How to Source Replacement Canopy Material Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for replacement canopy material

As international B2B buyers delve into the complexities of sourcing replacement canopy material, a common challenge arises: ensuring the right balance of quality, durability, and cost-effectiveness. The global market offers a plethora of options, ranging from high-performance awning fabrics to specialized materials suited for diverse applications such as RVs, commercial spaces, and residential outdoor settings. This guide aims to illuminate the multifaceted landscape of replacement canopy materials, providing insights into various types, applications, and essential considerations for supplier vetting.

In the pages ahead, you will explore the characteristics that define high-quality fabrics, such as UV resistance, weatherproofing, and mildew protection. Additionally, we will examine the cost implications associated with different materials and the importance of selecting suppliers who not only provide competitive pricing but also maintain rigorous quality standards. By empowering B2B buyers from regions including Africa, South America, the Middle East, and Europe—such as Saudi Arabia and Brazil—this guide facilitates informed purchasing decisions that align with specific business needs and environmental conditions.

Navigating this intricate market can be daunting, but with the right information and strategies at your fingertips, you can confidently choose replacement canopy materials that enhance your offerings and meet customer expectations. Embrace the opportunity to elevate your business with durable, aesthetically pleasing, and functional canopy solutions.

Understanding replacement canopy material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Acrylic Fabric | Water-resistant, UV protective, vibrant color retention | Commercial awnings, residential canopies | Pros: Excellent colorfastness; resistant to mildew. Cons: Can be less durable in extreme weather. |

| Vinyl Material | Heavy-duty, waterproof, and durable under harsh conditions | RV awnings, patio canopies, industrial tents | Pros: Highly durable; easy to clean. Cons: Heavier and may require more robust support structures. |

| Polyester Fabric | Lightweight, versatile, and often treated for weather resistance | Event tents, temporary canopies, promotional displays | Pros: Cost-effective; good UV protection. Cons: Less durable than acrylic or vinyl. |

| Canvas | Natural fiber, breathable, and often treated for water resistance | Outdoor furniture covers, market stalls | Pros: Eco-friendly; aesthetically pleasing. Cons: Requires regular maintenance to prevent mold. |

| Mesh Fabric | Allows airflow while providing shade, often UV resistant | Shade structures, outdoor patios, and gazebos | Pros: Lightweight; promotes ventilation. Cons: Limited protection from heavy rain. |

What Are the Characteristics of Acrylic Fabric for Replacement Canopies?

Acrylic fabric is known for its vibrant colors and excellent UV resistance, making it a popular choice for commercial and residential awnings. Its water-resistant properties ensure that it remains functional in various weather conditions, while its fade-resistant nature helps maintain its aesthetic appeal over time. For B2B buyers, considering acrylic fabric means investing in a product that combines durability with visual appeal, ideal for enhancing customer experiences in outdoor settings.

Why Choose Vinyl Material for Heavy-Duty Applications?

Vinyl material stands out for its heavy-duty characteristics, making it particularly suitable for applications that require resilience against harsh environmental conditions. This type of fabric is fully waterproof, which is essential for RV awnings and industrial tents. B2B buyers should note that while vinyl is durable and easy to clean, its weight necessitates stronger support structures, potentially increasing installation costs.

What Makes Polyester Fabric a Versatile Option?

Polyester fabric is lightweight and versatile, often treated to enhance its weather resistance. Its cost-effectiveness makes it a favorable option for temporary canopies and promotional displays. While polyester offers good UV protection, it may not be as durable as acrylic or vinyl. B2B buyers should weigh the balance between cost and longevity based on their specific application needs.

How Does Canvas Compare to Synthetic Options?

Canvas, made from natural fibers, provides a breathable option that is aesthetically pleasing for outdoor furniture covers and market stalls. While it is eco-friendly and offers good water resistance when treated, it requires regular maintenance to prevent mold growth. B2B buyers looking for a sustainable option should consider canvas, but they must also be prepared for the upkeep involved.

When Is Mesh Fabric the Best Choice for Shade Structures?

Mesh fabric is ideal for applications where airflow is essential, such as shade structures and outdoor patios. It provides a degree of UV protection while allowing breezes to flow through, which can enhance comfort in hot climates. However, it offers limited protection against heavy rain. B2B buyers should evaluate whether the ventilation benefits outweigh the potential downsides for their specific use cases.

Key Industrial Applications of replacement canopy material

| Industry/Sector | Specific Application of Replacement Canopy Material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Outdoor dining canopies for restaurants | Enhances customer experience, increases seating capacity | Durability, UV resistance, aesthetic appeal, ease of installation |

| Automotive | RV awning replacements | Protects vehicles from elements, enhances resale value | Weatherproof materials, compatibility with various models, color options |

| Retail | Storefront awnings | Attracts customers, provides shade and shelter | Customization options, branding potential, weather resistance |

| Events and Entertainment | Canopies for outdoor events and festivals | Provides shelter, improves guest comfort | Portability, ease of setup, durability against weather conditions |

| Residential | Home patio and garden canopies | Expands living space, adds value to property | Aesthetic variety, easy maintenance, climate adaptability |

How Are Replacement Canopy Materials Used in Hospitality Settings?

In the hospitality industry, replacement canopy materials are primarily used for outdoor dining areas at restaurants and cafes. They create an inviting atmosphere while providing shade and protection from the elements, which enhances the overall customer experience. For international buyers, particularly in regions with diverse climates, sourcing durable, UV-resistant fabrics is essential to withstand local weather conditions. Additionally, the aesthetic appeal of the canopy can be customized to align with the restaurant’s branding, making it a valuable investment that can increase seating capacity and attract more patrons.

What Role Do Replacement Canopy Materials Play in the Automotive Sector?

In the automotive sector, replacement canopy materials are frequently utilized for RV awnings. These materials protect vehicles from harsh weather conditions, thus preserving their exterior and interior quality. For international buyers, especially in regions like the Middle East and South America where UV exposure is significant, sourcing high-quality, weatherproof fabrics is crucial. The ability to choose from a variety of colors and patterns also allows for personalization, enhancing the vehicle’s resale value. Therefore, selecting durable, lightweight materials that can withstand varying climates is a key consideration.

How Do Retailers Benefit from Replacement Canopy Materials?

Retail businesses often employ replacement canopy materials for storefront awnings, which serve multiple purposes. They not only provide shade and shelter for customers but also enhance the visual appeal of the store, effectively attracting more foot traffic. For B2B buyers in regions with fluctuating weather, sourcing materials that are both durable and aesthetically pleasing is vital. Customization options allow retailers to incorporate branding into their awnings, further solidifying their market presence. The right canopy can ultimately lead to increased sales and improved customer satisfaction.

What Are the Applications of Replacement Canopy Materials in Events and Entertainment?

In the events and entertainment sector, replacement canopy materials are essential for outdoor events and festivals. They provide necessary shelter from rain or sun, ensuring guest comfort and safety. For international buyers, particularly in regions prone to unpredictable weather, sourcing portable and durable canopies that are easy to set up is critical. The ability to withstand harsh weather conditions while remaining visually appealing can significantly enhance the overall experience of attendees. Therefore, investing in high-quality materials that can be reused for various events is a practical consideration.

How Are Replacement Canopy Materials Used in Residential Applications?

For residential applications, replacement canopy materials are commonly used for patios and garden canopies. They help expand living spaces, providing shade and comfort for outdoor activities, thus increasing the property’s value. Buyers in diverse climates should prioritize materials that offer UV protection and are easy to maintain, ensuring longevity and aesthetic appeal. The availability of various colors and styles allows homeowners to personalize their outdoor spaces, making it an attractive option for enhancing their living environment.

3 Common User Pain Points for ‘replacement canopy material’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Replacement Canopy Material

The Problem: B2B buyers often struggle with choosing the appropriate replacement canopy material that meets specific performance standards, particularly in diverse climates. For instance, a company in Brazil might need a fabric that can withstand heavy rain and high UV exposure, while a buyer in Saudi Arabia may prioritize heat resistance and durability against sandstorms. The myriad of options—each with varying levels of weather resistance, durability, and aesthetic appeal—can lead to confusion and misinformed purchasing decisions.

The Solution: To alleviate this pain point, it’s crucial to conduct a thorough analysis of the environmental conditions where the canopy will be used. Buyers should prioritize materials that are specifically designed for their local weather patterns. For instance, look for fabrics like Sunbrella or Sattler, which offer UV protection, mildew resistance, and weatherproofing. Engaging with manufacturers or suppliers who can provide samples and detailed specifications can also facilitate informed decisions. Additionally, consider leveraging technology by using online configurators that allow users to visualize different materials and their applications, thus enhancing the decision-making process.

Scenario 2: Installation Complications with Replacement Canopy Fabric

The Problem: Many B2B buyers face challenges during the installation of replacement canopy fabrics, particularly when transitioning from old to new materials. This can lead to delays in project timelines and increased labor costs, especially if the installation process is not straightforward. For instance, a company replacing an awning fabric on a commercial property may find that the old hardware does not fit the new material correctly, leading to additional complications.

The Solution: To ensure a smooth installation, buyers should carefully assess the compatibility of new fabrics with existing hardware before making a purchase. It’s advisable to consult with the supplier for guidance on installation procedures and to understand any additional components that may be required. Providing comprehensive installation guides and video tutorials can also empower buyers to undertake the installation themselves or streamline the process for their teams. Furthermore, working with professional installers who have experience with the specific type of canopy material can mitigate risks and enhance the quality of the final setup.

Scenario 3: Longevity and Maintenance Concerns of Canopy Materials

The Problem: The durability and maintenance of replacement canopy materials are often overlooked, leading to frequent replacements and increased long-term costs. B2B buyers may be drawn to cheaper options without fully understanding the implications of reduced lifespan, particularly in harsh environments. For instance, a distributor in the Middle East may find that low-quality fabrics degrade quickly under intense sun exposure, leading to costly replacements and dissatisfied customers.

The Solution: To address concerns about longevity, buyers should invest in high-performance materials that are specifically engineered for durability. Fabrics such as heavy-duty vinyl or solution-dyed acrylic can provide superior resistance to fading, tearing, and environmental wear. Additionally, establishing a regular maintenance schedule can significantly extend the life of the canopy. Educating staff on proper cleaning techniques—like using gentle soaps and avoiding abrasive materials—will help maintain the fabric’s integrity. Suppliers should also offer warranties or guarantees on their products, providing buyers with confidence in their investment and reducing the likelihood of premature replacements.

Strategic Material Selection Guide for replacement canopy material

What Are the Key Properties of Different Replacement Canopy Materials?

When selecting replacement canopy materials, it is essential to consider various factors such as durability, weather resistance, and cost-effectiveness. Below is an analysis of four common materials used in replacement canopies, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Acrylic Fabric

Key Properties:

Acrylic fabrics are known for their excellent UV resistance and color retention. They are lightweight yet strong, with a temperature rating that allows them to withstand varying climates without degrading. Acrylic is also mildew resistant, making it suitable for humid environments.

Pros & Cons:

The durability of acrylic fabrics is a significant advantage, as they can last up to 10 years with proper care. However, they can be more expensive than other materials, which may deter budget-conscious buyers. Additionally, while they are water-resistant, prolonged exposure to heavy rain can lead to water penetration.

Impact on Application:

Acrylic fabrics are ideal for outdoor applications such as patio awnings and canopies in commercial settings. Their aesthetic appeal makes them popular for residential use as well.

Considerations for International Buyers:

In regions like Africa and the Middle East, where UV exposure is high, the UV resistance of acrylic can be a selling point. Compliance with international standards such as ASTM for fabric testing is crucial for ensuring product reliability.

2. Polyester Fabric

Key Properties:

Polyester fabrics are known for their strength and resistance to stretching and shrinking. They have a good temperature rating and are often treated with coatings for water and UV resistance.

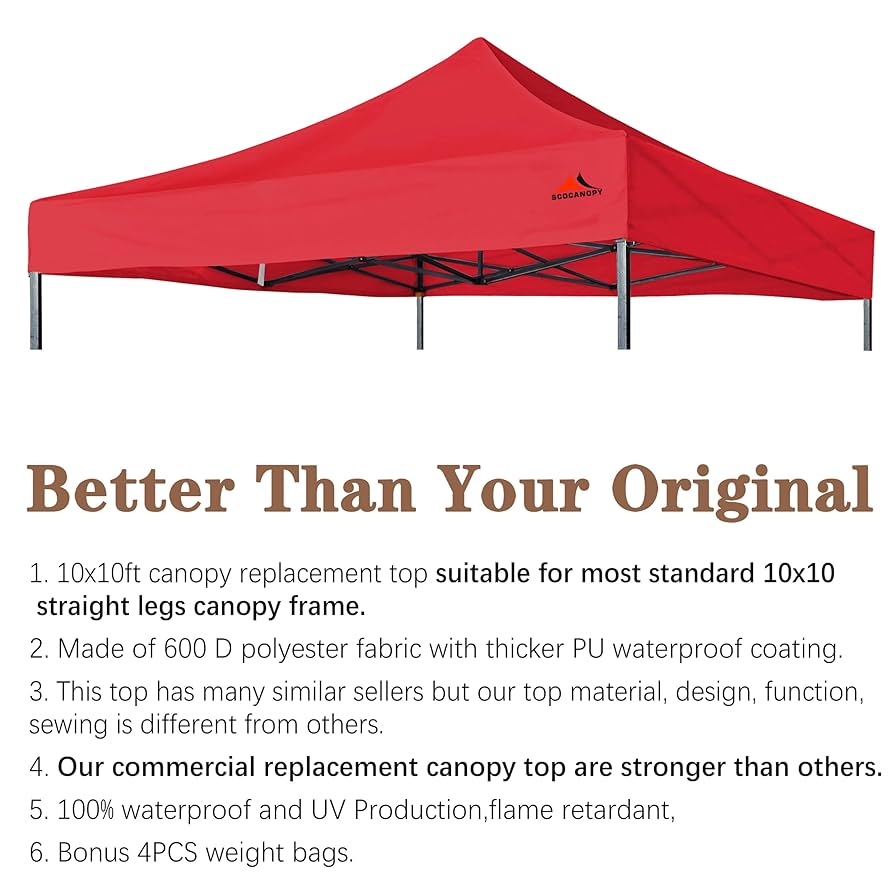

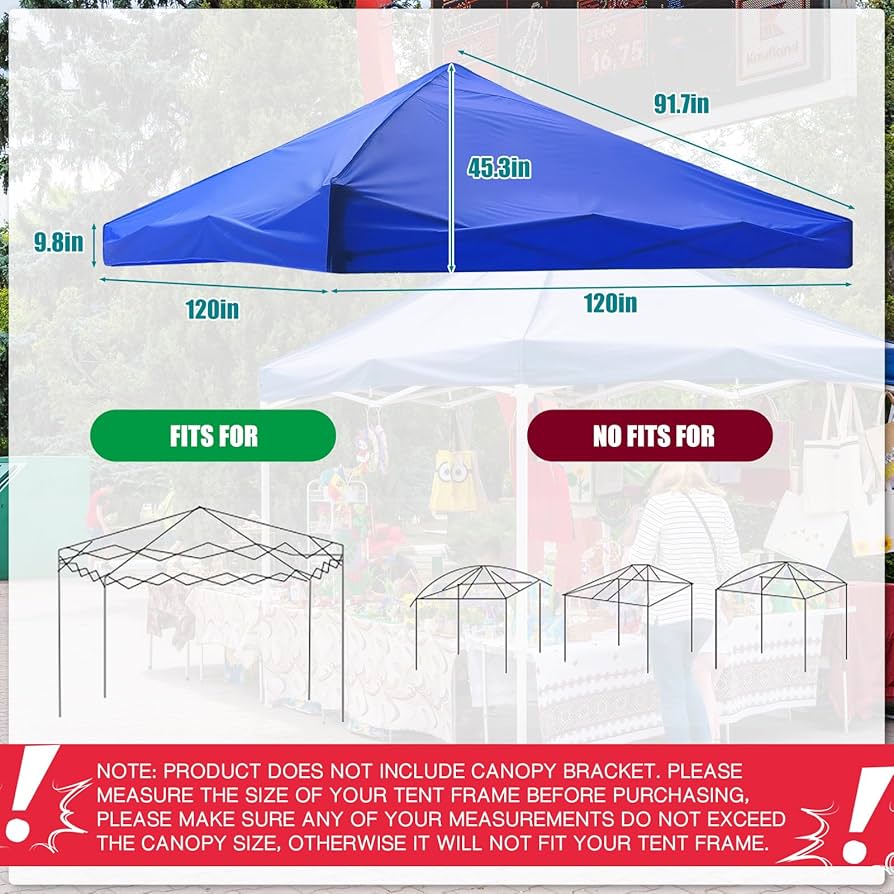

Illustrative image related to replacement canopy material

Pros & Cons:

The affordability of polyester makes it a popular choice for many applications. However, it may not be as durable as acrylic or vinyl, leading to a shorter lifespan. Additionally, polyester can be prone to fading over time, especially in high UV environments.

Impact on Application:

Polyester is suitable for a variety of applications, including commercial canopies and temporary structures. It is often used in regions with moderate weather conditions.

Considerations for International Buyers:

Buyers in South America may find polyester appealing due to its cost-effectiveness, but they should consider the local climate’s impact on longevity. Ensuring compliance with local standards can enhance marketability.

3. Vinyl Fabric

Key Properties:

Vinyl fabrics are highly durable and weather-resistant, with excellent corrosion resistance. They can withstand extreme temperatures and are often used in heavy-duty applications.

Pros & Cons:

The primary advantage of vinyl is its longevity and ability to resist tears and punctures. However, it tends to be heavier than other materials, which can complicate installation and transportation. Vinyl can also be more expensive due to its manufacturing complexity.

Impact on Application:

Vinyl is commonly used in industrial applications, such as truck tarps and heavy-duty canopies. Its robustness makes it suitable for areas with harsh weather conditions.

Considerations for International Buyers:

In regions like Europe, where standards for material safety and environmental impact are stringent, buyers must ensure that vinyl products comply with regulations such as REACH.

4. Canvas Fabric

Key Properties:

Canvas is a traditional material known for its strength and breathability. It has a good temperature rating and can be treated for water resistance, though it is not inherently waterproof.

Pros & Cons:

Canvas is relatively inexpensive and offers a classic aesthetic. However, it requires regular maintenance and treatment to prevent mildew and water damage, which can be a drawback for some users.

Impact on Application:

Canvas is often used for tents, awnings, and outdoor furniture covers. Its versatility makes it suitable for both commercial and residential applications.

Considerations for International Buyers:

In regions with high humidity, such as parts of Africa, buyers should be aware of the maintenance requirements for canvas to prevent mildew. Compliance with local standards for outdoor materials can enhance product acceptance.

Summary Table of Replacement Canopy Materials

| Material | Typical Use Case for replacement canopy material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Acrylic Fabric | Patio awnings, commercial canopies | Excellent UV resistance | Higher cost compared to others | High |

| Polyester Fabric | Temporary structures, commercial canopies | Cost-effective | Prone to fading | Low |

| Vinyl Fabric | Industrial applications, heavy-duty canopies | Highly durable | Heavier and more complex to install | High |

| Canvas Fabric | Tents, outdoor furniture covers | Inexpensive and versatile | Requires regular maintenance | Med |

This guide provides a comprehensive overview of the key materials available for replacement canopies, helping international B2B buyers make informed decisions tailored to their specific regional needs.

Illustrative image related to replacement canopy material

In-depth Look: Manufacturing Processes and Quality Assurance for replacement canopy material

What Are the Key Stages in the Manufacturing Process of Replacement Canopy Material?

The manufacturing process for replacement canopy material involves several critical stages that ensure durability, performance, and aesthetic appeal. Understanding these stages can help B2B buyers make informed decisions when sourcing materials.

1. Material Preparation: What Are the Initial Steps?

The first stage involves sourcing high-quality raw materials, which can include synthetic fibers like polyester or acrylic, as well as vinyl for heavy-duty applications. Manufacturers often use solution-dyed yarns, which provide inherent UV resistance and colorfastness. The raw materials undergo rigorous testing for quality before being accepted into the production line. This may include checking tensile strength, color accuracy, and resistance to environmental factors.

2. Forming: How Are Fabrics Created?

Once the materials are prepared, they are woven or knitted into fabrics. This process can employ various techniques, including warp knitting or weaving, depending on the desired characteristics of the canopy. The choice of technique significantly influences the final product’s durability and flexibility. Advanced manufacturing technologies, such as automated looms, enhance precision and reduce waste.

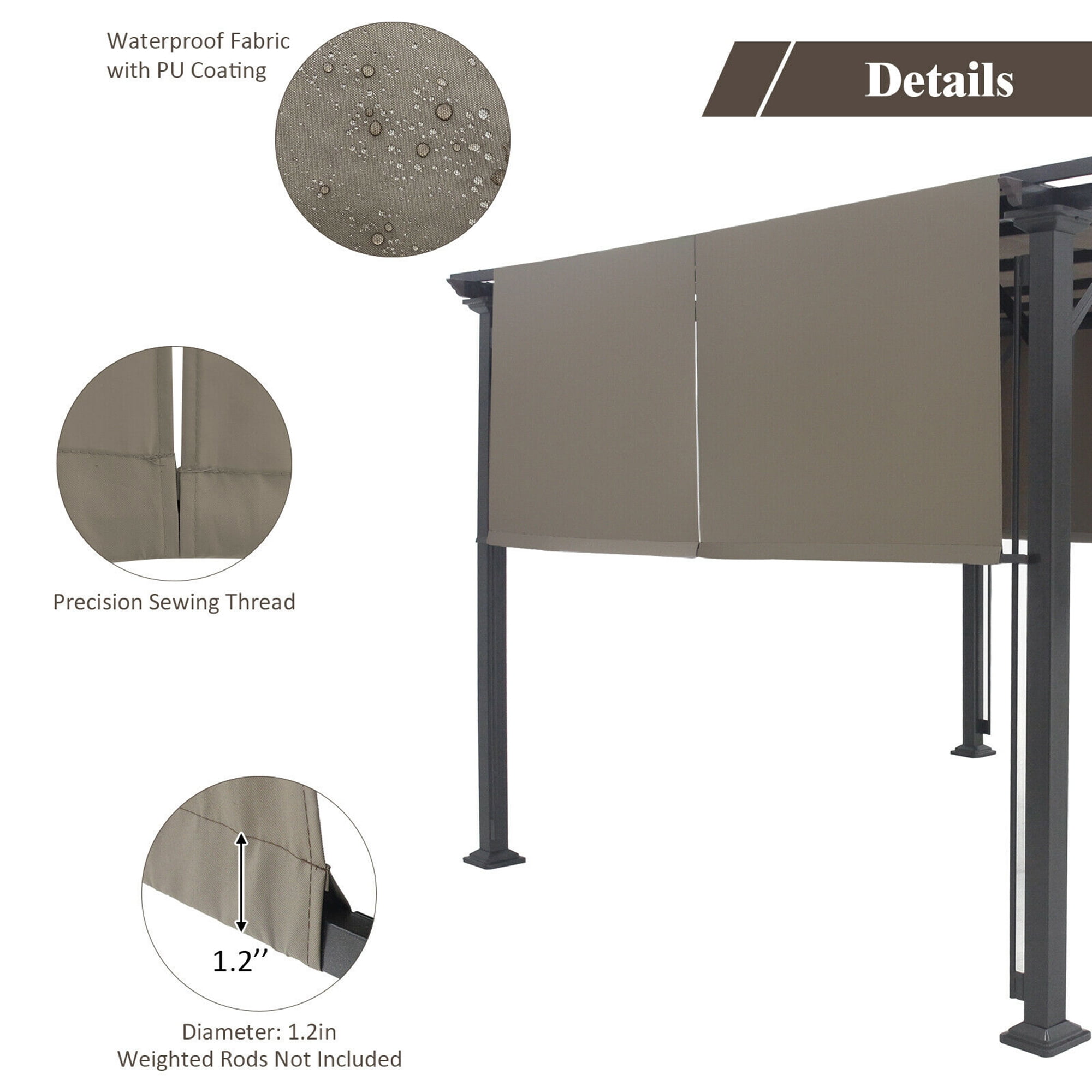

3. Assembly: What Involves the Joining Process?

After the fabric is formed, the next step is assembly. This typically involves cutting the fabric into specified sizes and shapes, followed by sewing or heat sealing the edges to ensure durability. Reinforcement techniques, such as adding grommets or reinforced stitching at stress points, are crucial to enhancing the canopy’s longevity, particularly for products designed for harsh environmental conditions.

4. Finishing: What Treatments Are Applied?

The finishing stage is where the fabric is treated to enhance its performance characteristics. This may include applying water-repellent coatings, UV inhibitors, or mildew-resistant treatments. The application of these finishes is crucial, as they help prolong the lifespan of the canopy material. Manufacturers may also conduct aesthetic treatments, such as dyeing or printing patterns, to meet customer preferences.

What Quality Assurance Measures Are Essential for Replacement Canopy Material?

Quality assurance (QA) is critical in ensuring that replacement canopy materials meet international standards and customer expectations. B2B buyers should familiarize themselves with the relevant QA processes and standards.

1. What International Standards Should Buyers Be Aware Of?

Manufacturers often adhere to international quality management standards, such as ISO 9001, which provides a framework for consistent quality across processes. Additionally, industry-specific certifications like CE for products sold in Europe or API for specific applications can further validate the quality of the materials. Buyers should verify that their suppliers possess these certifications, as they indicate a commitment to quality and safety.

2. How Are Quality Checkpoints Structured in the Production Process?

Quality control checkpoints are integrated throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards. This may include testing for color accuracy, strength, and chemical composition.

-

In-Process Quality Control (IPQC): During production, manufacturers conduct periodic checks to monitor the consistency of fabric quality. This includes testing the tensile strength and checking for defects in weaving or knitting.

-

Final Quality Control (FQC): Before shipment, a final inspection ensures that the finished products meet all quality criteria. This may involve durability testing, water resistance checks, and visual inspections for defects or inconsistencies.

What Common Testing Methods Are Used in Quality Control?

Several testing methods are standard in the quality assurance process for replacement canopy materials:

-

Tensile Testing: Measures the strength of the fabric under tension to ensure it can withstand environmental stresses.

-

UV Resistance Testing: Assesses the fabric’s ability to resist degradation from UV exposure, crucial for outdoor applications.

-

Water Resistance Testing: Evaluates how well the fabric repels water, which is essential for canopies exposed to rain and moisture.

-

Colorfastness Testing: Determines how well the fabric retains its color when exposed to sunlight and washing.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers, particularly those in diverse markets like Africa, South America, the Middle East, and Europe, should take proactive steps to verify supplier quality control practices:

-

Request Documentation: Buyers should ask for quality assurance documents, including certification copies, testing reports, and quality control checklists.

-

Conduct Audits: Regular supplier audits can provide insights into the manufacturing process and adherence to quality standards. This can be done by the buyer’s team or through third-party auditing firms.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can help ensure compliance with international standards and provide an unbiased assessment of the supplier’s quality practices.

-

Review Customer Feedback: Researching reviews and feedback from other businesses that have sourced from the supplier can offer valuable insights into their reliability and product quality.

What Are the Quality Control Nuances for International Buyers?

International buyers must navigate unique challenges related to quality control, including:

-

Cultural Differences: Understanding local manufacturing practices and quality standards can vary significantly. Buyers should be aware of these differences and communicate their quality expectations clearly.

-

Regulatory Compliance: Different regions may have specific regulations regarding product safety and environmental standards. Buyers should ensure that their suppliers comply with these regulations to avoid legal issues.

-

Logistical Challenges: International shipping can lead to issues like damage during transport. Buyers should discuss packaging and handling procedures with suppliers to minimize risks.

By understanding the manufacturing processes and quality assurance measures for replacement canopy materials, B2B buyers can make informed sourcing decisions that align with their operational needs and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘replacement canopy material’

To assist B2B buyers in procuring replacement canopy material effectively, this guide outlines a clear and actionable checklist. The goal is to help you navigate the complexities of sourcing, ensuring you choose the right materials and suppliers for your business needs.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it’s essential to outline the specific requirements for your replacement canopy material. Consider factors such as size, weight, and the type of environment the canopy will be exposed to.

– Durability: Ensure the material can withstand local weather conditions, including UV exposure, rain, and wind.

– Functionality: Determine if the canopy will be used for temporary or permanent installations, as this may affect your choice of fabric.

Step 2: Research Material Options

Investigate the various materials available for canopies, such as vinyl, polyester, or acrylic fabrics. Each material has unique properties that can impact performance and longevity.

– Water Resistance: Look for materials that offer water repellency and mildew resistance, especially if the canopy will be used outdoors.

– Color Fastness: Opt for fabrics that are solution-dyed to ensure they maintain their color and integrity over time.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

– Certification: Verify that suppliers adhere to industry standards and certifications, ensuring quality and safety.

– Reputation: Research customer feedback and reviews to gauge reliability and service quality.

Step 4: Request Samples

Once you have shortlisted potential suppliers, request samples of the canopy materials. This step is critical for assessing the texture, color, and overall quality of the fabric.

– Testing Durability: Consider conducting stress tests on samples to evaluate their performance under various conditions.

– Visual Assessment: Ensure the material’s appearance aligns with your brand’s aesthetics and customer expectations.

Step 5: Negotiate Terms and Pricing

Engage in discussions with your chosen suppliers to negotiate terms, including pricing, lead times, and payment options. A clear understanding of these elements can prevent misunderstandings later on.

– Bulk Pricing: Inquire about discounts for bulk orders, which can significantly impact your overall costs.

– Delivery Timelines: Confirm delivery schedules to align with your project timelines, especially if the canopies are needed for specific events or seasons.

Illustrative image related to replacement canopy material

Step 6: Confirm Installation Support

Verify if the supplier offers installation support or guidance, especially if your team lacks experience in handling canopy installations.

– Instructions and Resources: Ensure that the supplier provides detailed installation instructions or video tutorials.

– Technical Assistance: Assess the availability of customer support for troubleshooting during the installation process.

Step 7: Review Contracts and Finalize Orders

Before finalizing your purchase, carefully review all contracts and terms of service. Ensure that all specifications, warranties, and support services are clearly outlined.

– Warranties: Look for warranties that cover defects and ensure long-term protection for your investment.

– Return Policies: Understand the return policies in case the materials do not meet your expectations upon delivery.

By following this checklist, B2B buyers can navigate the sourcing process for replacement canopy materials with confidence, ensuring they make informed decisions that align with their business needs.

Illustrative image related to replacement canopy material

Comprehensive Cost and Pricing Analysis for replacement canopy material Sourcing

What Are the Key Cost Components for Sourcing Replacement Canopy Materials?

When sourcing replacement canopy materials, understanding the cost structure is essential for B2B buyers. The primary components include:

-

Materials: The type of fabric chosen significantly affects the overall cost. High-performance materials such as solution-dyed acrylics or heavy-duty vinyl are typically more expensive due to their durability and weather resistance. Brands like Sunbrella and Sattler are premium options that offer longevity but come at a higher price point.

-

Labor: Installation costs vary widely depending on the complexity of the project and local labor rates. For standard replacements, skilled labor may be required, particularly for custom fittings, which can add to the cost.

-

Manufacturing Overhead: This includes expenses related to the production process, such as utilities, maintenance of equipment, and workforce costs. Manufacturers that prioritize quality assurance and sustainable practices may have higher overheads, which can be reflected in the pricing.

-

Tooling: Specialized tools are often necessary for producing custom canopies or specific sizes. The investment in these tools can affect the pricing strategy, especially for smaller suppliers who may not have the same economies of scale as larger manufacturers.

-

Quality Control (QC): Ensuring that products meet industry standards requires rigorous testing and inspection processes. Quality certifications can add to the cost, but they provide assurance to buyers regarding the durability and safety of the materials.

-

Logistics: Shipping costs are a significant factor, especially for international buyers. Costs can fluctuate based on distance, shipping method, and any import duties or tariffs applicable to the destination country.

-

Margin: Suppliers will typically add a markup to cover their costs and generate profit. This margin can vary based on the supplier’s business model, market demand, and competition.

How Do Price Influencers Impact the Cost of Replacement Canopy Materials?

Several factors influence the pricing of replacement canopy materials:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to discounts. Buyers should negotiate MOQs to optimize pricing, especially when sourcing for multiple projects.

-

Specifications and Customization: Custom sizes, colors, and designs can increase costs. Standardized products are usually cheaper, so consider whether customization is necessary for your application.

-

Material Quality and Certifications: Higher-quality materials with certifications for UV resistance, mold prevention, and weatherproofing will command higher prices. However, investing in these materials can reduce long-term costs related to replacements and maintenance.

-

Supplier Factors: Established suppliers with a proven track record may charge more due to their reliability and reputation. Newer or less-known suppliers might offer lower prices, but this could come with risks regarding quality and service.

-

Incoterms: Understanding the terms of trade is crucial for managing costs. FOB (Free on Board) and CIF (Cost, Insurance, and Freight) terms can affect the final price. Buyers should clarify these terms to avoid unexpected costs.

What Are the Best Negotiation Strategies for B2B Buyers in the Replacement Canopy Market?

-

Research and Compare: Gather quotes from multiple suppliers to understand the market rate. This information empowers buyers to negotiate effectively.

-

Focus on Total Cost of Ownership (TCO): Instead of only considering the initial purchase price, evaluate long-term costs associated with maintenance, durability, and potential replacements. Highlighting TCO in negotiations can lead to better deals.

-

Leverage Volume Discounts: If purchasing for multiple projects or locations, emphasize your buying power to negotiate lower prices.

-

Be Aware of Regional Pricing Nuances: Prices can vary significantly based on geographical location. B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local market conditions and logistical challenges that may affect pricing.

-

Build Long-Term Relationships: Establishing a good rapport with suppliers can lead to better terms, discounts, and priority service in the future.

Conclusion

Understanding the cost structure and price influencers in the replacement canopy material market is critical for B2B buyers. By focusing on materials, labor, and logistics, and employing effective negotiation strategies, buyers can secure competitive pricing while ensuring quality and durability for their projects. Always consider the long-term implications of your sourcing decisions to optimize overall value.

Alternatives Analysis: Comparing replacement canopy material With Other Solutions

Exploring Alternatives for Canopy Solutions

In the realm of outdoor shade solutions, businesses often seek effective alternatives to traditional replacement canopy materials. These alternatives can offer varying benefits in terms of performance, cost, and ease of implementation. This analysis will compare replacement canopy material with two viable alternatives: retractable awnings and permanent structures such as pergolas.

Comparison Table

| Comparison Aspect | Replacement Canopy Material | Retractable Awnings | Permanent Structures (Pergolas) |

|---|---|---|---|

| Performance | High durability; UV and weather-resistant | Flexible shading options; can be retracted | Long-lasting; provides stable shade |

| Cost | Moderate initial cost; additional costs for installation | Higher initial cost; low maintenance | High initial investment; long-term value |

| Ease of Implementation | Moderate; requires precise measurement and fitting | Generally easy to install with clear instructions | Complex installation; may require permits |

| Maintenance | Low; simple cleaning needed | Low; minimal upkeep required | Moderate; periodic maintenance of wood or metal |

| Best Use Case | Ideal for RVs, homes, and commercial spaces needing quick replacements | Suitable for residential and commercial applications wanting flexibility | Best for permanent outdoor spaces where aesthetics and durability are key |

Detailed Breakdown of Alternatives

Retractable Awnings

Retractable awnings are a versatile option for businesses and homes that require flexible shading solutions. They allow users to extend or retract the fabric as needed, providing shade during peak sun hours while allowing for unobstructed views or light when desired. While the initial investment can be higher compared to replacement canopy materials, retractable awnings often require minimal maintenance and can enhance property aesthetics. However, their reliance on mechanical components can lead to higher repair costs over time.

Permanent Structures (Pergolas)

Pergolas represent a more permanent solution for outdoor shading, providing a solid structure that can support climbing plants or additional roofing materials. They are ideal for businesses that want to create an inviting outdoor space, such as cafes or restaurants. Although the initial cost is significant and installation can be complex, pergolas offer durability and long-term value. Maintenance is necessary to ensure the longevity of materials, especially if wood is used, which can be susceptible to rot and pests.

Conclusion: How to Choose the Right Solution for Your Needs

When evaluating canopy solutions, B2B buyers must consider their specific needs, including performance requirements, budget constraints, and the intended use case. Replacement canopy materials are ideal for those seeking a quick, effective solution for temporary or seasonal needs. In contrast, retractable awnings provide flexibility, while permanent structures like pergolas offer lasting beauty and stability. By carefully weighing these factors, businesses can make informed decisions that align with their operational goals and enhance their outdoor spaces.

Essential Technical Properties and Trade Terminology for replacement canopy material

What Are the Key Technical Properties of Replacement Canopy Material?

When selecting replacement canopy material, understanding the technical properties is crucial for ensuring durability and performance. Here are essential specifications to consider:

-

Material Grade

– The material grade refers to the quality and composition of the fabric used in canopies. Common materials include acrylic, vinyl, and polyester. High-grade fabrics like solution-dyed acrylic are favored for their longevity and UV resistance. For B2B buyers, selecting a higher grade can result in lower replacement frequency and enhanced customer satisfaction. -

Weather Resistance

– This property indicates how well the canopy can withstand various environmental conditions, including UV radiation, rain, and wind. Fabrics with high weather resistance are treated or manufactured to resist fading, mold, and mildew. For businesses operating in diverse climates, investing in weather-resistant materials can reduce maintenance costs and increase the lifespan of the product. -

Tensile Strength

– Tensile strength measures the fabric’s ability to resist pulling or stretching. It is typically expressed in pounds per square inch (PSI). A higher tensile strength ensures the canopy can endure tension without tearing, making it suitable for high-stress environments like outdoor events or commercial applications. This specification is vital for buyers looking to ensure safety and durability in their canopy installations. -

Water Repellency

– Water repellency indicates the fabric’s ability to resist water penetration. Fabrics that are treated with water-repellent coatings or are inherently water-resistant are ideal for outdoor applications. For B2B buyers, this property is essential for ensuring that canopies can provide effective shelter during rain, thus enhancing user experience and satisfaction. -

Colorfastness

– Colorfastness refers to the ability of a fabric to retain its color when exposed to sunlight and washing. Fabrics with high colorfastness ratings are less likely to fade over time, which is particularly important for businesses aiming to maintain a professional appearance. This property is crucial for B2B buyers as it affects the aesthetic appeal and longevity of the product.

What Are Common Trade Terms Related to Replacement Canopy Material?

Navigating the procurement process requires familiarity with industry jargon. Here are some essential terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers ensure they are sourcing high-quality replacement materials that fit their specific requirements. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to plan inventory and understand pricing dynamics. Suppliers may offer better rates for larger orders, making it important to align purchasing strategies accordingly. -

RFQ (Request for Quotation)

– An RFQ is a document issued by a buyer to request pricing and terms from suppliers. It typically includes specifications and quantities. Utilizing RFQs allows buyers to compare offers from multiple vendors, ensuring they receive competitive pricing and favorable terms. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, risk transfer, and cost allocation, which is crucial when importing replacement canopy materials from overseas suppliers. -

Lead Time

– Lead time is the duration from placing an order to receiving the product. Understanding lead times is essential for B2B buyers to manage their supply chain effectively and ensure timely availability of replacement materials for projects. -

Customization Options

– This term refers to the ability to modify products according to specific requirements, such as size, color, or material. Knowing available customization options allows buyers to tailor their orders to meet unique project needs, enhancing client satisfaction and project outcomes.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing replacement canopy materials, ultimately leading to successful business outcomes.

Navigating Market Dynamics and Sourcing Trends in the replacement canopy material Sector

What Are the Current Market Dynamics and Key Trends in the Replacement Canopy Material Sector?

The replacement canopy material sector is influenced by a variety of global drivers, including increasing demand for outdoor living spaces, a growing focus on aesthetics, and the need for durable, weather-resistant materials. In regions such as Africa, South America, the Middle East, and Europe, the trend towards enhancing outdoor environments—whether for residential, commercial, or recreational use—has led to a surge in demand for high-performance canopy fabrics. As international B2B buyers seek to capitalize on these trends, they must navigate a landscape characterized by the emergence of advanced materials, including UV-resistant and mildew-proof fabrics, which are essential for ensuring longevity in harsh climates.

Technological advancements in manufacturing processes are also transforming the sourcing landscape. Innovations such as solution-dyed fabrics enhance color retention and durability, making them attractive for buyers looking for long-lasting solutions. Additionally, the rise of e-commerce platforms enables buyers to access a broader range of products and suppliers, facilitating informed purchasing decisions. The integration of digital tools for supply chain management and inventory tracking is becoming essential for optimizing procurement processes, particularly for buyers in regions with complex logistics.

How Is Sustainability and Ethical Sourcing Impacting the Replacement Canopy Material Market?

Sustainability is a critical consideration for international B2B buyers in the replacement canopy material sector. The environmental impact of traditional manufacturing practices has prompted a shift towards more sustainable options. Buyers are increasingly prioritizing suppliers who utilize eco-friendly materials, such as recycled polyester or organic cotton, in their products. This shift is not only beneficial for the environment but also aligns with the growing consumer demand for green products, particularly in Europe and North America.

Ethical sourcing practices are equally important, as buyers are now more aware of the social implications of their procurement choices. Ensuring that materials are sourced from suppliers who adhere to fair labor practices and environmental regulations is essential for maintaining brand integrity and meeting regulatory requirements. Certifications like Global Organic Textile Standard (GOTS) or OEKO-TEX® Standard 100 provide assurance of a product’s sustainability credentials, making them valuable considerations for B2B buyers looking to enhance their supply chains while minimizing their ecological footprint.

What Is the Historical Context of Replacement Canopy Materials for B2B Buyers?

The evolution of replacement canopy materials can be traced back to the early 20th century when cotton and canvas were the predominant choices for awnings and canopies. However, as the demand for more durable and weather-resistant materials grew, synthetic fabrics such as acrylic and polyester emerged in the latter half of the century. These materials offered significant advantages in terms of UV resistance, color retention, and mold resistance, making them ideal for outdoor applications.

In recent years, the industry has continued to evolve with advancements in textile technology, leading to the development of high-performance fabrics that can withstand extreme weather conditions. This evolution has been driven by both consumer preferences and the need for sustainable solutions, prompting manufacturers to innovate continuously. As a result, today’s B2B buyers have access to a diverse range of materials that not only meet functional requirements but also align with sustainability goals, reflecting the changing dynamics of the market.

Frequently Asked Questions (FAQs) for B2B Buyers of replacement canopy material

1. How do I replace the fabric on my existing awning?

Replacing the fabric on your existing awning requires careful planning and execution. Start by removing the old fabric from the frame, taking note of how it was attached. Measure the dimensions accurately to ensure the new fabric fits perfectly. When selecting replacement fabric, opt for high-quality, weather-resistant materials designed for awning use, such as those from reputable brands like Sunbrella or Sattler. Installation can be done manually, but consider hiring professionals to ensure the best results and longevity of the new awning.

2. What is the best material for outdoor canopies and awnings?

The best materials for outdoor canopies and awnings are typically durable, water-resistant, and UV-resistant fabrics. Options like acrylic and vinyl are popular due to their long-lasting properties and ability to withstand harsh weather conditions. Acrylic fabrics, such as those made by Sunbrella, offer excellent color retention and mildew resistance. For commercial applications, heavy-duty fabrics that can endure frequent use and exposure to the elements are essential. Always assess the specific environmental conditions of your region when making a selection.

3. What should I consider when sourcing replacement canopy materials internationally?

When sourcing replacement canopy materials internationally, consider factors such as supplier reputation, material quality, and compliance with international standards. Verify supplier credentials through industry certifications and customer reviews. Additionally, inquire about the supplier’s ability to meet your specifications in terms of fabric type, color, and performance characteristics. Understand the logistical aspects, including shipping times and costs, as well as import regulations specific to your country, which can affect delivery timelines and budgets.

4. How can I vet suppliers for replacement canopy materials?

To vet suppliers, start by researching their industry experience and customer testimonials. Request samples of the materials to assess quality firsthand. Look for suppliers who are transparent about their manufacturing processes and quality assurance practices. Additionally, consider suppliers who participate in trade shows or industry associations, as this can indicate credibility and commitment to quality. Establish clear communication channels and ask for references from other B2B clients to gauge their reliability and service.

5. What are typical minimum order quantities (MOQs) for replacement canopy materials?

Minimum order quantities (MOQs) for replacement canopy materials can vary significantly by supplier and product type. Generally, MOQs range from a few yards for custom orders to several hundred yards for bulk purchases. For international orders, suppliers may offer flexible MOQs depending on your business needs and the relationship you establish. Always clarify MOQs before placing an order and discuss options for smaller test orders if you are unsure about the material’s suitability for your projects.

6. What payment terms should I expect when purchasing internationally?

Payment terms for international purchases can vary widely, but common practices include upfront payments, partial payments, or payment upon delivery. Many suppliers accept wire transfers, letters of credit, or PayPal for transactions. It is crucial to negotiate terms that protect both parties, particularly in terms of payment security and delivery timelines. Be aware of currency fluctuations and any additional fees that may arise from international transactions, which can impact your overall costs.

7. How can I ensure quality assurance for my canopy material orders?

To ensure quality assurance, establish clear specifications for the canopy materials before placing an order. Request samples for testing and evaluation, and communicate your quality standards with the supplier. Many reputable suppliers will offer inspection services or third-party quality checks before shipping. Additionally, consider implementing a quality control process that includes receiving inspections upon arrival to verify that the materials meet the agreed-upon specifications.

Illustrative image related to replacement canopy material

8. What logistics should I consider when importing replacement canopy materials?

When importing replacement canopy materials, consider logistics aspects such as shipping methods, customs clearance, and delivery timelines. Evaluate the best shipping options based on cost, speed, and reliability, including air freight for urgent needs or sea freight for larger orders. Understand the customs regulations of your country to avoid delays and additional fees. Collaborate with a logistics partner who specializes in international trade to streamline the process and ensure compliance with all legal requirements.

Top 6 Replacement Canopy Material Manufacturers & Suppliers List

1. Decorative Fabrics Direct – Sunbrella Marine Fabrics

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: This company, Decorative Fabrics Direct – Sunbrella Marine Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Sunbrella – Awnings, Canopies, and Pergolas

Domain: sunbrella.com

Registered: 1995 (30 years)

Introduction: Awnings, Canopies, and Pergolas featuring Sunbrella shade fabrics. Key features include:

– Innovative shade fabrics for outdoor living

– UV protective and fade resistant

– Durable fibers saturated with color and UV stabilized pigments

– Extensive range of colors and styles

– Recommended by The Skin Cancer Foundation for sun protection

– Designed to coordinate with cushions, pillows, and outd…

3. ALEKO – Retractable Awning Fabrics

Domain: alekoproducts.com

Registered: 2012 (13 years)

Introduction: Awning Fabric Replacements for Sale | ALEKO offers a variety of retractable patio awning fabrics in striped or solid designs, available in seven different sizes and multiple color options. The fabrics are made from UV-protective, weather-resistant polyester that is durable and smooth for easy retraction. Prices range from less than fifty dollars to over one hundred dollars. Installation is simple …

4. Velarium Awnings – Replacement Canopies

Domain: velariumawnings.com

Registered: 2022 (3 years)

Introduction: Replacement Canopies for Velarium, Carefree, and Lippert awnings. Direct-fit replacement canopies available in various sizes and colors. Made from high-grade materials for durability and vibrant colors. Popular styles and sizes include:

– Solid Black or White:

– 10-17′ – $236.99

– 18-21′ – $263.99

– 22′ – $270.99

– Gradient Faded Canopies:

– 10-17′ – $269.99

– 18-21′ – $304.99

…

5. Canopy Solutions – UV-Resistant Fabric

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The user wants to make a new top for a canopy and is seeking advice on suitable fabric. The existing fabric is brittle due to sun exposure. They are looking for a sturdy but affordable fabric that does not need to be waterproof, just to provide sun protection while working outside. Suggestions from comments include: 1. Nylon (100 g/m2 weight or more) – but concerns about UV exposure and strength w…

6. Coleman – Instant Canopy Replacement Fabric

Domain: coleman.com

Registered: 1999 (26 years)

Introduction: Instant Canopy Replacement Fabric, Size: 13 x 13

Strategic Sourcing Conclusion and Outlook for replacement canopy material

In the evolving landscape of replacement canopy materials, strategic sourcing stands out as a pivotal component for businesses aiming to enhance their offerings. By leveraging high-performance fabrics from reputable brands like Sunbrella and Sattler, companies can ensure they provide durable, UV-resistant, and weather-proof solutions that meet the diverse needs of their clients. International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should prioritize partnerships with reliable suppliers who can offer a variety of options tailored to specific applications, whether for residential or commercial use.

Understanding the importance of quality and adaptability in awning and canopy materials can drive competitive advantage. As environmental conditions vary across markets, sourcing materials designed to withstand harsh climates will be crucial for customer satisfaction and long-term viability.

Illustrative image related to replacement canopy material

Looking ahead, businesses should embrace innovation in material technology and sustainability practices to stay ahead of the curve. By investing in strategic sourcing now, companies can position themselves as leaders in the market, ready to meet the growing demand for high-quality, versatile replacement canopy materials. Engage with suppliers today to explore the best options for your business needs, ensuring a bright and protective future for your clients.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.