How to Source Rotameter Flow Meter Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for rotameter flow meter

In today’s competitive landscape, international B2B buyers face the pressing challenge of sourcing reliable rotameter flow meters that ensure accurate flow measurement for diverse applications. As industries across Africa, South America, the Middle East, and Europe increasingly rely on these devices for monitoring liquids and gases, understanding the nuances of rotameters is paramount. This guide serves as a comprehensive resource, covering the various types of rotameter flow meters, their specific applications, and the critical factors to consider when vetting suppliers.

From variable area flow meters to specialized designs for harsh environments, we delve into the features and benefits of each type, providing insights into their operational principles and suitability for different media. Additionally, we address key considerations in the purchasing process, including cost analysis, material compatibility, and certification requirements.

By equipping B2B buyers with essential knowledge and actionable insights, this guide empowers informed purchasing decisions, ensuring that your organization can effectively meet its flow measurement needs. Whether you are in Germany, Vietnam, or beyond, understanding the global market for rotameter flow meters will enhance your procurement strategy and drive operational efficiency.

Understanding rotameter flow meter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Glass Rotameter | Transparent tube for direct visual flow observation | Water treatment, laboratory experiments | Pros: Easy to read, low cost. Cons: Fragile, limited pressure range. |

| Metal Rotameter | Robust construction, suitable for high-pressure applications | Oil & gas, chemical processing | Pros: Durable, high accuracy. Cons: Higher initial cost. |

| Plastic Rotameter | Lightweight and corrosion-resistant materials | Food processing, pharmaceuticals | Pros: Low cost, good for corrosive fluids. Cons: Lower temperature limits. |

| Low-Volume Rotameter | Designed for precise measurement of low flow rates | Medical devices, microfluidics | Pros: High sensitivity, compact design. Cons: Limited flow range. |

| Digital Rotameter | Electronic readout with advanced features | Automation systems, HVAC | Pros: Enhanced accuracy, data logging capabilities. Cons: Requires power supply. |

What Are the Characteristics of Glass Rotameters?

Glass rotameters are characterized by their transparent conical tubes, allowing users to visually monitor the flow of liquids or gases. They are commonly used in applications where flow visibility is crucial, such as water treatment and laboratory experiments. While they are cost-effective and easy to read, buyers should consider their fragility and limited pressure capabilities, which may not be suitable for all industrial environments.

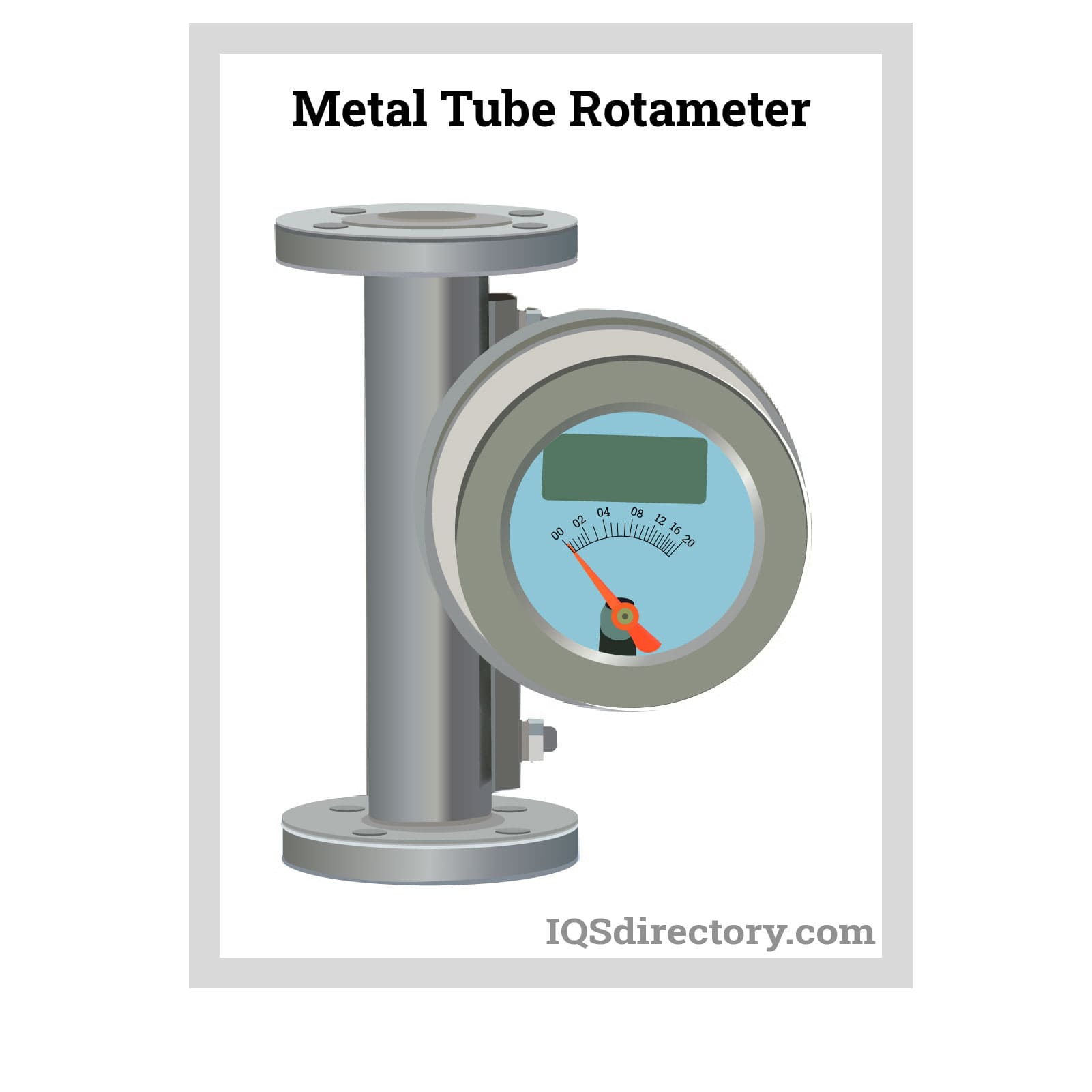

How Do Metal Rotameters Stand Out?

Metal rotameters are designed for durability and can handle high-pressure environments, making them ideal for industries like oil and gas and chemical processing. Their robust construction ensures reliable performance under challenging conditions. However, the initial investment is typically higher than that of glass or plastic alternatives, which could be a consideration for budget-conscious buyers.

Why Choose Plastic Rotameters?

Plastic rotameters are lightweight and resistant to corrosion, making them suitable for applications in food processing and pharmaceuticals. They offer a cost-effective solution for measuring flow rates of corrosive fluids. However, buyers should keep in mind that plastic rotameters may have lower temperature limits compared to metal options, which could restrict their use in certain high-heat processes.

What Are the Benefits of Low-Volume Rotameters?

Low-volume rotameters are engineered for precision measurement in applications that require monitoring of very low flow rates, such as in medical devices and microfluidics. Their compact design allows for easy integration into small systems. While they offer high sensitivity, potential buyers should be aware of their limited flow range, which may not meet the needs of higher-capacity applications.

How Do Digital Rotameters Enhance Flow Measurement?

Digital rotameters provide electronic readouts and often come with advanced features such as data logging and integration capabilities with automation systems. They are increasingly used in HVAC and other automated environments where accuracy and monitoring are critical. However, the reliance on a power supply can be a drawback, especially in remote locations or during power outages, making it essential for buyers to assess their operational environment before purchasing.

Key Industrial Applications of rotameter flow meter

| Industry/Sector | Specific Application of rotameter flow meter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Treatment | Monitoring flow rates in water purification systems | Ensures optimal chemical dosing and compliance with regulations | Accuracy, material compatibility, and installation options |

| Chemical Processing | Measuring flow rates of corrosive chemicals | Enhances process safety and efficiency | Chemical resistance of materials and pressure ratings |

| Food and Beverage | Controlling ingredient flow in production lines | Guarantees product quality and consistency | Hygienic design, compliance with food safety standards |

| Oil and Gas | Monitoring fuel and gas flow in pipelines | Improves efficiency and reduces operational costs | High-pressure ratings and temperature tolerance |

| Pharmaceuticals | Measuring active ingredient flow in drug production | Ensures precise dosages for effective medication | Certification compliance, accuracy, and low maintenance |

How Are Rotameter Flow Meters Used in Water Treatment?

In water treatment facilities, rotameter flow meters are utilized to monitor and control the flow rates of various chemicals used in purification processes, such as chlorine and coagulants. By providing real-time flow data, these meters help operators ensure that the right amount of chemicals is dosed, maintaining compliance with environmental regulations. For international buyers, sourcing rotameters with materials that resist corrosion and are suitable for varying water qualities is crucial, particularly in regions with extreme weather conditions.

What Role Do Rotameter Flow Meters Play in Chemical Processing?

In the chemical processing industry, rotameters are essential for measuring the flow rates of various liquids and gases, including corrosive substances. Their ability to deliver accurate measurements without requiring external power makes them ideal for hazardous environments. Buyers from regions with stringent safety regulations must prioritize rotameters made from compatible materials to prevent chemical reactions and ensure process reliability, while also considering pressure ratings suitable for their specific applications.

How Are Rotameter Flow Meters Applied in Food and Beverage Production?

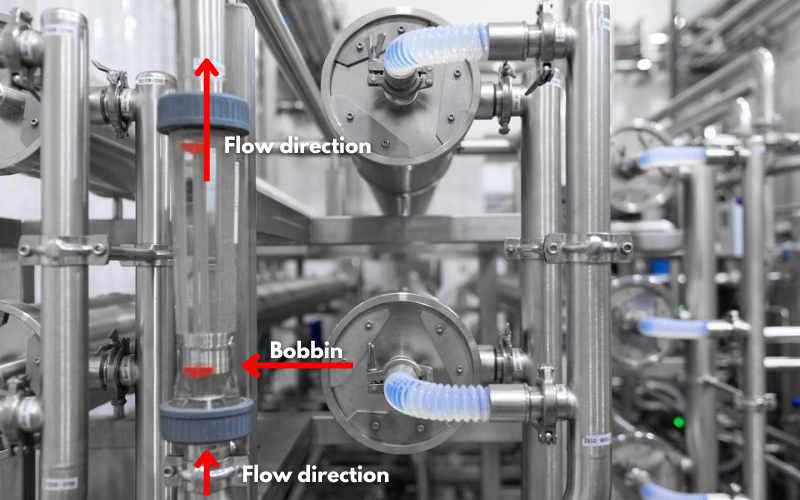

Rotameter flow meters are critical in the food and beverage sector for controlling the flow of ingredients, such as syrups, oils, and other liquids during production. Their transparent design allows for easy monitoring, ensuring that recipes are followed accurately, which is vital for maintaining product quality. For B2B buyers, sourcing rotameters that comply with food safety standards, such as FDA regulations, and are easy to clean is essential for ensuring hygienic production processes.

How Do Rotameter Flow Meters Enhance Efficiency in Oil and Gas?

In the oil and gas industry, rotameters are employed to monitor fuel and gas flow in pipelines, which is essential for maintaining operational efficiency and safety. By providing accurate flow measurements, they help prevent leaks and ensure optimal resource management. International buyers should consider rotameters with high-pressure ratings and robust materials capable of withstanding the harsh conditions often found in this sector, ensuring reliability and longevity.

Why Are Rotameter Flow Meters Important in Pharmaceuticals?

In pharmaceutical manufacturing, rotameters are used to measure the flow of active ingredients during the production of medications. Precision is paramount, as any variance can affect the efficacy of the final product. Buyers in this sector need to ensure that the rotameters they source are certified for pharmaceutical applications, with high accuracy and low maintenance requirements, to comply with industry standards and regulations, particularly in regions with strict health guidelines.

3 Common User Pain Points for ‘rotameter flow meter’ & Their Solutions

Scenario 1: Difficulty in Accurate Flow Measurement in Diverse Conditions

The Problem:

B2B buyers often encounter challenges when measuring flow rates in environments with fluctuating temperatures and pressures. For instance, a chemical processing plant in South America may experience extreme temperature variations, which can affect the accuracy of rotameters. Buyers might find that their existing flow meters cannot handle these changes, leading to unreliable data that can result in production inefficiencies, safety concerns, or costly errors in downstream processes.

The Solution:

To tackle this issue, buyers should select rotameters specifically designed to handle varying temperatures and pressures. Opt for models with robust materials like 316 stainless steel or PTFE, which offer superior resistance to temperature fluctuations and corrosive media. Furthermore, ensure that the rotameter features direct reading scales calibrated for the specific media and operating conditions of your application. This customization allows for better accuracy and reliability. Regular calibration and maintenance should also be scheduled to ensure the rotameter consistently provides precise measurements, even under extreme conditions.

Scenario 2: High Maintenance and Replacement Costs

The Problem:

Many businesses face high maintenance and replacement costs associated with traditional flow measurement devices. For instance, an oil and gas company operating in the Middle East might find that the wear and tear on their rotameters due to harsh operational environments leads to frequent breakdowns and the need for replacements. This not only impacts budget but can also disrupt operations, leading to significant downtime.

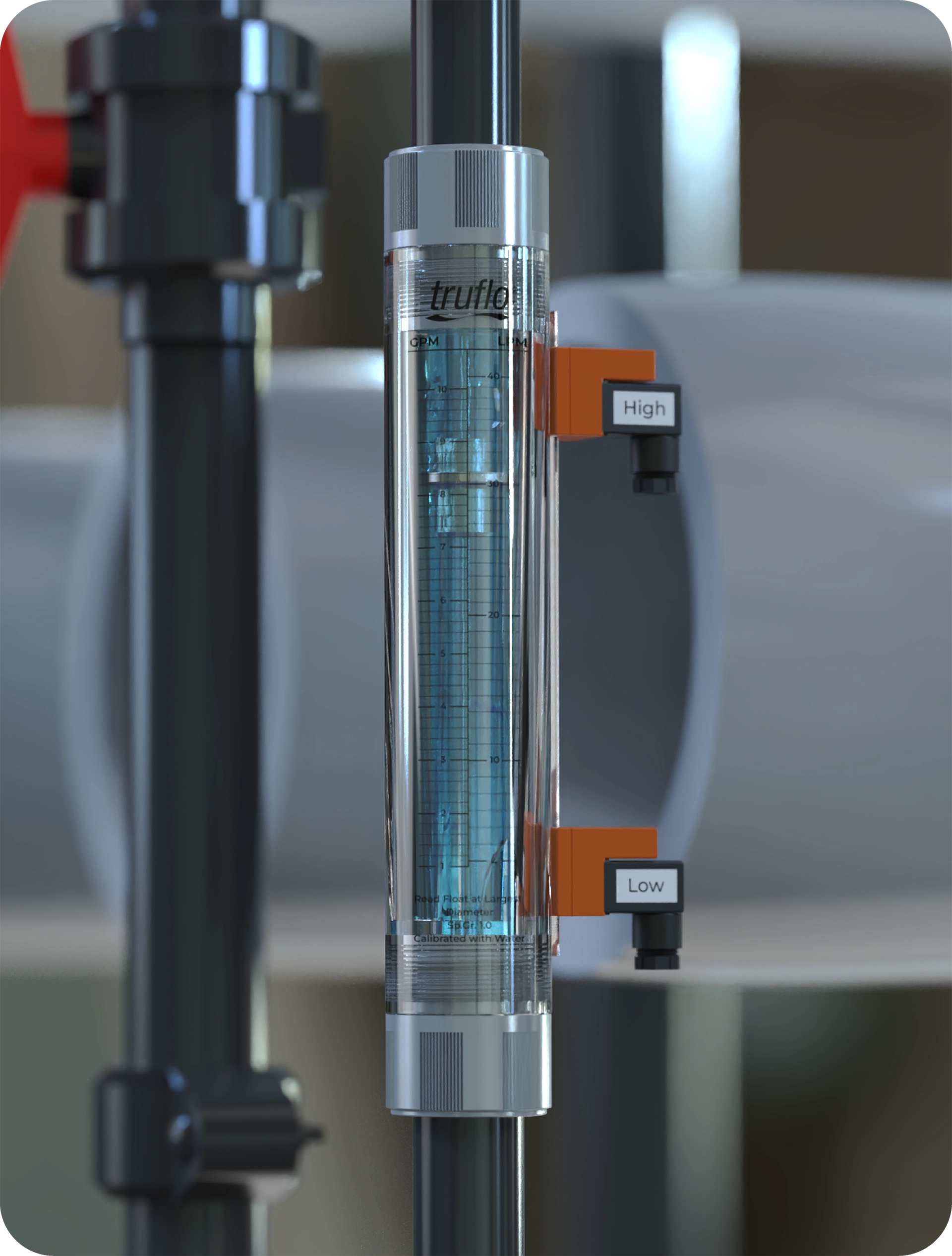

Illustrative image related to rotameter flow meter

The Solution:

Investing in heavy-duty industrial rotameters designed for high-pressure and high-temperature applications can mitigate these costs. Look for devices that are constructed with durable materials and that have a proven track record in similar environments. Models with all-metal designs typically offer increased longevity and lower overall maintenance needs. Additionally, consider rotameters that incorporate features such as analog outputs for remote monitoring and diagnostics. This can help in predicting potential failures before they occur, allowing for timely maintenance and reducing the risk of unexpected downtimes.

Scenario 3: Complexity in Installation and Integration

The Problem:

Another common pain point is the complexity involved in the installation and integration of rotameters into existing systems. For international B2B buyers, especially those in Africa and Europe, the difficulty in aligning flow meters with existing pipeline systems can lead to installation delays and increased costs. Misalignment can result in inaccurate readings and further complications in fluid dynamics, ultimately affecting operational efficiency.

The Solution:

To simplify installation, buyers should choose rotameters that offer flexible mounting options, such as those designed for both horizontal and vertical installations. Additionally, seek out models that come with comprehensive installation guides and support. It’s also advisable to work with manufacturers who provide technical assistance during the installation phase. Investing in rotameters with standard fittings that match existing pipeline sizes can further ease integration. Finally, consider using flow meters with built-in features like flow control valves or switches that can enhance operational efficiency while reducing the complexity of the overall system.

Strategic Material Selection Guide for rotameter flow meter

What Are the Key Properties of Common Materials Used in Rotameter Flow Meters?

Rotameter flow meters are widely utilized in various industries due to their simplicity and effectiveness in measuring flow rates of liquids and gases. The choice of material for the rotameter’s construction significantly impacts its performance, durability, and suitability for specific applications. Below, we analyze four common materials used in rotameter flow meters: glass, stainless steel, acrylic, and PTFE.

How Does Glass Perform in Rotameter Applications?

Glass is a traditional material used in rotameters, particularly for applications requiring visual flow indication. Key properties include its ability to withstand moderate pressure (up to 100 PSI) and temperature ratings typically around 150°F. Glass offers excellent clarity, allowing users to easily observe the flow.

Pros: Glass is highly resistant to chemical corrosion, making it suitable for various media, including aggressive chemicals. It is also cost-effective and readily available.

Cons: However, glass is fragile and can break under impact or thermal shock. Additionally, its weight can be a disadvantage in portable applications.

For international buyers, particularly in regions with stringent safety regulations like Germany and the Middle East, compliance with standards such as DIN is crucial. The fragility of glass may also necessitate additional protective measures during shipping and installation.

Illustrative image related to rotameter flow meter

What Advantages Does Stainless Steel Provide for Rotameters?

Stainless steel is a robust material choice for rotameters, especially in industrial applications. It can handle high pressures (up to 8700 PSI) and temperatures exceeding 662°F, making it suitable for extreme conditions.

Pros: Stainless steel is highly durable and resistant to corrosion, which extends the lifespan of the rotameter. It is also easy to clean and maintain, making it ideal for sanitary applications.

Cons: The primary drawback is the higher cost compared to glass or plastic alternatives. Manufacturing processes for stainless steel components can also be more complex, potentially leading to longer lead times.

International buyers should consider the material’s compliance with standards such as ASTM for North America and EN standards in Europe. The preference for stainless steel may vary by region, with industries in the Middle East often favoring it for its durability in harsh environments.

Why Choose Acrylic for Rotameter Flow Meters?

Acrylic is a lightweight and cost-effective alternative to glass, commonly used in low-flow applications. It typically supports pressures up to 90 PSI and temperatures around 145°F.

Pros: Acrylic is shatter-resistant, making it safer in environments where breakage is a concern. Its lower cost and ease of manufacturing make it attractive for budget-conscious projects.

Cons: However, acrylic is less chemically resistant than glass or stainless steel, limiting its use with certain aggressive chemicals. It can also scratch easily, which may impair visibility over time.

For B2B buyers in South America and Africa, acrylic rotameters can provide a balance of cost and functionality, but careful consideration of media compatibility is essential to avoid premature failure.

What Role Does PTFE Play in Rotameter Construction?

PTFE (Polytetrafluoroethylene) is increasingly used in rotameters, especially for applications involving corrosive chemicals. It can withstand temperatures up to 500°F and pressures around 300 PSI.

Pros: PTFE is highly resistant to chemical attack, making it suitable for a wide range of aggressive substances. It is also non-stick, which helps maintain accuracy over time.

Cons: The main disadvantage of PTFE is its higher cost compared to other materials. Additionally, it may not be suitable for high-pressure applications beyond its rated limits.

International buyers should be aware of PTFE’s compliance with various standards, including FDA regulations for food and pharmaceutical applications. Its use is often preferred in the Middle East and Europe for industries that prioritize chemical compatibility.

Summary Table of Material Selection for Rotameter Flow Meters

| Material | Typical Use Case for rotameter flow meter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Low to moderate pressure applications | Excellent chemical resistance | Fragile, prone to breakage | Low |

| Stainless Steel | High pressure and temperature applications | Durable and long-lasting | Higher cost, complex manufacturing | High |

| Acrylic | Low-flow applications | Lightweight and shatter-resistant | Less chemical resistance, scratches easily | Low |

| PTFE | Corrosive chemical applications | Exceptional chemical resistance | Higher cost, limited high-pressure use | Medium |

This material selection guide provides valuable insights for B2B buyers in various regions, helping them make informed decisions based on specific application needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for rotameter flow meter

What Are the Key Stages in the Manufacturing Process of Rotameter Flow Meters?

The manufacturing process of rotameter flow meters involves several critical stages, each ensuring that the final product meets stringent quality standards and performs reliably in various applications.

Material Preparation

The first stage is material preparation, where high-quality raw materials are sourced, including metals like stainless steel or specialized plastics for the body and float. Suppliers must adhere to strict material specifications to ensure compatibility with the fluids being measured. This stage may also involve testing materials for chemical resistance, temperature tolerance, and pressure ratings to ensure they meet the application requirements.

Forming Techniques

Once materials are prepared, the next step is forming. Advanced techniques such as precision machining, molding, or extrusion are employed to create the body of the rotameter and the float. For instance, glass or acrylic tubes are often used for visibility, while metal components may be machined to precise dimensions. The forming process is critical as it directly affects the accuracy and reliability of the flow measurement.

Illustrative image related to rotameter flow meter

Assembly Process

The assembly stage involves integrating various components, including the float, the tube, and any electronic parts. This is typically done in a clean environment to prevent contamination. Automated assembly lines may be used for high-volume production, while manual assembly might be preferred for custom or low-volume orders. During assembly, careful attention is paid to the alignment and sealing of components to prevent leaks and ensure optimal performance.

Finishing Touches

The final stage in manufacturing is finishing, where the rotameter undergoes processes such as polishing, coating, and labeling. This not only enhances the aesthetic appeal but also adds protective layers against corrosion and wear. The application of certifications and compliance marks, such as CE or ISO labels, is also part of this stage, ensuring that the product meets international standards.

What Quality Control Measures Are Essential for Rotameter Flow Meters?

Quality control (QC) is paramount in the manufacturing of rotameter flow meters, as these devices are critical for accurate fluid measurement in various industries. Effective QC processes help in maintaining product integrity and reliability.

What International Standards Should B2B Buyers Consider?

International quality standards, such as ISO 9001, are essential in guiding manufacturers to maintain high-quality management systems. Compliance with ISO standards ensures that the manufacturing processes are consistently monitored and improved, leading to enhanced product quality. Additionally, certifications like CE mark and industry-specific standards such as API provide assurance regarding product safety and reliability.

What Are the QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process. Key checkpoints include:

Illustrative image related to rotameter flow meter

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon receipt to ensure they meet the specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, operators conduct regular checks to monitor the quality of production and identify defects early. This includes dimensional checks and functional testing of components.

-

Final Quality Control (FQC): After assembly, the final product undergoes rigorous testing, including flow tests, pressure tests, and visual inspections. This ensures that the rotameter meets all performance specifications before it is shipped to customers.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, can take several steps to verify a supplier’s quality control measures:

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is an effective way to assess the quality management systems in place. Buyers should look for evidence of compliance with international standards and request access to quality management documentation, including process flow diagrams, inspection reports, and corrective action records. This helps in understanding the supplier’s commitment to quality.

How Important Are Third-Party Inspections?

Engaging third-party inspection agencies can provide an unbiased evaluation of a supplier’s manufacturing processes and quality control measures. These inspections can be crucial for buyers unfamiliar with local regulations or manufacturing practices. Third-party inspectors can verify compliance with international standards and provide detailed reports on findings.

What Are the Quality Control Nuances for International Buyers?

International buyers must be aware of the regulatory differences and quality standards that may exist in different regions. For instance, products intended for the European market must comply with CE marking requirements, while those for the U.S. market may need to meet ANSI standards. Understanding these nuances helps buyers make informed decisions and ensures compliance with local regulations.

Conclusion: Ensuring Quality in Rotameter Flow Meters

In summary, the manufacturing processes and quality assurance measures for rotameter flow meters are designed to ensure reliability, accuracy, and compliance with international standards. By understanding these processes, B2B buyers can make informed decisions and choose suppliers that adhere to high-quality manufacturing practices. This not only enhances operational efficiency but also minimizes risks associated with inaccurate flow measurement.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rotameter flow meter’

Introduction

Sourcing a rotameter flow meter requires careful consideration of technical specifications, supplier reliability, and compliance with industry standards. This guide provides B2B buyers with a structured checklist to ensure they make informed procurement decisions. Following these steps will help you select the right rotameter for your application while minimizing risks and maximizing value.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly outline your technical requirements. Consider factors such as the type of fluid (liquid or gas), flow range, pressure, and temperature ratings.

– Flow Rate: Ensure the rotameter can handle your expected flow rates, whether low or high.

– Material Compatibility: Select materials that are resistant to corrosion and suitable for the specific chemicals or gases being measured.

Illustrative image related to rotameter flow meter

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers to gauge their reputation and reliability. Look for established companies with a proven track record in manufacturing rotameters.

– Industry Experience: Assess how long the supplier has been in business and their expertise in your specific industry.

– Customer Reviews: Seek feedback from previous clients to understand their satisfaction levels regarding product quality and service.

Step 3: Evaluate Supplier Certifications

Verify that your chosen suppliers hold relevant certifications that demonstrate compliance with international standards. This is crucial for ensuring product reliability and safety.

– Quality Management Systems: Check for ISO certifications or equivalent that indicate robust quality control processes.

– Product Certifications: Ensure the rotameters are certified for safety standards applicable to your region, such as ATEX for hazardous environments.

Step 4: Request Product Samples

Whenever possible, request samples of the rotameters before making a bulk purchase. Testing a sample can help you assess the product’s performance in your specific application.

– Performance Testing: Evaluate the sample for accuracy, response time, and ease of installation.

– Visual Inspection: Look for any signs of manufacturing defects or material inconsistencies.

Step 5: Discuss Pricing and Terms

Engage in discussions about pricing, payment terms, and shipping options. Understanding the total cost of ownership, including any potential hidden fees, is vital for budget planning.

– Bulk Discounts: Inquire about discounts for larger orders or long-term contracts.

– Warranties and Support: Clarify warranty terms and the availability of technical support post-purchase.

Step 6: Review Lead Times and Delivery Options

Confirm the lead times for delivery to ensure they align with your project timelines. Timely procurement is essential to avoid disruptions in operations.

– Shipping Methods: Discuss available shipping options and associated costs.

– Stock Availability: Ensure that the supplier has sufficient stock or can produce the required rotameters within your timeframe.

Step 7: Finalize the Purchase Agreement

Once all details are confirmed, finalize the purchase agreement. Ensure that all terms discussed are documented to avoid misunderstandings.

– Contract Clarity: Review the contract for clarity on delivery schedules, payment terms, and return policies.

– Post-Purchase Support: Ensure the agreement includes details about support and maintenance services available after purchase.

By following this structured checklist, you can navigate the complexities of sourcing rotameter flow meters effectively, ensuring that you make a well-informed purchasing decision.

Comprehensive Cost and Pricing Analysis for rotameter flow meter Sourcing

What Are the Key Cost Components for Sourcing Rotameter Flow Meters?

When considering the cost structure of rotameter flow meters, several components contribute to the final pricing. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

-

Materials: The choice of materials significantly impacts the overall cost. For instance, rotameters made from stainless steel or specialized plastics typically command a higher price due to their durability and compatibility with various fluids. Customization options, such as specific material grades or finishes, also add to the cost.

-

Labor: Labor costs vary by region and can be influenced by the complexity of the manufacturing process. Skilled labor is often required for precise assembly and calibration, particularly for high-accuracy models.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce these costs.

-

Tooling: The initial investment in tooling for producing rotameters can be significant, especially if specialized molds or machinery are required for custom designs.

-

Quality Control: Ensuring compliance with international standards and certifications (like ATEX, IECEx, and SIL) incurs additional costs, as thorough testing and inspection processes are necessary.

-

Logistics: Transportation and warehousing costs can vary greatly depending on the origin of the product and the destination market. International shipping may also involve tariffs and duties, further influencing the overall cost.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can vary based on market conditions and the supplier’s positioning within the industry.

How Do Price Influencers Affect the Cost of Rotameter Flow Meters?

Several factors can influence the pricing of rotameter flow meters, which international buyers should be aware of:

-

Volume and Minimum Order Quantity (MOQ): Larger orders usually qualify for volume discounts, reducing the cost per unit. Buyers should negotiate to meet MOQs that align with their needs without overcommitting.

-

Specifications and Customization: Custom specifications, such as unique sizes or specialized materials, can lead to higher costs. Buyers should assess whether standard models meet their requirements before opting for customized solutions.

-

Materials and Quality Certifications: The quality and certification of materials used in the flow meters can significantly affect pricing. High-quality materials that comply with stringent regulations will typically be more expensive.

-

Supplier Factors: The reputation, reliability, and geographic location of the supplier can influence pricing. Established suppliers may charge a premium for their products due to their track record and customer service.

-

Incoterms: The choice of Incoterms can affect the total landed cost of the product. Buyers should carefully consider the shipping terms to understand their responsibilities regarding shipping, insurance, and tariffs.

What Buyer Tips Can Help Optimize Sourcing Costs for Rotameter Flow Meters?

To achieve cost-efficiency in sourcing rotameter flow meters, buyers should consider the following strategies:

-

Negotiation: Engaging in effective negotiation can lead to significant savings. Buyers should be prepared to discuss pricing, terms, and conditions, and leverage competitive quotes from multiple suppliers.

-

Total Cost of Ownership (TCO): Beyond the initial purchase price, buyers should evaluate the TCO, which includes maintenance, operational costs, and potential downtime. Choosing high-quality, reliable products can reduce long-term expenses.

-

Understanding Pricing Nuances for International Markets: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing differences due to factors such as local market dynamics, currency fluctuations, and import regulations.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, favorable terms, and increased flexibility in future orders.

-

Market Research: Staying informed about market trends, technological advancements, and competitor pricing can empower buyers to make informed purchasing decisions.

Disclaimer on Indicative Prices

Prices for rotameter flow meters can vary widely based on specifications, supplier, and market conditions. The figures provided in this analysis are indicative and should not be regarded as fixed quotes. Buyers are encouraged to conduct thorough research and obtain formal quotations tailored to their specific needs.

Alternatives Analysis: Comparing rotameter flow meter With Other Solutions

Exploring Alternatives to Rotameter Flow Meters for Flow Measurement

In the realm of industrial flow measurement, rotameter flow meters are a well-established choice due to their simplicity and reliability. However, various alternatives can cater to specific applications or operational needs, especially for international B2B buyers. Understanding these alternatives helps organizations make informed decisions tailored to their unique requirements.

| Comparison Aspect | Rotameter Flow Meter | Electromagnetic Flow Meter | Turbine Flow Meter |

|---|---|---|---|

| Performance | Accurate for low to moderate flow rates; suitable for liquids and gases. | Excellent for conductive fluids; high accuracy across a wide flow range. | High accuracy for liquids; performance decreases with low flow rates. |

| Cost | Generally low to moderate initial investment. | Higher upfront costs due to advanced technology. | Moderate initial costs, with maintenance costs depending on wear. |

| Ease of Implementation | Simple installation; no external power required. | Requires electrical power and specific installation considerations. | Relatively easy to install but may need calibration for accuracy. |

| Maintenance | Low maintenance; requires periodic visual checks. | Low maintenance but may need regular calibration. | Moderate maintenance due to moving parts that may wear out. |

| Best Use Case | Ideal for applications with low to moderate flow rates and where visibility is beneficial. | Best for large-scale operations handling conductive liquids. | Suitable for applications needing precise flow measurement in liquids, especially in custody transfer. |

What Are the Pros and Cons of Electromagnetic Flow Meters?

Electromagnetic flow meters are designed for measuring the flow of conductive fluids, such as water and certain chemicals. One of their significant advantages is their high accuracy across a wide range of flow rates, making them ideal for large-scale operations. However, they do come with a higher initial investment and require electrical power for operation. Additionally, they may not be suitable for non-conductive fluids, limiting their application scope.

How Do Turbine Flow Meters Compare in Terms of Performance?

Turbine flow meters utilize mechanical rotation to measure flow rates, providing high accuracy for liquids, particularly in applications such as custody transfer. While they are effective for a variety of liquids, their performance can diminish at low flow rates. They also require periodic maintenance due to the mechanical components that can wear over time. Their initial cost is moderate, making them a balanced option for many industrial applications.

Making the Right Choice for Your Flow Measurement Needs

When selecting a flow measurement solution, it’s crucial for B2B buyers to consider factors such as the specific application, the types of fluids being measured, and the required accuracy. Rotameter flow meters may be the best choice for applications needing low maintenance and visual flow indication. In contrast, electromagnetic flow meters are ideal for high-accuracy measurements of conductive fluids, while turbine flow meters excel in custody transfer scenarios. Evaluating these aspects will ensure that the chosen solution aligns with operational goals and budget constraints, ultimately leading to more efficient and effective flow measurement processes.

Essential Technical Properties and Trade Terminology for rotameter flow meter

What Are the Key Technical Properties of Rotameter Flow Meters?

When evaluating rotameter flow meters, several technical properties are critical for ensuring compatibility with specific applications and operational requirements. Here are some essential specifications:

-

Material Grade

The construction materials of a rotameter, such as stainless steel, acrylic, or glass, dictate its durability, chemical resistance, and suitability for various fluids. For instance, stainless steel is ideal for corrosive environments, while acrylic is often used for low-cost applications. Understanding the right material is crucial for maintaining the integrity of the measurement system over time. -

Flow Range

This specification indicates the minimum and maximum flow rates the rotameter can accurately measure, typically expressed in gallons per minute (GPM) or standard cubic feet per minute (SCFM). A broader flow range allows for greater versatility in applications, enabling businesses to use a single device across multiple processes, which can reduce inventory costs. -

Accuracy

Accuracy is often defined as a percentage of the full scale and indicates how closely the rotameter’s readings reflect the actual flow. For example, a flow meter with an accuracy of ±2% FS is crucial in processes where precise measurements are vital, such as in pharmaceuticals or food production. Higher accuracy can lead to improved product quality and regulatory compliance. -

Maximum Pressure Rating

This property specifies the highest pressure the rotameter can withstand without failure. Knowing the maximum pressure rating is essential for ensuring that the device can operate safely within the parameters of the application, particularly in high-pressure industrial environments. -

Operating Temperature Range

The operating temperature range outlines the conditions under which the rotameter can function effectively. For applications involving high temperatures, such as steam measurement, selecting a rotameter designed for elevated temperatures is critical to prevent damage and maintain accuracy. -

Fittings and Connections

The type of fittings (e.g., NPT, ANSI, or DIN) determines how the rotameter will integrate into existing piping systems. Choosing the correct fittings is essential for ensuring a leak-free connection and maintaining the integrity of the flow measurement.

Which Trade Terms Are Commonly Used in the Rotameter Industry?

Understanding industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some common terms related to rotameter flow meters:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that are used as components in another company’s product. In the context of rotameters, buyers may seek OEMs for custom solutions tailored to their specific needs, ensuring compatibility with their systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers, especially those looking to minimize upfront costs or secure favorable pricing. It can affect inventory management and purchasing strategies. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting a price quote for specific products or services. When seeking rotameters, submitting an RFQ allows buyers to compare pricing, specifications, and lead times from multiple suppliers, facilitating informed decision-making. -

Incoterms

Short for International Commercial Terms, Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for understanding shipping costs, risk transfer, and delivery obligations. -

Calibration

Calibration refers to the process of adjusting the accuracy of the flow meter against a standard. Regular calibration ensures that the rotameter delivers precise measurements, which is critical for compliance and operational efficiency. -

SIL (Safety Integrity Level)

SIL is a measure of the reliability of safety systems, particularly in hazardous applications. Rotameters with a specified SIL rating are designed to meet stringent safety standards, providing assurance to buyers regarding operational safety in critical processes.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing rotameter flow meters, ensuring they select the right products for their specific needs while navigating the complexities of the purchasing process.

Navigating Market Dynamics and Sourcing Trends in the rotameter flow meter Sector

What Are the Key Market Dynamics and Trends Influencing the Rotameter Flow Meter Sector?

The global rotameter flow meter market is experiencing significant growth driven by various factors, including the rising demand for accurate flow measurement across industries such as water treatment, pharmaceuticals, and oil and gas. In regions like Africa and South America, the need for efficient resource management and infrastructure development is propelling the adoption of rotameters, particularly in sectors reliant on fluid dynamics. Conversely, Europe and the Middle East are witnessing a surge in high-tech applications, with advanced rotameter designs integrating digital technologies for improved performance and data analytics.

Illustrative image related to rotameter flow meter

Emerging B2B tech trends include the incorporation of smart technologies, such as IoT-enabled rotameters that allow for real-time monitoring and predictive maintenance. This trend is particularly relevant for international buyers looking to enhance operational efficiency and reduce downtime. Additionally, sustainability has become a focal point, with manufacturers increasingly offering rotameters made from recyclable materials and designed for low energy consumption. The demand for customizable solutions that cater to specific industry requirements is also on the rise, reflecting a shift toward tailored sourcing strategies.

How Can Sustainability and Ethical Sourcing Impact the Rotameter Flow Meter Supply Chain?

Sustainability and ethical sourcing are becoming pivotal in the rotameter flow meter sector, with buyers increasingly prioritizing suppliers that adhere to environmentally responsible practices. The environmental impact of manufacturing processes, such as waste generation and carbon emissions, is under scrutiny. Consequently, B2B buyers are encouraged to evaluate suppliers based on their sustainability certifications and the environmental footprint of their products.

Green certifications, such as ISO 14001 and other eco-labels, serve as indicators of a supplier’s commitment to sustainable practices. Furthermore, the use of environmentally friendly materials in rotameter production not only minimizes ecological impact but can also enhance product appeal to end-users who prioritize sustainability. As the global market shifts towards greener alternatives, international buyers must ensure their sourcing strategies align with ethical supply chain practices to meet regulatory requirements and consumer expectations.

Illustrative image related to rotameter flow meter

How Has the Rotameter Flow Meter Evolved Over Time?

The evolution of the rotameter flow meter can be traced back to its inception in the early 20th century, where it served as a simple yet effective tool for measuring flow rates in various applications. Initially constructed from glass, early rotameters provided visual flow indications but were limited in terms of durability and range. As industries evolved and the demand for more robust solutions increased, manufacturers began to develop rotameters using materials such as stainless steel and advanced polymers, significantly enhancing their performance and longevity.

In recent years, technological advancements have further transformed the rotameter landscape, with the integration of digital displays, wireless communication, and smart sensor technologies. This evolution not only caters to the growing need for precise flow measurement but also aligns with the broader trend of digitization across industrial sectors. Today, rotameters are indispensable tools in diverse applications, reflecting a rich history of innovation that continues to adapt to the changing demands of global markets.

Frequently Asked Questions (FAQs) for B2B Buyers of rotameter flow meter

-

How do I choose the right rotameter flow meter for my application?

Choosing the right rotameter flow meter involves evaluating your specific application requirements, including the type of fluid (liquid or gas), flow rate, pressure, and temperature conditions. Consider the materials of construction to ensure compatibility with the fluid being measured, particularly for corrosive substances. Additionally, assess the required accuracy and whether you need features like visual flow indication or electronic output. Consulting with suppliers can provide valuable insights tailored to your operational needs. -

What is the best rotameter for low flow applications?

For low flow applications, a compact rotameter designed for low measurement ranges is ideal. Models with all-metal designs are preferred for their durability and reliability. Look for rotameters that offer high accuracy at low flow rates, such as those with ranges starting as low as 0.1 L/h. Ensure the selected model can handle the specific pressure and temperature conditions of your application, and verify certifications like ATEX for safety in hazardous environments. -

What are the common customization options available for rotameter flow meters?

Customization options for rotameter flow meters typically include material selection for the measuring tube and float, which can be tailored to resist corrosion or withstand extreme temperatures. You can also choose specific fittings, scales, and output types, such as analog or digital signals. Additionally, features like integrated switches or transmitters can be included based on your monitoring needs. Discussing customization with your supplier can help ensure the rotameter meets your exact specifications. -

What minimum order quantity (MOQ) should I expect when sourcing rotameters?

Minimum order quantities (MOQs) for rotameter flow meters can vary significantly based on the manufacturer and model. Some suppliers may have MOQs as low as one unit, especially for standard models, while others may require larger orders for customized designs. It is advisable to inquire directly with potential suppliers about their MOQ policies, as negotiating lower quantities may be possible, especially for first-time orders or long-term partnerships. -

How can I ensure the quality of the rotameter flow meter I purchase?

To ensure the quality of your rotameter flow meter, select suppliers with a solid reputation and proven track record in the industry. Request certifications and compliance documentation, such as ISO standards and ATEX approvals for safety in explosive environments. Conducting a thorough supplier vetting process, including checking references and past customer feedback, can also help. If possible, consider visiting the manufacturing facility or requesting samples for evaluation before placing a bulk order. -

What payment terms are typically offered by suppliers for rotameter flow meters?

Payment terms for rotameter flow meters can vary by supplier and may include options such as payment in advance, net 30, or letters of credit, particularly for international transactions. It’s essential to discuss payment options upfront and assess any potential risks associated with the chosen method. Establishing a clear agreement on payment terms can help facilitate smoother transactions and build trust between you and the supplier. -

How do I handle shipping and logistics when sourcing rotameters internationally?

When sourcing rotameters internationally, understanding shipping and logistics is crucial. Discuss shipping methods with your supplier, including options for air or sea freight, and consider the associated costs and delivery timelines. Ensure compliance with import/export regulations in your country to avoid delays. Utilizing a reliable freight forwarder can facilitate the process, helping manage documentation and customs clearance. Additionally, consider insurance for high-value shipments to mitigate risks. -

What are the typical lead times for rotameter flow meter production and delivery?

Lead times for rotameter flow meter production and delivery can vary widely based on factors such as the complexity of the order, customization requirements, and the supplier’s production capacity. Standard models may have lead times ranging from a few days to a few weeks, while custom configurations can take longer, often several weeks to months. It’s advisable to discuss expected lead times with your supplier early in the sourcing process to plan accordingly and avoid operational disruptions.

Top 7 Rotameter Flow Meter Manufacturers & Suppliers List

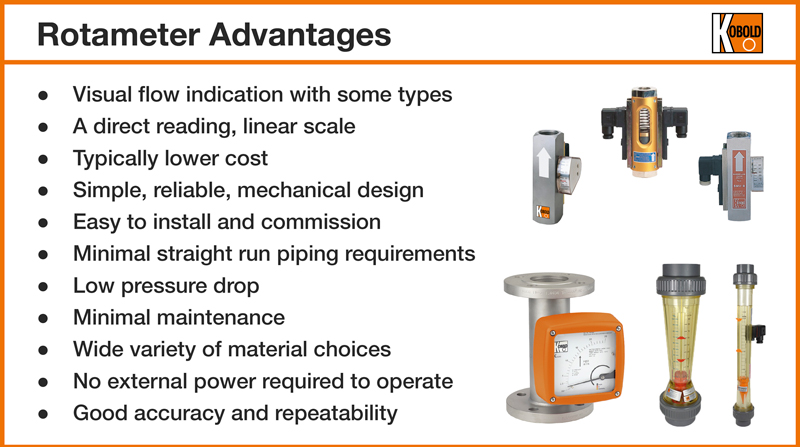

1. Kobold – Variable Area Flow Meters

Domain: koboldusa.com

Registered: 1996 (29 years)

Introduction: Variable Area/Rotameters Flow Meter and Switches operate on the principle of a float moving freely within a conical tube to balance gravitational force and fluid flow. They are suitable for low maintenance and easy-to-read measurements, measuring flow rates of liquid or gas without external power. Key products include:

1. **BGF Heavy-Duty Industrial All-Metal Variable Area Flow Meter**

– Flo…

2. Brooks Instrument – Variable Area Flow Meters

Domain: brooksinstrument.com

Registered: 1996 (29 years)

Introduction: Variable Area Flow Meters (Rotameters) from Brooks Instrument are designed for reliable and repeatable measurement of gas and liquid flow rates across various industries. Key features include:

– Reliable, easy-to-read displays for gas, fluid, and water flow meters.

– Fail-safe inline flow indication.

– Integral flow controller for pressure compensation.

– Materials suitable for multiple pressure …

3. Instrumart – Rotameters

Domain: instrumart.com

Registered: 2004 (21 years)

Introduction: Rotameters are flow measuring instruments that consist of a uniformly tapered flow tube, a float, and a measurement scale. They operate based on Bernoulli’s theorem, where the float rises with the fluid flow until the entire volume can pass, indicating the flow rate. Key features include:

– Simple, reliable, and inexpensive

– Generally low pressure drop

– Must be mounted vertically

– Moderate …

4. PRM Filtration – Rotameters for Air & Water Applications

Domain: shop.prmfiltration.com

Registered: 2016 (9 years)

Introduction: Rotameters for Air Applications, Rotameters for Water Applications

5. Yokogawa – Variable Area Flow Meters

Domain: yokogawa.com

Registered: 1998 (27 years)

Introduction: Yokogawa’s Variable Area Flow Meters (Rotameters) are designed for accurate flow measurement of liquids and gases. They feature a simple and robust design, allowing for easy installation and maintenance. The meters provide a visual indication of flow rate and are suitable for a wide range of applications. Key features include a wide measurement range, high accuracy, and compatibility with various …

6. DwyerOmega – Variable Area Flow Meters

Domain: dwyeromega.com

Registered: 2022 (3 years)

Introduction: Variable Area Flow Meter from DwyerOmega; Price Range: $0-$49.99 (1), $50-$199.99 (17), $200-$499.99 (34), $500-$999.99 (37), $1,000-$9,999.99 (34); In Stock; Brand: Dwyer (20), Omega (46); Media Compatibility: Air (34), Alcohols (1), Argon (3), Carbon dioxide (1), Helium (1), Hydraulic Oil (11), Hydrogen (1), Light Oil (10), Nitrogen (3), Oil (10), Oxygen (2), Water (50); Process Connection Sizes…

7. Water Anywhere – Rotameter Flowmeters

Domain: wateranywhere.com

Registered: 2000 (25 years)

Introduction: This company, Water Anywhere – Rotameter Flowmeters, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for rotameter flow meter

As the demand for efficient flow measurement solutions grows across various industries, the strategic sourcing of rotameter flow meters emerges as a critical factor for international B2B buyers. These devices stand out due to their simplicity, reliability, and cost-effectiveness, making them suitable for a wide range of applications—from oil and gas to water treatment. By investing in high-quality rotameters, businesses can ensure accurate flow measurement, reduce maintenance costs, and enhance operational efficiency.

In markets such as Africa, South America, the Middle East, and Europe, understanding local regulations and material compatibility is essential for successful sourcing. Collaborating with reputable suppliers who offer customization options can significantly improve performance in specific environments. Additionally, leveraging certifications like ATEX and IECEx can provide assurance regarding safety and compliance.

Looking ahead, the future of rotameter flow meters is bright, with innovations in materials and technology set to enhance their functionality. International B2B buyers are encouraged to explore partnerships with leading manufacturers and stay informed about emerging trends. By making informed sourcing decisions, businesses can position themselves for success in an increasingly competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.