How to Source Septic Tank Suppliers Near Me Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for septic tank suppliers near me

In the complex landscape of global infrastructure, sourcing reliable septic tank suppliers near you poses a significant challenge for businesses across various sectors. As urbanization and industrialization expand in regions like Africa, South America, the Middle East, and Europe, the demand for effective wastewater management solutions has never been more critical. This guide aims to assist international B2B buyers in navigating the multifaceted market of septic tanks, ensuring that your purchasing decisions are informed and strategic.

Throughout this comprehensive resource, we will explore the diverse types of septic tanks available, their applications in both residential and commercial settings, and the essential factors for supplier vetting. Understanding the nuances of compliance and certification, particularly in regions such as Germany and Saudi Arabia, is paramount to ensuring quality and reliability. Additionally, we will delve into cost considerations, helping you identify budget-friendly options without compromising on standards.

By equipping you with actionable insights and expert recommendations, this guide empowers B2B buyers to make informed decisions that align with their specific needs and regulatory requirements. Whether you are looking to streamline your supply chain or ensure sustainable practices in wastewater management, this resource is designed to enhance your procurement process and ultimately support your business’s growth and compliance in the global market.

Understanding septic tank suppliers near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Concrete Septic Tanks | Durable, long-lasting, heavy-duty construction | Commercial properties, industrial sites | Pros: Highly durable, resistant to impacts. Cons: Heavy, difficult to install. |

| Plastic Septic Tanks | Lightweight, corrosion-resistant, easy to install | Residential applications, small businesses | Pros: Easy installation, cost-effective. Cons: Less durable than concrete. |

| Fiberglass Septic Tanks | Lightweight, resistant to corrosion and chemicals | Remote areas, vacation homes | Pros: Lightweight, easy to transport. Cons: Can be prone to cracking if not handled properly. |

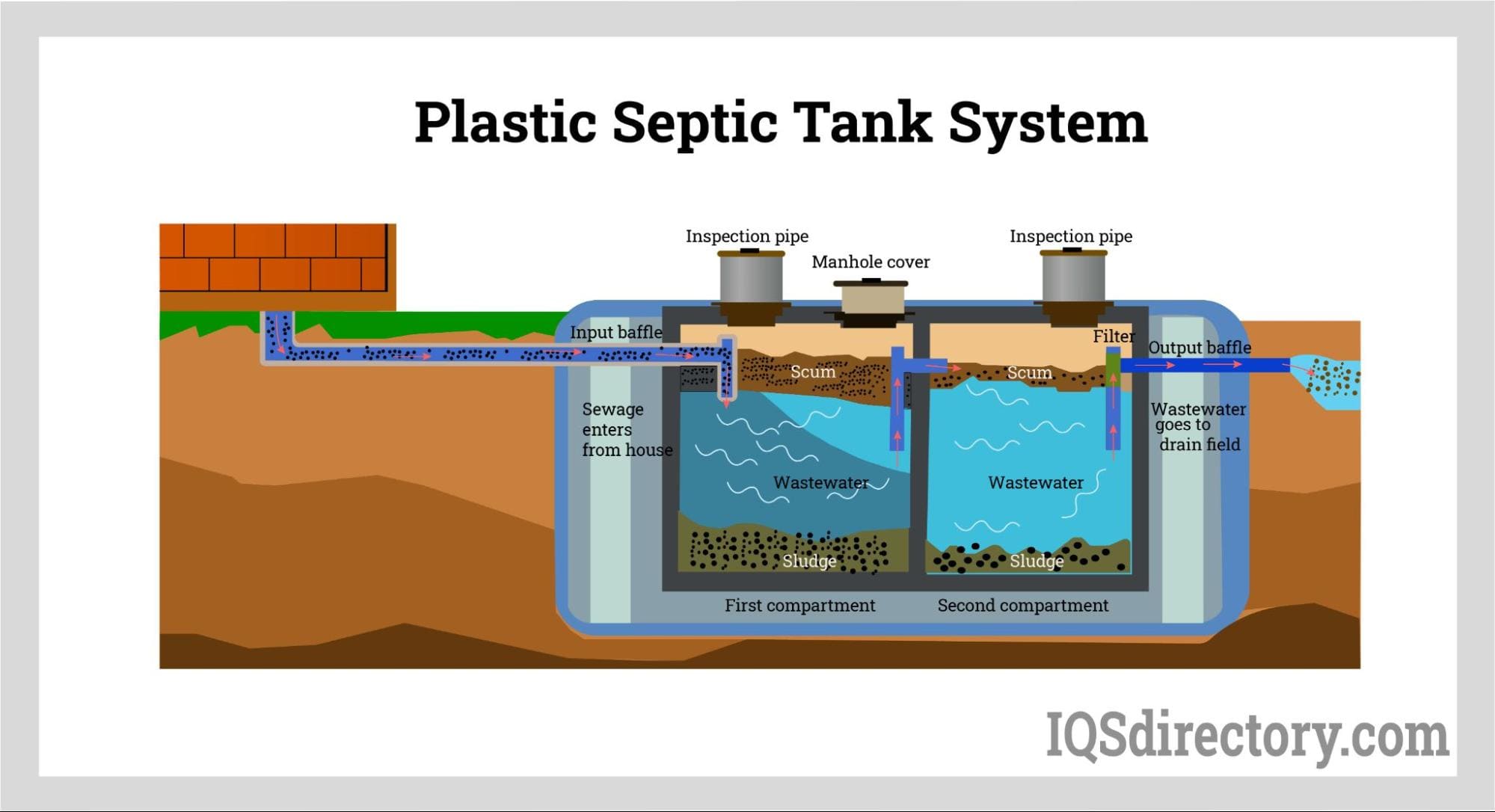

| Dual Compartment Tanks | Two separate chambers for enhanced treatment | Larger households, commercial properties | Pros: More efficient waste treatment, better separation. Cons: Higher initial cost. |

| Septic Tank Accessories | Components like risers, filters, and pumps | Maintenance and installation services | Pros: Enhances tank performance, necessary for operation. Cons: Additional costs for installation and maintenance. |

What Are the Characteristics of Concrete Septic Tanks?

Concrete septic tanks are known for their robust construction and long lifespan. They are ideal for commercial properties and industrial sites where heavy-duty performance is required. Their durability makes them resistant to impacts and environmental conditions, ensuring reliable waste management. However, their weight can make installation challenging, requiring specialized equipment and labor.

Why Choose Plastic Septic Tanks for B2B Applications?

Plastic septic tanks are favored for their lightweight and corrosion-resistant properties, making them easy to transport and install. They are particularly suitable for residential applications and small businesses due to their cost-effectiveness. While they offer convenience, it’s important to note that they may not provide the same longevity as concrete options, which can be a consideration for long-term investments.

How Do Fiberglass Septic Tanks Compare?

Fiberglass septic tanks are lightweight and resistant to corrosion, making them ideal for remote areas and vacation homes. Their ease of transport can reduce logistics costs, but they require careful handling as they can crack under stress. B2B buyers should weigh the benefits of portability against potential durability issues when considering fiberglass tanks for their projects.

What Are the Advantages of Dual Compartment Tanks?

Dual compartment tanks feature two separate chambers that enhance the treatment process by allowing better separation of solids and liquids. This design is particularly beneficial for larger households and commercial properties that generate more waste. While they can come at a higher initial cost, the efficiency in waste treatment often justifies the investment, leading to long-term savings on maintenance.

Why Are Septic Tank Accessories Important for B2B Buyers?

Septic tank accessories, such as risers, filters, and pumps, are crucial for maintaining and optimizing the functionality of septic systems. These components enhance the overall performance of the tanks and are necessary for effective operation. B2B buyers should consider the additional costs associated with these accessories, as they can impact the overall budget for installation and ongoing maintenance.

Key Industrial Applications of septic tank suppliers near me

| Industry/Sector | Specific Application of septic tank suppliers near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | On-site wastewater management for residential projects | Ensures compliance with local regulations and environmental standards | Quality certifications, tank capacity, and installation services |

| Agriculture | Waste treatment for livestock operations | Protects local water sources and enhances farm sustainability | Material durability, size options, and local supplier availability |

| Hospitality | Waste management for hotels and resorts | Improves sanitation and guest experience | Emergency service availability, tank maintenance options, and local regulations compliance |

| Industrial Facilities | Wastewater management for manufacturing plants | Reduces operational downtime and environmental impact | Custom tank designs, material specifications, and regulatory compliance |

| Remote Communities | Septic solutions for rural or isolated areas | Provides essential sanitation without centralized systems | Transport logistics, installation expertise, and compliance with local health codes |

How are Septic Tank Suppliers Integral to Construction Projects?

In the construction industry, septic tank suppliers near you are crucial for managing wastewater in residential developments. These suppliers provide tanks that meet local regulations, ensuring that the construction projects adhere to environmental standards. For international buyers, particularly in regions like Africa and South America, understanding local compliance is vital. Suppliers must offer tanks in various sizes and materials, along with installation services to facilitate smooth project execution.

What Role Do Septic Tanks Play in Agricultural Waste Management?

For agricultural operations, septic tank suppliers provide essential waste treatment solutions for livestock facilities. Properly managed waste systems not only protect local water sources from contamination but also promote sustainable farming practices. Buyers in agricultural sectors need to consider the durability of materials and the capacity of tanks, particularly in rural areas where access to maintenance services may be limited. Suppliers must also demonstrate compliance with environmental regulations specific to their region.

How Do Septic Tank Suppliers Enhance Hospitality Operations?

In the hospitality sector, septic tank suppliers are vital for hotels and resorts that require efficient waste management systems. A reliable septic system enhances sanitation and improves the overall guest experience. International buyers must prioritize suppliers who offer robust maintenance options and can respond to emergencies, especially in remote locations. Compliance with local health regulations is also essential, making it crucial for suppliers to understand the specific needs of hospitality businesses.

Why Are Industrial Facilities Dependent on Septic Solutions?

Manufacturing plants often face significant challenges regarding wastewater management. Septic tank suppliers provide tailored solutions that minimize operational downtime while ensuring environmental compliance. Buyers in this sector should look for suppliers who can offer custom tank designs and materials that meet specific industrial requirements. Additionally, understanding local regulations and sourcing suppliers who can navigate these requirements is critical for international B2B buyers.

How Do Remote Communities Benefit from Local Septic Tank Suppliers?

For remote communities, septic tank suppliers offer vital sanitation solutions that are often lacking in infrastructure. These suppliers provide tanks that can function independently of centralized systems, ensuring that essential sanitation needs are met. Buyers must consider transport logistics and the supplier’s expertise in installation, as well as their knowledge of local health codes. This understanding is especially important for international buyers seeking sustainable solutions in less accessible regions.

3 Common User Pain Points for ‘septic tank suppliers near me’ & Their Solutions

Scenario 1: Navigating Compliance and Regulatory Challenges

The Problem: B2B buyers often face significant hurdles when it comes to understanding the compliance requirements for septic tank installations. Different regions have varying regulations, and failing to meet these can lead to costly penalties and project delays. For instance, buyers in Europe may struggle with stringent EU environmental regulations, while those in Africa might encounter a lack of clear guidelines or inconsistent enforcement. This confusion can result in selecting inappropriate products or missing crucial permits, causing operational setbacks.

The Solution: To navigate these regulatory complexities, B2B buyers should engage directly with local septic tank suppliers who have a deep understanding of regional regulations. Initiating a dialogue about compliance requirements can help clarify which septic systems are approved in specific areas. Additionally, buyers should ask for documentation of certifications and compliance from manufacturers, ensuring that products meet all local standards. Building relationships with suppliers that offer installation services can also simplify the compliance process, as these suppliers often have experience with local regulations and can assist with necessary permits.

Scenario 2: Difficulty in Identifying Quality and Reliability

The Problem: The septic tank supply market is flooded with options, making it challenging for buyers to identify suppliers that offer high-quality products. Inconsistent product quality can lead to system failures, resulting in additional costs and reputational damage for the buyer. This is particularly concerning for buyers in regions like South America or the Middle East, where the climatic conditions can exacerbate issues related to substandard tanks, such as leaks or structural failures.

The Solution: To ensure the quality of septic tanks, buyers should conduct thorough due diligence on potential suppliers. This includes checking for reviews, testimonials, and case studies from previous clients. Buyers can also request samples or detailed product specifications to assess the materials and construction methods used. Engaging with suppliers that have a proven track record in the industry, particularly those with recognized certifications (like ISO or local equivalents), can further mitigate risks. Additionally, consider establishing a trial order to test the product’s performance before committing to larger purchases.

Scenario 3: Challenges in Logistics and Timely Delivery

The Problem: Timely delivery of septic tanks is critical for maintaining project schedules, yet logistics issues often plague international buyers. Delays in shipping can arise from various factors, including customs clearance, transportation strikes, or suppliers’ inventory mismanagement. For instance, a construction project in a remote area of Africa may face significant delays if septic tanks do not arrive on schedule, jeopardizing the entire timeline.

The Solution: To mitigate logistics challenges, B2B buyers should establish clear communication channels with their suppliers regarding delivery timelines and potential risks. It is advisable to inquire about the supplier’s logistics capabilities and their experience with international shipping. Buyers should also consider working with suppliers that offer comprehensive tracking systems, allowing them to monitor shipments in real-time. Additionally, planning for contingencies by ordering tanks well in advance of the installation date can provide a buffer against unexpected delays. Finally, fostering a partnership with local logistics firms can enhance the efficiency of the supply chain and ensure that products reach their destination without undue delay.

Strategic Material Selection Guide for septic tank suppliers near me

What are the Common Materials Used in Septic Tanks and Their Properties?

When selecting materials for septic tanks, suppliers must consider various factors, including durability, cost, and compliance with international standards. The following analysis highlights four common materials used in septic tank manufacturing: concrete, polyethylene, fiberglass, and steel.

How Does Concrete Perform as a Septic Tank Material?

Concrete is a traditional choice for septic tanks due to its strength and durability. It can withstand high pressure and temperature variations, making it suitable for various environmental conditions. Concrete tanks are resistant to corrosion and can last for decades with proper maintenance. However, they can be heavy and require significant labor for installation, which can increase overall costs.

The primary advantage of concrete is its robustness and longevity. However, it is prone to cracking if not properly installed or maintained, which can lead to leaks. For international buyers, especially in regions with stringent building codes like Germany, compliance with local standards such as DIN is crucial. Concrete septic tanks are also often preferred in rural areas of Africa and South America due to their availability and cost-effectiveness.

What Benefits Does Polyethylene Offer for Septic Tanks?

Polyethylene is a lightweight, corrosion-resistant plastic that has gained popularity in septic tank manufacturing. Its resistance to chemicals and ease of installation make it an appealing option for many suppliers. Polyethylene tanks are also less prone to cracking compared to concrete, which enhances their durability.

The main advantage of polyethylene is its cost-effectiveness and ease of transport. However, it may not be suitable for areas with extreme temperature fluctuations, as it can become brittle in cold conditions. International buyers should ensure that the polyethylene tanks meet compliance standards such as ASTM F794. This material is increasingly favored in the Middle East, where lightweight options are advantageous for transportation and installation.

Why Choose Fiberglass for Septic Tanks?

Fiberglass septic tanks are known for their lightweight and strength. They are resistant to corrosion and can be molded into various shapes, making them versatile for different applications. Fiberglass tanks are also less likely to crack under stress, providing a reliable option for long-term use.

The key advantage of fiberglass is its resistance to environmental factors, which makes it suitable for various climates. However, the manufacturing process can be more complex and costly than other materials. For B2B buyers in Europe, ensuring that fiberglass tanks comply with relevant standards, such as EN 12566, is essential for market acceptance. Countries like Germany have specific regulations regarding the use of fiberglass in construction.

What Role Does Steel Play in Septic Tank Construction?

Steel septic tanks are less common but are used in specific applications requiring high strength and durability. They are resistant to impact and can handle heavy loads, making them suitable for industrial applications. However, steel is susceptible to corrosion, which necessitates protective coatings to prolong its lifespan.

The primary advantage of steel is its strength and ability to withstand extreme conditions. On the downside, the risk of rust and corrosion can lead to higher maintenance costs. For international buyers, particularly in humid regions like parts of South America, selecting coated steel tanks that meet local standards is critical to ensure longevity and compliance.

Summary Table of Septic Tank Materials

| Material | Typical Use Case for septic tank suppliers near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Concrete | Rural installations, long-term residential use | High durability and longevity | Prone to cracking without maintenance | Medium |

| Polyethylene | Residential and commercial installations | Lightweight and corrosion-resistant | May become brittle in cold climates | Low |

| Fiberglass | Versatile applications, especially in harsh climates | Resistant to environmental factors | Higher manufacturing complexity | High |

| Steel | Industrial applications requiring high strength | Excellent impact resistance | Susceptible to corrosion | Medium |

This strategic material selection guide provides essential insights for B2B buyers in the septic tank industry, enabling informed decisions tailored to their specific regional needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for septic tank suppliers near me

What Are the Main Stages in the Manufacturing Process of Septic Tanks?

The manufacturing process of septic tanks typically involves several key stages, each crucial for ensuring the final product meets quality and regulatory standards.

-

Material Preparation: The first stage involves selecting the appropriate materials, which commonly include polyethylene, fiberglass, or concrete. For plastic tanks, high-density polyethylene (HDPE) is often chosen for its durability and resistance to corrosion. In the case of concrete tanks, the raw materials must be of high quality to ensure structural integrity. This stage also includes the treatment of materials to remove impurities and enhance their performance characteristics.

-

Forming: In this stage, the prepared materials are shaped into the desired tank configurations. For polyethylene tanks, rotational molding is a common technique, allowing for the creation of seamless structures that can withstand soil pressure and liquid pressure. For concrete tanks, precast methods are typically employed, where concrete is poured into molds and allowed to cure. This process is essential for achieving the correct dimensions and structural strength.

-

Assembly: After forming, tanks may require assembly, especially if they are designed with multiple compartments or include additional features such as access ports and baffles. This stage often involves the use of adhesives, welding, or mechanical fastening to ensure that all components are securely attached and properly aligned.

-

Finishing: The final stage includes surface finishing and any required treatments to enhance the tank’s resistance to environmental factors. This may involve applying protective coatings, inspecting for any manufacturing defects, and preparing the tanks for shipping. Quality checks during this stage ensure that the tanks meet all specified standards for appearance and functionality.

How Is Quality Assurance Implemented in Septic Tank Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that septic tanks are reliable, durable, and compliant with international standards. Here are some key aspects of QA in septic tank manufacturing:

-

International Standards: Many manufacturers adhere to ISO 9001, which outlines criteria for a quality management system. Compliance with this standard demonstrates a commitment to consistent quality and customer satisfaction. Additionally, industry-specific certifications such as CE marking in Europe and API standards for certain tank types may apply.

-

Quality Control Checkpoints: Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. These include:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality standards.

– In-Process Quality Control (IPQC): Ongoing inspections during the forming and assembly stages help identify and rectify defects early in the process.

– Final Quality Control (FQC): The final inspection checks the completed tanks for any defects and verifies compliance with specifications before shipment. -

Common Testing Methods: Testing methods may include pressure testing to assess structural integrity, leak testing to ensure no fluids escape, and environmental resistance testing to evaluate durability under various conditions. Each of these tests is designed to simulate real-world conditions and ensure the tanks can perform as expected.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are several strategies to ensure confidence in supplier quality:

-

Supplier Audits: Conducting on-site audits can provide valuable insights into a supplier’s manufacturing processes and quality control measures. This includes reviewing their adherence to international standards and their internal QA processes.

-

Quality Reports: Requesting detailed quality reports that outline the results of IQC, IPQC, and FQC can give buyers a clear view of the supplier’s quality assurance practices. These reports should include data on testing methods, outcomes, and any corrective actions taken for defects.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing and quality control processes. This can be particularly important for buyers unfamiliar with local regulations or standards.

-

Certification Verification: Buyers should verify the authenticity of any certifications claimed by the supplier. This can often be done through industry associations or regulatory bodies that issue certifications.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers face unique challenges when it comes to quality control, particularly concerning compliance with different regional regulations and standards. Here are some considerations:

-

Understanding Local Regulations: Each country may have different regulations concerning septic tank manufacturing and installation. Buyers should familiarize themselves with these regulations to ensure that the products meet local compliance requirements.

-

Cultural Differences in Quality Standards: Quality perceptions can vary significantly by region. What is considered acceptable in one country may not meet the standards in another. Understanding these differences is crucial for international negotiations and ensuring mutual satisfaction.

-

Logistical Challenges: Transportation and shipping can impact product quality. Buyers should discuss how suppliers manage logistics to prevent damage during shipping, especially for large or heavy septic tanks.

-

After-Sales Support: Quality assurance doesn’t end with the sale. Buyers should consider the supplier’s ability to provide after-sales support, including installation guidance and warranty services, which can be critical for long-term satisfaction.

In conclusion, understanding the manufacturing processes and quality assurance measures of septic tank suppliers is vital for B2B buyers. By focusing on these aspects, buyers can ensure they choose reliable suppliers that meet their quality and compliance expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘septic tank suppliers near me’

Introduction

Navigating the procurement of septic tanks requires a strategic approach to ensure you select the most suitable suppliers for your business needs. This guide outlines a practical checklist tailored for B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. By following these steps, you can efficiently identify and evaluate potential septic tank suppliers.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is crucial when sourcing septic tanks. Identify the size, material, and capacity you need, as well as any special features such as dual compartments or eco-friendly options. This clarity will help you communicate effectively with suppliers and ensure they can meet your expectations.

Step 2: Research Local Regulations and Standards

Each region has its own regulations regarding septic tank installations and operations. Familiarize yourself with local building codes, environmental regulations, and any certifications required for septic tanks. This knowledge is essential to ensure compliance and avoid potential legal issues down the line.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, financial stability reports, and references from existing clients, especially those in similar industries or regions. This vetting process ensures that the supplier has a proven track record and can deliver quality products consistently.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers hold relevant certifications, such as IAPMO or ANSI/NSF approvals. These certifications indicate compliance with industry standards for safety and quality. Additionally, inquire about any awards or recognitions the supplier has received, which can further validate their credibility.

Step 5: Assess Manufacturing Capabilities

Investigate the supplier’s manufacturing processes and capabilities. Understanding their production capacity, technology used, and materials sourcing can help you gauge their ability to meet your demands. Look for suppliers who use advanced techniques and offer customization options to better suit your specific needs.

Step 6: Request Samples and Product Demos

Before making a large purchase, request samples or arrange for product demonstrations. This step allows you to inspect the quality of the septic tanks firsthand and assess their suitability for your projects. It also gives you an opportunity to ask questions about maintenance and installation processes.

Step 7: Negotiate Terms and Conditions

Once you’ve identified a preferred supplier, engage in negotiations regarding pricing, delivery times, and warranty terms. Ensure that all agreements are documented clearly to prevent misunderstandings later. A well-negotiated contract will safeguard your interests and foster a better working relationship with the supplier.

By following this checklist, you can streamline your sourcing process for septic tanks, making informed decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for septic tank suppliers near me Sourcing

What Are the Key Cost Components for Septic Tank Suppliers?

When sourcing septic tanks, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. Common materials such as polyethylene, concrete, and fiberglass each have different cost implications. For instance, polyethylene tanks are typically lighter and easier to install, which may reduce logistics costs.

-

Labor: Labor costs can vary depending on the complexity of the tank design and the manufacturing process. Customizations often require skilled labor, which can increase overall costs.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, equipment maintenance, and administrative expenses. Suppliers with advanced manufacturing technologies may have lower overhead costs, allowing them to offer competitive pricing.

-

Tooling: Custom molds or tools for unique tank designs can be a significant upfront cost. Buyers should consider whether they need standard tanks or customized solutions.

-

Quality Control (QC): Implementing stringent QC processes ensures product reliability and compliance with local regulations. However, this adds to the overall production cost, which is reflected in the final price.

-

Logistics: Shipping costs can vary based on the tank size and weight, as well as the distance to the buyer. International shipping may incur additional tariffs or fees, influencing the total cost.

-

Margin: Suppliers typically apply a profit margin to cover their expenses and ensure business sustainability. This margin can vary based on market competition and supplier reputation.

How Do Pricing Influencers Affect Septic Tank Costs?

Several factors influence the pricing of septic tanks:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk purchases. Understanding the MOQ can help buyers negotiate better pricing, especially for large-scale projects.

-

Specifications and Customization: Customized tanks designed to meet specific needs may incur higher costs due to the additional labor and materials required. Buyers should weigh the need for customization against standard options.

-

Material Quality and Certifications: Tanks that meet higher quality standards or possess specific certifications (e.g., IAPMO, ANSI/NSF) typically command higher prices. Buyers should consider the long-term benefits of investing in certified products.

-

Supplier Factors: The supplier’s location, reputation, and production capacity can affect pricing. Established suppliers with a track record may charge a premium, but they often offer reliability and quality assurance.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) is essential for calculating total costs. Incoterms dictate who bears the risk and cost at different stages of the shipping process.

What Buyer Tips Can Help in Negotiating Septic Tank Prices?

B2B buyers can employ several strategies to optimize costs when sourcing septic tanks:

-

Effective Negotiation: Engage suppliers in discussions about pricing, especially if you are considering bulk orders. Leverage your commitment to long-term partnerships to negotiate better terms.

-

Assessing Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider installation, maintenance, and potential replacement costs to determine the true value of your investment.

-

Understanding Pricing Nuances for International Buyers: For buyers from Africa, South America, the Middle East, and Europe, familiarize yourself with local regulations and market conditions. Currency fluctuations and import duties can affect the final cost.

-

Requesting Multiple Quotes: Obtain quotes from several suppliers to gauge market pricing. This will provide leverage in negotiations and help identify competitive offers.

Disclaimer on Pricing

Prices for septic tanks can vary widely based on the factors mentioned above. The information provided is indicative and should be verified with suppliers for accurate and current pricing based on specific project requirements.

Illustrative image related to septic tank suppliers near me

Alternatives Analysis: Comparing septic tank suppliers near me With Other Solutions

Introduction to Alternatives for Septic Tank Suppliers

When considering wastewater management solutions, it’s essential for international B2B buyers to evaluate various options beyond traditional septic tanks. While local septic tank suppliers offer a range of products and services tailored to specific regional needs, alternative technologies can provide competitive advantages in performance, cost, and sustainability. This analysis aims to compare the conventional septic tank suppliers with other viable solutions, helping decision-makers choose the most suitable approach for their wastewater management requirements.

Comparison Table

| Comparison Aspect | Septic Tank Suppliers Near Me | Advanced Aerobic Treatment Units | Composting Toilets |

|---|---|---|---|

| Performance | Reliable for residential use; capacity varies | High efficiency; reduces pollutants significantly | Effective in low-water areas; nutrient-rich compost produced |

| Cost | Moderate initial investment; ongoing maintenance costs | Higher initial costs; potential long-term savings on maintenance | Lower initial cost; savings on water bills |

| Ease of Implementation | Requires installation by professionals; local codes apply | Complex installation; may need permits | Simple installation; minimal plumbing required |

| Maintenance | Regular pumping required; tank lifespan ~20-30 years | Requires periodic maintenance; less frequent than septic tanks | Minimal maintenance; compost needs turning |

| Best Use Case | Ideal for rural or suburban areas with sufficient land | Suitable for areas with strict environmental regulations | Excellent for eco-friendly projects and remote locations |

Detailed Breakdown of Alternatives

Advanced Aerobic Treatment Units (AATUs)

Advanced Aerobic Treatment Units are an innovative alternative to traditional septic systems. They utilize aerobic bacteria to break down waste, resulting in cleaner effluent that can be safely released into the environment or reused for irrigation. The main advantages of AATUs include their high efficiency and reduced environmental impact. However, they come with higher initial costs and require more complex installation processes, which may necessitate permits or professional installation. Maintenance is also required, though it is generally less frequent compared to conventional septic systems.

Composting Toilets

Composting toilets are an environmentally friendly alternative that can be particularly beneficial in areas with limited water access. These toilets work by breaking down waste into compost through aerobic decomposition, creating nutrient-rich material that can be used to enrich soil. They are cost-effective, as they require little water and can significantly lower water bills. Installation is straightforward, often not requiring extensive plumbing. However, their use may be limited by local regulations and cultural perceptions of waste management. Additionally, regular maintenance involves turning the compost and managing odors, which may deter some users.

Conclusion: How to Choose the Right Wastewater Management Solution

Selecting the right wastewater management solution depends on various factors, including budget, environmental considerations, and specific site conditions. For B2B buyers, understanding the advantages and limitations of septic tank suppliers, advanced aerobic treatment units, and composting toilets is crucial. Buyers should assess their unique needs, including land availability, regulatory requirements, and long-term operational costs, to make an informed decision. Engaging with experts in the field can provide further insights tailored to specific regional contexts, ultimately leading to a sustainable and efficient wastewater management strategy.

Essential Technical Properties and Trade Terminology for septic tank suppliers near me

What Are the Key Technical Properties of Septic Tanks for B2B Buyers?

When sourcing septic tanks, understanding their technical properties is crucial for ensuring compliance with local regulations and meeting specific project requirements. Here are several essential specifications that B2B buyers should consider:

-

Material Composition

Septic tanks are commonly made from materials such as polyethylene, concrete, and fiberglass. Each material has its advantages: polyethylene is lightweight and resistant to corrosion, concrete offers durability and structural integrity, while fiberglass is often favored for its resistance to chemicals. Selecting the right material is essential for ensuring longevity and performance, particularly in varying environmental conditions. -

Tank Capacity

The capacity of septic tanks can range significantly, typically from 250 gallons to over 2,500 gallons. It is vital to choose a tank size that matches the projected wastewater flow based on the number of users or connected fixtures. This capacity directly influences the effectiveness of the septic system and helps prevent overflows and backups. -

Compartment Configuration

Septic tanks can be designed as single or dual compartments. Dual-compartment tanks allow for better separation of solids and liquids, enhancing the treatment process. Understanding the configuration is essential for buyers to ensure optimal performance and adherence to local health regulations. -

Compliance Standards

Septic tanks must comply with various local, national, and international standards, including those set by organizations such as the IAPMO (International Association of Plumbing and Mechanical Officials) and NSF (National Sanitation Foundation). Buyers should verify compliance to ensure that the tanks meet safety and environmental regulations in their respective markets. -

Installation Requirements

Understanding the installation requirements, including necessary site preparations and local permitting processes, is vital. Some tanks may require specific installation techniques or additional components, such as risers for access or filters for improved effluent quality. This knowledge helps prevent costly delays and ensures a smooth installation process. -

Durability and Lifespan

The expected lifespan of a septic tank varies by material and environmental conditions. Concrete tanks generally last longer than plastic or fiberglass tanks. Buyers should assess the durability of the tank based on local soil conditions, climate, and potential exposure to corrosive substances.

What Are Common Trade Terms Used by Septic Tank Suppliers?

Familiarity with industry terminology can enhance communication and negotiation with suppliers. Here are several key terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the septic tank industry, understanding OEMs can help buyers identify reliable suppliers for specific components or systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchases effectively, especially when budgeting for large-scale projects or managing inventory. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For septic tank buyers, issuing an RFQ can help gather competitive quotes from multiple suppliers, enabling informed decision-making. -

Incoterms (International Commercial Terms)

These are internationally recognized terms that define the responsibilities of buyers and sellers regarding shipping costs, risks, and liabilities. Familiarity with Incoterms helps buyers understand their obligations and negotiate better shipping arrangements. -

Lead Time

This term refers to the amount of time it takes for a supplier to fulfill an order after it has been placed. Understanding lead times is crucial for project planning, especially in regions where wastewater management solutions are urgently needed. -

Warranty

A warranty is a promise made by the manufacturer regarding the quality and longevity of the septic tank. Buyers should evaluate warranty terms to ensure they are covered for defects and ensure the investment is protected.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing septic tanks, ensuring that they meet their specific needs while adhering to industry standards.

Navigating Market Dynamics and Sourcing Trends in the septic tank suppliers near me Sector

What Are the Key Market Dynamics and Trends Impacting Septic Tank Suppliers?

The global market for septic tanks is experiencing significant growth, driven by urbanization, increasing population, and the urgent need for effective waste management solutions. Particularly in regions such as Africa, South America, the Middle East, and Europe, where infrastructure development is accelerating, septic tank suppliers are witnessing rising demand. The trend towards decentralized wastewater treatment systems is gaining traction, as these solutions offer flexibility and reduced installation costs compared to traditional centralized systems. Additionally, technological advancements in septic tank designs and materials are enhancing efficiency and longevity, appealing to environmentally conscious buyers.

Emerging technologies such as IoT (Internet of Things) and smart monitoring systems are reshaping the sourcing landscape. B2B buyers are increasingly looking for suppliers that integrate smart technologies into their products, enabling real-time monitoring and maintenance alerts, which can significantly reduce operational costs. Furthermore, the rise of online marketplaces is transforming how buyers source septic tanks, allowing them to compare products and suppliers more efficiently, thus fostering competitive pricing.

How Can Sustainability and Ethical Sourcing Influence Septic Tank Procurement?

Sustainability is becoming a crucial factor for B2B buyers in the septic tank sector. Suppliers that prioritize environmentally friendly materials and processes not only appeal to eco-conscious clients but also align with global sustainability goals. The environmental impact of septic tanks can be significant; therefore, suppliers are increasingly adopting ‘green’ certifications, such as ISO 14001, to demonstrate their commitment to minimizing ecological footprints.

Ethical sourcing practices are equally important, especially for international buyers. Ensuring that suppliers adhere to fair labor practices and sustainable resource management is vital in maintaining a responsible supply chain. Buyers should consider suppliers that utilize recycled materials or innovative designs that reduce waste generation. The demand for sustainable septic solutions is leading to the development of new materials, such as biodegradable plastics and recycled composites, which can significantly lower the environmental impact of septic systems.

What Is the Historical Context of Septic Tank Development for Today’s B2B Buyers?

The evolution of septic tank systems dates back to the late 19th century when the need for effective sanitation solutions became paramount in rapidly urbanizing areas. Initially, septic tanks were simple underground structures designed to manage household waste. Over the decades, advancements in materials and engineering practices have transformed septic systems into sophisticated, multi-compartment tanks capable of treating wastewater efficiently.

Today, B2B buyers benefit from decades of innovation, with options ranging from traditional concrete tanks to modern plastic models that offer improved durability and ease of installation. This historical perspective emphasizes the importance of selecting suppliers that not only understand the technical aspects of septic systems but also the evolving needs of the market, ensuring that they can provide reliable and innovative solutions tailored to specific regional requirements.

In conclusion, understanding the dynamics of the septic tank market, the importance of sustainability, and the historical context of septic systems can significantly enhance the decision-making process for international B2B buyers. By aligning with suppliers that prioritize innovation and ethical practices, buyers can ensure that their procurement strategies contribute to both operational efficiency and environmental responsibility.

Frequently Asked Questions (FAQs) for B2B Buyers of septic tank suppliers near me

-

How do I determine the right septic tank size for my needs?

To determine the appropriate septic tank size, consider factors such as the number of users, the daily water usage, and local regulations. Generally, a 1,000-gallon tank is suitable for a household of 3-4 people, while larger families or commercial operations may require tanks exceeding 1,500 gallons. Consulting with local suppliers can provide insights into community standards and regulations, ensuring compliance and optimal performance. -

What are the most common materials used in septic tank manufacturing?

Septic tanks are typically made from materials such as concrete, fiberglass, and polyethylene. Concrete tanks are durable and widely used in residential applications, while fiberglass tanks are lighter and resistant to corrosion. Polyethylene tanks are also popular due to their lightweight nature and resistance to rust. Each material has its advantages, so consider your specific installation conditions, budget, and local regulations when making a choice. -

What customization options are available for septic tanks?

Many suppliers offer customization options, including tank size, compartment design, and access features. You can specify additional features like risers for easy access, baffles for better waste management, and specific inlet/outlet configurations. When discussing your needs with suppliers, clearly outline your requirements to ensure that the final product meets your operational and regulatory standards. -

What is the typical minimum order quantity (MOQ) for septic tanks?

The minimum order quantity (MOQ) for septic tanks can vary significantly among suppliers. Some may allow single-unit purchases, especially for small-scale projects or first-time buyers, while others may require larger quantities to benefit from competitive pricing. It’s advisable to inquire directly with suppliers about their MOQ policies to assess how they align with your purchasing needs. -

What payment terms should I expect when ordering septic tanks internationally?

Payment terms can vary by supplier and region but typically include options such as wire transfers, letters of credit, or payment upon delivery. Some suppliers may require a deposit upfront, especially for customized orders. It’s crucial to clarify these terms before finalizing your order to avoid misunderstandings and ensure smooth transactions. -

How can I verify the quality and compliance of septic tanks from suppliers?

To verify quality and compliance, request certifications and test results that demonstrate adherence to local and international standards (e.g., IAPMO, NSF). Check for customer testimonials and reviews to gauge supplier reliability. Conducting a factory visit or utilizing third-party inspection services can further ensure that the tanks meet your quality expectations and regulatory requirements. -

What logistical considerations should I keep in mind when sourcing septic tanks?

Logistical considerations include shipping methods, delivery times, and import regulations in your country. Ensure that the supplier can provide reliable shipping options that align with your project timelines. Additionally, be aware of customs duties and any specific documentation required for importing septic tanks to avoid delays upon arrival. -

What after-sales support can I expect from septic tank suppliers?

After-sales support can include installation guidance, maintenance recommendations, and warranty services. Many suppliers offer technical support to help with installation and troubleshooting. Always inquire about the extent of after-sales support before purchasing, as this can significantly affect your experience and the longevity of your septic system.

Top 3 Septic Tank Suppliers Near Me Manufacturers & Suppliers List

1. Septic Solutions – Septic Air Pumps

Domain: septicsolutions.com

Registered: 2003 (22 years)

Introduction: Septic Solutions offers a wide range of septic system parts and supplies, including:

1. **Septic Air Pumps**: Various models including Hiblow, Gast, Cyclone, Thomas, Medo, Secoh, and Alita air pumps, along with refurbished options and dual port regenerative blowers.

2. **Septic Aerators**: Products like the SepAerator® and alternative aerators for different septic systems.

3. **Replacement Parts*…

2. Garett Precast – Concrete Septic Solutions

Domain: garrettprecast.com

Registered: 2023 (2 years)

Introduction: Concrete septic tanks, septic tank lids, septic tank risers, concrete distribution boxes, lift stations, concrete grease trap tanks, concrete parking stops, Infiltrator products (IM-1530, IM-1060, IM-540 septic tanks), Eco Filter Pump Vault, Ecopod commercial and advanced wastewater treatment units, Enviro-Aire advanced wastewater treatment unit, Spec-Check Enviro-Septic, Advanced Enviro-Septic, A…

3. Septic Systems of Maine – Leaching & Pre-Treatment Solutions

Domain: septicsystemsofmaine.com

Registered: 2017 (8 years)

Introduction: Leaching Systems: AeroFin ™, Advanced Enviro-Septic®, Enviro-Septic® Leaching System, Multi-Level Leaching System; Pre-Treatment Systems: Delta Commercial Wastewater Treatment Systems, Delta Residential; Ecopod Systems; Aquaworx Remediator; ECOFILTER; Pump Vault; The Presby Maze®; Infiltrator Plastic Tanks and Accessories; Plastic Septic Tanks; Potable Water Tanks; Tank Risers; Safety Star Vent Co…

Strategic Sourcing Conclusion and Outlook for septic tank suppliers near me

In conclusion, the strategic sourcing of septic tanks is essential for B2B buyers looking to ensure compliance, quality, and sustainability in their wastewater management solutions. By identifying reliable suppliers that adhere to international standards and regional regulations, businesses can mitigate risks and enhance operational efficiency. The growing demand for eco-friendly and cost-effective septic systems presents a significant opportunity for international buyers, particularly in emerging markets in Africa, South America, the Middle East, and Europe.

As you explore suppliers near you, consider leveraging local expertise and established relationships to facilitate smoother transactions and logistics. Engaging with manufacturers that offer a diverse range of products—from traditional concrete tanks to innovative plastic solutions—can also provide flexibility in meeting specific project needs.

Looking ahead, it is vital for B2B buyers to stay informed about advancements in septic technology and regulatory changes that may affect sourcing decisions. By prioritizing strategic partnerships and innovative solutions, your organization can position itself for success in the evolving landscape of wastewater management. Take the next step today—connect with reputable septic tank suppliers and enhance your sourcing strategy for a more sustainable future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.