How to Source Rubber Toy Squeaky Shrimp Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for rubber toy squeaky shrimp

In an increasingly competitive marketplace, sourcing rubber toy squeaky shrimp presents a unique challenge for international B2B buyers. With the rising demand for innovative pet products, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of this niche market is crucial. Buyers must navigate various factors, including product types, supplier reliability, and cost considerations, to make informed purchasing decisions that align with their business objectives.

This comprehensive guide delves into the essential aspects of the rubber toy squeaky shrimp market, offering insights into the different types available and their applications across diverse consumer segments. From understanding the materials used in manufacturing to identifying the most reputable suppliers, this resource equips businesses with the tools necessary to vet potential partners effectively. Additionally, we will explore pricing strategies and market trends, enabling buyers to negotiate better deals and enhance their competitive edge.

By leveraging the knowledge presented in this guide, B2B buyers can confidently approach the rubber toy squeaky shrimp market, ensuring they source high-quality products that meet the demands of their customers. Whether you are based in Brazil, Nigeria, or any other region, our insights will empower you to make strategic decisions that drive growth and satisfaction in your business.

Understanding rubber toy squeaky shrimp Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Squeaky Shrimp | Traditional design, bright colors, and squeaker | Pet stores, online marketplaces | Pros: Popular choice, appealing design; Cons: May not withstand aggressive chewing. |

| Eco-Friendly Shrimp | Made from sustainable materials, non-toxic | Eco-conscious retailers, specialty shops | Pros: Appeals to eco-friendly consumers; Cons: Higher production costs. |

| Multi-Textured Shrimp | Various textures for sensory stimulation | Pet boutiques, premium pet supply outlets | Pros: Engages pets longer, higher perceived value; Cons: More complex manufacturing. |

| Interactive Squeaky Shrimp | Incorporates features like lights or sounds | Specialty pet shops, online retailers | Pros: Enhances playtime, attracts attention; Cons: Potentially higher price point. |

| Customizable Shrimp | Options for personalization (colors, sizes, logos) | Corporate promotional items, branding | Pros: Unique selling proposition, brand visibility; Cons: Longer lead times for production. |

What Are the Key Features of Classic Squeaky Shrimp Toys?

Classic squeaky shrimp toys are characterized by their traditional design, vibrant colors, and built-in squeaker. These toys are highly popular among pet owners and are often found in pet stores and online marketplaces. When considering a purchase, B2B buyers should note their widespread appeal, making them a staple item. However, they may not be suitable for heavy chewers, as they can wear out quickly under aggressive use.

How Do Eco-Friendly Shrimp Toys Stand Out?

Eco-friendly shrimp toys are crafted from sustainable, non-toxic materials, appealing to environmentally conscious consumers. They are ideal for retailers targeting eco-friendly markets, such as specialty shops or pet boutiques. While these toys can command a premium price due to their sustainable nature, buyers should consider the higher production costs and potential for increased margins in eco-focused markets.

Why Choose Multi-Textured Shrimp Toys?

Multi-textured shrimp toys are designed with various surfaces that provide sensory stimulation for pets. These toys are particularly effective in engaging pets for longer periods, making them a favored choice in premium pet supply outlets and boutiques. While they often carry a higher perceived value, buyers must account for the complexities involved in their manufacturing, which could affect supply chain logistics.

What Are the Benefits of Interactive Squeaky Shrimp Toys?

Interactive squeaky shrimp toys incorporate additional features like lights or sounds to enhance playtime. These toys are particularly popular in specialty pet shops and online retailers, where unique offerings can attract more customers. While they offer significant engagement benefits, B2B buyers should be aware of the higher price point and the potential need for specialized marketing strategies to promote these products effectively.

How Can Customizable Shrimp Toys Meet Diverse Needs?

Customizable shrimp toys offer options for personalization, including different colors, sizes, and branding opportunities. These products are particularly valuable for corporate promotional items, allowing businesses to enhance brand visibility. While they provide a unique selling proposition, buyers should factor in the longer lead times associated with customization, which can impact inventory management and fulfillment strategies.

Key Industrial Applications of rubber toy squeaky shrimp

| Industry/Sector | Specific Application of rubber toy squeaky shrimp | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pet Products | Interactive pet toys for cats and dogs | Enhances pet engagement and reduces boredom, increasing sales. | Quality of materials, safety certifications, and durability. |

| Educational Toys | Learning tools in early childhood education | Promotes sensory development and motor skills in children. | Compliance with international safety standards for toys. |

| Promotional Merchandise | Brand awareness and customer engagement | Unique promotional items that attract attention and foster brand loyalty. | Customization options and minimum order quantities. |

| Marine-Themed Events | Event giveaways and decorations | Creates a fun atmosphere that resonates with marine enthusiasts. | Bulk pricing and delivery timelines for event planning. |

| Veterinary Clinics | Stress-relief toys for pets in waiting areas | Helps calm anxious pets, improving client satisfaction and retention. | Hygiene standards and ease of cleaning for repeated use. |

How Are Rubber Toy Squeaky Shrimp Used in the Pet Products Industry?

Rubber toy squeaky shrimp are widely used as interactive toys for pets, particularly cats and dogs. These toys stimulate pets’ natural instincts to hunt and play, significantly reducing boredom and promoting physical activity. For businesses in the pet product industry, sourcing high-quality rubber toys that are durable and safe is crucial, as pet owners prioritize the well-being of their animals. International buyers should consider local regulations regarding pet toy safety to ensure compliance and enhance marketability in diverse regions.

What Role Do Rubber Toy Squeaky Shrimp Play in Educational Toys?

In the educational sector, rubber toy squeaky shrimp serve as engaging tools for early childhood development. These toys can promote sensory exploration and fine motor skills among young children, making them valuable for schools and daycare centers. For B2B buyers, it is essential to ensure that these toys meet international safety standards, particularly in terms of non-toxic materials and age-appropriateness. Understanding the educational curriculum and how these toys fit into play-based learning can also aid in effective marketing strategies.

How Can Rubber Toy Squeaky Shrimp Be Utilized as Promotional Merchandise?

Rubber toy squeaky shrimp can be leveraged as unique promotional merchandise for businesses looking to enhance brand visibility. These toys can be customized with company logos and colors, making them attractive giveaways at events or trade shows. The playful nature of these toys can capture the attention of potential customers, fostering brand loyalty. When sourcing, businesses should consider the minimum order quantities and customization options to align with their marketing strategies effectively.

Illustrative image related to rubber toy squeaky shrimp

What Benefits Do Rubber Toy Squeaky Shrimp Offer at Marine-Themed Events?

At marine-themed events, rubber toy squeaky shrimp can serve as both giveaways and decorative elements, creating a fun and engaging atmosphere for attendees. They resonate well with marine enthusiasts and can enhance the overall experience of the event. For event organizers, it is crucial to negotiate bulk pricing and ensure timely delivery to accommodate the logistics of event planning. Additionally, incorporating these toys into event activities can further engage participants.

How Do Rubber Toy Squeaky Shrimp Contribute to Veterinary Clinics?

Veterinary clinics can utilize rubber toy squeaky shrimp as stress-relief tools for pets in waiting areas. These toys can help calm anxious animals, improving their experience and reducing stress for pet owners during visits. For clinics, sourcing toys that are easy to clean and maintain hygiene standards is vital. Ensuring that these toys are durable enough for repeated use can also enhance client satisfaction and retention, making them a worthwhile investment.

3 Common User Pain Points for ‘rubber toy squeaky shrimp’ & Their Solutions

Scenario 1: Sourcing Quality Rubber Toy Squeaky Shrimp for Diverse Markets

The Problem: Many B2B buyers struggle to find reliable suppliers of rubber toy squeaky shrimp that meet both quality and safety standards. In regions like Africa and South America, the challenge is compounded by varying import regulations and quality expectations. Buyers often face the risk of receiving subpar products that do not pass local safety tests, leading to financial losses and damage to their brand reputation.

The Solution: To mitigate these risks, buyers should prioritize sourcing from manufacturers with internationally recognized certifications, such as ISO and CE marks. Conducting due diligence on potential suppliers is crucial; this can be done through visits, audits, or third-party verification services. Additionally, engaging in trade shows and industry expos can provide valuable networking opportunities to meet reliable suppliers. Establishing clear specifications and quality benchmarks in your contracts can also safeguard against receiving inferior products. Consider forming long-term partnerships with a few trusted manufacturers rather than constantly switching suppliers, as this can lead to more consistent quality control.

Scenario 2: Addressing Durability Concerns in Rubber Toy Squeaky Shrimp

The Problem: Durability is a significant concern for retailers, especially in regions where pets may be more aggressive chewers. Buyers often receive complaints from customers about squeaky shrimp toys that fall apart or lose their squeak after minimal use, resulting in high return rates and dissatisfied customers. This can severely impact a retailer’s bottom line and brand loyalty.

The Solution: To address durability concerns, buyers should look for rubber toy squeaky shrimp made from high-quality, non-toxic materials specifically designed for heavy chewing. Request samples from suppliers and conduct in-house testing to evaluate the longevity of the toys under realistic conditions. Incorporating customer feedback into the design and material selection process can also enhance durability. Additionally, consider offering a warranty or satisfaction guarantee to reassure customers and build trust in the product. Educating retailers about the best practices for toy care can also help improve customer satisfaction and reduce returns.

Scenario 3: Navigating Marketing and Positioning Challenges for Rubber Toy Squeaky Shrimp

The Problem: Many B2B buyers find it difficult to effectively market rubber toy squeaky shrimp in a crowded marketplace. With numerous similar products available, distinguishing their offerings to attract retailers can be a daunting task. This is particularly true in competitive markets across Europe and the Middle East, where consumer preferences are rapidly evolving.

The Solution: To enhance market positioning, buyers should invest in comprehensive market research to understand consumer trends and preferences. Identifying unique selling points (USPs) for the rubber toy squeaky shrimp—such as eco-friendliness, unique designs, or added features like multi-textures or interactive squeaks—can help differentiate the product. Collaborating with pet influencers or bloggers for product reviews and promotions can also increase visibility and credibility. Creating engaging content that highlights the benefits and fun aspects of the toys through social media campaigns or informative blogs can resonate well with potential buyers. Lastly, leveraging data analytics to track sales trends and customer feedback can guide future product development and marketing strategies, ensuring that offerings remain relevant and appealing.

Strategic Material Selection Guide for rubber toy squeaky shrimp

When selecting materials for rubber toy squeaky shrimp, several factors come into play that can significantly affect product performance, durability, and marketability. Below is an analysis of four common materials used in the manufacturing of these toys, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to rubber toy squeaky shrimp

What are the Key Properties of Natural Rubber for Squeaky Shrimp Toys?

Natural rubber is a popular choice for squeaky toys due to its excellent elasticity and resilience. It can withstand repeated stretching and compressing, making it ideal for toys that are frequently chewed or squeezed. Natural rubber also has a high-temperature resistance, which is beneficial for maintaining shape and performance in various climates. However, it is susceptible to degradation from UV exposure and certain chemicals, which can limit its longevity if not properly treated.

Pros: Natural rubber is biodegradable, making it an environmentally friendly option. It also offers a soft texture that is appealing to pets.

Cons: The susceptibility to UV and chemical degradation can lead to shorter product life, especially in harsh environments.

How Does Thermoplastic Elastomer (TPE) Compare for Toy Applications?

Thermoplastic elastomers (TPE) combine the properties of rubber and plastic, providing excellent flexibility and durability. TPE is resistant to UV light, ozone, and a range of chemicals, making it suitable for outdoor use. Its manufacturing process is less complex than that of traditional rubber, allowing for easier production and customization.

Pros: TPE is non-toxic and can be produced in various colors and textures, enhancing market appeal. Its durability makes it ideal for high-usage scenarios.

Cons: While TPE is generally cost-effective, the initial investment can be higher compared to natural rubber, depending on the quality and formulation.

What Advantages Does Silicone Offer for Rubber Toy Squeaky Shrimp?

Silicone is another material increasingly used in pet toys due to its superior temperature resistance and durability. It can withstand extreme temperatures without losing its shape or performance, making it suitable for various climates. Silicone is also non-toxic and hypoallergenic, which is a significant advantage for pet safety.

Pros: Silicone is highly durable and resistant to UV light and chemicals, ensuring a long product life. Its softness and flexibility make it appealing for pets.

Cons: The primary drawback of silicone is its higher cost compared to other materials, which may affect pricing strategies in competitive markets.

What Are the Benefits and Limitations of PVC in Toy Manufacturing?

Polyvinyl chloride (PVC) is a widely used plastic in toy manufacturing due to its low cost and versatility. PVC can be formulated to be soft and flexible, making it suitable for squeaky toys. However, it is less durable than rubber or silicone and can become brittle over time, especially when exposed to sunlight or extreme temperatures.

Pros: PVC is cost-effective and can be produced in various colors and shapes, allowing for creative designs.

Cons: The potential for harmful chemical leaching and environmental concerns regarding PVC production can be significant drawbacks for international buyers, especially in regions with strict regulations.

Summary Table of Material Selection for Rubber Toy Squeaky Shrimp

| Material | Typical Use Case for rubber toy squeaky shrimp | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | Chewable and squeaky toys for pets | Biodegradable and soft texture | Susceptible to UV degradation | Medium |

| Thermoplastic Elastomer | Durable and colorful squeaky toys | Non-toxic and customizable | Higher initial investment | Medium |

| Silicone | High-performance squeaky toys | Superior durability and temperature resistance | Higher cost compared to other materials | High |

| Polyvinyl Chloride (PVC) | Economical squeaky toys | Versatile and cost-effective | Potential chemical leaching and brittleness | Low |

In conclusion, selecting the right material for rubber toy squeaky shrimp involves balancing performance, durability, cost, and compliance with international standards. Understanding the properties and limitations of each material will empower B2B buyers to make informed decisions that align with market demands and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for rubber toy squeaky shrimp

What Are the Key Manufacturing Processes for Rubber Toy Squeaky Shrimp?

The manufacturing of rubber toy squeaky shrimp involves several critical stages that ensure the final product meets quality standards while also being safe for pets. Understanding these processes can help B2B buyers identify reliable suppliers and assess the quality of their offerings.

1. Material Preparation: What Materials Are Used?

The primary materials used in the production of rubber squeaky toys include natural rubber, synthetic rubber (such as thermoplastic elastomer – TPE), and food-grade colorants. Natural rubber is favored for its elasticity and durability, while TPE is often used for its flexibility and ease of molding. The preparation phase involves sourcing high-quality raw materials that comply with international safety standards, particularly for pet toys.

Before production, materials undergo thorough inspection to ensure they meet specified quality criteria. Buyers should inquire about the suppliers’ sourcing practices and any certifications of the raw materials, as these can impact the overall safety and quality of the finished product.

2. Forming: How Are Rubber Toys Molded?

The forming process typically employs injection molding or blow molding techniques. In injection molding, heated rubber is injected into a mold that shapes the toy. This method allows for high precision and the ability to create complex designs, such as the intricate features of a shrimp.

Blow molding may also be used, particularly for hollow toys that need to contain air for squeaking mechanisms. Each method has its advantages, and buyers should consider the production capabilities of their suppliers to ensure they can meet specific design requirements.

Illustrative image related to rubber toy squeaky shrimp

3. Assembly: What Does the Assembly Process Involve?

Once the individual components are formed, they may require assembly, especially if the toy includes additional features like squeakers or other interactive elements. This stage may involve gluing or heat sealing parts together. Quality control is crucial here to ensure that all components fit securely and function as intended.

Buyers should verify whether the assembly processes adhere to stringent quality standards and whether workers are trained in best practices for assembling pet toys.

4. Finishing: How Is the Final Product Prepared?

The finishing stage includes processes like painting, polishing, and applying any surface treatments to enhance durability and safety. The application of non-toxic paints is essential, and suppliers should be able to provide documentation proving compliance with safety regulations.

After finishing, each toy is typically inspected for defects, ensuring that only products that meet quality standards proceed to packaging. Buyers should ask about the specific finishing techniques used and any certifications related to the safety of these processes.

What Quality Control Measures Are Essential for Rubber Toy Squeaky Shrimp?

Quality assurance in the manufacturing of rubber toys is critical to ensure safety and compliance with international standards. Here’s a closer look at the essential quality control measures.

1. What Are the Relevant International Standards for Rubber Toys?

International standards, such as ISO 9001 for quality management systems, are fundamental in ensuring that manufacturers maintain consistent quality across their production processes. Additionally, specific certifications relevant to pet toys include:

- CE Marking: Indicates compliance with health and safety standards in the European Economic Area.

- ASTM F963: A standard that outlines safety requirements for toys sold in the United States.

- EN71: The European standard for toy safety, covering mechanical and physical properties, flammability, and chemical properties.

B2B buyers should prioritize suppliers who possess these certifications, as they reflect a commitment to quality and safety.

2. What Are the Common Quality Control Checkpoints?

Quality control in rubber toy manufacturing typically involves several checkpoints throughout the production process:

- Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitors production processes to catch defects in real-time.

- Final Quality Control (FQC): Conducts thorough inspections on finished products to ensure they meet quality and safety standards before shipping.

These checkpoints are critical for maintaining product quality and should be documented through detailed reports, which buyers can request for review.

Illustrative image related to rubber toy squeaky shrimp

3. What Testing Methods Are Commonly Used for Rubber Toys?

Various testing methods are employed to ensure the safety and quality of rubber squeaky shrimp toys, including:

- Mechanical Testing: Evaluates the strength and durability of the toy, ensuring it can withstand typical use by pets.

- Chemical Testing: Assesses the toy for harmful substances, ensuring compliance with safety standards.

- Squeak Testing: Checks the functionality of the squeaker mechanism to ensure it operates correctly.

Buyers should inquire about the specific testing methods their suppliers employ and ask for test reports to verify compliance with safety standards.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that a supplier maintains high-quality standards, B2B buyers should engage in thorough vetting processes.

1. What Steps Can Buyers Take to Audit Suppliers?

Conducting supplier audits is a proactive approach to verify quality control practices. Buyers can request to visit manufacturing facilities, observe production processes, and review quality control documentation. During these audits, buyers should look for:

- Compliance with relevant quality standards.

- Proper documentation of quality control processes.

- Evidence of training programs for employees on quality assurance.

2. How Can Buyers Access Quality Reports and Certifications?

Buyers should request copies of quality control reports and certifications from suppliers. These documents should include:

- Certificates of compliance with international standards (e.g., ISO, CE, ASTM).

- Results from recent quality audits or inspections.

- Documentation of any third-party testing conducted on the products.

Having access to these reports can help buyers make informed decisions and build confidence in their suppliers.

3. What Are the Nuances of Quality Control for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of the specific regulations and standards that apply to their markets. Understanding local regulations regarding pet toy safety is crucial, as non-compliance can lead to product recalls or legal issues.

Additionally, buyers should consider logistical factors, such as the potential for differences in quality perception and standards across regions. Engaging with suppliers who have experience exporting to specific markets can mitigate these risks.

Conclusion

In summary, a comprehensive understanding of the manufacturing processes and quality assurance measures for rubber toy squeaky shrimp is essential for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and robust quality control practices, buyers can ensure they partner with suppliers who deliver safe, high-quality products that meet international standards. This diligence not only enhances product safety but also strengthens brand reputation in competitive markets.

Illustrative image related to rubber toy squeaky shrimp

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rubber toy squeaky shrimp’

Introduction

Sourcing rubber toy squeaky shrimp for your business can be a rewarding venture, but it requires careful planning and execution. This guide provides a structured checklist to help B2B buyers navigate the procurement process effectively. By following these steps, you can ensure that you select high-quality products that meet your market’s demands and comply with industry standards.

1. Define Your Product Specifications

Clearly outlining your product specifications is the foundation of a successful sourcing strategy. Consider the size, color, material composition, and design features of the rubber toy squeaky shrimp you wish to procure. Ensure your specifications align with market trends and customer preferences in your target regions, such as Africa or South America.

2. Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in rubber toys. Utilize trade directories, online platforms, and industry networks to compile a list of candidates. Prioritize suppliers with a proven track record in the toy industry, particularly those familiar with international shipping and regulations.

3. ✅ Verify Supplier Certifications

Before proceeding with any supplier, it’s essential to verify their certifications. Look for compliance with safety standards such as ASTM F963 or EN71, which ensure the toys are safe for children and pets. Additionally, check for ISO certifications that indicate quality management systems in place.

4. Request Samples for Quality Assessment

Once you have shortlisted suppliers, request samples to evaluate the quality of their products. Inspect the materials used, the durability of the toy, and the effectiveness of the squeaker. This step is crucial to ensure that the products meet your specifications and will satisfy your customers.

5. Evaluate Pricing and Payment Terms

Understanding the pricing structure and payment terms is vital for budgeting and cash flow management. Request detailed quotes from each supplier, including bulk pricing options, shipping costs, and payment methods. Negotiate terms that are favorable for your business while ensuring the supplier can maintain product quality.

6. Assess Production Capabilities and Lead Times

Inquire about the supplier’s production capabilities and lead times. Understanding their capacity to meet your order volume and timeline is essential to avoid stockouts. Ask for information on their production process and any potential bottlenecks that could affect delivery schedules.

7. Establish a Communication Plan

Effective communication is key to a successful sourcing relationship. Set clear expectations for communication frequency and preferred channels (e.g., email, phone). Establishing a communication plan helps to address any issues promptly and fosters a collaborative relationship with your supplier.

By following this checklist, you can streamline your sourcing process for rubber toy squeaky shrimp, ensuring that you select the right suppliers and products for your business needs. Adopting a methodical approach will help mitigate risks and enhance your overall procurement strategy.

Comprehensive Cost and Pricing Analysis for rubber toy squeaky shrimp Sourcing

What Are the Key Cost Components in Sourcing Rubber Toy Squeaky Shrimp?

When sourcing rubber toy squeaky shrimp, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of rubber significantly impacts costs. Natural rubber may be more expensive than synthetic alternatives, but it offers superior durability and safety, which could justify a higher price point for certain markets.

-

Labor: Labor costs vary by region. In countries with lower labor costs, such as some parts of Africa and South America, production may be cheaper. However, consider the skill level required for quality production, as skilled labor can command higher wages.

-

Manufacturing Overhead: This encompasses utilities, rent, and equipment depreciation. Factories with advanced machinery may have higher overhead but can produce higher-quality products faster.

-

Tooling: Initial tooling costs for molds and machinery can be significant. Custom designs will increase these costs, but they may be necessary for differentiation in competitive markets.

-

Quality Control (QC): Implementing rigorous QC processes ensures product safety and compliance with international standards. Investing in QC can prevent costly recalls and enhance brand reputation.

-

Logistics: Shipping costs fluctuate based on distance, shipping method, and current fuel prices. Incoterms should be clearly defined to understand who bears these costs and risks.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure sustainability. Margins can vary based on competition and perceived product value.

How Do Price Influencers Affect Sourcing Decisions for Rubber Toy Squeaky Shrimp?

Several factors can influence the pricing of rubber toy squeaky shrimp:

-

Volume/MOQ: Minimum Order Quantities (MOQ) can significantly affect pricing. Larger orders often lead to bulk discounts, which can substantially reduce the per-unit cost.

-

Specifications and Customization: Custom designs or specific specifications (like size or color) can increase costs. It’s essential to balance the need for customization with budget constraints.

-

Materials and Quality Certifications: The type of rubber used and any quality certifications (such as ASTM or EN71) can affect pricing. Higher quality materials and certifications typically command higher prices but may be necessary for specific markets.

-

Supplier Factors: The supplier’s reputation, reliability, and experience can influence costs. Established suppliers may charge more due to their proven track record, but this could lead to long-term savings through reduced risk.

-

Incoterms: Understanding Incoterms (like FOB, CIF, etc.) is vital for determining who is responsible for shipping and risk. This can affect overall costs and should be negotiated clearly to avoid misunderstandings.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Rubber Toy Squeaky Shrimp?

B2B buyers should consider several strategies to optimize their sourcing process:

-

Negotiation: Engage suppliers in discussions about pricing, especially if you have a long-term partnership. Leverage volume commitments to negotiate better terms.

-

Total Cost of Ownership: Look beyond the initial purchase price. Consider shipping, handling, storage, and potential warranty costs when evaluating suppliers. This holistic view can lead to better purchasing decisions.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, and the Middle East should be aware of local market dynamics and currency fluctuations. Establishing contracts in stable currencies can mitigate risks associated with exchange rates.

-

Market Research: Conduct thorough market research to understand competitive pricing and trends. This knowledge can empower negotiations and help identify the best suppliers.

Conclusion

Sourcing rubber toy squeaky shrimp requires a deep understanding of both cost components and pricing influencers. By leveraging negotiation strategies and considering the total cost of ownership, international B2B buyers can achieve cost-effective solutions while ensuring product quality and compliance with market standards. Always remember that the prices mentioned are indicative and can vary based on market conditions and supplier negotiations.

Illustrative image related to rubber toy squeaky shrimp

Alternatives Analysis: Comparing rubber toy squeaky shrimp With Other Solutions

When evaluating pet toy options, particularly for the vibrant and interactive rubber toy squeaky shrimp, it’s essential to consider various alternatives available in the market. Understanding the strengths and weaknesses of each option can help B2B buyers make informed decisions that align with their business strategies and customer needs.

| Comparison Aspect | Rubber Toy Squeaky Shrimp | Plush Cat Toy | Interactive Electronic Toy |

|---|---|---|---|

| Performance | Durable with consistent squeak; engages pets effectively | Soft and cuddly; may not engage as actively | Highly engaging; can simulate real-life interactions |

| Cost | Moderate price point, generally affordable | Lower price point, budget-friendly | Higher initial investment; ongoing costs for batteries |

| Ease of Implementation | Simple to stock and sell; no setup required | Easy to display and market | Requires technical knowledge for setup and promotion |

| Maintenance | Low maintenance; easy to clean | May require washing; can wear out faster | Maintenance needed for battery replacement and software updates |

| Best Use Case | Ideal for active play and chewing | Best for comfort and quiet play | Suitable for stimulating play and mental engagement |

What Are the Pros and Cons of Plush Cat Toys Compared to Rubber Toy Squeaky Shrimp?

Plush cat toys are often a popular alternative due to their soft texture and comforting appeal. These toys are generally more affordable, making them attractive for budget-conscious consumers. However, while they are excellent for snuggling, they may not engage pets as actively as rubber squeaky shrimp. Plush toys can wear out more quickly, requiring replacement more frequently, which could lead to higher long-term costs for retailers.

How Do Interactive Electronic Toys Stack Up Against Rubber Toy Squeaky Shrimp?

Interactive electronic toys represent a modern alternative that appeals to tech-savvy pet owners. These toys can offer dynamic play experiences, simulating real-life interactions that can keep pets engaged for longer periods. However, they come with a higher price tag and may require ongoing costs for batteries or maintenance. Additionally, the complexity of these toys may pose a challenge for retailers in terms of setup and customer education, which could affect sales.

Illustrative image related to rubber toy squeaky shrimp

Conclusion: How Should B2B Buyers Choose Between Rubber Toy Squeaky Shrimp and Its Alternatives?

When selecting the right toy for their inventory, B2B buyers should assess their target market’s preferences and behaviors. If customers prioritize durability and active engagement, the rubber toy squeaky shrimp could be the best fit. However, if the market leans towards budget-friendly or tech-enhanced options, exploring plush cat toys or interactive electronic toys may yield better results. Ultimately, a thorough understanding of customer needs, price sensitivity, and product lifecycle will guide buyers in making informed decisions that enhance their product offerings and customer satisfaction.

Essential Technical Properties and Trade Terminology for rubber toy squeaky shrimp

What Are the Key Technical Properties of Rubber Toy Squeaky Shrimp?

When sourcing rubber toy squeaky shrimp, understanding their technical properties is crucial for B2B buyers. These properties ensure product quality, safety, and compliance with international standards.

1. Material Grade

The primary material used in rubber toy squeaky shrimp is typically thermoplastic rubber (TPR) or natural rubber. TPR is favored for its flexibility, durability, and resistance to various environmental conditions. The material grade directly impacts the toy’s safety and longevity, making it vital for buyers to confirm that the toys meet relevant safety regulations, such as EN71 or ASTM F963.

2. Size and Tolerance

Size specifications and tolerances are essential for ensuring that the toys are safe and suitable for pets. Variances in size can affect how pets interact with the toy, influencing both playability and safety. Precise tolerances must be maintained during production to avoid sharp edges or small parts that could pose choking hazards.

3. Squeaker Quality

The squeaker component is integral to the toy’s appeal, providing auditory stimulation for pets. Buyers should inquire about the squeaker’s durability and sound quality, as a low-quality squeaker may fail quickly, leading to product returns and dissatisfied customers. Testing the squeaker’s volume and longevity is essential for maintaining product integrity.

4. Surface Texture and Finish

The surface texture of rubber toys can enhance grip and encourage play. Textured surfaces may also help with dental health by providing a mild abrasive action during chewing. Buyers should consider the finish—whether it is smooth or textured—and its impact on both pet engagement and ease of cleaning.

5. Color Fastness

Color fastness refers to the resistance of the toy’s colors to fading or bleeding during use. This property is particularly important for toys intended for outdoor play or exposure to sunlight. Ensuring that colors remain vibrant can enhance the product’s appeal and reduce returns due to fading.

6. Safety Certifications

Safety certifications are critical for compliance with regional regulations. For instance, toys sold in the EU must adhere to EN71 standards, while those in the U.S. should comply with ASTM F963. Buyers should verify that suppliers provide the necessary documentation to ensure that the products are safe for pets and meet market demands.

What Are Common Trade Terms in the Rubber Toy Industry?

Familiarity with trade terminology is essential for effective communication and negotiations in the rubber toy market.

Illustrative image related to rubber toy squeaky shrimp

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on specifications provided by another company, often a brand. For B2B buyers, understanding OEM relationships can help in sourcing customized rubber toy designs tailored to specific market needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for budgeting and inventory management. Buyers should negotiate MOQs based on their sales forecasts to avoid overstocking or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for a specific quantity of goods. For B2B buyers, submitting an RFQ can streamline the procurement process and facilitate comparisons among suppliers.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Understanding these terms helps buyers clarify shipping costs, risks, and logistics. Common Incoterms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight), which dictate when ownership and responsibility transfer from seller to buyer.

5. Lead Time

Lead time is the duration from placing an order to receiving the goods. This term is essential for supply chain management. Buyers should factor in lead times when planning inventory levels and product launches to avoid disruptions.

Illustrative image related to rubber toy squeaky shrimp

6. Quality Assurance (QA)

QA refers to the systematic process of ensuring that products meet specified quality standards. For B2B buyers, implementing QA measures can reduce defects and improve customer satisfaction, ultimately impacting brand reputation and sales.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they source high-quality rubber toy squeaky shrimp that meet market demands and safety standards.

Navigating Market Dynamics and Sourcing Trends in the rubber toy squeaky shrimp Sector

What are the Key Trends Influencing the Rubber Toy Squeaky Shrimp Market?

The rubber toy squeaky shrimp sector is witnessing significant growth, driven by rising disposable incomes and changing pet ownership dynamics across various regions, particularly in Africa, South America, the Middle East, and Europe. As urbanization increases, pet ownership is becoming more common, leading to a growing demand for engaging and durable pet toys. This trend is compounded by an increasing focus on mental stimulation and physical activity for pets, making squeaky toys, such as rubber shrimp, highly sought after.

Emerging B2B technologies are transforming sourcing practices in this sector. E-commerce platforms and digital supply chain solutions are enabling international buyers to access a wider range of products efficiently. For instance, platforms like Alibaba and Amazon Business facilitate direct connections between manufacturers and retailers, streamlining the procurement process. Additionally, advancements in data analytics are helping businesses understand consumer preferences and optimize inventory management, ensuring that popular items, such as rubber toy squeaky shrimps, are readily available.

Market dynamics are also shaped by the competitive landscape, where differentiation through design and features is crucial. Manufacturers are introducing innovative designs and eco-friendly materials to attract environmentally-conscious consumers. This evolution is particularly relevant for buyers in regions like Brazil and Nigeria, where awareness of sustainable products is on the rise. Thus, international B2B buyers must stay informed about these trends to remain competitive and meet evolving consumer demands.

How is Sustainability and Ethical Sourcing Affecting the Rubber Toy Squeaky Shrimp Market?

Sustainability and ethical sourcing are increasingly vital considerations for B2B buyers in the rubber toy squeaky shrimp sector. The environmental impact of production processes is under scrutiny, pushing manufacturers to adopt more sustainable practices. This includes the use of non-toxic, biodegradable materials and environmentally friendly production methods. Buyers should prioritize suppliers who demonstrate a commitment to reducing their carbon footprint and minimizing waste.

The importance of ethical supply chains cannot be overstated. Consumers are becoming more discerning, and many are willing to pay a premium for products that align with their values. Certifications such as the Global Organic Textile Standard (GOTS) or the OEKO-TEX Standard 100 can serve as indicators of a supplier’s commitment to sustainability. Additionally, transparency in sourcing practices is crucial; buyers should seek out manufacturers who provide clear information about their supply chains, labor practices, and environmental policies.

Incorporating sustainable practices not only meets consumer demand but also enhances brand reputation and loyalty. For B2B buyers, aligning with suppliers that prioritize sustainability can lead to long-term partnerships and a competitive edge in the market.

What is the Historical Context of Rubber Toy Squeaky Shrimp?

The rubber toy squeaky shrimp’s evolution traces back to the broader development of pet toys in the mid-20th century. Originally designed as simple rubber figures, these toys have transformed into sophisticated products catering to specific pet behaviors. The introduction of squeakers revolutionized the market, making toys more interactive and engaging for pets.

As pet ownership gained popularity, particularly in urban areas, the demand for diverse and durable toys surged. Rubber, known for its resilience and safety, became a preferred material. Over the years, manufacturers have responded to changing consumer preferences by incorporating vibrant designs, varied sizes, and even eco-friendly materials into their product lines. This evolution reflects a broader trend in the pet industry, where innovation and consumer awareness are shaping product offerings. As a result, rubber toy squeaky shrimps have become not just playthings but integral components of pet care and companionship.

Frequently Asked Questions (FAQs) for B2B Buyers of rubber toy squeaky shrimp

-

How can I ensure the quality of rubber toy squeaky shrimp from suppliers?

To ensure quality, request samples from potential suppliers before placing a bulk order. Evaluate the materials used, especially the rubber’s durability and safety certifications, such as ASTM or EN71 standards. Conduct factory audits if feasible, or utilize third-party inspection services to assess production processes. Additionally, review feedback from other buyers and check the supplier’s reputation on platforms like Alibaba or Global Sources. -

What are the typical minimum order quantities (MOQs) for rubber toy squeaky shrimp?

MOQs can vary significantly depending on the supplier and the specific toy design. Generally, MOQs for rubber toys may range from 500 to 5,000 units. It’s advisable to discuss your needs directly with suppliers, as some may be flexible with MOQs, especially for first-time buyers. Negotiating lower MOQs can be beneficial if you’re testing the market or starting small. -

What payment terms should I expect when sourcing rubber toy squeaky shrimp?

Payment terms can vary widely, but common practices include a 30% deposit upfront with the balance due before shipment. Some suppliers may offer credit terms or accept letters of credit for larger orders. Ensure to clarify payment methods accepted, such as bank transfers, PayPal, or credit cards, and be cautious of suppliers requesting full payment upfront, as this can indicate higher risk. -

How can I customize rubber toy squeaky shrimp for my brand?

Most manufacturers offer customization options, including design, color, and packaging. To initiate customization, provide clear specifications and any necessary artwork. Discuss the costs associated with molds or design changes, as these can affect the overall price. Be prepared for longer lead times for custom orders, typically ranging from 4 to 12 weeks, depending on the complexity. -

What logistics considerations should I keep in mind when importing rubber toy squeaky shrimp?

When importing, consider shipping methods (air vs. sea), as they significantly affect delivery time and cost. Ensure to factor in customs duties and taxes applicable in your country. Work with a reliable freight forwarder familiar with your region’s regulations to streamline the import process. Additionally, confirm the supplier’s capability to provide necessary shipping documents, such as invoices and certificates of origin. -

What certifications should I look for in rubber toy squeaky shrimp for international markets?

When sourcing rubber toys, certifications like ASTM F963 (USA) and EN71 (Europe) are crucial for ensuring safety and compliance with international standards. Check if the supplier can provide testing reports from accredited laboratories. For markets in Africa and South America, ensure compliance with local regulations, as they may have specific requirements for toy safety. -

How do I evaluate the reliability of a supplier for rubber toy squeaky shrimp?

To evaluate supplier reliability, research their business history, client testimonials, and industry certifications. Request references from previous clients to gauge their satisfaction. Utilize platforms such as Alibaba or Trade Assurance to assess their ratings. Additionally, consider suppliers with established trade histories and a track record of on-time delivery to minimize risk. -

What are common challenges faced when sourcing rubber toy squeaky shrimp internationally?

Common challenges include navigating different regulatory standards, potential language barriers, and varying production timelines. Additionally, quality control can be difficult when dealing with suppliers from distant regions. To mitigate these issues, maintain clear communication, consider hiring local agents to facilitate the process, and conduct regular follow-ups to ensure that timelines and quality expectations are met.

Top 1 Rubber Toy Squeaky Shrimp Manufacturers & Suppliers List

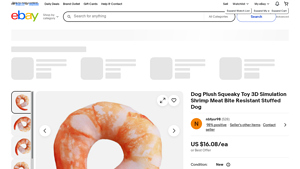

1. Dog Plush Squeaky Toy – 3D Simulation Shrimp Meat

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Dog Plush Squeaky Toy 3D Simulation Shrimp Meat”, “Condition”: “New”, “Price”: “$16.08/ea”, “Bulk Savings”: {“Buy 1”: “$16.08/ea”, “Buy 2”: “$15.12/ea”, “Buy 3”: “$14.63/ea”, “Buy 4 or more”: “$14.31/ea”}, “Quantity Available”: “10”, “Shipping”: “Free eBay SpeedPAK Standard”, “Location”: “Shenzhen, China”, “Delivery Estimate”: “Between Wed, Sep 24 and Tue, Sep 30”, “Returns”: “Se…

Strategic Sourcing Conclusion and Outlook for rubber toy squeaky shrimp

In the rapidly evolving market for rubber toy squeaky shrimp, strategic sourcing emerges as a critical factor for international B2B buyers. By understanding local preferences and trends in regions such as Africa, South America, the Middle East, and Europe, companies can better align their product offerings with consumer demands. Sourcing high-quality, durable materials is essential to ensure product longevity and customer satisfaction, especially in competitive markets.

Moreover, establishing reliable supply chains can mitigate risks associated with fluctuating demand and regulatory changes. Buyers should leverage partnerships with reputable manufacturers who prioritize sustainability and safety standards, as these factors increasingly influence purchasing decisions.

Looking ahead, the demand for innovative pet toys is expected to grow, driven by increased pet ownership and consumer spending in emerging markets. Now is the time for international buyers to capitalize on this trend by diversifying their product lines and exploring new sourcing opportunities. Engage with suppliers who demonstrate a commitment to quality and innovation, and consider how strategic sourcing can enhance your competitive edge in this vibrant market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to rubber toy squeaky shrimp

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.