How to Source Semi Concealed Hinges For Cabinets Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for semi concealed hinges for cabinets

In the fast-evolving global market for semi concealed hinges for cabinets, international B2B buyers face the pressing challenge of sourcing quality hardware that meets diverse regional demands. The intricacies of selecting the right hinges extend beyond mere aesthetics; they encompass functionality, durability, and compatibility with various cabinet styles. This comprehensive guide is designed to empower buyers by delving into the myriad types of semi concealed hinges, their applications across different industries, and the essential factors to consider during supplier vetting.

As you navigate through this resource, you will gain insights into the latest trends and innovations in hinge technology, as well as a thorough understanding of pricing structures and cost considerations. By addressing the specific needs of markets in Africa, South America, the Middle East, and Europe—including key players like Nigeria and Vietnam—this guide aims to facilitate informed purchasing decisions that align with local preferences and standards.

Equipped with actionable insights and expert recommendations, you will be better positioned to enhance your procurement strategy, ensuring that your projects benefit from high-quality, reliable hardware solutions. Whether you are a manufacturer, contractor, or retailer, understanding the global landscape of semi concealed hinges is crucial to maintaining a competitive edge in today’s dynamic market.

Understanding semi concealed hinges for cabinets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 1/2″ Inset Semi-Concealed Hinge | Fits flush with cabinet frame, minimal visibility | Kitchen cabinets, custom furniture | Pros: Seamless look, durable. Cons: Limited adjustability. |

| Variable Overlay Semi-Concealed Hinge | Adjustable overlay for various door thicknesses | Commercial cabinetry, office furniture | Pros: Versatile fit, easy installation. Cons: May require precise measurements. |

| 3/8″ Inset Self-Closing Hinge | Automatically closes doors, compact design | Residential kitchens, retail displays | Pros: Enhanced convenience, space-saving. Cons: Higher cost compared to non-self-closing options. |

| 1/4″ Overlay Double Demountable Hinge | Allows for easy removal of doors, flexible design | Modular cabinetry, temporary setups | Pros: Easy maintenance, adaptable. Cons: May be less stable for heavy doors. |

| Heavy-Duty Semi-Concealed Hinge | Reinforced materials for high weight capacity | Industrial cabinets, heavy-duty furniture | Pros: Exceptional strength, long lifespan. Cons: Bulkier design may not suit all aesthetics. |

What Are the Characteristics of the 1/2″ Inset Semi-Concealed Hinge?

The 1/2″ inset semi-concealed hinge is designed to fit flush with the cabinet frame, providing a sleek and minimalistic appearance. This type is ideal for kitchen cabinets and custom furniture where aesthetics are paramount. B2B buyers should consider the durability of the materials used, as this hinge needs to withstand frequent use. Its limited adjustability is a consideration, especially in projects requiring precise alignments.

Why Choose a Variable Overlay Semi-Concealed Hinge?

Variable overlay semi-concealed hinges offer the flexibility of adjusting the overlay to accommodate various door thicknesses, making them suitable for commercial cabinetry and office furniture. Their ease of installation is a significant advantage for contractors and designers, allowing for quicker project turnaround. However, precise measurements are crucial to ensure a proper fit, which can be a potential drawback if not handled correctly.

What Benefits Do 3/8″ Inset Self-Closing Hinges Provide?

The 3/8″ inset self-closing hinge features a mechanism that automatically closes the cabinet door, promoting convenience and efficiency in residential kitchens and retail displays. This hinge’s compact design is advantageous in space-constrained environments. While it offers enhanced functionality, buyers should weigh the higher initial cost against the long-term benefits of reduced wear and tear on cabinetry.

How Does the 1/4″ Overlay Double Demountable Hinge Work?

The 1/4″ overlay double demountable hinge is designed for easy removal of cabinet doors, making it a practical choice for modular cabinetry and temporary setups. Its flexible design allows for straightforward maintenance and adjustments, appealing to B2B buyers involved in modular furniture solutions. However, its adaptability may come at the cost of stability for heavier doors, which should be taken into account during selection.

What Makes Heavy-Duty Semi-Concealed Hinges Unique?

Heavy-duty semi-concealed hinges are constructed from reinforced materials, providing exceptional strength suitable for industrial cabinets and heavy-duty furniture. Their long lifespan is a significant selling point for B2B buyers looking for reliable solutions in demanding environments. However, the bulkier design may not suit all aesthetic preferences, making it essential for buyers to consider the visual impact alongside functionality.

Key Industrial Applications of semi concealed hinges for cabinets

| Industry/Sector | Specific Application of semi concealed hinges for cabinets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Used in the assembly of cabinets and furniture pieces | Enhances aesthetic appeal while providing functionality | Durability, weight capacity, and finish options |

| Hospitality | Application in hotel room cabinets and storage solutions | Improves guest experience through sleek design | Reliability, ease of installation, and maintenance |

| Retail | Utilized in display cabinets and shelving units | Maximizes space while maintaining visual appeal | Customization options and compatibility with existing fixtures |

| Commercial Construction | Essential for built-in cabinetry in offices | Supports efficient use of space and modern design | Compliance with building codes and safety standards |

| Kitchen Remodeling | Installed in residential kitchen cabinets | Facilitates smooth operation and enhances usability | Variety in overlay types and self-closing features |

How are Semi Concealed Hinges Used in Furniture Manufacturing?

In the furniture manufacturing industry, semi concealed hinges are integral to the assembly of cabinets and other furniture pieces. They provide a clean, modern look by minimizing the visibility of the hinge while allowing for smooth door operation. This application solves the problem of bulky, exposed hardware that can detract from design aesthetics. Buyers in this sector should prioritize durability and weight capacity, ensuring that the hinges can support the functionality of larger furniture items, especially in markets like Africa and South America where durability is crucial.

What Role do Semi Concealed Hinges Play in the Hospitality Sector?

In the hospitality sector, semi concealed hinges are commonly found in hotel room cabinets and storage solutions. Their design not only enhances the aesthetic appeal of guest rooms but also ensures a quiet and smooth operation, improving the overall guest experience. The key considerations for procurement include the reliability of the hinges, ease of installation, and low maintenance requirements, as hotels often seek long-lasting solutions that can withstand frequent use. This is particularly important in regions like the Middle East, where luxury hospitality is a growing market.

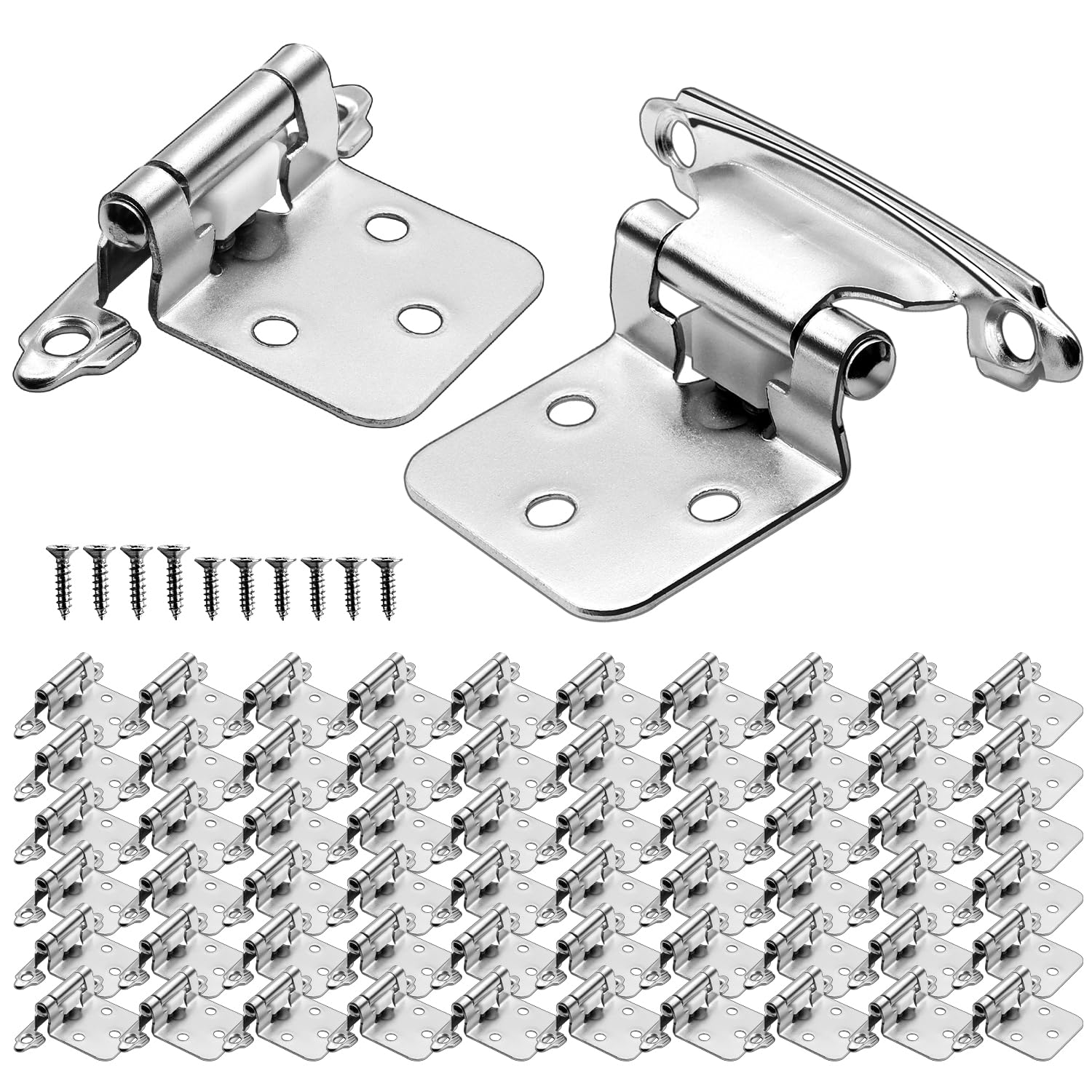

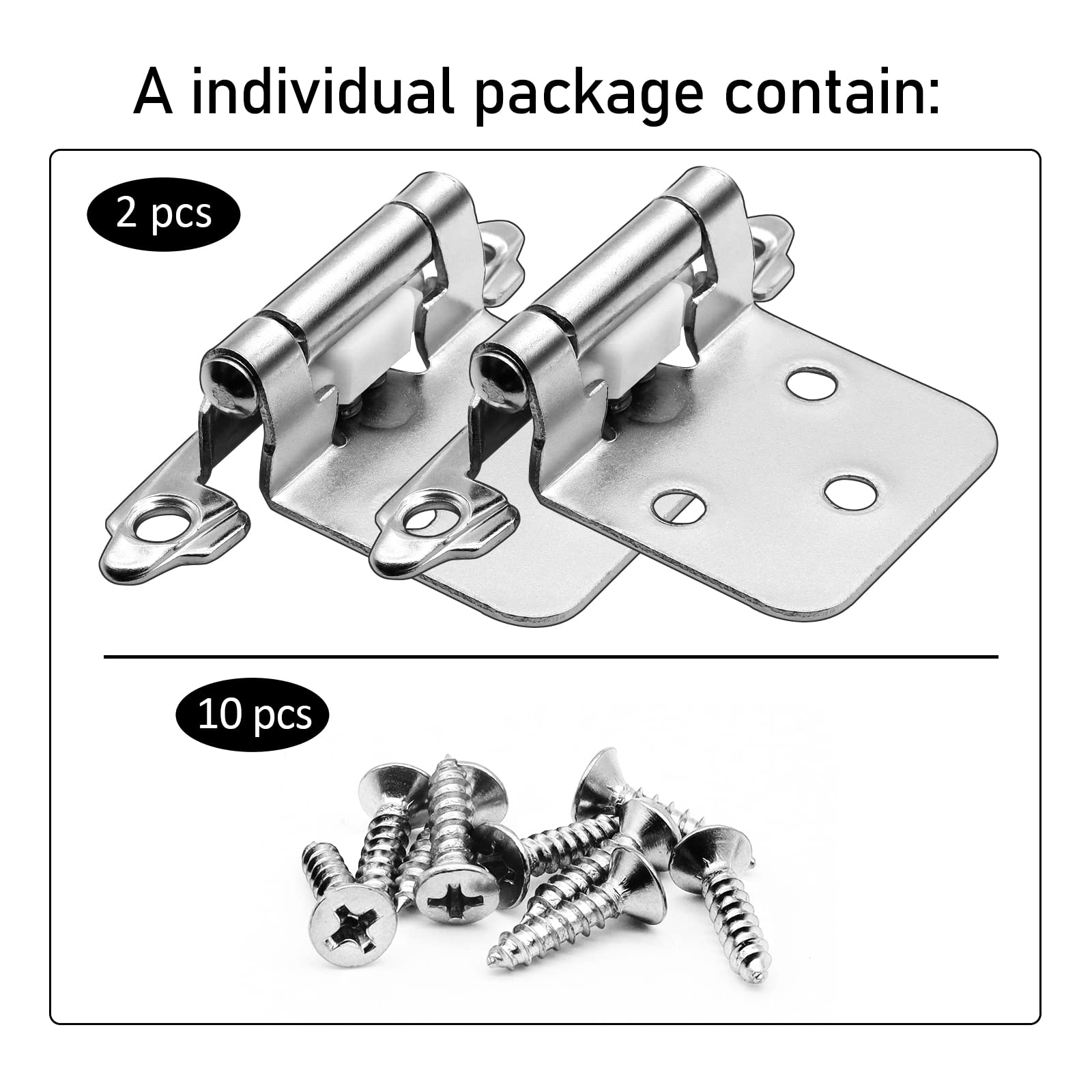

Illustrative image related to semi concealed hinges for cabinets

How are Semi Concealed Hinges Beneficial for Retail Applications?

Retail environments utilize semi concealed hinges in display cabinets and shelving units to maximize space while maintaining a visually appealing presentation of merchandise. The use of these hinges allows for a seamless look that can attract customers and enhance the shopping experience. Retail buyers should focus on customization options, ensuring that the hinges can be tailored to fit various display designs and are compatible with existing fixtures. In regions like Europe, where retail competition is fierce, the aesthetic and functional benefits of these hinges can significantly influence customer engagement.

What is the Importance of Semi Concealed Hinges in Commercial Construction?

In commercial construction, semi concealed hinges are essential for built-in cabinetry found in offices and other professional environments. They support efficient use of space while contributing to a modern, polished design that can impress clients and employees alike. When sourcing these hinges, businesses must consider compliance with building codes and safety standards, especially in regions with stringent regulations. This is crucial for international buyers who need to navigate diverse compliance landscapes, particularly in developing markets.

How do Semi Concealed Hinges Enhance Kitchen Remodeling Projects?

For kitchen remodeling projects, semi concealed hinges are increasingly favored for their ability to facilitate smooth door operation while enhancing usability. They are particularly useful in creating a streamlined look in modern kitchens, where aesthetics are paramount. Buyers in this sector should consider the variety of overlay types available and the benefits of self-closing features, which add convenience and safety. As home improvement trends continue to rise in various global markets, including Nigeria and Vietnam, the demand for such functional yet stylish hardware is expected to grow.

3 Common User Pain Points for ‘semi concealed hinges for cabinets’ & Their Solutions

Scenario 1: Difficulty in Matching Hinges with Cabinet Designs

The Problem: One of the most pressing challenges B2B buyers face is the compatibility of semi-concealed hinges with existing cabinet designs. Buyers often encounter cabinets that have unique dimensions or finishes, making it difficult to find hinges that not only fit properly but also maintain the aesthetic appeal of the furniture. This mismatch can lead to increased costs due to returns and delays in project timelines, impacting both customer satisfaction and overall profitability.

The Solution: To effectively address this issue, buyers should conduct a thorough analysis of the cabinet specifications before selecting hinges. Utilize detailed measurements of the cabinet frames and doors, including overlay and inset dimensions. Engaging with suppliers who offer customizable solutions or a wide range of finishes can also provide an edge. Buyers should prioritize suppliers that provide detailed product specifications and samples, enabling them to test compatibility before making bulk purchases. Additionally, leveraging CAD software can help visualize how different hinge styles will look on various cabinet designs, ensuring a perfect fit and finish.

Illustrative image related to semi concealed hinges for cabinets

Scenario 2: Challenges in Installation and Adjustability

The Problem: Many B2B buyers experience difficulties during the installation of semi-concealed hinges, particularly regarding their adjustability. Incorrect alignment can lead to doors that do not open or close smoothly, compromising functionality and user experience. This issue is often exacerbated when multiple hinges are involved, leading to inconsistencies in door positioning. The time and labor required to rectify these issues can significantly inflate project costs.

The Solution: To minimize installation challenges, buyers should select semi-concealed hinges known for their ease of adjustability. Look for hinges that feature built-in adjustment mechanisms, allowing for simple tweaks post-installation. Providing comprehensive training to installation teams on the correct methods and tools for hinge installation is crucial. Consider creating a detailed installation guide, perhaps even incorporating video tutorials, to standardize processes across different teams. Lastly, establishing a good relationship with suppliers who offer technical support can be invaluable for resolving any installation-related queries swiftly.

Scenario 3: Lack of Information on Compliance and Standards

The Problem: B2B buyers often find themselves navigating a complex landscape of building codes and safety standards when sourcing semi-concealed hinges. In regions like Africa and South America, where regulations can vary widely, the lack of clear information can lead to costly mistakes, including non-compliance penalties or the need for expensive retrofits. This uncertainty can deter businesses from making significant investments in cabinetry, impacting their growth and profitability.

The Solution: To mitigate compliance risks, buyers should invest time in understanding local regulations and industry standards related to cabinet hardware. Engaging with local industry associations or regulatory bodies can provide insights into the necessary standards for hinges. Additionally, working with suppliers who are knowledgeable about compliance requirements can streamline this process. Buyers should also consider sourcing hinges that come with certifications or compliance documentation, ensuring they meet the required safety and quality standards. Developing a checklist of compliance requirements specific to their market can further aid in sourcing decisions, ensuring peace of mind and adherence to necessary regulations.

Strategic Material Selection Guide for semi concealed hinges for cabinets

What Are the Key Materials Used for Semi-Concealed Hinges in Cabinet Applications?

In the realm of semi-concealed hinges for cabinets, the choice of material significantly influences performance, durability, and overall cost-effectiveness. Below, we analyze four common materials used in the manufacturing of these hinges, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Steel Perform as a Material for Semi-Concealed Hinges?

Steel, particularly stainless steel, is a popular choice for semi-concealed hinges due to its strength and durability. Stainless steel offers excellent corrosion resistance, making it suitable for environments with high humidity or exposure to moisture, such as kitchens and bathrooms. It can withstand significant weight and pressure, ensuring reliable performance over time.

Pros: Steel hinges are robust and can support heavy cabinet doors without bending or breaking. They are also relatively affordable compared to other materials, making them a cost-effective choice for bulk purchases.

Cons: While stainless steel is resistant to rust, it can still corrode under certain conditions, especially if the surface is scratched. Additionally, the manufacturing process can be complex, leading to higher production costs for custom designs.

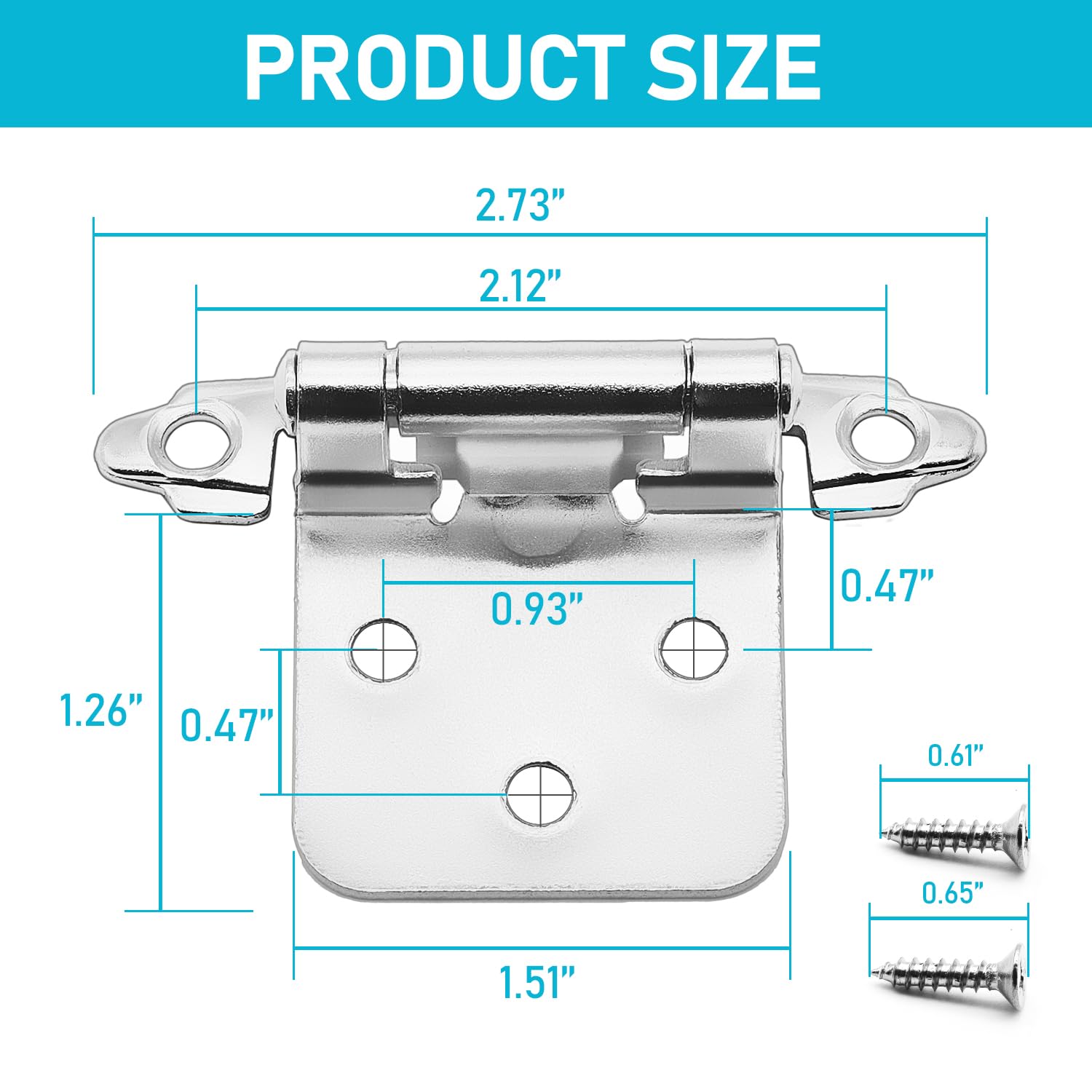

Illustrative image related to semi concealed hinges for cabinets

For international buyers, compliance with standards such as ASTM A240 for stainless steel is crucial. Buyers in regions like Africa and South America may also need to consider local sourcing options to reduce lead times and costs.

Why Choose Brass for Semi-Concealed Hinges?

Brass is another common material for semi-concealed hinges, known for its aesthetic appeal and resistance to corrosion. Its natural anti-bacterial properties make it suitable for applications in healthcare settings or kitchens.

Pros: Brass hinges provide a classic look, often preferred in high-end cabinetry. They are resistant to tarnishing and corrosion, which enhances their longevity.

Cons: Brass is generally more expensive than steel and can be less durable under heavy loads. Over time, brass may require polishing to maintain its appearance, which can add to maintenance costs.

International buyers should be aware of the varying quality of brass available in the market. Compliance with standards such as ASTM B36 is essential to ensure quality and performance.

Illustrative image related to semi concealed hinges for cabinets

What Are the Benefits of Using Plastic or Polymer Materials?

Plastic or polymer hinges are increasingly popular in specific applications due to their lightweight nature and resistance to corrosion. These materials are often used in environments where moisture exposure is a concern.

Pros: Plastic hinges are lightweight, which makes them easy to install and handle. They are also resistant to rust and corrosion, making them suitable for outdoor or humid environments.

Cons: While they are cost-effective, plastic hinges may not offer the same strength and durability as metal options. They can also be less aesthetically pleasing, which may not meet the design expectations of high-end cabinetry.

For B2B buyers, understanding the specific type of plastic used (e.g., nylon, polycarbonate) is crucial, as different plastics have varying temperature and pressure ratings. Compliance with international standards like ISO 9001 can also ensure product quality.

How Does Aluminum Compare as a Material for Hinges?

Aluminum is gaining traction in the hinge market due to its lightweight and corrosion-resistant properties. It is particularly useful in applications requiring frequent movement or exposure to the elements.

Pros: Aluminum hinges are lightweight and easy to install. They also resist corrosion, making them suitable for outdoor applications or humid environments.

Cons: Aluminum is generally less durable than stainless steel and may not support as much weight. It can also be more expensive than plastic options.

International buyers should consider the specific alloy used in aluminum hinges, as this can impact strength and performance. Compliance with standards such as ASTM B221 for aluminum extrusions is important for ensuring quality.

Summary Table of Materials for Semi-Concealed Hinges

| Material | Typical Use Case for Semi Concealed Hinges for Cabinets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty cabinetry in kitchens and bathrooms | High strength and durability | Susceptible to corrosion if scratched | Medium |

| Brass | High-end cabinetry and decorative applications | Aesthetic appeal and corrosion resistance | Higher cost and requires maintenance | High |

| Plastic | Moisture-prone environments, lightweight applications | Lightweight and corrosion-resistant | Less durable than metal options | Low |

| Aluminum | Outdoor or frequently used cabinets | Lightweight and corrosion-resistant | Less durable than steel | Medium |

This analysis provides a comprehensive overview of the materials used in semi-concealed hinges, helping B2B buyers make informed decisions based on performance, cost, and application suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for semi concealed hinges for cabinets

What Are the Key Stages in the Manufacturing Process of Semi-Concealed Hinges for Cabinets?

The manufacturing of semi-concealed hinges for cabinets involves several key stages, each essential for ensuring the quality and performance of the final product. Understanding these stages can empower B2B buyers to make informed decisions when selecting suppliers.

How is Material Prepared for Semi-Concealed Hinges?

The first step in the manufacturing process is material preparation. High-quality materials, typically stainless steel, brass, or zinc alloy, are selected for their durability and resistance to corrosion. The raw materials undergo thorough inspections to ensure they meet industry specifications.

Once the materials are approved, they are cut into specific dimensions based on the design requirements. This can involve processes like shearing or laser cutting, which provide precision and reduce waste. Buyers should inquire about the sourcing of materials and whether suppliers have certifications that guarantee material quality.

What Forming Techniques Are Used in the Production of Hinges?

Forming is the next critical stage, where the cut materials are shaped into the hinge components. Techniques such as stamping, forging, or CNC machining are commonly employed. Stamping is especially prevalent due to its efficiency and ability to produce high volumes of parts with consistent quality.

During this stage, manufacturers may also incorporate advanced technologies like robotic arms for automation, enhancing precision and reducing human error. Buyers should look for suppliers that utilize modern forming techniques, as this can significantly impact the hinge’s performance and longevity.

How Are Semi-Concealed Hinges Assembled?

After forming, the components are assembled. This process typically includes attaching the hinge arms, springs, and mounting plates. Some manufacturers use automated assembly lines, while others may rely on skilled labor for more intricate designs.

A key consideration for buyers is whether the assembly process allows for customization. Many suppliers offer options for bespoke designs that cater to specific customer needs, which can be particularly advantageous in international markets where preferences vary widely.

What Finishing Techniques Are Essential for Quality Semi-Concealed Hinges?

Finishing processes play a vital role in enhancing the aesthetic appeal and durability of hinges. Common finishing techniques include electroplating, powder coating, and anodizing, which provide a protective layer against corrosion and wear.

Electroplating is particularly popular for achieving a polished look while adding a layer of protection. Buyers should ask suppliers about the specific finishing techniques used and any certifications related to environmental compliance, especially if they are sourcing from regions with strict regulations.

What Quality Assurance Standards Should B2B Buyers Expect?

Quality assurance (QA) is paramount in the production of semi-concealed hinges, ensuring that products meet both safety and performance standards. B2B buyers should familiarize themselves with international and industry-specific standards that suppliers should adhere to.

Which International Standards Are Relevant for Manufacturing Hinges?

ISO 9001 is a widely recognized standard for quality management systems, applicable across various industries, including hardware manufacturing. Compliance with this standard indicates that the supplier has established processes for consistent quality control.

Additionally, CE marking is essential for products sold within the European Economic Area, demonstrating compliance with health, safety, and environmental protection standards. Buyers should verify that their suppliers have the necessary certifications and understand the implications of these standards on product quality.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are critical at various stages of production. These typically include:

- Incoming Quality Control (IQC): This involves the inspection of raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): This stage includes monitoring the manufacturing process to detect defects in real-time, allowing for immediate corrective actions.

- Final Quality Control (FQC): After assembly, finished products undergo thorough inspections, including functional testing and visual checks, before being packaged.

B2B buyers should seek suppliers that have robust QC processes in place, as this can significantly reduce the risk of defects and returns.

How Can Buyers Verify Supplier Quality Assurance Practices?

For international buyers, verifying a supplier’s quality assurance practices is essential. Here are several methods to ensure that suppliers adhere to the necessary quality standards:

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess quality assurance practices. These audits can be scheduled or unscheduled, providing insights into the supplier’s operational processes, compliance with standards, and overall quality culture.

During an audit, buyers should focus on the effectiveness of the supplier’s quality management systems, employee training programs, and adherence to safety protocols.

How Can Third-Party Inspections Enhance Trust?

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct inspections at various stages of production and provide unbiased reports on quality compliance.

Buyers in regions like Africa and South America, where manufacturing standards may vary, can particularly benefit from third-party inspections to ensure that suppliers meet international quality benchmarks.

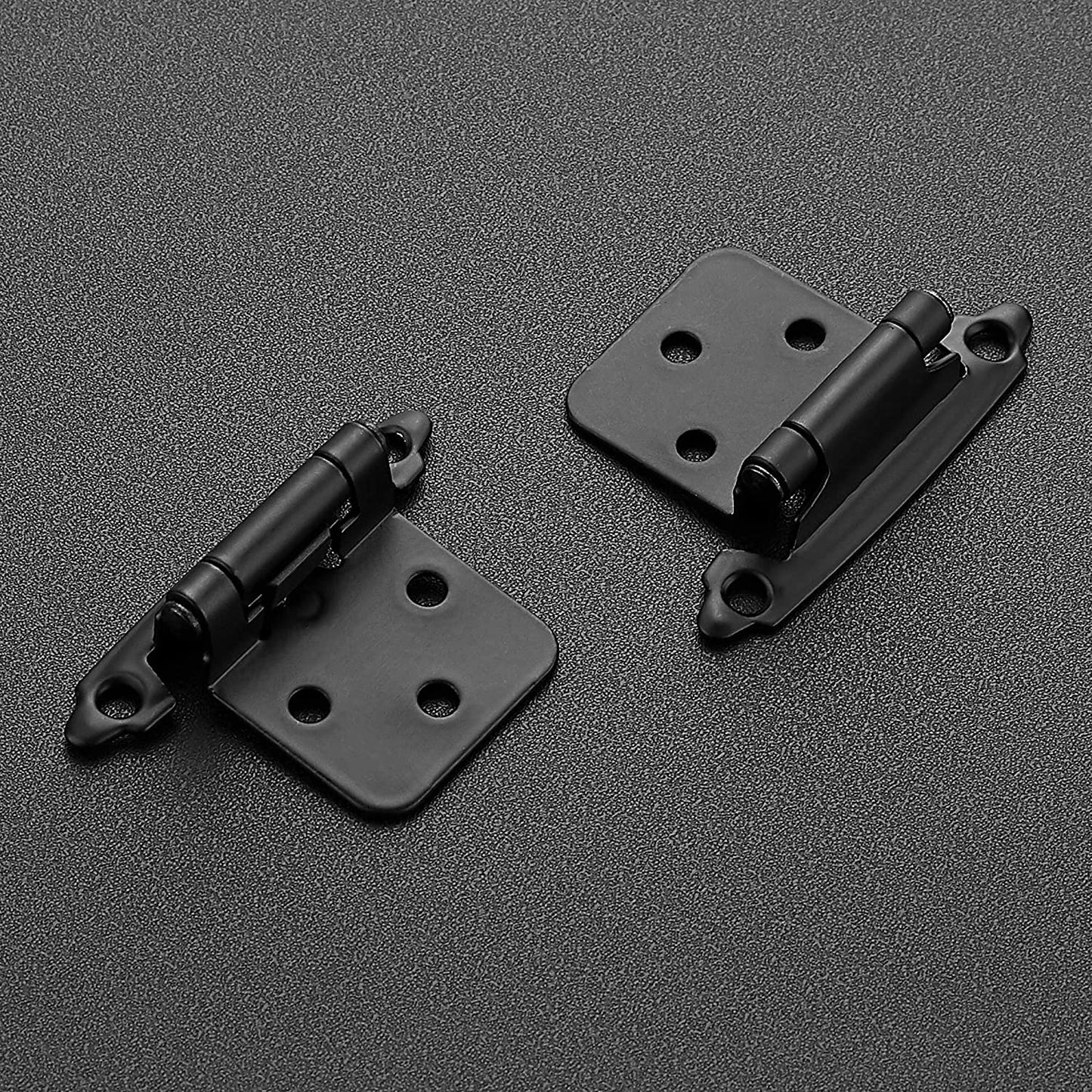

Illustrative image related to semi concealed hinges for cabinets

What Documentation Should Buyers Request?

Buyers should request documentation from suppliers that includes quality control reports, certifications, and testing results. Regular updates on quality metrics and any corrective actions taken for defects should also be documented and shared with clients.

In summary, understanding the manufacturing processes and quality assurance standards for semi-concealed hinges can significantly enhance the purchasing decisions of B2B buyers. By focusing on material preparation, forming techniques, assembly, finishing, and rigorous quality control practices, buyers can ensure they source reliable and high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘semi concealed hinges for cabinets’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure semi-concealed hinges for cabinets. Selecting the right hinges is crucial not only for the aesthetic appeal of cabinetry but also for the functional longevity of the installations. By following this checklist, buyers can ensure they source high-quality products that meet their specific needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements for the hinges. Consider factors such as the type of cabinet (face frame or frameless), overlay specifications, and the desired materials and finishes.

– Overlay Types: Identify whether you need variable, full, or partial overlays.

– Material Choices: Decide on materials like stainless steel, brass, or nickel, which can affect durability and appearance.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in semi-concealed hinges. Look for companies that have a proven track record in your target markets, particularly in regions such as Africa, South America, the Middle East, and Europe.

– Supplier Reviews: Check online reviews and ratings on platforms like Google, Trustpilot, or industry-specific forums.

– Case Studies: Request case studies or testimonials that showcase their experience with similar projects.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications and adhere to industry standards. Certifications can indicate quality assurance and compliance with international regulations.

– ISO Certifications: Look for ISO 9001 or similar quality management standards.

– Sustainability Certifications: If important to your brand, check for eco-labels that reflect environmental responsibility.

Step 4: Request Samples for Quality Assessment

Before making a bulk order, request samples of the hinges to assess their quality firsthand. This step allows you to evaluate the hinge’s functionality, finish, and construction.

– Testing Functionality: Check for smooth operation, weight tolerance, and self-closing features.

– Finish Quality: Inspect the finish for consistency and resistance to wear and tear.

Step 5: Compare Pricing and Terms

Once you have shortlisted suppliers, compare pricing structures and payment terms. Pricing can vary significantly based on material, design complexity, and order volume.

– Bulk Discounts: Inquire about bulk purchase discounts or loyalty programs.

– Payment Flexibility: Look for suppliers that offer favorable payment terms, such as net 30 or 60 days.

Step 6: Confirm Shipping and Delivery Options

Evaluate the shipping methods and delivery timelines offered by suppliers. Efficient logistics are crucial for timely project completion.

– Shipping Costs: Ensure you understand shipping costs, especially for international orders, which can impact your budget.

– Delivery Times: Confirm lead times and whether the supplier can meet your project deadlines.

Step 7: Establish After-Sales Support and Warranty Terms

Finally, verify the after-sales support and warranty terms provided by the suppliers. Reliable support can save costs and headaches in case of issues post-purchase.

– Warranty Coverage: Look for warranties that cover defects and performance issues.

– Customer Support Availability: Ensure that the supplier offers accessible customer service for troubleshooting and inquiries.

By following this checklist, B2B buyers can streamline their sourcing process for semi-concealed hinges, ensuring they make informed decisions that align with their project requirements and budget constraints.

Comprehensive Cost and Pricing Analysis for semi concealed hinges for cabinets Sourcing

When considering sourcing semi-concealed hinges for cabinets, it’s essential to understand the comprehensive cost structure and pricing dynamics involved. This analysis will provide valuable insights for B2B buyers, particularly those operating in diverse international markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Semi-Concealed Hinges Manufacturing?

The cost structure of semi-concealed hinges encompasses several critical components:

-

Materials: The choice of materials directly impacts the cost. Common materials include stainless steel, brass, and various finishes like satin nickel or oil-rubbed bronze. Higher-quality materials may increase initial costs but can lead to longer product life and better performance.

-

Labor: Labor costs vary by region and depend on the skill level required for manufacturing. In regions with lower labor costs, such as parts of Asia, manufacturers may offer competitive pricing. However, labor costs in Europe or North America tend to be higher, influencing the final product price.

-

Manufacturing Overhead: This includes costs associated with running the factory, such as utilities, rent, and salaries of administrative staff. Efficient production processes can help minimize these costs, benefiting the overall pricing strategy.

-

Tooling: Custom tooling for specific hinge designs can be a significant upfront investment. Buyers should consider whether they need standard designs or custom solutions, as this will affect the tooling costs.

-

Quality Control (QC): Ensuring that hinges meet quality standards is crucial. QC processes may add to costs but are essential for maintaining product reliability and compliance with international standards.

-

Logistics: Shipping costs can fluctuate based on distance, weight, and shipping methods. International buyers must factor in customs duties and import taxes, which can significantly affect the total cost.

-

Margin: Suppliers typically mark up prices to ensure profitability. Understanding the margin expectations in the market can aid buyers in negotiations.

What Factors Influence Pricing for Semi-Concealed Hinges?

Several factors can significantly influence the pricing of semi-concealed hinges:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to reduced per-unit costs. Negotiating MOQs can be beneficial for buyers looking to optimize their budgets.

-

Specifications and Customization: Customized hinges may incur higher costs due to unique tooling and design requirements. Buyers should evaluate whether customization is necessary or if standard options will suffice.

-

Material and Quality Certifications: Hinges that meet specific industry standards or certifications may command higher prices. Buyers should assess the importance of these certifications for their applications.

-

Supplier Factors: Supplier reputation, reliability, and service levels can impact pricing. Established suppliers may charge more but offer better quality assurance and support.

-

Incoterms: Understanding shipping terms is crucial for international transactions. Different Incoterms (e.g., FOB, CIF) can affect the final landed cost of the product.

What Buyer Tips Should Be Considered for Cost Efficiency?

International B2B buyers should consider several strategies to enhance cost efficiency when sourcing semi-concealed hinges:

-

Negotiation: Engage suppliers in discussions regarding pricing, especially for bulk orders or long-term contracts. Highlighting potential future orders can incentivize suppliers to provide better rates.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, durability, and performance. Investing in higher-quality hinges may yield savings over time.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import tariffs, and local market conditions that can impact pricing. Establishing relationships with local distributors may also help mitigate some logistical challenges.

-

Research and Comparison: Conduct thorough market research to compare prices across different suppliers and regions. Online platforms can provide insights into available options and pricing trends.

In conclusion, understanding the cost components, pricing influencers, and strategic negotiation tips can empower international B2B buyers to make informed sourcing decisions for semi-concealed hinges. As prices can vary widely based on multiple factors, it’s crucial to approach sourcing with a comprehensive strategy tailored to specific business needs.

Alternatives Analysis: Comparing semi concealed hinges for cabinets With Other Solutions

Introduction to Alternative Solutions for Cabinet Hinges

When selecting hardware for cabinetry, particularly hinges, understanding the available alternatives is crucial for making an informed decision. While semi-concealed hinges offer a range of benefits, there are other solutions that may also suit specific needs and preferences. This section compares semi-concealed hinges with alternative options to help B2B buyers identify the most appropriate choice for their projects.

Illustrative image related to semi concealed hinges for cabinets

Comparison Table

| Comparison Aspect | Semi Concealed Hinges For Cabinets | Concealed Hinges | Surface-Mounted Hinges |

|---|---|---|---|

| Performance | Provides smooth operation with hidden visibility | Offers a clean look with full concealment | Easy to install, visible outside |

| Cost | Moderate, varying by material and features | Generally higher due to complexity | Lower cost, simple design |

| Ease of Implementation | Requires precise installation, may need adjustments | More complex installation, may require specialized tools | Quick installation, minimal tools needed |

| Maintenance | Low maintenance, durable options available | Very low maintenance, but replacement can be tricky | Moderate maintenance, visible wear over time |

| Best Use Case | Ideal for modern cabinetry, aesthetic appeal | Perfect for sleek, contemporary designs | Suitable for budget-friendly projects or quick fixes |

Detailed Breakdown of Alternatives

Concealed Hinges

Concealed hinges, often referred to as hidden hinges, are designed to be completely out of sight when the cabinet door is closed. This offers a seamless aesthetic that is particularly favored in modern cabinetry. However, their installation can be more complex, requiring precise cutting and alignment to ensure proper function. While they tend to be more expensive than semi-concealed options, they provide a sleek finish that many high-end projects demand. The trade-off is that if these hinges fail, they can be more challenging to replace due to their hidden nature.

Surface-Mounted Hinges

Surface-mounted hinges are a straightforward alternative characterized by their external visibility and ease of installation. These hinges can be attached directly to the surface of the cabinet door and frame, making them a popular choice for quick projects or budget-conscious renovations. Their cost-effectiveness is appealing, but they may not offer the same aesthetic quality as semi-concealed or concealed hinges. Additionally, because they are visible, they can detract from the overall design, and over time, they may require more maintenance as wear becomes apparent.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the right hinge solution for cabinetry, B2B buyers should carefully consider their specific requirements, including performance, cost, and aesthetic preferences. Semi-concealed hinges strike a balance between visibility and functionality, making them ideal for modern applications. However, for projects prioritizing a seamless look, concealed hinges may be worth the investment. Conversely, surface-mounted hinges can be a practical choice for cost-sensitive projects that prioritize ease of installation. Ultimately, understanding the pros and cons of each option will empower buyers to make the best decision for their cabinetry needs.

Essential Technical Properties and Trade Terminology for semi concealed hinges for cabinets

What Are the Key Technical Properties of Semi-Concealed Hinges for Cabinets?

When selecting semi-concealed hinges for cabinets, understanding the technical properties is crucial for ensuring durability, functionality, and compatibility with various cabinet designs. Here are several key specifications to consider:

1. Material Grade

The material used in the manufacture of semi-concealed hinges greatly impacts their performance and longevity. Common materials include stainless steel, brass, and zinc alloys. Stainless steel offers corrosion resistance, making it ideal for humid environments, while brass provides a classic aesthetic and durability. For B2B buyers, specifying the material grade ensures that the hinges meet the environmental and aesthetic requirements of their projects.

2. Load Capacity

Load capacity refers to the maximum weight that a hinge can support without compromising its structural integrity. This specification is critical for applications involving heavy cabinet doors, such as those found in commercial kitchens or large storage units. Buyers must assess the load capacity to ensure that the hinges will maintain functionality over time, reducing the risk of failure and subsequent costs associated with repairs or replacements.

3. Hinge Type and Overlay

Understanding hinge type (e.g., inset, partial overlay, full overlay) is essential for compatibility with different cabinet designs. Semi-concealed hinges can be tailored to specific overlay requirements, which affects how much of the cabinet frame is visible when the door is closed. This specification is vital for achieving the desired aesthetic and ensuring proper door alignment, which directly impacts user experience and cabinet functionality.

4. Self-Closing Mechanism

Many semi-concealed hinges feature self-closing mechanisms that automatically pull the door closed when it is nearly shut. This property enhances convenience and safety, particularly in high-traffic environments. For buyers, specifying self-closing hinges can reduce the need for additional hardware, streamlining procurement processes and minimizing installation complexities.

5. Finish and Coating

The finish of semi-concealed hinges—such as matte, polished, or oil-rubbed—affects both appearance and corrosion resistance. A high-quality finish can enhance the hinge’s longevity and aesthetic appeal, making it essential for projects that prioritize design. B2B buyers should consider the finish when sourcing hinges, as it can influence customer satisfaction and product performance.

What Are Common Trade Terms Related to Semi-Concealed Hinges?

Familiarity with industry jargon can streamline communication and negotiations between buyers and suppliers. Here are several key terms often encountered in the procurement of semi-concealed hinges:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that manufactures products that are then marketed by another company. In the context of hinges, buyers may source products from OEMs to ensure quality and compatibility with their existing products. Understanding OEM relationships can help buyers assess the reliability and reputation of their suppliers.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is crucial for buyers to understand their purchasing constraints and budget planning. Knowing the MOQ can help avoid excess inventory and ensure that orders align with project timelines.

Illustrative image related to semi concealed hinges for cabinets

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request price proposals from suppliers. This term is essential for B2B buyers who are looking to compare costs and terms from different vendors. An effective RFQ can lead to better pricing and improved supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk management, and delivery responsibilities, which is particularly important for international sourcing of cabinet hardware.

5. Lead Time

Lead time refers to the amount of time from placing an order to receiving the product. This term is critical for B2B buyers, especially in industries with tight project deadlines. Understanding lead times allows for better project management and inventory control, ensuring that products arrive when needed.

Illustrative image related to semi concealed hinges for cabinets

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing semi-concealed hinges for cabinets, ultimately contributing to more successful project outcomes.

Navigating Market Dynamics and Sourcing Trends in the semi concealed hinges for cabinets Sector

What Are the Key Market Drivers and Trends for Semi-Concealed Hinges?

The global market for semi-concealed hinges is influenced by several key drivers, particularly the growing demand for aesthetic and functional hardware in both residential and commercial cabinetry. As consumers increasingly prioritize design and functionality, manufacturers are innovating to produce hinges that blend seamlessly into cabinetry, enhancing the overall look while offering durability. Emerging trends in B2B sourcing include the integration of smart technologies, such as self-closing mechanisms and adjustable hinges, which cater to modern cabinetry needs.

International B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, are witnessing a shift towards online procurement platforms that streamline the sourcing process. The rise of digital marketplaces allows buyers to compare products, prices, and supplier ratings, facilitating informed purchasing decisions. Additionally, there is a notable increase in demand for customized hinge solutions tailored to specific cabinet designs, underscoring the need for suppliers to be adaptable and responsive to buyer requirements.

How Is Sustainability Shaping the Sourcing of Semi-Concealed Hinges?

Sustainability has become a pivotal concern in the sourcing of semi-concealed hinges. As businesses and consumers alike become more environmentally conscious, there is a growing emphasis on ethical sourcing practices and materials. The environmental impact of hinge production is under scrutiny, prompting manufacturers to adopt greener processes that minimize waste and energy consumption.

Buyers are increasingly seeking suppliers that offer certifications for sustainable practices, such as ISO 14001 or FSC (Forest Stewardship Council) certification for wood-based components. The use of recycled materials and eco-friendly finishes is also gaining traction in the market. In addition to environmental considerations, ethical supply chains are crucial, with buyers prioritizing suppliers that ensure fair labor practices and transparency throughout the manufacturing process. This shift not only aligns with corporate social responsibility goals but also appeals to a growing segment of eco-conscious consumers.

What Is the Historical Context of Semi-Concealed Hinges in B2B Markets?

The evolution of semi-concealed hinges can be traced back to the increasing demand for modern cabinetry solutions that prioritize both aesthetics and functionality. Initially, cabinet hinges were primarily exposed, often detracting from the overall design. The introduction of semi-concealed hinges in the late 20th century marked a significant advancement, allowing for a cleaner look while maintaining the necessary functionality.

As cabinetry trends evolved, so did the designs and materials used in hinge manufacturing. The transition to more durable materials, such as stainless steel and advanced polymers, has enhanced the performance and longevity of these products. This evolution reflects broader trends in the furniture and cabinetry industry, where innovation and design are paramount. Today, semi-concealed hinges are a staple in both residential and commercial applications, supported by ongoing technological advancements that cater to the needs of a diverse, global market.

Conclusion

In summary, the market for semi-concealed hinges is characterized by dynamic trends driven by consumer preferences for aesthetics, functionality, and sustainability. International B2B buyers are encouraged to stay abreast of these trends, leveraging technology and ethical sourcing practices to make informed decisions. The historical context of these products underscores their significance in modern cabinetry solutions, making them an essential consideration for any buyer in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of semi concealed hinges for cabinets

-

How do I ensure the quality of semi concealed hinges when sourcing internationally?

To ensure quality when sourcing semi concealed hinges internationally, start by vetting potential suppliers thoroughly. Request samples to evaluate the material, finish, and functionality. Check for certifications such as ISO or ASTM, which indicate adherence to international standards. It’s also beneficial to review customer testimonials and case studies from previous clients. Engaging in a factory audit, if feasible, can provide deeper insights into the manufacturing processes and quality control measures in place. -

What is the best type of semi concealed hinge for kitchen cabinets?

The best type of semi concealed hinge for kitchen cabinets often depends on the cabinet design and usage. For heavy doors, consider self-closing hinges that ensure the door remains closed, while providing a smooth operation. If aesthetics are a priority, look for hinges with a finish that complements your cabinetry. Variable overlay hinges are also popular for their flexibility in installation. Ultimately, the choice should balance functionality, durability, and design compatibility. -

What are the minimum order quantities (MOQs) for semi concealed hinges?

Minimum order quantities (MOQs) for semi concealed hinges can vary significantly by supplier. Typically, MOQs range from 100 to 500 pairs, depending on the manufacturer and product line. It’s essential to communicate your specific needs with suppliers, as some may offer flexibility for larger orders or ongoing partnerships. Additionally, consider the implications of shipping costs and inventory management when negotiating MOQs. -

What payment terms should I expect when sourcing hinges internationally?

When sourcing semi concealed hinges internationally, payment terms can vary widely. Common terms include a 30% deposit upfront with the balance due before shipment, or net 30 days after receipt of goods. Some suppliers may offer letters of credit or escrow services for larger orders to ensure security for both parties. Always clarify payment methods accepted, and consider using secure payment platforms to mitigate risks. -

How can I customize semi concealed hinges for my specific needs?

Customization options for semi concealed hinges often include variations in size, finish, and functionality. When discussing customization with suppliers, provide detailed specifications and any design sketches. Some manufacturers may offer bespoke solutions, including unique finishes or specialized mechanisms. Be prepared to meet minimum order requirements for customized products, and factor in additional lead times for production. -

What logistics considerations should I keep in mind when importing hinges?

When importing semi concealed hinges, consider logistics factors such as shipping method, delivery timelines, and customs regulations. Sea freight is generally cost-effective for larger shipments, while air freight offers quicker delivery but at a higher cost. Ensure that your supplier provides accurate documentation to facilitate smooth customs clearance. Additionally, stay informed about tariffs and import duties in your country to avoid unexpected costs. -

How do I evaluate the reliability of a supplier for hinges?

To evaluate a supplier’s reliability for semi concealed hinges, conduct comprehensive background checks. Look for industry experience, production capacity, and customer service responsiveness. Request references from previous clients and inquire about their satisfaction with product quality and delivery times. Engaging in a trial order can also provide insights into the supplier’s reliability and commitment to quality before entering into a larger contract. -

What are the common finishes available for semi concealed hinges?

Semi concealed hinges come in a variety of finishes to match diverse cabinetry styles. Common finishes include satin nickel, oil-rubbed bronze, polished chrome, and antique brass. Each finish offers different aesthetic and durability characteristics, so it’s crucial to choose one that complements your cabinetry while ensuring resistance to wear and corrosion. Discuss available finishes with suppliers to find the best match for your project requirements.

Top 4 Semi Concealed Hinges For Cabinets Manufacturers & Suppliers List

1. HingeOutlet – Semi Concealed Cabinet Hinges

Domain: hingeoutlet.com

Registered: 2004 (21 years)

Introduction: Semi Concealed Cabinet Hinges available at HingeOutlet. Free shipping on orders over $160. Various types of cabinet hinges including concealed, demountable, European, frameless, inset, overlay, self-closing, soft close, and more. Suitable for both residential and commercial applications. Expert support available at 888-250-8133.

2. Hardwaresource – Semi-Concealed Cabinet Hinges

Domain: hardwaresource.com

Registered: 1996 (29 years)

Introduction: Semi-Concealed Cabinet Hinges are designed for face frame cabinets, with half of the hinge visible on the face frame and the other half hidden, mounted to the back of the cabinet door. They come in various finishes including Oil Rubbed Bronze, Polished Chrome, Polished Brass, Antique Brass, Satin Nickel, and more. The product range includes options such as 1/2″ Inset, 1/2″ Lip, 1/4″ Overlay, 3/8″ …

3. Ovis Online – Semi-Concealed Face Frame Hinges

Domain: ovisonline.com

Registered: 1999 (26 years)

Introduction: Semi-Concealed Face Frame Hinges:

– Used for retrofitting replacements

– Partially exposed when cabinet door is closed

– Hinge color and finish should match door knob or pull

– Options with wrap around mounting plate have fixed overlay

– Front mount options can be used with any door overlay

– 3/8″ inset available for a thinner door look

– Features a 3/8″ x 3/8″ rabbit milled in the back of …

4. Rockler – Cabinet Hinges

Domain: rockler.com

Registered: 1997 (28 years)

Introduction: This company, Rockler – Cabinet Hinges, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for semi concealed hinges for cabinets

In the competitive landscape of cabinet hardware, strategic sourcing of semi-concealed hinges emerges as a pivotal decision for international B2B buyers. The diverse range of products available—ranging from self-closing options to various finishes—offers buyers the ability to enhance both functionality and aesthetics in cabinetry. By leveraging strong supplier relationships and understanding market trends, buyers can secure quality products at competitive prices, ultimately driving profitability and customer satisfaction.

The importance of aligning procurement strategies with regional demands cannot be overstated. As markets in Africa, South America, the Middle East, and Europe evolve, buyers must stay attuned to local preferences and emerging trends. This adaptability will not only foster stronger connections with clients but also position businesses to capitalize on new opportunities in the cabinetry sector.

Looking ahead, the ongoing evolution of design and manufacturing techniques promises exciting developments in semi-concealed hinges. International buyers are encouraged to engage with suppliers who prioritize innovation and sustainability. By taking proactive steps in their sourcing strategies, businesses can ensure they remain competitive and responsive to market dynamics. Embrace the future of cabinet hardware with confidence and strategic intent.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.