How to Source Proportional Solenoid Valve Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for proportional solenoid valve

In today’s rapidly evolving industrial landscape, sourcing proportional solenoid valves presents a unique set of challenges for B2B buyers, especially those operating across diverse markets in Africa, South America, the Middle East, and Europe. These critical components, essential for precise fluid control in various applications, require careful consideration of factors such as performance, reliability, and compliance with regional standards. This guide is designed to empower international buyers by offering a comprehensive overview of proportional solenoid valves, covering the various types available, their specific applications in industries like HVAC, food and beverage automation, and medical technology, and strategies for effective supplier vetting.

As global markets become increasingly interconnected, understanding the nuances of sourcing these valves becomes vital. This guide not only addresses cost considerations and pricing structures but also highlights the importance of selecting suppliers who can meet stringent quality and service expectations. By equipping buyers with the knowledge needed to make informed decisions, we aim to streamline the procurement process and enhance operational efficiency. Whether you are looking to optimize your supply chain or ensure compliance with local regulations, this resource serves as your roadmap to successfully navigating the global market for proportional solenoid valves.

Understanding proportional solenoid valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Direct-Acting Proportional Valve | Operates directly with electrical input, offering quick response times and compact design. | Medical devices, HVAC systems, and food processing. | Pros: High accuracy and fast response. Cons: Limited flow capacity compared to larger types. |

| Pilot-Operated Proportional Valve | Utilizes a pilot signal to control larger flows, providing greater versatility and capacity. | Heavy machinery, automotive applications, and industrial automation. | Pros: Handles high flow rates. Cons: More complex and may require additional maintenance. |

| Pressure-Compensated Proportional Valve | Maintains consistent flow despite pressure variations, ensuring stable operation. | Chemical processing, water treatment, and oil & gas industries. | Pros: Reliable under fluctuating conditions. Cons: Higher cost due to advanced technology. |

| Servo Proportional Valve | Incorporates feedback mechanisms for precise control of position and flow. | Robotics, aerospace, and advanced manufacturing. | Pros: Exceptional precision and control. Cons: Complexity may lead to higher installation costs. |

| Low-Power Proportional Valve | Designed for energy efficiency, operating on lower power inputs while maintaining performance. | Portable medical devices, renewable energy systems. | Pros: Energy savings and compact design. Cons: Potentially lower output capacity. |

What Are the Characteristics of Direct-Acting Proportional Valves?

Direct-acting proportional valves are known for their straightforward operation, where the valve directly responds to electrical signals to adjust fluid flow. These valves are compact and suitable for applications requiring quick response times, such as in medical devices and HVAC systems. When purchasing, consider the specific flow capacity and response time needed for your application, as these valves may not handle larger flow rates effectively.

How Do Pilot-Operated Proportional Valves Function?

Pilot-operated proportional valves utilize a smaller pilot signal to manage larger flow rates, making them ideal for heavy-duty applications in industrial automation and automotive sectors. They offer greater versatility and can control substantial fluid flows, but their complexity may lead to additional maintenance requirements. Buyers should evaluate the balance between the required flow capacity and the complexity of installation and upkeep.

What Advantages Do Pressure-Compensated Proportional Valves Offer?

Pressure-compensated proportional valves are engineered to maintain consistent flow rates despite changes in pressure, making them essential in industries like chemical processing and oil & gas. Their ability to provide stable operation under varying conditions is a significant advantage. However, the advanced technology involved may increase initial costs, so buyers should assess the long-term benefits against the upfront investment.

Why Choose Servo Proportional Valves for Precision Control?

Servo proportional valves are equipped with feedback systems that ensure precise control over fluid flow and position, making them suitable for high-tech applications like robotics and aerospace. While they deliver exceptional accuracy, their complexity can lead to higher installation and maintenance costs. B2B buyers should consider the critical nature of precision in their applications when investing in these systems.

How Do Low-Power Proportional Valves Enhance Energy Efficiency?

Low-power proportional valves are designed for energy efficiency, operating effectively at reduced power inputs. They are ideal for portable applications such as medical devices and renewable energy systems. Although they provide energy savings and are typically compact, their output capacity may be lower than other types. Buyers should weigh the benefits of energy efficiency against the potential limitations in flow capacity for their specific needs.

Illustrative image related to proportional solenoid valve

Key Industrial Applications of proportional solenoid valve

| Industry/Sector | Specific Application of Proportional Solenoid Valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Devices | Flow control in infusion pumps | Ensures precise medication delivery, enhancing patient safety | Compliance with medical standards and certifications |

| Food & Beverage Automation | Ingredient dosing in processing lines | Increases efficiency and accuracy in production processes | Food-grade materials and hygiene compliance |

| HVAC Systems | Temperature regulation in climate control systems | Optimizes energy usage and improves comfort for users | Energy efficiency ratings and compatibility with existing systems |

| Life Sciences | Fluid handling in laboratory equipment | Facilitates accurate experiments and research outcomes | Reliability and precision in fluid dynamics |

| Agriculture | Irrigation control in precision farming | Enhances crop yields and conserves water resources | Adaptability to different environmental conditions |

How are Proportional Solenoid Valves Used in Medical Devices?

In the medical sector, proportional solenoid valves are integral to the operation of infusion pumps, which require precise control of fluid flow to deliver medication accurately. These valves respond dynamically to electrical signals, allowing for variable flow rates that are crucial in patient care. For international buyers, particularly from regions like Africa and the Middle East, ensuring compliance with stringent medical regulations and certifications is essential. Additionally, sourcing valves that can withstand the rigorous demands of healthcare environments is critical for maintaining operational integrity.

What Role Do Proportional Solenoid Valves Play in Food & Beverage Automation?

In food and beverage processing, proportional solenoid valves manage the dosing of ingredients with high accuracy. This capability enhances production efficiency and ensures consistency in product quality. Buyers in this sector, especially in South America and Europe, must consider valves made from food-grade materials that comply with hygiene standards to prevent contamination. Understanding local regulations and certifications can also facilitate smoother operations and market entry.

How Are Proportional Solenoid Valves Utilized in HVAC Systems?

Proportional solenoid valves are vital in HVAC systems for regulating temperature and airflow. By modulating the flow of refrigerants or air based on real-time data, these valves help optimize energy consumption and enhance user comfort. B2B buyers in Europe and the Middle East should prioritize valves that offer high energy efficiency ratings and are compatible with existing HVAC infrastructure. This ensures seamless integration and long-term performance stability.

What Is the Application of Proportional Solenoid Valves in Life Sciences?

In the life sciences field, proportional solenoid valves are used extensively in laboratory equipment for precise fluid handling. These valves allow for controlled dispensing of reagents and samples, which is critical for research accuracy. International buyers, particularly in Africa and South America, need to focus on sourcing valves that provide high reliability and precision to support experimental integrity. Additionally, the ability to adapt to various laboratory conditions is a significant consideration.

How Do Proportional Solenoid Valves Enhance Agricultural Practices?

In agriculture, proportional solenoid valves are employed in precision irrigation systems to control water flow effectively. This technology enables farmers to optimize water usage, leading to improved crop yields and sustainability. For buyers in regions like Africa, where water scarcity is a concern, sourcing adaptable valves that can operate under diverse environmental conditions is essential. Understanding the local agricultural practices and regulations can also guide effective procurement strategies.

3 Common User Pain Points for ‘proportional solenoid valve’ & Their Solutions

Scenario 1: Difficulty Achieving Precise Flow Control in Applications

The Problem: One of the most common challenges faced by B2B buyers in sectors such as food and beverage, HVAC, and medical device manufacturing is achieving precise flow control. In these industries, a slight deviation in flow rate can lead to significant quality issues, production downtime, or even safety hazards. Buyers often find that standard solenoid valves cannot accommodate the dynamic changes in pressure and flow that their applications require, resulting in inconsistent performance and potential financial losses.

The Solution: To overcome this challenge, buyers should consider investing in high-performance proportional solenoid valves designed for precision control. When sourcing these valves, it is crucial to specify the required flow rate, pressure range, and response time based on the application’s unique demands. Additionally, integrating advanced control systems that allow for real-time monitoring and adjustments can significantly enhance performance. Collaborating with manufacturers who offer customization options will ensure that the selected valve meets specific operational needs, facilitating smooth and consistent flow control.

Scenario 2: Frequent Valve Failures Due to Environmental Conditions

The Problem: In many regions, particularly in Africa and South America, extreme environmental conditions can lead to frequent valve failures, causing unexpected downtime and costly repairs. Buyers often struggle with valves that are not adequately rated for temperature, humidity, or corrosive substances present in their operating environments. This leads to increased maintenance costs and can disrupt production schedules.

The Solution: To mitigate this issue, it is essential for buyers to thoroughly assess the environmental conditions where the proportional solenoid valves will be installed. Selecting valves made from robust materials that are resistant to corrosion and suitable for high or low-temperature applications is vital. Buyers should also consult with suppliers about the availability of valves with IP ratings that guarantee protection against dust and moisture ingress. Utilizing protective enclosures or climate control systems can further enhance the longevity of the valves, ensuring consistent operation under harsh conditions.

Scenario 3: Complexity in Integration with Existing Systems

The Problem: Many B2B buyers face integration challenges when attempting to incorporate new proportional solenoid valves into existing automation systems. The complexity of interfacing these valves with current control systems often leads to compatibility issues, resulting in inefficient operation and increased installation costs. This can be particularly frustrating for buyers in industries that rely on precise automation, such as automotive and pharmaceuticals.

The Solution: To streamline the integration process, buyers should prioritize proportional solenoid valves that are compatible with industry-standard communication protocols, such as CANbus, Modbus, or Ethernet/IP. Engaging with suppliers who offer comprehensive technical support during the installation phase can provide valuable insights into overcoming compatibility hurdles. Additionally, investing in modular solutions or valve kits that come with onboard drivers can simplify the installation process, reducing the need for extensive rewiring or system modifications. Providing your engineering team with detailed specifications and guidelines from the manufacturer will also facilitate a smoother integration process, ultimately enhancing operational efficiency.

By addressing these common pain points with targeted solutions, B2B buyers can make informed decisions that enhance the performance and reliability of proportional solenoid valves in their operations.

Strategic Material Selection Guide for proportional solenoid valve

What Materials Are Commonly Used in Proportional Solenoid Valves?

Proportional solenoid valves are critical components in various industrial applications, and selecting the right material is essential for optimal performance. Below, we analyze several common materials used in the construction of these valves, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Do Brass and Bronze Compare for Proportional Solenoid Valves?

Brass is a popular choice for proportional solenoid valves due to its excellent machinability and corrosion resistance. It typically has a temperature rating of up to 200°C and can withstand moderate pressures. Bronze, a copper alloy with tin or aluminum, offers similar properties but with improved corrosion resistance, particularly in marine environments.

Pros of brass include its cost-effectiveness and ease of manufacturing, making it suitable for high-volume applications. However, it is less durable than some alternatives, especially under extreme conditions. Bronze, while more durable, often comes at a higher cost and can complicate manufacturing processes due to its hardness.

For applications involving water, air, or mild chemicals, brass and bronze are effective. However, buyers must consider local regulations regarding material compliance, particularly in regions like Europe, where standards such as ASTM and DIN are strictly enforced.

What Role Does Stainless Steel Play in Proportional Solenoid Valve Applications?

Stainless Steel is favored for its superior strength, durability, and corrosion resistance, making it ideal for harsh environments. It can withstand high temperatures (up to 400°C) and pressures, making it suitable for demanding applications in industries like oil and gas.

The key advantage of stainless steel is its longevity and reliability, which can reduce maintenance costs over time. However, it is more expensive than brass or bronze, and its manufacturing complexity can lead to higher initial costs.

For applications involving aggressive chemicals or high-pressure systems, stainless steel is often the best choice. Buyers in regions like the Middle East, where oil and gas applications are prevalent, should ensure compliance with relevant standards to avoid costly downtimes.

How Does Plastic Material Impact Proportional Solenoid Valve Performance?

Plastics, such as polyamide (nylon) and polyvinyl chloride (PVC), are increasingly used in proportional solenoid valves, especially for lightweight applications. These materials are resistant to corrosion and can handle moderate pressure and temperature ranges (typically up to 80°C).

The advantage of using plastics is their low cost and lightweight nature, which can simplify installation and reduce shipping costs. However, they are less durable than metals and may not perform well in high-temperature or high-pressure environments.

Plastics are suitable for applications involving water, air, and some chemicals. However, international buyers should be cautious of the material’s compatibility with specific media and ensure compliance with local regulations, especially in regions with stringent environmental standards.

What Are the Benefits of Using Aluminum in Proportional Solenoid Valves?

Aluminum is another material option for proportional solenoid valves, known for its lightweight and good corrosion resistance. It can typically handle temperatures up to 150°C and moderate pressures.

The key advantage of aluminum is its balance of weight, strength, and cost, making it an attractive option for applications requiring lightweight components without sacrificing performance. However, it is less robust than stainless steel and may not be suitable for aggressive media.

Aluminum is ideal for applications in automotive and HVAC systems. Buyers should consider the specific requirements of their applications and ensure that the aluminum used complies with international standards, particularly in regions like Africa and South America, where local sourcing may be a factor.

Summary Table of Material Selection for Proportional Solenoid Valves

| Material | Typical Use Case for proportional solenoid valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Water, air, mild chemicals | Cost-effective, easy to manufacture | Less durable under extreme conditions | Low |

| Bronze | Marine applications, mild chemicals | Excellent corrosion resistance | Higher cost, complex manufacturing | Med |

| Stainless Steel | Oil and gas, high-pressure systems | Superior strength and longevity | Higher cost, complex manufacturing | High |

| Plastic | Lightweight applications, water, air | Low cost, lightweight | Less durable, limited temperature range | Low |

| Aluminum | Automotive, HVAC systems | Balance of weight, strength, and cost | Less robust than stainless steel | Med |

Selecting the right material for proportional solenoid valves is crucial for ensuring optimal performance and compliance with industry standards. International buyers should carefully consider their specific application requirements and regional regulations when making material choices.

In-depth Look: Manufacturing Processes and Quality Assurance for proportional solenoid valve

What Are the Main Stages of Manufacturing Proportional Solenoid Valves?

The manufacturing process for proportional solenoid valves involves several critical stages, each essential for ensuring the final product meets performance and quality standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The manufacturing journey begins with the selection of high-quality materials, typically including various metals and polymers that can withstand the operational demands of the valve. Common materials include brass, stainless steel, and specialized plastics. The materials are sourced from certified suppliers to ensure compliance with industry standards.

-

Forming: The next stage is forming, where raw materials are shaped into the necessary components. Techniques such as machining, die-casting, and injection molding are commonly used. CNC machining is particularly prevalent due to its precision, allowing for the accurate production of intricate parts like the solenoid coil and valve body.

-

Assembly: After forming, components are assembled. This stage often involves the use of automated assembly lines that enhance efficiency and consistency. Skilled technicians may also perform manual assembly for complex parts, ensuring each component fits perfectly and operates as intended. The assembly process also includes the installation of electronic components, such as sensors and controllers, which are integral for proportional control functionality.

-

Finishing: The final stage is finishing, which involves surface treatments and coatings to enhance durability and corrosion resistance. This may include processes such as anodizing, plating, or painting. Finishing not only improves the aesthetic appeal but also protects the valve from environmental factors, extending its lifespan.

How Is Quality Assurance Implemented in Proportional Solenoid Valve Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of proportional solenoid valves to ensure they perform reliably and meet safety standards. Various international and industry-specific standards guide QA processes.

-

Relevant International Standards: Compliance with ISO 9001 is a fundamental requirement for manufacturers. This standard focuses on quality management systems and requires organizations to demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Additionally, certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for the oil and gas sector are crucial for validating product quality and safety.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon receipt to ensure they meet specified quality criteria.

– In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor processes and detect any deviations from standards. This may include measuring dimensions, checking assembly accuracy, and testing electronic components.

– Final Quality Control (FQC): The final inspection verifies that the completed valves meet all specifications and performance criteria before they are shipped. This includes functional testing under various operational conditions. -

Common Testing Methods: Various testing methods are employed to validate performance and safety, including:

– Pressure Testing: Ensuring the valve can withstand specified pressure levels without leakage.

– Electrical Testing: Verifying the functionality of electronic components and ensuring they respond accurately to input signals.

– Flow Testing: Assessing the flow rate and response time to ensure the valve meets operational specifications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability and compliance with local regulations.

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. Buyers should look for evidence of compliance with international standards and the presence of a robust quality management system.

-

Quality Control Reports: Requesting detailed quality control reports can help buyers assess the effectiveness of a supplier’s QA processes. These reports should include information on testing results, compliance with standards, and any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s manufacturing and quality assurance processes. These agencies can conduct audits, witness testing, and verify compliance with international standards, offering additional peace of mind to buyers.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers must navigate various quality control and certification nuances when sourcing proportional solenoid valves from global suppliers.

-

Regional Standards and Compliance: Different regions have specific standards that may impact product certification. For example, products sold in Europe must comply with CE marking requirements, while those in the U.S. may need to adhere to ANSI (American National Standards Institute) standards. Understanding these regional requirements is critical for international buyers.

-

Language and Documentation: Quality control documentation may be available in different languages, depending on the supplier’s location. Buyers should ensure that they can understand all technical specifications, test results, and compliance certifications.

-

Cultural Considerations: Engaging with suppliers from diverse cultures may require sensitivity to different business practices and communication styles. Building strong relationships and clear communication can aid in ensuring that quality expectations are met.

In conclusion, the manufacturing processes and quality assurance practices for proportional solenoid valves are intricate and essential for product reliability and performance. By understanding these processes and verification methods, B2B buyers can make informed decisions, ensuring they partner with suppliers who uphold the highest standards of quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘proportional solenoid valve’

To streamline the procurement process of proportional solenoid valves, this guide serves as a comprehensive checklist for B2B buyers. By following these steps, you can ensure that you select a product that meets your operational needs while also fostering a fruitful supplier relationship.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it’s vital to clearly outline your technical requirements. Consider factors such as pressure range, flow rate, and the type of fluid (liquid or gas) involved in your application. This precision will help you filter potential products effectively and ensure compatibility with your existing systems.

- Key considerations:

- Maximum and minimum pressure ratings.

- Required flow characteristics (e.g., dynamic response, precision).

- Compatibility with specific media (e.g., aggressive chemicals, temperature constraints).

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to identify potential suppliers with a solid track record in manufacturing proportional solenoid valves. Look for companies with industry certifications, positive customer reviews, and a portfolio of successful projects in your sector.

- Where to find suppliers:

- Industry-specific trade shows and exhibitions.

- Online marketplaces and B2B platforms.

- Professional networks and associations.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. A well-established supplier should be willing to share relevant information to build trust.

- Checklist for evaluation:

- Review their certifications (ISO, CE, etc.).

- Assess their manufacturing capabilities and technology.

- Understand their customer service and support structure.

Step 4: Request Product Samples

Once you have shortlisted suppliers, request samples of the proportional solenoid valves you are considering. Testing samples in your application environment allows you to evaluate performance, reliability, and overall fit.

- Testing criteria:

- Assess responsiveness to control signals.

- Check for leaks and material integrity under operational conditions.

- Evaluate ease of installation and maintenance.

Step 5: Review Pricing and Terms of Sale

After evaluating product samples, compare the pricing structures of your shortlisted suppliers. Beyond the base price, consider additional costs such as shipping, taxes, and potential duties. Ensure the terms of sale align with your purchasing policies.

- Important aspects to clarify:

- Bulk order discounts and payment terms.

- Warranty, return policy, and after-sales support.

- Lead times for delivery and availability of replacement parts.

Step 6: Assess After-Sales Support and Service

A strong after-sales support system can significantly enhance the value of your purchase. Ensure that the supplier provides adequate technical support, training, and maintenance services, which are essential for optimal valve performance.

- Support services to inquire about:

- Availability of technical assistance and troubleshooting.

- Training programs for your team.

- Access to spare parts and service agreements.

Step 7: Finalize the Purchase Agreement

Once you have evaluated all factors, finalize the purchase agreement with your chosen supplier. Ensure that all negotiated terms are documented, including pricing, delivery schedules, and warranty provisions.

- Key elements to include:

- Detailed product specifications and quantities.

- Shipping and delivery timelines.

- Any agreed-upon service or maintenance clauses.

By following these steps, you can confidently navigate the sourcing process for proportional solenoid valves, ensuring that you select the right product and supplier for your specific needs.

Comprehensive Cost and Pricing Analysis for proportional solenoid valve Sourcing

What Are the Key Cost Components of Proportional Solenoid Valves?

The cost structure for proportional solenoid valves encompasses various components that significantly influence pricing. Understanding these elements is crucial for international B2B buyers looking to make informed purchasing decisions.

-

Materials: The choice of materials used in manufacturing solenoid valves directly impacts the cost. High-performance materials, such as stainless steel or specialized polymers, can enhance durability and functionality but may also increase expenses. Buyers should consider the application’s specific requirements when evaluating material options.

-

Labor: Labor costs can vary based on geographic location and the complexity of the manufacturing process. Regions with higher labor costs may result in higher prices for solenoid valves. However, investing in skilled labor can lead to better quality products, which may justify the increased expense.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, depreciation, and facility maintenance. Understanding these costs helps buyers gauge the overall pricing strategy of suppliers.

-

Tooling: Tooling costs refer to the expense of creating the molds and fixtures necessary for manufacturing. Custom tooling can be significant for specialized valve designs, impacting the price, especially for low-volume orders.

-

Quality Control (QC): Rigorous QC processes ensure that solenoid valves meet industry standards and specifications. While enhanced QC measures may increase costs, they also mitigate the risk of defects, providing long-term cost savings through reduced warranty claims and improved reliability.

-

Logistics: Shipping costs, including freight and insurance, can vary widely based on the geographical distance from the supplier and the chosen Incoterms. For international buyers, understanding these logistics costs is essential for accurate budgeting.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary based on market demand, competition, and the supplier’s positioning strategy.

What Influences the Pricing of Proportional Solenoid Valves?

Several factors can affect the pricing of proportional solenoid valves, especially in a global market:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly influence pricing. Larger orders often lead to lower per-unit costs, making it advantageous for buyers to consolidate purchases when possible.

-

Specifications and Customization: Custom features or specifications can drive up costs. Buyers should clearly define their requirements to avoid unnecessary expenses associated with modifications.

-

Materials and Quality Certifications: Premium materials and certifications (e.g., ISO, FDA) can enhance product reliability but will also increase costs. Buyers in regulated industries, such as medical or food and beverage, should prioritize quality certifications to ensure compliance.

-

Supplier Factors: The reputation and reliability of suppliers play a crucial role in pricing. Established suppliers with a track record of quality may charge more, but they often provide better service and support.

-

Incoterms: The terms of shipping and delivery can affect the overall cost. Understanding Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is vital for evaluating total landed costs.

How Can Buyers Negotiate for Better Pricing on Proportional Solenoid Valves?

-

Leverage Volume Discounts: Buyers should explore the possibility of negotiating for bulk pricing. Even small increases in order size can lead to significant savings.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial purchase prices, consider long-term costs, including maintenance, operational efficiency, and warranty claims. Opting for higher-quality valves may result in lower TCO.

-

Understand Market Trends: Keeping abreast of market conditions can provide leverage during negotiations. Awareness of supply chain disruptions or material shortages can help buyers negotiate more effectively.

-

Build Relationships with Suppliers: Developing strong relationships with suppliers can lead to better pricing and service. Frequent communication and feedback can foster trust, which may result in more favorable terms.

-

Be Prepared to Walk Away: If the pricing does not meet budgetary constraints, buyers should be prepared to seek alternative suppliers. This approach not only strengthens negotiation power but also encourages suppliers to offer competitive pricing.

Conclusion

In summary, a thorough understanding of the cost components, pricing influencers, and negotiation strategies is essential for international B2B buyers sourcing proportional solenoid valves. By carefully analyzing these factors, buyers can make informed decisions that align with their operational needs and budgetary constraints.

Alternatives Analysis: Comparing proportional solenoid valve With Other Solutions

Introduction to Alternative Solutions for Fluid Control

In the realm of fluid control systems, proportional solenoid valves are widely recognized for their ability to manage variable fluid flows based on electrical input. However, businesses seeking efficiency and effectiveness must consider various alternatives that may offer specific advantages tailored to their operational needs. The choice of fluid control solution can significantly impact performance, cost-efficiency, and overall system reliability. This analysis compares proportional solenoid valves with two viable alternatives: servo valves and motorized ball valves.

Comparison Table

| Comparison Aspect | Proportional Solenoid Valve | Servo Valve | Motorized Ball Valve |

|---|---|---|---|

| Performance | High responsiveness for flow control | Excellent precision and control | Good for on/off control, limited flow modulation |

| Cost | Moderate initial investment | Higher initial investment | Lower initial investment |

| Ease of Implementation | Requires electrical setup | Complex installation and tuning | Simple installation |

| Maintenance | Moderate; regular checks needed | Higher due to complexity | Low; fewer moving parts |

| Best Use Case | Medical devices, HVAC, automation | Aerospace, robotics | Water treatment, irrigation |

Detailed Breakdown of Alternatives

Servo Valve

Servo valves are known for their high precision and dynamic control capabilities. They utilize feedback systems to adjust the flow rate accurately, making them ideal for applications requiring fine-tuned control, such as in aerospace and robotics. However, the complexity of installation and the need for regular calibration can lead to higher maintenance costs. Additionally, their initial investment is generally higher than that of proportional solenoid valves, which may be a barrier for some businesses.

Motorized Ball Valve

Motorized ball valves provide a straightforward solution for applications requiring simple on/off control. They are typically less expensive than proportional solenoid valves and have fewer moving parts, resulting in lower maintenance requirements. However, their functionality is limited when it comes to flow modulation, making them less suitable for applications that demand variable flow rates. They are best suited for systems like water treatment and irrigation where full flow or complete closure is sufficient.

Illustrative image related to proportional solenoid valve

Conclusion: How to Choose the Right Fluid Control Solution

Selecting the right fluid control solution depends on a variety of factors, including application requirements, budget constraints, and maintenance capabilities. Proportional solenoid valves excel in environments that demand precise flow control and responsiveness, making them suitable for high-tech industries like healthcare and HVAC. In contrast, servo valves may be the best option for applications that prioritize precision and dynamic performance despite their higher costs and complexity. For simpler applications requiring basic flow management, motorized ball valves could be the most cost-effective solution. By carefully evaluating these aspects, B2B buyers can make informed decisions that align with their operational needs and financial considerations.

Essential Technical Properties and Trade Terminology for proportional solenoid valve

What Are the Key Technical Properties of Proportional Solenoid Valves?

Proportional solenoid valves are crucial components in various industrial applications, from medical devices to HVAC systems. Understanding their essential technical properties can significantly impact operational efficiency and performance. Here are some critical specifications to consider:

-

Material Grade

The material used in the construction of proportional solenoid valves is vital for ensuring durability and resistance to corrosion. Common materials include stainless steel, brass, and various plastics. Selecting the right material can enhance the valve’s lifespan, particularly in harsh environments, which is essential for minimizing maintenance costs and downtime. -

Flow Rate

Flow rate, typically measured in liters per minute (L/min), indicates the volume of fluid the valve can handle. This specification is crucial for ensuring that the valve meets the requirements of specific applications, such as precise fluid control in automation systems. An inadequate flow rate can lead to inefficiencies or system failures, making this a critical parameter for B2B buyers. -

Pressure Rating

The pressure rating defines the maximum pressure the valve can withstand without failure. This is usually specified in bar or psi. Understanding the pressure requirements of your application ensures that the selected valve can operate safely under expected conditions, thus avoiding potential leaks or catastrophic failures. -

Electrical Input Signal

Proportional solenoid valves operate based on electrical input signals, often in the form of a voltage or current. Common input signals include 4-20 mA or 0-10 V. Knowing the required input signal helps buyers select compatible control systems, ensuring smooth integration into existing setups. -

Tolerance and Hysteresis

Tolerance refers to the allowable deviation in the valve’s performance, while hysteresis is the difference in response for increasing and decreasing signals. Both specifications are essential for applications requiring high precision, as they affect the valve’s ability to maintain consistent performance. Understanding these factors can help in choosing a valve that meets stringent operational standards.

What Are Common Trade Terms Related to Proportional Solenoid Valves?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms related to proportional solenoid valves:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of proportional solenoid valves, OEMs often provide specialized components designed for specific applications, making it crucial for buyers to verify compatibility with their systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for budgeting and inventory management, particularly for companies that may not require large quantities at once. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For B2B buyers, issuing an RFQ can be an effective way to compare costs and terms among multiple suppliers, ensuring competitive pricing and favorable terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps in clarifying logistics, payment, and risk management, which is crucial for international B2B transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. This term is critical for planning production schedules and ensuring timely project completion, particularly in industries where delays can have significant repercussions. -

Pilot Operated

This term describes a type of valve that uses a small pilot signal to control a larger flow of fluid. Understanding whether a valve is pilot operated can help buyers choose the right type of valve for their specific control needs, particularly in applications requiring high flow rates without large actuators.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the proportional solenoid valve Sector

What Are the Current Market Dynamics and Key Trends Affecting Proportional Solenoid Valves?

The proportional solenoid valve market is witnessing substantial growth driven by advancements in automation and control systems across various industries. Key sectors such as medical technology, HVAC, and food and beverage are increasingly adopting these valves for their precision in regulating fluid flow based on electrical input signals. International B2B buyers, especially from emerging markets in Africa, South America, and the Middle East, are focusing on acquiring technologically advanced solutions that enhance efficiency and reduce operational costs.

Emerging trends include the integration of IoT and smart technology in valve systems, allowing for real-time monitoring and data collection. This shift not only improves operational efficiency but also facilitates predictive maintenance, reducing downtime and maintenance costs. Additionally, manufacturers are increasingly offering customized solutions tailored to specific industry needs, which is becoming a critical factor for B2B buyers looking to optimize their processes.

Sourcing strategies are evolving as buyers seek suppliers with robust technological capabilities and a proven track record in delivering high-quality products. Partnerships with manufacturers who emphasize innovation and reliability can significantly impact operational performance. Buyers should also consider the geographical location of suppliers to mitigate logistics challenges, particularly in regions like Nigeria and Saudi Arabia, where supply chain reliability is crucial.

How Is Sustainability Influencing Sourcing Decisions for Proportional Solenoid Valves?

Sustainability is increasingly shaping sourcing decisions in the proportional solenoid valve sector. B2B buyers are becoming more aware of the environmental impact of their procurement choices, driving a demand for products that adhere to sustainability standards. This includes the use of eco-friendly materials and manufacturing processes that minimize waste and energy consumption.

Ethical sourcing has emerged as a critical factor, with buyers prioritizing suppliers who demonstrate a commitment to responsible practices. Certifications such as ISO 14001 for environmental management and RoHS for hazardous substances are becoming essential for manufacturers aiming to establish credibility in the market. Buyers are encouraged to engage with suppliers who can provide transparency in their supply chains, ensuring that every component of the solenoid valve is sourced sustainably.

Moreover, the growing trend towards circular economy practices is prompting manufacturers to develop valves that can be easily recycled or reconditioned. This not only reduces the environmental footprint but also aligns with the corporate social responsibility goals of many international businesses. As such, B2B buyers should evaluate the sustainability credentials of potential suppliers as part of their sourcing strategy.

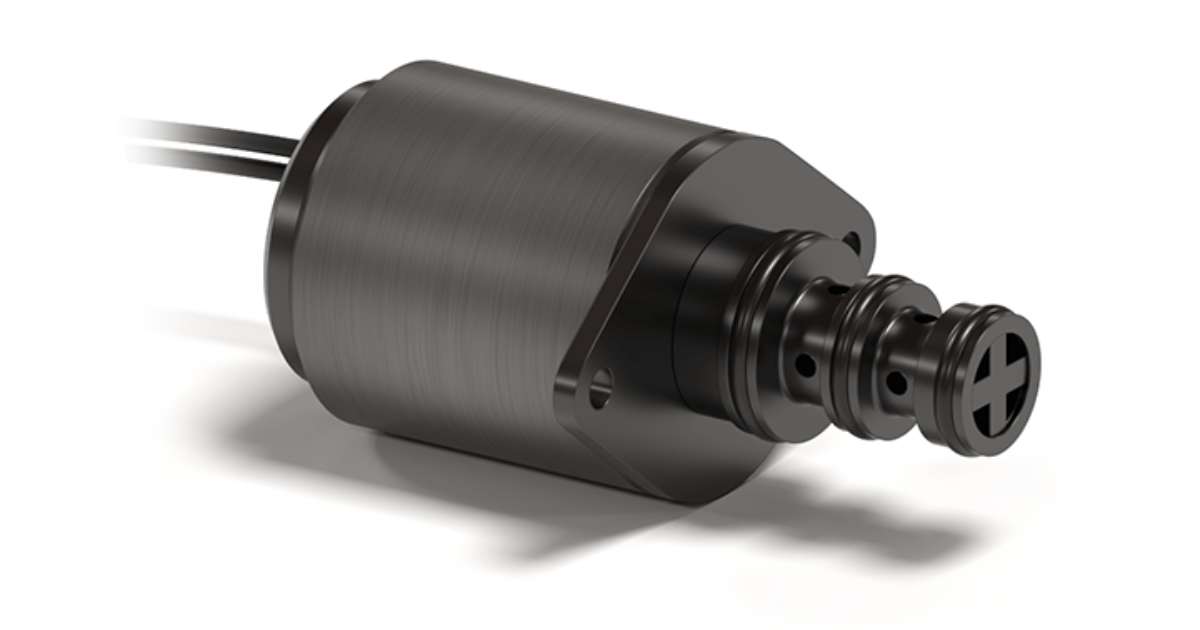

Illustrative image related to proportional solenoid valve

What Is the Evolution of Proportional Solenoid Valves and Its Relevance Today?

The evolution of proportional solenoid valves can be traced back to the early 20th century when basic solenoid technology was first developed. Over the decades, these valves have transformed significantly, integrating advancements in materials science, electronics, and automation technologies. Initially used in simple on-off applications, modern proportional solenoid valves now offer precise control over flow and pressure, enabling complex automation processes in various industries.

Today, their relevance is underscored by the shift towards automation and smart technologies, with proportional solenoid valves playing a crucial role in applications requiring precise fluid control. This evolution not only enhances operational efficiencies but also meets the demands of increasingly stringent regulatory requirements across industries. For B2B buyers, understanding this historical context is essential in recognizing the value that modern proportional solenoid valves bring to their operations.

Frequently Asked Questions (FAQs) for B2B Buyers of proportional solenoid valve

-

How do I select the right proportional solenoid valve for my application?

When selecting a proportional solenoid valve, consider factors such as the type of fluid (liquid or gas), flow rate, pressure requirements, and the specific application (e.g., medical devices, HVAC, or food processing). Evaluate the valve’s control method, such as direct or pilot-operated, to ensure it meets your performance needs. Additionally, look for features like response time, temperature ratings, and compatibility with your existing systems. Consulting with suppliers can provide insights into the best options based on your unique operational demands. -

What are the key benefits of using proportional solenoid valves in industrial applications?

Proportional solenoid valves offer precise control over fluid flow and pressure, allowing for dynamic adjustments based on real-time input signals. This capability enhances system efficiency and responsiveness, making them ideal for applications that require accuracy, such as in medical devices and automation systems. Their ability to handle varying flow rates and pressures also reduces wear and tear on other system components, contributing to longer equipment life and lower maintenance costs. -

What should I consider when evaluating international suppliers for proportional solenoid valves?

When sourcing from international suppliers, assess their certifications, quality assurance processes, and track record in delivering high-quality products. It’s crucial to verify their compliance with international standards relevant to your industry, such as ISO certifications. Additionally, consider their experience with logistics and customs regulations in your region, as well as their responsiveness and support capabilities. Requesting samples or visiting their facilities can further ensure they meet your quality expectations. -

What customization options are available for proportional solenoid valves?

Many manufacturers offer customization options for proportional solenoid valves, including specific materials, sizes, electrical specifications, and control methods. Custom solutions can address unique operational challenges, such as extreme temperatures or corrosive environments. Discuss your requirements with potential suppliers to explore available options, and ensure they can provide documentation and testing to validate the customized solutions meet your application standards. -

What are the typical minimum order quantities (MOQs) for proportional solenoid valves?

Minimum order quantities can vary significantly between suppliers and depend on the type of valve and customization options. Standard products may have lower MOQs, while specialized or custom-built valves could require larger orders. It’s advisable to discuss your needs with potential suppliers to understand their policies and explore options for smaller initial orders or trial runs that can help you evaluate their products without significant upfront investment. -

What payment terms are commonly offered by international suppliers?

Payment terms can differ based on supplier policies, geographical location, and the buyer’s relationship with the supplier. Common terms include net 30, 60, or 90 days, requiring payment after delivery. Some suppliers may offer discounts for early payment or bulk orders. It’s essential to negotiate favorable terms that align with your cash flow requirements and ensure that the supplier is trustworthy to mitigate risks associated with international transactions. -

How can I ensure quality assurance when purchasing proportional solenoid valves?

To ensure quality assurance, request documentation such as certificates of compliance and test reports for the valves you plan to purchase. Establish a clear quality control process with your supplier, including inspections at various stages of production and prior to shipping. It may also be beneficial to conduct third-party inspections or audits of the supplier’s facilities. Building a strong relationship with your supplier can enhance communication regarding quality expectations and improvements. -

What logistics considerations should I keep in mind when importing proportional solenoid valves?

When importing valves, consider shipping methods, lead times, and costs associated with customs clearance. Ensure the supplier provides all necessary documentation, such as invoices, packing lists, and certificates of origin, to facilitate smooth customs processing. It’s also important to understand local regulations regarding imports to avoid delays or penalties. Collaborating with a freight forwarder experienced in your industry can simplify logistics and help ensure timely delivery of your valves.

Top 9 Proportional Solenoid Valve Manufacturers & Suppliers List

1. Tameson – Proportional Solenoid Control Valve

Domain: tameson.com

Registered: 2015 (10 years)

Introduction: A proportional solenoid control valve is designed to manage fluid flow rates by adjusting the passage size using a restrictor. It influences key process parameters such as level, pressure, and temperature, as well as weight, thickness, humidity, density, pH, color, and viscosity. The valve operates through a range of valve positioning, unlike standard solenoid valves that provide only on/off state…

2. McMaster – Proportional Solenoid Valves

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Proportional Solenoid Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Emerson – Proportional Solenoid Valves

Domain: emerson.com

Registered: 1995 (30 years)

Introduction: This company, Emerson – Proportional Solenoid Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Dwyer – SVP Proportioning Solenoid Valve

Domain: dwyeromega.com

Registered: 2022 (3 years)

Introduction: Series SVP Proportioning Solenoid Valve

– Type: Normally Closed (NC) Shut-off

– Flow Modulation: Controls flow in proportion to a variable voltage input (0-24 Vdc)

– Media Compatibility: Wide range of gases and liquids

– Materials: Wetted parts made of 316 Stainless Steel, FKM, Stainless Steel

– Operating Current: 400 mA

– Operating Temperature: Max 130 °F, Min -40 °F

– Measurement Pressure: Max 5…

5. Humphrey Products – ProControl™ Proportional Solenoid Valves

Domain: humphrey-products.com

Registered: 2000 (25 years)

Introduction: Proportional Solenoid Valves:

– Series: ProControl™

– Types: Small 2-Port, Large 2-Port, Proportional Valve Driver

– Features:

– Low hysteresis

– Excellent turndown ratios (resolution)

– Cycle repeatability

– Applications:

– Medical equipment (critical care patient ventilation)

– Compressed air or inert gas control

– Flow Control:

– Dynamically (continuous high-frequency adj…

6. Enfield Tech – PFV-K14 Proportional Solenoid Valve Kit

Domain: enfieldtech.com

Registered: 2002 (23 years)

Introduction: {“product_name”: “PFV-K14 Proportional Solenoid Valve Kit”, “availability”: “0 IN STOCK”, “price”: “$383.00”, “lead_time”: “Qty:”, “features”: {“application”: “liquids and gases”, “design”: “simplifies design and construction of medical, life-science, semiconductor and other OEM equipment”, “wetted_path_materials”: [“300 series stainless steel”, “400 series stainless steel”, “FKM”, “EPDM”, “FFKM”]…

7. Burkert – Proportional Valve Type 2863

Domain: burkert.com

Registered: 1995 (30 years)

Introduction: Proportional valve Type 2863 / Article No. 249140; 2/2 – A – normally closed; inlet port 1 (P/NC); direct-acting; 1.20 mm; FKM (Fluor rubber); Brass; Inner thread – G; Voltage: 24.00 V; Pressure range: -1.00 bar to 12.00 bar; Temperature range: -10.00 °C to 90.00 °C.

8. SMC – PVQ30 Compact Proportional Solenoid Valves

Domain: smcusa.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “PVQ30 Compact Proportional Solenoid Valves”, “manufacturer”: “SMC”, “type”: “Proportional Solenoid Valve”, “features”: [“Compact design”, “High response speed”, “Low power consumption”, “Various voltage options”], “applications”: [“Industrial automation”, “Fluid control systems”, “Robotics”], “specifications”: {“pressure_range”: “0.1 to 0.7 MPa”, “flow_rate”: “0.5 to 5.0 L/min”, …

9. JHFoster – Proportional Solenoid Valves

Domain: jhfoster.com

Registered: 1998 (27 years)

Introduction: Proportional Solenoid Valves are used in manufacturing processes for applications requiring flow or output pressure variations, remote control, and precision. They are commonly utilized in medical device manufacturing, semiconductor production, and life sciences product manufacturing. Key features include dependability, cost-effectiveness, fast response times, accuracy in flow or pressure control,…

Strategic Sourcing Conclusion and Outlook for proportional solenoid valve

What Are the Key Takeaways for Sourcing Proportional Solenoid Valves?

In summary, effective strategic sourcing of proportional solenoid valves is pivotal for optimizing operational efficiency and ensuring product reliability across diverse applications, from medical devices to industrial automation. Buyers should prioritize suppliers that offer a comprehensive range of products, including options for high-flow and pressure-compensated systems, tailored to specific industry requirements. Establishing long-term partnerships with reputable manufacturers can lead to better pricing, enhanced product support, and access to cutting-edge technologies.

How Can International Buyers Prepare for Future Trends in Proportional Solenoid Valves?

As industries continue to evolve, the demand for more precise and adaptable control solutions will only increase. Buyers from Africa, South America, the Middle East, and Europe should remain vigilant about emerging trends, such as the integration of smart technologies and IoT capabilities within solenoid valve systems. By proactively engaging with suppliers and participating in industry forums, businesses can stay ahead of market shifts and technological advancements.

What Steps Should Buyers Take Now?

Now is the time for international B2B buyers to leverage the insights gained from this guide. By aligning with strategic suppliers and investing in quality proportional solenoid valves, companies can enhance their operational resilience and drive growth. Embrace the future of fluid control technology and make informed sourcing decisions that will set your business apart in a competitive landscape.

Illustrative image related to proportional solenoid valve

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.