meet the specific requirements of various retail and industrial settings. These systems can be easily expanded or reconfigured, providing flexibility as business needs evolve. B2B buyers should consider the ease of installation and the potential for future expansion when investing in modular systems. While the complexity in assembly may pose challenges, the adaptability of these systems often justifies the investment, particularly for businesses anticipating growth or changes in operations.

Key Industrial Applications of shopping conveyor belt

| Industry/Sector | Specific Application of Shopping Conveyor Belt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail Grocery Stores | Checkout Counter Operations | Enhances customer flow and reduces wait times | Durability, ease of cleaning, and compliance with food safety standards |

| E-commerce Fulfillment Centers | Order Processing and Packing | Streamlines packing operations and increases throughput | Flexibility in design, integration with existing systems, and load capacity |

| Food Processing Facilities | Packaging and Sorting of Food Products | Ensures efficient handling and minimizes contamination risks | USDA certification, material compatibility, and temperature resistance |

| Supermarkets | Product Restocking and Inventory Management | Improves operational efficiency and reduces labor costs | Custom configurations, automation options, and maintenance support |

| Distribution Centers | Loading and Unloading Operations | Speeds up supply chain processes and reduces product damage | Adaptability to various loads, ease of installation, and reliability |

How Are Shopping Conveyor Belts Utilized in Retail Grocery Stores?

In retail grocery stores, shopping conveyor belts are primarily used at checkout counters to facilitate the smooth flow of customers and their purchases. By automating the checkout process, these belts reduce wait times, enhancing customer satisfaction. For international buyers, especially in regions like Africa and Europe, sourcing durable belts that can withstand high foot traffic and are easy to clean is crucial. Additionally, compliance with food safety standards is imperative to ensure the safety of products being processed.

Illustrative image related to shopping conveyor belt

What Role Do Shopping Conveyor Belts Play in E-commerce Fulfillment Centers?

E-commerce fulfillment centers leverage shopping conveyor belts for efficient order processing and packing. These systems streamline the movement of products from storage to packing stations, significantly increasing throughput. For B2B buyers in South America and the Middle East, flexibility in design to accommodate varying product sizes and weights is essential. Furthermore, integration with existing warehouse management systems can enhance operational efficiency, making it a vital consideration when sourcing these conveyor solutions.

How Are Shopping Conveyor Belts Applied in Food Processing Facilities?

In food processing facilities, shopping conveyor belts are utilized for packaging and sorting food products. These belts help maintain hygiene standards while ensuring that products are handled efficiently and without contamination. For buyers from regions like Nigeria, sourcing USDA-certified belts that meet food safety regulations is critical. Additionally, materials must be compatible with the specific food types being processed, and temperature resistance is often a requirement for certain applications.

Why Are Shopping Conveyor Belts Important for Supermarkets?

Supermarkets use shopping conveyor belts not only at checkout but also for product restocking and inventory management. These systems help streamline operations, reduce labor costs, and minimize the risk of product loss due to mishandling. For European buyers, custom configurations that fit specific store layouts are often necessary. Moreover, the availability of automation options can further enhance efficiency, making it an essential aspect of supermarket operations.

Illustrative image related to shopping conveyor belt

How Do Shopping Conveyor Belts Benefit Distribution Centers?

In distribution centers, shopping conveyor belts are crucial for loading and unloading operations. They expedite the movement of goods, ensuring that products are processed quickly and with minimal damage. For international B2B buyers, adaptability to various load sizes and types is a key consideration when sourcing these systems. Reliability and ease of installation are also significant factors that can influence purchasing decisions, ultimately impacting supply chain efficiency.

3 Common User Pain Points for ‘shopping conveyor belt’ & Their Solutions

Scenario 1: Inefficient Checkout Experience Leading to Customer Dissatisfaction

The Problem: Many retail businesses face the challenge of long wait times at checkout due to inefficient conveyor belt systems. This often results in frustrated customers who may abandon their purchases or leave negative reviews, impacting overall sales and customer loyalty. B2B buyers need to understand that investing in a high-quality conveyor belt system is crucial to streamline operations and improve customer satisfaction. In markets where competition is fierce, a sluggish checkout process can be a significant differentiator that businesses cannot afford.

The Solution: To enhance the checkout experience, B2B buyers should consider investing in high-speed, durable conveyor belts designed for quick product movement. Opt for systems that integrate seamlessly with existing checkout counters and are equipped with features such as automatic speed adjustments based on the volume of products. Additionally, it is essential to conduct a thorough assessment of the store layout and customer flow to ensure the conveyor belt configuration minimizes bottlenecks. Engaging with suppliers who offer customization options can result in a tailored solution that meets specific business needs, ultimately leading to reduced wait times and increased customer satisfaction.

Scenario 2: Frequent Equipment Breakdowns Causing Operational Disruptions

The Problem: Retailers often experience unplanned downtime due to conveyor belt malfunctions, leading to operational disruptions and financial losses. Frequent breakdowns not only slow down the checkout process but also require costly repairs and replacements. For B2B buyers, this issue emphasizes the importance of selecting robust conveyor systems that can withstand daily wear and tear, particularly in high-traffic environments.

The Solution: To mitigate the risk of equipment failures, B2B buyers should prioritize sourcing conveyor belts made from high-quality, durable materials that are specifically designed for retail applications. Implementing a regular maintenance schedule is vital; this includes routine inspections, cleaning, and timely replacements of worn components. Partnering with manufacturers that offer comprehensive warranties and customer support can provide peace of mind, ensuring that any issues are addressed swiftly. Additionally, investing in smart technology that monitors conveyor performance can help detect potential failures before they occur, allowing businesses to take proactive measures and avoid costly downtime.

Illustrative image related to shopping conveyor belt

Scenario 3: Limited Space and Flexibility in Store Layouts

The Problem: Many retailers struggle with limited floor space, making it challenging to implement traditional conveyor belt systems. This is especially true for small grocery stores or convenience shops where every square meter counts. B2B buyers in these markets must find solutions that optimize space without compromising efficiency or customer experience.

The Solution: For retailers facing space constraints, flexible and modular conveyor systems can be a game-changer. B2B buyers should consider investing in gravity or powered flexible conveyor belts that can be easily reconfigured based on current needs. These systems allow for quick adjustments, enabling retailers to adapt to varying customer volumes without permanently altering the store layout. Furthermore, utilizing multi-functional counters that integrate conveyor belts can maximize space utilization while enhancing the overall shopping experience. Consulting with suppliers who specialize in custom solutions can provide insights into innovative designs that fit within existing constraints while maintaining operational efficiency.

Strategic Material Selection Guide for shopping conveyor belt

What Are the Key Materials for Shopping Conveyor Belts?

When selecting materials for shopping conveyor belts, it is essential to consider their properties, advantages, and limitations. This analysis focuses on four common materials: PVC, polyurethane, rubber, and stainless steel. Each material has unique characteristics that can significantly impact performance, durability, and overall suitability for specific applications.

How Does PVC Perform in Shopping Conveyor Belts?

Polyvinyl Chloride (PVC) is a widely used material for conveyor belts due to its excellent flexibility and resistance to abrasion. PVC conveyor belts can withstand moderate temperatures and are generally resistant to many chemicals, making them suitable for various retail environments.

Illustrative image related to shopping conveyor belt

Pros: PVC belts are cost-effective and easy to manufacture, which makes them a popular choice for budget-conscious buyers. They are available in various colors and textures, allowing for customization to match store aesthetics.

Cons: However, PVC has limitations in high-temperature applications and may not perform well in extreme conditions, leading to potential degradation over time.

Impact on Application: PVC is compatible with a range of media, but it may not be suitable for applications involving heavy loads or sharp objects.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that PVC belts meet local safety and environmental regulations, as some countries have restrictions on certain materials.

What Advantages Does Polyurethane Offer for Conveyor Belts?

Polyurethane is another popular choice for shopping conveyor belts, known for its high abrasion resistance and durability. This material can handle higher temperatures than PVC and is resistant to oils and greases, making it ideal for grocery stores that handle food products.

Pros: The longevity and strength of polyurethane belts can lead to lower replacement costs over time, making them a sound investment for larger retailers.

Cons: On the downside, polyurethane can be more expensive than PVC, and its manufacturing process can be more complex, which may lead to longer lead times.

Impact on Application: Polyurethane belts excel in environments where hygiene is paramount, as they can be easily cleaned and are resistant to microbial growth.

Considerations for International Buyers: Compliance with food safety standards, such as those set by the FDA or EU regulations, is crucial for buyers in Europe and the Middle East.

How Does Rubber Compare as a Material for Conveyor Belts?

Rubber conveyor belts are known for their exceptional durability and grip, making them suitable for high-traffic areas in supermarkets. They can handle heavy loads and are resistant to wear, ensuring long-term performance.

Pros: The slip-resistant surface of rubber belts enhances safety, reducing the risk of accidents in busy retail environments.

Cons: However, rubber can be heavier and more expensive than other materials, which may increase shipping costs. Additionally, rubber may not be as resistant to certain chemicals compared to PVC or polyurethane.

Impact on Application: Rubber belts are ideal for transporting heavy items but may not be suitable for delicate products due to potential scuffing.

Considerations for International Buyers: Buyers should check for compliance with local standards, such as ASTM or DIN, especially in Europe, where regulations may be stringent.

Illustrative image related to shopping conveyor belt

What Role Does Stainless Steel Play in Conveyor Belt Applications?

Stainless steel conveyor belts are often used in environments that require high sanitation standards, such as food processing areas. They offer excellent strength and durability, making them suitable for heavy-duty applications.

Pros: Stainless steel is resistant to corrosion and can withstand high temperatures, making it ideal for various applications, including those involving hot or cold products.

Cons: The primary drawback is the higher cost associated with stainless steel, which may not be feasible for all retailers, especially smaller operations.

Impact on Application: Stainless steel belts are perfect for applications where hygiene and durability are critical, but they may not be suitable for all retail environments due to their weight and cost.

Considerations for International Buyers: Buyers should ensure that stainless steel belts meet international standards for food safety and hygiene, particularly in regions with strict regulations like Germany.

Summary Table of Material Selection for Shopping Conveyor Belts

| Material | Typical Use Case for Shopping Conveyor Belt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General retail environments | Cost-effective and customizable | Limited high-temperature resistance | Low |

| Polyurethane | Grocery stores handling food products | High durability and abrasion resistance | Higher cost and complexity | Med |

| Rubber | High-traffic areas in supermarkets | Excellent grip and durability | Heavier and potentially more expensive | Med |

| Stainless Steel | Food processing and high sanitation areas | Corrosion-resistant and durable | Higher initial investment | High |

This guide aims to assist international B2B buyers in making informed decisions regarding the selection of materials for shopping conveyor belts, considering both performance and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for shopping conveyor belt

What Are the Main Stages in the Manufacturing Process of Shopping Conveyor Belts?

The manufacturing process of shopping conveyor belts involves several crucial stages that ensure both functionality and durability. Understanding these stages is essential for B2B buyers looking to invest in reliable conveyor systems for retail environments.

-

Material Preparation

The first step in manufacturing shopping conveyor belts is selecting appropriate materials. Common materials include high-grade rubber, PVC, and polyurethane, chosen for their durability, flexibility, and resistance to wear and tear. This phase also involves cutting the materials to specified dimensions, ensuring that they meet the design requirements for the intended application. -

Forming

Once the materials are prepared, they undergo forming processes such as molding or extrusion. In the molding process, heated materials are shaped into specific forms using molds, which allows for the creation of custom profiles suited to various applications, including grocery store layouts. Extrusion involves forcing the material through a die to create continuous lengths of belting, ideal for longer conveyor systems. -

Assembly

Following the forming stage, the conveyor belts are assembled. This includes integrating components like rollers, side guides, and drive systems. For shopping conveyor belts, the assembly process is critical because it ensures that the belt operates smoothly and efficiently. Attention to detail during assembly helps prevent misalignment and reduces operational issues later. -

Finishing

The final stage involves finishing processes such as coating, testing, and quality checks. Coatings may be applied to enhance the belt’s resistance to chemicals or abrasion. Additionally, any necessary adjustments are made to ensure the conveyor belt meets performance specifications. This stage is vital for ensuring the longevity and reliability of the product.

How Is Quality Assurance Implemented in the Manufacturing of Shopping Conveyor Belts?

Quality assurance (QA) is integral to the manufacturing of shopping conveyor belts. It involves several international standards and industry-specific certifications that ensure products meet safety and performance benchmarks.

-

Adherence to International Standards

Many manufacturers comply with ISO 9001, which outlines requirements for a quality management system. This certification ensures that companies consistently produce quality products and enhance customer satisfaction. Other relevant certifications may include CE marking for products sold in Europe and API standards for specific applications. -

Quality Control Checkpoints

Implementing quality control checkpoints throughout the manufacturing process is essential. Common checkpoints include:

– Incoming Quality Control (IQC): At this stage, raw materials are inspected for compliance with quality standards before they enter the production line.

– In-Process Quality Control (IPQC): This involves monitoring the manufacturing process to ensure that all parameters remain within specified limits.

– Final Quality Control (FQC): After assembly, the final product undergoes rigorous testing to validate its performance and safety before shipping. -

Common Testing Methods

Manufacturers employ various testing methods to ensure the quality of shopping conveyor belts, including:

– Tensile Strength Tests: To assess the material’s ability to withstand pulling forces.

– Abrasion Resistance Tests: To measure how well the belt can endure wear and tear.

– Load Testing: To verify that the conveyor can handle the maximum expected load without failure.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial in making informed purchasing decisions.

-

Conducting Supplier Audits

One of the most effective ways to assess a supplier’s quality control is through on-site audits. These audits allow buyers to evaluate the manufacturing processes, quality management systems, and compliance with international standards. During an audit, buyers can inspect facilities, review documentation, and interview staff to ensure adherence to quality protocols. -

Requesting Quality Assurance Reports

Suppliers should provide comprehensive quality assurance reports that detail their QA processes, including results from testing and inspections. These documents can offer insights into the reliability of the supplier’s manufacturing practices and product performance. -

Engaging Third-Party Inspection Services

Utilizing third-party inspection services is another strategy to verify quality control. Independent inspectors can evaluate the manufacturing facility and the final product, providing unbiased assessments that help mitigate risks associated with purchasing decisions.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate specific challenges related to quality control that can vary significantly based on regional standards and regulations.

-

Understanding Regional Compliance Requirements

Buyers should familiarize themselves with the specific compliance requirements in their region. For instance, European buyers may require CE certification, while those in Africa might need to adhere to local safety regulations. Understanding these nuances can prevent costly delays and ensure that products meet local standards. -

Evaluating Supplier Certifications

When considering suppliers, it’s essential to evaluate their certifications and quality management systems. This can include checking for ISO certifications or industry-specific certifications relevant to the buyer’s location and market. -

Cultural and Communication Considerations

Effective communication is vital when dealing with international suppliers. Cultural differences can affect expectations regarding quality and delivery. Establishing clear communication channels and expectations helps ensure that both parties are aligned on quality standards.

Conclusion

Understanding the manufacturing processes and quality assurance measures for shopping conveyor belts is crucial for B2B buyers. By familiarizing themselves with the stages of production, quality control standards, and verification methods, buyers can make informed decisions that enhance operational efficiency and ensure product reliability. This knowledge is especially valuable for international buyers navigating the complexities of regional regulations and supplier relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shopping conveyor belt’

To assist international B2B buyers in sourcing shopping conveyor belts, this guide provides a practical checklist to ensure a successful procurement process. Understanding the critical steps involved will help you make informed decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Begin by outlining the specific technical requirements for the conveyor belt. Consider factors such as length, width, material type, and load capacity. This clarity will help you communicate your needs effectively to suppliers and ensure that the conveyor belt fits seamlessly into your existing infrastructure.

- Material Requirements: Determine if you need food-grade materials or specialized coatings for hygiene.

- Load Capacity: Assess the maximum weight the conveyor needs to handle to prevent operational issues.

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers to identify those with a strong reputation in the market. Look for companies that specialize in shopping conveyor belts and have a proven track record of reliability and quality.

- Supplier Experience: Check how long the supplier has been in business and their experience with similar projects.

- Customer Reviews: Look for testimonials and case studies to gauge customer satisfaction and product performance.

Step 3: Evaluate Supplier Certifications

Before making any commitments, verify the certifications and compliance of potential suppliers. This is crucial for ensuring product quality and adherence to industry standards.

Illustrative image related to shopping conveyor belt

- Quality Certifications: Look for ISO certifications or industry-specific quality assurance that indicates high standards.

- Regulatory Compliance: Ensure that the conveyor belts meet local and international regulations, particularly if they are to be used in food handling.

Step 4: Request Samples and Conduct Testing

Once you have shortlisted suppliers, request samples to evaluate the quality of their conveyor belts. Testing the samples will provide insights into the performance and durability of the products.

- Performance Testing: Assess how the conveyor belt performs under load and its ease of maintenance.

- Compatibility Check: Ensure the samples fit well with your existing systems and meet your operational requirements.

Step 5: Compare Pricing and Terms

After evaluating the samples, compare pricing structures and payment terms from different suppliers. This step is essential for budgeting and ensuring you receive the best value for your investment.

- Total Cost of Ownership: Consider not just the upfront cost but also maintenance, warranty, and potential downtime costs.

- Negotiation Flexibility: Look for suppliers who offer flexible payment terms or discounts for bulk orders.

Step 6: Assess After-Sales Support and Service

Strong after-sales support is vital for the long-term success of your conveyor belt system. Evaluate the level of service that suppliers provide post-purchase.

- Maintenance Services: Check if the supplier offers maintenance services or training for your staff.

- Response Time: Assess the supplier’s responsiveness to service requests or emergencies to minimize downtime.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, finalize the purchase agreement. Ensure all terms are clearly defined and documented to avoid any misunderstandings.

- Delivery Timeline: Confirm the expected delivery date and any penalties for delays.

- Warranty Details: Understand the warranty coverage and the process for handling defects or issues.

By following this step-by-step checklist, B2B buyers can effectively navigate the procurement process for shopping conveyor belts, ensuring they select a product that meets their operational needs and contributes to a smooth-running business.

Comprehensive Cost and Pricing Analysis for shopping conveyor belt Sourcing

What Are the Key Cost Components in Shopping Conveyor Belt Sourcing?

When sourcing shopping conveyor belts, understanding the cost structure is crucial for effective budgeting and strategic planning. The primary components of cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the cost. Conveyor belts may be made from various materials such as PVC, rubber, or specialized food-grade materials, each with different price points. High-quality, durable materials tend to have a higher upfront cost but offer better longevity and lower maintenance expenses.

-

Labor: Labor costs encompass the workforce involved in manufacturing and installation. This includes direct labor for assembly and indirect labor for administration and management. Companies may also need to consider training costs for their personnel, particularly in markets where skilled labor is scarce.

-

Manufacturing Overhead: This includes costs related to the production facility, utilities, and equipment maintenance. Efficient manufacturing processes can help lower these costs, making it essential to choose suppliers that leverage advanced technologies.

-

Tooling: Investment in specialized tooling is necessary for custom conveyor belt designs. This cost can vary significantly based on the complexity of the design and the level of customization required by the buyer.

-

Quality Control (QC): Ensuring product quality can add to the overall cost. However, rigorous QC processes can prevent costly defects and returns, making it a worthwhile investment.

-

Logistics: Shipping and handling costs can vary widely, particularly for international buyers. Factors such as distance, mode of transportation, and customs duties will influence these costs.

-

Margin: Suppliers will add a profit margin to their costs, which can vary based on market demand and competition. Understanding the market landscape can help buyers negotiate better pricing.

How Do Price Influencers Affect Shopping Conveyor Belt Costs?

Numerous factors influence the pricing of shopping conveyor belts. Key price influencers include:

-

Volume/MOQ: Purchasing in larger quantities often leads to discounts. Establishing a Minimum Order Quantity (MOQ) can also help negotiate better pricing.

-

Specifications/Customization: Customization can increase costs. Buyers should clearly define their specifications to avoid unnecessary expenses.

-

Materials: As mentioned earlier, the choice of materials affects pricing. Investing in high-quality materials can save costs in the long run.

-

Quality and Certifications: Products that meet specific industry standards (e.g., USDA certifications for food safety) may come at a premium but are essential for compliance and quality assurance.

-

Supplier Factors: The supplier’s reputation, experience, and geographical location can impact pricing. Established suppliers may charge more due to their reliability and service quality.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They determine the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, all of which can affect the total cost.

What Buyer Tips Can Help Optimize Costs in Shopping Conveyor Belt Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can optimize costs:

-

Negotiate Effectively: Always be prepared to negotiate prices, especially when placing large orders. Leverage your purchasing power to secure favorable terms.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. TCO includes maintenance, operational costs, and potential downtime, which can significantly affect overall expenses.

-

Understand Pricing Nuances: Be aware of regional pricing differences and currency fluctuations that could impact costs when sourcing from international suppliers.

-

Build Long-term Relationships: Establishing a long-term relationship with a supplier can lead to better pricing and service over time.

Disclaimer on Indicative Prices

Prices for shopping conveyor belts can vary widely based on the factors mentioned above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they receive the best value for their investment.

Alternatives Analysis: Comparing shopping conveyor belt With Other Solutions

In the fast-paced retail environment, choosing the right technology for product movement and customer service is crucial. While shopping conveyor belts are a popular solution for managing checkout processes, several alternatives exist that may better suit specific operational needs. This analysis will compare shopping conveyor belts with other viable solutions, helping B2B buyers make informed decisions based on their unique requirements.

| Comparison Aspect | Shopping Conveyor Belt | Automated Checkout Systems | Manual Checkout Stations |

|---|---|---|---|

| Performance | High throughput; efficient for high-volume transactions | Very high; can handle multiple customers simultaneously | Moderate; depends on staff efficiency |

| Cost | Moderate initial investment; low operational costs | High initial investment; potential savings on labor | Low initial cost; variable operational costs |

| Ease of Implementation | Relatively easy to integrate into existing layouts | Complex installation; may require significant infrastructure changes | Simple setup; minimal training required |

| Maintenance | Low maintenance; occasional belt replacement needed | Moderate; requires software updates and hardware servicing | Low; requires minimal upkeep |

| Best Use Case | Ideal for busy retail environments with high foot traffic | Suitable for large supermarkets and tech-savvy customers | Best for smaller stores or markets with low transaction volumes |

What Are the Pros and Cons of Automated Checkout Systems?

Automated checkout systems offer a high-tech alternative to shopping conveyor belts. These systems allow customers to scan and pay for items without cashier assistance, significantly speeding up the checkout process. The primary advantage is their ability to handle multiple customers at once, which can drastically reduce wait times. However, the high initial investment and the need for ongoing maintenance and updates can be a barrier for some retailers. Additionally, the reliance on technology may deter customers who prefer personal interaction.

How Do Manual Checkout Stations Compare?

Manual checkout stations remain a staple in many retail environments, especially in smaller stores. These stations require minimal setup and are cost-effective, making them accessible for businesses with limited budgets. The downside is that their performance heavily relies on the efficiency of staff, which can lead to longer wait times during peak hours. Moreover, manual stations do not provide the same level of throughput as automated solutions or conveyor belts, which can impact customer satisfaction in high-traffic scenarios.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When deciding between shopping conveyor belts and alternative solutions, B2B buyers should carefully evaluate their specific operational needs, budget constraints, and customer preferences. For high-volume environments where speed and efficiency are paramount, shopping conveyor belts or automated checkout systems might be the best fit. Conversely, smaller retailers may find manual checkout stations more practical and cost-effective. Ultimately, the right choice will depend on a thorough analysis of each solution’s performance, cost implications, and ease of integration into existing workflows.

Essential Technical Properties and Trade Terminology for shopping conveyor belt

What Are the Key Technical Properties of Shopping Conveyor Belts?

When selecting a shopping conveyor belt, understanding its technical specifications is crucial for ensuring efficiency, safety, and durability in retail operations. Here are some of the essential properties that B2B buyers should consider:

-

Material Grade

Conveyor belts are typically constructed from materials like PVC, polyurethane, or rubber. The choice of material affects the belt’s durability, flexibility, and resistance to wear and tear. High-grade materials are essential for environments with heavy loads or exposure to harsh chemicals, ensuring longevity and minimizing replacement costs. -

Belt Width and Length

The dimensions of the conveyor belt are vital for fitting into specific store layouts. Standard widths range from 12 to 30 inches, while lengths can vary based on the checkout counter or storage requirements. Ensuring the right size is crucial for optimizing workflow and preventing bottlenecks during busy shopping hours. -

Load Capacity

This specification defines the maximum weight the conveyor belt can handle without compromising its integrity. Knowing the load capacity helps in selecting the appropriate belt for different products, reducing the risk of damage or accidents during operation. It is particularly important for supermarkets handling bulky items. -

Surface Texture

The surface of the conveyor belt can be smooth or textured, affecting its grip on products. Textured surfaces can prevent slippage and ensure products remain stable as they move through the checkout process. This is especially important in environments where fragile items are common. -

Temperature Resistance

Some conveyor belts are designed to operate in environments with extreme temperatures, whether hot or cold. This property is critical for supermarkets that handle perishable goods. Selecting a belt with appropriate temperature resistance can enhance food safety and operational efficiency. -

Belt Speed

The speed at which a conveyor belt operates can significantly impact customer experience and checkout efficiency. A belt that moves too slowly can lead to long lines and customer dissatisfaction, while a belt that operates too quickly may risk product damage. Understanding and configuring belt speed according to store traffic patterns is essential.

What Are Common Trade Terms in the Conveyor Belt Industry?

Familiarity with industry terminology can streamline communication and negotiations for B2B buyers. Here are several key terms that are commonly used:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of conveyor belts, working with an OEM can ensure that you receive high-quality, compatible products tailored to your operational needs. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. Understanding the MOQ is crucial for budgeting and inventory management, particularly for smaller retailers who may need to balance costs with supply needs. -

RFQ (Request for Quotation)

An RFQ is a document that potential buyers send to suppliers requesting pricing and other details for specific products. This process is essential for comparing options, negotiating prices, and ensuring that the selected conveyor belt meets the desired specifications. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers in international transactions, including who is responsible for shipping, insurance, and tariffs, thereby minimizing disputes and misunderstandings. -

Lead Time

This term refers to the time it takes from placing an order to receiving the product. Understanding lead times is vital for inventory management and planning, especially for businesses that need to maintain a steady supply of conveyor belts. -

Maintenance Schedule

A maintenance schedule outlines the routine checks and services required to keep conveyor belts operating efficiently. Regular maintenance is key to minimizing downtime and extending the lifespan of the equipment, which is particularly important for high-traffic retail environments.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that optimize their shopping conveyor belt investments and enhance their operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the shopping conveyor belt Sector

What Are the Key Market Dynamics and Trends Affecting the Shopping Conveyor Belt Sector?

The shopping conveyor belt sector is experiencing significant transformations driven by several global dynamics. The rise of e-commerce has accelerated the demand for efficient logistics and streamlined in-store operations, prompting retailers to invest in advanced conveyor solutions. Particularly for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. For instance, buyers in Nigeria may focus on affordability and durability, while those in Germany might prioritize automation and integration with existing technologies.

Emerging technologies, such as AI and IoT, are reshaping the conveyor belt landscape. Automated systems that use real-time data analytics not only enhance operational efficiency but also reduce labor costs and minimize human error. Furthermore, with an increasing focus on customer experience, retailers are adopting customizable conveyor systems that can adapt to various store layouts and customer flow patterns. This trend is particularly relevant for large retailers in Europe, where space optimization and quick product turnover are essential.

Sourcing trends indicate a shift towards suppliers who offer comprehensive solutions, including maintenance and support services. Buyers are increasingly looking for partners who can provide not only high-quality conveyor belts but also related products like casters and maintenance tools, thereby streamlining procurement processes. This trend highlights the importance of establishing long-term relationships with suppliers who understand local market nuances and can cater to diverse operational needs.

Illustrative image related to shopping conveyor belt

How Can Sustainability and Ethical Sourcing Impact the Shopping Conveyor Belt Market?

Sustainability and ethical sourcing are becoming paramount in the shopping conveyor belt sector. As global awareness of environmental issues grows, B2B buyers are increasingly scrutinizing the ecological impact of their procurement choices. Conveyor belt manufacturers that utilize recyclable materials and sustainable production processes are gaining a competitive edge. For international buyers, this trend is particularly significant in regions with stringent environmental regulations, such as Europe, where compliance with ‘green’ certifications can enhance brand reputation.

Moreover, ethical supply chains are essential for fostering trust and transparency. Retailers are more inclined to partner with suppliers who demonstrate a commitment to responsible sourcing practices. This includes ensuring fair labor conditions and minimizing waste throughout the supply chain. For instance, B2B buyers in South America may prioritize suppliers who not only offer high-quality products but also engage in community development and sustainable practices.

In terms of ‘green’ certifications, buyers should look for suppliers with certifications such as ISO 14001 or those that adhere to USDA organic standards for food-grade conveyor belts. These certifications not only assure quality but also reflect a commitment to environmental stewardship, which is increasingly becoming a deciding factor in procurement decisions.

What Is the Historical Context of the Shopping Conveyor Belt Sector?

The evolution of shopping conveyor belts can be traced back to the early 20th century, initially serving as simple mechanisms in manufacturing and transportation. Over the decades, technological advancements have transformed these systems into essential components of modern retail operations. The introduction of powered conveyor belts in the 1950s marked a significant milestone, allowing for faster and more efficient movement of goods.

As retail environments evolved, so did the design and functionality of conveyor belts. The shift towards automation and the integration of advanced technologies, such as sensors and AI, have further enhanced their capabilities, making them indispensable for today’s supermarkets and retail chains. This historical context is vital for B2B buyers to understand the ongoing innovations and the potential for future developments in the shopping conveyor belt sector.

By recognizing these trends and historical shifts, international B2B buyers can make informed decisions that align with their operational needs while contributing to sustainable practices in the retail landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of shopping conveyor belt

-

How do I choose the right shopping conveyor belt for my retail business?

Choosing the right shopping conveyor belt involves assessing your store’s layout, customer flow, and specific operational needs. Consider factors such as the size of your checkout area, the volume of customers, and the types of products you sell. For high-traffic environments, opt for durable, easy-to-clean materials that can withstand heavy use. Additionally, consult with suppliers about customizable options that can be tailored to your unique requirements, ensuring optimal efficiency and customer experience. -

What are the benefits of using a conveyor belt in my supermarket?

Using a conveyor belt in your supermarket can significantly enhance operational efficiency. It streamlines the checkout process, reduces wait times for customers, and minimizes labor costs by automating product handling. Moreover, conveyor belts can help prevent product damage and loss, improving your overall profit margins. With the right system, you can also adapt to changing customer demands and optimize the space in your checkout area. -

What customization options are available for shopping conveyor belts?

Many suppliers offer customization options for shopping conveyor belts, including size, speed, and material. You can select belts designed for specific product types, such as food-grade materials for grocery stores or heavier-duty belts for larger items. Additionally, consider customization features like adjustable height, integrated signage, and color options that align with your branding. Discuss your needs with potential suppliers to explore the best solutions for your store. -

What is the minimum order quantity (MOQ) for shopping conveyor belts?

The minimum order quantity (MOQ) for shopping conveyor belts can vary significantly between suppliers. Generally, larger manufacturers may have a higher MOQ due to production costs, while smaller or specialized suppliers might offer lower MOQs to accommodate smaller retailers. It’s advisable to directly communicate with suppliers about their MOQs, as they may also provide flexibility based on your specific requirements or future order potential. -

What payment terms should I expect when sourcing conveyor belts internationally?

When sourcing conveyor belts internationally, payment terms can vary widely based on the supplier’s policies and your location. Common arrangements include upfront payments, partial deposits, or net payment terms after delivery. It’s crucial to establish clear agreements on payment methods, such as bank transfers or letters of credit, to mitigate risks. Always review the payment terms carefully and consider negotiating favorable conditions that align with your cash flow needs. -

How can I vet suppliers of shopping conveyor belts effectively?

To effectively vet suppliers, conduct thorough research on their reputation, experience, and product quality. Look for customer testimonials, case studies, and industry certifications. Request samples of their conveyor belts to assess quality firsthand. Additionally, consider visiting their manufacturing facilities if feasible, or arranging virtual tours. Engaging in discussions about their manufacturing processes and after-sales support can also provide valuable insights into their reliability and commitment to customer service. -

What quality assurance measures should I look for when purchasing conveyor belts?

Quality assurance measures are critical when purchasing conveyor belts. Ensure that the supplier adheres to relevant industry standards and certifications, such as ISO or FDA compliance for food-grade belts. Inquire about their testing procedures, including stress tests and durability assessments. Request documentation of quality control processes, and consider a warranty or guarantee for the product to protect against defects or performance issues. -

What logistics considerations should I keep in mind when importing conveyor belts?

When importing conveyor belts, logistics considerations include shipping methods, customs regulations, and lead times. Determine whether you need air or sea freight based on urgency and budget. Familiarize yourself with import duties, taxes, and documentation required for customs clearance in your country. Collaborate with logistics providers to ensure efficient transportation and delivery. It’s also wise to plan for potential delays and have contingency measures in place to maintain your operations smoothly.

Top 5 Shopping Conveyor Belt Manufacturers & Suppliers List

1. JFFixtures – Supermarket Checkout Counter

Domain: jffixtures.com

Registered: 2000 (25 years)

Introduction: Supermarket checkout counter with conveyor belt designed to streamline transactions and enhance shopper convenience. Benefits include speed, organization, and improved customer experience. Key considerations for choosing a conveyor belt include length and width, speed settings, and material durability. Design tips focus on optimal placement, clear layout, and accessibility. Maintenance tips includ…

2. Miprcorp – Checkout Counter Conveyor Belts & Teflon Food Belts

Domain: miprcorp.com

Registered: 2003 (22 years)

Introduction: Checkout Counter Conveyor Belts: Durable black mat top covers, easy to clean, non-reflective under fluorescent lighting, hot process endless or stainless steel lacing with nylon-coated pins, same-day shipping available. Teflon Food Belts: USDA-certified, suitable for packaging meats, tortillas, salads, and sandwiches, customizable for various applications. Grocery Cart Wheels and Other Caster Whee…

3. Adobe Stock – Conveyor Belt Grocery Assets

Domain: stock.adobe.com

Registered: 1986 (39 years)

Introduction: Conveyor Belt Grocery Images – 6,039 Stock Photos, Vectors, and Videos available on Adobe Stock. Includes options for free trial to access images and videos. Categories include photos, illustrations, vectors, audio, templates, and 3D assets. Users can sort results and find similar content. License terms and support information provided.

4. Food Republic – Grocery Etiquette Tips

Domain: foodrepublic.com

Registered: 2002 (23 years)

Introduction: This company, Food Republic – Grocery Etiquette Tips, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. iStock – Conveyor Belt Grocery Store Images

Domain: istockphoto.com

Registered: 2000 (25 years)

Introduction: 650+ Conveyor Belt Grocery Store Stock Photos, Pictures & Royalty-Free Images – iStock

Strategic Sourcing Conclusion and Outlook for shopping conveyor belt

In conclusion, effective strategic sourcing of shopping conveyor belts is essential for optimizing retail operations across various markets. By investing in high-quality conveyor systems, businesses can enhance efficiency, reduce labor costs, and minimize product loss, which are critical factors for maintaining competitiveness in the fast-paced retail environment. Key takeaways include the importance of selecting suppliers with a strong reputation for reliability, customization options, and comprehensive support services.

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe evaluate their procurement strategies, aligning with suppliers who offer innovative solutions tailored to specific operational needs will be vital. Whether you are in Nigeria seeking to modernize your grocery store or in Germany looking to streamline checkout processes, focusing on strategic sourcing can significantly impact your bottom line.

Illustrative image related to shopping conveyor belt

Looking ahead, the demand for advanced shopping conveyor belts is poised to grow, driven by ongoing retail innovations and consumer expectations. Now is the time to engage with reputable suppliers to explore customized solutions that can propel your business forward. Don’t hesitate—take the next step towards transforming your retail operations today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.