How to Source Sandblasting Parts Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for sandblasting parts

In the dynamic landscape of industrial operations, sourcing reliable sandblasting parts is essential for businesses looking to enhance efficiency and maintain high-quality standards. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, face unique challenges in navigating a global market filled with diverse suppliers and varying product specifications. This guide serves as a comprehensive resource, covering essential aspects such as the types of sandblasting parts available, their applications across different industries, and practical tips for vetting suppliers to ensure quality and reliability.

Understanding the intricacies of cost structures, shipping logistics, and local regulations is crucial for making informed purchasing decisions. By delving into the nuances of sandblasting equipment—from nozzles and hoses to safety gear and specialized machines—this guide empowers buyers to identify the best solutions tailored to their operational needs. With insights into market trends and best practices, B2B buyers will be equipped to navigate the complexities of sourcing sandblasting parts effectively, ultimately leading to improved operational efficiency and cost savings. Whether you’re in Saudi Arabia or Nigeria, our guide aims to streamline your procurement process, ensuring that your investment translates into tangible benefits for your business.

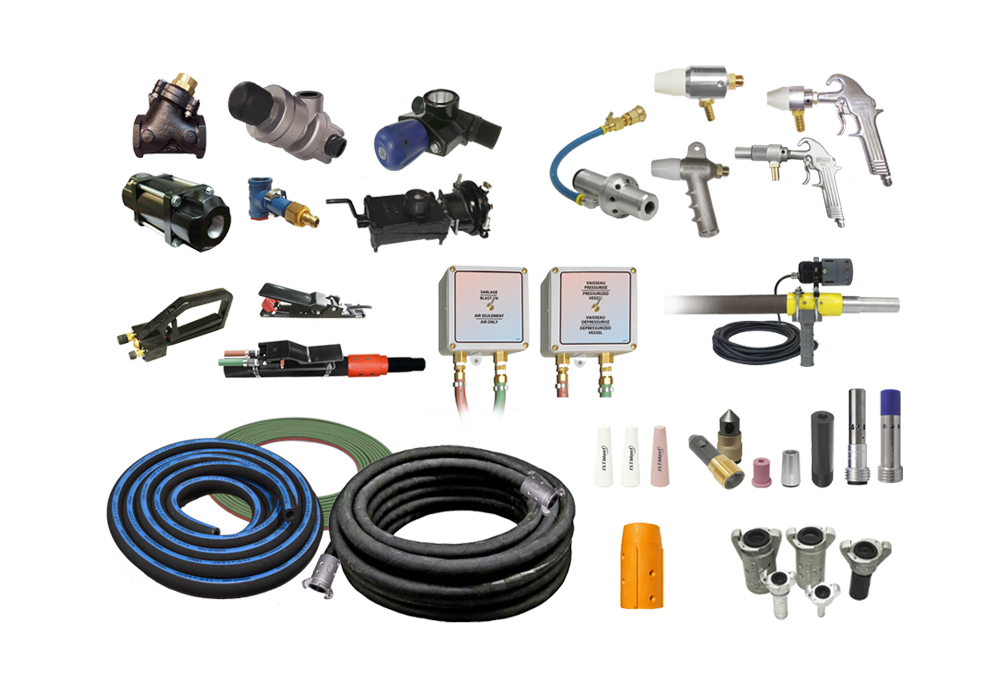

Understanding sandblasting parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Sandblasting Guns | Handheld or automated, varying nozzle types and sizes | Surface preparation, cleaning | Pros: Versatile, easy to use; Cons: Maintenance can be frequent. |

| Blast Pots | Pressure vessels for storing and delivering abrasive media | Industrial cleaning, coating removal | Pros: Efficient for large jobs; Cons: Bulkier, requires more setup. |

| Nozzles | Different shapes (Venturi, straight bore) for airflow | Precision blasting, material removal | Pros: Enhanced performance; Cons: Requires proper selection for optimal use. |

| Hoses | Varying diameters and materials for air and abrasive flow | Connecting equipment, mobility | Pros: Flexible, durable; Cons: Can wear out quickly with heavy use. |

| Safety Equipment | Helmets, gloves, and suits designed for protection | Operator safety in blasting areas | Pros: Essential for worker safety; Cons: Initial investment can be high. |

What Are the Key Characteristics of Sandblasting Guns?

Sandblasting guns are critical components in the sandblasting process, designed to deliver abrasive media at high velocity. They come in various forms, including handheld and automated models, and feature different nozzle types that affect the spray pattern and intensity. When selecting a sandblasting gun, B2B buyers should consider the specific application, as certain guns are better suited for detailed work while others excel in broader surface preparation tasks. Maintenance is a key consideration, as wear and tear can affect performance over time.

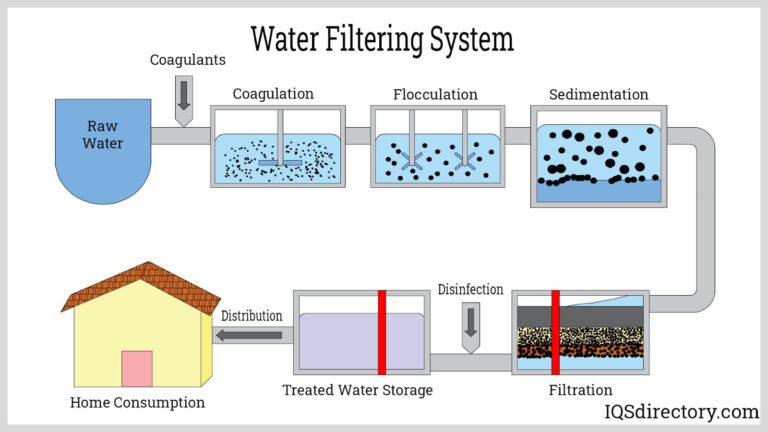

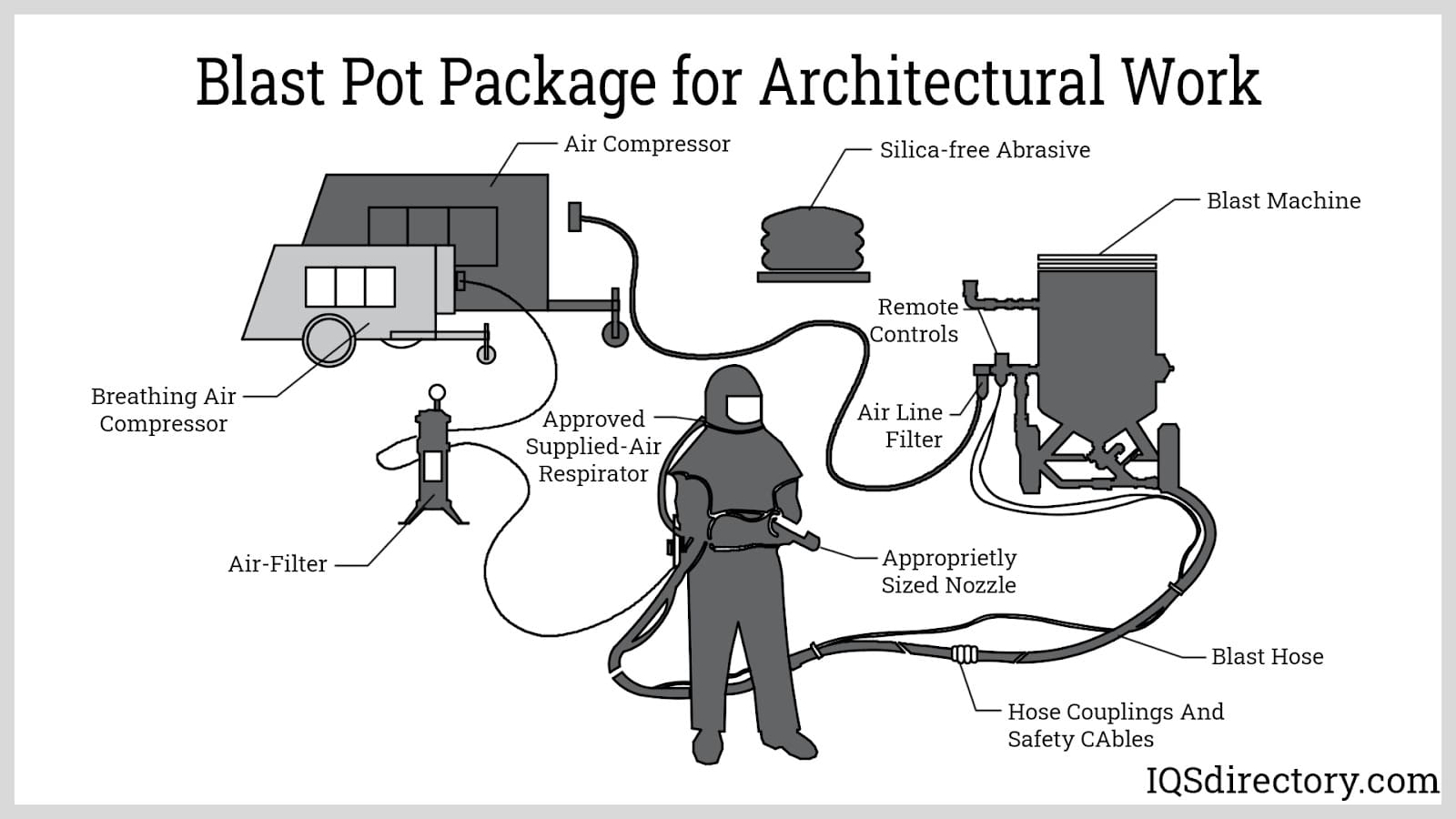

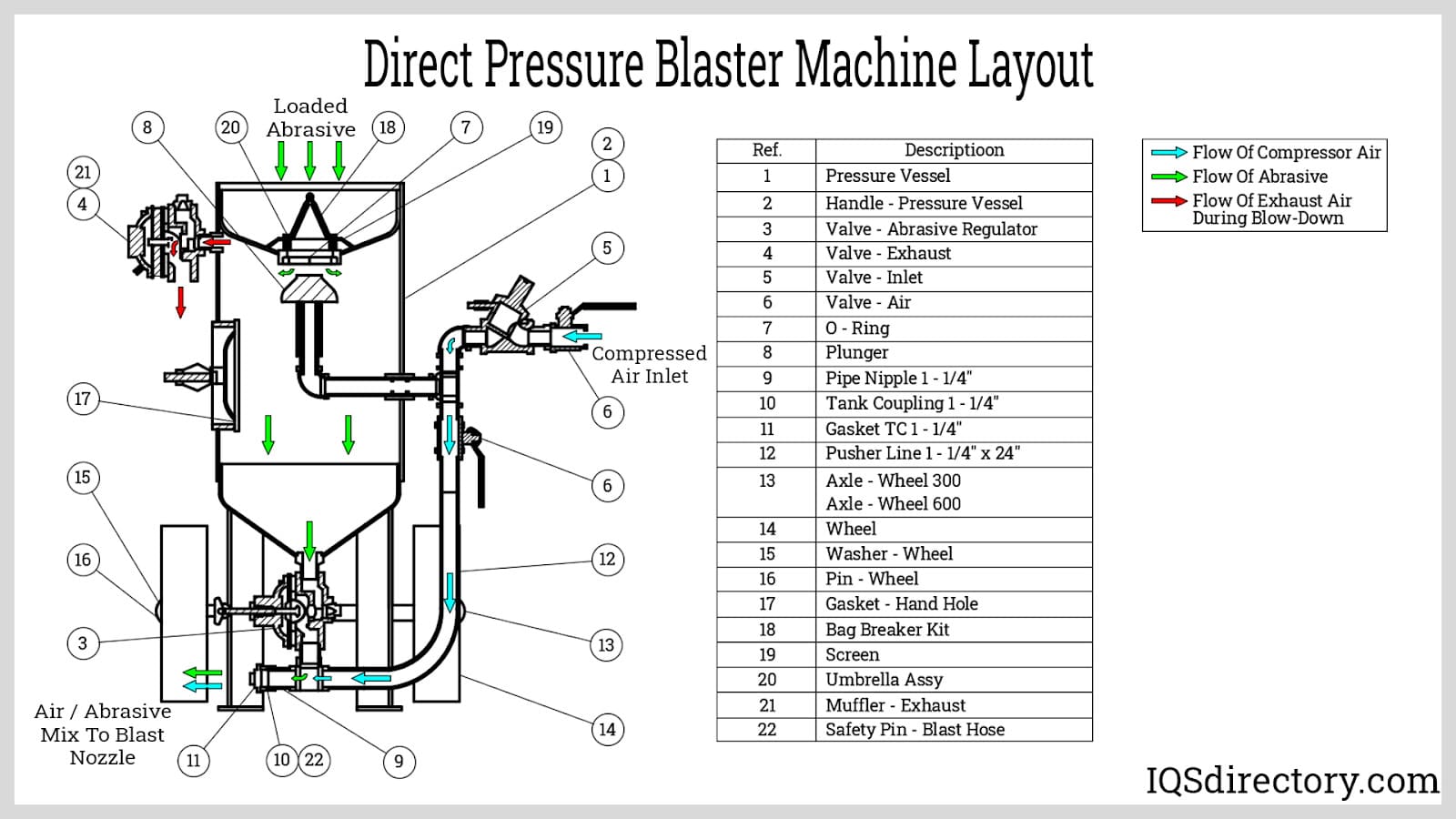

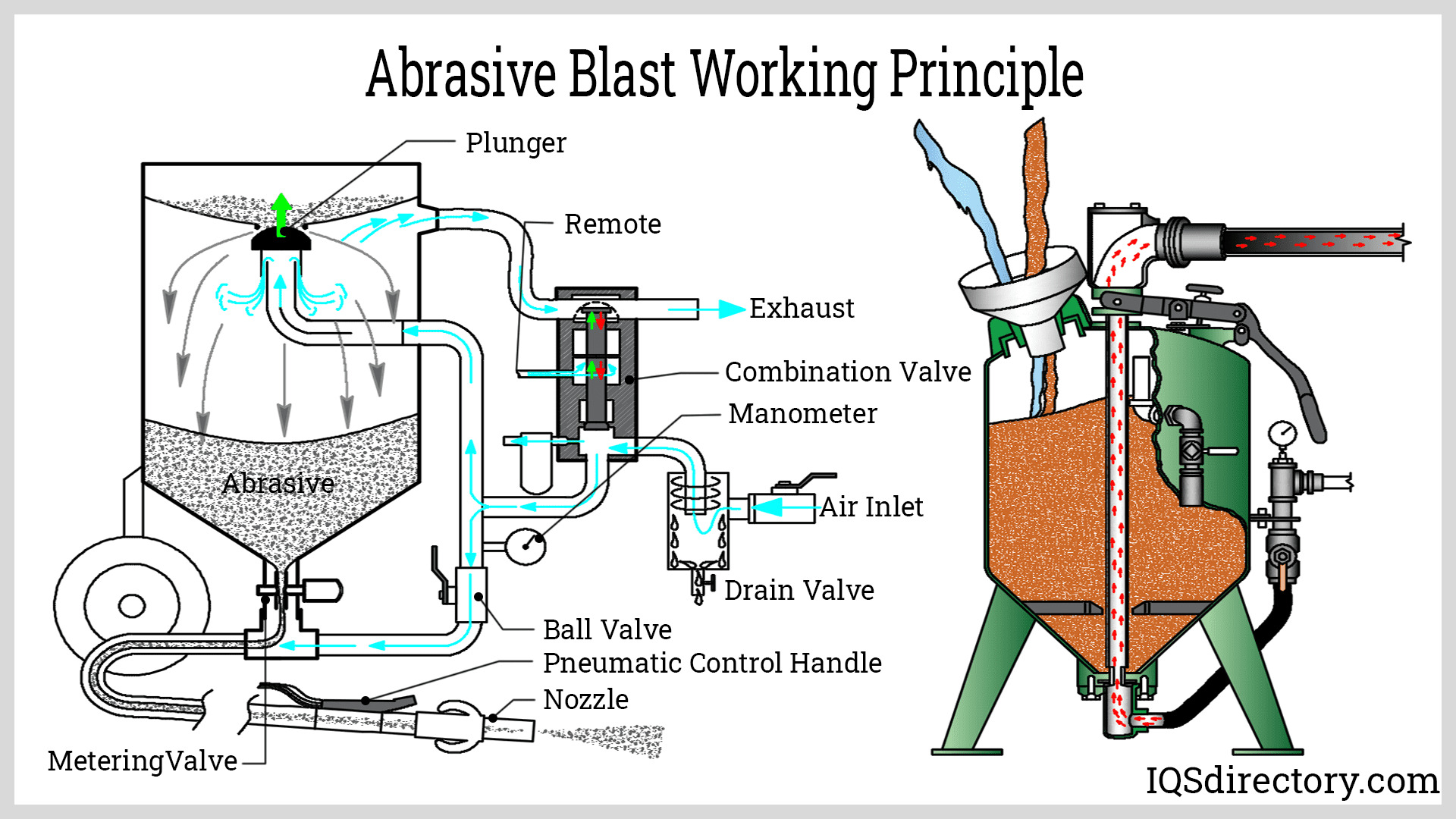

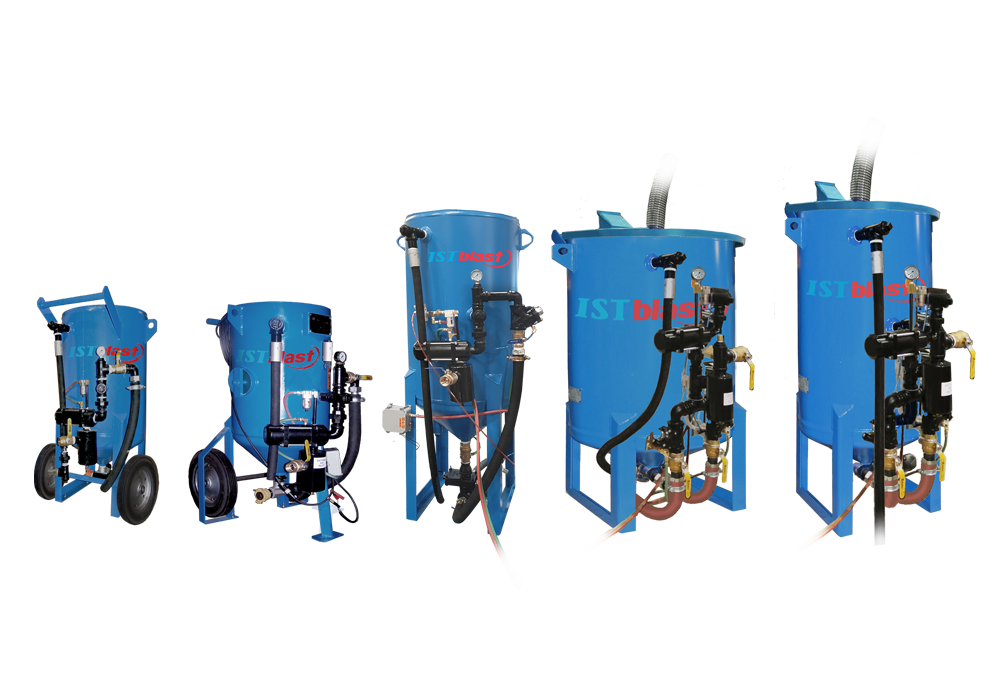

How Do Blast Pots Function in Industrial Applications?

Blast pots are pressure vessels that store and release abrasive media in a controlled manner, making them ideal for large-scale industrial cleaning and coating removal. They are designed to handle various types of abrasives and can be used in conjunction with different blasting systems. When purchasing a blast pot, businesses should evaluate the size and capacity based on project requirements. While they offer efficiency for extensive jobs, their bulkiness and setup requirements may pose challenges in smaller workspaces.

What Should Buyers Consider When Choosing Nozzles?

Nozzles play a pivotal role in determining the effectiveness of sandblasting operations. They come in various shapes such as Venturi and straight bore, each impacting airflow and abrasive velocity. Selecting the right nozzle is crucial for achieving desired results, such as precision blasting or aggressive material removal. Buyers must assess their specific needs and the compatibility of nozzles with their existing systems. While high-quality nozzles can enhance performance, they require careful handling and maintenance to ensure longevity.

Why Are Hoses Important in Sandblasting Operations?

Hoses are essential for connecting various sandblasting equipment, facilitating the flow of air and abrasive media. They come in different diameters and materials, allowing for flexibility and durability in various environments. When selecting hoses, B2B buyers should consider the specific requirements of their operations, including the type of abrasives used and the length needed for mobility. While high-quality hoses can withstand heavy use, they are subject to wear and may require regular replacement, impacting overall operational costs.

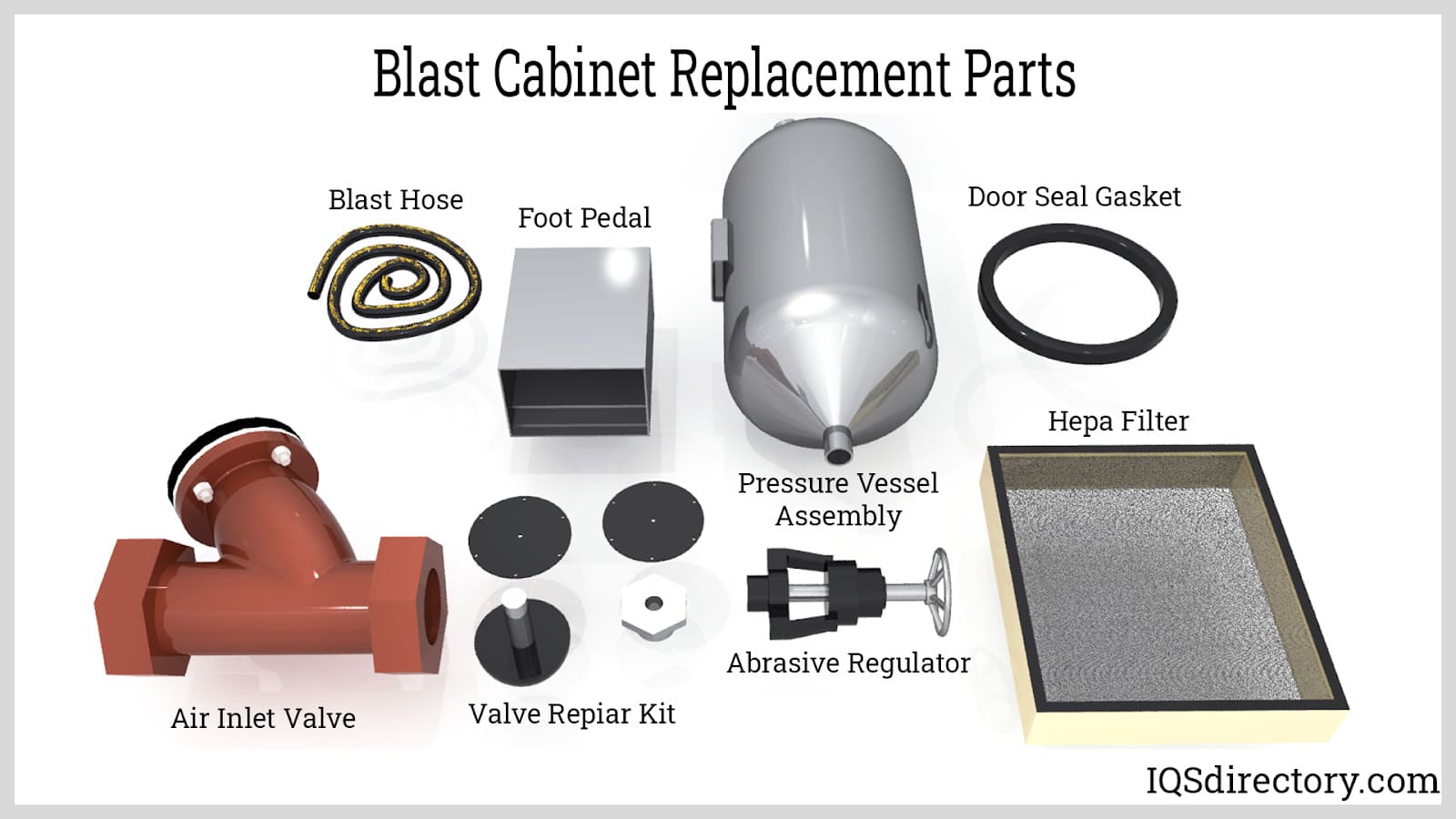

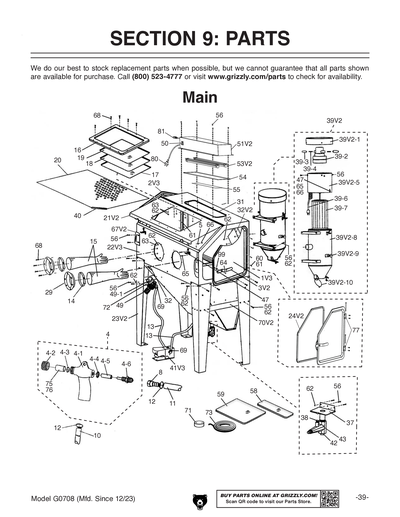

Illustrative image related to sandblasting parts

What Role Does Safety Equipment Play in Sandblasting?

Safety equipment is vital in sandblasting operations, protecting workers from hazardous materials and high-pressure environments. This includes helmets, gloves, and protective suits specifically designed for blasting conditions. Investing in high-quality safety gear is essential for compliance with industry regulations and ensuring worker safety. While the initial cost may be significant, the long-term benefits include reduced injury risk and improved worker morale. Buyers should prioritize safety equipment that meets international safety standards to safeguard their workforce effectively.

Key Industrial Applications of sandblasting parts

| Industry/Sector | Specific Application of sandblasting parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Surface preparation for metal components | Enhances adhesion of coatings and improves product durability | Quality of abrasives, compatibility with existing systems, and compliance with safety standards |

| Construction | Restoration of concrete surfaces | Increases lifespan of structures and reduces maintenance costs | Availability of specialized nozzles and safety equipment for high-rise applications |

| Automotive | Cleaning and refurbishing automotive parts | Improves aesthetic appeal and performance of vehicles | Sourcing high-quality sandblasting equipment and parts that meet automotive industry standards |

| Aerospace | Cleaning and preparing aircraft components | Ensures safety and compliance with stringent regulations | Need for precision equipment and parts that minimize contamination risks |

| Shipbuilding | Hull cleaning and surface preparation | Enhances vessel performance and reduces fuel consumption | Consideration for marine-grade materials and parts resistant to corrosion |

How is Sandblasting Used in Manufacturing to Enhance Product Quality?

In the manufacturing sector, sandblasting is crucial for surface preparation, particularly for metal components. This process removes rust, old paint, and other contaminants, allowing for better adhesion of coatings. For international buyers, particularly from Africa and South America, the quality of abrasives and compatibility with existing sandblasting systems are key considerations. Ensuring that the sandblasting parts comply with local safety standards is also essential to mitigate risks during operations.

What Role Does Sandblasting Play in Construction Projects?

In construction, sandblasting is widely used for the restoration of concrete surfaces, which can suffer from wear and tear over time. This application not only improves the aesthetic appeal of structures but also extends their lifespan, thereby reducing maintenance costs. Buyers from the Middle East and Europe should prioritize sourcing specialized nozzles and safety equipment, particularly for high-rise applications, to ensure efficient and safe operations.

How Does the Automotive Industry Benefit from Sandblasting?

The automotive industry employs sandblasting for cleaning and refurbishing parts, significantly enhancing both their aesthetic appeal and performance. By effectively removing contaminants and preparing surfaces for painting or coating, businesses can improve their product offerings. B2B buyers in this sector should focus on sourcing high-quality sandblasting equipment that meets industry standards, ensuring reliability and efficiency in their operations.

Illustrative image related to sandblasting parts

Why is Sandblasting Essential in the Aerospace Sector?

In the aerospace industry, sandblasting is critical for cleaning and preparing aircraft components. This application ensures compliance with stringent safety regulations, as any contaminants can compromise aircraft performance and safety. Buyers must seek precision equipment and parts that minimize contamination risks, particularly when sourcing internationally, to maintain high safety standards.

How Does Sandblasting Improve Shipbuilding Efficiency?

Sandblasting is vital in shipbuilding for hull cleaning and surface preparation, which enhances vessel performance and reduces fuel consumption. Properly prepared surfaces ensure better coatings and longer-lasting protection against the harsh marine environment. International buyers should consider marine-grade materials and corrosion-resistant parts when sourcing sandblasting equipment to ensure durability and efficiency in their operations.

3 Common User Pain Points for ‘sandblasting parts’ & Their Solutions

Scenario 1: Sourcing Quality Sandblasting Parts for Diverse Applications

The Problem: Many B2B buyers struggle with sourcing quality sandblasting parts suitable for specific applications, especially when dealing with different materials and environmental conditions. For instance, companies in regions like Africa and the Middle East may face unique challenges such as high temperatures and dust, which can affect the performance of sandblasting equipment. Furthermore, the lack of reliable suppliers can lead to the procurement of subpar parts, resulting in operational inefficiencies and increased downtime.

The Solution: To effectively source high-quality sandblasting parts, buyers should begin by identifying their specific needs based on the materials and conditions they will be working with. Engage with reputable suppliers who offer a wide variety of products tailored to different applications. Look for parts made from durable materials that can withstand environmental stressors, such as tungsten carbide nozzles for abrasive materials or specialized hoses that can handle extreme temperatures. Establishing a relationship with suppliers who understand local conditions can also provide insights into the best products for your specific context, ensuring optimal performance and longevity of your sandblasting equipment.

Scenario 2: Managing Downtime Due to Equipment Failure

The Problem: Equipment failure in sandblasting operations can lead to significant downtime, causing delays in project timelines and increased costs. For instance, if a critical component such as a blast nozzle or pressure gauge fails, it can halt the entire operation, affecting productivity and client satisfaction. Buyers often find it challenging to quickly procure replacement parts, especially when suppliers are located far away or do not have an adequate inventory.

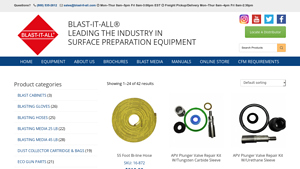

Illustrative image related to sandblasting parts

The Solution: To mitigate the risk of downtime due to equipment failure, companies should implement a proactive maintenance strategy that includes regular inspections and timely replacements of wear parts. Maintaining an inventory of critical spare parts, such as nozzles, hoses, and safety equipment, is essential. Establishing a local or regional supplier network can expedite the procurement process. Additionally, consider using predictive maintenance technologies that monitor equipment performance and alert teams to potential failures before they occur. This approach not only minimizes downtime but also extends the lifespan of sandblasting equipment, ensuring consistent operational efficiency.

Scenario 3: Ensuring Worker Safety During Sandblasting Operations

The Problem: Ensuring worker safety is a paramount concern in sandblasting operations, where exposure to harmful dust and debris is prevalent. B2B buyers often face challenges in sourcing appropriate personal protective equipment (PPE) that meets regulatory standards and provides adequate protection. For example, inadequate helmets or respirators can put workers at risk, leading to health issues and potential legal liabilities.

The Solution: To enhance worker safety, companies should prioritize sourcing high-quality PPE specifically designed for sandblasting operations. This includes investing in helmets with proper filtration systems, gloves, and full-body suits that provide comprehensive protection against abrasive materials. Engage with suppliers who can provide safety certifications and compliance with local regulations. Conduct regular training sessions for workers on the importance of using PPE and how to properly maintain it. Furthermore, consider conducting safety audits to ensure that all equipment and safety measures are up to standard, fostering a culture of safety that can significantly reduce the risk of workplace accidents.

Illustrative image related to sandblasting parts

Strategic Material Selection Guide for sandblasting parts

What Are the Common Materials Used in Sandblasting Parts?

When selecting materials for sandblasting parts, it is crucial to consider the specific properties and performance characteristics that will impact the efficiency and effectiveness of the sandblasting process. Here, we analyze four common materials used in sandblasting components: aluminum, steel, tungsten carbide, and rubber.

How Does Aluminum Perform in Sandblasting Applications?

Aluminum is widely used in sandblasting parts due to its lightweight nature and resistance to corrosion. It typically has a temperature rating of up to 150°C and can withstand moderate pressure levels. The key advantages of aluminum include its ease of manufacturing and lower cost compared to other metals. However, its durability is less than that of steel or tungsten carbide, making it less suitable for high-impact applications. For international buyers, especially in regions like Africa and South America, aluminum components may be favored for their cost-effectiveness, but compliance with local standards (like ASTM) should be verified.

What Are the Benefits and Limitations of Steel in Sandblasting Parts?

Steel is another common material for sandblasting parts, known for its high strength and durability. It can handle higher temperatures and pressures compared to aluminum, making it suitable for heavy-duty applications. However, steel is prone to corrosion, which can be mitigated through coatings or treatments. The cost of steel is generally moderate, and while it offers excellent performance, its weight can be a drawback in portable sandblasting equipment. Buyers in the Middle East and Europe should consider the availability of high-quality steel that meets local standards (like DIN) to ensure compliance and performance.

Why Choose Tungsten Carbide for Sandblasting Components?

Tungsten carbide is renowned for its exceptional hardness and wear resistance, making it ideal for high-impact applications in sandblasting. It can withstand extreme temperatures and pressures, often exceeding 200°C, and is compatible with a wide range of abrasive media. The primary disadvantage is its high cost, which can be a significant factor for budget-conscious buyers. Additionally, the manufacturing complexity of tungsten carbide parts may lead to longer lead times. For international buyers, particularly in regions with stringent quality standards, tungsten carbide can provide a reliable option, but they must weigh the cost against performance benefits.

What Role Does Rubber Play in Sandblasting Equipment?

Rubber is primarily used in hoses and seals within sandblasting systems. It offers excellent flexibility and resistance to abrasion, making it suitable for various sandblasting applications. The temperature and pressure ratings of rubber can vary, but it generally performs well in moderate conditions. The advantages of rubber include its low cost and ease of replacement, but it may not be suitable for high-temperature applications. Buyers from diverse regions, including Africa and South America, should ensure that the rubber used complies with relevant standards to avoid premature wear and failure.

Summary Table of Material Selection for Sandblasting Parts

| Material | Typical Use Case for sandblasting parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Sandblasting guns and lightweight parts | Lightweight and corrosion-resistant | Lower durability compared to metals | Low |

| Steel | Heavy-duty sandblasting equipment | High strength and durability | Prone to corrosion | Med |

| Tungsten Carbide | Nozzles and high-wear components | Exceptional hardness and wear resistance | High cost and manufacturing complexity | High |

| Rubber | Hoses and seals | Flexible and abrasion-resistant | Not suitable for high-temperature use | Low |

This strategic material selection guide provides B2B buyers with a comprehensive understanding of the materials commonly used in sandblasting parts, enabling informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for sandblasting parts

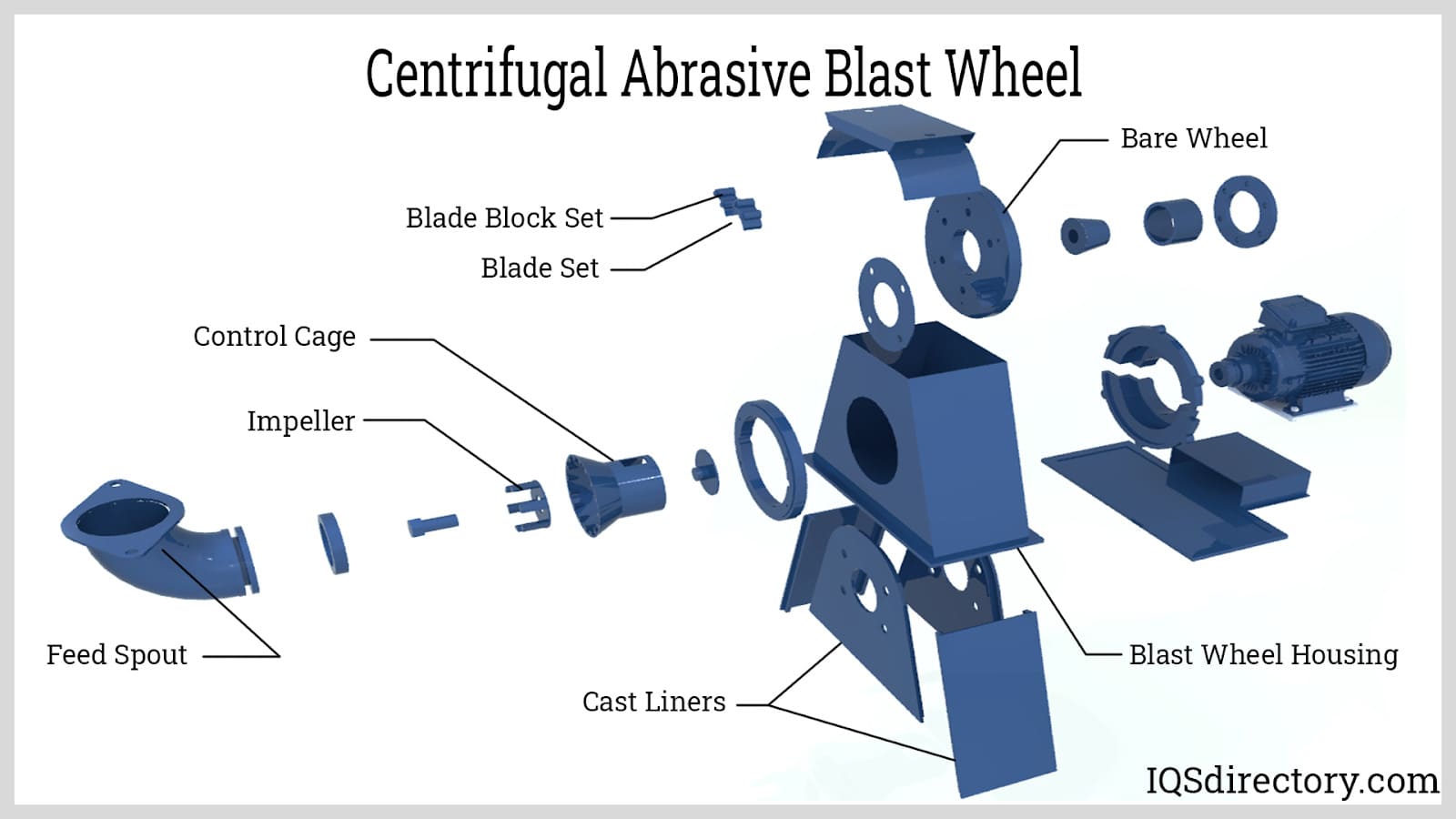

What Are the Key Manufacturing Processes for Sandblasting Parts?

The manufacturing of sandblasting parts involves several critical stages, ensuring the components meet performance and safety standards. The main stages include material preparation, forming, assembly, and finishing, each employing specific techniques that contribute to the durability and functionality of the final products.

How Is Material Prepared for Sandblasting Parts?

Material preparation is a foundational step in the manufacturing process. It typically involves selecting high-grade materials such as steel, aluminum, or specialized alloys that can withstand the abrasive nature of sandblasting. The materials undergo cleaning processes to remove any contaminants, such as oils or rust, which could affect the final product’s performance. Techniques like sandblasting or chemical cleaning may be used at this stage to ensure a clean surface.

What Forming Techniques Are Used in Sandblasting Parts Manufacturing?

Once the materials are prepared, they are subjected to forming processes, which can include machining, casting, or forging. Machining is particularly common for components requiring high precision, such as nozzles and valves, where tolerances are critical. Casting can be employed for more complex shapes that would be difficult to achieve through machining alone. Forging, on the other hand, is used for components that need enhanced strength and resilience, making them ideal for high-pressure applications.

How Are Sandblasting Parts Assembled?

The assembly stage involves bringing together the various components manufactured in the previous stages. This may include the integration of nozzles, hoses, valves, and safety equipment. Assembly techniques can vary from manual to automated processes, depending on the complexity of the product and the production scale. Each assembly line is typically designed to optimize efficiency while maintaining strict adherence to quality standards.

What Finishing Processes Are Critical for Sandblasting Parts?

Finishing processes are essential for enhancing the performance and longevity of sandblasting parts. Techniques such as coating, polishing, or anodizing are commonly employed to provide corrosion resistance and improve the aesthetic appeal of the components. Additionally, finishing processes can reduce surface roughness, which is crucial for the performance of parts that will be in contact with abrasive materials.

What Quality Assurance Measures Are Essential in Sandblasting Parts Manufacturing?

Quality assurance (QA) is paramount in the production of sandblasting parts, ensuring that the components meet international and industry-specific standards. The QA process typically includes several checkpoints and testing methods, essential for B2B buyers to consider when selecting suppliers.

Which International Standards Should B2B Buyers Be Aware Of?

Compliance with international standards such as ISO 9001 is critical for manufacturers in the sandblasting industry. ISO 9001 sets the framework for a quality management system, focusing on customer satisfaction and continuous improvement. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are relevant for specific applications, particularly for parts used in hazardous environments.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process, ensuring that any defects are identified and rectified promptly. Key checkpoints include:

Illustrative image related to sandblasting parts

- Incoming Quality Control (IQC): This stage assesses the quality of raw materials before they enter the production line.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing to ensure processes are adhered to and that any deviations are addressed immediately.

- Final Quality Control (FQC): A thorough inspection of the finished products to ensure they meet specified standards before shipping.

What Common Testing Methods Are Utilized to Ensure Product Quality?

Testing methods play a crucial role in validating the quality and performance of sandblasting parts. Common methods include:

- Pressure Testing: Ensures that components can withstand specified pressure levels.

- Dimensional Inspection: Verifies that parts meet precise dimensions and tolerances.

- Material Composition Testing: Confirms that the materials used meet the specified standards and are free from defects.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for mitigating risks associated with substandard products.

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting supplier audits is one of the most effective ways to verify quality control practices. Buyers should consider the following steps:

- Request Documentation: Ask for quality control manuals, certifications, and inspection reports to understand the supplier’s QA processes.

- On-Site Audits: If feasible, perform on-site evaluations to assess the manufacturing environment, production capabilities, and adherence to quality standards.

- Third-Party Inspections: Engage independent third-party inspectors to conduct comprehensive evaluations of the supplier’s facilities and processes.

What Are the QC Certification Nuances for International Buyers?

Understanding certification nuances is critical for international buyers. Certifications such as ISO and CE may have different implications based on regional regulations. Buyers should ensure that the certifications held by suppliers are recognized in their respective markets to avoid compliance issues. Additionally, familiarity with local standards in countries like Saudi Arabia or Nigeria can help buyers navigate the complexities of international sourcing effectively.

Illustrative image related to sandblasting parts

Conclusion

The manufacturing processes and quality assurance measures for sandblasting parts are intricate and multi-faceted. By understanding these processes and actively engaging in quality verification, B2B buyers can make informed decisions, ensuring they procure high-quality components that meet their operational needs. This diligence not only enhances the reliability of their equipment but also contributes to the overall efficiency and safety of their sandblasting operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sandblasting parts’

Introduction

Sourcing sandblasting parts requires a systematic approach to ensure you obtain high-quality components that meet your operational needs. This guide provides a practical checklist that will assist B2B buyers in navigating the procurement process effectively, whether you are operating in Africa, South America, the Middle East, or Europe. By following these steps, you can ensure a successful and efficient purchasing experience.

Step 1: Define Your Technical Specifications

Before beginning your search, clearly outline the technical specifications required for your sandblasting operations. This includes the type of sandblaster, the materials being blasted, and the size and type of parts needed. Precise specifications help in narrowing down suppliers who can meet your exact needs and prevent costly mistakes in procurement.

- Identify Equipment Compatibility: Ensure that parts are compatible with existing machinery.

- Consider Material Requirements: Different projects may require specific materials for durability and performance.

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers to understand their offerings and market reputation. Look for suppliers with a track record of providing quality sandblasting parts and excellent customer service.

Illustrative image related to sandblasting parts

- Check Online Reviews: Utilize platforms like Trustpilot or industry-specific forums to gauge customer feedback.

- Verify Industry Experience: Suppliers with extensive experience in sandblasting components are more likely to understand your needs.

Step 3: Evaluate Supplier Certifications

Before making a commitment, it’s essential to verify that suppliers possess the necessary certifications and compliance with industry standards. This ensures that the products meet safety and quality regulations, which is crucial for operational efficiency.

- Request Documentation: Ask for certifications such as ISO 9001, which indicates a commitment to quality management.

- Check for Compliance: Ensure that parts comply with local and international safety standards relevant to your region.

Step 4: Request Samples or Demonstrations

If possible, request samples or product demonstrations from shortlisted suppliers. This step allows you to evaluate the quality and performance of their products firsthand.

- Assess Quality: Analyze the material and construction of the parts to ensure they meet your specifications.

- Test Compatibility: Use samples in your operational environment to confirm they work seamlessly with your equipment.

Step 5: Compare Pricing and Payment Terms

Once you have identified suitable suppliers, compare their pricing and payment terms. While cost is a significant factor, it should not be the only consideration.

- Look for Bulk Discounts: Many suppliers offer discounts for larger orders, which can significantly reduce costs.

- Evaluate Payment Flexibility: Consider suppliers who offer flexible payment options, which can ease cash flow management.

Step 6: Review Shipping and Delivery Options

Understand the shipping policies and delivery timelines of potential suppliers. Efficient logistics are critical to maintaining your production schedule.

- Check Shipping Locations: Ensure the supplier can ship to your location, particularly if you operate in regions with logistical challenges.

- Inquire About Lead Times: Confirm how long it will take for parts to arrive and whether expedited options are available if needed.

Step 7: Establish Ongoing Communication

After selecting a supplier, establish clear lines of communication for ongoing support and future orders. Good communication can enhance your relationship and lead to better service over time.

- Set Up Regular Check-Ins: Schedule periodic updates to discuss inventory levels, new products, and any issues that may arise.

- Provide Feedback: Share your experiences and suggestions, which can help suppliers improve their offerings and service.

By following this checklist, B2B buyers can streamline their procurement process for sandblasting parts, ensuring they receive quality products that meet their operational demands.

Comprehensive Cost and Pricing Analysis for sandblasting parts Sourcing

What Are the Key Cost Components in Sandblasting Parts Sourcing?

When sourcing sandblasting parts, understanding the cost structure is essential for effective budgeting and decision-making. The major cost components include:

-

Materials: The primary cost driver, materials can range from basic steel to advanced composites, depending on the part. For instance, tungsten carbide nozzles are more expensive than standard aluminum ones due to their durability and performance.

-

Labor: Labor costs vary significantly based on geographic location and the complexity of the manufacturing process. Regions with higher labor costs might affect the final price, especially if specialized skills are required.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Specialized tooling for custom parts can add to upfront costs. However, investing in quality tooling can lead to better production efficiency and lower defect rates.

-

Quality Control (QC): Ensuring that parts meet industry standards incurs additional costs. Certification processes, such as ISO compliance, can further influence pricing.

-

Logistics: Shipping costs, particularly for international buyers, can significantly affect total costs. Factors such as distance, mode of transport, and Incoterms play critical roles.

-

Margin: Suppliers will add a profit margin to cover their costs and risks. Understanding industry standards for margins can help buyers gauge whether they are receiving a fair price.

How Do Price Influencers Affect Sandblasting Parts Costs?

Several factors can influence the pricing of sandblasting parts, including:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk often leads to discounts. Buyers should assess their needs to determine whether they can meet MOQs for better pricing.

-

Specifications and Customization: Custom parts typically come at a premium due to the added complexity in design and production. Buyers should weigh the benefits of customization against potential cost increases.

-

Materials and Quality Certifications: Higher-quality materials and certifications may increase costs but can lead to better performance and longer lifespans. This is particularly relevant for safety equipment like helmets and gloves.

-

Supplier Factors: Different suppliers may have varied pricing structures based on their operational efficiencies, supply chain logistics, and market positioning. Building strong relationships can lead to better negotiation outcomes.

-

Incoterms: Understanding Incoterms is crucial for international buyers, as they dictate who is responsible for shipping costs, insurance, and risk during transportation. Properly negotiating these terms can lead to cost savings.

What Buyer Tips Can Enhance Cost-Efficiency in Sandblasting Parts Procurement?

To optimize sourcing strategies, consider the following tips:

-

Negotiate Effectively: Leverage your purchasing power by negotiating prices, especially if you are a repeat buyer. Highlighting your commitment to long-term partnerships can encourage suppliers to offer better rates.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on purchase price, consider the TCO, which includes maintenance, operational costs, and longevity of the parts. This broader view can uncover more cost-effective options.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations, tariffs, and import duties can significantly affect costs. Buyers in Africa, South America, the Middle East, and Europe should stay informed about these factors to avoid unexpected expenses.

-

Research Local Suppliers: Whenever possible, sourcing from local suppliers can reduce shipping costs and lead times, enhancing overall supply chain efficiency.

-

Stay Informed on Market Trends: Regularly review market trends in materials and technology to anticipate price changes and adjust sourcing strategies accordingly.

Disclaimer on Pricing

Prices for sandblasting parts can vary widely based on the aforementioned factors. It is advisable to obtain multiple quotes and conduct thorough market research to ensure you are getting competitive pricing. Always request detailed breakdowns from suppliers to understand what influences their pricing.

Alternatives Analysis: Comparing sandblasting parts With Other Solutions

Exploring Alternatives to Sandblasting Parts: Key Comparisons

In the realm of surface preparation and finishing, sandblasting parts play a vital role in achieving optimal results. However, various alternative methods can also serve similar purposes, offering distinct advantages and disadvantages. This analysis will compare sandblasting parts against two prominent alternatives: wet blasting and laser cleaning. Each alternative presents unique benefits that cater to different operational needs and constraints.

| Comparison Aspect | Sandblasting Parts | Wet Blasting | Laser Cleaning |

|---|---|---|---|

| Performance | High efficiency in removing coatings and rust; suitable for various surfaces. | Effective for delicate surfaces; minimizes dust and heat damage. | Exceptional precision; ideal for intricate designs and sensitive materials. |

| Cost | Moderate initial investment; ongoing costs for abrasives and maintenance. | Generally higher setup costs; lower abrasive costs due to water use. | High upfront cost for equipment; minimal ongoing costs but requires skilled operators. |

| Ease of Implementation | Relatively easy to set up and operate with proper training. | More complex setup; requires water supply and drainage considerations. | Requires specialized training and expertise; potential regulatory compliance issues. |

| Maintenance | Regular maintenance needed for parts and equipment. | Lower maintenance, but water systems require monitoring. | Minimal maintenance; primarily involves keeping laser optics clean. |

| Best Use Case | Ideal for heavy-duty applications like industrial cleaning and surface preparation. | Best for sensitive materials where traditional blasting may cause damage. | Perfect for applications requiring precision, such as removing coatings without affecting the substrate. |

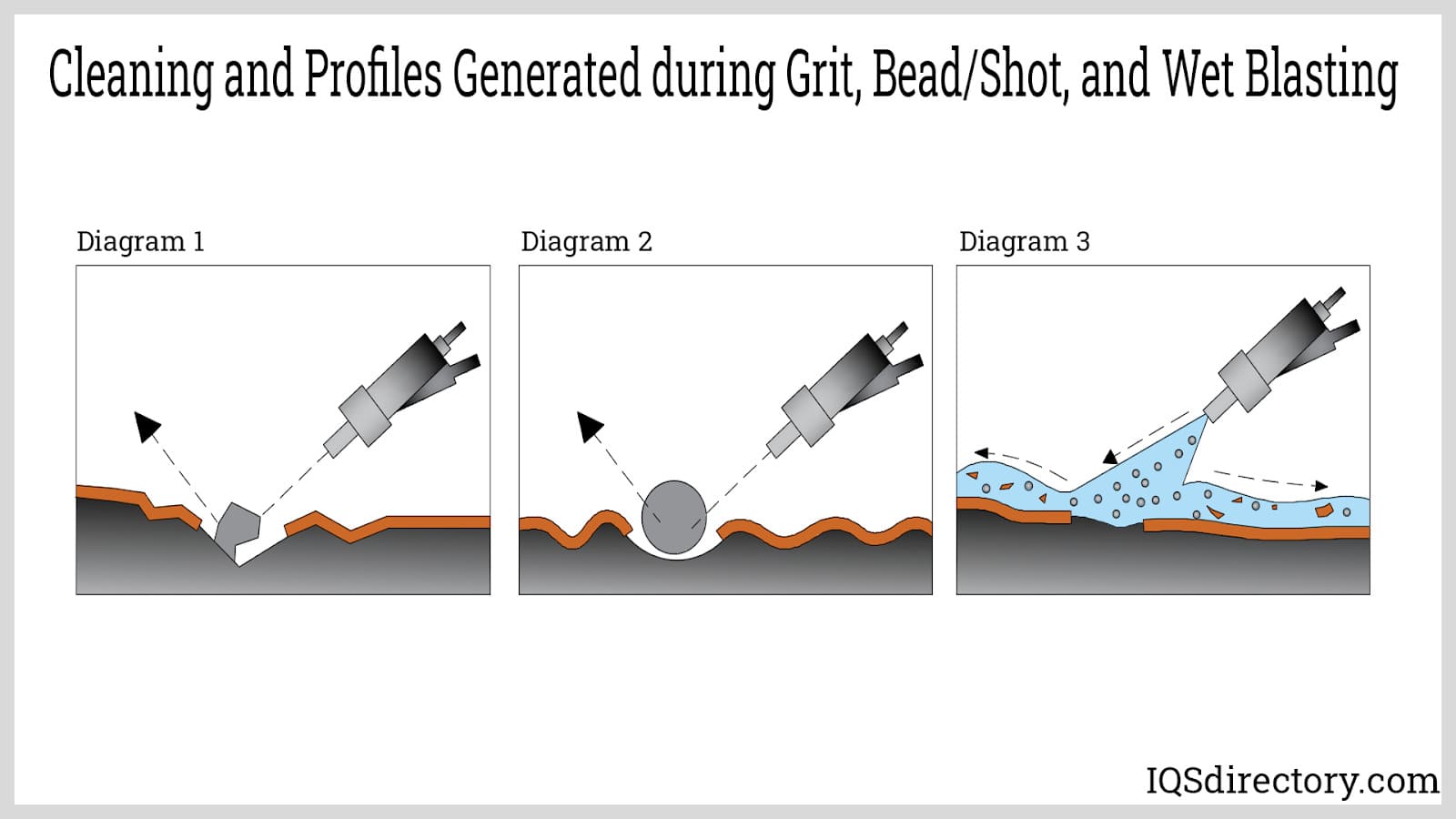

What are the Advantages and Disadvantages of Wet Blasting?

Wet blasting utilizes a mixture of water and abrasives, effectively reducing airborne dust and minimizing heat generation during the process. This method is particularly beneficial for delicate materials that might suffer from damage due to traditional dry sandblasting. However, the initial costs can be higher due to the need for specialized equipment and ongoing water management. Additionally, while wet blasting is gentler on surfaces, it may not be as effective for heavy rust or thick coatings as traditional sandblasting.

How Does Laser Cleaning Compare to Sandblasting Parts?

Laser cleaning employs high-intensity lasers to remove contaminants from surfaces with remarkable precision. This technique is particularly advantageous for intricate components where traditional methods may cause damage. The precision of laser cleaning minimizes the need for secondary processes, such as re-polishing. However, the high upfront costs and the requirement for skilled operators can be significant barriers for many businesses. Additionally, the technology may not be suitable for large-scale applications where sandblasting is typically more efficient.

How Should B2B Buyers Choose the Right Solution?

When selecting between sandblasting parts and alternative methods like wet blasting or laser cleaning, B2B buyers should consider their specific application requirements, budget constraints, and the materials involved. For heavy-duty industrial applications, sandblasting remains a reliable choice. Conversely, if working with sensitive materials or intricate designs, wet blasting or laser cleaning may offer the best results. Ultimately, understanding the unique advantages and limitations of each method will enable buyers to make informed decisions tailored to their operational needs.

Illustrative image related to sandblasting parts

Essential Technical Properties and Trade Terminology for sandblasting parts

What Are the Key Technical Properties of Sandblasting Parts?

Understanding the technical specifications of sandblasting parts is crucial for B2B buyers, particularly when selecting equipment that meets operational demands and industry standards. Here are several key properties to consider:

-

Material Grade

– The material grade of sandblasting parts, such as nozzles and hoses, is vital for durability and performance. Common materials include steel, aluminum, and various polymers. Higher grades typically offer better resistance to wear and corrosion, which can significantly affect the longevity of the equipment. For instance, tungsten carbide nozzles are preferred for their abrasion resistance, making them ideal for heavy-duty applications. -

Pressure Rating

– Each sandblasting component has a specific pressure rating, indicating the maximum pressure it can safely handle. This is critical for ensuring safety and efficiency during operations. Parts that are not rated for the operating pressure may fail, leading to equipment damage and safety hazards. Buyers should match the pressure rating of components with their sandblasting machine to ensure optimal performance. -

Tolerance

– Tolerance refers to the acceptable range of variation in a part’s dimensions. In sandblasting applications, precise tolerances are essential for ensuring that parts fit together correctly, which helps maintain operational efficiency and safety. Components with tight tolerances reduce the risk of leaks and improve the effectiveness of the blasting process. -

Flow Rate

– The flow rate of materials through hoses and nozzles affects the efficiency and effectiveness of the sandblasting process. A higher flow rate can increase productivity but may require more robust equipment. Understanding the required flow rates for specific applications helps buyers select the right components to optimize their operations. -

Abrasion Resistance

– The ability of a part to withstand wear caused by abrasive materials is crucial in sandblasting operations. Parts with high abrasion resistance, such as specially coated nozzles or reinforced hoses, can significantly reduce maintenance costs and downtime. Buyers should consider the abrasiveness of the media used in their processes when selecting parts.

What Are Common Trade Terminology in the Sandblasting Industry?

Familiarity with industry jargon helps B2B buyers navigate the procurement process more effectively. Here are several common terms relevant to sandblasting parts:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts that are sold under another company’s brand. When sourcing sandblasting parts, understanding whether a product is OEM can indicate its quality and compatibility with existing equipment. -

MOQ (Minimum Order Quantity)

– MOQ specifies the smallest quantity of a product that a supplier is willing to sell. Buyers should consider MOQs when planning their purchases, especially for bulk orders, as they can impact overall costs and inventory management. -

RFQ (Request for Quotation)

– An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. It is a critical step in the procurement process, allowing buyers to compare options and make informed purchasing decisions. -

Incoterms

– Short for International Commercial Terms, Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Understanding these terms can help buyers from regions like Africa and South America navigate logistics more effectively. -

PPE (Personal Protective Equipment)

– PPE refers to safety gear required when performing sandblasting operations, including helmets, gloves, and suits. Ensuring that all personnel are equipped with appropriate PPE is essential for compliance with safety regulations and to protect workers from hazards.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when purchasing sandblasting parts, ultimately enhancing their operational efficiency and safety.

Navigating Market Dynamics and Sourcing Trends in the sandblasting parts Sector

What Are the Key Market Drivers and Trends in the Sandblasting Parts Sector?

The sandblasting parts sector is experiencing dynamic changes driven by technological advancements and evolving market needs. Internationally, there is a growing demand for high-performance, durable components that can withstand rigorous industrial applications. This trend is particularly prominent in emerging markets in Africa, South America, the Middle East, and Europe, where infrastructure development and industrialization are accelerating. As a result, companies are increasingly investing in advanced technologies such as automated sandblasting systems, which enhance efficiency and reduce labor costs.

Additionally, the rise of e-commerce platforms is transforming the sourcing landscape for B2B buyers. International buyers can now access a wider range of products and suppliers, allowing for better price comparisons and streamlined purchasing processes. This is especially beneficial for regions like Nigeria and Saudi Arabia, where traditional supply chains may be less developed. Furthermore, buyers are increasingly looking for suppliers who offer customization options for sandblasting parts, enabling them to tailor solutions to specific project requirements.

Emerging technologies such as 3D printing are also beginning to impact the sector by providing innovative solutions for producing complex parts with reduced lead times. This not only enhances the availability of replacement parts but also opens avenues for cost-effective manufacturing. As these trends continue to unfold, international B2B buyers must stay informed about technological advancements and be prepared to adapt their sourcing strategies accordingly.

How Is Sustainability Influencing Sourcing Decisions in the Sandblasting Parts Market?

Sustainability is becoming a critical factor in the sourcing of sandblasting parts. Environmental concerns, including the impact of abrasive materials and waste generated during sandblasting processes, are prompting companies to seek eco-friendly alternatives. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using recyclable materials and implementing waste reduction strategies.

Ethical sourcing is also gaining traction, with buyers looking for manufacturers who adhere to responsible labor practices and have transparent supply chains. Certifications like ISO 14001 for environmental management and other green certifications can provide assurance to buyers that their suppliers are committed to minimizing environmental impact. This trend is particularly relevant for regions where regulatory frameworks are evolving to encourage sustainable practices.

Illustrative image related to sandblasting parts

Moreover, the demand for ‘green’ materials is on the rise. For instance, biodegradable abrasives and non-toxic coatings are being preferred over traditional options. This shift not only aligns with corporate social responsibility goals but also helps companies enhance their brand image and meet customer expectations for sustainability.

What Is the Historical Context of the Sandblasting Parts Industry?

The sandblasting parts industry has evolved significantly since its inception in the late 19th century. Originally developed for cleaning and preparing surfaces for painting, sandblasting has expanded to include various applications across multiple industries, including automotive, aerospace, and construction. Early systems relied heavily on manual processes, but advancements in technology have led to the development of automated and semi-automated systems that enhance efficiency and precision.

As the industry has matured, the focus has shifted towards improving safety standards and reducing environmental impact. Innovations such as closed-loop systems and advanced filtration technologies have emerged to address the health risks associated with dust and debris produced during sandblasting. This evolution not only reflects technological advancements but also a growing awareness of the need for safer and more sustainable practices in industrial operations.

In conclusion, understanding market dynamics, sourcing trends, and the historical context of the sandblasting parts sector is essential for international B2B buyers. By staying informed and adapting to these changes, businesses can position themselves for success in a competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of sandblasting parts

-

1. How do I solve issues with sandblasting equipment compatibility?

To resolve compatibility issues with sandblasting equipment, first, confirm the specifications of your existing equipment, including nozzle size, hose diameter, and pressure ratings. Consult with your supplier to ensure the new parts are compatible with your current setup. It’s also advisable to refer to the manufacturer’s guidelines for your sandblasting system. If in doubt, seek expert advice from your supplier or a technician familiar with your equipment to avoid costly errors. -

2. What is the best sandblasting nozzle for different materials?

The best sandblasting nozzle varies depending on the material you are working with. For softer materials, a wider nozzle may be ideal to prevent damage, while harder surfaces may require a more focused nozzle to ensure effective abrasion. Tungsten carbide nozzles are often recommended for their durability and efficiency across various applications. Always consider the material type, desired finish, and the specific job requirements when selecting a nozzle to maximize performance. -

3. How can I vet suppliers of sandblasting parts?

Vetting suppliers involves several key steps: researching their reputation through reviews and testimonials, verifying their certifications and compliance with international standards, and assessing their customer service responsiveness. Request references from other businesses that have purchased from them. Additionally, consider visiting their facility, if feasible, to inspect their inventory and quality control processes. This thorough approach helps ensure you partner with reliable suppliers that meet your quality and service expectations. -

4. What are common minimum order quantities (MOQs) for sandblasting parts?

Minimum order quantities (MOQs) for sandblasting parts can vary significantly based on the supplier and the specific parts ordered. Typically, MOQs can range from a few units for smaller, less expensive items to larger quantities for custom or specialized parts. It’s essential to discuss MOQs upfront with your supplier to understand their policies and negotiate terms that suit your business needs, especially if you are looking to manage inventory costs effectively. -

5. What payment terms should I expect when sourcing sandblasting parts internationally?

Payment terms for international purchases of sandblasting parts often include options like advance payment, letters of credit, or net payment terms (e.g., 30, 60, or 90 days). Many suppliers may require a deposit upfront, especially for larger orders or customized parts. It’s crucial to clarify these terms during negotiation to ensure both parties are aligned, and to consider using secure payment methods to mitigate risks associated with international transactions. -

6. How do I ensure quality assurance (QA) when purchasing sandblasting parts?

To ensure quality assurance when purchasing sandblasting parts, request detailed specifications and certifications from your supplier. Inquire about their quality control processes and whether they perform routine testing on their products. It’s also beneficial to ask for samples before placing a large order, allowing you to evaluate the parts firsthand. Establishing a clear return policy in case of defects can further safeguard your investment. -

7. What logistics considerations should I be aware of when importing sandblasting parts?

Logistics considerations include shipping methods, customs regulations, and potential tariffs or duties applicable to your region. Choose a reliable logistics provider experienced in handling industrial equipment to navigate these complexities. Ensure that the supplier provides accurate documentation for customs clearance, and factor in lead times for both production and delivery. Planning for contingencies, such as delays or additional costs, will help you maintain efficient operations. -

8. How can I customize sandblasting parts to meet specific operational needs?

Customization of sandblasting parts often involves discussing your specific requirements with the supplier, including dimensions, materials, and performance specifications. Many suppliers offer tailored solutions, but it’s important to communicate your needs clearly. Be prepared to provide detailed information about your application, including the types of materials you are blasting and the desired outcomes. Collaborating closely with the supplier during the design and manufacturing process will help ensure the final product meets your operational standards.

Top 8 Sandblasting Parts Manufacturers & Suppliers List

1. Sandblaster Parts – Sandblasting Helmets & Accessories

Domain: sandblaster-parts.com

Registered: 2009 (16 years)

Introduction: Sandblasting Gloves, Sandblasting Helmets, NOVA 3 Sandblasting Helmets, NOVA 2000 Sandblasting Helmets, Astro Sandblasting Helmets, Climate Control for RPB Sandblasting Helmets, Lenses for Sandblasting Helmets, BULLARD Sandblasting Helmets, Paint Hoods, T100 T-Link Respirator, Sandblasting Helmet Accessories, Radex Breathing Filters, Sandblasting Suits, Breathing Pump, Portable Sandblasters, Stati…

2. Clemco – Classic Blast Pots & Parts

Domain: sandblastingmachines.com

Registered: 2005 (20 years)

Introduction: Clemco Classic Blast Pot Replacement Parts & Accessories, Free Shipping on orders over $99, Customer Service contact at 1-855-358-2850. Various models of Classic Blast Pots available: 0.5 CU FT Model 1028, 1 CU FT Model 1042, 3 CU FT Model 1648, 6 CU FT Model 2452, 6 CU FT Lo Pot Model 2443, 10 CU FT Model 3661, 20 CU FT Model 3680. Parts categorized by model numbers for easy searching. Emphasis o…

3. Norton – Nova 3 Blast Hood Lens Kit

Domain: nortonsandblasting.com

Registered: 1998 (27 years)

Introduction: {“products”:[{“name”:”Lens Kit for Nova 3 Blast Hood”,”item_number”:”NV3LK”,”price”:”$115.84″},{“name”:”Lens, Tear-Away for Nova 3 Blast Helmet (50 pack)”,”item_number”:”NV3-725″,”price”:”$47.49″},{“name”:”Lens, Outer, for Nova 3 Blast Hood (Helmet) (50 pack)”,”item_number”:”NV3-724″,”price”:”$35.71″},{“name”:”Lens, Inner, For Nova 3 Blast Hoods (10 pack)”,”item_number”:”NV3-722″,”price”:”$38.32″}…

4. Blast-It-All – Essential Hose and Valve Repair Kits

Domain: blast-it-all.com

Registered: 1997 (28 years)

Introduction: 55 Foot Bi-line Hose SKU: 16-872 $210.00; APV Plunger Valve Repair Kit W/Tungsten Carbide Sleeve SKU: 16-843-SC $785.00; APV Plunger Valve Repair Kit W/Urethane Sleeve SKU: 16-843UB $603.00; Blow Down Restrictor SKU: 011318 $185.00; Combination 1 1/4″ Valve Repair Kit SKU: 16-877RK $79.00; Coupling (Nylon) Blast Hose Size 1 1/4″ SKU: 14-104N $16.00; Coupling (Nylon) Blast Hose Size 1 7/8″ SKU: 14-…

5. TP Tools – Sandblast Cabinet Parts & Supplies

Domain: tptools.com

Registered: 1999 (26 years)

Introduction: Sandblast Cabinet Parts & Supplies for Abrasive Blasting Cabinets – TP Tools & Equipment. Key categories include: Skat Blast® Sandblasting Cabinets (Bench Top Series, Slant Top Series, Skat Cat Series, Pro Shop, Commercial), Abrasives & Accessories, Sandblast Cabinet Parts & Supplies (Cabinet Blasting Gloves, Nozzles, Air Jets, Gaskets, Lenses/Window Components, Trigger & Foot-Pedal Siphon Guns & …

6. Cyclone Blasters – Sandblaster Parts

Domain: cycloneblasters.com

Registered: 2004 (21 years)

Introduction: Sandblaster Parts include various components for sandblasting equipment such as: 1. Sandblast Cabinet Turntable ET150 2. Large Dust Collector Filter Cartridge (DC4000) 3. O-Ring & Washer Set for Gun Assembly 7100 4. Sandblast Nozzle 5 CFM TC 7084 5. 25 CFM Delron Nozzle Holder 7010 6. 5 CFM Ceramic Nozzle 7009 7. 25 CFM Tungsten Carbide Nozzle 7008 8. Sandblast Nozzle Holder 14 CFM Tungsten Carbid…

7. Eastwood – Abrasive Blasting Parts

Domain: eastwood.com

Registered: 1995 (30 years)

Introduction: This company, Eastwood – Abrasive Blasting Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Miles Supply – Sandblasting Equipment & Supplies

Domain: milessupply.com

Registered: 1997 (28 years)

Introduction: Sandblasting equipment and supplies include: Stencil supplies, stone paint, SandHandler Automatic sandblast & recovery system, compressors, abrasives (MilezBlast, White Lightning), nozzles, sandblast safety equipment, and more.

Strategic Sourcing Conclusion and Outlook for sandblasting parts

In today’s competitive landscape, strategic sourcing of sandblasting parts is essential for optimizing operational efficiency and reducing costs. By understanding the diverse offerings available—from nozzles and hoses to safety equipment—international B2B buyers can make informed decisions that enhance their procurement strategies. It’s crucial to partner with reliable suppliers who provide high-quality products and support, ensuring that your sandblasting systems operate at peak performance.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for superior sandblasting equipment and parts will only increase. Buyers should prioritize suppliers with a strong commitment to quality and customer service, as these factors significantly impact long-term operational success.

Looking ahead, the industry is poised for growth driven by technological advancements and an increasing focus on sustainability. Now is the time to explore innovative solutions and build strong relationships with trusted suppliers. Embrace the opportunities in the sandblasting sector, and let your sourcing strategies propel your business forward in this dynamic market.

Illustrative image related to sandblasting parts

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to sandblasting parts