How to Source Seton Identification Products Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for seton identification products

In today’s global marketplace, sourcing seton identification products presents a unique challenge for B2B buyers aiming to enhance workplace safety and compliance. As organizations increasingly prioritize safety protocols, the demand for high-quality identification solutions—ranging from workplace safety signs to asset tagging systems—continues to rise. This guide delves into the multifaceted world of seton identification products, providing a comprehensive overview of their various types and applications. We will explore essential factors such as supplier vetting processes, cost considerations, and regulatory compliance, ensuring that you have the tools needed to make informed purchasing decisions.

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, navigating this complex landscape can be daunting. This guide empowers you by consolidating critical insights and actionable strategies tailored to your specific needs. Whether you’re operating in a manufacturing facility in Nigeria or a construction site in Vietnam, understanding the nuances of seton identification products is vital for fostering a safer work environment. By leveraging this resource, you can streamline your procurement process, enhance workplace safety standards, and ultimately drive productivity within your organization.

Understanding seton identification products Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Workplace Safety Signs | Various materials, customizable designs, compliance with OSHA | Manufacturing, Warehousing, Construction | Pros: Enhances safety, ensures compliance. Cons: May require regular updates to remain relevant. |

| Pipe Marking Labels | Self-adhesive, snap-around, and specialty options | Industrial facilities, Chemical plants | Pros: Improves safety and identification. Cons: Adhesion may vary based on surface conditions. |

| Asset Tags & Labels | RFID, barcode options, customizable for specific needs | Equipment management, Inventory tracking | Pros: Streamlines asset tracking, reduces loss. Cons: Initial investment can be high for tech solutions. |

| Traffic & Parking Signs | Durable materials, clear visibility, various signage options | Parking lots, Warehouses, Public facilities | Pros: Enhances traffic flow and safety. Cons: Limited effectiveness without proper placement. |

| Lockout Tagout Devices | Color-coded, durable, compliant with safety regulations | Manufacturing, Maintenance operations | Pros: Essential for safety during maintenance. Cons: Requires training for effective use. |

What are the Key Characteristics of Workplace Safety Signs?

Workplace safety signs are essential for communicating hazards and safety protocols in various environments. They come in multiple materials and designs, allowing customization to meet specific regulatory requirements, such as OSHA compliance. Businesses in manufacturing, warehousing, and construction often utilize these signs to enhance workplace safety. When purchasing, consider the durability of materials and the need for regular updates to ensure messages remain relevant and visible.

How Do Pipe Marking Labels Improve Safety?

Pipe marking labels are crucial for identifying the contents flowing through pipes, which is vital for safety in industrial settings. Available in self-adhesive and snap-around options, these labels facilitate quick identification and compliance with safety regulations. They are particularly useful in chemical plants and industrial facilities where misidentification can lead to accidents. Buyers should assess the adhesion quality and compatibility with various surfaces to ensure longevity and effectiveness.

Why Invest in Asset Tags & Labels?

Asset tags and labels, including RFID and barcode options, are pivotal for efficient equipment management and inventory tracking. They help businesses monitor assets, reducing loss and improving operational efficiency. Suitable for various industries, including manufacturing and logistics, these tags can be customized to fit specific needs. When considering a purchase, evaluate the initial investment against potential long-term savings from improved asset management.

What Are the Benefits of Traffic & Parking Signs?

Traffic and parking signs play a critical role in directing vehicle and pedestrian traffic, enhancing safety in public and private spaces. Made from durable materials for visibility and longevity, these signs are adaptable for use in parking lots, warehouses, and other facilities. Buyers should focus on the clarity of signage and placement strategies to maximize effectiveness in managing traffic flow and preventing accidents.

How Do Lockout Tagout Devices Contribute to Safety?

Lockout tagout devices are essential for ensuring safety during maintenance activities by preventing accidental equipment startup. These devices are color-coded and designed to comply with safety regulations, making them vital in manufacturing and maintenance environments. When selecting lockout tagout solutions, businesses should consider the training required for effective use and ensure employees are familiar with proper procedures to maximize safety benefits.

Key Industrial Applications of seton identification products

| Industry/Sector | Specific Application of Seton Identification Products | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Pipe Marking and Valve Tags | Enhances safety by clearly identifying hazardous materials, reducing risk of accidents. | Compliance with local regulations and standards, material durability, and visibility in various environments. |

| Logistics and Warehousing | Asset Tagging and Labeling | Improves inventory management and minimizes loss or theft of equipment. | Customization options, RFID or barcode capabilities, and durability under harsh conditions. |

| Construction | Workplace Safety Signs | Ensures compliance with safety regulations, reducing liability and promoting worker safety. | Compliance with OSHA and local regulations, variety of sign options, and weather resistance. |

| Oil and Gas | Hazardous Material Identification Labels | Critical for safety in handling and transporting hazardous materials, mitigating environmental risks. | Compliance with international safety standards, clear visibility, and weatherproof materials. |

| Healthcare | Safety and Compliance Labels | Protects staff and patients by clearly marking hazardous areas and materials, enhancing safety protocols. | Compliance with health regulations, clear communication, and durability against cleaning agents. |

How Are Seton Identification Products Used in Manufacturing?

In the manufacturing sector, Seton identification products such as pipe marking and valve tags play a crucial role in enhancing workplace safety. By clearly labeling pipes and valves that contain hazardous materials, businesses can significantly reduce the risk of accidents and injuries. Buyers in this sector must ensure that the products meet local regulatory standards and are made from durable materials that can withstand the manufacturing environment, including extreme temperatures and exposure to chemicals.

What Are the Benefits of Seton Products in Logistics and Warehousing?

In logistics and warehousing, asset tagging and labeling are essential for efficient inventory management. Seton’s asset tags help businesses track equipment and reduce the risk of loss or theft, ultimately improving operational efficiency. International buyers should consider the customization options available, including RFID and barcode capabilities, to suit their specific tracking needs. Durability is also a key factor, as tags must withstand various conditions, including humidity and temperature fluctuations.

Why Are Workplace Safety Signs Important in Construction?

Workplace safety signs from Seton are vital in the construction industry, where compliance with safety regulations is paramount. These signs help communicate critical safety information to workers, reducing liability and promoting a safer work environment. Buyers must focus on compliance with OSHA and local regulations, ensuring that the signs are visible and suitable for outdoor use, particularly in harsh weather conditions.

How Do Seton Products Ensure Safety in the Oil and Gas Industry?

In the oil and gas sector, hazardous material identification labels are essential for safe handling and transportation of dangerous substances. Seton’s products help mitigate environmental risks by clearly marking hazardous materials, ensuring that employees are aware of potential dangers. Buyers should prioritize compliance with international safety standards and select labels that are weatherproof and highly visible, as they are often used in challenging outdoor environments.

What Role Do Seton Identification Products Play in Healthcare?

In healthcare settings, safety and compliance labels are critical for protecting both staff and patients. Seton identification products mark hazardous areas and materials, thereby enhancing safety protocols and compliance with health regulations. Buyers in this sector should ensure that the labels communicate clearly and are durable enough to withstand frequent cleaning and disinfecting, which is essential in maintaining a safe healthcare environment.

3 Common User Pain Points for ‘seton identification products’ & Their Solutions

Scenario 1: Navigating Compliance Challenges with Safety Regulations

The Problem: For many international B2B buyers, especially those operating in regions with stringent safety regulations, ensuring compliance with local laws can be a daunting task. Buyers often struggle to identify the correct safety signage and labels that adhere to regulations such as OSHA, ANSI, or even local equivalents. This can lead to costly fines, legal liabilities, or workplace accidents due to insufficient safety communication. The challenge is compounded when buyers are unfamiliar with the specific compliance requirements relevant to their industry and location.

The Solution: To effectively navigate compliance challenges, B2B buyers should conduct thorough research on the specific safety regulations applicable to their operations. Start by consulting local regulatory bodies or industry associations that provide guidelines on safety signage and labeling. Once you have a clear understanding of the requirements, leverage resources from suppliers like Seton that offer compliance-focused products. For example, Seton provides a wide range of OSHA-compliant safety signs and labels that can be customized to fit your specific needs. Additionally, consider creating a compliance checklist that outlines the necessary products for your facility. This proactive approach not only mitigates risks but also enhances the safety culture within your organization.

Scenario 2: Managing Inventory and Asset Visibility Issues

The Problem: Many organizations face significant challenges in tracking their assets due to poor labeling and insufficient identification methods. This issue is particularly prevalent in large warehouses and manufacturing facilities where assets are frequently moved or borrowed. Without effective asset tagging solutions, businesses risk losing valuable equipment, experiencing operational delays, and incurring unnecessary costs. The lack of visibility into asset locations can also hinder maintenance schedules and compliance tracking.

The Solution: To address inventory and asset visibility challenges, B2B buyers should implement a systematic asset tagging strategy using Seton’s diverse range of identification products. Start by categorizing your assets based on their usage and importance. Then, select appropriate asset tags—such as RFID, barcode labels, or durable nameplates—tailored to each asset’s environment and handling requirements. Seton’s asset tagging solutions are designed for easy application and can significantly improve tracking efficiency. Furthermore, consider integrating an asset management software that can work in conjunction with your tagging system, providing real-time data on asset locations and statuses. This comprehensive approach not only enhances visibility but also optimizes inventory management and reduces operational disruptions.

Scenario 3: Overcoming Communication Barriers in Multilingual Work Environments

The Problem: In diverse workplaces, particularly those with a multilingual workforce, clear communication is crucial for maintaining safety and operational efficiency. B2B buyers often struggle to source identification products that cater to multiple languages, leading to misunderstandings and potential safety hazards. When safety signs and labels are only available in one language, non-native speakers may misinterpret important information, which can result in accidents or compliance issues.

The Solution: To effectively overcome communication barriers, B2B buyers should prioritize sourcing multilingual safety signage and labeling solutions. Seton offers customizable signage that can be printed in various languages, ensuring that all employees understand critical safety information. When ordering, provide specific details about the languages needed and the context in which the signage will be used. Additionally, consider involving your workforce in the process by conducting surveys to identify which languages are most relevant. This not only fosters inclusivity but also reinforces the importance of safety across the organization. By ensuring that all employees have access to clear and comprehensible safety communications, you can significantly reduce the risk of workplace incidents and enhance overall safety compliance.

Strategic Material Selection Guide for seton identification products

What Are the Key Properties of Common Materials Used in Seton Identification Products?

When selecting materials for seton identification products, understanding the properties of various materials is crucial for ensuring optimal performance and longevity. Here, we analyze four common materials: vinyl, polyester, aluminum, and polycarbonate, focusing on their properties, advantages, disadvantages, and international considerations.

How Does Vinyl Perform as a Material for Seton Identification Products?

Vinyl is a widely used material for labels and decals due to its flexibility and durability. It has excellent resistance to moisture, chemicals, and UV light, making it suitable for both indoor and outdoor applications. Vinyl can withstand temperatures ranging from -40°F to 180°F (-40°C to 82°C), which is beneficial for environments with fluctuating conditions.

Pros: Vinyl is cost-effective and easy to print on, allowing for vibrant colors and clear text. Its flexibility also means it can adhere well to various surfaces.

Cons: While vinyl is durable, it can be prone to tearing under extreme stress or impact. Additionally, it may not be suitable for high-temperature applications beyond its rated limits.

Impact on Application: Vinyl labels are ideal for general-purpose identification, including asset tagging and safety signage. However, they may not be the best choice for environments with extreme heat or physical wear.

International Considerations: Buyers from regions like Africa and South America should ensure that vinyl products meet local environmental regulations, as some countries have restrictions on PVC materials.

What Advantages Does Polyester Offer for Seton Identification Products?

Polyester is another popular choice for seton identification products, particularly for labels that require high durability. It has superior resistance to abrasion, chemicals, and moisture, withstanding temperatures from -40°F to 300°F (-40°C to 149°C).

Pros: The durability of polyester makes it suitable for harsh environments, including industrial settings. Its resistance to fading also ensures that labels remain legible over time.

Cons: Polyester can be more expensive than vinyl, which may be a consideration for budget-conscious buyers. Additionally, its rigidity might limit its application on uneven surfaces.

Impact on Application: Polyester is ideal for asset tags and labels in environments where exposure to chemicals or harsh conditions is common.

International Considerations: Compliance with standards such as ASTM or DIN is essential for polyester products, especially in Europe, where regulations are stringent regarding material safety and environmental impact.

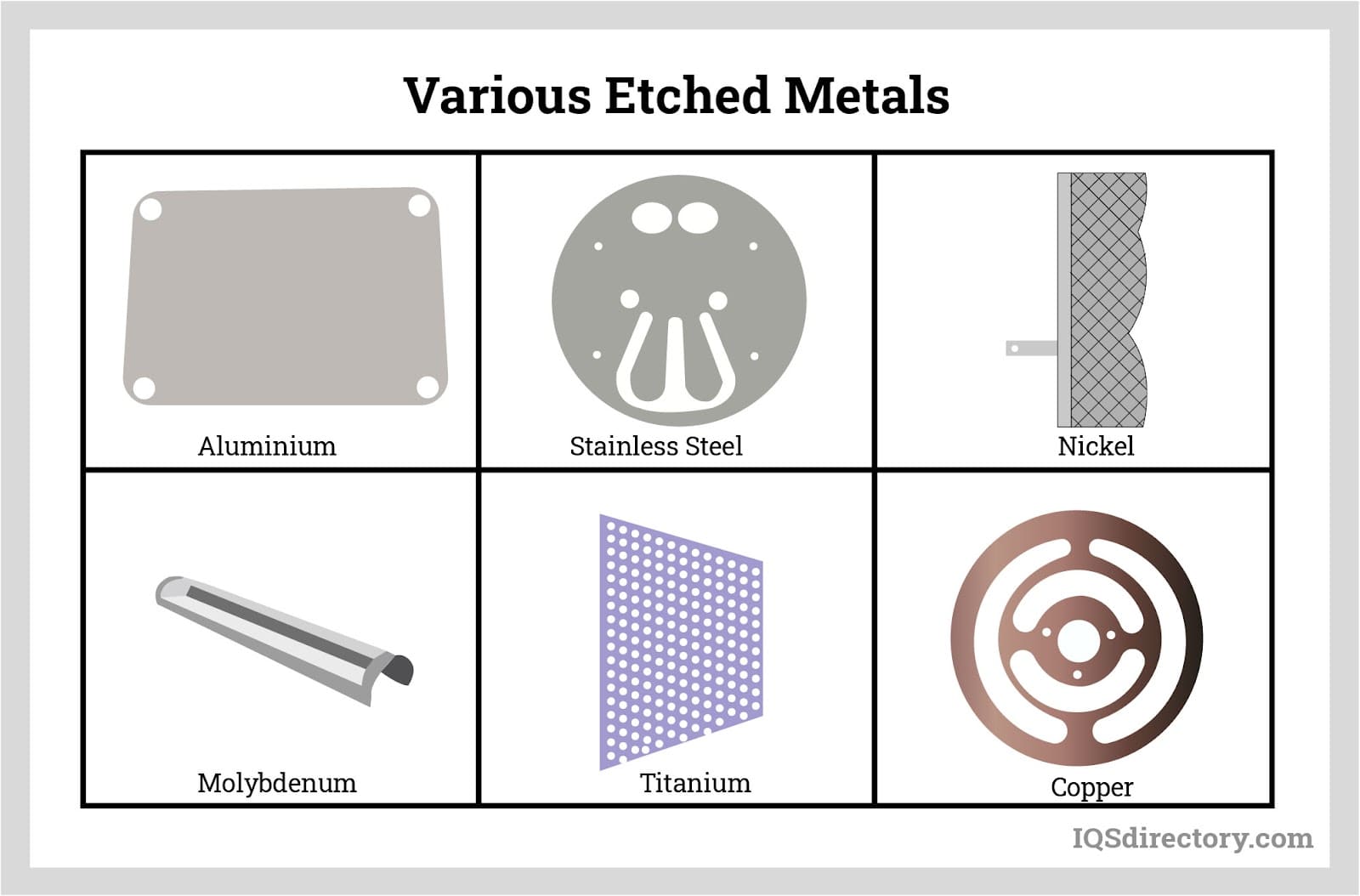

How Does Aluminum Compare for Seton Identification Products?

Aluminum is a robust material often used for tags and signage that require a high level of durability and resistance to environmental factors. It is lightweight yet strong, with excellent corrosion resistance, making it suitable for outdoor applications.

Pros: Aluminum tags are highly durable and can last for years without fading or deteriorating. They are also resistant to extreme temperatures and can be used in a wide range of applications.

Cons: The cost of aluminum products is generally higher than that of vinyl or polyester. Additionally, the manufacturing process can be more complex, leading to longer lead times.

Impact on Application: Aluminum is particularly effective for long-term outdoor signage and identification in industrial settings, where durability is paramount.

International Considerations: Buyers should be aware of any import tariffs or regulations related to aluminum products in their region, particularly in the Middle East and Africa, where trade policies can vary.

What Role Does Polycarbonate Play in Seton Identification Products?

Polycarbonate is a high-performance plastic known for its impact resistance and clarity. It can withstand temperatures from -40°F to 240°F (-40°C to 116°C) and is often used in environments where visibility and durability are critical.

Pros: Polycarbonate is highly resistant to impact and can endure harsh weather conditions, making it suitable for both indoor and outdoor use. Its clarity allows for high-quality printing.

Cons: While polycarbonate is durable, it can be more expensive than other materials. It may also be prone to scratching if not treated with a protective coating.

Impact on Application: Polycarbonate is ideal for high-visibility applications, such as safety signs and labels in environments where clarity and durability are essential.

International Considerations: Compliance with international safety standards is critical for polycarbonate products, especially in Europe, where regulations are strict regarding material safety.

Summary Table of Material Selection for Seton Identification Products

| Material | Typical Use Case for seton identification products | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vinyl | General-purpose labels and decals | Cost-effective and easy to print | Prone to tearing under stress | Low |

| Polyester | Asset tags and durable labels | High durability and chemical resistance | More expensive than vinyl | Medium |

| Aluminum | Long-term outdoor signage and industrial tags | Highly durable and corrosion-resistant | Higher cost and complex manufacturing | High |

| Polycarbonate | High-visibility safety signs and labels | Impact-resistant and clear | More expensive and prone to scratching | Medium to High |

By carefully considering the properties and applications of these materials, international B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for seton identification products

What Are the Main Stages of Manufacturing Seton Identification Products?

Manufacturing seton identification products involves several key stages that ensure quality, durability, and compliance with safety standards. Understanding these stages can help B2B buyers make informed decisions when sourcing these essential items.

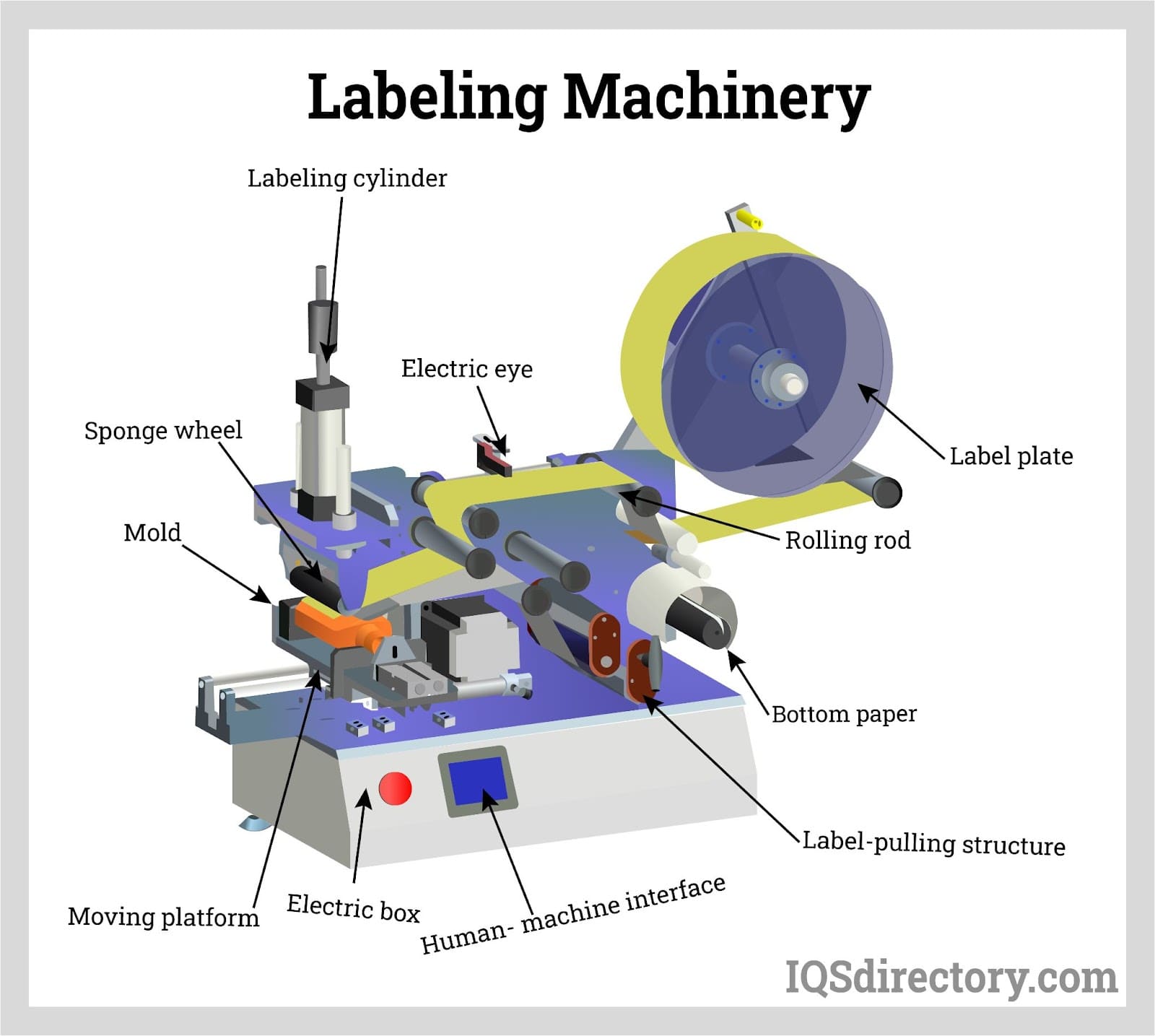

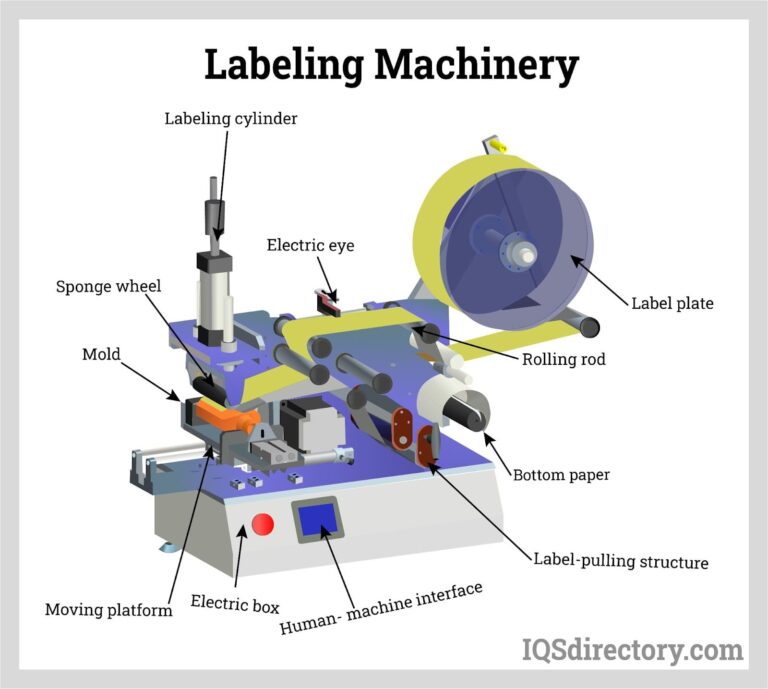

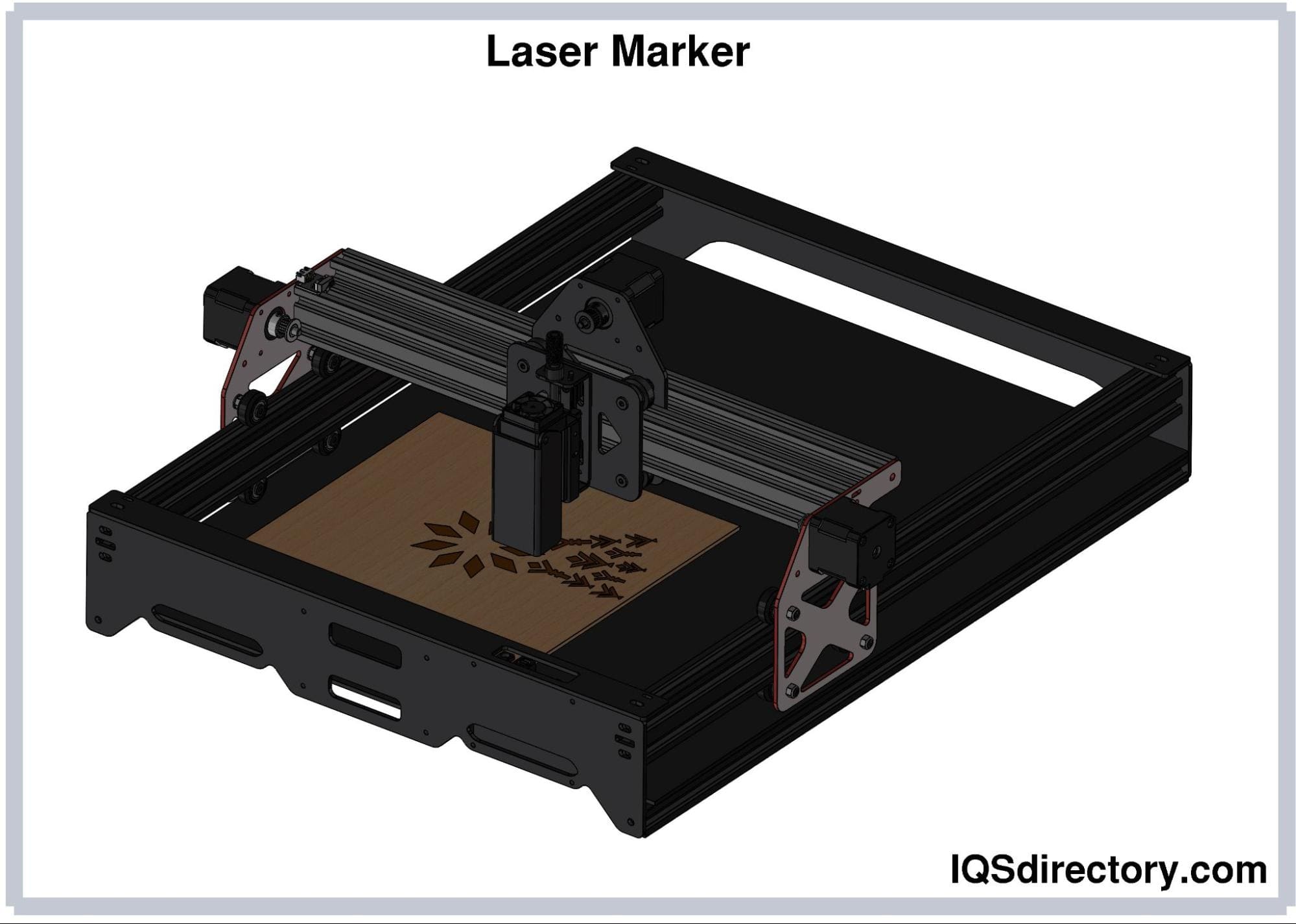

Illustrative image related to seton identification products

Material Preparation: How Are Raw Materials Selected and Prepared?

The first step in the manufacturing process is material preparation. Manufacturers typically use high-quality materials such as vinyl, polyethylene, and aluminum, selected based on the specific application of the identification products. For example, outdoor signs may require weather-resistant materials to withstand harsh conditions.

Once the materials are chosen, they undergo treatment processes to enhance their durability. This can include surface treatments like lamination or UV coating, which protect against fading and physical damage. Buyers should inquire about the types of materials used and their certifications to ensure compliance with industry standards.

Forming: What Techniques Are Used to Shape Identification Products?

The forming stage involves shaping the prepared materials into the final product. Common techniques include die-cutting, screen printing, and digital printing.

- Die-Cutting: This method is often used for creating custom shapes and sizes of labels or signs, ensuring precision and consistency across batches.

- Screen Printing: Ideal for high-volume orders, this technique applies inks directly onto the material, providing vibrant colors and durability.

- Digital Printing: This technique is increasingly popular for smaller runs and custom orders, allowing for high-resolution images and complex designs.

B2B buyers should understand the manufacturing techniques employed, as they can significantly affect the product’s quality and longevity.

Assembly: How Are Different Components Joined Together?

In the assembly stage, various components of the identification products are brought together. For instance, labels may require adhesive backing, while signs may need mounting hardware. This stage also includes quality checks to ensure that all components fit correctly and function as intended.

Illustrative image related to seton identification products

Automated assembly lines are commonly used to enhance efficiency and reduce human error. However, manual assembly may still be employed for more complex products. Buyers should ask about the assembly process to understand how it impacts lead times and overall product quality.

Finishing: What Final Touches Ensure Quality and Compliance?

The finishing stage involves applying protective coatings, lamination, or additional treatments to enhance the product’s performance. This may include anti-slip coatings for floor signs or reflective materials for safety signage.

Final inspections are crucial at this stage to verify that products meet the required specifications and standards. B2B buyers should inquire about the finishing processes and any additional certifications that may apply.

How Is Quality Control Implemented in Seton Identification Product Manufacturing?

Quality control (QC) is integral to the manufacturing process, ensuring that products meet safety and performance standards. Understanding the QC protocols can help B2B buyers assess the reliability of their suppliers.

What International Standards Are Relevant for Quality Control?

Manufacturers often adhere to international standards such as ISO 9001, which outlines quality management principles. Compliance with ISO 9001 demonstrates a commitment to continuous improvement and customer satisfaction.

Additionally, industry-specific standards like CE marking for products sold in the European Economic Area (EEA) and API standards for certain industrial applications may apply. Buyers should verify that suppliers comply with relevant standards to ensure product safety and regulatory compliance.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are established at various stages of the manufacturing process, including:

- Incoming Quality Control (IQC): This initial inspection checks the raw materials for defects or inconsistencies before they enter production.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify any issues early, allowing for immediate corrective actions.

- Final Quality Control (FQC): The final inspection ensures that the finished products meet all specifications and standards before shipment.

These checkpoints are critical for maintaining product quality and minimizing defects.

What Common Testing Methods Are Used for Seton Identification Products?

Manufacturers employ various testing methods to verify product quality, including:

- Adhesion Testing: Ensures labels and signs adhere properly to surfaces under different environmental conditions.

- Durability Testing: Products are subjected to conditions simulating real-world use, including exposure to UV light, moisture, and extreme temperatures.

- Reflectivity Testing: For safety signs, reflectivity tests ensure they meet visibility standards under low-light conditions.

B2B buyers should ask about the specific testing methods used by suppliers to gauge the reliability and performance of the products.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is essential for B2B buyers, particularly in international markets where standards may vary.

What Steps Can Buyers Take to Ensure Supplier Compliance with QC Standards?

- Request Documentation: Buyers should ask for quality control documentation, including certificates of compliance with international standards and testing reports.

- Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and adherence to quality standards.

- Engage Third-Party Inspectors: Utilizing independent inspectors can offer an unbiased assessment of the supplier’s quality control practices.

What Are the Nuances of QC and Certification for International Buyers?

International B2B buyers must navigate various regulatory landscapes, which can affect product compliance. For example, products sold in Europe must meet CE marking requirements, while those in the Middle East may need to adhere to specific local standards.

Buyers should familiarize themselves with the regulatory requirements in their target markets to avoid compliance issues. Additionally, understanding the certifications held by suppliers can provide assurance of product quality and safety.

Conclusion: Why Is Understanding Manufacturing and QC Critical for B2B Buyers?

For B2B buyers sourcing seton identification products, a deep understanding of manufacturing processes and quality control practices is essential. This knowledge not only aids in selecting reliable suppliers but also ensures that the products meet safety and regulatory standards. By asking the right questions and verifying compliance, buyers can secure high-quality identification products that enhance workplace safety and efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘seton identification products’

To effectively source Seton identification products, international B2B buyers must navigate a structured approach that ensures compliance, quality, and suitability for their specific needs. This guide provides a step-by-step checklist to help you streamline your procurement process.

Step 1: Identify Your Specific Needs

Understanding your requirements is crucial before sourcing. Determine the types of Seton identification products you need, such as safety signs, asset tags, or pipe markers. Consider the specific applications and regulatory compliance required in your industry and region.

- Key Considerations:

- Are you focusing on safety compliance (e.g., OSHA standards)?

- What materials and durability standards are necessary for your environment?

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers of Seton products. Look for vendors with a strong reputation in workplace safety solutions and a diverse product range. Online platforms, industry directories, and trade shows can provide valuable insights.

- What to Look For:

- Supplier certifications (e.g., ISO, OSHA compliance).

- Customer reviews and testimonials to gauge reliability.

Step 3: Evaluate Supplier Capabilities

Before committing to a supplier, assess their capabilities and product offerings. This includes evaluating their manufacturing processes, product quality, and customization options. A supplier that offers tailored solutions can better meet your unique requirements.

- Assessment Criteria:

- Product quality certifications (e.g., UL, CE).

- Availability of custom products or specialized labels.

Step 4: Request Samples

Once you have shortlisted potential suppliers, request samples of the products you intend to purchase. This allows you to evaluate the quality, durability, and usability of the items before making a bulk purchase.

- What to Observe:

- Material quality and resistance to environmental factors.

- Clarity and effectiveness of labels and signage.

Step 5: Verify Compliance and Certifications

Ensure that the products you intend to source comply with relevant regulations and safety standards. This step is essential for avoiding legal issues and ensuring worker safety.

- Compliance Checks:

- Confirm adherence to local and international standards (e.g., ANSI, ISO).

- Request documentation to validate compliance.

Step 6: Negotiate Terms and Pricing

Engage in discussions with suppliers regarding pricing, minimum order quantities, and delivery timelines. Effective negotiation can lead to better pricing and terms that suit your budget and operational needs.

- Negotiation Tips:

- Inquire about bulk purchase discounts.

- Clarify return policies and warranties.

Step 7: Establish a Long-Term Relationship

Once you have finalized your supplier, focus on building a long-term partnership. Regular communication and feedback can lead to improved service and potentially better deals over time.

- Building Relationships:

- Schedule periodic reviews to discuss product performance.

- Keep suppliers informed about your evolving needs.

By following this structured approach, B2B buyers can ensure they procure the right Seton identification products effectively and efficiently, enhancing workplace safety and compliance in their operations.

Comprehensive Cost and Pricing Analysis for seton identification products Sourcing

What Are the Key Cost Components in Sourcing Seton Identification Products?

When sourcing Seton identification products, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type of materials used in the production of safety signs, labels, and tags significantly influences the overall cost. High-quality, durable materials may come at a premium but ensure longevity and compliance with safety standards.

-

Labor: Labor costs can vary based on the region and the complexity of the manufacturing process. Skilled labor may be required for custom products, which can increase costs.

-

Manufacturing Overhead: This includes expenses related to the production process, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce these costs.

-

Tooling: Initial tooling costs for custom items can be substantial. This cost is often amortized over larger production runs, making it essential to consider the volume of your order.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the products meet safety and compliance standards. This can add to the overall cost but is vital for maintaining product integrity.

-

Logistics: Shipping and handling expenses are significant, especially for international orders. Factors such as distance, shipping method, and customs duties will affect the final cost.

-

Margin: Suppliers will add a profit margin to cover their costs and risks. Understanding typical margins in your industry can help in negotiating better prices.

How Do Price Influencers Affect the Cost of Seton Identification Products?

Several factors influence the pricing of Seton identification products:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Understanding the supplier’s MOQ can help in planning your purchases effectively.

-

Specifications and Customization: Custom products tailored to specific needs may incur additional costs. Buyers should weigh the benefits of customization against budget constraints.

-

Materials and Quality Certifications: Products that require specific materials or certifications (like OSHA compliance) can be more expensive. Ensure that any additional quality requirements are factored into your budget.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to perceived quality, while newer entrants might offer competitive pricing.

-

Incoterms: The agreed-upon terms of shipment (e.g., FOB, CIF) will impact the overall cost. Understanding these terms helps in anticipating additional charges, such as freight and insurance.

What Are the Best Buyer Tips for Cost-Efficiency in Sourcing?

To maximize cost-efficiency when sourcing Seton identification products, consider the following strategies:

-

Negotiate Pricing: Don’t hesitate to negotiate prices, especially for larger orders. Suppliers may be willing to offer discounts to secure bulk purchases.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, durability, and compliance costs to determine the true cost of ownership.

-

Understand Pricing Nuances for International Buyers: For B2B buyers from Africa, South America, the Middle East, and Europe, currency fluctuations and import duties can significantly affect costs. Be prepared for these variables in your budgeting.

-

Research Supplier Options: Compare multiple suppliers to find the best combination of price, quality, and service. Read reviews and seek recommendations to identify reliable partners.

-

Plan for Future Needs: Anticipate future demands and consider purchasing in bulk to lock in lower prices. This strategy can be particularly effective for items with stable pricing and demand.

Conclusion

In summary, a comprehensive understanding of the cost structure, pricing influencers, and effective negotiation strategies is essential for B2B buyers sourcing Seton identification products. By considering these factors, businesses can make informed purchasing decisions that align with their safety and compliance needs while optimizing costs. Always keep in mind that prices can vary widely based on specific requirements and market conditions, so it’s wise to seek multiple quotes and carefully assess each supplier’s offer.

Alternatives Analysis: Comparing seton identification products With Other Solutions

Introduction: Exploring Alternatives to Seton Identification Products

In the realm of workplace safety and asset identification, Seton identification products stand out for their comprehensive range of solutions. However, businesses often seek alternatives that might better suit their specific operational needs, budget constraints, or compliance requirements. Understanding these alternatives can empower international B2B buyers to make informed decisions that enhance safety, efficiency, and regulatory compliance in their organizations.

Comparison Table

| Comparison Aspect | Seton Identification Products | Alternative 1: RFID Solutions | Alternative 2: Custom Label Printing |

|---|---|---|---|

| Performance | High durability and visibility; compliant with OSHA and ANSI standards | Offers real-time tracking and data management | Varies based on material and design; can be customized for various applications |

| Cost | Moderate pricing with bulk discounts available | Higher initial investment; long-term cost savings with reduced manual labor | Generally lower cost per unit, but variable based on complexity |

| Ease of Implementation | Quick setup with ready-to-use products | Requires integration with existing systems and training | Simple to implement for small batches; more complex for large orders |

| Maintenance | Low maintenance; durable materials | Requires ongoing system updates and maintenance | Minimal maintenance; however, quality can degrade over time if not stored properly |

| Best Use Case | Ideal for static identification needs, compliance, and safety signage | Best for dynamic environments needing real-time tracking and inventory management | Suitable for customized solutions in small to medium-sized businesses needing specific labels |

Detailed Breakdown of Alternatives

Alternative 1: RFID Solutions

RFID (Radio Frequency Identification) technology provides a modern approach to asset tracking and identification. Its primary advantage lies in the ability to track items in real-time, reducing the risk of loss and improving inventory management. However, the initial investment can be significant due to the cost of RFID tags, readers, and the necessary software systems. Additionally, implementing RFID solutions requires training for staff, which can pose a challenge for companies with limited technical expertise. Overall, RFID is best suited for businesses that handle large volumes of assets and require precise tracking.

Alternative 2: Custom Label Printing

Custom label printing offers flexibility and can be tailored to meet specific branding and compliance needs. Businesses can create unique labels that communicate essential information about their assets or safety protocols. The cost is generally lower, particularly for smaller batches, making it an attractive option for startups or smaller enterprises. However, the performance of these labels can vary based on the materials used and environmental factors, such as exposure to chemicals or extreme temperatures. For organizations that require highly specialized labeling solutions, custom printing can be a viable alternative, though it may not provide the same level of durability as Seton products.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting identification products for workplace safety or asset management, B2B buyers should assess their specific operational requirements, budget, and compliance obligations. Seton identification products excel in durability and regulatory compliance, making them suitable for many industries. However, alternatives like RFID solutions or custom label printing may provide unique advantages depending on the context. By carefully evaluating the performance, cost, and ease of implementation of each option, buyers can choose the most appropriate solution that aligns with their strategic goals and enhances workplace safety.

Essential Technical Properties and Trade Terminology for seton identification products

What Are the Key Technical Properties of Seton Identification Products?

When considering seton identification products, understanding their technical specifications is crucial for ensuring compliance, safety, and operational efficiency. Below are some of the essential properties to consider:

1. Material Grade

The material grade of identification products, such as labels and tags, is critical for durability and performance. Common materials include vinyl, polyester, and metal. Each material offers different levels of resistance to environmental factors such as moisture, chemicals, and UV light. B2B buyers should select materials that align with their specific application needs, particularly in industries such as manufacturing and construction where exposure to harsh conditions is common.

2. Adhesive Strength

The adhesive strength determines how well a label or tag adheres to surfaces. Products may feature permanent, removable, or repositionable adhesives. Understanding adhesive properties is vital for ensuring that labels stay in place throughout their intended use, especially in high-traffic environments. Selecting the appropriate adhesive can prevent costly replacements and enhance operational efficiency.

3. Temperature Resistance

Temperature resistance is a key specification, especially for products used in environments that experience extreme heat or cold. Labels and tags may be rated for specific temperature ranges, ensuring they maintain integrity and legibility under varying conditions. For B2B buyers, this property is essential for compliance with safety regulations and for maintaining clear communication in challenging environments.

Illustrative image related to seton identification products

4. Print Quality and Resolution

The print quality and resolution of labels and tags can impact readability and compliance with safety standards. High-resolution printing ensures that text and graphics are clear and legible, which is crucial for conveying important safety information. B2B buyers should assess print quality to ensure that it meets industry standards and enhances workplace safety.

5. Size and Shape Variability

Seton identification products come in various sizes and shapes to accommodate different applications. Customization options allow businesses to select products that fit specific equipment or facility requirements. Understanding size and shape variability is important for ensuring that identification products can be effectively utilized in diverse settings, from warehouses to manufacturing plants.

6. Compliance Standards

Many identification products must adhere to specific regulatory compliance standards, such as OSHA or ANSI. Ensuring that products meet these standards is vital for legal compliance and workplace safety. B2B buyers should prioritize purchasing products that are certified and compliant to avoid potential fines and enhance overall safety in their operations.

What Are Common Trade Terms Related to Seton Identification Products?

Familiarity with industry terminology can enhance communication and decision-making in the procurement process. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help B2B buyers identify reliable suppliers and ensure that products meet specific quality standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is important for businesses to manage inventory levels and budget constraints effectively.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products or services. B2B buyers often use RFQs to compare prices and terms, making it easier to make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a series of international sales terms that define the responsibilities of buyers and sellers in the shipping process. Understanding Incoterms is crucial for B2B transactions, especially for international buyers, as they clarify who is responsible for shipping costs, insurance, and risk during transit.

5. SKU (Stock Keeping Unit)

SKU is a unique identifier for each distinct product and service that can be purchased. Familiarity with SKUs helps buyers manage inventory and streamline purchasing processes.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when selecting seton identification products, ultimately enhancing workplace safety and compliance.

Illustrative image related to seton identification products

Navigating Market Dynamics and Sourcing Trends in the seton identification products Sector

What Are the Current Market Dynamics for Seton Identification Products?

The global market for seton identification products is shaped by several key drivers, including increasing safety regulations, the rising importance of workplace safety, and the growth of industrial sectors in emerging markets. In regions such as Africa, South America, the Middle East, and Europe, there is a heightened focus on compliance with local and international safety standards, which is fueling demand for high-quality identification products. The COVID-19 pandemic has further accelerated the need for clear signage and safety communication, as companies prioritize health and safety measures to protect employees and visitors.

Emerging B2B technology trends are also influencing sourcing strategies. The integration of digital asset management systems allows companies to track and manage their identification products more efficiently. Additionally, advancements in printing technology enable the production of customized labels and signs, tailored to specific operational needs. This flexibility is particularly beneficial for international buyers who require localized solutions that meet diverse regulatory frameworks.

For B2B buyers, understanding these dynamics is crucial. Sourcing trends indicate a shift towards online procurement platforms that facilitate easier access to product catalogs and faster delivery options. Furthermore, as competition increases, buyers are encouraged to seek suppliers that not only offer competitive pricing but also demonstrate a commitment to quality and compliance with industry standards.

How Is Sustainability and Ethical Sourcing Addressed in the Seton Identification Products Market?

Sustainability has become a critical consideration for B2B buyers in the seton identification products sector. The environmental impact of manufacturing processes and materials used in products like labels, signs, and tags is under scrutiny. As businesses aim to reduce their carbon footprint, there is a growing demand for environmentally friendly materials and production methods.

Ethical sourcing plays a vital role in this context. Buyers are increasingly seeking suppliers who adhere to sustainable practices, such as using recycled materials or biodegradable options for their identification products. Certifications such as ISO 14001, which pertains to effective environmental management systems, can provide assurance to buyers regarding a supplier’s commitment to sustainability.

By prioritizing ethical supply chains, companies not only contribute to environmental conservation but also enhance their brand reputation. This is particularly relevant in regions where consumers and businesses are more conscious of corporate social responsibility. Suppliers that can demonstrate sustainability through transparent practices and certifications are likely to gain a competitive edge in the market.

What Is the Evolution of Seton Identification Products in the B2B Landscape?

The evolution of seton identification products can be traced back to the mid-20th century, when the need for workplace safety and compliance began to gain prominence. Established in 1956, Seton has played a significant role in this sector by pioneering innovative solutions that cater to various industries, from manufacturing to healthcare.

Initially focused on basic signage, the range of products has expanded dramatically over the years to include high-tech options like RFID tags and custom labels. As businesses faced increasing regulatory pressures, the demand for high-quality identification products grew, leading to the development of specialized solutions that address specific safety and compliance needs.

Today, the market continues to evolve, driven by technological advancements and a greater emphasis on safety culture within organizations. B2B buyers can benefit from this rich history by leveraging the expertise and innovations of established suppliers to enhance their workplace safety protocols effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of seton identification products

-

How do I ensure compliance with safety regulations when purchasing Seton identification products?

To ensure compliance with safety regulations, first identify the specific regulations applicable to your industry and region, such as OSHA in the U.S. or local equivalents in Africa or Europe. Review the product specifications from Seton to confirm they meet these standards, such as MUTCD or ANSI compliance for signage. Additionally, consult with your supplier’s compliance documentation and seek guidance from their customer support team if you have questions about regulatory requirements. -

What is the best type of asset tagging solution for my inventory needs?

The best asset tagging solution depends on your specific inventory management requirements. For high-value items, consider RFID tags for real-time tracking and enhanced security. For less critical inventory, barcode labels may suffice, providing a cost-effective and easy-to-implement solution. Evaluate the environment in which tags will be used, as options vary in durability and resistance to elements like moisture or heat. Consulting with an expert can help tailor the solution to your needs. -

How can I customize Seton products for my specific business requirements?

Seton offers various customization options for their products, including signs, labels, and tags. You can specify dimensions, colors, and even add your company logo or specific messaging. To initiate customization, reach out directly to Seton’s customer service or use their online customization tool, if available. Ensure you provide clear specifications to avoid delays and confirm that your design adheres to any regulatory requirements. -

What are the minimum order quantities (MOQs) for Seton identification products?

Minimum order quantities (MOQs) for Seton identification products can vary based on the type of product and supplier agreements. Generally, for standard items, MOQs may be low, while custom products might require higher quantities. To get accurate information, consult the product listings on the supplier’s website or contact their sales team directly. Understanding MOQs is crucial for budgeting and inventory planning. -

What payment terms should I expect when sourcing from Seton?

Payment terms can vary based on the supplier’s policies and your creditworthiness. Common terms include net 30 or net 60, meaning payment is due within 30 or 60 days after the invoice date. International buyers may also encounter upfront payment requirements or letters of credit, depending on the transaction size and risk factors involved. Always clarify payment terms before placing an order to avoid misunderstandings. -

How do I vet suppliers of Seton identification products for reliability and quality?

Vetting suppliers involves researching their reputation, certifications, and customer reviews. Check for compliance with industry standards and look for testimonials from other businesses, particularly in your region. Request product samples to assess quality firsthand. Additionally, inquire about their return policies and customer support to ensure they are responsive and reliable. A thorough vetting process helps mitigate risks associated with sourcing. -

What logistics considerations should I keep in mind when importing Seton products?

Logistics considerations include shipping methods, customs clearance, and delivery timelines. Assess the reliability of shipping options available, as well as associated costs. Ensure you have a clear understanding of import duties and taxes that may apply in your country. Communicate with your supplier about their shipping policies and confirm that they provide tracking information to monitor your order’s progress. -

How can I ensure quality assurance (QA) for my Seton identification products?

To ensure quality assurance, establish clear specifications and standards before placing an order. Request quality control documentation from your supplier, including certificates of compliance and inspection reports. Consider implementing a sampling process to evaluate products upon arrival. Additionally, maintain open communication with the supplier for any concerns and establish a feedback loop to address issues promptly, thus ensuring ongoing product quality.

Top 4 Seton Identification Products Manufacturers & Suppliers List

1. Ferguson – Seton Identification Products

Domain: ferguson.com

Registered: 1999 (26 years)

Introduction: This company, Ferguson – Seton Identification Products, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Seton – Name Plates

Domain: nameplate-manufacturers.com

Registered: 2007 (18 years)

Introduction: Seton Identification Products is a leading provider of high-quality industrial identification and safety products, established in 1956. Their core product line includes Name Plates, which are essential for identifying equipment, products, and areas within a facility, contributing to workplace safety and efficiency. Name Plates are available in various materials such as aluminum, brass, stainless s…

3. Seton – Safety and Identification Products

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, Seton – Safety and Identification Products, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Seton Identification Products – Pipe Markers and Tags

Domain: arcat.com

Registered: 1995 (30 years)

Introduction: Seton Identification Products offers a range of products including Pipe Markers, Valve Tags, and Outdoor Pipe Markers. The catalog includes resources such as ANSI Pipe Marker Selection Guide, Safety Products Catalog, and Arrow-On-A-Roll Tape. Additional offerings include Beaded Chain and various downloadable specifications and videos.

Strategic Sourcing Conclusion and Outlook for seton identification products

How Can Strategic Sourcing Enhance Your Procurement of Seton Identification Products?

In today’s competitive landscape, strategic sourcing of seton identification products is not just a procurement choice; it’s a vital component of operational success. By investing in high-quality safety signage, labels, and asset tags, businesses can significantly enhance workplace safety, ensure regulatory compliance, and protect valuable assets. The comprehensive range of products available—from pipe marking labels to traffic control signage—ensures that every company can find tailored solutions to meet its unique safety needs.

For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, the benefits of strategic sourcing extend beyond compliance; they promote a culture of safety that can lead to improved employee morale and productivity. Engaging with reputable suppliers like Seton not only guarantees access to quality products but also provides invaluable expertise in navigating complex safety regulations.

As you look to the future, consider how strategic partnerships can facilitate your sourcing decisions and drive long-term value. Empower your organization with the right tools today—invest in seton identification products and build a safer, more efficient workplace for tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.