How to Source Reel Of Cable Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for reel of cable

In the dynamic landscape of global commerce, sourcing the right reel of cable poses a significant challenge for international B2B buyers. With varied specifications, quality standards, and logistical considerations, it is essential to navigate these complexities effectively to ensure optimal performance and compliance with industry regulations. This comprehensive guide aims to provide a robust framework for understanding the diverse types of cable reels, their applications across different sectors, and the critical factors in supplier vetting.

From industrial applications in energy and telecommunications to specialized uses in audiovisual and entertainment sectors, the guide covers a wide spectrum of cable reel options. Buyers will gain insights into key considerations such as material durability, load capacity, and environmental resistance, which are pivotal in making informed purchasing decisions. Furthermore, we delve into cost analysis, providing clarity on pricing structures and potential cost-saving strategies without compromising quality.

Designed specifically for B2B buyers in regions like Africa, South America, the Middle East, and Europe—including markets such as Saudi Arabia and Brazil—this guide empowers organizations to confidently navigate the complexities of the global market. By equipping decision-makers with essential knowledge, we aim to enhance procurement strategies, ensuring that businesses not only meet their immediate needs but also position themselves for long-term success in an increasingly competitive environment.

Understanding reel of cable Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plastic Cable Reels | Lightweight, corrosion-resistant, available in various sizes | Electrical installations, telecommunications | Pros: Cost-effective, portable. Cons: Less durable than metal options. |

| Metal Cable Reels | Robust construction, high load capacity, often stackable | Heavy-duty industrial applications, construction | Pros: Durable, suitable for harsh environments. Cons: Heavier, may be more expensive. |

| Welding Cable Reels | Designed for high-temperature and heavy-duty applications | Welding, manufacturing, automotive repair | Pros: High performance under stress, specialized. Cons: Limited to specific uses. |

| Retractable Cable Reels | Automatic retraction, integrated safety features | Maintenance, service industries | Pros: Reduces tangling, easy to use. Cons: Higher upfront cost, may require maintenance. |

| Custom Cable Reels | Tailored designs for specific cable types and lengths | Specialized industries, unique project needs | Pros: Meets exact specifications, flexibility. Cons: Longer lead times, potentially higher costs. |

What Are the Characteristics of Plastic Cable Reels?

Plastic cable reels are known for their lightweight design and resistance to corrosion, making them ideal for a range of applications. They are commonly used in electrical installations and telecommunications due to their versatility and availability in various sizes. When purchasing plastic reels, buyers should consider the specific weight and size requirements of their projects, as well as the intended environment, since these reels may not withstand extreme conditions as well as metal options.

Why Choose Metal Cable Reels for Heavy-Duty Applications?

Metal cable reels are characterized by their robust construction and high load capacity, making them suitable for heavy-duty industrial applications such as construction and manufacturing. These reels can endure harsh environments, providing longevity and reliability. B2B buyers should evaluate their specific load requirements and consider the total weight of the reels, as the increased durability often comes with a higher price tag and additional weight.

How Do Welding Cable Reels Enhance Performance?

Welding cable reels are specifically designed to handle high temperatures and heavy-duty applications, making them indispensable in welding and manufacturing industries. Their construction ensures that they can endure the rigors of welding tasks, providing consistent performance. When purchasing welding cable reels, businesses should ensure compatibility with their welding equipment and assess the reel’s capacity to manage the specific cable types used in their operations.

What Are the Advantages of Retractable Cable Reels?

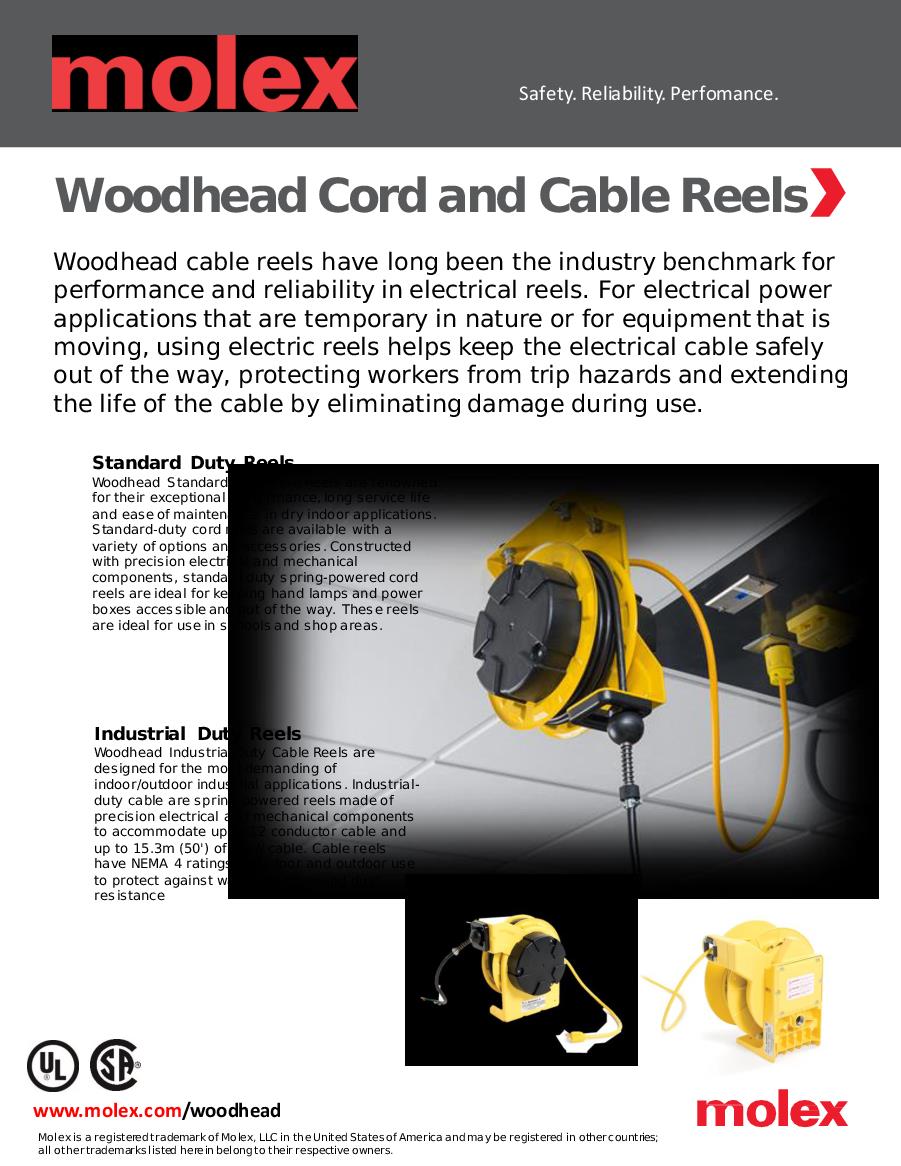

Retractable cable reels feature automatic retraction mechanisms that help prevent tangling and damage to cables, making them ideal for maintenance and service industries. These reels often come with integrated safety features, enhancing workplace safety. Buyers should consider the installation environment and whether the benefits of convenience and reduced cable wear justify the typically higher upfront costs and potential maintenance requirements.

When Should Businesses Consider Custom Cable Reels?

Custom cable reels are tailored to meet specific project needs, offering flexibility in design for unique cable types and lengths. This option is particularly beneficial for specialized industries with unique requirements. However, buyers should be aware of the longer lead times and potentially higher costs associated with custom orders. Evaluating the specific needs of a project against the available standard options can help determine if customization is necessary.

Key Industrial Applications of reel of cable

| Industry/Sector | Specific Application of reel of cable | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Power Distribution in Construction Sites | Ensures reliable power supply for tools and machinery | Durability, voltage rating, length, and environmental resistance |

| Telecommunications | Cable Management for Network Installations | Facilitates organized installations and maintenance | Compatibility with existing systems, cable type, and reel capacity |

| Oil & Gas | Cable Deployment for Offshore Operations | Supports safe and efficient operation in remote areas | Corrosion resistance, reel size, and weight capacity |

| Event Management | Audio/Visual Equipment Setup | Streamlines setup and teardown of event equipment | Portability, material strength, and ease of use |

| Renewable Energy | Solar Panel Wiring Solutions | Optimizes energy generation and minimizes losses | UV resistance, gauge specifications, and compliance certifications |

How is ‘reel of cable’ utilized in the construction industry?

In the construction sector, reels of cable play a crucial role in power distribution across job sites. They provide a reliable means to deliver electricity to tools and heavy machinery, ensuring that operations run smoothly. The reels must be durable and able to withstand harsh environmental conditions, which is particularly important in regions with extreme weather, such as parts of Africa and the Middle East. Buyers should consider the voltage rating and length of the cables, as well as their resistance to abrasion and UV exposure, to ensure they meet specific site requirements.

What are the benefits of using reels of cable in telecommunications?

In telecommunications, reels of cable are essential for managing and deploying network installations. They facilitate the organization of cables, reducing clutter and making maintenance easier. For international buyers, especially in South America and Europe, compatibility with existing systems and the type of cable being used are critical factors. Sourcing cables that are robust yet flexible can help minimize installation time and costs while ensuring long-term reliability in network performance.

How do reels of cable enhance operations in the oil and gas industry?

The oil and gas industry relies on reels of cable for deploying equipment in offshore and remote locations. These reels are designed to support heavy-duty cables that must withstand harsh environmental conditions, including saltwater exposure and extreme temperatures. Buyers in this sector should prioritize reels that offer corrosion resistance and adequate weight capacity to handle the specific demands of their operations. Ensuring that cables meet industry safety standards is also crucial to mitigate risks associated with hazardous environments.

In what ways do reels of cable support event management?

In the event management industry, reels of cable are invaluable for the setup and teardown of audio and visual equipment. They allow for quick deployment and organization of cables, which is essential for maintaining a tidy workspace and ensuring safety. Portability and ease of use are key considerations for buyers, especially in regions with varied event setups, such as Europe and the Middle East. Selecting reels made from strong materials can enhance durability, ensuring they withstand repeated use across multiple events.

How are reels of cable critical for renewable energy applications?

Reels of cable are increasingly being used in renewable energy applications, particularly for solar panel installations. They allow for efficient wiring solutions that optimize energy generation while minimizing losses. International buyers should consider UV resistance and compliance with local regulations when sourcing these cables, as these factors can significantly impact the longevity and performance of solar installations. The gauge specifications of the cables must also align with the energy requirements of the system to ensure optimal functionality.

3 Common User Pain Points for ‘reel of cable’ & Their Solutions

Scenario 1: Inconsistent Quality of Cable Reels

The Problem: B2B buyers often encounter issues with inconsistent quality when sourcing reels of cable. This inconsistency can lead to operational inefficiencies, as inferior reels may cause cable damage, reduce lifespan, or fail during critical operations. Companies that rely on high-quality cable reels for their projects, such as construction or manufacturing, cannot afford to have downtime or additional costs stemming from damaged cables. Buyers may struggle to find reliable suppliers who can guarantee the quality and durability of their products, leading to frustration and financial loss.

The Solution: To ensure consistent quality, B2B buyers should conduct thorough supplier evaluations before making a purchase. This involves checking for certifications, such as ISO standards, which indicate adherence to quality management principles. Additionally, buyers should request samples or trial orders to assess the reel’s material and construction firsthand. Engaging with suppliers who offer warranties or guarantees can provide extra assurance of quality. It’s also beneficial to build long-term relationships with trusted manufacturers who have a proven track record in the industry. This way, buyers can rely on consistent delivery of high-quality reels tailored to their specific needs.

Scenario 2: Complicated Sizing and Specifications for Cable Reels

The Problem: Many B2B buyers face challenges when it comes to selecting the right size and specifications for cable reels. With a variety of gauges, lengths, and materials available, making the wrong choice can result in inefficient use of resources or even project delays. For instance, using a reel that is too small may lead to tangled cables, while oversized reels can be cumbersome and hard to handle. Buyers may feel overwhelmed by the multitude of options, which can complicate the procurement process.

The Solution: To navigate the complexities of sizing and specifications, buyers should start by clearly understanding their operational requirements. This includes assessing the type of cables being used, the environment in which they will be deployed, and the typical distance they need to cover. Creating a detailed specification sheet that outlines these requirements can streamline the decision-making process. Additionally, consulting with suppliers for their expertise can provide insights into the most suitable reel options. Many suppliers also offer custom solutions, allowing buyers to specify unique dimensions or materials that meet their exact needs. Utilizing tools like calculators or configurators available on supplier websites can further assist in selecting the right reel.

Scenario 3: Limited Availability and Long Lead Times

The Problem: B2B buyers often experience frustrations due to limited availability of specific types of cable reels and long lead times for delivery. This issue can be particularly pronounced in regions such as Africa and South America, where supply chain disruptions and local market constraints can hinder timely access to essential materials. Delays in receiving cable reels can stall projects, affect timelines, and ultimately impact profitability.

The Solution: To mitigate the risk of limited availability and long lead times, B2B buyers should diversify their supplier base. This means not relying on a single source but instead establishing relationships with multiple vendors across different regions. Buyers should also consider keeping a safety stock of essential reels to buffer against supply chain disruptions. Leveraging technology, such as inventory management systems, can help track usage patterns and forecast demand, enabling proactive ordering. Furthermore, engaging with suppliers who have robust logistics capabilities and can provide real-time updates on inventory status can enhance planning and reduce lead times. Implementing these strategies will not only streamline procurement but also ensure that projects proceed without unnecessary delays.

Strategic Material Selection Guide for reel of cable

What Are the Key Materials for Cable Reels and Their Properties?

When selecting materials for cable reels, it is essential to consider the specific properties and applications that will affect performance and durability. Below are analyses of four common materials used in the manufacturing of cable reels, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Steel

Key Properties: Steel reels are known for their high strength and durability. They typically have excellent temperature resistance and can withstand significant mechanical stress. Steel also offers good corrosion resistance when treated with protective coatings.

Pros & Cons: The primary advantage of steel is its robustness, making it suitable for heavy-duty applications. However, steel reels can be heavier than alternatives, which may complicate handling and transportation. The cost of steel can vary significantly based on market conditions, and manufacturing processes can be complex, requiring specialized techniques for coating and finishing.

Impact on Application: Steel reels are ideal for industrial environments where heavy cables are used, such as construction sites or manufacturing plants. They can handle various media types, including electrical and fiber optic cables.

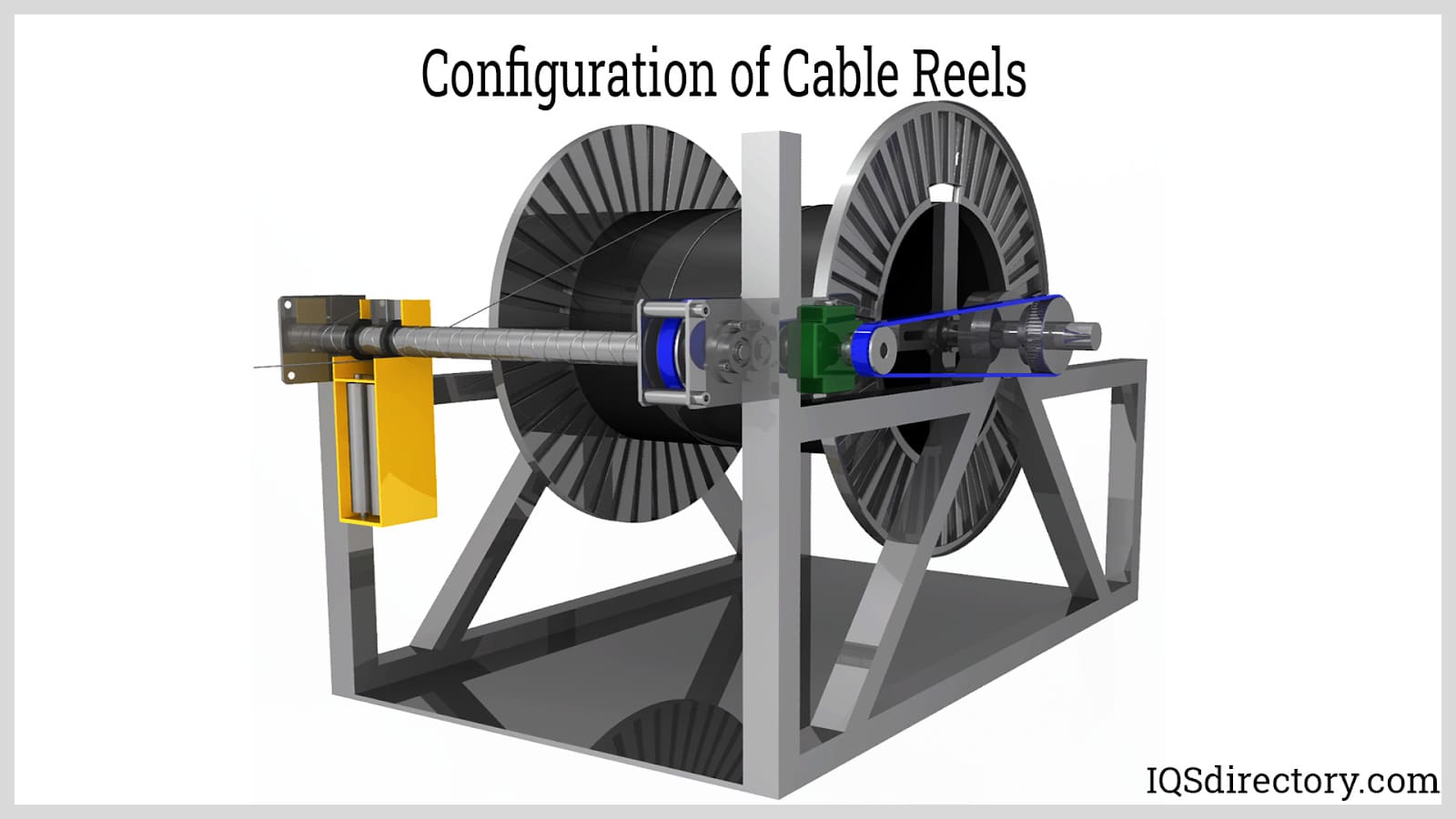

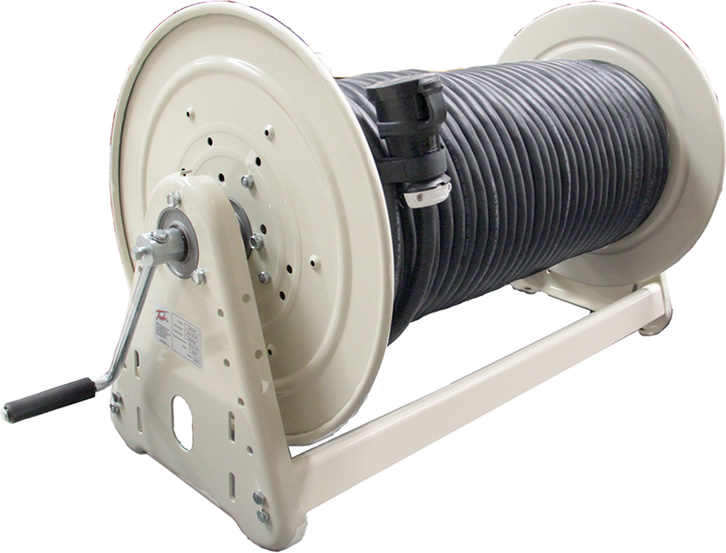

Illustrative image related to reel of cable

Considerations for International Buyers: Buyers in regions like the Middle East and Africa should ensure compliance with local standards, such as ASTM or DIN, for safety and performance. Corrosion resistance is particularly crucial in humid or coastal areas.

2. Aluminum

Key Properties: Aluminum reels are lightweight and have good corrosion resistance. They can handle moderate temperature variations, making them suitable for various environments.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which facilitates easier handling and transport. However, aluminum is not as strong as steel, making it less suitable for heavy-duty applications. The cost of aluminum is generally higher than that of steel, which may affect budget considerations.

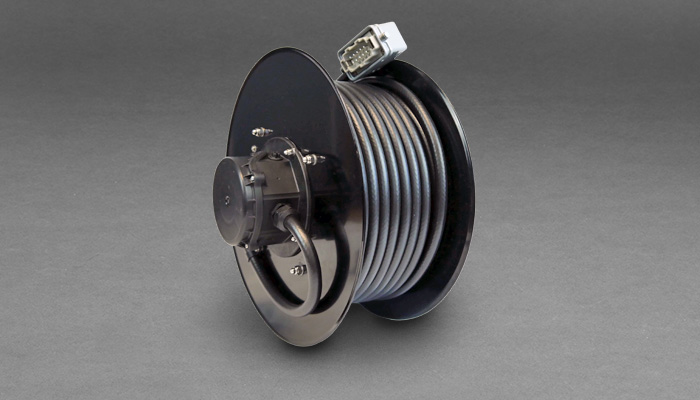

Illustrative image related to reel of cable

Impact on Application: Aluminum reels are often used in applications where weight is a critical factor, such as in telecommunications or portable power systems. They are compatible with various media, including low-voltage electrical cables.

Considerations for International Buyers: Compliance with international standards is essential, especially for buyers in Europe, where regulations may dictate specific material properties. Buyers should also consider the environmental impact of aluminum production and recycling.

3. Plastic (Polypropylene or PVC)

Key Properties: Plastic reels made from materials like polypropylene or PVC are lightweight and resistant to moisture and chemicals. They can operate effectively within a range of temperatures but may not withstand extreme conditions as well as metal reels.

Pros & Cons: The main advantage of plastic reels is their resistance to corrosion and chemicals, making them suitable for various environments. However, they may not offer the same structural integrity as metal reels, limiting their use to lighter applications. The cost is generally lower than that of metal options, making them an economical choice.

Illustrative image related to reel of cable

Impact on Application: Plastic reels are commonly used for low-voltage cables and in environments where exposure to moisture or chemicals is a concern. They are often used in agricultural or outdoor settings.

Considerations for International Buyers: Buyers should be aware of local regulations regarding plastic materials, especially in regions with stringent environmental laws. Compliance with standards such as JIS may also be necessary.

4. Composite Materials

Key Properties: Composite reels, often made from a combination of materials like fiberglass and resin, offer high strength-to-weight ratios and excellent resistance to corrosion and environmental factors.

Pros & Cons: The key advantage of composite reels is their durability and lightweight nature, making them suitable for various applications. However, they can be more expensive to produce, and the manufacturing process can be more complex than traditional materials.

Impact on Application: Composite reels are ideal for applications requiring high strength and low weight, such as in aerospace or military settings. They can handle various media types, including high-voltage cables.

Considerations for International Buyers: Buyers should consider the availability of composite materials in their region and any compliance requirements with international standards. The higher cost may also be a factor in budget-sensitive projects.

Summary Table of Material Selection for Cable Reels

| Material | Typical Use Case for reel of cable | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial applications | High strength and durability | Heavier, complex manufacturing | Medium |

| Aluminum | Telecommunications, portable power | Lightweight and corrosion-resistant | Less strong than steel | High |

| Plastic | Low-voltage cables, outdoor use | Corrosion and chemical resistance | Limited structural integrity | Low |

| Composite | Aerospace, military applications | High strength-to-weight ratio | Higher production cost | High |

This guide provides a comprehensive overview of the materials available for cable reels, enabling international B2B buyers to make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for reel of cable

What Are the Main Stages in the Manufacturing Process of Cable Reels?

The manufacturing process of cable reels typically involves several critical stages, each essential for ensuring the durability and functionality of the final product. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage focuses on sourcing high-quality materials, such as plastics, metals, and composites. Suppliers often utilize advanced sourcing techniques to ensure that materials meet stringent specifications. The materials are then cut and shaped into usable forms, ready for the next stage of production.

-

Forming: During this phase, materials are shaped into the desired forms using various techniques such as injection molding for plastic components and stamping or bending for metal parts. Advanced machinery is often employed to enhance precision, ensuring that components fit together seamlessly.

-

Assembly: Once the individual components are formed, they are assembled into the final product. This may involve manual assembly or the use of automated systems, depending on the complexity of the reel design. Attention to detail is crucial during assembly to prevent defects that could compromise the reel’s functionality.

-

Finishing: The final stage includes surface treatments, painting, or coating to enhance aesthetics and provide protection against environmental factors. Quality checks are performed at each stage to ensure compliance with specifications, leading to a high-quality final product.

How Do Quality Assurance Processes Ensure High Standards in Cable Reel Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of cable reels, ensuring that products meet international standards and customer expectations. A robust QA process includes adherence to various international standards such as ISO 9001, which outlines requirements for a quality management system, and industry-specific certifications like CE and API, depending on the application of the cable reels.

-

Quality Control Checkpoints: Quality control (QC) checkpoints are strategically placed throughout the manufacturing process:

– Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified quality standards.

– In-Process Quality Control (IPQC): Regular checks are conducted during the manufacturing process to identify defects early, allowing for immediate corrections.

– Final Quality Control (FQC): Once production is complete, the final products undergo thorough testing to verify that they meet all specifications before shipment. -

Common Testing Methods: Various testing methods are employed to assess the performance and safety of cable reels. These may include tensile strength tests, electrical insulation tests, and environmental exposure tests. Each method is chosen based on the reel’s intended use and the materials used in its construction.

What International Standards Should B2B Buyers Look for in Cable Reel Suppliers?

B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, should prioritize suppliers who adhere to recognized international standards. Compliance with standards like ISO 9001, CE marking, and other industry-specific certifications not only ensures product quality but also enhances supplier credibility.

-

ISO 9001 Certification: This certification indicates a commitment to maintaining a high-quality management system. Suppliers with this certification typically have established processes for continuous improvement, which can be beneficial for long-term partnerships.

-

CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards. Buyers should ensure that the cable reels they are purchasing have this mark, as it is often a legal requirement.

-

API Certification: For cable reels used in oil and gas or other specialized industries, API certification may be necessary. This certification ensures that the products meet specific industry requirements.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers can take several steps to verify the quality control measures of potential suppliers. Conducting thorough due diligence is essential for ensuring that suppliers can consistently deliver high-quality products.

-

Supplier Audits: Buyers should consider conducting on-site audits to assess the supplier’s manufacturing processes and quality assurance practices. An audit can reveal the supplier’s adherence to quality standards and their commitment to continuous improvement.

-

Quality Reports: Requesting quality reports and documentation from the supplier can provide insights into their QC processes. These documents often include test results, compliance certifications, and records of previous inspections.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These services often conduct tests and inspections to ensure that the products meet specified standards.

What Nuances Should International B2B Buyers Consider Regarding QC Certifications?

International B2B buyers must be aware of the nuances surrounding quality control certifications, particularly when sourcing from different regions. The recognition of certifications can vary significantly based on local regulations and market standards.

-

Local Regulations: In some regions, certain certifications may be mandatory, while others are optional. Understanding local regulations is crucial for compliance and avoiding potential legal issues.

-

Market-Specific Standards: Certain industries may have specific quality requirements that differ from general standards. Buyers should research and understand these requirements to ensure that the products meet their needs.

-

Cultural Differences in Quality Expectations: Quality expectations can vary by region. Buyers should communicate their quality standards clearly and ensure that suppliers understand these expectations to avoid misunderstandings.

Conclusion

In summary, the manufacturing processes and quality assurance for cable reels are complex but essential for delivering high-quality products to B2B buyers. By understanding the stages of manufacturing, the importance of quality assurance, and the relevant international standards, buyers can make informed decisions when sourcing cable reels. By verifying supplier QC measures and considering regional nuances, buyers can establish successful partnerships that drive business growth.

Illustrative image related to reel of cable

Practical Sourcing Guide: A Step-by-Step Checklist for ‘reel of cable’

Introduction

Navigating the procurement of a reel of cable requires careful consideration of various factors to ensure that you meet both your operational needs and regulatory requirements. This guide provides a step-by-step checklist designed for B2B buyers, particularly in international markets such as Africa, South America, the Middle East, and Europe. By following these steps, you can streamline your sourcing process and make informed decisions that align with your business objectives.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the cable reels meet your operational requirements. Consider factors such as gauge size, material composition, temperature ratings, and voltage ratings. Be specific about the type of cables you will be using with the reels, as this will dictate the design and features needed.

Step 2: Research Market Trends and Standards

Understanding current market trends and industry standards can provide insights into the best products available. This includes familiarizing yourself with international standards such as UL, IEC, and others relevant to your region. Additionally, keeping an eye on emerging technologies can help you select cable reels that not only meet today’s needs but are also future-proof.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to conduct thorough evaluations. Review company profiles, request case studies, and seek references from businesses within your industry or region. Look for suppliers who demonstrate a track record of reliability, quality, and customer service.

- Check for certifications: Ensure that potential suppliers hold relevant certifications that validate their adherence to industry standards.

- Assess manufacturing capabilities: Understand their production capacity and whether they can meet your volume requirements.

Step 4: Request Samples and Specifications

Obtaining samples allows you to evaluate the quality and suitability of the reels before making a bulk purchase. Request detailed product specifications along with samples to assess the materials and craftsmanship.

- Test durability: Evaluate the reels under conditions similar to your intended use to ensure they can withstand operational demands.

- Check compatibility: Ensure that the reels are compatible with the types of cables you plan to use.

Step 5: Negotiate Pricing and Terms

Engaging in negotiations can significantly impact your overall procurement costs. When discussing prices, consider not only the unit cost but also the total cost of ownership, which may include shipping, duties, and potential after-sales support.

- Inquire about bulk discounts: If you plan to purchase large quantities, ask about discounts or flexible payment terms.

- Clarify warranties and return policies: Understand what warranties are offered and the return policies in case of defects or issues.

Step 6: Review Logistics and Delivery Options

Logistics can significantly affect the timely delivery of your order. Discuss delivery timelines with your supplier and assess their ability to meet your deadlines.

- Evaluate shipping methods: Consider the most cost-effective shipping options that still ensure timely delivery.

- Plan for customs and import regulations: Familiarize yourself with the import regulations in your country to avoid unexpected delays.

Step 7: Finalize the Purchase Agreement

Once you have chosen a supplier, ensure that all agreed-upon terms are documented in a formal purchase agreement. This should include pricing, delivery timelines, specifications, and any warranties or after-sales support.

- Ensure clarity: Both parties should have a clear understanding of the terms to avoid disputes later on.

- Keep communication open: Maintain ongoing communication with the supplier to address any issues that may arise during the fulfillment process.

By following this checklist, B2B buyers can approach the procurement of cable reels with confidence, ensuring that they secure products that meet their needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for reel of cable Sourcing

What Are the Key Cost Components in Sourcing Reels of Cable?

When sourcing reels of cable, understanding the cost structure is crucial for B2B buyers. The main cost components typically include:

-

Materials: The cost of raw materials, such as synthetic rubber, steel, or plastic, significantly impacts the final price. Higher-quality materials may lead to increased durability and performance but will also raise initial costs.

-

Labor: Labor costs can vary based on the region and the complexity of manufacturing. Skilled labor is essential for producing high-quality reels, and regions with higher wage standards may reflect this in their pricing.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these costs.

-

Tooling: The investment in specialized tools and machinery is necessary for producing custom or specialized reels. This cost is often amortized over the production run, making it a critical factor for larger orders.

-

Quality Control (QC): Ensuring that products meet specific standards incurs costs associated with testing and inspection. High-quality certifications can enhance product value but may also increase pricing.

-

Logistics: Transportation costs are essential, particularly for international shipments. Factors such as distance, mode of transport, and local regulations can influence this component significantly.

-

Margin: Suppliers will add a margin to cover their costs and ensure profitability. This can vary widely based on market conditions and competition.

How Do Price Influencers Affect Reel of Cable Costs?

Several factors influence pricing in the market for reels of cable:

-

Volume/MOQ: Buyers ordering in bulk can often negotiate better pricing due to economies of scale. Minimum Order Quantities (MOQ) may affect pricing flexibility, so it’s vital to assess your needs accurately.

-

Specifications and Customization: Custom reels designed to specific requirements can lead to higher costs. Buyers should carefully evaluate whether the added customization justifies the expense.

-

Materials and Quality Certifications: The choice of materials directly correlates to the product’s durability and performance. Additionally, certifications (e.g., UL, ISO) may add to costs but can provide assurance of quality.

-

Supplier Factors: The supplier’s location, reputation, and capabilities can influence pricing. Established suppliers may offer better quality but at a premium price.

-

Incoterms: The agreed-upon Incoterms dictate who is responsible for shipping, insurance, and tariffs. Understanding these terms can help buyers avoid unexpected costs.

What Are the Best Buyer Tips for Negotiating Reel of Cable Prices?

To maximize cost-efficiency in sourcing reels of cable, consider the following strategies:

-

Negotiate Effectively: Always engage in negotiations. Suppliers may have flexibility in pricing, especially for larger orders. Establishing a good relationship can also lead to better terms in future transactions.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, longevity, and potential replacement costs to understand the true value of the reels over time.

-

Understand Pricing Nuances for International Purchases: For buyers in regions like Africa, South America, the Middle East, and Europe, currency fluctuations, import duties, and shipping costs can significantly impact total expenses. Always factor these into your budget.

-

Research Market Trends: Staying informed about market trends and pricing shifts can provide leverage during negotiations. This knowledge will help buyers make informed decisions and potentially secure better deals.

Final Thoughts on Pricing Analysis for Reels of Cable

While indicative prices can serve as a starting point for negotiations, it’s essential to conduct thorough research and engage with multiple suppliers to ensure competitive pricing. The complexity of sourcing reels of cable demands a strategic approach that considers all cost components and price influencers. By leveraging effective negotiation tactics and understanding the total cost of ownership, international B2B buyers can make informed, cost-effective sourcing decisions.

Alternatives Analysis: Comparing reel of cable With Other Solutions

Understanding Alternative Solutions to Reel of Cable

In the realm of industrial and commercial applications, the selection of appropriate cable management solutions is crucial for operational efficiency. While reels of cable offer a convenient way to store and manage electrical wires, other alternatives exist that may better suit specific needs. This analysis will compare reels of cable with two viable alternatives: Cable Trays and Cable Conduits.

Illustrative image related to reel of cable

Comparison Table

| Comparison Aspect | Reel Of Cable | Cable Tray | Cable Conduit |

|---|---|---|---|

| Performance | High portability; ideal for temporary setups | Excellent for permanent installations; good airflow | Provides robust protection; limits exposure to elements |

| Cost | Moderate initial cost; long-term savings on maintenance | Higher upfront cost; cost-effective for large projects | Varies widely based on materials; potentially costly installation |

| Ease of Implementation | Simple to deploy; requires minimal tools | Requires planning and installation; can be complex | Installation can be labor-intensive; needs skilled labor |

| Maintenance | Low maintenance; easy to replace cables | Moderate maintenance; needs periodic inspections | Low maintenance; durable but may require sealing |

| Best Use Case | Ideal for temporary events, outdoor use, or mobile applications | Best for data centers, large facilities, and permanent setups | Suitable for high-risk environments needing protection from physical damage |

What Are the Advantages and Disadvantages of Cable Trays?

Cable trays offer a structured approach to managing cables, making them an excellent choice for larger installations where numerous cables are present. They facilitate airflow, which can prevent overheating of cables. However, the initial cost of installing cable trays can be significantly higher than using reels, and they require careful planning to ensure optimal layout and space utilization. Maintenance involves regular inspections to ensure cables are secured and that the tray itself remains intact.

How Do Cable Conduits Compare to Reels of Cable?

Cable conduits are designed to provide a protective pathway for electrical wiring, making them ideal for environments where cables may be exposed to physical damage or harsh conditions. They are durable and can be made from various materials, including metal and PVC, to suit different applications. However, the installation of conduits is often more labor-intensive and may require specialized skills, contributing to higher installation costs. While they offer excellent protection, the rigidity of conduits may limit flexibility in re-routing cables compared to the adaptability of reels.

Making the Right Choice: How Should B2B Buyers Select the Best Solution?

When selecting a cable management solution, B2B buyers should consider the specific needs of their operation. For temporary setups or applications requiring mobility, reels of cable may be the best fit due to their ease of use and low maintenance. Conversely, for permanent installations in larger facilities, cable trays could provide better organization and airflow. In high-risk environments, cable conduits offer the necessary protection against physical hazards. Ultimately, understanding the unique requirements of the project and balancing factors such as performance, cost, and ease of implementation will guide buyers toward the most effective solution for their needs.

Essential Technical Properties and Trade Terminology for reel of cable

What are the Key Technical Properties of a Cable Reel?

When sourcing cable reels, understanding their technical properties is crucial for ensuring they meet specific operational needs. Here are some essential specifications that international B2B buyers should consider:

-

Material Composition

Cable reels are commonly made from materials such as steel, aluminum, or synthetic rubber. Steel reels offer high durability and strength, making them suitable for heavy-duty applications, while aluminum reels are lightweight and corrosion-resistant. Synthetic rubber reels provide flexibility and shock resistance, ideal for environments with temperature fluctuations. Choosing the right material affects the reel’s longevity and performance, particularly in demanding conditions. -

Reel Diameter and Width

The diameter and width of a cable reel influence how much cable it can hold and the ease of cable dispensing. A larger diameter allows for more cable length, which is beneficial for extended applications, while wider reels can accommodate thicker cables without causing damage. Understanding these dimensions helps buyers select reels that match their project requirements. -

Load Capacity

Load capacity refers to the maximum weight a reel can support without compromising its integrity. This specification is vital for ensuring that the reel can handle the weight of the cable it carries, preventing accidents or failures during operation. Buyers must assess their specific cable weights and choose a reel with an appropriate load capacity. -

Tolerance Levels

Tolerance levels indicate the precision with which the reel is manufactured. This specification is important for ensuring that the reel fits well with associated equipment and that cables are dispensed smoothly without snagging. High tolerance levels often correlate with higher manufacturing standards, leading to better performance and reliability. -

Temperature Rating

The temperature rating defines the range of temperatures within which the reel can operate effectively. This is particularly important for applications in extreme environments, such as outdoor installations in hot or cold climates. A reel with a suitable temperature rating ensures that the material does not degrade or fail under stress.

What are Common Trade Terms Related to Cable Reels?

Familiarizing oneself with industry jargon can streamline communications and negotiations. Here are some key terms relevant to the cable reel market:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in another company’s end product. For cable reels, buyers may deal with OEMs to source custom reels that fit specific requirements for their applications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers as it affects inventory management and cash flow. A higher MOQ may necessitate larger upfront investments, while a lower MOQ allows for more flexibility. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. In the context of cable reels, buyers use RFQs to compare pricing and terms from multiple manufacturers, ensuring they secure the best deal. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B transactions involving cable reels, as they specify who is responsible for shipping, insurance, and tariffs, thus influencing overall costs. -

Lead Time

This term refers to the time taken from placing an order to the delivery of the product. Knowing the lead time for cable reels helps businesses plan their projects and manage timelines effectively, especially in industries with tight deadlines.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right cable reels for their specific needs while optimizing their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the reel of cable Sector

What Are the Current Market Dynamics and Key Trends in the Reel of Cable Sector?

The reel of cable market is witnessing transformative shifts driven by technological advancements, evolving customer preferences, and increasing demand across various industries, including construction, telecommunications, and renewable energy. Global drivers such as urbanization in Africa and South America, and infrastructure development in the Middle East and Europe, are propelling the demand for high-quality cable reels. The rise of smart technologies is also influencing sourcing trends, as businesses increasingly seek solutions that enhance efficiency and reduce operational costs.

Illustrative image related to reel of cable

Emerging trends include the adoption of automation and IoT technologies in manufacturing processes, which streamline production and improve product quality. Additionally, there is a noticeable shift towards customization, where manufacturers offer tailored solutions to meet specific customer requirements. This trend is particularly relevant for international buyers from diverse markets, including Saudi Arabia and Brazil, who are looking for specialized products that align with their unique operational needs.

Market dynamics are further shaped by fluctuating raw material costs and geopolitical factors, which can impact supply chains and pricing structures. Buyers must remain vigilant and adaptable, leveraging data analytics to forecast trends and make informed purchasing decisions. Building strong relationships with reliable suppliers can also mitigate risks associated with market volatility.

How Does Sustainability and Ethical Sourcing Impact the Reel of Cable Sector?

Sustainability has emerged as a crucial consideration in the reel of cable sector, as environmental impacts of production processes and materials come under increasing scrutiny. International B2B buyers are now prioritizing suppliers that demonstrate a commitment to sustainable practices, which includes responsible sourcing of raw materials and reducing carbon footprints in manufacturing. This trend is especially pronounced in regions like Europe, where regulatory frameworks are stringent and consumer awareness is high.

The importance of ethical supply chains cannot be overstated, as businesses face growing pressure to ensure transparency and accountability in their sourcing practices. Suppliers that utilize ‘green’ certifications and eco-friendly materials, such as recyclable plastics and low-impact metals, position themselves favorably in the marketplace. Certifications such as ISO 14001 (Environmental Management) can serve as a strong signal to buyers regarding a supplier’s commitment to sustainability.

Illustrative image related to reel of cable

Moreover, as buyers increasingly evaluate the lifecycle impacts of their purchases, there is a growing demand for products that offer durability and longevity. High-quality cable reels that minimize waste and reduce the need for frequent replacements can significantly contribute to a buyer’s sustainability goals.

What Is the Brief History and Evolution of the Reel of Cable Sector?

The reel of cable sector has evolved significantly from its origins in manual winding processes to the modern automated systems in use today. Initially, cable reels were simple wooden or metal spools used primarily for storage and transport. The industrial revolution marked a turning point, as advances in materials and manufacturing techniques introduced more durable and efficient designs.

In recent decades, the sector has embraced technological advancements, leading to the development of specialized reels that cater to specific applications, such as heavy-duty reels for construction and lightweight options for telecommunications. This evolution reflects a broader trend towards customization and innovation, driven by the diverse needs of international B2B buyers across various sectors.

As the market continues to grow, the integration of smart technology and sustainable practices will likely define the next chapter in the reel of cable sector, shaping how businesses source and utilize these essential components.

Frequently Asked Questions (FAQs) for B2B Buyers of reel of cable

-

How do I choose the right reel of cable for my project needs?

Selecting the appropriate reel of cable involves considering several factors such as the type of cable required (e.g., low voltage, high temperature), the gauge of the wire, and the specific application (industrial, commercial, or residential). Assess the environmental conditions where the cable will be used, such as temperature extremes or exposure to moisture. Additionally, evaluate the length of cable needed and ensure the reel can accommodate this without risk of tangling. Always consult with suppliers to understand the specifications and limitations of the cables you are considering. -

What are the advantages of using custom reels of cable?

Custom reels of cable offer flexibility in terms of wire gauge, length, and insulation type, allowing businesses to tailor products to their specific requirements. This customization can enhance efficiency and safety, especially in specialized applications like renewable energy or industrial machinery. Custom reels can also improve handling and storage, as they can be designed to fit specific equipment or transport methods. Working with a supplier who provides customization options can lead to optimized performance and reduced waste in your operations. -

What is the typical minimum order quantity (MOQ) for reels of cable?

Minimum order quantities for reels of cable can vary significantly by supplier and product type. Generally, MOQs can range from a few hundred meters for standard cables to several kilometers for specialized products. Suppliers often set MOQs based on production costs, inventory management, and market demand. It is advisable to discuss your specific needs with potential suppliers to negotiate MOQs that align with your purchasing strategy and project timelines. -

What payment terms should I expect when sourcing reels of cable internationally?

Payment terms can differ widely among suppliers and regions, but common practices include advance payment, net 30, or net 60 days. International buyers should also consider payment methods such as letters of credit or wire transfers for larger orders. It is crucial to establish clear payment terms before finalizing contracts to avoid misunderstandings. Additionally, be aware of currency exchange rates and any associated fees that could impact the total cost of procurement. -

How can I ensure the quality of reels of cable from international suppliers?

Ensuring quality begins with thorough supplier vetting. Request samples to evaluate the materials and craftsmanship before placing larger orders. Look for suppliers with certifications such as ISO or relevant industry standards that demonstrate their commitment to quality. Consider conducting factory audits or using third-party inspection services to verify compliance with specifications and safety regulations. Establishing a clear quality assurance process, including detailed product specifications, can also help maintain high standards. -

What logistics considerations should I keep in mind when importing reels of cable?

Logistics for importing reels of cable involve several key considerations, including shipping methods (air vs. sea), customs regulations, and potential tariffs. Understand the lead times associated with each shipping method and factor this into your project timelines. Collaborate with logistics providers experienced in handling electrical components to ensure compliance with all regulatory requirements. Additionally, consider warehousing solutions in the destination country to facilitate efficient distribution upon arrival. -

What documentation is needed for international trade of reels of cable?

Importing reels of cable typically requires several key documents, including a commercial invoice, packing list, bill of lading, and certificate of origin. Depending on the destination country, additional documentation such as safety certifications or compliance declarations may be necessary. Ensure all documents are accurately completed to prevent customs delays. Collaborating with a freight forwarder can help streamline the documentation process and ensure compliance with local regulations. -

How do I assess and compare suppliers of reels of cable?

When assessing suppliers, consider factors such as product range, pricing, delivery timelines, and customer service. Review their reputation through customer testimonials and industry ratings. Request quotes from multiple suppliers to compare costs and terms. Additionally, evaluate their capacity to meet your specific needs, including customization options and MOQs. Establishing a relationship with suppliers who demonstrate reliability and responsiveness can lead to long-term partnerships that benefit your business.

Top 4 Reel Of Cable Manufacturers & Suppliers List

1. Powerwerx – Wire & Cable Reels

Domain: powerwerx.com

Registered: 1999 (26 years)

Introduction: Wire & Cable Reels featuring Red/Black bonded zip cord from 24 to 2 gauge. Available in stranded and solid hookup wire, UL1007, and PTFE insulated high temperature wire. Flexible abrasion resistant wire suitable for extreme environments. Variety of spool sizes from 25 to 5,000 feet. Additional wire products include welding cable, ultra-flexible power wire, test lead, and magnet wire.

2. Schill US – GT380 Cable Reel

Domain: markertek.com

Registered: 1995 (30 years)

Introduction: {“products”:[{“name”:”Schill GT380 19×11 Plastic Rubberized Cable Reel”,”brand”:”Schill US”,”item_number”:”SCHILL-GT380″,”specifications”:{“Reel Diameter”:”15 inches”,”Drum Diameter”:”9.29 inches”,”Overall Height”:”19 inches”,”Depth”:”11 inches”,”Weight”:”8.6 lbs”},”capacity”:{“.280″:”731 feet”,”.310″:”570 feet”,”.390″:”354 feet”,”.430″:”285 feet”,”.510″:”190 feet”,”.590″:”137 feet”,”.630″:”124 fe…

3. Clark Wire & Cable – Professional Audio Video Reels

Domain: clarkwire.com

Registered: 2002 (23 years)

Introduction: Clark Wire & Cable offers a wide selection of reels specifically designed for the professional audio video industry. Key features include:

– Stackable reels for easy transport.

– Custom cable reel assembly design available through Clark’s termination shop.

– All reels meet international standards and are constructed for the audio video and entertainment industries.

Product options include:

– Schi…

4. Cables Plus USA – Electric Cable Reels

Domain: store.cablesplususa.com

Registered: 2002 (23 years)

Introduction: This company, Cables Plus USA – Electric Cable Reels, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for reel of cable

In the evolving landscape of cable sourcing, strategic partnerships and informed procurement decisions are paramount for international B2B buyers. Engaging with suppliers who prioritize quality, reliability, and innovation can significantly enhance operational efficiency and reduce long-term costs. The diversity of cable reels available—ranging from synthetic rubber to heavy-duty steel—offers buyers the flexibility to choose products tailored to their specific needs, whether for industrial applications or specialized installations.

Understanding regional market dynamics is crucial, especially for buyers in Africa, South America, the Middle East, and Europe. These regions present unique opportunities and challenges, necessitating a nuanced approach to sourcing. By leveraging local insights and global best practices, businesses can optimize their supply chains and ensure timely delivery of high-quality cable solutions.

As we look ahead, the demand for advanced cable products will only continue to grow. Now is the time to solidify relationships with trusted manufacturers and suppliers, ensuring your business stays at the forefront of technological advancements. Embrace strategic sourcing as a vital component of your procurement strategy, and position your organization for sustained success in an increasingly competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.