How to Source Rubber Bushings By Size Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for rubber bushings by size

In today’s dynamic global market, sourcing rubber bushings by size presents a significant challenge for B2B buyers, particularly in diverse regions like Africa, South America, the Middle East, and Europe. With a multitude of options available, selecting the right rubber bushings that meet specific application requirements can be daunting. This guide serves as a comprehensive resource, addressing key aspects such as the various types of rubber bushings, their applications across industries, and the crucial factors to consider when vetting suppliers.

From flanged stem bushings to rubber/metal combinations, understanding the nuances of each type ensures that buyers make informed decisions that align with their operational needs. Additionally, we delve into the cost implications and sourcing strategies that can enhance procurement efficiency. By equipping international B2B buyers—whether in Nigeria, Vietnam, or elsewhere—with actionable insights, this guide empowers them to navigate the complexities of the rubber bushing market confidently. Ultimately, our goal is to facilitate smarter purchasing decisions that lead to enhanced product performance and operational success.

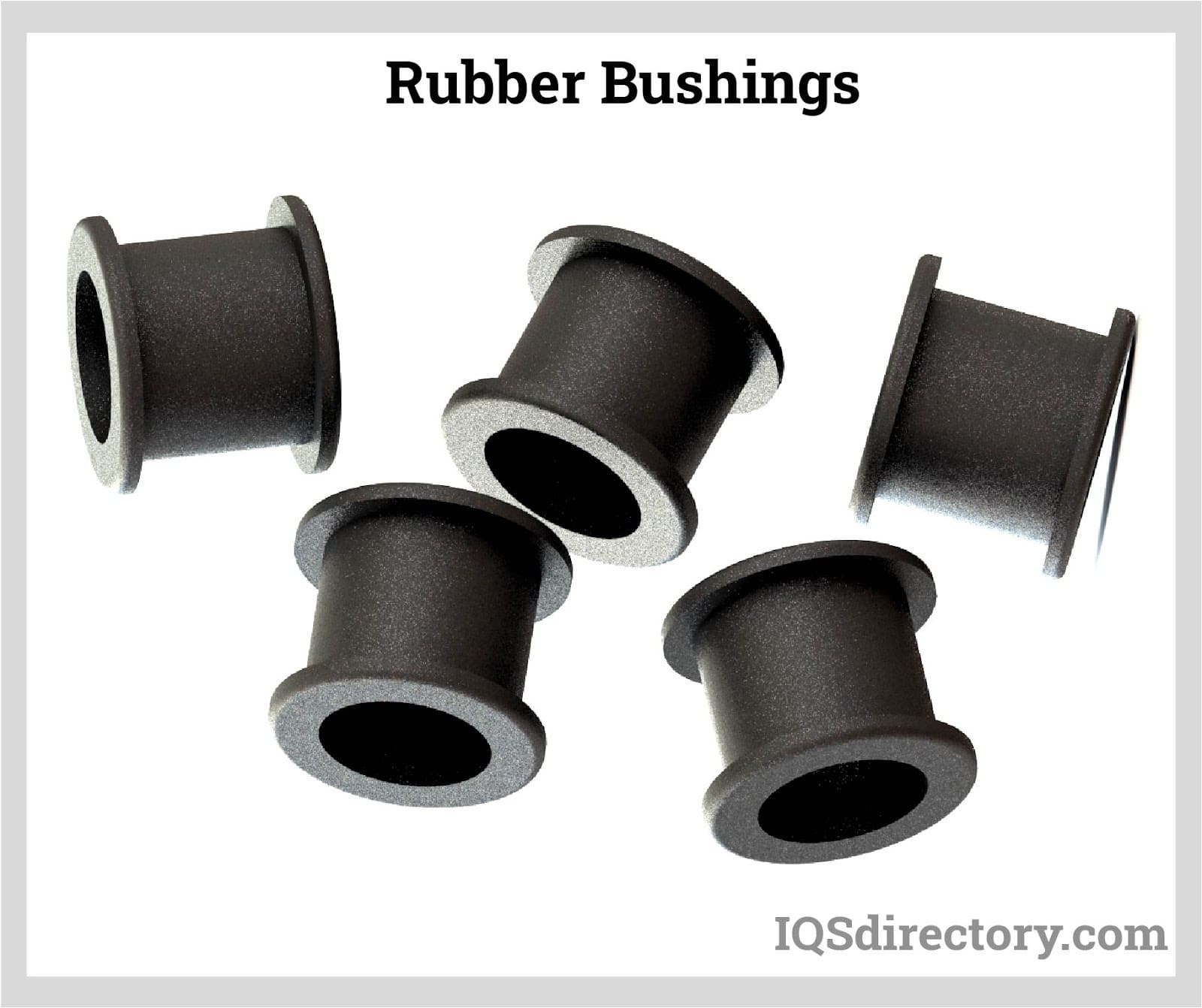

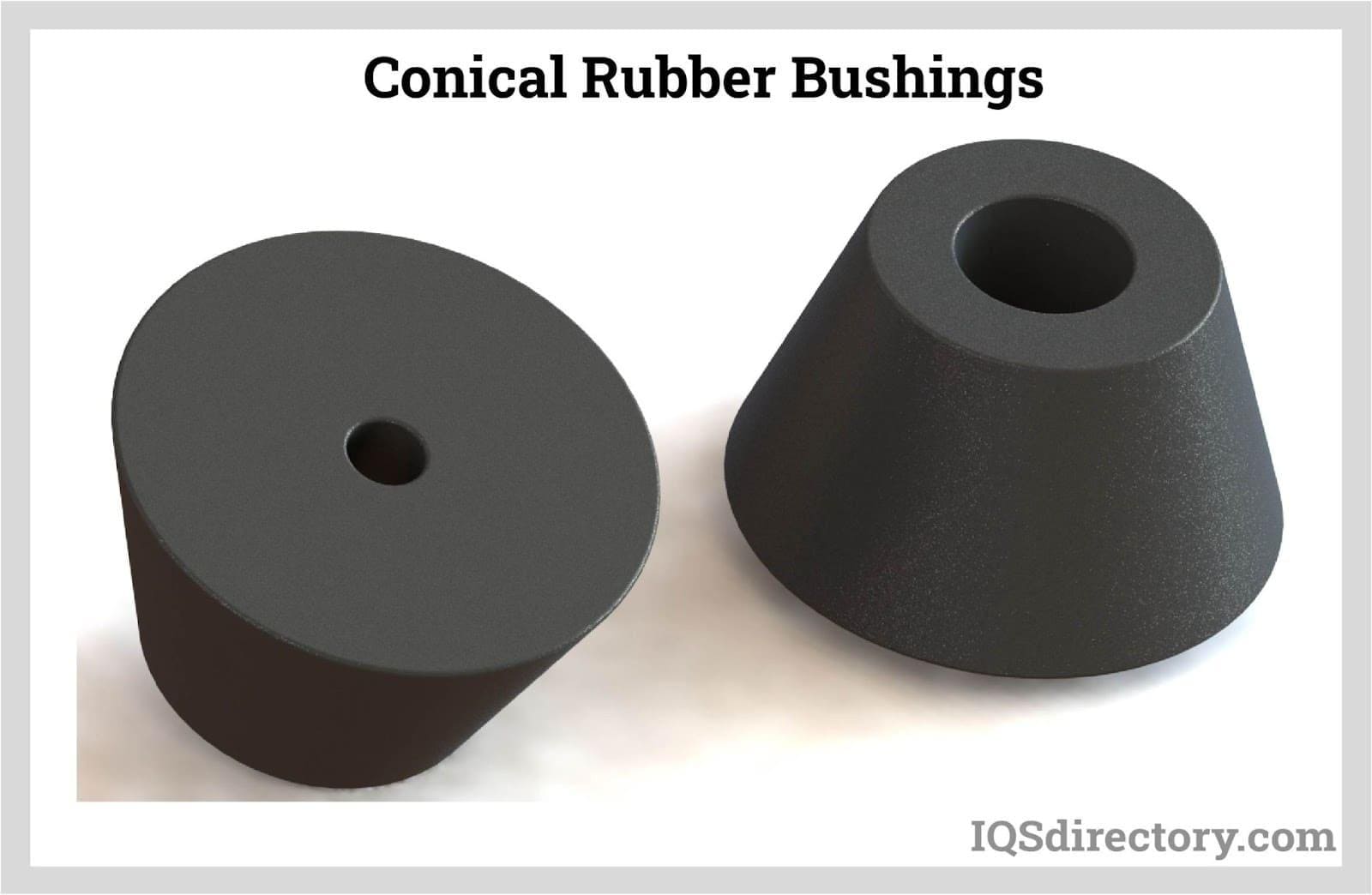

Understanding rubber bushings by size Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flanged Stem Bushings | Internal, stem, and flange diameters; customizable sizes | Automotive, machinery, and industrial equipment | Pros: Versatile, customizable; Cons: Requires precise measurements for fit. |

| Rubber/Metal Bushings | Combination of rubber and metal for enhanced durability | Automotive suspension systems, heavy machinery | Pros: High strength and load-bearing capacity; Cons: Potential for corrosion over time. |

| Universal Polyurethane | Available in various sizes; high tear resistance | Custom vehicles, industrial applications, machinery | Pros: Durable, resistant to wear; Cons: May not fit all applications without modification. |

| Standard Rubber Bushings | Simple design with varying internal and external dimensions | General automotive, construction, and manufacturing | Pros: Cost-effective, widely available; Cons: Limited customization options. |

| Vibration Control Bushings | Designed specifically for vibration dampening | Heavy machinery, automotive applications | Pros: Reduces noise and vibration; Cons: Can be more expensive than standard options. |

What Are Flanged Stem Bushings and Their B2B Relevance?

Flanged stem bushings are characterized by their unique design, which includes specific internal, stem, and flange diameters. They are often made from materials like SBR and EPDM, allowing for customization based on the application. These bushings are widely used in automotive and industrial machinery, where they serve to protect, isolate, and insulate components. B2B buyers should consider the precise measurements needed for proper fitment, as incorrect sizing can lead to performance issues.

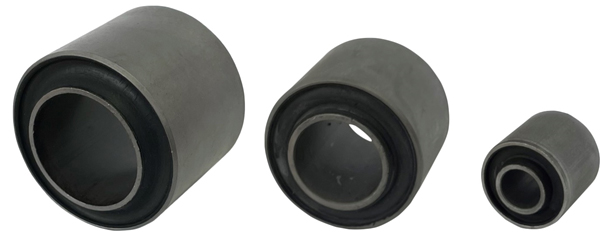

How Do Rubber/Metal Bushings Stand Out in the Market?

Rubber/metal bushings combine the flexibility of rubber with the strength of metal, making them suitable for high-load applications such as automotive suspension systems and heavy machinery. Their durability is a key selling point, but buyers should also be aware of potential corrosion issues that may arise over time. When sourcing these bushings, businesses should evaluate the specific environmental conditions in which they will be used to ensure longevity and performance.

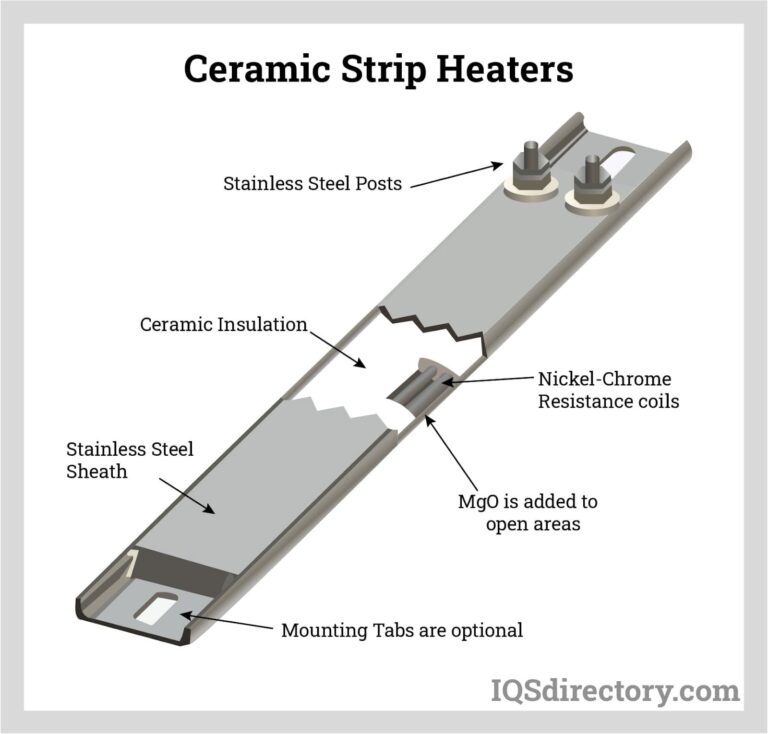

Illustrative image related to rubber bushings by size

What Makes Universal Polyurethane Bushings a Versatile Option?

Universal polyurethane bushings are designed for a range of applications, from automotive to industrial machinery. They are known for their high tear resistance and durability, making them ideal for environments where wear and stress are prevalent. However, their universal nature means they may require modifications for specific applications. B2B buyers should assess their particular needs and consider whether customization will be necessary for optimal performance.

Why Choose Standard Rubber Bushings for General Applications?

Standard rubber bushings are a cost-effective solution widely used across various industries, including automotive and manufacturing. Their simple design allows for easy installation and replacement, making them a popular choice for general applications. However, the trade-off for affordability is limited customization options. Businesses should consider their specific requirements and the potential need for standardization in their operations when selecting these bushings.

How Do Vibration Control Bushings Enhance Equipment Performance?

Vibration control bushings are specifically engineered to reduce noise and vibration in heavy machinery and automotive applications. This feature not only enhances comfort but also prolongs the lifespan of equipment by minimizing wear and tear. While these bushings can be more expensive than standard options, the investment can lead to significant savings in maintenance and operational efficiency. B2B buyers should evaluate the cost-benefit ratio based on their equipment’s vibration levels and operational requirements.

Key Industrial Applications of rubber bushings by size

| Industry/Sector | Specific Application of rubber bushings by size | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Suspension systems in vehicles | Enhances ride quality and reduces noise and vibrations | Consider material durability, size specifications, and compatibility with existing systems. |

| Industrial Machinery | Vibration dampening in heavy equipment | Increases equipment lifespan and operational efficiency | Assess load capacity, environmental resistance, and customization options based on machinery specifications. |

| Construction | Isolation in structural supports and frames | Reduces stress on joints and enhances structural integrity | Evaluate size, load-bearing capacity, and compliance with local building codes. |

| Aerospace | Engine mounts and component isolation | Enhances safety and performance by minimizing vibrations | Ensure compliance with aerospace standards and rigorous testing for reliability under extreme conditions. |

| Agricultural Equipment | Shock absorption in tractors and harvesters | Improves operator comfort and reduces equipment wear | Focus on weather resistance, size compatibility, and availability of replacement parts. |

How Are Rubber Bushings by Size Used in the Automotive Sector?

In the automotive industry, rubber bushings are integral to suspension systems, where they serve to absorb shocks and vibrations from the road. This application enhances ride quality and minimizes noise, creating a more comfortable experience for passengers. Buyers in this sector need to ensure that the bushings they source are compatible with specific vehicle models and can withstand varying loads and environmental conditions, particularly in regions like Africa and South America where road conditions can be challenging.

What Role Do Rubber Bushings Play in Industrial Machinery?

Rubber bushings are crucial in industrial machinery for vibration dampening, particularly in heavy equipment like cranes and excavators. By absorbing vibrations, these bushings help extend the lifespan of machinery and improve operational efficiency. B2B buyers must consider the load capacity and environmental factors, such as temperature and exposure to chemicals, when sourcing these components, especially in industrial hubs across the Middle East and Europe.

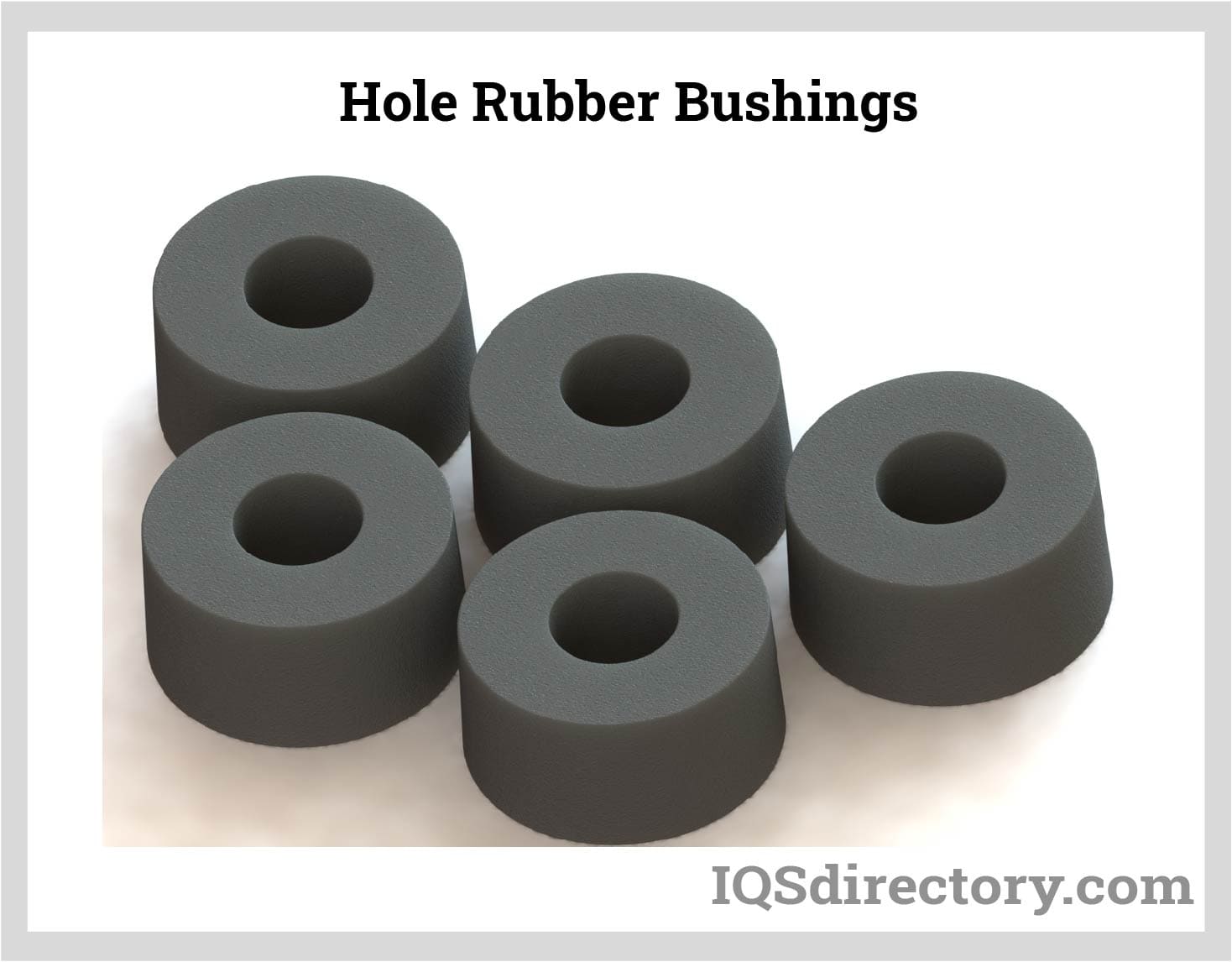

Illustrative image related to rubber bushings by size

How Are Rubber Bushings Used in Construction Applications?

In construction, rubber bushings are used to isolate vibrations in structural supports and frames, reducing stress on joints and enhancing overall structural integrity. This application is vital for ensuring safety and durability in buildings and bridges. Buyers should evaluate the size and load-bearing capacity of the bushings, as well as compliance with local building codes, particularly in regions with stringent safety regulations.

What Are the Benefits of Rubber Bushings in Aerospace Applications?

In the aerospace sector, rubber bushings are employed for engine mounts and component isolation to minimize vibrations that could affect performance and safety. The reliability of these bushings is paramount, as they must withstand extreme conditions. Buyers should prioritize sourcing bushings that meet aerospace standards and have undergone rigorous testing to ensure reliability, particularly for international projects that may involve compliance with multiple regulations.

How Do Rubber Bushings Enhance Agricultural Equipment Performance?

In agricultural machinery, rubber bushings are used for shock absorption in tractors and harvesters, improving operator comfort and reducing wear on the equipment. This is particularly important in regions where agricultural activities are intensive. Buyers should focus on sourcing bushings that are resistant to weather and environmental conditions, ensuring they are appropriately sized for the specific equipment used in diverse agricultural settings.

3 Common User Pain Points for ‘rubber bushings by size’ & Their Solutions

Scenario 1: Sizing Errors Leading to Increased Costs

The Problem: Many B2B buyers experience significant frustration when the rubber bushings they order do not fit their machinery or equipment. This issue often arises from a lack of clarity around size specifications. For instance, a buyer may assume that the listed dimensions correspond to the inner diameter only, neglecting to consider the outer diameter or flange height. This miscalculation can lead to costly returns, production delays, and wasted materials, especially in industries such as automotive or heavy machinery where downtime can equate to lost revenue.

Illustrative image related to rubber bushings by size

The Solution: To mitigate sizing errors, B2B buyers should adopt a systematic approach to sourcing rubber bushings. First, it’s essential to establish precise requirements based on the application’s needs. This includes measuring all relevant dimensions: inner diameter, outer diameter, flange height, and stem dimensions. Buyers can utilize tools such as calipers for accurate measurements. Additionally, engaging with suppliers who offer customizable options can be beneficial. When placing an order, confirm the specifications in writing and request a sample if possible. This proactive approach minimizes the risk of errors and ensures that the bushings will fit the intended application perfectly.

Scenario 2: Material Selection Challenges Impacting Performance

The Problem: Another common pain point for B2B buyers is the confusion surrounding the selection of appropriate materials for rubber bushings. Different applications require specific elastomer types, such as SBR for general use or EPDM for environments exposed to weather and ozone. Without a thorough understanding of material properties, buyers may select bushings that degrade quickly or fail under stress, resulting in frequent replacements and increased operational costs.

The Solution: To address material selection challenges, buyers should conduct a comprehensive analysis of their application environment. This includes considering factors such as temperature fluctuations, exposure to chemicals, and mechanical stress. Suppliers often provide technical data sheets detailing the properties of various elastomers. Buyers should leverage this information and consult with suppliers to match the right material to their specific needs. Furthermore, requesting samples or prototypes for testing before placing bulk orders can help ensure the selected material performs as expected in real-world conditions.

Scenario 3: Difficulty in Finding Reliable Suppliers

The Problem: B2B buyers often face the challenge of sourcing rubber bushings from reliable suppliers, especially when dealing with international vendors. Issues such as inconsistent quality, delayed shipments, and poor communication can arise, leading to frustrations that disrupt the supply chain. This is particularly critical in regions where local options are limited, forcing buyers to rely on international suppliers who may not fully understand local market needs.

The Solution: To navigate the supplier selection process effectively, buyers should prioritize due diligence. Start by researching potential suppliers through industry directories and customer reviews to gauge their reputation. Engaging in initial conversations can also help assess their responsiveness and willingness to understand specific requirements. Additionally, establishing partnerships with suppliers who have a proven track record of international shipping and local market knowledge can enhance reliability. It may also be beneficial to attend industry trade shows or forums where buyers can meet suppliers face-to-face, fostering stronger relationships and clearer communication channels. By investing time in supplier selection, buyers can build a more stable and responsive supply chain for their rubber bushing needs.

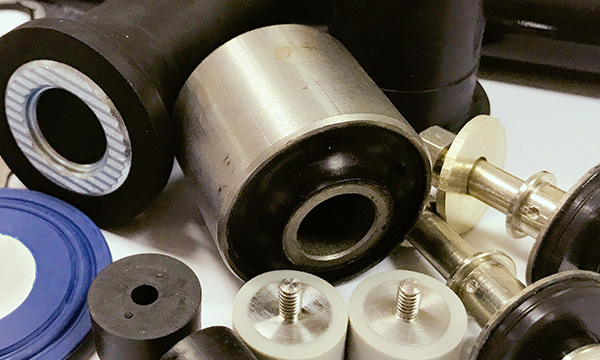

Strategic Material Selection Guide for rubber bushings by size

When selecting rubber bushings by size, the choice of material is critical for ensuring optimal performance and longevity in various applications. Below, we analyze four common materials used in rubber bushings, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of SBR Rubber for Bushings?

Styrene-Butadiene Rubber (SBR) is a synthetic rubber known for its excellent abrasion resistance and resilience. It typically operates effectively in temperatures ranging from -40°C to 100°C, making it suitable for many automotive and industrial applications. SBR exhibits good tensile strength and is resistant to wear, which is crucial for applications involving dynamic loads.

Pros and Cons of SBR Rubber

SBR is relatively inexpensive compared to other elastomers, making it an attractive option for cost-sensitive projects. However, it has limited resistance to oils and chemicals, which can affect its durability in certain environments. Furthermore, SBR may not perform well under extreme temperatures or prolonged exposure to UV light, which could lead to premature failure in outdoor applications.

Illustrative image related to rubber bushings by size

How Does EPDM Rubber Enhance Performance in Bushings?

Ethylene Propylene Diene Monomer (EPDM) rubber is known for its outstanding weather, ozone, and UV resistance. It maintains flexibility at low temperatures and can withstand temperatures up to 150°C. EPDM is particularly suited for applications that require exposure to harsh environmental conditions, such as automotive seals and outdoor equipment.

Pros and Cons of EPDM Rubber

The primary advantage of EPDM is its excellent resistance to aging and degradation, which results in a longer lifespan for bushings. However, EPDM is generally more expensive than SBR and may not offer the same level of tensile strength. Additionally, it has limited compatibility with petroleum-based oils, which should be considered in applications where oil exposure is likely.

What Are the Benefits of Neoprene Rubber in Bushing Applications?

Neoprene, or polychloroprene, is a versatile synthetic rubber that offers good resistance to oil, chemicals, and weathering. It operates effectively in a temperature range of -30°C to 100°C. Its balanced properties make it suitable for a variety of applications, including automotive and industrial machinery.

Pros and Cons of Neoprene Rubber

Neoprene’s resistance to various chemicals and oils makes it a reliable choice for applications exposed to harsh substances. However, it tends to be more expensive than SBR and EPDM, which may deter cost-sensitive buyers. Additionally, while it offers good mechanical properties, it may not perform as well as other materials under extreme temperatures.

Illustrative image related to rubber bushings by size

Why Consider Polyurethane for High-Performance Applications?

Polyurethane is a high-performance elastomer known for its superior tensile strength, tear resistance, and durability. It can handle temperatures ranging from -30°C to 80°C and is often used in applications requiring high load-bearing capabilities, such as in automotive suspension systems.

Pros and Cons of Polyurethane

The key advantage of polyurethane is its exceptional mechanical properties, making it suitable for heavy-duty applications. However, it is typically more costly than traditional rubber materials and may require specialized manufacturing processes. Polyurethane also has limited resistance to UV light, which can lead to degradation over time if not properly protected.

Summary Table of Material Selection for Rubber Bushings by Size

| Material | Typical Use Case for rubber bushings by size | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| SBR | Automotive parts, industrial machinery | Cost-effective and abrasion-resistant | Poor oil resistance and UV stability | Low |

| EPDM | Outdoor equipment, automotive seals | Excellent weather and ozone resistance | Higher cost and limited oil compatibility | Medium |

| Neoprene | Chemical processing, automotive applications | Good chemical resistance | More expensive than SBR and EPDM | Medium |

| Polyurethane | Heavy-duty automotive suspension systems | Superior mechanical properties | High cost and UV sensitivity | High |

This strategic material selection guide provides valuable insights for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. Understanding the properties, advantages, and limitations of each material will enable buyers to make informed decisions that align with their specific application requirements and compliance standards.

Illustrative image related to rubber bushings by size

In-depth Look: Manufacturing Processes and Quality Assurance for rubber bushings by size

What Are the Key Stages in the Manufacturing Process of Rubber Bushings?

The manufacturing process of rubber bushings involves several critical stages, ensuring that the end product meets the specific requirements for various applications. These stages can be broadly categorized into material preparation, forming, assembly, and finishing.

How Is Material Prepared for Rubber Bushing Production?

The first step in the manufacturing process is the preparation of raw materials. Typically, this involves selecting high-quality elastomers, such as SBR (Styrene-Butadiene Rubber) or EPDM (Ethylene Propylene Diene Monomer), based on the desired properties of the final product. The materials are then compounded with additives to enhance characteristics such as durability, flexibility, and resistance to environmental factors.

Once compounded, the rubber is processed into sheets or slabs for easier handling. This step may involve using a mill or extruder to achieve the desired thickness and consistency. Additionally, suppliers may offer custom formulations tailored to specific applications, which can be a significant advantage for international buyers needing specialized products.

Illustrative image related to rubber bushings by size

What Techniques Are Used for Forming Rubber Bushings?

The forming stage is where the prepared rubber is shaped into bushings. This is typically achieved through molding techniques, which can include compression molding, transfer molding, or injection molding, depending on the complexity and size of the bushing.

-

Compression Molding: This method is commonly used for simple shapes and larger bushings. It involves placing the rubber compound into a heated mold and applying pressure to shape it.

-

Transfer Molding: This technique is suitable for more complex designs, allowing for better control over the material flow and density.

-

Injection Molding: This method is ideal for high-volume production of intricate parts, providing excellent precision and surface finish.

Each technique has its benefits and is chosen based on the specific requirements of the bushings, including size, shape, and performance characteristics.

How Are Rubber Bushings Assembled and Finished?

After forming, the rubber bushings may undergo an assembly process, particularly when they incorporate metal components or require additional features like flanges. This stage might involve bonding rubber to metal parts or integrating sleeves, ensuring that the final product meets the design specifications.

The finishing stage includes processes such as trimming excess material, surface treatment, and applying protective coatings if necessary. These steps enhance the aesthetic quality and performance of the bushings, ensuring they meet industry standards and customer expectations.

Illustrative image related to rubber bushings by size

What Quality Assurance Measures Are Implemented in Rubber Bushing Production?

Quality assurance is crucial in the manufacturing of rubber bushings, particularly for international B2B buyers who require consistent and reliable products.

Which International Standards Govern Quality Control in Rubber Bushing Manufacturing?

Manufacturers typically adhere to international standards such as ISO 9001, which outlines the requirements for a quality management system. This certification demonstrates a commitment to quality and continuous improvement. Additionally, specific industries may require compliance with standards such as CE (Conformité Européenne) for products sold in the European market or API (American Petroleum Institute) standards for oil and gas applications.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) is generally divided into three main checkpoints:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival at the manufacturing facility to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, continuous monitoring is performed to identify any deviations from quality standards. This may include measuring dimensions, observing the molding process, and testing material properties.

-

Final Quality Control (FQC): Once the bushings are completed, they undergo thorough testing and inspection before shipment. This includes functional testing, dimensional checks, and visual inspections to ensure that all specifications are met.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Buyers can conduct:

-

Audits: Regular audits of the manufacturing facility can provide insight into the supplier’s adherence to quality standards and manufacturing practices.

-

Reports: Requesting detailed quality control reports, including test results and compliance certifications, can help assess the supplier’s reliability.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality management practices and product performance.

What Common Testing Methods Are Used for Rubber Bushings?

Various testing methods are employed to ensure that rubber bushings meet the required performance specifications. Common tests include:

-

Tensile Strength Testing: This assesses the rubber’s ability to withstand tension before breaking.

-

Compression Set Testing: This measures the rubber’s ability to return to its original shape after being compressed over time.

-

Dynamic Fatigue Testing: This evaluates how well the rubber can withstand repeated stress and strain during operation.

-

Environmental Resistance Testing: This determines the rubber’s resistance to factors like heat, ozone, and chemicals, which is vital for ensuring durability in various applications.

What Quality Control Nuances Should International B2B Buyers Consider?

International B2B buyers should be aware of the specific quality control nuances that may vary by region. For instance, compliance with local regulations and standards may differ significantly between markets. Understanding these differences is crucial to ensure that products not only meet the buyer’s expectations but also comply with local laws.

Additionally, buyers should consider the logistical aspects of quality assurance, such as the reliability of shipping and customs clearance processes, which can impact the timely delivery of products.

By thoroughly understanding the manufacturing processes and quality assurance measures for rubber bushings, B2B buyers can make informed decisions, ensuring they procure high-quality products that meet their specific requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rubber bushings by size’

To successfully procure rubber bushings by size, it’s essential to follow a structured approach that ensures you make informed decisions. This guide provides a checklist of critical steps to help you navigate the sourcing process efficiently.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly define the technical specifications of the rubber bushings you need. This includes dimensions such as inside diameter, stem diameter, flange diameter, and height measurements.

– Why it matters: Precise specifications will help you communicate your requirements effectively and ensure that the products you receive meet your operational needs.

Illustrative image related to rubber bushings by size

Step 2: Research Material Options

Consider the materials used in manufacturing the bushings, such as SBR, EPDM, or polyurethane. Each material has unique properties suited for specific applications, such as temperature resistance, elasticity, and durability.

– Why it matters: Selecting the right material can greatly affect the performance and lifespan of the bushings in your application, especially in demanding environments.

Step 3: Identify Potential Suppliers

Compile a list of potential suppliers who specialize in rubber bushings. Look for manufacturers with a proven track record in your industry or those who offer customization options.

– Why it matters: Partnering with experienced suppliers ensures you receive high-quality products and reliable service. Their expertise can also guide you in making the best material and design choices.

Step 4: Request Samples for Evaluation

Before making a bulk purchase, request samples of the rubber bushings. This allows you to assess the quality, fit, and performance in your specific application.

– Why it matters: Testing samples helps you avoid costly mistakes and ensures that the bushings meet your operational standards before committing to larger orders.

Step 5: Verify Supplier Certifications and Compliance

Ensure that your chosen suppliers have relevant certifications and comply with industry standards. This could include ISO certifications or compliance with specific regulations applicable to your region.

– Why it matters: Certifications are indicative of a supplier’s commitment to quality and can also help mitigate risks associated with non-compliance, particularly in international trade.

Step 6: Evaluate Pricing and Payment Terms

Obtain detailed quotes from your shortlisted suppliers, comparing not only the prices but also the payment terms and delivery schedules. This transparency will help you assess the overall value.

– Why it matters: Understanding the total cost of ownership, including shipping and potential tariffs, will help you make more informed financial decisions and budget effectively.

Step 7: Establish a Communication Plan

Once you select a supplier, establish a clear communication plan for ongoing updates regarding your order, including timelines and any potential issues that may arise.

– Why it matters: Effective communication fosters a strong supplier relationship and ensures that any challenges are addressed promptly, minimizing disruptions to your operations.

By following these steps, B2B buyers can effectively navigate the sourcing process for rubber bushings, ensuring they procure the right products for their specific needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for rubber bushings by size Sourcing

What Are the Key Cost Components Influencing Rubber Bushings Pricing?

The cost structure for rubber bushings encompasses several critical components. Materials represent a significant portion of the total cost, with common elastomers like SBR and EPDM being widely used. Specialty materials may incur higher costs due to their enhanced properties, such as durability or resistance to extreme temperatures. Labor costs vary depending on the complexity of the manufacturing process and the region of production. For instance, labor costs in developing regions may be lower, impacting the overall pricing.

Manufacturing overhead also contributes to the final price, as it includes expenses related to facilities, utilities, and administrative costs. Tooling costs can be substantial, especially for custom designs or specialized sizes, necessitating upfront investments that are typically amortized over larger production volumes. Quality control (QC) processes are essential to ensure product reliability and compliance with industry standards, adding another layer to the cost structure. Lastly, logistics costs, including transportation and warehousing, play a crucial role, particularly for international shipments, where costs can fluctuate based on distance and shipping conditions.

How Do Price Influencers Affect Rubber Bushings Sourcing?

Several factors influence the pricing of rubber bushings. Volume and minimum order quantities (MOQ) are critical; larger orders often lead to lower per-unit costs due to economies of scale. Customization requests, such as specific sizes or materials, can also drive up costs, as they may require additional manufacturing processes or specialized tooling.

The quality and certifications of materials used can significantly impact pricing. Buyers should consider suppliers that comply with international standards to ensure product reliability. Supplier reputation and reliability also affect pricing; established suppliers may charge a premium due to their proven track record, while new entrants might offer competitive rates to gain market share.

Illustrative image related to rubber bushings by size

Furthermore, understanding Incoterms is essential for international buyers. These terms define responsibilities regarding shipping, insurance, and tariffs, which can influence the total landed cost of goods.

What Buyer Tips Can Lead to Cost-Efficiency in Rubber Bushings Sourcing?

To achieve cost-efficiency, buyers should focus on negotiation tactics. Engaging in discussions about bulk purchasing and long-term contracts can yield favorable pricing. It’s also beneficial to solicit quotes from multiple suppliers to compare costs and terms comprehensively.

Consider the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and potential downtime costs. Sometimes, opting for a higher-quality bushing might result in lower long-term costs due to reduced maintenance and replacement needs.

Illustrative image related to rubber bushings by size

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, being aware of pricing nuances is essential. Factors such as local tariffs, currency fluctuations, and transportation costs can significantly affect the final price. Building strong relationships with suppliers and understanding their pricing structures can also provide leverage in negotiations.

Are There Any Disclaimers Regarding Indicative Prices?

It’s crucial to note that the prices for rubber bushings can vary widely based on the aforementioned factors. Prices listed by suppliers are often indicative and subject to change based on material availability, production costs, and market demand. Buyers should always verify current pricing and negotiate terms before finalizing any orders.

By understanding these components, influencers, and tips, international B2B buyers can make informed decisions in sourcing rubber bushings that meet their specific needs while optimizing costs.

Illustrative image related to rubber bushings by size

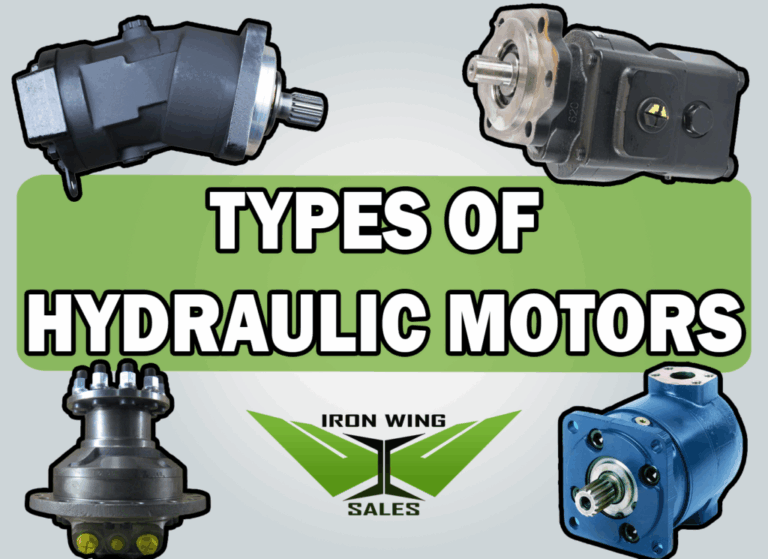

Alternatives Analysis: Comparing rubber bushings by size With Other Solutions

Exploring Alternatives to Rubber Bushings by Size

In the realm of industrial applications, the selection of the right bushing type can significantly influence performance, longevity, and maintenance costs. While rubber bushings by size are widely used for their vibration-damping properties and ease of installation, it’s essential to explore alternative solutions that may offer specific advantages depending on the context. This analysis will compare rubber bushings with two viable alternatives: Polyurethane Bushings and Metal Bushings.

Comparison Table

| Comparison Aspect | Rubber Bushings By Size | Polyurethane Bushings | Metal Bushings |

|---|---|---|---|

| Performance | Good vibration dampening; flexibility | High tensile strength; durability | Excellent load-bearing capacity; rigidity |

| Cost | Generally low cost | Moderate cost | Higher initial cost |

| Ease of Implementation | Easy to install | Requires precise alignment | Installation can be complex |

| Maintenance | Low maintenance | Moderate maintenance; may require periodic inspection | Low maintenance; high durability |

| Best Use Case | General applications requiring vibration isolation | Heavy-duty applications, automotive use | Structural applications, high-stress environments |

Understanding the Alternatives

What Are the Advantages and Disadvantages of Polyurethane Bushings?

Polyurethane bushings are known for their enhanced durability and resistance to wear and tear compared to rubber. They offer superior performance in high-load applications, making them ideal for automotive and industrial settings where longevity is critical. However, they can be more expensive than rubber bushings, and their installation requires careful alignment to avoid premature wear. Additionally, while they provide excellent vibration dampening, they may not perform as well in extreme temperature fluctuations compared to rubber.

How Do Metal Bushings Compare to Rubber Bushings?

Metal bushings provide exceptional strength and rigidity, making them suitable for applications where high load-bearing capacity is necessary. They are often used in structural applications and heavy machinery. While metal bushings have a long lifespan and require minimal maintenance, their rigidity can lead to increased vibrations being transmitted through the system, which may not be desirable in applications requiring shock absorption. Moreover, the initial cost of metal bushings is typically higher, and installation can be more complex due to the need for precision fitting.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting a bushing solution, B2B buyers should carefully consider the specific needs of their applications. Rubber bushings by size are ideal for general use where flexibility and cost-effectiveness are paramount. However, if the application involves heavy loads or requires additional durability, polyurethane or metal bushings may be more suitable despite their higher costs and installation complexities. Ultimately, the choice will depend on balancing performance requirements, budget constraints, and installation capabilities to ensure optimal functionality and longevity of the equipment.

Essential Technical Properties and Trade Terminology for rubber bushings by size

What Are the Key Technical Properties of Rubber Bushings by Size?

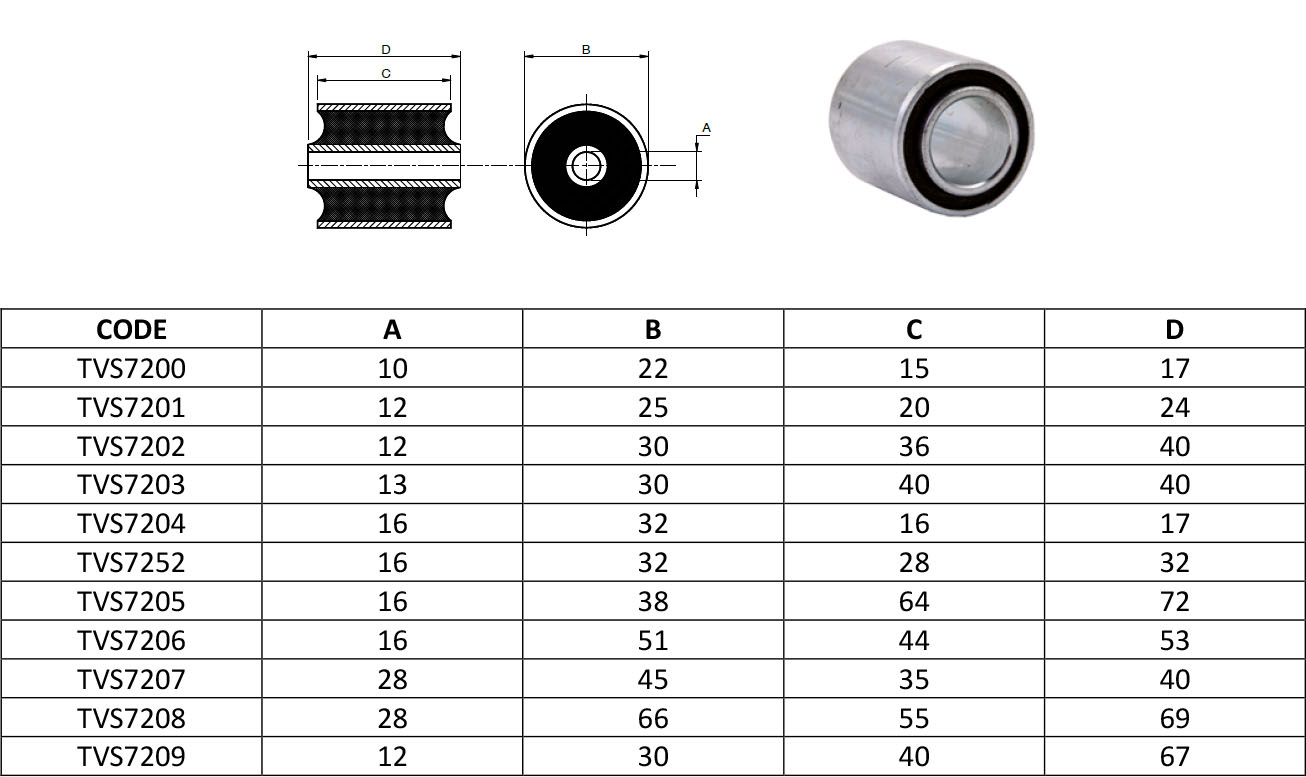

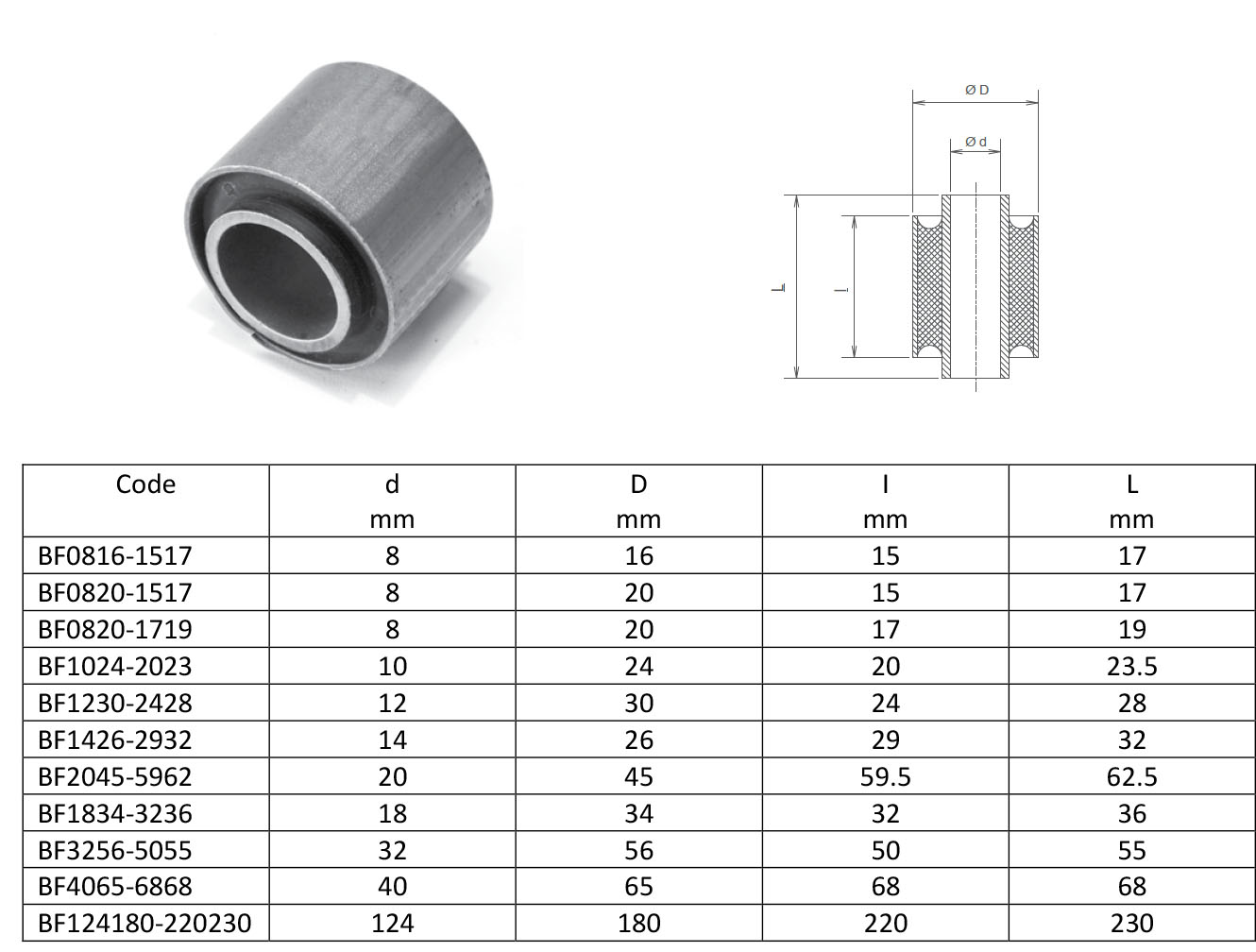

Rubber bushings are critical components in various mechanical applications, offering support, vibration dampening, and load distribution. Understanding the technical properties of rubber bushings is essential for B2B buyers to ensure they select the right components for their specific needs. Here are some critical specifications to consider:

-

Material Grade: The material from which a bushing is made significantly affects its performance. Common materials include SBR (Styrene-Butadiene Rubber) and EPDM (Ethylene Propylene Diene Monomer). Each material has unique properties such as temperature resistance, chemical compatibility, and durability. For instance, EPDM is often preferred for outdoor applications due to its excellent weather resistance.

-

Inside and Outside Diameter (ID and OD): These measurements are crucial for ensuring a proper fit within the assembly. The inside diameter must match the shaft or bolt it is designed to fit, while the outside diameter affects how the bushing interfaces with surrounding components. Precision in these measurements is vital to prevent operational issues such as misalignment or excessive wear.

-

Flange Height and Diameter: For flanged bushings, the flange height and diameter are important specifications that dictate the bushing’s ability to support loads and its stability within the assembly. A well-designed flange can help prevent movement within the housing, reducing wear and prolonging the bushing’s lifespan.

-

Tensile Strength and Hardness: These mechanical properties define how much load a bushing can withstand before deforming or failing. Tensile strength indicates the maximum stress a material can endure, while hardness (often measured using the Shore durometer scale) reflects its resistance to indentation. Selecting bushings with appropriate tensile strength and hardness is critical for applications involving heavy loads or dynamic forces.

-

Tolerance: This refers to the permissible limit of variation in the dimensions of the bushing. Tighter tolerances generally result in better performance and longevity, especially in high-precision applications. Understanding the required tolerances is essential for ensuring compatibility with other components and for minimizing the risk of failure.

What Are the Common Trade Terms Used in Rubber Bushing Procurement?

Navigating the procurement process for rubber bushings involves familiarizing oneself with industry-specific terminology. Here are several key terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce components that are used in another company’s products. For example, a rubber bushing manufacturer may supply parts to an automotive OEM. Knowing whether a product is OEM-certified can indicate its quality and compatibility.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for budgeting and inventory management, especially for companies that may not require large quantities of bushings.

-

RFQ (Request for Quotation): An RFQ is a standard business process wherein a buyer requests pricing and terms from suppliers. It’s essential for comparing offers and ensuring that buyers receive competitive pricing and favorable terms.

-

Incoterms: Short for International Commercial Terms, these are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They help clarify who is responsible for shipping, insurance, and tariffs, which can significantly impact the total cost of procurement.

-

Lead Time: This refers to the time it takes from placing an order to receiving the products. Understanding lead times is essential for planning and ensuring that production schedules are not disrupted.

-

Customization: Many suppliers offer the option to customize rubber bushings based on specific requirements. This can include alterations in size, material, or design. Knowing the customization options available can help buyers get the exact product they need for their applications.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance their operations and ensure the reliability of their machinery.

Navigating Market Dynamics and Sourcing Trends in the rubber bushings by size Sector

What Are the Current Market Dynamics Influencing Rubber Bushings Sourcing?

The global rubber bushings market is witnessing robust growth, driven by increasing demand across various industries such as automotive, aerospace, and industrial machinery. Key drivers include the rising need for vibration control and noise reduction in vehicles, as well as the expanding infrastructure projects in emerging markets like Africa and South America. Furthermore, technological advancements in manufacturing processes are enabling the production of more durable and efficient rubber bushings, tailored to specific applications.

In terms of sourcing trends, international B2B buyers are increasingly leaning towards suppliers that offer customizable solutions. This trend is particularly pronounced in regions like Europe and the Middle East, where businesses require specific sizes and materials to meet stringent quality standards. The advent of Industry 4.0 technologies, such as IoT and AI, is transforming the way manufacturers and suppliers interact, facilitating better inventory management and predictive maintenance. This shift allows for a more agile supply chain, which is crucial for buyers who need timely access to parts.

Illustrative image related to rubber bushings by size

Moreover, the globalization of supply chains is prompting buyers to consider not only price but also the reliability and reputation of suppliers. Suppliers who can provide comprehensive data on product specifications, including internal and external diameters, flange height, and materials used, will have a competitive edge. As buyers from regions like Nigeria and Vietnam become more discerning, they seek suppliers that can demonstrate both product quality and service excellence.

How Is Sustainability Shaping the Rubber Bushings Supply Chain?

Sustainability has emerged as a pivotal concern in the sourcing of rubber bushings. The environmental impact of traditional rubber manufacturing processes, including high carbon emissions and waste generation, is prompting businesses to seek more sustainable alternatives. B2B buyers are increasingly prioritizing suppliers who adopt environmentally friendly practices and utilize sustainable materials.

Ethical sourcing is becoming integral to supply chain decisions, with buyers looking for transparency in their suppliers’ operations. Certifications such as ISO 14001 for environmental management systems and materials derived from renewable sources are becoming essential criteria for procurement. This shift not only enhances brand reputation but also aligns with the growing regulatory pressures in many regions, particularly in Europe, where sustainability regulations are tightening.

Additionally, the use of recycled materials in the production of rubber bushings is gaining traction. Suppliers who can offer products made from recycled rubber or other eco-friendly materials can appeal to a broader range of clients, particularly those in industries focused on sustainability. This trend is particularly relevant for international buyers who are keen on reducing their carbon footprint and enhancing the sustainability of their supply chains.

What Historical Trends Have Shaped the Rubber Bushings Industry?

The rubber bushings industry has evolved significantly over the decades, initially relying on natural rubber sourced from tropical regions. The post-World War II era saw a surge in demand, particularly in the automotive sector, leading to advancements in synthetic rubber technologies. This evolution was driven by the need for more durable and versatile materials that could withstand various environmental conditions.

In recent years, the industry has experienced a shift towards high-performance materials, such as polyurethane and advanced elastomers, which provide superior performance characteristics. This transition has enabled manufacturers to cater to specialized applications in automotive and industrial markets, enhancing the functional capabilities of rubber bushings.

The globalization of manufacturing has also played a crucial role in the industry’s evolution, allowing for cost-effective production while expanding the reach of suppliers into new markets. As the industry continues to evolve, the focus on customization, sustainability, and technological innovation will remain key drivers shaping the future of rubber bushings.

Frequently Asked Questions (FAQs) for B2B Buyers of rubber bushings by size

-

1. How do I choose the right size of rubber bushings for my application?

Choosing the right size of rubber bushings involves understanding the specific requirements of your application. Start by measuring the internal diameter, stem diameter, flange diameter, and overall height of the space where the bushing will fit. Consult technical specifications from manufacturers to ensure compatibility. Additionally, consider the load-bearing capacity and environmental factors, such as temperature and exposure to chemicals, which may affect the material choice. If you have custom requirements, reach out to suppliers who can produce bushings according to your specifications. -

2. What is the best material for rubber bushings in harsh environments?

For applications in harsh environments, such as those exposed to extreme temperatures or chemicals, EPDM (Ethylene Propylene Diene Monomer) rubber is often the best choice due to its excellent weather resistance and durability. SBR (Styrene-Butadiene Rubber) is more cost-effective for general applications but may not withstand severe conditions. Always consult with suppliers to determine the optimal material based on specific environmental challenges and load requirements. -

3. How can I ensure the quality of rubber bushings from international suppliers?

To ensure the quality of rubber bushings from international suppliers, request certifications such as ISO 9001 or specific industry standards relevant to your application. Conduct thorough vetting, which may include asking for product samples and testing them in your operational conditions. Establishing strong communication and understanding the supplier’s manufacturing processes can also provide insights into their quality assurance practices. Regular audits or third-party inspections can further guarantee product reliability. -

4. What customization options are available for rubber bushings?

Many manufacturers offer customization options for rubber bushings, including variations in size, shape, and material. Customization may also extend to specific performance characteristics, such as hardness, color, or resistance to certain chemicals. When seeking custom bushings, provide detailed drawings or specifications to the supplier to ensure they can meet your requirements accurately. Discuss lead times and any associated costs for custom orders to avoid delays in your supply chain. -

5. What are typical minimum order quantities (MOQs) for rubber bushings?

Minimum order quantities (MOQs) for rubber bushings can vary widely based on the supplier and the specific product. Generally, MOQs can range from a few dozen to several hundred units. For custom orders, MOQs may be higher due to the setup costs involved in production. It’s advisable to discuss your needs with potential suppliers to find flexible options that align with your purchasing strategy, especially if you are a smaller buyer or are testing a new product. -

6. What payment terms should I expect when sourcing rubber bushings internationally?

Payment terms for sourcing rubber bushings internationally can vary based on supplier policies and the buyer’s relationship with them. Common payment terms include net 30 or net 60, where payment is due within 30 or 60 days after invoice receipt. Some suppliers may require a deposit upfront, particularly for custom orders. It’s important to negotiate favorable terms that protect your cash flow while ensuring timely order fulfillment. Always confirm these details before finalizing agreements to avoid misunderstandings. -

7. How can I manage logistics for importing rubber bushings?

Managing logistics for importing rubber bushings involves several key steps. First, understand the shipping options available, including air freight for quicker deliveries or sea freight for cost savings. Collaborate with a reliable freight forwarder who can handle customs clearance and ensure compliance with international trade regulations. Consider potential tariffs and taxes that may apply to your imports. Lastly, maintain clear communication with your supplier regarding shipping schedules to anticipate delivery timelines effectively. -

8. What should I do if I receive defective rubber bushings?

If you receive defective rubber bushings, first document the issues with photos and detailed descriptions. Contact the supplier immediately to discuss the problem and explore return or replacement options. Most reputable suppliers will have policies in place for defective products, including warranties or guarantees. Establishing a clear communication channel and understanding their return policy will facilitate a smoother resolution process. Keeping records of your transactions can also support your claims effectively.

Top 5 Rubber Bushings By Size Manufacturers & Suppliers List

1. Ikon Suspension – Rubber/Metal Bush

Domain: ikonsuspensionusa.com

Registered: 2007 (18 years)

Introduction: {“product_name”: “Rubber/Metal Bush”, “price”: “$14.95”, “description”: “Rubber/Metal Bushings, Various sizes available.”, “sizes_available”: [“Bush, rubber/metal 16x26x26mm”, “Bush, rubber/metal 12x26x23.5mm”, “Bush, rubber/metal 12x26x22mm”, “Bush, rubber/metal 12x26x20mm”, “Bush, rubber/metal 12x26x18mm”, “Bush, rubber/metal 14x26x20mm”, “Bush, rubber/metal 16x26x20mm”, “Bush, rubber/metal 14×2…

2. Suspension.com – Universal Polyurethane Bushings

Domain: suspension.com

Introduction: Universal Polyurethane Bushings from Energy Suspension and Prothane. Applications include Control Arm Bushings, Track Rod Bushings, 4-Bar Systems, Tire Carrier Racks, Engine Mounts, and Transmission Mounts. Each set includes 4 bushing halves and 2 metal sleeves. Features high tensile strength and tear resistance. Various sizes and specifications available, including outer diameter, inner diameter,…

3. McMaster – Rubber Bushings

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Rubber Bushings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Mid Atlantic Rubber – Custom Shock Absorbing Bushings

Domain: midatlanticrubber.com

Registered: 1996 (29 years)

Introduction: Custom rubber bushings designed to absorb shock and reduce vibration. A large selection available, including custom-made options to meet specific needs. Most items are in stock, with a complete online catalog for selection assistance. Contact for custom engineering solutions.

5. Hanna Rubber Company – Bushings 2

Domain: hannarubbercompany.com

Registered: 2004 (21 years)

Introduction: Bushings 2″ from Hanna Rubber Company

Strategic Sourcing Conclusion and Outlook for rubber bushings by size

In conclusion, the strategic sourcing of rubber bushings by size presents a significant opportunity for international B2B buyers to enhance their supply chains and improve product performance. Understanding the specific dimensions and material properties of rubber bushings, such as inside diameter, stem diameter, and flange height, allows for more informed procurement decisions. By leveraging insights into diverse applications—from automotive to industrial machinery—buyers can identify suitable products that meet their unique operational requirements.

Moreover, engaging with suppliers who offer customization options can lead to tailored solutions that enhance efficiency and reduce downtime. As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for reliable rubber bushing solutions will only grow.

International buyers are encouraged to explore partnerships with manufacturers that prioritize quality and innovation. By doing so, they not only secure a competitive edge but also contribute to the sustainable development of their industries. As you move forward, consider how strategic sourcing can elevate your operational effectiveness and drive long-term success in an increasingly interconnected global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.