How to Source Power Cord Types Chart Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for power cord types chart

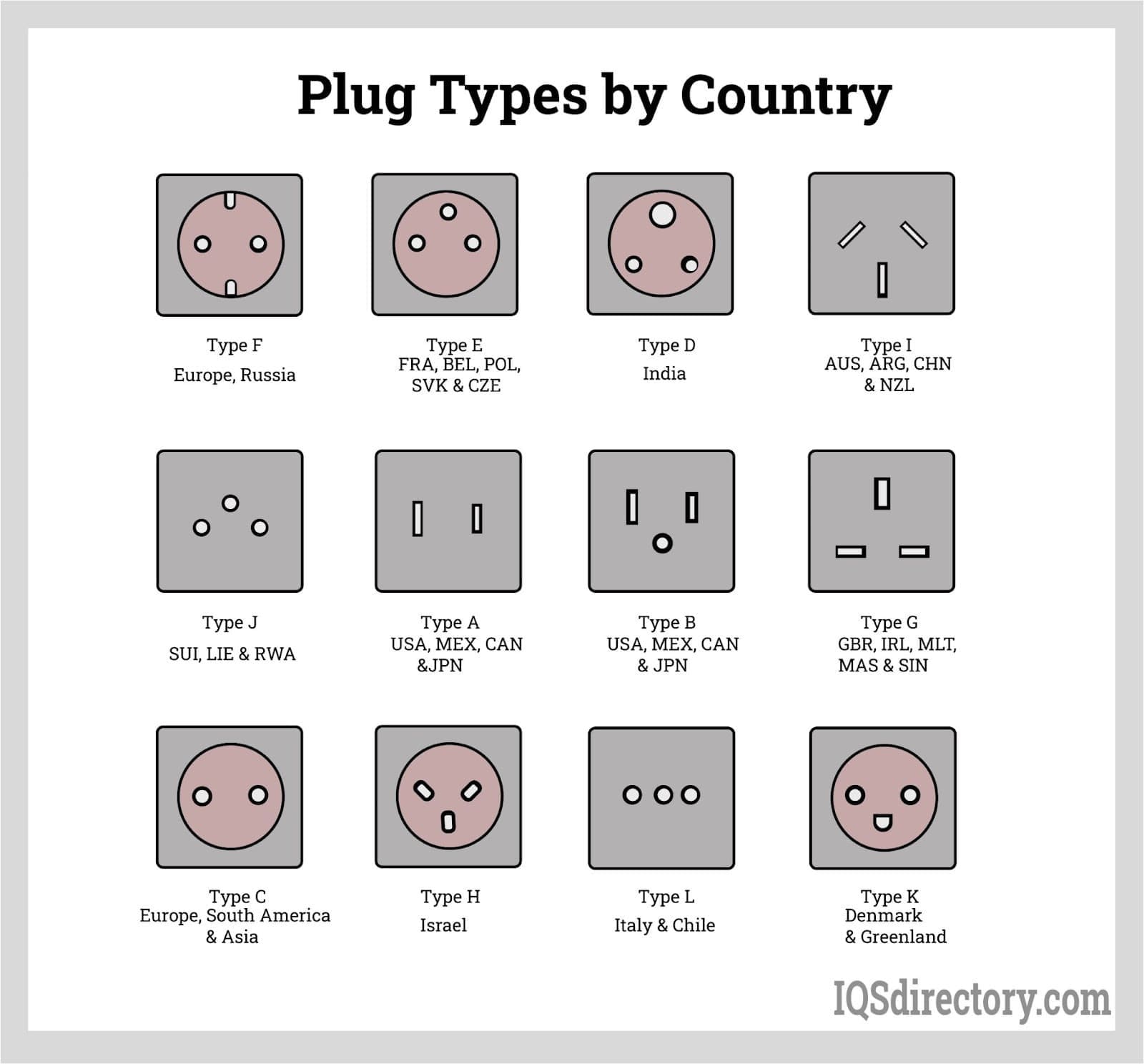

In today’s interconnected global market, sourcing the right power cord types can be a daunting task for international B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With varying standards, voltage requirements, and environmental conditions, ensuring compliance and compatibility is crucial to maintaining operational efficiency. This comprehensive guide offers an in-depth power cord types chart, detailing a variety of cord specifications, including gauge sizes, insulation materials, and voltage ratings, tailored to meet the unique needs of different industries.

Throughout this guide, you will discover essential insights into the various applications of power cords, helping you identify the best solutions for your specific requirements. Moreover, we will explore the critical aspects of supplier vetting, ensuring that you engage with reputable manufacturers who can deliver high-quality products. Understanding cost implications will also be a focal point, empowering you to make informed purchasing decisions that align with your budgetary constraints.

By leveraging the information presented in this guide, B2B buyers can navigate the complexities of the power cord market with confidence. From selecting the appropriate cord type to establishing strong supplier relationships, this resource is designed to facilitate seamless procurement processes and enhance your operational capabilities across borders.

Understanding power cord types chart Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| SPT Series (SPT-1, SPT-2, SPT-3) | Lightweight, PVC insulation, available in 2 or 3 conductors | Indoor appliances, small electronic devices | Pros: Cost-effective, flexible; Cons: Limited voltage capacity (300V), not suitable for outdoor use. |

| SJT/SJTW | Heavy-duty, available in multiple gauges (18-10 AWG), weather-resistant options | Industrial equipment, outdoor tools | Pros: High durability, suitable for harsh conditions; Cons: Heavier and less flexible than lighter cords. |

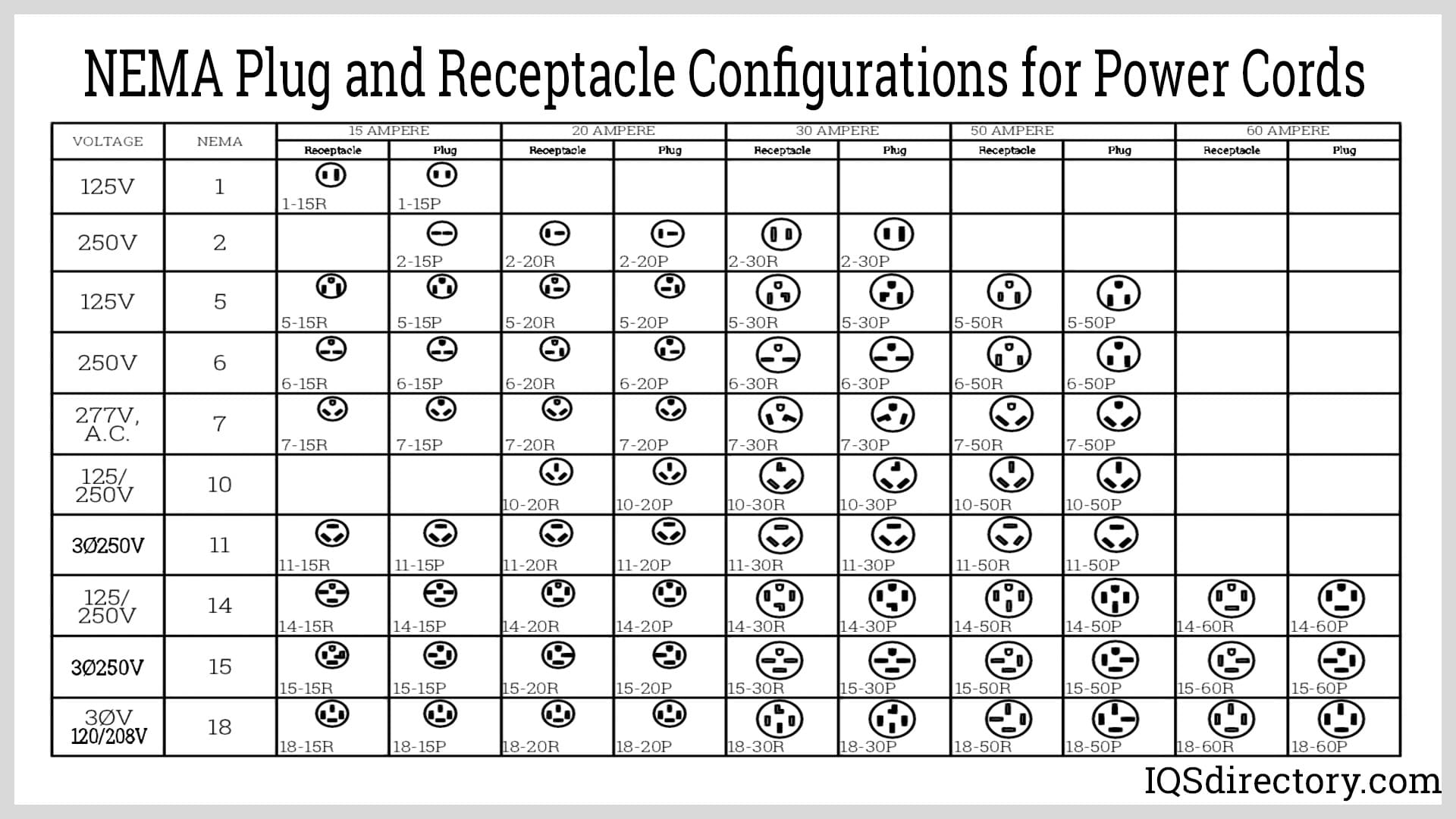

| NEMA Power Cords (e.g., NEMA 5-15, NEMA 6-20) | Standardized plugs and connectors, rated for different amperages and voltages | Commercial electronics, IT equipment | Pros: Wide compatibility, reliable performance; Cons: Specific to North American standards, may require adapters in other regions. |

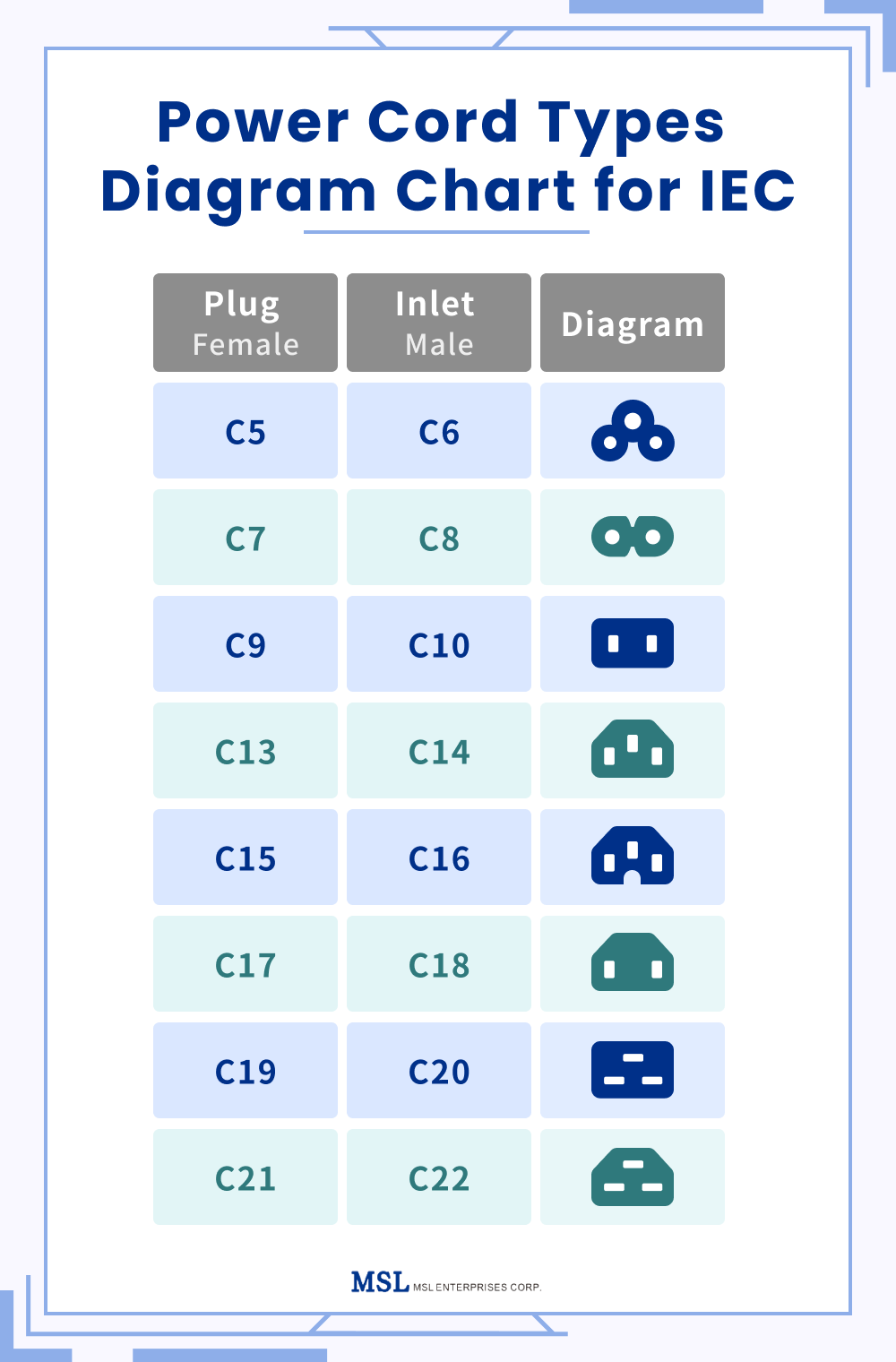

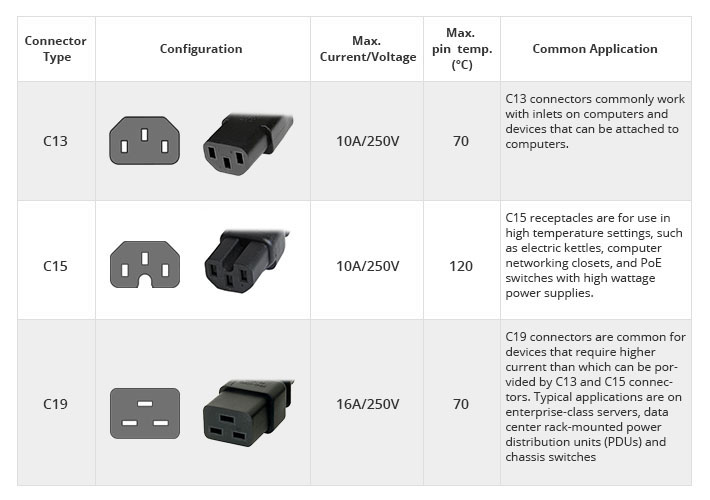

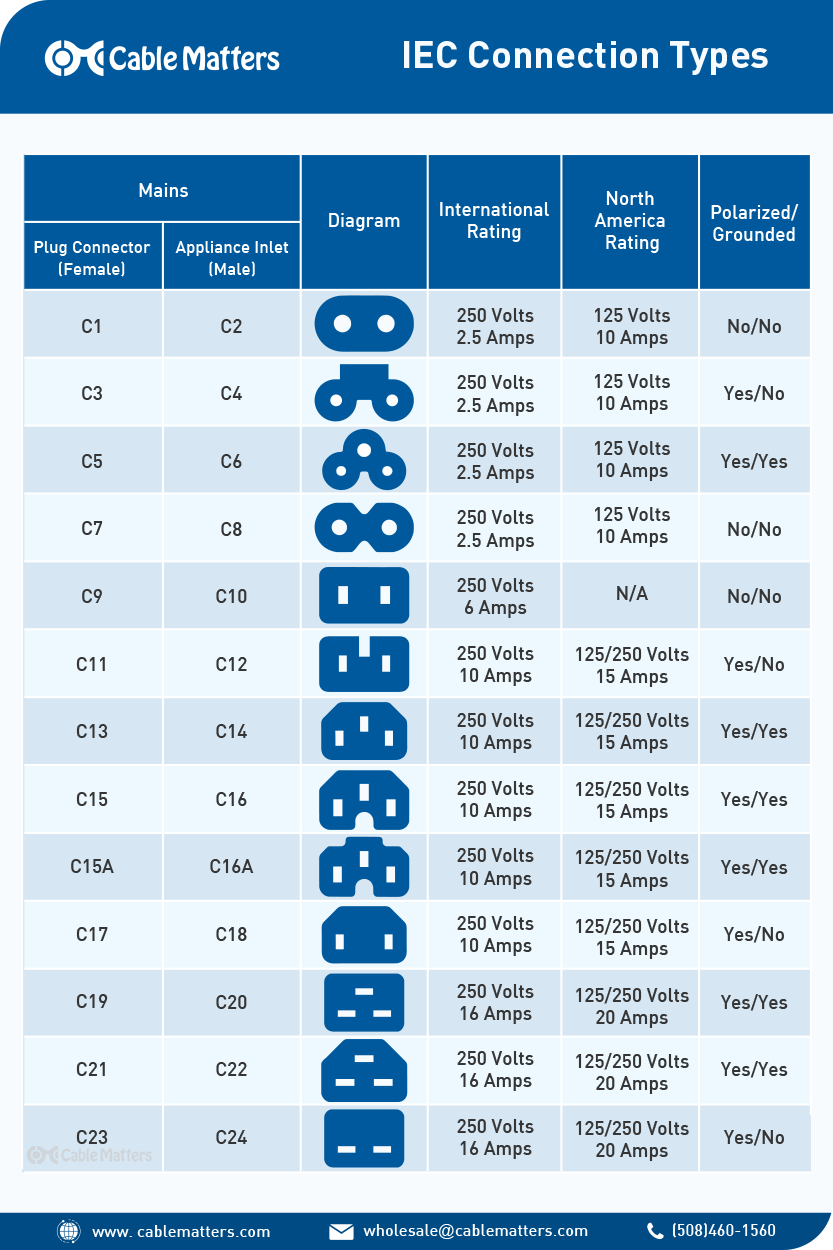

| IEC 60320 Cords (e.g., C13, C14) | Modular design, used in data centers and IT environments | Computer equipment, servers, power strips | Pros: International standard, versatile; Cons: Limited to specific equipment types. |

| SOOW | Oil and weather-resistant, rubber insulation, heavy-duty gauge | Construction sites, outdoor machinery | Pros: Extremely durable, suitable for extreme conditions; Cons: Higher cost compared to standard cords. |

What Are the Key Characteristics of SPT Series Power Cords?

SPT Series power cords, including SPT-1, SPT-2, and SPT-3, are characterized by their lightweight construction and PVC insulation. These cords typically feature 2 or 3 conductors and are designed for indoor use only. They are commonly used in household appliances and small electronic devices, making them a cost-effective choice for businesses that require basic power solutions. However, their limited voltage capacity of 300 volts makes them unsuitable for heavy-duty applications.

How Do SJT and SJTW Power Cords Stand Out?

SJT and SJTW power cords are recognized for their heavy-duty performance, with a range of gauge sizes from 18 to 10 AWG. These cords are designed for both indoor and outdoor use, with SJTW specifically offering weather-resistant features. They are ideal for industrial equipment and outdoor tools, providing high durability in harsh conditions. While their robustness is a significant advantage, buyers should consider their weight and reduced flexibility compared to lighter alternatives.

Why Are NEMA Power Cords Essential for B2B Applications?

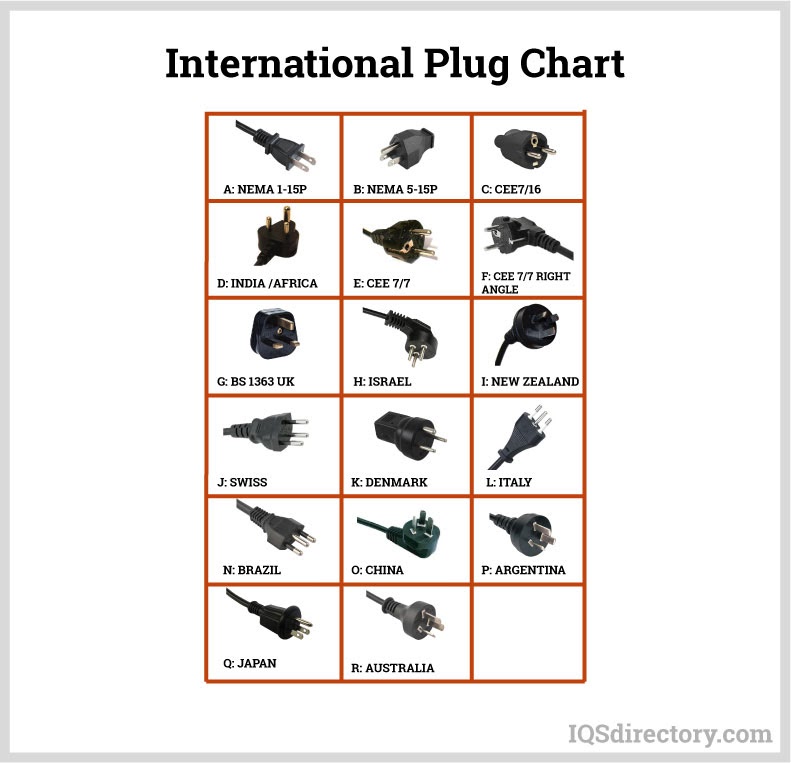

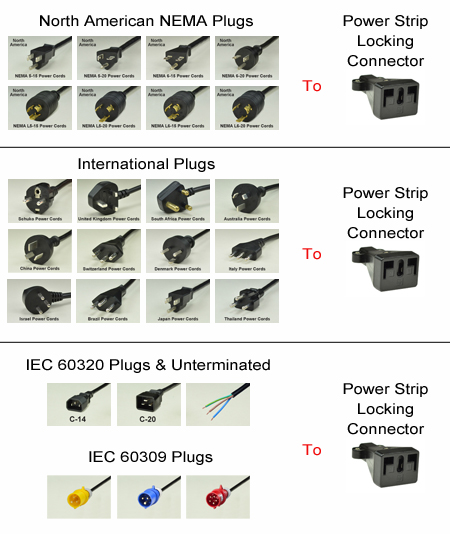

NEMA power cords, such as NEMA 5-15 and NEMA 6-20, feature standardized plugs and connectors that cater to various amperages and voltages. These cords are widely used in commercial electronics and IT equipment, ensuring reliable performance and compatibility across devices. However, their design is specific to North American standards, which may necessitate the use of adapters for international buyers, potentially complicating procurement.

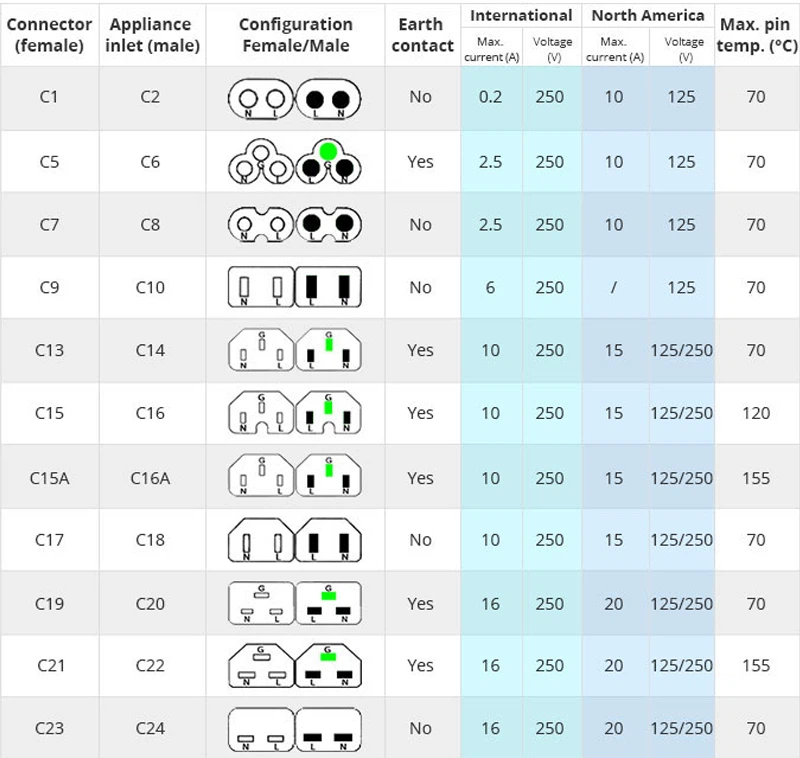

What Makes IEC 60320 Cords a Preferred Choice in IT Environments?

IEC 60320 cords, like the C13 and C14 types, are modular and adhere to international standards, making them particularly suitable for data centers and IT environments. Their versatility allows them to connect a wide range of computer equipment and power strips. While their standardized design offers compatibility across various devices, buyers must ensure they are purchasing the correct type to match their specific equipment requirements.

What Are the Advantages of SOOW Power Cords in Extreme Conditions?

SOOW power cords are designed for heavy-duty applications, featuring oil and weather-resistant properties with rubber insulation. They are commonly used in construction sites and for outdoor machinery, providing exceptional durability in extreme conditions. Although they offer superior protection and longevity, the higher cost compared to standard power cords may be a consideration for budget-conscious buyers.

Illustrative image related to power cord types chart

Key Industrial Applications of power cord types chart

| Industry/Sector | Specific Application of power cord types chart | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering industrial machinery and equipment | Ensures reliable operation of critical machinery, minimizing downtime | Voltage ratings, durability, and compatibility with local standards |

| Construction | Temporary power supply for tools and equipment | Enhances productivity on job sites by providing consistent power | Weather resistance, gauge size, and length for various applications |

| Healthcare | Medical equipment power connections | Critical for patient safety and equipment reliability | Compliance with safety standards, hospital-grade certifications |

| Telecommunications | Data center equipment connectivity | Supports high availability and performance of network services | Cable type (e.g., C13/C14), cooling requirements, and length |

| Event Management | Powering audiovisual and lighting equipment at events | Facilitates seamless operations and enhances event experiences | Portability, flexibility in configurations, and voltage compatibility |

How is the ‘Power Cord Types Chart’ Used in Manufacturing Applications?

In the manufacturing sector, the power cord types chart is essential for powering various industrial machinery and equipment. Different machines require specific cord types based on their voltage and current needs. Using the correct power cord minimizes downtime and ensures that equipment operates efficiently. International buyers should consider voltage ratings, durability, and compatibility with local electrical standards to ensure seamless integration into their operations.

What Role Does the Power Cord Types Chart Play in Construction?

The construction industry often relies on temporary power supplies for tools and heavy equipment on job sites. The power cord types chart helps identify suitable cords that can withstand tough environmental conditions while providing consistent power. This ensures that construction projects remain on schedule and that workers can operate tools without interruption. Buyers should prioritize weather resistance, gauge size, and length to accommodate various equipment and site layouts.

Why is the Power Cord Types Chart Important in Healthcare Settings?

In healthcare, the power cord types chart is critical for connecting medical equipment to reliable power sources. Given the life-saving nature of many devices, using the correct power cord is vital for patient safety and equipment reliability. Buyers in this sector must ensure that cords comply with strict safety standards and are hospital-grade certified to prevent electrical failures. Sourcing from reputable manufacturers who understand these requirements is essential.

How Does the Power Cord Types Chart Support Telecommunications?

Telecommunications companies utilize the power cord types chart to ensure that data center equipment is properly connected and powered. High availability and performance are crucial for network services, and the right power cords help maintain this. Buyers need to consider cable types like C13/C14, cooling requirements, and lengths that fit their specific data center configurations. Proper sourcing can prevent outages and improve overall service quality.

In What Ways is the Power Cord Types Chart Beneficial for Event Management?

Event management professionals often need to power audiovisual and lighting equipment, making the power cord types chart an invaluable resource. It assists in identifying flexible and portable power solutions that can adapt to different event setups. Ensuring that the cords are compatible with various voltage levels and configurations is critical for smooth operations. Buyers should focus on the portability and adaptability of power cords to enhance the overall event experience.

3 Common User Pain Points for ‘power cord types chart’ & Their Solutions

Scenario 1: Sourcing the Right Power Cord for Diverse Applications

The Problem: B2B buyers often face the challenge of selecting the appropriate power cords for various applications, especially when dealing with different equipment specifications and environmental conditions. This can be particularly complex in regions like Africa and South America, where electrical standards vary widely. A buyer may mistakenly purchase cords that do not meet the voltage requirements or are unsuitable for indoor versus outdoor use, leading to equipment failures or safety hazards.

Illustrative image related to power cord types chart

The Solution: To overcome this issue, B2B buyers should utilize a comprehensive power cord types chart that clearly categorizes cords based on their specifications, such as gauge size, insulation type, voltage ratings, and intended applications. Buyers can start by assessing their equipment requirements and match these with the correct cord type from the chart. For example, if sourcing cords for outdoor equipment, buyers should prioritize weather-resistant options like SJTW or SOOW cords that can withstand environmental stressors. Additionally, collaborating with a supplier who understands local regulations and standards can help ensure compliance and optimal performance.

Scenario 2: Ensuring Compatibility with International Standards

The Problem: In a global marketplace, compatibility with international power standards is a significant pain point for B2B buyers. For instance, a company in Europe might struggle to find power cords that are compatible with American-made equipment, which often uses NEMA connectors. This not only complicates the purchasing process but can also lead to costly delays in project timelines due to equipment incompatibility.

The Solution: Buyers should refer to a detailed power cord types chart that includes international standards and connector types. By identifying the specific NEMA or IEC standards required for their equipment, buyers can make informed decisions when sourcing power cords. It’s advisable to create a checklist of required specifications before contacting suppliers. Additionally, engaging with manufacturers who offer universal or adaptable power cords can provide a versatile solution, ensuring compatibility across different standards. Establishing clear communication with suppliers about the intended use and geographical location can further enhance compatibility and efficiency.

Illustrative image related to power cord types chart

Scenario 3: Navigating Supply Chain and Lead Time Challenges

The Problem: Supply chain disruptions can severely impact B2B buyers, especially when sourcing specialized power cords that may have extended lead times. For example, a company in the Middle East may require specific power cords for a construction project but faces delays due to international shipping issues or local sourcing limitations. This can result in project delays and increased costs.

The Solution: To mitigate this challenge, buyers should proactively assess their supply chain options by leveraging a power cord types chart that highlights local and international suppliers. Understanding the lead times associated with different types of cords can help buyers plan their procurement strategies effectively. For instance, opting for locally manufactured cords can significantly reduce lead times and shipping costs. Additionally, establishing strong relationships with multiple suppliers can provide alternative sourcing options in case of disruptions. It is also beneficial to keep a buffer stock of essential cords to ensure operational continuity during unforeseen delays. Regularly reviewing supplier performance and lead times will aid in making more agile sourcing decisions moving forward.

Strategic Material Selection Guide for power cord types chart

What Are the Key Properties of Common Materials Used in Power Cords?

When selecting materials for power cords, several factors influence performance, durability, and application suitability. The most common materials include PVC, rubber, thermoplastic elastomers (TPE), and silicone. Each material has distinct properties that can significantly impact the functionality of power cords in various environments.

Illustrative image related to power cord types chart

How Does PVC Impact Power Cord Performance?

Polyvinyl Chloride (PVC) is one of the most widely used materials for power cords due to its excellent insulation properties and cost-effectiveness. PVC can withstand temperatures ranging from -10°C to 60°C and offers good resistance to moisture and chemicals. However, it has limitations in high-temperature applications and may become brittle over time when exposed to UV light.

Pros: PVC is durable, affordable, and easy to manufacture, making it suitable for indoor applications where extreme conditions are not a concern.

Cons: Its performance can degrade under high temperatures or prolonged UV exposure, limiting its use in outdoor or high-heat environments.

Impact on Application: PVC is ideal for indoor power cords, but buyers in regions with high humidity or UV exposure should consider alternatives.

Considerations for International Buyers: PVC complies with various international standards, including ASTM and DIN, but buyers should verify local regulations regarding chemical emissions and environmental impact.

What Are the Advantages of Rubber in Power Cords?

Rubber is another popular material, especially for heavy-duty power cords. It boasts excellent flexibility, high-temperature resistance (up to 90°C), and superior durability against abrasion and impact. Rubber is also resistant to oils and chemicals, making it suitable for industrial applications.

Illustrative image related to power cord types chart

Pros: Rubber’s flexibility and durability make it ideal for outdoor and industrial use, where cords may be exposed to harsh conditions.

Cons: The manufacturing process for rubber cords can be more complex and costly compared to PVC, which may affect pricing.

Impact on Application: Rubber power cords are suitable for environments where mechanical stress and exposure to oils or chemicals are prevalent.

Considerations for International Buyers: Rubber cords often meet stringent international safety standards, making them a reliable choice for buyers in diverse markets, including those in Africa and the Middle East.

How Do Thermoplastic Elastomers (TPE) Compare to Other Materials?

Thermoplastic elastomers (TPE) combine the properties of rubber and plastic, offering flexibility, durability, and resistance to a wide temperature range (-40°C to 90°C). TPEs are also lightweight and can be produced in various colors, enhancing aesthetic appeal.

Pros: TPEs provide excellent performance in both low and high temperatures, making them versatile for various applications.

Cons: They can be more expensive to produce than PVC and may not be as widely available in all regions.

Impact on Application: TPEs are suitable for applications requiring flexibility and durability, such as consumer electronics and automotive components.

Considerations for International Buyers: Buyers should check for compliance with local standards, as TPEs may not be as commonly recognized as PVC or rubber in some markets.

What Role Does Silicone Play in Power Cord Applications?

Silicone is known for its exceptional temperature resistance, capable of withstanding temperatures from -60°C to 200°C. It is also highly resistant to UV light, ozone, and extreme weather conditions, making it ideal for outdoor applications.

Illustrative image related to power cord types chart

Pros: Silicone’s high-performance characteristics make it suitable for extreme environments, ensuring longevity and reliability.

Cons: The cost of silicone is significantly higher than other materials, which may deter budget-conscious buyers.

Impact on Application: Silicone is ideal for applications in harsh environments, such as outdoor power tools and medical devices.

Considerations for International Buyers: Silicone meets various international safety standards, but its higher cost may require justification based on the application’s demands.

Summary Table of Material Selection for Power Cords

| Material | Typical Use Case for power cord types chart | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Indoor power cords | Cost-effective and durable | Limited high-temperature resistance | Low |

| Rubber | Heavy-duty and outdoor applications | Excellent flexibility and durability | Higher manufacturing complexity | Med |

| TPE | Versatile applications (electronics, automotive) | Wide temperature range and lightweight | Higher production cost | Med |

| Silicone | Harsh environment applications | Exceptional temperature resistance | Significantly higher cost | High |

This guide provides a comprehensive overview of the materials commonly used in power cords, equipping international B2B buyers with the insights needed to make informed decisions based on their specific application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for power cord types chart

What Are the Main Stages of Power Cord Manufacturing?

The manufacturing of power cords involves a systematic approach that ensures both functionality and safety. The process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

Illustrative image related to power cord types chart

-

Material Preparation: This initial stage involves selecting and preparing the raw materials, which typically include copper or aluminum for conductors, various types of insulation (like PVC, rubber, or thermoplastic), and outer jackets. Quality of materials is critical; manufacturers often source materials from certified suppliers to ensure compliance with international standards.

-

Forming: During this stage, the prepared materials are formed into the desired shapes. This includes cutting wires to length, applying insulation to conductors, and molding the outer jacket. Techniques such as extrusion for insulation and molding for connectors are commonly employed. Precision in this stage is vital to maintain the electrical characteristics and ensure safety standards.

-

Assembly: In this stage, the various components are brought together. Conductors are connected to terminals or plugs, and assemblies are tested for proper connections. Automation technology is often utilized to enhance efficiency and consistency. Manual inspections are also performed to identify any visible defects.

-

Finishing: The final stage involves applying any necessary coatings, packaging, and labeling of the cords. This is also when final quality checks are conducted. This stage ensures that the finished product not only meets functional requirements but also complies with aesthetic and regulatory standards.

What Quality Control Processes Are Essential in Power Cord Manufacturing?

Quality control (QC) is paramount in power cord manufacturing, ensuring that products meet both safety and performance standards. Several international and industry-specific standards guide these processes.

-

International Standards: Adherence to ISO 9001 is crucial, as it outlines requirements for a quality management system. This certification assures buyers that the manufacturer has robust processes in place for quality assurance.

-

Industry-Specific Standards: Compliance with standards such as CE (Conformité Européenne) for European markets and UL (Underwriters Laboratories) for North America is often required. These certifications indicate that products have undergone rigorous testing for safety and performance.

-

QC Checkpoints: The QC process typically includes several checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring occurs throughout the manufacturing process, allowing for immediate corrections if defects are detected.

– Final Quality Control (FQC): The finished products undergo comprehensive testing to verify that they function correctly and comply with relevant standards.

What Testing Methods Are Commonly Used in Power Cord Quality Control?

Testing is a critical component of the QC process, with several methods employed to validate the performance and safety of power cords.

-

Electrical Testing: This includes insulation resistance tests, continuity tests, and voltage drop tests to ensure electrical integrity and safety.

-

Mechanical Testing: Manufacturers often conduct pull tests, twist tests, and bend tests to evaluate the mechanical durability of the cords under various conditions.

-

Environmental Testing: Exposure to extreme temperatures, humidity, and UV light can affect the longevity and reliability of power cords. Manufacturers perform tests to simulate these conditions and assess performance over time.

-

Third-Party Testing: Many manufacturers partner with accredited third-party testing laboratories to conduct comprehensive assessments and validate compliance with international standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure product reliability and safety.

-

Audits: Conducting regular audits of suppliers’ manufacturing facilities can provide insights into their QC practices. This includes reviewing documentation, inspecting processes, and assessing the overall quality management system.

-

Quality Reports: Requesting detailed quality reports from suppliers can help assess their adherence to standards. These reports should outline QC processes, testing results, and any corrective actions taken in response to defects.

-

Third-Party Inspection: Engaging third-party inspection services before shipment can offer an additional layer of assurance. These inspectors can verify that products meet the required specifications and standards.

-

Certification Verification: Buyers should request copies of relevant certifications and verify their authenticity. This includes checking ISO certifications and compliance with regional standards like CE or UL.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating the complexities of international standards can be challenging for B2B buyers. Here are some nuances to consider:

-

Regional Compliance: Different markets have varying compliance requirements. For example, products sold in Europe must meet CE standards, while those in the U.S. require UL certification. Understanding these nuances is crucial for avoiding regulatory issues.

-

Cultural Factors: Quality expectations can vary by region. Buyers should be aware of local perceptions of quality and safety, which can influence purchasing decisions.

-

Supply Chain Considerations: The global supply chain can introduce variability in quality. B2B buyers should evaluate the entire supply chain, from raw material suppliers to final product manufacturers, to ensure consistent quality.

-

Language Barriers: Communication can pose challenges, particularly when dealing with suppliers from different linguistic backgrounds. Clear documentation and bilingual staff can help mitigate misunderstandings regarding quality expectations.

In conclusion, understanding the manufacturing processes and quality assurance measures for power cords is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, as well as rigorous quality control practices, buyers can ensure that they source reliable and compliant products from their suppliers.

Illustrative image related to power cord types chart

Practical Sourcing Guide: A Step-by-Step Checklist for ‘power cord types chart’

In the dynamic landscape of international B2B procurement, understanding the nuances of power cord types is crucial for making informed decisions. This practical sourcing guide aims to equip buyers with a step-by-step checklist to navigate the complexities of selecting the appropriate power cord types for their specific needs, particularly focusing on the diverse requirements across regions such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

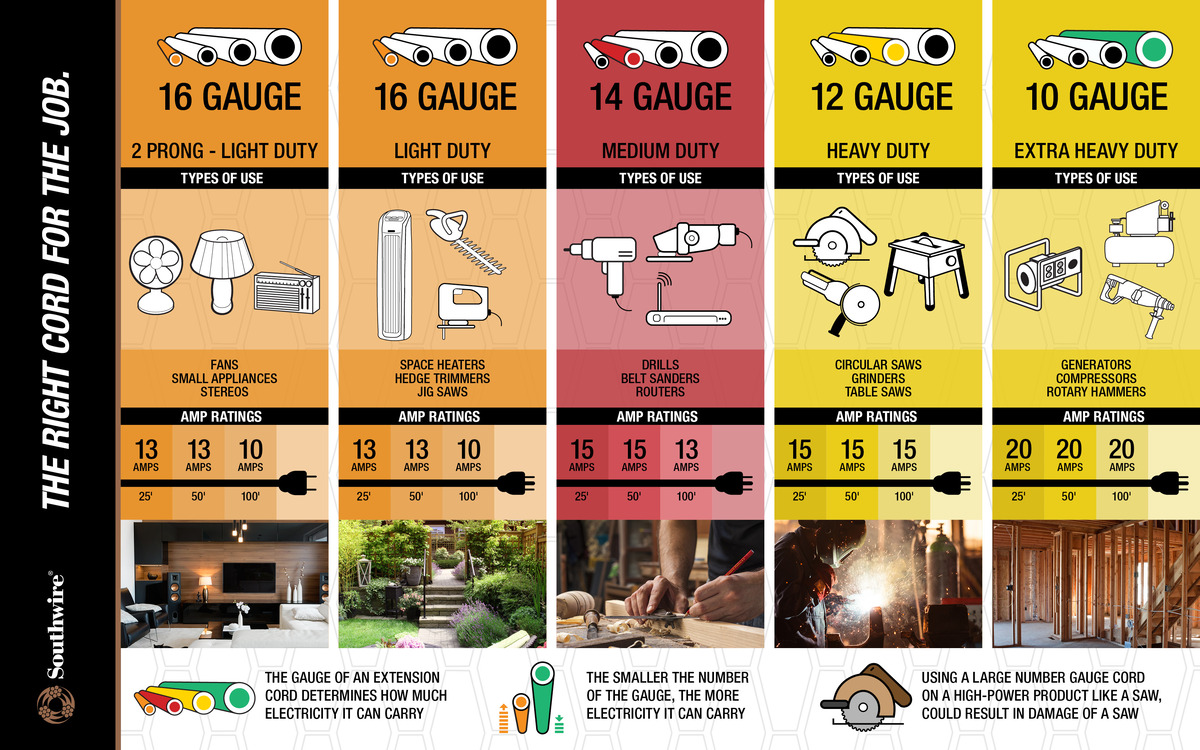

Before initiating the sourcing process, clearly outline your technical requirements. This includes voltage ratings, gauge sizes, insulation types, and conductor numbers. Specifications can vary significantly between regions, so understanding local standards is essential to ensure compatibility and safety.

- Voltage Ratings: Confirm the voltage levels your equipment will operate at, as this impacts the cord type needed.

- Gauge Size: Select the appropriate gauge based on the current load; heavier loads require thicker wires.

Step 2: Research International Standards and Compliance

Investigate the international standards that apply to power cords in your target markets. Compliance with local regulations is critical to avoid legal issues and ensure product safety.

Illustrative image related to power cord types chart

- Certification Requirements: Look for certifications such as CE, UL, or IEC, depending on the market.

- Regional Differences: Be aware of variations in standards between countries, particularly in Europe and North America.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers before making any commitments. A reliable supplier can make a significant difference in product quality and customer service.

- Request Documentation: Ask for company profiles, quality certifications, and case studies to assess reliability.

- Check References: Reach out to other buyers in your industry to gather insights on supplier performance.

Step 4: Assess Product Samples

Request samples of the power cords you are considering. This step is vital to evaluate the quality and suitability of the products for your applications.

- Quality Check: Inspect samples for durability, flexibility, and overall construction quality.

- Performance Testing: If possible, conduct performance tests to ensure they meet your specifications.

Step 5: Negotiate Pricing and Terms

Once you have identified potential suppliers and evaluated their products, engage in negotiations to secure favorable pricing and terms.

- Bulk Discounts: Inquire about discounts for larger orders, which can significantly reduce costs.

- Payment Terms: Clarify payment options and terms to avoid cash flow issues.

Step 6: Plan for Logistics and Shipping

Consider the logistics involved in importing power cords from suppliers, especially when dealing with international shipments.

- Shipping Costs: Factor in shipping fees, taxes, and potential tariffs that may apply.

- Delivery Times: Confirm lead times to ensure your supply chain remains uninterrupted.

Step 7: Establish a Long-Term Relationship

After the initial order, focus on building a long-term partnership with your supplier. This can lead to better pricing, improved service, and more tailored solutions.

- Regular Communication: Maintain open lines of communication to address any issues promptly.

- Feedback Loop: Provide feedback to your supplier on product performance to help them improve their offerings.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing power cords, ensuring that they select the right products to meet their operational needs while complying with international standards.

Comprehensive Cost and Pricing Analysis for power cord types chart Sourcing

What Are the Key Cost Components in Power Cord Manufacturing?

The cost structure for power cords involves several key components that B2B buyers should understand when sourcing products. The primary cost components include:

-

Materials: The choice of materials significantly affects the overall cost. For instance, using high-quality PVC or rubber jackets can increase the price but may lead to better durability and performance. Conductors made from copper are typically more expensive than aluminum but offer superior conductivity.

-

Labor: Labor costs vary by region and affect the total cost of production. Countries with lower labor costs may offer more competitive pricing, but buyers should consider the trade-off with quality.

-

Manufacturing Overhead: This includes utilities, rent, and other operational costs incurred during production. Efficient factories may have lower overhead costs, allowing for more competitive pricing.

-

Tooling: Custom tooling can be a significant upfront cost, especially for specialized power cords. Buyers should assess whether the tooling costs will be amortized over a large order volume to lower the per-unit price.

-

Quality Control (QC): Ensuring that power cords meet safety and performance standards incurs additional costs. Robust QC processes may raise prices but are essential for ensuring compliance with international certifications.

-

Logistics: Shipping and handling costs can vary widely based on the destination and shipping method. International shipping, particularly to regions like Africa and South America, can add significant costs that buyers should factor into their total budget.

-

Margin: Suppliers will incorporate their desired profit margin into the final pricing. Understanding the typical margins in the industry can help buyers negotiate better terms.

What Influences Pricing in the Power Cord Market?

Several factors influence pricing in the power cord market, which B2B buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs due to economies of scale. Buyers should negotiate for better pricing based on anticipated volume.

-

Specifications and Customization: Customized power cords that meet specific requirements may incur higher costs. Buyers should clarify their specifications upfront to avoid unexpected costs later.

-

Material Quality and Certifications: High-quality materials and recognized certifications (e.g., UL, CE) can increase costs but are crucial for safety and compliance in many markets.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their quality assurance and customer service.

-

Incoterms: Understanding Incoterms is vital for international transactions, as they dictate who bears the costs and risks during shipping. This can significantly impact the total cost of ownership.

What Are the Best Negotiation Tips for International Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, negotiating effectively can yield significant savings:

-

Research and Benchmarking: Conduct market research to understand typical pricing structures. Benchmark against competitors to inform your negotiation strategy.

-

Total Cost of Ownership (TCO): Consider not just the initial purchase price but the TCO, including logistics, installation, and potential maintenance costs. This broader view can provide leverage in negotiations.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better pricing and terms. Long-term partnerships often yield benefits that short-term transactions do not.

-

Flexibility in Terms: Be open to different terms that can lead to better pricing. For instance, offering to pay in advance or accept longer lead times might result in discounts.

-

Understand Local Regulations: Knowledge of local import regulations can help avoid unexpected tariffs or fees, which can significantly affect the final cost.

Disclaimer on Indicative Prices

Prices for power cords can vary widely based on the factors mentioned above. Buyers are encouraged to seek quotes from multiple suppliers and consider all cost components before making purchasing decisions.

Alternatives Analysis: Comparing power cord types chart With Other Solutions

In the realm of electrical connectivity, businesses often seek optimal solutions to power their equipment efficiently and safely. While a power cord types chart provides a comprehensive overview of various cord specifications, it is essential to consider alternative solutions that may offer similar benefits or address specific operational needs. This analysis will compare the power cord types chart against two viable alternatives: Power Distribution Units (PDUs) and Wireless Power Transfer (WPT) technologies.

Illustrative image related to power cord types chart

Comparison Table

| Comparison Aspect | Power Cord Types Chart | Power Distribution Units (PDUs) | Wireless Power Transfer (WPT) |

|---|---|---|---|

| Performance | High, specific to cord types | Very high, supports multiple devices | Moderate, limited by distance and power levels |

| Cost | Generally low, varies by type | Moderate to high, depending on features | High initial investment, ongoing costs may vary |

| Ease of Implementation | Simple to understand and use | Moderate, requires installation and configuration | Complex, requires specialized equipment and setup |

| Maintenance | Low, minimal upkeep required | Moderate, periodic monitoring needed | Low, but technology may need updates |

| Best Use Case | Individual devices in specific settings | Data centers, server rooms, and high-density environments | Charging mobile devices or low-power applications |

In-Depth Analysis of Alternatives

What are Power Distribution Units (PDUs)?

Power Distribution Units (PDUs) are essential in environments where numerous devices require power. They distribute electrical power from a single source to multiple devices, allowing for efficient management of power usage and load balancing.

Pros: PDUs offer scalability, advanced monitoring capabilities, and protection against overloads, making them ideal for data centers and commercial applications. They can also support various power configurations (e.g., single-phase or three-phase).

Cons: The cost of PDUs can be significant, especially for advanced models with monitoring features. Additionally, installation may require professional assistance, which can complicate deployment.

How Does Wireless Power Transfer (WPT) Work?

Wireless Power Transfer (WPT) is an innovative technology that uses electromagnetic fields to transfer energy between two objects without direct electrical connections. This method is gaining traction, particularly for charging devices like smartphones and electric vehicles.

Pros: WPT eliminates the need for physical cables, reducing wear and tear on connectors and improving flexibility in device placement. It is especially useful in environments where traditional wiring is impractical or unsafe.

Illustrative image related to power cord types chart

Cons: The performance of WPT is often limited by distance and efficiency, particularly for high-power applications. Moreover, the initial investment in WPT infrastructure can be high, and it may not be suitable for all environments.

How Should B2B Buyers Choose the Right Solution?

Selecting the appropriate power solution depends on various factors, including the specific application, budget constraints, and operational requirements. A power cord types chart is an excellent resource for straightforward applications where individual devices are powered. However, for environments with high device density, like data centers, PDUs may provide more efficient power management. Conversely, if flexibility and mobility are paramount, WPT could be the best choice, despite its higher initial costs.

Ultimately, buyers should evaluate their unique needs, considering performance requirements, installation complexity, and long-term operational costs to make an informed decision that aligns with their business objectives.

Essential Technical Properties and Trade Terminology for power cord types chart

What Are the Key Technical Properties of Power Cord Types?

When selecting power cords for various applications, understanding the essential technical properties is crucial for ensuring performance, safety, and compliance with international standards. Here are several critical specifications that B2B buyers should consider:

Illustrative image related to power cord types chart

-

Material Grade

The materials used for insulation and jacket (typically PVC, rubber, or thermoplastic) significantly influence the cord’s durability and flexibility. For instance, rubber provides excellent abrasion resistance and is suitable for heavy-duty applications, while PVC is often used for standard indoor cords. Choosing the right material grade helps in reducing maintenance costs and enhancing product longevity. -

Gauge Size

The gauge of the wire (measured in AWG – American Wire Gauge) indicates the wire’s diameter, affecting its current-carrying capacity. Lower AWG numbers mean thicker wires, which can handle higher loads. Understanding gauge size is vital for ensuring that the power cord can safely support the electrical demands of connected equipment, thus preventing overheating and potential fire hazards. -

Voltage Rating

Each power cord type has a specific voltage rating, indicating the maximum voltage it can safely carry. For example, cords rated for 300 volts are suitable for light-duty applications, while those rated for 600 volts are designed for heavier loads. Matching the voltage rating with the intended application is crucial for compliance with local electrical codes and ensuring user safety. -

Number of Conductors

Power cords can have two or more conductors, which allow for different configurations, such as grounding. Understanding the required number of conductors helps buyers select the appropriate cord for their specific application, ensuring proper electrical functionality and safety. -

Insulation and Jacket Type

The insulation and outer jacket provide protection against environmental factors like moisture, oil, and UV rays. Options such as oil-resistant or weather-resistant jackets are essential for outdoor and industrial applications. Choosing the correct insulation type can prevent premature wear and enhance the safety of electrical installations.

What Trade Terminology Should B2B Buyers Understand?

In the B2B landscape, familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are several common terms related to power cords that buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of power cords, buyers may source OEM products to ensure compatibility with their equipment, benefiting from specialized manufacturing processes and quality assurances. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory costs effectively and negotiate better pricing. Suppliers may set MOQs based on manufacturing capabilities and market demand. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products. Buyers use RFQs to compare offers from different manufacturers, enabling informed decision-making when selecting power cords or related components. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping obligations, risks, and costs, which is particularly important for international sourcing of power cords. -

UL Certification

UL (Underwriters Laboratories) certification indicates that a product has been tested for safety and meets specific performance standards. For power cords, UL certification is essential for ensuring compliance with safety regulations, especially in markets like North America.

Understanding these technical properties and trade terminology will empower B2B buyers to make informed decisions when sourcing power cords, ultimately enhancing operational efficiency and safety in their applications.

Navigating Market Dynamics and Sourcing Trends in the power cord types chart Sector

What Are the Key Trends and Market Dynamics in the Power Cord Types Sector?

The power cord types market is witnessing significant transformation driven by technological advancements and changing consumer preferences. Global demand for power cords is largely influenced by the proliferation of electronic devices and the rapid growth of industries such as renewable energy, telecommunications, and automotive. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate a complex landscape characterized by varying standards and regulations across different markets. For instance, while NEMA connectors dominate the North American market, IEC standards are more prevalent in European and Asian markets.

Emerging trends include the increasing demand for custom power solutions tailored to specific applications, including industrial, medical, and consumer electronics. Additionally, the rise of smart devices has led to innovations in power cord designs, such as those incorporating smart technology for enhanced safety and efficiency. Buyers are increasingly seeking suppliers that offer flexibility in manufacturing and the ability to meet short lead times, reflecting a shift towards just-in-time inventory management practices.

Moreover, the focus on energy efficiency is prompting manufacturers to develop cords that minimize energy loss during transmission. As sustainability becomes a key consideration for businesses worldwide, the demand for eco-friendly power cords—constructed from recyclable materials and featuring energy-efficient designs—is on the rise.

Illustrative image related to power cord types chart

How Does Sustainability Impact Sourcing Decisions in the Power Cord Sector?

Sustainability is becoming a crucial factor in B2B purchasing decisions, particularly in the power cord sector. The environmental impact of power cords—stemming from production processes and end-of-life disposal—necessitates a shift towards ethical sourcing and sustainable materials. Buyers are increasingly prioritizing suppliers that can demonstrate a commitment to sustainable practices, including the use of recyclable or biodegradable materials in their products.

Certifications such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) play a vital role in ensuring that power cords are manufactured in an environmentally responsible manner. These certifications not only help mitigate the environmental impact but also enhance the marketability of products, providing an edge in competitive landscapes.

Furthermore, transparency in the supply chain is becoming essential. Buyers are now more inclined to engage with suppliers who can provide insight into their sourcing practices and demonstrate compliance with ethical labor standards. The drive for a circular economy is pushing companies to consider the entire lifecycle of products, from sourcing raw materials to the recycling of end products, making it imperative for suppliers to adopt sustainable practices.

How Has the Power Cord Industry Evolved Over Time?

The evolution of the power cord industry reflects broader technological advancements and changing consumer needs. Historically, power cords were predominantly standardized for basic electrical appliances, primarily focusing on functionality and safety. Over the decades, the increasing complexity of electronic devices and the need for higher power capacities have led to the development of diverse cord types, including specialized connectors and enhanced insulation materials.

In the last two decades, the rise of digital technology and smart devices has further transformed the market. Innovations such as USB-C connectors and power-over-Ethernet capabilities have emerged, enabling more efficient power delivery and data transmission. This evolution is not only shaping the types of cords available but also influencing the way they are manufactured, with an emphasis on customization and adaptability to meet specific industry requirements.

Illustrative image related to power cord types chart

As the global market continues to expand, understanding these historical shifts helps international B2B buyers make informed sourcing decisions that align with current technological trends and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of power cord types chart

-

How do I choose the right power cord type for my equipment?

Choosing the right power cord type depends on several factors including the voltage, amperage, and application of your equipment. Assess the specifications of your devices, such as their power requirements and environmental conditions (indoor vs. outdoor use). For example, cords rated for higher voltage and amperage, like SOOW, are suitable for heavy-duty applications in harsh environments. Additionally, consider the geographical standards and plug types relevant to your region to ensure compatibility. -

What are the key factors to consider when sourcing power cords internationally?

When sourcing power cords internationally, evaluate factors such as compliance with local regulations, certifications (like UL or CE), and the supplier’s manufacturing practices. It’s crucial to verify that the cords meet safety standards specific to your market to avoid legal issues. Additionally, consider the supplier’s capacity for quality assurance, lead times, and logistics capabilities to ensure timely delivery and product reliability. -

How can I customize power cords to meet my specific requirements?

Customization options for power cords often include adjusting length, gauge size, insulation materials, and connector types. When engaging with suppliers, clearly outline your specifications and desired modifications. Many manufacturers offer tailored solutions to meet unique business needs, whether for increased durability, flexibility, or environmental resistance. Be prepared to discuss minimum order quantities (MOQs) and any associated costs for custom orders. -

What are the common payment terms for international power cord purchases?

Payment terms can vary significantly based on supplier policies and the nature of the transaction. Common terms include advance payment, letters of credit, or payment upon delivery. For large orders, negotiating favorable terms such as partial payment upfront and the balance upon shipment can help manage cash flow. Always ensure that payment terms are clearly documented in the contract to avoid misunderstandings. -

What quality assurance practices should I expect from power cord suppliers?

Reputable power cord suppliers should implement robust quality assurance practices, including regular testing of products against international safety standards. Look for suppliers who provide certifications and detailed documentation of their testing processes. Regular audits and inspections during production can also enhance quality control. Establishing clear quality expectations upfront can help ensure the final product meets your business standards. -

How do I verify the reliability of a power cord supplier?

To verify the reliability of a power cord supplier, conduct thorough due diligence, including checking references, customer reviews, and industry certifications. Request information on their manufacturing processes, lead times, and past project experiences. A reliable supplier should be transparent about their capabilities and willing to share case studies or testimonials from other B2B clients. Engaging in a trial order can also provide insights into their reliability and product quality. -

What are the logistics considerations when importing power cords?

Logistics considerations include understanding shipping methods, customs regulations, and import duties specific to your country. Work with suppliers who have experience in international shipping to navigate these complexities. Additionally, consider lead times for production and shipping, as well as the potential for delays due to customs clearance. Establishing a clear logistics plan will help ensure timely delivery and minimize disruptions to your supply chain. -

Are there specific power cord types better suited for outdoor use?

Yes, certain power cord types are specifically designed for outdoor use and can withstand environmental conditions. For example, SJTW and SOOW cords are weather-resistant and suitable for outdoor applications. They are constructed with materials that resist moisture, UV rays, and extreme temperatures, making them ideal for use in gardens, construction sites, and outdoor events. Always verify the cord’s specifications to ensure they meet the demands of your intended outdoor applications.

Top 6 Power Cord Types Chart Manufacturers & Suppliers List

1. StayOnline – Power Cord Types Reference Chart

Domain: stayonline.com

Registered: 1996 (29 years)

Introduction: Power Cord Types Reference Chart includes various types of power cords such as C14 Data Center Power Cords, C20 Data Center Power Cords, NEMA Locking Power Cords, International Power Cords, and Splitter Power Cords. Specific types include C14 to C13, C14 to C15, C20 to C19, NEMA 5-15 to C13, and many others. The chart also features locking options like Raritan SecureLock and various international …

2. International Configurations – Power Cord Selector Guide

Domain: internationalconfigurations.com

Registered: 2010 (15 years)

Introduction: Power cord directory guide, Reference guide, Power cord selector and plug type directory, Power supply cord finder guide, Foreign Electricity guide, Worldwide electricity guide, Electrical current standards guide, Electricity by Country travel guide, International Power plugs and outlets guide. Country specific plugs, outlets, connectors, RCDs/GFCIs for various countries including United States, C…

3. World Cord Sets – IEC 60320 Power Cords & Adapters

Domain: shop.worldcordsets.com

Registered: 2001 (24 years)

Introduction: IEC 60320 Reference Chart includes various power cords and adapters categorized by type and specifications. Key product details include: 1. IEC 60320 Power Cords: C14 C13, C20 C19, C14 C5, C14 C7, C14 C19, C20 C13, C14 C15, C20 C15, C20 C21, C14 C21. 2. Adapter Cords: NEMA 5-15P, NEMA 5-20P, NEMA 6-20P, European Schuko, UK BS1363, IEC 60320 C14 and C20 Plug Adapters. 3. NEMA Power Cords: 15A 125V,…

4. Cables To Go – Power Connectors

Domain: cablestogo.com

Registered: 1995 (30 years)

Introduction: This company, Cables To Go – Power Connectors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. IEC – Global Plug Guide

Domain: iec.ch

Introduction: World plugs provide information on the various plug types, voltages, and frequencies used in different countries around the world. Users can select a location, electric potential, or frequency to discover the specific plug type(s) utilized in that area.

6. Interpower – North American Cable Types

Domain: interpower.com

Registered: 1996 (29 years)

Introduction: North American Cable Types include: SJT (Junior hard service, thermoplastic-insulated conductors and jacket), SJTO (Oil-resistant thermoplastic outer jacket), SJTOO (Both conductor insulation and jacket oil resistant), SJTOW (Weather-resistant rated), SJTOOW (Both conductor insulation and jacket oil resistant), SJTW (Hard-usage thermoplastic or rubber-insulated conductors, weather-resistant for ou…

Strategic Sourcing Conclusion and Outlook for power cord types chart

In the evolving landscape of global commerce, understanding the various power cord types is crucial for businesses seeking to enhance operational efficiency and ensure safety compliance. Strategic sourcing not only enables organizations to identify the right power cords tailored to their specific applications but also fosters partnerships with reliable suppliers. This approach can lead to significant cost savings, improved supply chain resilience, and access to innovative solutions that meet diverse regional standards.

For B2B buyers in Africa, South America, the Middle East, and Europe, it’s essential to consider local regulations and market demands when selecting power cords. By leveraging a comprehensive power cord types chart, companies can make informed decisions that align with their operational needs and regional compliance requirements.

Looking ahead, international buyers are encouraged to engage with manufacturers and distributors that prioritize quality and sustainability. As the market continues to evolve, staying proactive in sourcing the right power cords will be pivotal for maintaining competitive advantage. Embrace this opportunity to enhance your supply chain strategy and ensure your business is well-equipped for the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to power cord types chart

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.