How to Source Pressure Switch Motor Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for pressure switch motor

Navigating the complexities of the global market for pressure switch motors can be a daunting task for international B2B buyers, especially in diverse regions like Africa, South America, the Middle East, and Europe. One of the primary challenges buyers face is sourcing reliable and efficient pressure switch motors that meet specific operational requirements while ensuring cost-effectiveness. This guide aims to demystify the procurement process by providing a comprehensive overview of various types of pressure switch motors, their applications across industries, and insights into the supplier vetting process.

In this guide, we will delve into the nuances of different pressure switch motor types, highlighting their unique features and suitable applications. We will also explore critical factors influencing pricing, allowing you to make informed financial decisions. Additionally, we will offer actionable strategies for evaluating suppliers to ensure you partner with manufacturers that uphold quality and reliability.

By equipping international B2B buyers with the knowledge needed to navigate the pressure switch motor landscape, this guide empowers you to make confident purchasing decisions. Whether you are sourcing for agricultural, industrial, or commercial applications, understanding these elements will streamline your procurement process and enhance operational efficiency. Join us as we explore the essential aspects of pressure switch motors, paving the way for smarter investments and successful business outcomes.

Understanding pressure switch motor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mechanical Pressure Switch | Operates via direct mechanical contact; factory-set cut-on and cut-off points | Well water systems, irrigation | Pros: Cost-effective, reliable; Cons: Limited configurability, may require manual adjustments. |

| Electronic Pressure Switch | Utilizes electronic sensors for pressure detection; configurable settings | HVAC systems, industrial applications | Pros: High precision, programmable; Cons: Higher cost, dependent on continuous power supply. |

| Low-Pressure Cut-Off Switch | Specifically designed to prevent damage by shutting off pumps at low pressure | Water treatment plants, aquaculture | Pros: Protects equipment, enhances longevity; Cons: May restrict flow if not calibrated correctly. |

| High-Pressure Cut-Off Switch | Prevents over-pressurization by shutting down pumps at high pressure | Oil and gas industries, manufacturing | Pros: Safety-focused, prevents system failures; Cons: Can lead to downtime if overly sensitive. |

| Dual Pressure Switch | Combines both high and low-pressure functionalities in one unit | Versatile applications in agriculture and industry | Pros: Multifunctional, space-saving; Cons: More complex, potential for higher maintenance needs. |

What Are the Characteristics of Mechanical Pressure Switches?

Mechanical pressure switches are characterized by their reliance on physical components to detect pressure changes. They feature factory-set cut-on and cut-off points, making them a straightforward and cost-effective choice for many applications, especially in well water systems and irrigation. B2B buyers should consider their reliability and ease of use, though they may require manual adjustments for optimal performance. Mechanical switches are particularly suitable for businesses looking to minimize initial costs while maintaining essential functionality.

How Do Electronic Pressure Switches Stand Out?

Electronic pressure switches are distinguished by their use of electronic sensors, which allow for precise pressure detection and the ability to configure settings according to specific operational needs. These switches are commonly used in HVAC systems and industrial applications where accuracy is paramount. While they offer high precision and programmability, B2B buyers should weigh the higher upfront costs and the necessity for a continuous power supply against the benefits of enhanced control and efficiency.

Why Are Low-Pressure Cut-Off Switches Important?

Low-pressure cut-off switches are essential for preventing equipment damage by shutting down pumps when pressure falls below a safe threshold. They are widely used in water treatment plants and aquaculture settings to protect sensitive systems. When purchasing, B2B buyers should consider the calibration requirements, as improper settings could restrict water flow. The primary advantage lies in their ability to extend the life of pumps and associated equipment, making them a valuable investment for businesses focused on operational longevity.

What Are the Benefits of High-Pressure Cut-Off Switches?

High-pressure cut-off switches are designed to prevent over-pressurization, a critical safety feature in industries such as oil and gas. These switches automatically shut down pumps when pressure exceeds safe levels, reducing the risk of system failures. B2B buyers must consider the sensitivity of these switches, as overly sensitive models may lead to unnecessary downtime. However, their primary benefit is enhancing safety and reliability, making them indispensable in high-stakes environments.

How Do Dual Pressure Switches Enhance Versatility?

Dual pressure switches combine the functionalities of both high and low-pressure cut-off systems into a single unit, providing a versatile solution for various applications, particularly in agriculture and industry. They save space and simplify installations, but their complexity may lead to higher maintenance needs. B2B buyers should evaluate the potential for increased efficiency against the complexity of setup and maintenance. These switches are ideal for businesses looking to streamline operations while ensuring comprehensive pressure management.

Key Industrial Applications of pressure switch motor

| Industry/Sector | Specific Application of pressure switch motor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Management | Control of well pumps for irrigation systems | Efficient water usage, reduced energy costs | Compatibility with local voltage standards, durability in harsh environments |

| HVAC Systems | Regulation of pressure in heating and cooling systems | Enhanced system efficiency, improved comfort levels | Calibration options, responsiveness to pressure changes |

| Manufacturing | Monitoring and controlling hydraulic systems | Increased operational safety, reduced downtime | Reliability under varying pressure conditions, ease of integration |

| Oil and Gas | Pressure monitoring in drilling operations | Enhanced safety, prevention of equipment failure | Compliance with industry standards, robustness against corrosive environments |

| Food and Beverage | Pressure control in processing equipment | Consistent product quality, compliance with safety standards | Sanitary design, resistance to cleaning agents, precise pressure settings |

How is a Pressure Switch Motor Used in Water Management Systems?

In water management, particularly for irrigation, pressure switch motors are essential for controlling well pumps. They activate and deactivate pumps based on preset pressure levels, ensuring consistent water supply while optimizing energy use. This functionality is crucial for businesses in regions like Africa and South America, where water scarcity is a significant concern. Buyers should consider the switch’s compatibility with local voltage standards and its durability, given the often harsh environmental conditions.

What Role Does a Pressure Switch Motor Play in HVAC Systems?

In HVAC systems, pressure switch motors are utilized to regulate airflow and pressure levels within heating and cooling units. This regulation not only enhances system efficiency but also improves indoor comfort. For international buyers, especially in Europe and the Middle East, it is vital to source pressure switches that offer calibration options and quick responsiveness to pressure changes, ensuring that the HVAC systems operate smoothly under varying conditions.

How Does a Pressure Switch Motor Improve Manufacturing Operations?

Manufacturing facilities rely on pressure switch motors to monitor and control hydraulic systems, which are integral to various production processes. These motors enhance operational safety and minimize downtime by ensuring that hydraulic systems operate within safe pressure limits. Businesses should prioritize sourcing reliable switches that perform well under varying pressure conditions, as this can significantly impact overall productivity and safety.

In What Ways is a Pressure Switch Motor Critical in Oil and Gas Operations?

In the oil and gas industry, pressure switch motors are vital for monitoring pressure during drilling operations. They help prevent equipment failures by providing real-time pressure readings, which is critical for safety. Buyers in this sector must ensure that the pressure switches comply with industry standards and are robust enough to withstand corrosive environments, particularly in offshore applications.

Why is a Pressure Switch Motor Important in Food and Beverage Processing?

In the food and beverage industry, pressure switch motors control pressure in processing equipment to maintain product quality and ensure safety compliance. These motors help in achieving consistent pressure levels during production, which is essential for quality control. Buyers should look for pressure switches designed with sanitary features and resistance to cleaning agents, as these factors are crucial for maintaining hygiene standards in food processing environments.

3 Common User Pain Points for ‘pressure switch motor’ & Their Solutions

Scenario 1: Inconsistent Water Pressure Delivery in Industrial Applications

The Problem: Many B2B buyers in sectors like manufacturing or agriculture face challenges with inconsistent water pressure delivery, leading to inefficient operations. When the pressure switch motor fails to activate the pump at the right pressure levels, it can result in either excess water pressure, causing leaks and damages, or insufficient pressure, leading to inadequate supply for machinery or irrigation systems. This inconsistency can halt production lines or compromise crop yields, ultimately affecting profitability.

The Solution: To address this issue, buyers should ensure they select a pressure switch motor with adjustable cut-in and cut-out settings tailored to their specific operational needs. Investing in high-quality, programmable models allows for precise calibration of pressure levels. Additionally, regular maintenance checks should be scheduled to inspect the pressure switch for wear and tear, ensuring optimal functionality. Establishing a partnership with a reputable supplier who offers technical support and guidance on selecting the right model can further mitigate risks associated with pressure inconsistency.

Scenario 2: Frequent System Failures Due to Poor Quality Components

The Problem: B2B buyers often encounter frequent system failures when utilizing low-quality pressure switch motors, leading to increased downtime and repair costs. These components may not be able to withstand the harsh conditions of industrial environments, such as extreme temperatures or exposure to chemicals. As a result, buyers face the dual challenges of lost productivity and the financial burden of unplanned maintenance and replacements.

The Solution: Buyers should prioritize sourcing pressure switch motors from reputable manufacturers known for their durability and reliability. Conducting thorough research, including checking product reviews and performance ratings, is essential. Additionally, buyers can request samples or trial periods to evaluate the motor’s performance in their specific environment before making a bulk purchase. Implementing a rigorous quality assurance process when integrating new components into existing systems can also help in identifying potential issues early, minimizing long-term disruptions.

Scenario 3: Difficulty in Integration with Existing Systems

The Problem: Integrating new pressure switch motors into existing water management systems can be a significant pain point for B2B buyers. Often, these motors are not compatible with older systems, leading to complex installation processes and additional costs for retrofitting or system upgrades. This challenge can delay project timelines and strain budgets, frustrating buyers who expect seamless transitions.

The Solution: To navigate this integration challenge, buyers should conduct a comprehensive compatibility assessment before purchasing a new pressure switch motor. This involves reviewing the specifications of the existing systems and consulting with suppliers about compatibility. Buyers may also consider investing in modular pressure switch motors designed for easy integration with various systems. Moreover, involving an experienced technician during the selection and installation process can ensure that the motor is correctly configured, enhancing overall system efficiency and reducing the risk of future compatibility issues.

Strategic Material Selection Guide for pressure switch motor

What Are the Common Materials Used in Pressure Switch Motors?

When selecting materials for pressure switch motors, it’s essential to consider properties that directly influence performance, durability, and compatibility with various applications. Here, we analyze four common materials used in the construction of pressure switch motors: brass, stainless steel, plastic, and aluminum.

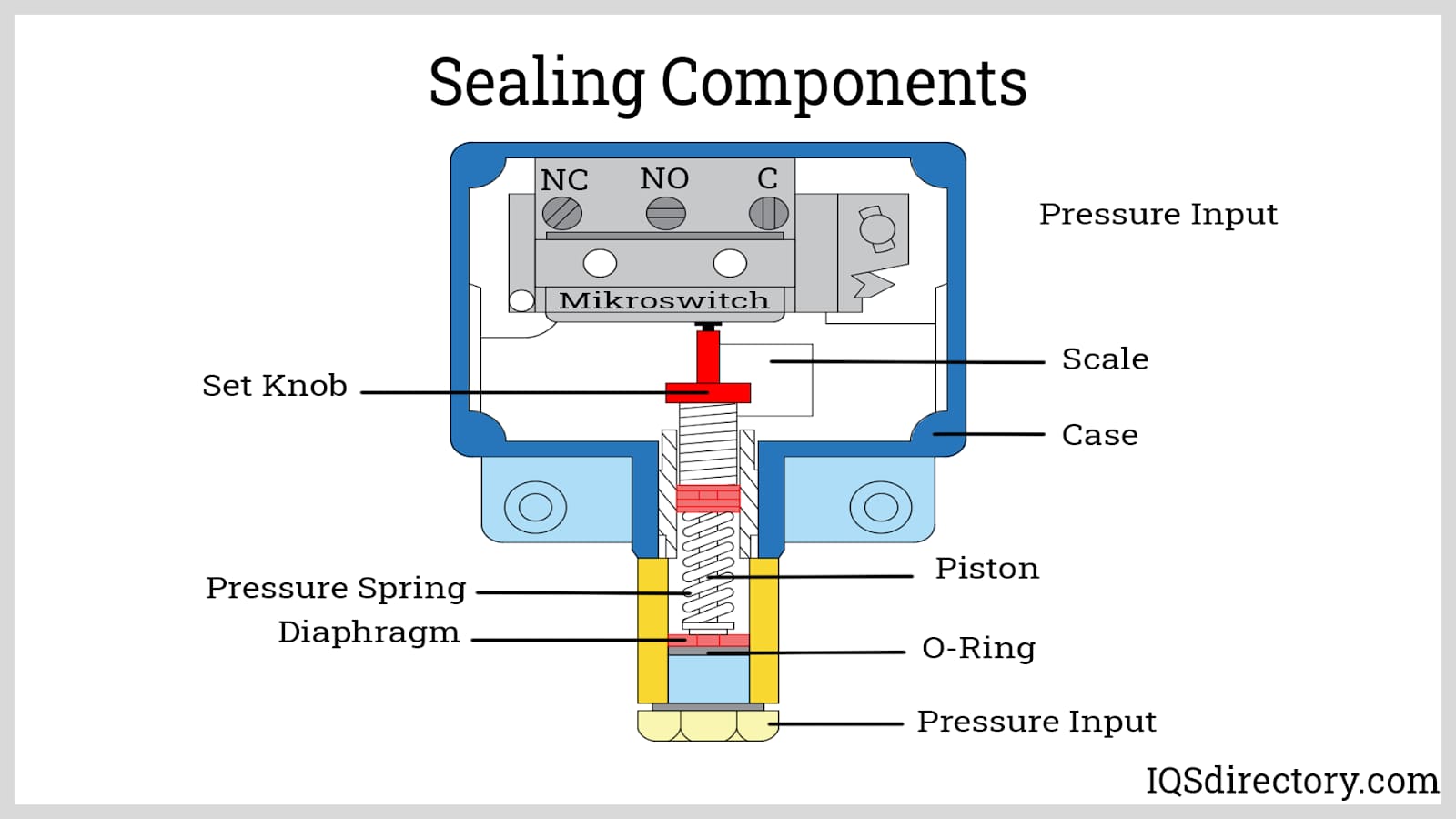

Illustrative image related to pressure switch motor

How Does Brass Perform in Pressure Switch Motors?

Brass is a popular choice for pressure switch motors due to its excellent corrosion resistance and mechanical properties. It can withstand high pressures and temperatures, making it suitable for various industrial applications. The key advantages of brass include its durability and ease of machining, which allows for intricate designs.

However, brass can be more expensive than other materials, and its performance may degrade in highly acidic or alkaline environments. For international B2B buyers, particularly in regions like Africa and South America, compliance with local standards such as ASTM B16 (for fittings) is crucial. Additionally, buyers should consider the availability of brass components in their respective markets.

What Are the Benefits of Using Stainless Steel in Pressure Switch Motors?

Stainless steel is another widely used material for pressure switch motors, known for its exceptional strength and resistance to corrosion, particularly in harsh environments. It can handle high temperatures and pressures, making it ideal for applications in the oil and gas industry or in regions with extreme weather conditions.

The primary disadvantage of stainless steel is its higher cost compared to other materials, which may affect budget-sensitive projects. Additionally, its weight can be a consideration for applications where weight reduction is critical. International buyers should be aware of compliance with standards such as ASTM A276 for stainless steel bars and shapes, which can vary by region.

Why Choose Plastic for Pressure Switch Motors?

Plastic materials, such as polycarbonate or nylon, are often selected for pressure switch motors due to their lightweight nature and resistance to corrosion. They are particularly suitable for applications where moisture is present, as they do not corrode like metals. Plastics can also be molded into complex shapes, allowing for versatile designs.

However, plastics generally have lower temperature and pressure ratings compared to metals, which may limit their application in high-stress environments. For buyers in Europe and the Middle East, compliance with standards like ISO 9001 for quality management systems is essential when sourcing plastic components.

What Role Does Aluminum Play in Pressure Switch Motors?

Aluminum is valued for its lightweight and good corrosion resistance, making it a suitable option for pressure switch motors in various applications, including automotive and HVAC systems. Its thermal conductivity is also beneficial in applications requiring efficient heat dissipation.

The main drawback of aluminum is its lower strength compared to brass and stainless steel, which may limit its use in high-pressure applications. Additionally, international buyers should consider the need for anodizing or other treatments to enhance corrosion resistance, especially in humid climates prevalent in parts of Africa and South America.

Summary of Material Selection for Pressure Switch Motors

| Material | Typical Use Case for pressure switch motor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Industrial applications, plumbing systems | Excellent corrosion resistance | Higher cost, sensitive to acids | Medium |

| Stainless Steel | Oil and gas, extreme environments | High strength and durability | Expensive, heavier | High |

| Plastic | Moisture-prone applications, lightweight designs | Lightweight, corrosion-resistant | Lower temperature/pressure rating | Low |

| Aluminum | Automotive, HVAC systems | Lightweight, good corrosion resistance | Lower strength, may require treatment | Medium |

This guide provides a comprehensive overview of material options for pressure switch motors, helping international B2B buyers make informed decisions based on performance requirements, cost considerations, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for pressure switch motor

What Are the Key Stages in the Manufacturing Process of Pressure Switch Motors?

The manufacturing of pressure switch motors involves several critical stages that ensure the final product meets performance and reliability standards. These stages typically include material preparation, forming, assembly, and finishing.

Material Preparation: The process begins with sourcing high-quality materials such as metals (brass, stainless steel) and polymers for the switch casing and internal components. Suppliers often provide certificates of compliance to verify material properties. Buyers should ensure materials are sourced from reputable suppliers to guarantee durability and performance.

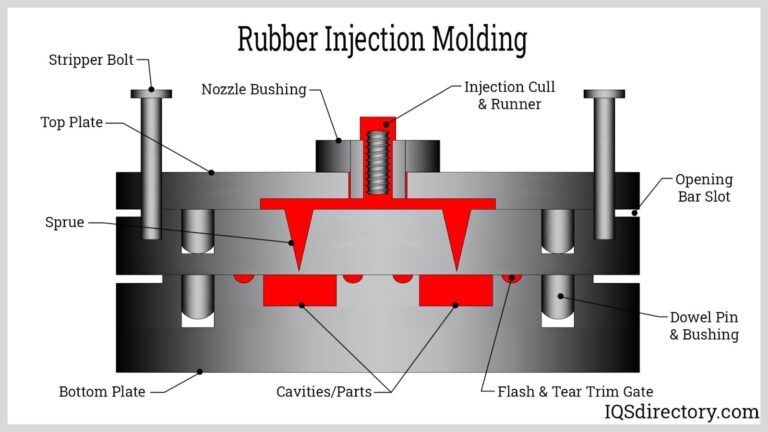

Forming: This stage involves shaping the raw materials into usable components. Techniques such as stamping, machining, and injection molding are commonly used. For instance, metal parts may be stamped or machined to achieve precise dimensions, while plastic components are typically produced through injection molding. Precision in this stage is crucial, as any deviation can affect the switch’s operational efficiency.

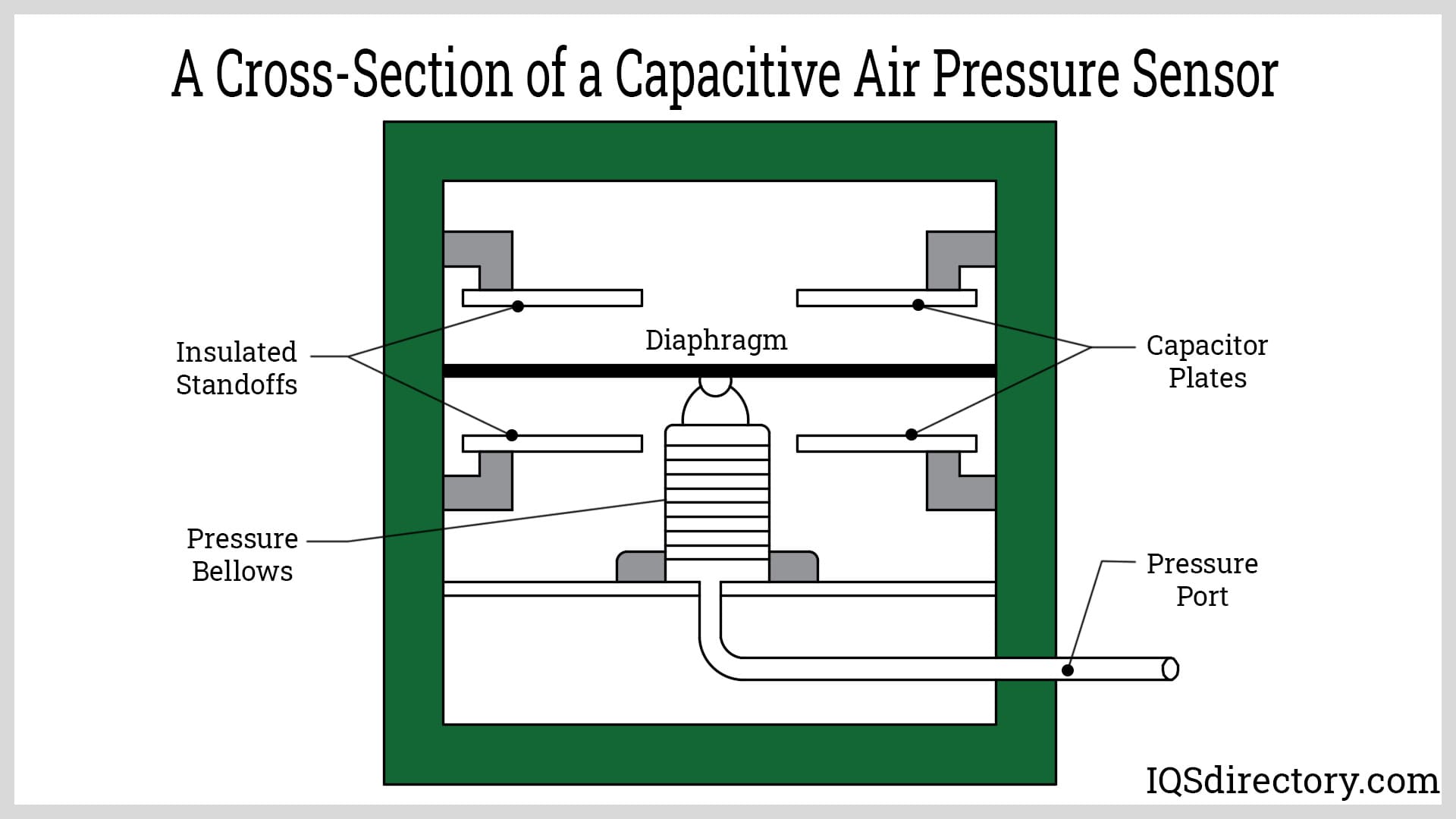

Assembly: During assembly, the formed components are put together. This can be a manual or automated process, depending on the scale of production. Key components such as diaphragms, springs, and electrical contacts are carefully assembled to ensure they operate correctly under varying pressure conditions. Assembly quality is paramount, as improper assembly can lead to malfunction or failure of the pressure switch motor.

Finishing: The final stage involves surface treatment and quality checks. Components may undergo processes such as coating, painting, or plating to enhance corrosion resistance and improve aesthetics. Additionally, finishing includes rigorous testing to ensure each unit meets specified operational parameters.

What International Standards Govern Quality Assurance in Pressure Switch Motor Manufacturing?

Quality assurance in manufacturing pressure switch motors is guided by several international standards, ensuring that products meet safety, performance, and reliability benchmarks.

ISO 9001: This widely recognized standard outlines a framework for quality management systems (QMS) that organizations must adhere to. Compliance with ISO 9001 indicates that the manufacturer has established processes to enhance customer satisfaction through effective system implementation.

CE Marking: In Europe, CE marking is essential for demonstrating compliance with health, safety, and environmental protection standards. It is crucial for B2B buyers in Europe to ensure that their suppliers have CE-certified products, as this can affect market access.

API Standards: For buyers in industries such as oil and gas, adherence to American Petroleum Institute (API) standards is vital. These standards ensure that pressure switch motors can withstand the demanding conditions of these sectors.

What Are the Critical Quality Control Checkpoints in Manufacturing Pressure Switch Motors?

Implementing effective quality control (QC) checkpoints throughout the manufacturing process is essential to ensure product reliability. Key checkpoints typically include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon delivery. The goal is to verify that materials meet predefined specifications before they are used in production. IQC helps prevent defective materials from entering the production process.

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC monitors production processes to ensure that they adhere to established standards. This involves regular inspections and testing of components as they are formed and assembled. IPQC allows for the identification of issues in real-time, minimizing waste and rework.

Final Quality Control (FQC): The final checkpoint occurs after assembly and finishing. FQC involves comprehensive testing of the completed pressure switch motors against performance criteria. Common tests include pressure testing, electrical testing, and lifecycle testing to ensure the product operates correctly under expected conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to ensure their suppliers maintain robust quality control processes. Here are some effective methods for verification:

Supplier Audits: Conducting on-site audits allows buyers to evaluate a supplier’s manufacturing processes and quality control measures firsthand. This provides insight into their operational capabilities and adherence to quality standards.

Quality Reports: Requesting detailed quality control reports can help buyers assess a supplier’s commitment to quality. These reports should outline testing procedures, results, and any corrective actions taken in response to failures.

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes. These services can conduct pre-shipment inspections to ensure products meet required standards before they leave the factory.

What Are the Unique Quality Control Considerations for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges in ensuring quality control. Here are some considerations:

Regulatory Compliance: Different regions have varying regulatory requirements that can affect product acceptance. Buyers should be aware of local regulations and ensure that suppliers are compliant with them.

Cultural and Language Barriers: Differences in language and business practices can create misunderstandings. Establishing clear communication channels and utilizing local representatives can help bridge these gaps.

Logistics and Supply Chain Integrity: International shipping can introduce risks such as damage during transit or delays that affect product quality. Buyers should work closely with suppliers to establish robust logistics plans and consider using quality control checkpoints at various stages of the supply chain.

By understanding the manufacturing processes and quality assurance protocols for pressure switch motors, B2B buyers can make informed decisions when selecting suppliers, ensuring they receive reliable and high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pressure switch motor’

Introduction

Procuring a pressure switch motor is a critical process for ensuring the efficiency and reliability of your industrial or agricultural applications. This guide provides a step-by-step checklist to help B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, navigate the sourcing process effectively. By following these steps, you can make informed decisions that align with your operational requirements and budget constraints.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s essential to clearly outline the technical specifications of the pressure switch motor you need. Consider factors such as pressure range, power requirements, and intended application. This clarity will help streamline your search and ensure that the products you evaluate meet your operational needs.

- Pressure Range: Specify the cut-on and cut-off pressures required for your system.

- Power Requirements: Determine the voltage and current specifications to avoid compatibility issues.

Step 2: Research Suppliers and Manufacturers

Conduct thorough research to identify potential suppliers and manufacturers that specialize in pressure switch motors. Utilize online platforms, industry directories, and trade shows to gather a list of reputable companies.

- Industry Reputation: Look for suppliers with a strong track record in your industry.

- Global Reach: Ensure that the suppliers can ship to your region, considering any import regulations.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers possess the necessary certifications and quality standards relevant to your industry. Certifications such as ISO 9001 or CE mark can indicate a commitment to quality and safety.

- Quality Assurance: Certifications can help mitigate risks associated with product failures.

- Regulatory Compliance: Ensure that the products meet local and international standards applicable to your industry.

Step 4: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations that include pricing, lead times, and terms of sale. This step is vital for comparing offers and understanding the total cost of ownership.

- Price Breakdown: Look for transparency in pricing, including shipping and handling fees.

- Lead Times: Assess the delivery timelines to ensure they align with your project schedules.

Step 5: Assess Customer Support and Warranty Options

Evaluate the level of customer support offered by suppliers and inquire about warranty options for the pressure switch motors. Reliable support can be crucial for troubleshooting and maintenance.

Illustrative image related to pressure switch motor

- After-Sales Support: Determine if the supplier provides installation guidance and ongoing technical support.

- Warranty Coverage: Understand the warranty terms to protect your investment against defects and failures.

Step 6: Review Customer Feedback and Case Studies

Seek out customer testimonials and case studies to gauge the experiences of other businesses with the suppliers you are considering. This feedback can provide insights into product performance and supplier reliability.

- User Experience: Look for reviews that highlight both positive and negative aspects of the products.

- Real-World Applications: Case studies can illustrate how the motors perform in similar applications to yours.

Step 7: Finalize Your Decision and Place Your Order

After careful consideration of all factors, finalize your decision on the supplier that best meets your criteria. Ensure that you have all necessary documentation and agreements in place before placing your order.

- Contract Review: Review terms and conditions to avoid any misunderstandings.

- Order Confirmation: Confirm all details, including specifications and delivery dates, to ensure a smooth transaction.

By following this checklist, B2B buyers can effectively source pressure switch motors that meet their specific requirements and ensure operational success.

Comprehensive Cost and Pricing Analysis for pressure switch motor Sourcing

What Are the Key Cost Components in Sourcing Pressure Switch Motors?

When sourcing pressure switch motors, understanding the cost structure is crucial for effective budgeting and pricing strategy. The primary cost components include:

-

Materials: The quality and type of materials used significantly affect the cost. Common materials include metals for casing and wiring, plastics for housings, and specialized components like diaphragms and springs. High-quality materials may increase initial costs but can lead to better performance and longevity.

-

Labor: Labor costs vary by region and can be influenced by local wage rates and the complexity of the manufacturing process. Skilled labor for assembly and quality control is often more expensive but essential for ensuring product reliability.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these overheads, impacting overall pricing.

-

Tooling: The initial investment in tools and machinery for production can be significant, especially for custom designs. This cost is usually amortized over the production volume, meaning larger orders can help reduce the per-unit tooling expense.

-

Quality Control (QC): Ensuring that each pressure switch motor meets quality standards requires investment in testing and inspection processes. While these costs can raise the price, they are vital for maintaining product integrity and customer satisfaction.

-

Logistics: Transportation and warehousing costs can vary significantly based on the supplier’s location and the destination. International shipping can add tariffs and customs fees, impacting the total cost.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. This margin can vary widely based on competition, brand positioning, and market demand.

What Influences Pricing for Pressure Switch Motors?

Several factors influence the pricing of pressure switch motors, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders generally result in lower per-unit costs due to economies of scale. Buyers should consider negotiating MOQs to optimize pricing.

-

Specifications and Customization: Customized pressure switch motors tailored to specific applications or environments can incur additional costs. It’s essential to balance customization needs with budget constraints.

-

Quality and Certifications: Motors that meet industry standards and certifications (e.g., ISO, CE) often command higher prices. Buyers should assess the importance of certifications relative to their application.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a proven track record may charge more but offer greater assurance of quality and service.

-

Incoterms: The chosen Incoterms can impact the total cost of ownership by defining responsibilities for shipping, insurance, and duties. Understanding these terms is crucial for accurate cost forecasting.

How Can Buyers Negotiate Effectively for Pressure Switch Motors?

To secure the best pricing, buyers should consider the following strategies:

-

Research and Compare: Conduct thorough market research to understand typical pricing and options available. Comparing multiple suppliers can provide leverage in negotiations.

-

Highlight Long-Term Relationships: Emphasizing the potential for ongoing business can motivate suppliers to offer better pricing or terms.

-

Consider Total Cost of Ownership (TCO): Analyze not just the purchase price but also maintenance, operational efficiency, and potential downtime costs associated with the motor. A slightly higher initial cost may lead to lower long-term expenses.

-

Flexibility in Specifications: Being open to alternative specifications or models can lead to significant cost savings. Discussing these options with suppliers can uncover budget-friendly solutions.

-

Local vs. International Sourcing: Evaluate the benefits of sourcing locally versus internationally. While international suppliers may offer lower prices, local sourcing can reduce shipping costs and lead times.

Conclusion

Understanding the comprehensive cost structure and pricing influences associated with pressure switch motors is essential for international B2B buyers. By considering these factors and employing effective negotiation strategies, buyers can make informed decisions that align with their operational needs and budget constraints. Always consult with multiple suppliers and be aware of the market dynamics to achieve the best possible outcome.

Illustrative image related to pressure switch motor

Alternatives Analysis: Comparing pressure switch motor With Other Solutions

In the realm of industrial automation and fluid control, the pressure switch motor serves a critical function by regulating the operation of pumps based on pressure levels. However, various alternative solutions exist that can fulfill similar roles. Understanding these alternatives helps businesses make informed decisions that align with their operational requirements and budget constraints.

| Comparison Aspect | Pressure Switch Motor | Mechanical Pressure Switch | Electronic Pressure Control System |

|---|---|---|---|

| Performance | Reliable for maintaining consistent pressure; offers basic on/off control. | Similar reliability; may have limited adjustment capabilities. | Provides precise control with adjustable settings and feedback. |

| Cost | Generally affordable, suitable for basic applications. | Typically lower initial cost; limited features. | Higher upfront investment; cost-effective in long-term efficiency. |

| Ease of Implementation | Simple installation; compatible with most pump systems. | Easy to install; direct mechanical operation. | More complex installation; may require programming and calibration. |

| Maintenance | Requires periodic checks; durable but can wear out over time. | Low maintenance; mechanical wear can occur. | Minimal maintenance; software updates may be needed. |

| Best Use Case | Ideal for basic well water systems and general pump control. | Suitable for simple applications where cost is a priority. | Best for sophisticated systems needing precise pressure management. |

What Are the Advantages and Disadvantages of Mechanical Pressure Switches?

Mechanical pressure switches operate through physical mechanisms, making them a straightforward alternative to pressure switch motors. Their advantages include lower costs and simplicity in installation, making them an attractive option for basic applications. However, they often lack the flexibility of adjustable settings, which can limit their effectiveness in dynamic environments where pressure levels fluctuate significantly.

How Do Electronic Pressure Control Systems Compare?

Electronic pressure control systems are a more advanced solution that offers superior performance and precision. These systems allow for programmable settings and can provide real-time feedback on pressure levels, enhancing efficiency and control. While they involve a higher initial investment and more complex installation, their long-term benefits can outweigh these drawbacks, especially in systems where maintaining specific pressure levels is critical.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate pressure regulation solution hinges on a variety of factors, including performance requirements, budget constraints, and the complexity of the system in use. Businesses operating in environments with fluctuating pressure demands may find electronic pressure control systems to be the most effective, despite their higher costs. Conversely, for straightforward applications with budget limitations, mechanical pressure switches may suffice. By carefully evaluating operational needs and potential long-term benefits, B2B buyers can make a well-informed decision that ensures efficient and reliable operation of their systems.

Essential Technical Properties and Trade Terminology for pressure switch motor

What Are the Critical Technical Properties of a Pressure Switch Motor?

Understanding the essential technical properties of pressure switch motors is crucial for B2B buyers, particularly when sourcing components for industrial applications. Here are several key specifications that define their performance and reliability:

Illustrative image related to pressure switch motor

-

Material Grade

Pressure switch motors are typically constructed from materials such as stainless steel, brass, or thermoplastic. Stainless steel is favored for its corrosion resistance and durability, making it suitable for harsh environments, while brass offers excellent conductivity. Selecting the right material ensures longevity and optimal performance in specific applications. -

Pressure Range

The pressure range, often expressed in psi (pounds per square inch), indicates the operational limits of the switch. Common ranges include 20-40 psi, 30-50 psi, and 40-60 psi. Understanding the pressure range is essential for ensuring that the motor operates effectively within the required parameters, which can prevent system failures and enhance efficiency. -

Electrical Ratings

This specification includes voltage and current ratings, typically expressed in volts (V) and amperes (A). For instance, a pressure switch motor might be rated for 120V and 15A. Knowing the electrical ratings is crucial for compatibility with existing systems and for ensuring safe operation without overheating or causing electrical failures. -

Tolerance Levels

Tolerance refers to the permissible limits of variation in pressure settings. A typical tolerance might be ±5 psi. This specification is important as it affects the precision with which the pressure switch can operate, directly impacting system efficiency and reliability. Tight tolerances are often required in applications where consistent pressure levels are critical. -

Response Time

The response time is the duration it takes for the switch to activate upon reaching the cut-on pressure. This can range from milliseconds to seconds, depending on the design. A shorter response time is vital for applications requiring rapid adjustments to maintain optimal system performance, such as in hydraulic systems. -

Cycle Life

This metric indicates the number of operational cycles a pressure switch can undergo before failure. A higher cycle life means less frequent replacements, which is significant for reducing operational costs and downtime. Industries with high usage rates should prioritize switches with extended cycle life ratings.

What Are Common Trade Terms Used in Pressure Switch Motor Transactions?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are several key terms commonly encountered in the procurement of pressure switch motors:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM products is crucial for ensuring quality and compatibility, especially when integrating components into existing systems. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This is a critical factor for B2B buyers as it can affect inventory management and cash flow. Buyers should negotiate MOQs to align with their operational needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It is an essential step in the procurement process, allowing buyers to compare offers and select the best value based on price, delivery, and terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, defining responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for managing logistics, costs, and risks associated with shipping and delivery. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. This is particularly important in B2B settings where delays can disrupt production schedules. Buyers should clarify lead times to ensure they align with project timelines. -

Warranty Terms

Warranty terms specify the conditions under which a supplier will repair or replace defective products. Knowing these terms is vital for risk management and can influence purchasing decisions, as strong warranty offerings often indicate supplier confidence in product quality.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing pressure switch motors, ultimately enhancing operational efficiency and reducing costs.

Navigating Market Dynamics and Sourcing Trends in the pressure switch motor Sector

What Are the Key Market Dynamics and Trends Influencing the Pressure Switch Motor Sector?

The global pressure switch motor market is driven by various factors, including the rising demand for automation in industrial processes and the increasing need for efficient water management systems. The growth of sectors such as agriculture, manufacturing, and construction, particularly in regions like Africa and South America, is propelling the demand for reliable pressure switch motors. Additionally, the trend towards smart technologies is influencing sourcing decisions, as businesses look for pressure switches that integrate with IoT systems for enhanced monitoring and control.

Emerging technologies are reshaping the market landscape. The adoption of digital twins and predictive maintenance techniques is gaining traction, allowing companies to optimize the performance of pressure switch motors. Furthermore, advancements in materials science are leading to the development of more durable and efficient components, reducing the total cost of ownership for end-users. B2B buyers should pay close attention to suppliers who are investing in these technologies, as they can provide competitive advantages through enhanced reliability and efficiency.

In the context of international markets, understanding local regulations and compliance standards is crucial. Buyers from the Middle East and Europe, for instance, must navigate stringent environmental regulations that affect sourcing decisions. Additionally, buyers should be aware of currency fluctuations and geopolitical factors that can impact supply chains, particularly when sourcing from regions like Vietnam and Brazil. Building strong relationships with suppliers who can provide insights into these dynamics will be essential for successful procurement strategies.

How Can Sustainability and Ethical Sourcing Shape the Pressure Switch Motor Market?

Sustainability has become a cornerstone of sourcing strategies in the pressure switch motor sector. Companies are increasingly aware of their environmental impact, leading to a demand for products that minimize waste and energy consumption. B2B buyers are encouraged to seek out manufacturers that prioritize eco-friendly practices, such as using recyclable materials and reducing carbon footprints in their production processes.

Illustrative image related to pressure switch motor

Ethical sourcing is also gaining prominence as buyers recognize the importance of transparent supply chains. Suppliers that adhere to fair labor practices and ethical sourcing standards can help companies mitigate risks associated with reputational damage and regulatory penalties. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Moreover, the integration of ‘green’ materials into the manufacturing of pressure switch motors can enhance product appeal. Buyers should consider suppliers that utilize sustainable materials, such as biodegradable plastics or recycled metals, which can contribute to a circular economy. By prioritizing sustainability and ethical sourcing, businesses not only comply with regulatory requirements but also appeal to a growing base of environmentally conscious consumers.

What Is the Historical Context Behind the Pressure Switch Motor Sector?

The pressure switch motor sector has evolved significantly over the decades, transitioning from purely mechanical systems to highly sophisticated electronic solutions. Initially, mechanical pressure switches dominated the market, relying on physical components to regulate pressure. However, advancements in technology have paved the way for electronic pressure switches that offer greater precision and reliability.

The introduction of microprocessor-based control systems in the late 20th century marked a significant turning point. These systems allowed for more accurate pressure monitoring and control, leading to improved efficiency in various applications, from industrial processes to residential water systems. As industries continue to embrace automation and smart technology, the pressure switch motor sector is likely to see further innovations that enhance functionality and sustainability, positioning it as a critical component in modern industrial ecosystems.

By understanding these dynamics, B2B buyers can make informed sourcing decisions that align with their operational goals and sustainability objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of pressure switch motor

-

How do I solve issues with a malfunctioning pressure switch motor?

To address a malfunctioning pressure switch motor, first, ensure that the electrical connections are secure and that the power supply is stable. Inspect the switch for any physical damage or corrosion, which can impede its function. Additionally, check the pressure settings; they may need recalibration to match the operational requirements of your system. If the problem persists, consider consulting a professional technician who specializes in well systems to diagnose and resolve underlying issues effectively. -

What is the best pressure switch motor for industrial applications?

The best pressure switch motor for industrial applications typically features robust construction, adjustable pressure settings, and compatibility with various pump types. Look for models that offer a high cycle rate, reliable performance under heavy loads, and built-in safety features such as low-pressure cut-off. Brands like Square D and Everbilt are known for their durability and efficiency. Additionally, evaluate the switch’s specifications to ensure it meets the specific demands of your operational environment. -

How can I vet suppliers for pressure switch motors internationally?

To vet suppliers for pressure switch motors, start by checking their certifications and compliance with international quality standards, such as ISO 9001. Request references from previous clients and review their track record for reliability and customer service. It’s also beneficial to visit their manufacturing facility, if possible, to assess their production capabilities and quality control processes. Finally, consider using platforms that specialize in B2B transactions to find verified suppliers and gather additional insights from user reviews. -

What customization options are available for pressure switch motors?

Many manufacturers offer customization options for pressure switch motors, including tailored pressure settings, different electrical configurations, and housing materials suitable for specific environments. You can also request modifications such as added features for enhanced durability or improved safety mechanisms. When discussing customization with suppliers, clearly outline your operational requirements to ensure the final product meets your specific needs. -

What is the minimum order quantity (MOQ) for pressure switch motors?

Minimum order quantities (MOQs) for pressure switch motors can vary significantly between suppliers, generally ranging from 10 to 100 units. Some manufacturers may offer lower MOQs for first-time buyers or for specific models. It’s essential to negotiate MOQs based on your procurement needs, and consider bulk purchasing to secure better pricing. Always confirm the MOQ with the supplier before placing an order to avoid unexpected costs. -

What payment terms should I expect when sourcing pressure switch motors?

Payment terms for sourcing pressure switch motors can differ based on supplier policies and the nature of the transaction. Common arrangements include upfront payments, partial payments upon order confirmation, or payment upon delivery. For international orders, consider using secure payment methods like letters of credit or escrow services to protect your investment. Always clarify payment terms in advance to prevent misunderstandings and ensure smooth transactions. -

How can I ensure quality assurance for pressure switch motors?

To ensure quality assurance for pressure switch motors, request detailed documentation of the manufacturer’s quality control processes, including inspection and testing protocols. Ask for certifications that validate compliance with industry standards. Additionally, consider conducting third-party inspections or audits to verify the quality of the products before shipment. Establishing a clear communication channel with the supplier regarding quality expectations can also help mitigate potential issues. -

What logistics considerations should I keep in mind when importing pressure switch motors?

When importing pressure switch motors, consider logistics factors such as shipping methods, lead times, and customs regulations in your country. Evaluate the total landed cost, which includes shipping, duties, and taxes, to avoid unexpected expenses. Partnering with a reliable freight forwarder can streamline the logistics process and ensure compliance with all international shipping regulations. It’s also wise to plan for potential delays and ensure that your supply chain can adapt to any disruptions.

Top 1 Pressure Switch Motor Manufacturers & Suppliers List

1. CentriPro – Pressure Switch 30-50 PSI, 2 HP

Domain: store.waterpumpsupply.com

Registered: 2003 (22 years)

Introduction: Pressure Switches: 1. CentriPro Pressure Switch 30-50 PSI, 2 HP # AS4 – Price: $62.00, Sale Price: $42.45 2. CentriPro Pressure Switch 30-50 PSI, 2 HP # AS10 – Price: $72.00, Sale Price: $49.90 3. Harvard Pressure Switch 30-50 PSI, 2 HP # CPS3050 – Price: $30.83 4. Low Pressure Furnas Cut-off “Gard-it” Switch # 69WC7.

Strategic Sourcing Conclusion and Outlook for pressure switch motor

As the demand for pressure switch motors continues to grow across international markets, strategic sourcing becomes an essential practice for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. Understanding the technical specifications, operational efficiencies, and market trends surrounding pressure switch motors can significantly impact procurement decisions. By focusing on reliable suppliers and leveraging data-driven insights, businesses can optimize their supply chains, reduce costs, and enhance the longevity of their equipment.

Furthermore, embracing the latest innovations in pressure switch technology can lead to improved system performance and energy efficiency. Buyers should prioritize partnerships with manufacturers who demonstrate a commitment to quality and sustainability, ensuring that their sourcing decisions align with broader organizational goals.

Looking ahead, the landscape for pressure switch motors is poised for continued evolution, driven by advancements in automation and IoT integration. International B2B buyers are encouraged to stay informed about emerging trends and technologies to capitalize on opportunities in this dynamic market. Engage with suppliers who can provide not just products, but also valuable insights and support to foster long-term business growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to pressure switch motor

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.