How to Source Pulse Dust Collector Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for pulse dust collector

In the ever-evolving landscape of industrial operations, sourcing a pulse dust collector that meets specific regulatory and operational needs can pose significant challenges for businesses across the globe. With stringent environmental regulations and the need for efficient dust management systems, international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe—including countries like Saudi Arabia and Vietnam—must navigate a complex array of options. This guide delves into the various types of pulse dust collectors available, their diverse applications, and the critical factors to consider when evaluating suppliers.

Our comprehensive exploration encompasses essential topics including the latest technologies in pulse jet dust collection, operational efficiencies, cost considerations, and supplier vetting processes. By providing actionable insights into the selection and implementation of these systems, this guide empowers businesses to make informed purchasing decisions. Whether you are looking to enhance your facility’s performance or comply with environmental standards, understanding the pulse dust collector market is crucial for optimizing operations and achieving sustainable growth. Equip yourself with the knowledge to tackle dust management challenges head-on and ensure your investment aligns with your operational goals.

Understanding pulse dust collector Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Modular Pulse Jet Collectors | Modular design for easy scalability; filter media area options | Manufacturing, metalworking, woodworking | Pros: Scalable, flexible installation. Cons: Initial setup can be complex. |

| Multi-Modular Pulse Jet Collectors | Prewired sections for large applications; high efficiency | Large industrial plants | Pros: Cost-effective for large operations. Cons: Requires significant space. |

| Round Pulse Jet Collectors | Designed for high vacuum or pressure applications; compact size | Chemical processing, pharmaceuticals | Pros: Efficient for specialized applications. Cons: Limited filter area options. |

| Flat Bag Pulse Jet Filters | Horizontal design for easy maintenance; large filter area | Food processing, plastics | Pros: Easier access for maintenance. Cons: May require more floor space. |

| Long Bag Pulse Jet Collectors | Extended bag length for enhanced dust collection; high capacity | Heavy industries, mining | Pros: Higher dust load capacity. Cons: Longer bags may complicate installation. |

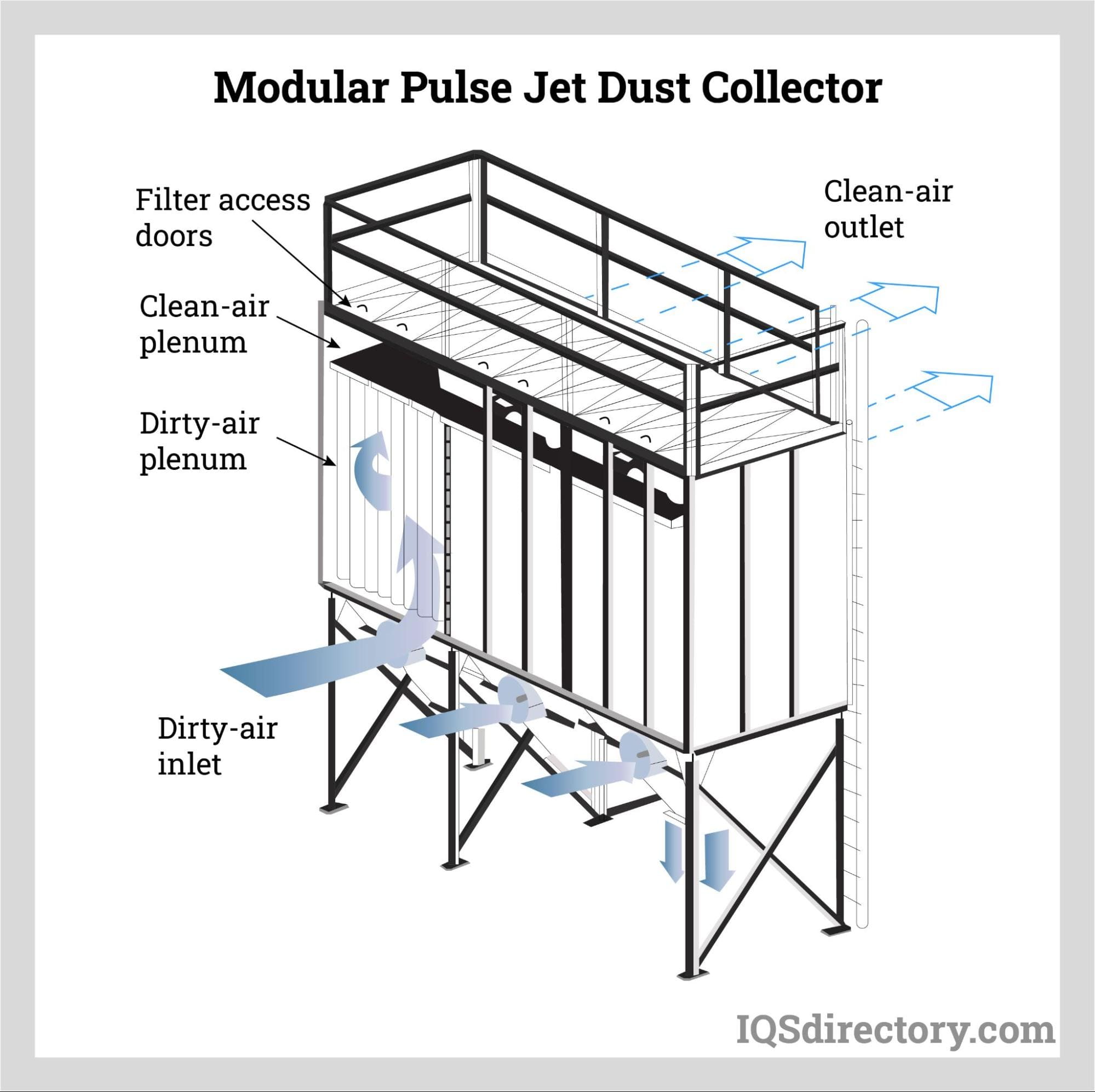

What Are Modular Pulse Jet Collectors and Their Applications?

Modular pulse jet collectors are characterized by their ability to be assembled in sections, allowing for easy scalability based on the specific dust collection needs of a facility. This design is particularly advantageous for businesses that anticipate growth or fluctuating production levels. Common applications include manufacturing and metalworking industries, where dust generation is frequent. Buyers should consider the initial complexity of setup, but appreciate the long-term flexibility this type offers.

How Do Multi-Modular Pulse Jet Collectors Work for Large Operations?

Multi-modular pulse jet collectors are designed for extensive applications, typically exceeding 4,500 square feet of filter media area. They come prewired to facilitate easier installation and are ideal for large industrial plants that require efficient dust management without compromising operational uptime. While they provide cost savings for larger operations, potential buyers should be aware of the need for adequate space and the implications of their large footprint.

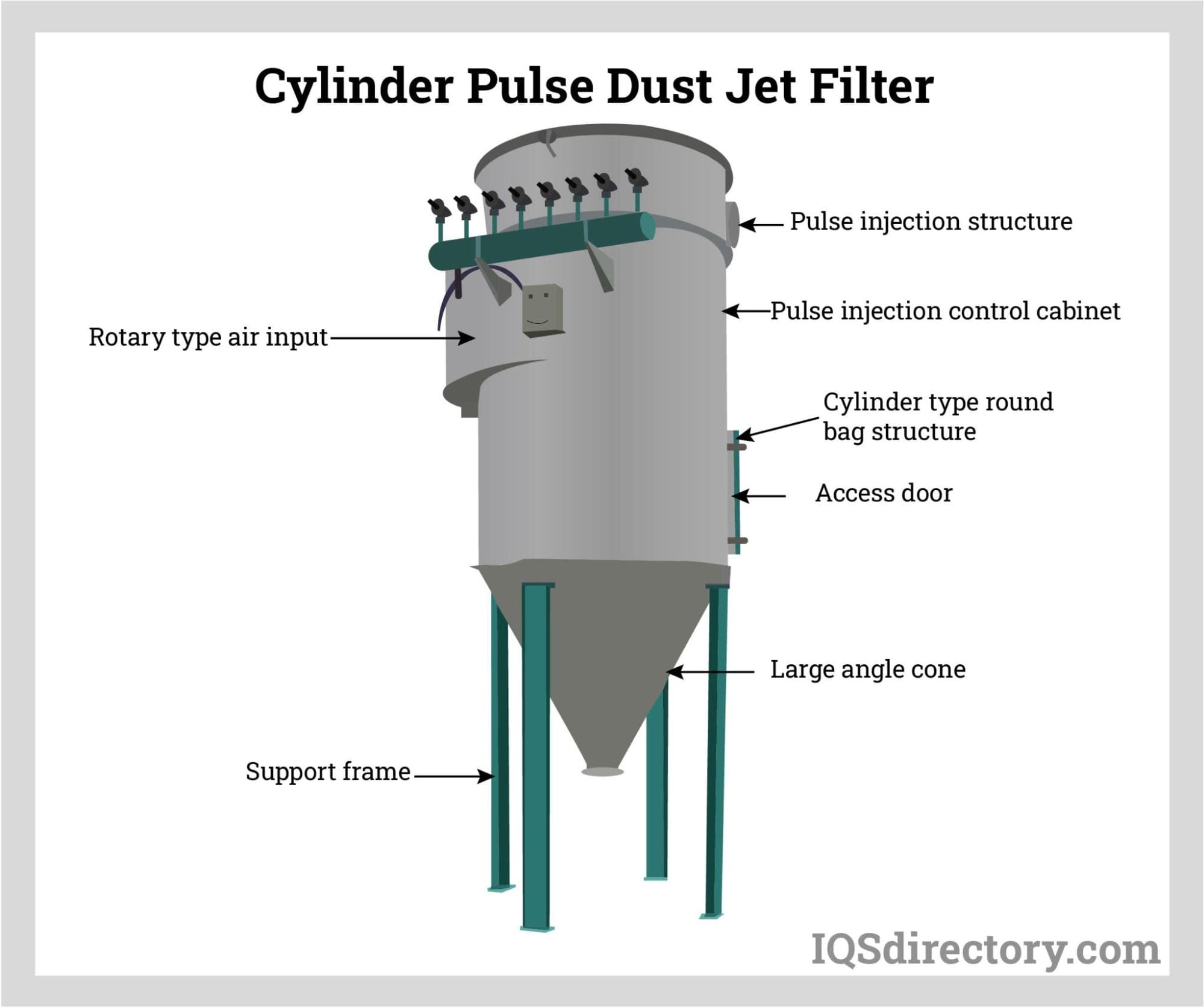

What Are the Benefits of Round Pulse Jet Collectors?

Round pulse jet collectors are tailored for high vacuum or pressure applications, making them suitable for industries like chemical processing and pharmaceuticals. Their compact design allows for efficient dust removal in specialized environments. While they offer high performance, businesses should weigh the limited filter area options against their specific dust collection needs to ensure they select the right configuration.

Why Choose Flat Bag Pulse Jet Filters?

Flat bag pulse jet filters feature a horizontal design that facilitates easier maintenance and cleaning, making them particularly useful in food processing and plastics industries. Their large filter area allows for effective dust collection while maintaining operational efficiency. However, potential buyers should consider the space requirements, as these systems may take up more floor area compared to other designs.

What Are Long Bag Pulse Jet Collectors Best Suited For?

Long bag pulse jet collectors are designed with extended bags that enhance dust collection capabilities, making them ideal for heavy industries such as mining. Their high capacity for dust load allows for extended periods between maintenance and filter replacements. While their installation might present challenges due to the longer bags, the benefits of increased efficiency and reduced downtime can make them an attractive option for businesses focused on maximizing productivity.

Key Industrial Applications of pulse dust collector

| Industry/Sector | Specific Application of pulse dust collector | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Metalworking and Machining | Reduces airborne particulate, improving worker safety and compliance with health regulations. | Compatibility with existing machinery and airflow needs. |

| Food Processing | Grain Milling and Flour Production | Ensures product purity by minimizing contamination and maintaining air quality. | Compliance with food safety standards and sanitation requirements. |

| Pharmaceuticals | Active Pharmaceutical Ingredient (API) Production | Enhances operational efficiency by maintaining clean air and reducing downtime. | Need for specialized filters that meet stringent industry standards. |

| Construction & Demolition | Concrete and Asphalt Production | Controls dust emissions, ensuring regulatory compliance and protecting worker health. | Durability and efficiency in high-dust environments. |

| Chemical Processing | Powder Coating and Chemical Manufacturing | Improves air quality and reduces the risk of combustible dust explosions. | Consideration for explosion-proof designs and material compatibility. |

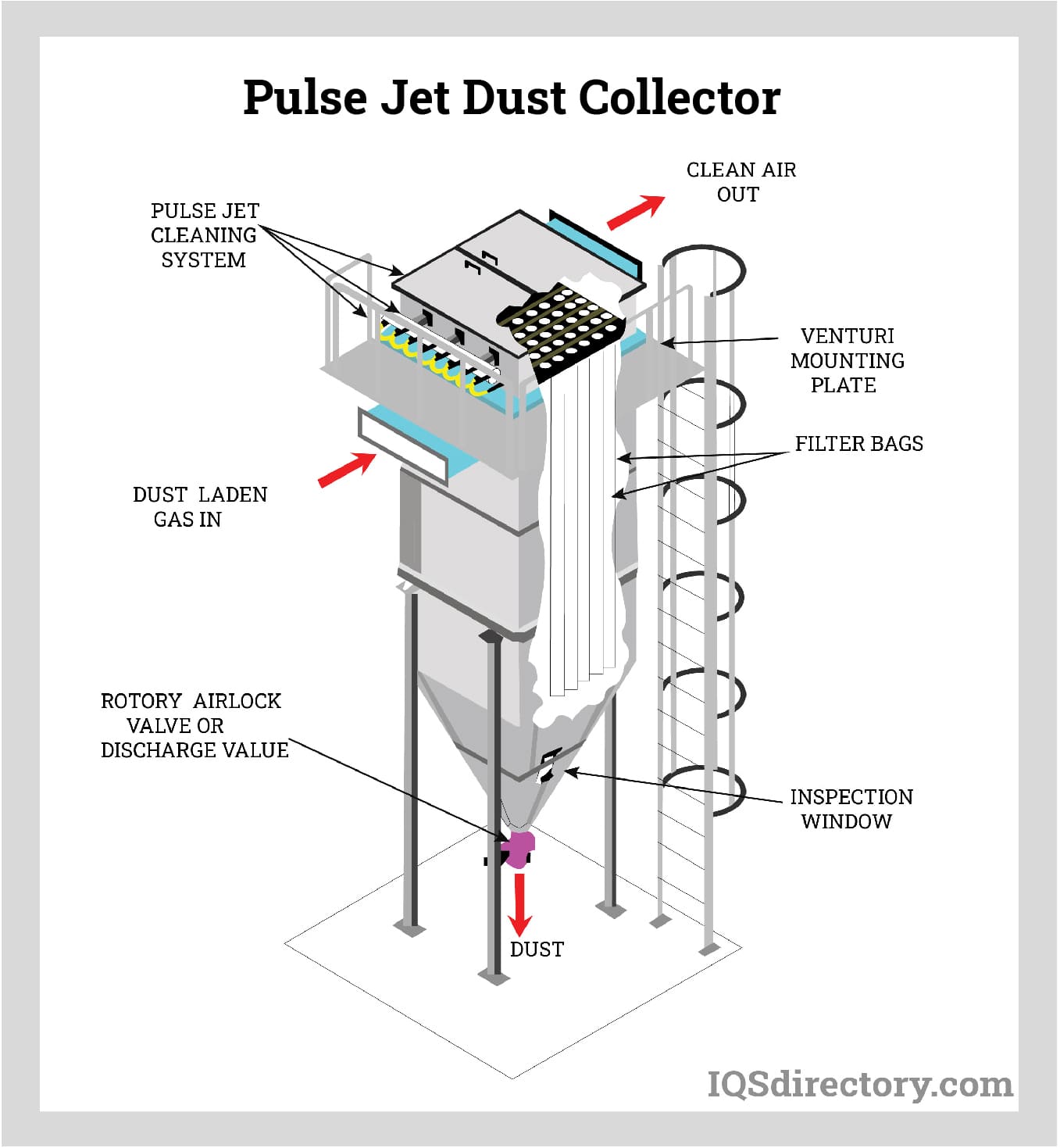

How is Pulse Dust Collector Used in Manufacturing, and What Problems Does It Solve?

In the manufacturing sector, particularly in metalworking and machining, pulse dust collectors are essential for maintaining a safe working environment. These systems utilize compressed air to dislodge accumulated dust from filter bags, ensuring continuous operation without manual cleaning interruptions. This technology not only enhances worker safety by reducing airborne particulates but also aids compliance with stringent health regulations. International buyers should consider factors such as compatibility with existing machinery and the specific airflow requirements of their operations when sourcing these systems.

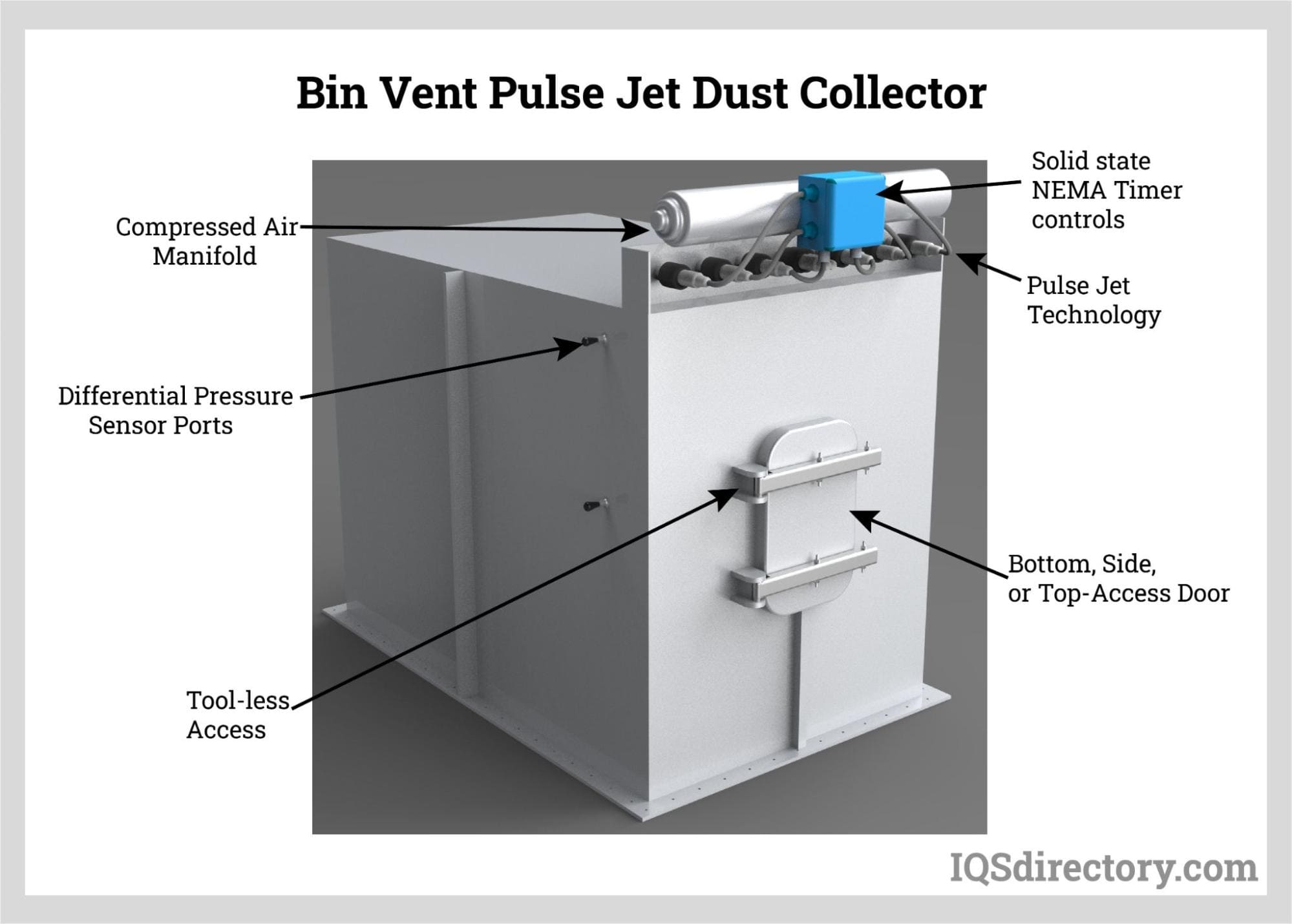

Illustrative image related to pulse dust collector

What Role Does Pulse Dust Collector Play in Food Processing?

In food processing, particularly in grain milling and flour production, pulse dust collectors help maintain product integrity by minimizing contamination risks. The efficient filtration system captures fine particles, thus preserving the quality of the final product and ensuring a clean production environment. Buyers must ensure that the dust collector meets food safety standards and sanitation requirements, which may vary by region, especially in diverse markets such as Africa and South America.

Why is Pulse Dust Collector Critical in Pharmaceuticals?

The pharmaceutical industry relies on pulse dust collectors during the production of Active Pharmaceutical Ingredients (APIs) to enhance operational efficiency. By maintaining clean air, these systems reduce the risk of contamination and downtime, which is crucial for meeting production targets and regulatory compliance. Buyers in this sector should prioritize sourcing specialized filters that adhere to stringent industry standards, ensuring the collector can handle the unique challenges of pharmaceutical manufacturing.

How Does Pulse Dust Collector Benefit Construction and Demolition?

In construction and demolition, pulse dust collectors are vital for controlling dust emissions during concrete and asphalt production. These systems not only ensure regulatory compliance but also protect worker health by minimizing exposure to harmful dust. Buyers should look for dust collectors that offer durability and efficiency in high-dust environments, as these factors can significantly impact operational performance and safety.

Illustrative image related to pulse dust collector

What Considerations are Important in Chemical Processing with Pulse Dust Collectors?

In chemical processing, particularly in powder coating and manufacturing, pulse dust collectors play a crucial role in improving air quality and reducing the risk of combustible dust explosions. The ability to effectively manage airborne particulates is essential for maintaining a safe workplace. When sourcing these systems, buyers should consider the need for explosion-proof designs and ensure that materials used in the dust collector are compatible with the chemicals being processed.

3 Common User Pain Points for ‘pulse dust collector’ & Their Solutions

Scenario 1: High Maintenance Costs Due to Frequent Filter Changes

The Problem: Many B2B buyers face escalating maintenance costs stemming from the frequent need to replace filter bags in pulse dust collectors. This is especially true in industries with high dust volumes, such as woodworking or metalworking. Frequent filter changes not only incur direct costs but also lead to unplanned downtime, disrupting production schedules and impacting overall efficiency. Buyers often feel pressured to find a cost-effective solution without compromising on air quality or compliance with environmental regulations.

The Solution: To mitigate these costs, it is essential to invest in high-performance filter options. Filters like the Dura-Life® and Ultra-Web SB pleated bags significantly enhance filtration efficiency and longevity. These advanced filter bags are engineered to trap more dust on the surface, leading to longer life spans—often up to two to three times longer than standard bags. B2B buyers should conduct a thorough analysis of their dust collection needs and choose filter media that aligns with their specific application. Partnering with manufacturers that offer remote monitoring technologies, such as Donaldson’s iCue™ system, can provide insights into filter performance and maintenance needs, thus minimizing unexpected downtimes and maintenance costs.

Scenario 2: Inefficient Dust Collection Leading to Safety Concerns

The Problem: In many industries, ineffective dust collection can lead to unsafe working conditions. Dust accumulation not only poses a respiratory hazard to workers but can also increase the risk of fires and explosions, particularly in environments dealing with combustible materials. B2B buyers are often concerned about compliance with safety regulations and maintaining a safe workplace for their employees.

The Solution: To ensure efficient dust collection, it is crucial to properly size and configure the pulse dust collector for the specific application. Buyers should assess the type and volume of dust generated and consult with manufacturers to determine the optimal collector design, whether it be modular systems for larger applications or specialized round collectors for high vacuum needs. Implementing a pulse jet cleaning system that can operate without shutting down the collector enhances operational efficiency and safety. Regular maintenance and inspection schedules should be established to keep the equipment functioning optimally, thereby safeguarding both the workers and the facility.

Scenario 3: Compliance Challenges with Environmental Regulations

The Problem: B2B buyers often struggle to keep up with the stringent environmental regulations concerning emissions and air quality. Non-compliance can result in hefty fines, legal issues, and damage to the company’s reputation. Industries such as pharmaceuticals and food processing are under constant scrutiny, making it imperative for companies to maintain effective dust collection systems that meet or exceed regulatory standards.

The Solution: To navigate these compliance challenges, buyers should invest in pulse dust collectors equipped with advanced filtration technologies. Systems using Ultra-Web SB pleated bags, for example, offer reduced emissions and improved filtration efficiency, helping companies stay compliant with EPA standards. It is also beneficial to work with suppliers who provide detailed compliance documentation and support services. Establishing a proactive monitoring system, such as integrating sensors that track air quality and emissions levels, can help organizations maintain compliance and quickly address any deviations. Regular training for staff on the importance of dust management and compliance can further enhance operational adherence to environmental standards.

Strategic Material Selection Guide for pulse dust collector

What Are the Key Materials Used in Pulse Dust Collectors?

When selecting materials for pulse dust collectors, several options stand out due to their performance characteristics and suitability for various applications. Understanding the properties, advantages, and limitations of these materials is crucial for B2B buyers, particularly in regions with diverse industrial requirements like Africa, South America, the Middle East, and Europe.

Illustrative image related to pulse dust collector

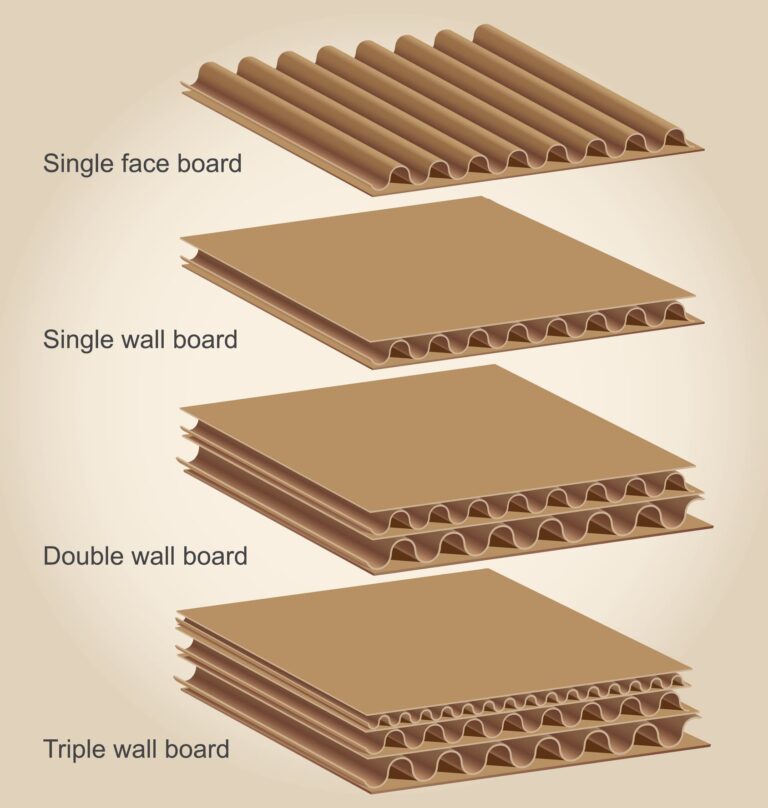

What Are the Key Properties of Polyester in Pulse Dust Collectors?

Polyester is a widely used material for filter bags in pulse dust collectors. It has a temperature rating of up to 150°C (302°F) and offers good chemical resistance, making it suitable for a variety of industrial applications. The lightweight nature of polyester contributes to lower energy costs due to reduced pressure drop across the filter media.

Pros: Polyester bags are cost-effective, lightweight, and easy to install. They provide adequate filtration efficiency for many dust types, making them versatile for different industries.

Cons: However, polyester may not withstand high temperatures or aggressive chemicals, which could limit its application in extreme environments. Additionally, the fabric may degrade over time, necessitating more frequent replacements.

Impact on Application: Polyester is compatible with a wide range of dust types, but its limitations in high-temperature applications must be considered, especially in industries like metalworking or chemical processing.

How Does Polypropylene Compare for Use in Pulse Dust Collectors?

Polypropylene is another common material used in dust collector applications, particularly where chemical resistance is paramount. It offers excellent resistance to acids and bases, with a temperature rating similar to polyester.

Pros: Polypropylene is highly resistant to chemical degradation, making it ideal for industries dealing with corrosive materials. It is also lightweight and cost-effective.

Cons: The primary drawback of polypropylene is its lower temperature resistance, which typically caps at around 90°C (194°F). This limitation can restrict its use in high-temperature environments.

Impact on Application: Buyers in chemical processing industries may find polypropylene particularly useful due to its chemical resistance, but they should be cautious of its temperature limitations.

What Are the Advantages of Using Fiberglass in Pulse Dust Collectors?

Fiberglass filter media is known for its high-temperature resistance, often exceeding 200°C (392°F). It is particularly effective in applications involving hot air or gases.

Pros: Fiberglass is durable and can withstand harsh conditions, making it suitable for industries such as power generation and metal processing. Its high filtration efficiency also contributes to lower emissions.

Cons: However, fiberglass is typically more expensive than polyester and polypropylene, which could impact budget considerations. Additionally, it may be more complex to manufacture and install.

Impact on Application: For applications involving high temperatures and aggressive dust types, fiberglass is an excellent choice, although the cost may deter some buyers.

Why Consider Stainless Steel for Pulse Dust Collector Components?

Stainless steel is often used for structural components of pulse dust collectors, such as housings and frames, due to its strength and corrosion resistance.

Pros: Stainless steel offers exceptional durability and longevity, making it suitable for harsh environments. Its resistance to corrosion ensures a longer lifespan for the equipment.

Cons: The main disadvantage is the higher cost associated with stainless steel compared to other materials. Additionally, its weight can complicate installation and transport.

Impact on Application: Buyers in regions with high humidity or corrosive environments, such as coastal areas, may find stainless steel an essential choice for ensuring the longevity of their dust collection systems.

Summary Table of Material Selection for Pulse Dust Collectors

| Material | Typical Use Case for pulse dust collector | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | General industrial dust collection | Cost-effective and lightweight | Limited high-temperature resistance | Low |

| Polypropylene | Chemical processing applications | Excellent chemical resistance | Lower temperature resistance | Low |

| Fiberglass | High-temperature applications | High durability and filtration efficiency | Higher cost and complex installation | High |

| Stainless Steel | Structural components of dust collectors | Exceptional durability and corrosion resistance | Higher cost and weight | High |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions regarding the materials used in pulse dust collectors, ensuring optimal performance and compliance with industry standards.

Illustrative image related to pulse dust collector

In-depth Look: Manufacturing Processes and Quality Assurance for pulse dust collector

What are the Main Stages in the Manufacturing Process of Pulse Dust Collectors?

The manufacturing process of pulse dust collectors involves several critical stages, each designed to ensure optimal performance and reliability. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Raw Materials Are Used?

The first step in manufacturing pulse dust collectors is the selection and preparation of raw materials. Common materials include high-quality carbon steel or stainless steel for the frame and casing, as well as specialized filter media like polyester or polypropylene. The choice of materials impacts the durability and efficiency of the dust collector. For instance, advanced filter media, such as Dura-Life® and Ultra-Web® SB bags, are engineered to enhance filtration efficiency and longevity. These materials undergo rigorous quality checks to ensure they meet industry standards before proceeding to the next stage.

How Are Components Formed and Assembled?

Once the materials are prepared, the next stage involves the forming of components. This may include processes such as cutting, bending, and welding to create the structural framework of the dust collector. Advanced techniques like hydroforming can be employed to create complex shapes that maximize airflow and filtration efficiency.

Illustrative image related to pulse dust collector

After forming, components are assembled. This stage often utilizes modular construction techniques, allowing for efficient assembly and easier shipping. For instance, multi-modular pulse jet collectors are prewired and assembled in sections, making them suitable for large-scale applications. Quality assurance checks are integrated throughout this phase to catch any defects early, ensuring that each component fits perfectly.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance is crucial in the manufacturing of pulse dust collectors, especially given the high stakes involved in industrial applications. International standards such as ISO 9001 are fundamental, as they provide a framework for quality management systems. Compliance with these standards indicates that the manufacturer adheres to stringent quality processes.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) are essential for ensuring that dust collectors meet safety and performance standards. For B2B buyers, verifying these certifications can provide peace of mind regarding product quality and compliance.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) is implemented at several checkpoints throughout the manufacturing process. These include:

Illustrative image related to pulse dust collector

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components as they arrive at the facility. Suppliers are evaluated based on their ability to meet specified quality criteria, and materials that do not pass inspection are rejected.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, ongoing inspections are conducted to monitor the quality of assembly and fabrication. This step is crucial for detecting defects early, which can save time and resources in the long run.

-

Final Quality Control (FQC): Once the dust collector is fully assembled, a comprehensive final inspection is performed. This includes functional testing to ensure that the dust collector performs as expected, along with visual inspections for any cosmetic defects.

What Testing Methods Are Commonly Used in Quality Assurance?

To ensure the performance and safety of pulse dust collectors, various testing methods are employed. These include:

-

Airflow Testing: This evaluates the efficiency of dust collection and ensures that the system operates within specified airflow parameters.

-

Leak Testing: Conducted to verify that there are no leaks in the system, which could compromise performance and safety.

-

Filter Efficiency Testing: This assesses the dust collector’s ability to capture particulates of different sizes, ensuring compliance with environmental regulations.

-

Durability Testing: Subjecting the dust collector to simulated operational conditions helps assess its long-term reliability and performance under stress.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying the quality control practices of suppliers is essential. Here are several strategies to ensure that a supplier maintains high standards:

-

Conduct Supplier Audits: Regular audits of the manufacturing facility can provide insights into the supplier’s quality control processes and overall operational efficiency. This can be done in person or through third-party agencies.

-

Request Quality Assurance Reports: Suppliers should provide detailed reports documenting their quality assurance practices, including results from testing and inspections. This transparency can help buyers assess the reliability of the products.

-

Engage Third-Party Inspection Services: Employing third-party inspectors to assess the quality of the dust collectors before shipment can provide an unbiased evaluation of compliance with specified standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Regulatory requirements may vary significantly between countries, and it’s crucial to ensure that the dust collector complies with local regulations as well as international standards.

Additionally, language barriers and differing business practices can complicate communication regarding quality expectations. Establishing clear lines of communication and setting explicit quality requirements in contracts can mitigate these issues. Furthermore, understanding the cultural context can foster better relationships with suppliers and enhance collaboration on quality assurance.

Conclusion: Ensuring Quality in Pulse Dust Collectors

In summary, the manufacturing and quality assurance processes for pulse dust collectors are multifaceted and critical to ensuring operational efficiency and safety. By understanding the manufacturing stages, quality assurance standards, testing methods, and verification strategies, B2B buyers can make informed decisions when selecting suppliers. This diligence not only safeguards investments but also enhances overall operational effectiveness in dust management applications across various industries.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pulse dust collector’

In this guide, we provide a practical checklist for international B2B buyers seeking to procure a pulse dust collector. This step-by-step approach ensures that buyers make informed decisions, aligning their operational needs with the right technology and suppliers.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for your pulse dust collector. Consider factors such as the type of dust generated, airflow capacity, and the required filtration efficiency. Understanding these specifications is crucial for ensuring that the selected system will effectively handle your operational demands.

- Dust Type: Identify whether you are dealing with fine dust, coarse particles, or hazardous materials.

- Airflow Requirements: Calculate the necessary airflow in cubic feet per minute (CFM) to maintain optimal performance.

Step 2: Assess Compliance and Safety Standards

Ensure that the pulse dust collector meets local and international safety and environmental regulations. Compliance with standards such as OSHA, EPA, and ATEX (for explosive dust) is vital to avoid legal issues and ensure workplace safety.

- Documentation: Request documentation that verifies compliance with relevant standards.

- Safety Features: Look for built-in safety features such as explosion vents or fire suppression systems.

Step 3: Evaluate Supplier Experience and Reputation

Choosing a reputable supplier is essential for long-term reliability and support. Research potential suppliers by reviewing their industry experience, customer testimonials, and case studies.

- Industry Experience: Prefer suppliers with a proven track record in your specific industry.

- References: Ask for references from similar businesses to gauge customer satisfaction.

Step 4: Analyze Filter Technology and Maintenance Needs

Consider the type of filters used in the dust collector. Advanced filter technologies, such as pleated bags or hydroentangled materials, can enhance performance and reduce maintenance costs.

- Filter Longevity: Inquire about the expected lifespan of the filters and the frequency of maintenance required.

- Cleaning Mechanisms: Evaluate the efficiency of the pulse cleaning mechanism, as it directly impacts operational downtime.

Step 5: Request Quotes and Compare Total Cost of Ownership

Gather detailed quotes from multiple suppliers to compare pricing. However, focus on the total cost of ownership rather than just the initial purchase price, as factors like energy consumption and maintenance can significantly impact long-term costs.

- Energy Efficiency: Look for specifications that indicate lower energy consumption.

- Maintenance Costs: Factor in the costs associated with filter replacements and routine maintenance.

Step 6: Inquire About After-Sales Support and Training

Robust after-sales support is critical for the successful implementation of your dust collection system. Confirm that the supplier offers comprehensive training and ongoing technical support.

- Training Programs: Ensure that the supplier provides adequate training for your staff on operating and maintaining the system.

- Technical Support: Verify the availability of technical support for troubleshooting and repairs.

Step 7: Plan for Installation and Integration

Finally, consider how the pulse dust collector will be installed and integrated into your existing operations. Effective planning can minimize disruptions during the installation phase.

- Installation Services: Check if the supplier provides installation services or if you will need to hire a third party.

- Integration with Existing Systems: Ensure that the new system will seamlessly integrate with your current equipment and processes.

By following this checklist, B2B buyers can confidently procure a pulse dust collector that meets their operational needs while ensuring compliance, safety, and cost-effectiveness.

Comprehensive Cost and Pricing Analysis for pulse dust collector Sourcing

What Are the Key Cost Components in Pulse Dust Collector Sourcing?

When sourcing pulse dust collectors, it’s essential to understand the various cost components that contribute to the final price. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of filter media, such as Dura-Life or Ultra-Web SB pleated bags, significantly impacts costs. High-quality materials may increase initial expenses but often lead to longer product life and reduced maintenance costs, making them more cost-effective in the long run.

-

Labor: Labor costs include both direct and indirect expenses associated with manufacturing and assembly. Skilled labor is often necessary for ensuring high-quality production, particularly for specialized dust collector systems.

-

Manufacturing Overhead: This encompasses all costs associated with running the production facility, including utilities, equipment depreciation, and administrative expenses. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: The cost of tooling is crucial, especially for custom designs. Specialized tooling can be expensive, but it is often necessary for producing tailored solutions that meet specific customer requirements.

-

Quality Control: Implementing rigorous QC processes is vital for ensuring product reliability and compliance with industry standards. This may add to the cost but is essential for minimizing long-term risks associated with equipment failures.

-

Logistics: Transportation and handling costs can vary significantly based on the size of the equipment and the shipping distance. Understanding Incoterms is crucial for determining which party is responsible for these costs, as they can impact total pricing.

-

Margin: Supplier margins vary based on brand reputation, market demand, and competition. Established brands may command higher prices due to perceived quality and reliability.

How Do Price Influencers Affect Pulse Dust Collector Sourcing?

Several factors influence the pricing of pulse dust collectors, including volume, specifications, materials, quality certifications, supplier relationships, and Incoterms.

-

Volume/MOQ: Manufacturers often offer discounts for larger orders due to economies of scale. Understanding the minimum order quantity (MOQ) can help buyers negotiate better pricing.

-

Specifications and Customization: Custom-built solutions typically incur higher costs. Buyers should clearly define their requirements to avoid unexpected expenses related to modifications.

-

Materials and Quality: High-quality materials and certifications (e.g., ISO, EPA compliance) may come at a premium but can result in lower total costs over the equipment’s lifespan due to fewer replacements and maintenance needs.

-

Supplier Factors: Building strong relationships with suppliers can lead to better pricing and service. Buyers should research potential suppliers’ reputations and capabilities to ensure quality and reliability.

-

Incoterms: Understanding the implications of different Incoterms is essential for cost management. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect the total landed cost.

What Tips Can Help Buyers Optimize Costs in Pulse Dust Collector Procurement?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies to enhance cost-efficiency:

-

Negotiation: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Leverage volume commitments to secure discounts.

-

Total Cost of Ownership (TCO): Assess not only the upfront cost but also the long-term costs associated with maintenance, energy consumption, and potential downtime. Investing in more efficient systems can lead to significant savings over time.

-

Pricing Nuances: Be aware of regional pricing variations influenced by local market conditions, import duties, and currency fluctuations. This knowledge can enhance negotiation strategies.

-

Supplier Diversification: Avoid reliance on a single supplier. Exploring multiple options can provide leverage in negotiations and potentially uncover more competitive pricing.

Disclaimer

The prices and cost structures discussed are indicative and may vary based on specific supplier agreements, market conditions, and regional factors. Always conduct thorough research and consult with industry experts when making procurement decisions.

Alternatives Analysis: Comparing pulse dust collector With Other Solutions

Understanding Alternatives in Dust Collection Systems

In industrial environments, effective dust collection is crucial for maintaining air quality and ensuring compliance with health and safety regulations. While pulse dust collectors are widely recognized for their efficiency, there are several alternative solutions that can also achieve effective dust management. This analysis will compare pulse dust collectors with two viable alternatives: cyclonic dust collectors and cartridge dust collectors, focusing on key aspects that influence B2B purchasing decisions.

| Comparison Aspect | Pulse Dust Collector | Cyclonic Dust Collector | Cartridge Dust Collector |

|---|---|---|---|

| Performance | High filtration efficiency; suitable for fine dust. | Good for larger particles; lower efficiency on fine dust. | Excellent for fine dust with high airflow. |

| Cost | Moderate initial investment; low operating costs due to energy efficiency. | Lower upfront cost; potential higher maintenance costs. | Higher initial investment; long-term savings through reduced filter replacements. |

| Ease of Implementation | Requires professional installation; adaptable to various applications. | Relatively easy to install; requires adequate space. | Simple installation; compact designs available. |

| Maintenance | Requires regular maintenance; filter replacements can be costly. | Low maintenance; occasional cleaning needed. | Easy filter replacements; less frequent maintenance. |

| Best Use Case | High-volume dust applications in manufacturing and processing. | Woodworking and other industries with larger particulate matter. | Industries needing high filtration for fine dust, like pharmaceuticals or food processing. |

Detailed Breakdown of Alternatives

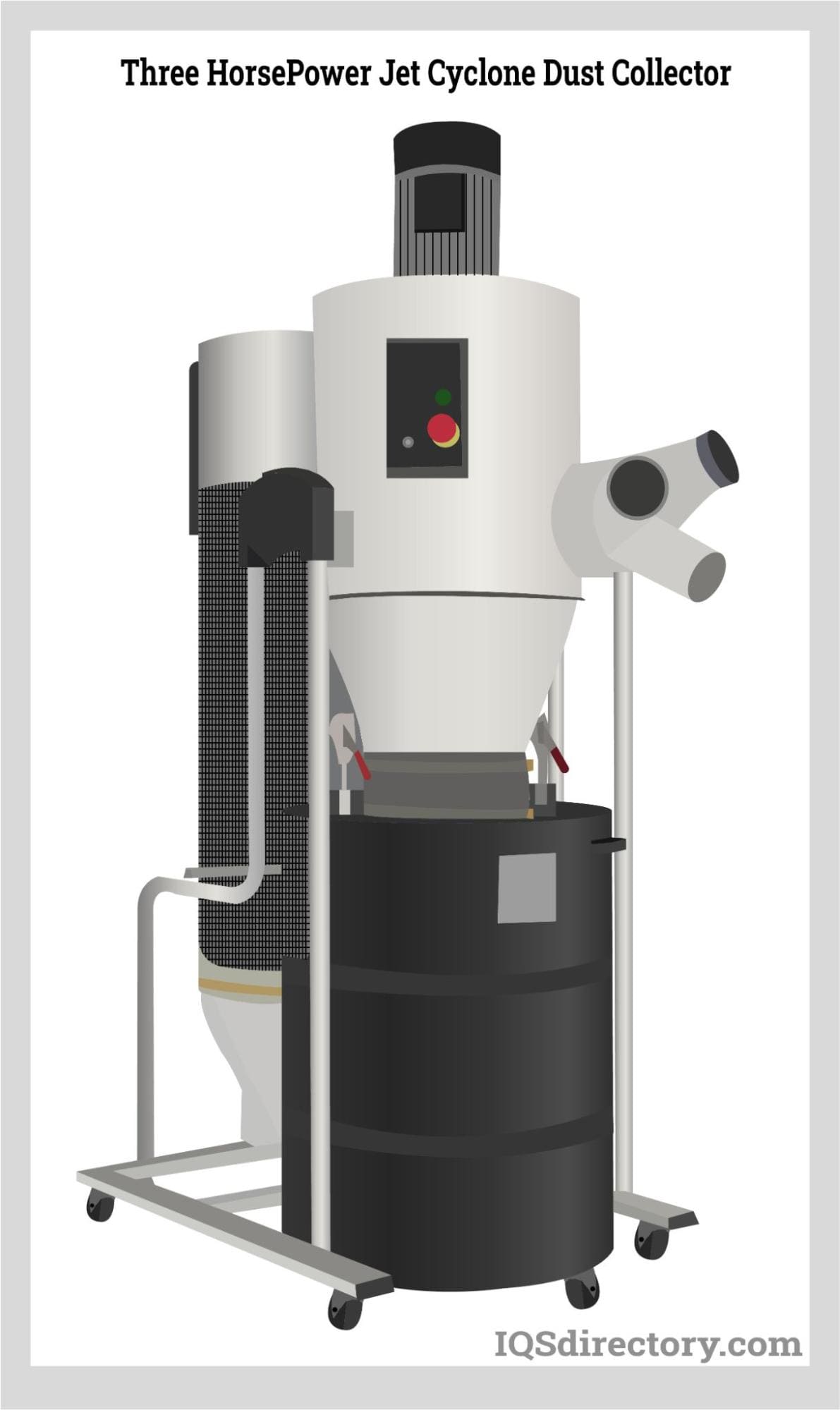

Cyclonic Dust Collectors

Cyclonic dust collectors utilize centrifugal force to separate dust from the air. This method is effective for larger particles and is often used in industries such as woodworking and metalworking. The primary advantage of cyclonic systems is their lower initial cost and minimal maintenance requirements. However, they are less effective at capturing fine dust, which may lead to compliance issues in certain industries. For companies dealing primarily with coarse materials, cyclonic collectors can be a cost-effective solution.

Cartridge Dust Collectors

Cartridge dust collectors are designed for high airflow applications and provide superior filtration for fine dust particles. These systems utilize pleated filter cartridges that maximize surface area, resulting in longer filter life and reduced maintenance needs. While the initial investment may be higher compared to pulse dust collectors, the long-term savings from fewer filter replacements and lower energy consumption can offset these costs. They are ideal for applications in industries like pharmaceuticals and food processing where air quality standards are stringent.

Illustrative image related to pulse dust collector

Conclusion: How to Choose the Right Dust Collection Solution

When selecting a dust collection solution, B2B buyers should consider their specific operational needs, including the type of dust generated, space availability, and budget constraints. Pulse dust collectors offer high efficiency and adaptability for various applications, making them suitable for large-scale manufacturing environments. In contrast, cyclonic collectors provide a budget-friendly option for managing larger particulates, while cartridge collectors excel in environments requiring stringent air quality control. By evaluating the performance, cost, ease of implementation, maintenance requirements, and best use cases of each alternative, businesses can make informed decisions that enhance their operational efficiency and compliance with industry standards.

Essential Technical Properties and Trade Terminology for pulse dust collector

What Are the Essential Technical Properties of Pulse Dust Collectors?

Understanding the technical properties of pulse dust collectors is crucial for businesses looking to invest in efficient dust management systems. Here are key specifications that buyers should consider:

1. Filter Media Type

The filter media is a critical component, directly affecting filtration efficiency and maintenance. Common options include polyester, Dura-Life, and Ultra-Web SB pleated bags. Each offers unique benefits, such as longer service life and reduced emissions. For instance, Dura-Life bags can provide up to twice the lifespan of standard polyester bags, translating to lower operational costs and less frequent replacements.

2. Airflow Capacity

This specification measures the volume of air the dust collector can handle, typically expressed in cubic feet per minute (CFM). Understanding airflow capacity is vital for ensuring the system meets the demands of your application. A collector with inadequate airflow can lead to poor dust control and increased downtime, negatively impacting productivity.

Illustrative image related to pulse dust collector

3. Pressure Drop

Pressure drop refers to the resistance the air faces while passing through the filter media. A lower pressure drop indicates a more efficient system, as it requires less energy for operation. Buyers should assess the pressure drop to evaluate energy consumption and operational costs, as a significant drop can lead to higher utility bills.

4. Cleaning Mechanism

Pulse jet cleaning is a key feature of these collectors, where a burst of compressed air dislodges accumulated dust from the filter bags. This mechanism allows for continuous operation without the need for shutdowns for maintenance. Understanding the efficiency of the cleaning system can help businesses minimize downtime and maximize productivity.

5. Construction Material

The material used in the construction of the dust collector impacts its durability and resistance to corrosion. Common materials include carbon steel and stainless steel, with the latter offering superior resistance in harsh environments. Selecting the right construction material is essential for longevity, especially for operations in challenging conditions.

6. Hopper Design

Hopper design affects dust disposal efficiency. Options like pyramid hoppers or flanged discharge can influence how well the dust is contained and removed. A well-designed hopper can reduce clogs and improve overall system efficiency, making it a crucial consideration for buyers.

Illustrative image related to pulse dust collector

What Are Common Trade Terms Related to Pulse Dust Collectors?

Familiarizing yourself with industry terminology can enhance communication with suppliers and facilitate smoother transactions. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

An OEM produces the original parts that are later used in the assembly of a final product. In the context of pulse dust collectors, knowing the OEM can provide insights into quality and compatibility, especially when sourcing replacement parts.

2. MOQ (Minimum Order Quantity)

This term refers to the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is important for budget planning and inventory management, as it can affect the total cost of procurement.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing on specific products or services. When considering a pulse dust collector, submitting an RFQ can help businesses obtain competitive pricing and assess different suppliers’ offerings.

4. Incoterms

International Commercial Terms (Incoterms) are pre-defined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which is essential for international transactions of dust collectors.

5. Warranties and Service Agreements

These terms outline the guarantees provided by manufacturers regarding the performance and longevity of the dust collector. Understanding warranty terms can protect your investment and provide peace of mind regarding maintenance and repairs.

By grasping these technical properties and trade terms, businesses can make informed purchasing decisions, ensuring that their pulse dust collector meets operational requirements and contributes to a cleaner, safer work environment.

Navigating Market Dynamics and Sourcing Trends in the pulse dust collector Sector

What Are the Current Market Dynamics and Key Trends in the Pulse Dust Collector Sector?

The pulse dust collector market is experiencing robust growth, driven by increasing regulatory pressures on air quality and dust emissions across various industries. Global initiatives aiming for sustainable manufacturing processes further fuel demand, particularly in emerging markets in Africa, South America, the Middle East, and Europe. Companies are increasingly adopting advanced filtration technologies, such as pulse jet systems, which offer high efficiency and reduced operational costs. Notable trends include the integration of IoT technologies for remote monitoring and predictive maintenance, enabling manufacturers to optimize performance and minimize unplanned downtime.

Additionally, modular designs are gaining traction, allowing for scalable installations that cater to diverse industrial applications. This flexibility is particularly appealing to international buyers, as it accommodates varying production capacities and helps manage costs effectively. For example, the ability to customize pulse jet systems for specific operational needs enhances their appeal across sectors such as mining, pharmaceuticals, and food processing.

As companies focus on improving their environmental footprint, the demand for high-efficiency dust collectors that minimize energy consumption and emissions is set to rise. This shift aligns with global sustainability goals, driving manufacturers to innovate continuously and refine their product offerings to meet the evolving needs of international buyers.

How Important Is Sustainability and Ethical Sourcing in the Pulse Dust Collector Industry?

Sustainability has become a cornerstone of purchasing decisions in the pulse dust collector sector. B2B buyers increasingly prioritize suppliers who demonstrate a commitment to environmental stewardship and ethical sourcing practices. This includes the use of recyclable materials, energy-efficient manufacturing processes, and compliance with international environmental regulations.

The adoption of ‘green’ certifications, such as ISO 14001, is becoming essential for suppliers aiming to establish credibility in the market. These certifications assure buyers that their suppliers adhere to stringent environmental management standards, thereby reducing the overall environmental impact of their operations. Additionally, innovations in filter technologies, such as the use of Dura-Life® and Ultra-Web® materials, not only enhance performance but also contribute to lower emissions and longer product lifespans, aligning with sustainability goals.

Moreover, companies that engage in ethical sourcing practices are more likely to foster strong, long-term relationships with their clients. This approach not only enhances brand loyalty but also mitigates risks associated with supply chain disruptions. As global buyers increasingly scrutinize their supply chains, suppliers who prioritize sustainability and ethical practices will likely gain a competitive advantage.

How Has the Pulse Dust Collector Market Evolved Over Time?

The pulse dust collector market has evolved significantly over the past few decades, transitioning from basic filtration systems to advanced, technology-driven solutions. Initially, dust collection systems focused primarily on compliance with regulatory standards. However, as industries grew more aware of environmental concerns and operational efficiency, the focus shifted toward enhancing filtration capabilities and minimizing energy consumption.

The introduction of pulse jet technology marked a pivotal moment in this evolution, allowing for continuous operation without the need for manual cleaning. This innovation has enabled manufacturers to maintain optimal filtration efficiency and reduce maintenance costs, a key selling point for B2B buyers. As industries continue to prioritize cleaner air and sustainable practices, the pulse dust collector sector is poised for further growth, driven by technological advancements and an increasing emphasis on environmental responsibility.

In summary, understanding these market dynamics, sustainability imperatives, and the historical context of the pulse dust collector sector equips international B2B buyers with the insights needed to make informed sourcing decisions that align with their operational goals and environmental commitments.

Illustrative image related to pulse dust collector

Frequently Asked Questions (FAQs) for B2B Buyers of pulse dust collector

-

How do I solve dust collection issues in my facility?

To effectively solve dust collection issues, first assess the specific type of dust generated in your operations and the volume produced. Selecting the appropriate pulse dust collector is crucial; ensure it has the right filtration technology and capacity to meet your needs. Consider systems with advanced features like automatic bag cleaning and real-time monitoring to maintain efficiency. Additionally, regular maintenance and monitoring of your dust collection system can help prevent downtime and ensure compliance with health and safety regulations. -

What is the best pulse dust collector for high-volume operations?

For high-volume operations, a modular pulse jet dust collector is often the best choice. These systems are designed to handle large amounts of particulate without needing to shut down for cleaning. Look for models with features such as high-efficiency filter media and automated cleaning mechanisms to enhance performance. Brands like Donaldson and Nederman MikroPul offer advanced technologies that can significantly reduce emissions and maintenance costs, making them suitable for industries with rigorous dust control needs. -

How can I ensure compliance with international dust collection regulations?

To ensure compliance with international dust collection regulations, familiarize yourself with the specific standards applicable in your region. This often includes limits on emissions and requirements for regular maintenance and monitoring. Partnering with suppliers who provide equipment compliant with local regulations can simplify this process. Additionally, request documentation and certifications from manufacturers that demonstrate their products meet relevant environmental standards to facilitate smoother customs clearance and regulatory compliance. -

What customization options are available for pulse dust collectors?

Many manufacturers offer customization options for pulse dust collectors to meet specific operational requirements. This can include modifications in size, filter media, and the type of cleaning mechanism employed. You may also request enhancements such as integrated monitoring systems or specialized hoppers for different types of dust. When discussing customization, communicate your operational needs clearly to your supplier, and inquire about the implications on lead times and costs. -

What should I consider when vetting suppliers for pulse dust collectors?

When vetting suppliers for pulse dust collectors, consider their industry reputation, experience, and product quality. Look for customer reviews and case studies to gauge performance and reliability. Additionally, assess their ability to provide after-sales support and maintenance services. It’s also wise to request product samples or demonstrations to evaluate the equipment firsthand. Finally, ensure that they have the capability to meet your specific needs, including compliance with local regulations and customization options. -

What are the typical minimum order quantities (MOQ) for pulse dust collectors?

Minimum order quantities (MOQ) for pulse dust collectors can vary significantly depending on the supplier and the complexity of the system. Some manufacturers may require a minimum purchase for certain models, while others may offer flexibility for smaller operations. It’s advisable to discuss your needs upfront with potential suppliers to understand their MOQ policies. Additionally, inquire whether they offer financing options or leasing arrangements for smaller businesses that may not meet standard MOQ requirements. -

What payment terms are commonly offered for international B2B transactions?

Payment terms for international B2B transactions can vary widely among suppliers. Common options include upfront payments, partial payments upon order confirmation, and balance upon delivery. Some suppliers may offer credit terms or financing options for established clients. It’s crucial to clarify payment terms before finalizing an order to ensure they align with your cash flow requirements. Additionally, consider the impact of currency exchange rates and transaction fees on your overall costs. -

How do I manage logistics and shipping for pulse dust collectors?

Managing logistics and shipping for pulse dust collectors involves coordinating with your supplier to determine the best shipping method and timeline. Discuss options such as air freight for urgent needs or sea freight for cost-effective solutions. Ensure that your supplier provides necessary documentation, including commercial invoices and packing lists, to facilitate customs clearance. Additionally, consider working with a logistics partner experienced in international shipping to navigate potential challenges, including import duties and local regulations in your country.

Top 4 Pulse Dust Collector Manufacturers & Suppliers List

1. Donaldson – FT Pulse Jet Baghouse Dust Collector

Domain: donaldson.com

Registered: 1995 (30 years)

Introduction: FT Pulse Jet Baghouse Dust Collector offers easy and dependable operation for high-volume dust collection applications. Key features include: 1. Dura-Life® Filter Bags – Twice the life over standard polyester bags, engineered with a unique hydroentanglement process for better pulse cleaning and longer bag life. 2. Ultra-Web SB Pleated Bags – Provide longer life, reduced emissions, and energy savin…

2. Nederman MikroPul – Pulse Jet Dust Collectors

Domain: nedermanmikropul.com

Registered: 2015 (10 years)

Introduction: Nederman MikroPul Pulse Jet Dust Collectors are designed for applications where it is impractical to shut down the dust collector for bag cleaning. They utilize a pulse of compressed air to clean the bags, maintaining optimal filtration efficiency. Key product details include:

– Fully assembled Mikro-Pulsaire™ pulse jet dust collectors suitable for filter media areas between 151 – 8,246 ft² (14 m…

3. Ametek – NCC Dust Collector Controls

Domain: store.ametekiscd.com

Registered: 2009 (16 years)

Introduction: {“product_name”: “NCC Dust Collector Controls”, “input_type”: “AC Input”, “function”: “Pulse Cleaning of Bag House Dust Collector”, “outputs”: 20, “SKU”: “DNC-T2020-R20”, “features”: {“universal_voltage_input”: “95 to 265 VAC 50/60 Hz”, “technology”: “Advanced surface mount component technology”, “circuitry”: “Digital microprocessor-controlled”, “memory”: “Non-volatile memory”, “display”: “3-digit…

4. Gulf Atlantic – Belgrade 330 Pulse Jet Silo Top Dust Collector

Domain: gulfatlanticequipment.com

Registered: 2001 (24 years)

Introduction: {“model”:”Belgrade 330 Pulse Jet Silo Top Dust Collector”,”total_filtration_area_sq_ft”:330,”air_to_cloth_ratio”:4.8,”pressure_drop_inches”:6,”air_capacity”:1600,”outlet_area_sq_ft”:0.83,”cleaning_method”:”pulse jet”,”inlet_dust_concentration_gr_cu”:15,”outlet_emissions_gr_min”:2.5,”outlet_dust_loading_gr_cu”:0.0015,”air_consumption_CFM”:8,”solenoids”:”board”}

Strategic Sourcing Conclusion and Outlook for pulse dust collector

In the realm of industrial dust management, pulse jet dust collectors represent a pivotal investment for businesses aiming to enhance operational efficiency and ensure compliance with environmental standards. By leveraging advanced technologies such as Dura-Life® filter bags and Ultra-Web® SB pleated filters, companies can achieve longer filter life, reduced maintenance costs, and lower emissions. This translates to significant savings and improved sustainability, aligning with the global push for eco-friendly practices.

Strategic sourcing of pulse jet dust collectors is not merely a procurement decision; it is a comprehensive approach that emphasizes long-term partnerships with reputable manufacturers. Engaging with suppliers who offer remote monitoring and operational insights, like Donaldson’s Industrial Filtration Services, empowers businesses to minimize downtime and optimize maintenance schedules.

As international markets continue to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, it is crucial for B2B buyers to stay ahead of technological advancements and regulatory requirements. By investing in state-of-the-art pulse jet dust collection solutions, companies can position themselves for future growth and resilience. We encourage you to explore partnerships with leading manufacturers to secure the best solutions for your dust management needs, ensuring your operations remain efficient, compliant, and sustainable.

Illustrative image related to pulse dust collector

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to pulse dust collector